Raw Material Variability and Its Impact on the Online Adaptive Control of Cohesive Powder Blend Homogeneity Using NIR Spectroscopy

Abstract

HIGHLIGHT

- >

- The near infrared (NIR) spectroscopy combined with modified adaptive algorithm was used to monitor the blending process of natural product powders and excipient systems.

- >

- The effectiveness of the online monitoring platform was justified through 16 batches of commercial blending operations.

- >

- An empirical relationship between raw material variability and detected blending end time were established.

- >

- The particle irregularity and powder flowability were identified as critical material attributes affecting the cohesive powder blending process.

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Physical Characterization of Powder Materials

2.3. Near Infrared Spectroscopy

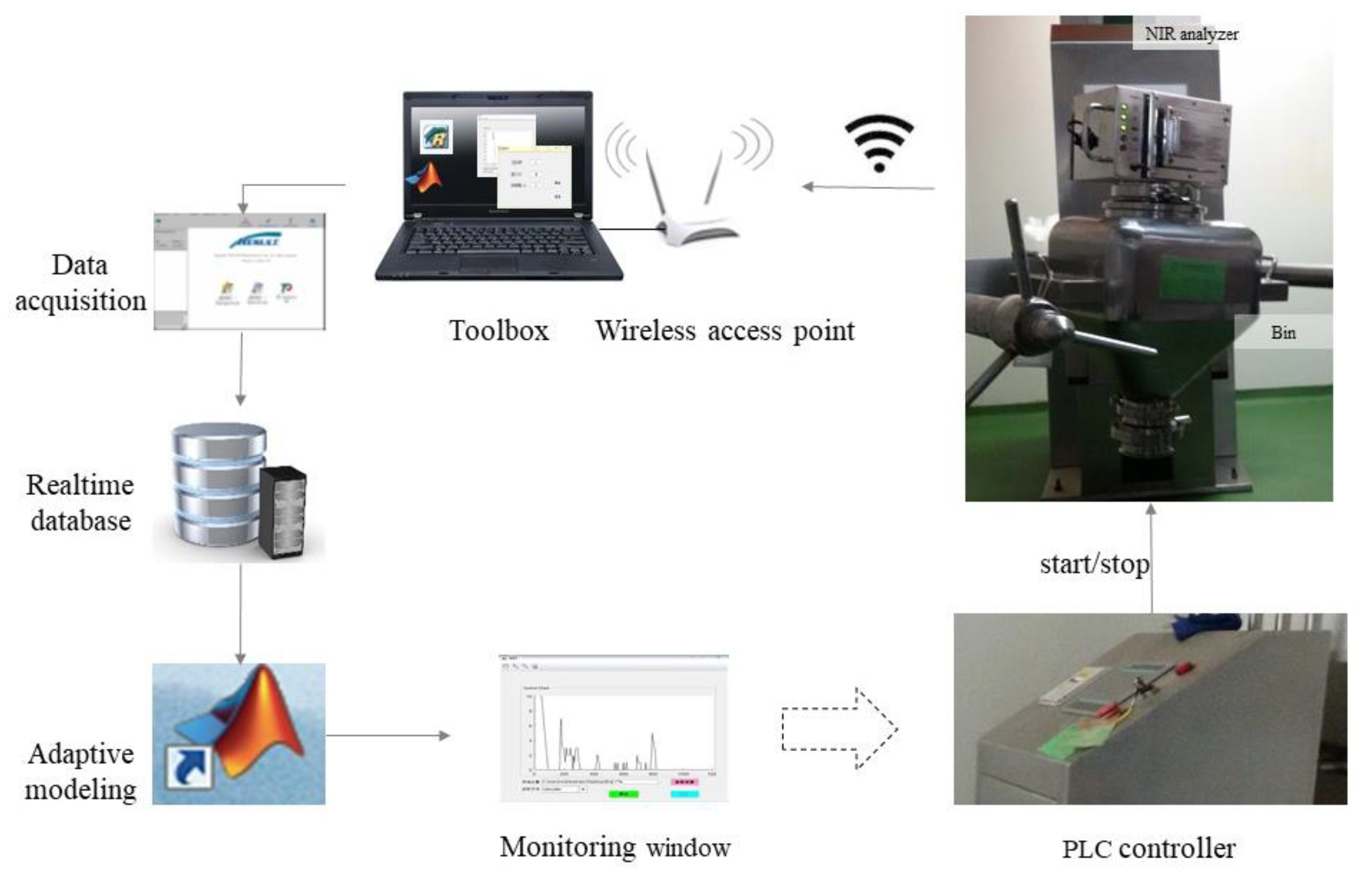

2.4. Principles of the Adaptive Modeling Algorithm

2.5. Reference Analysis

2.6. Software

3. Results and Discussion

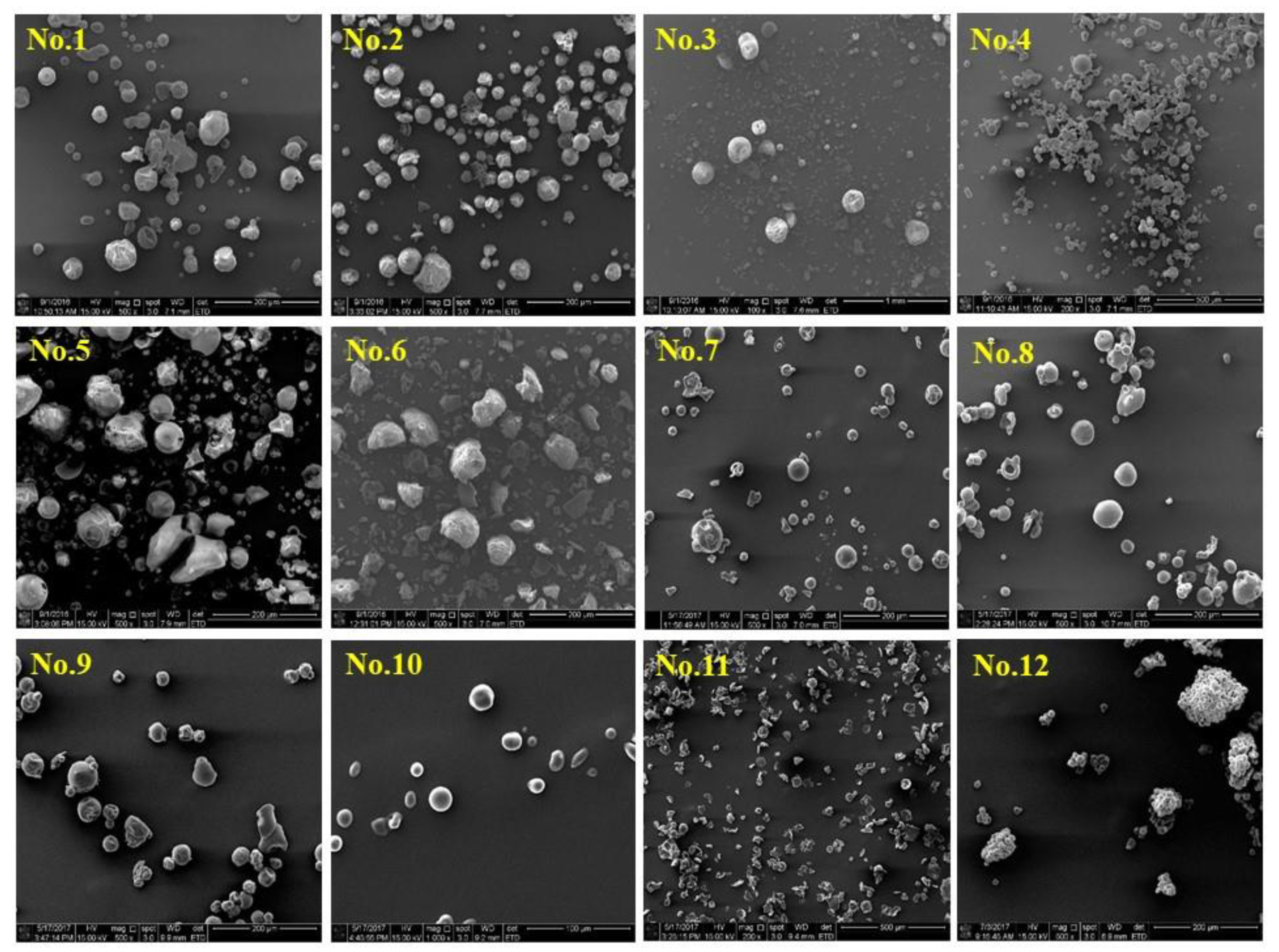

3.1. Physical Properties of Powder Materials

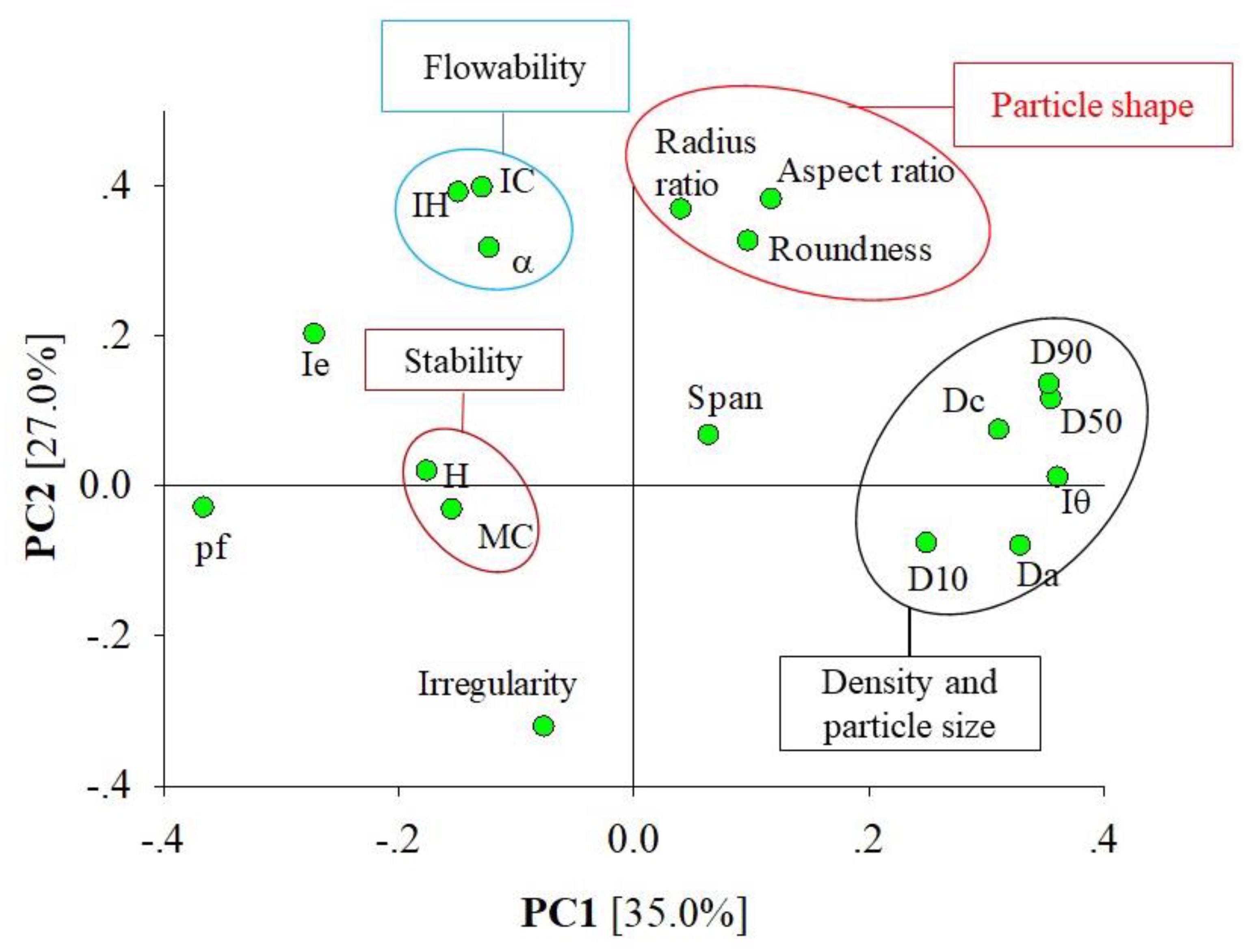

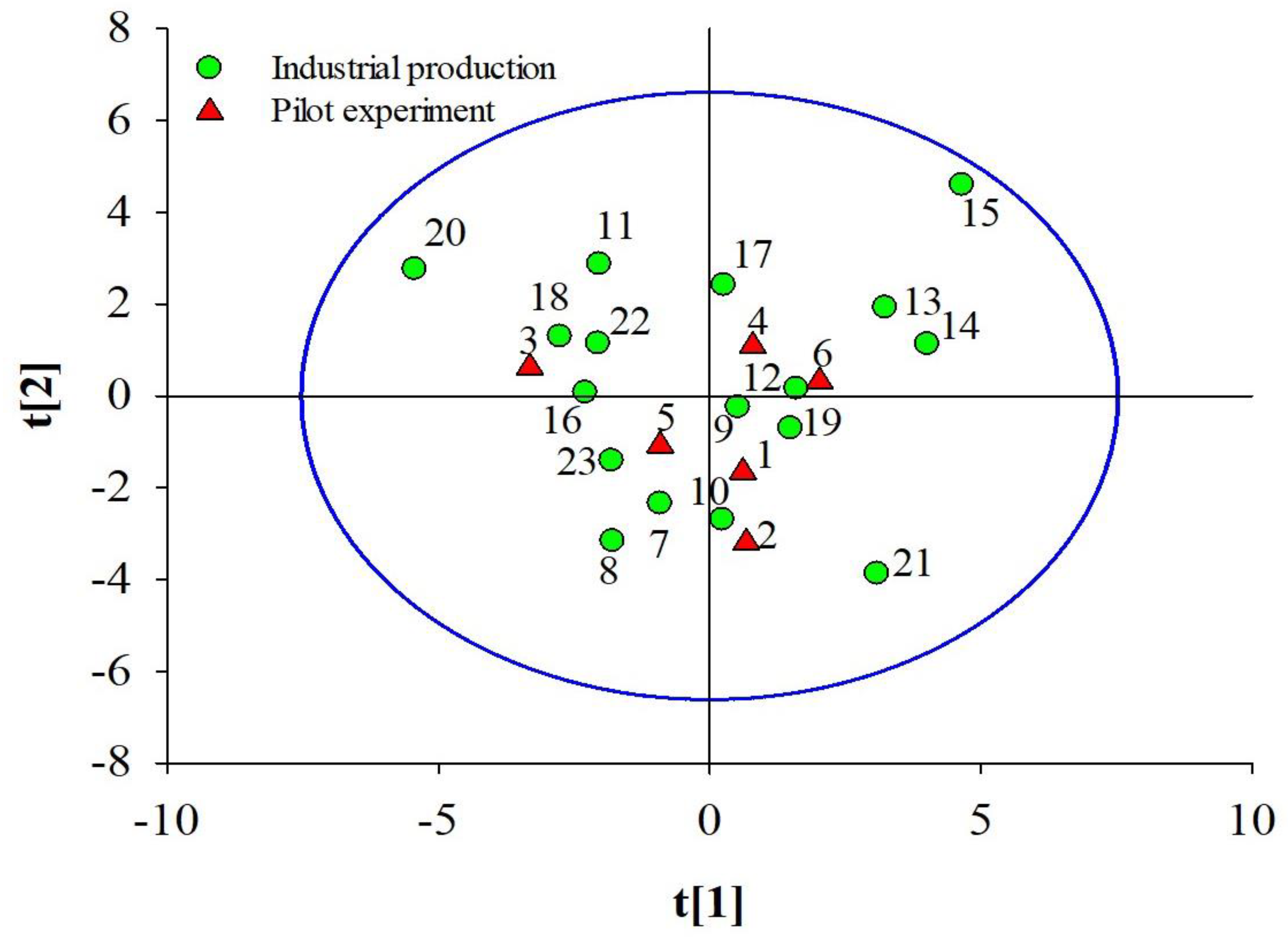

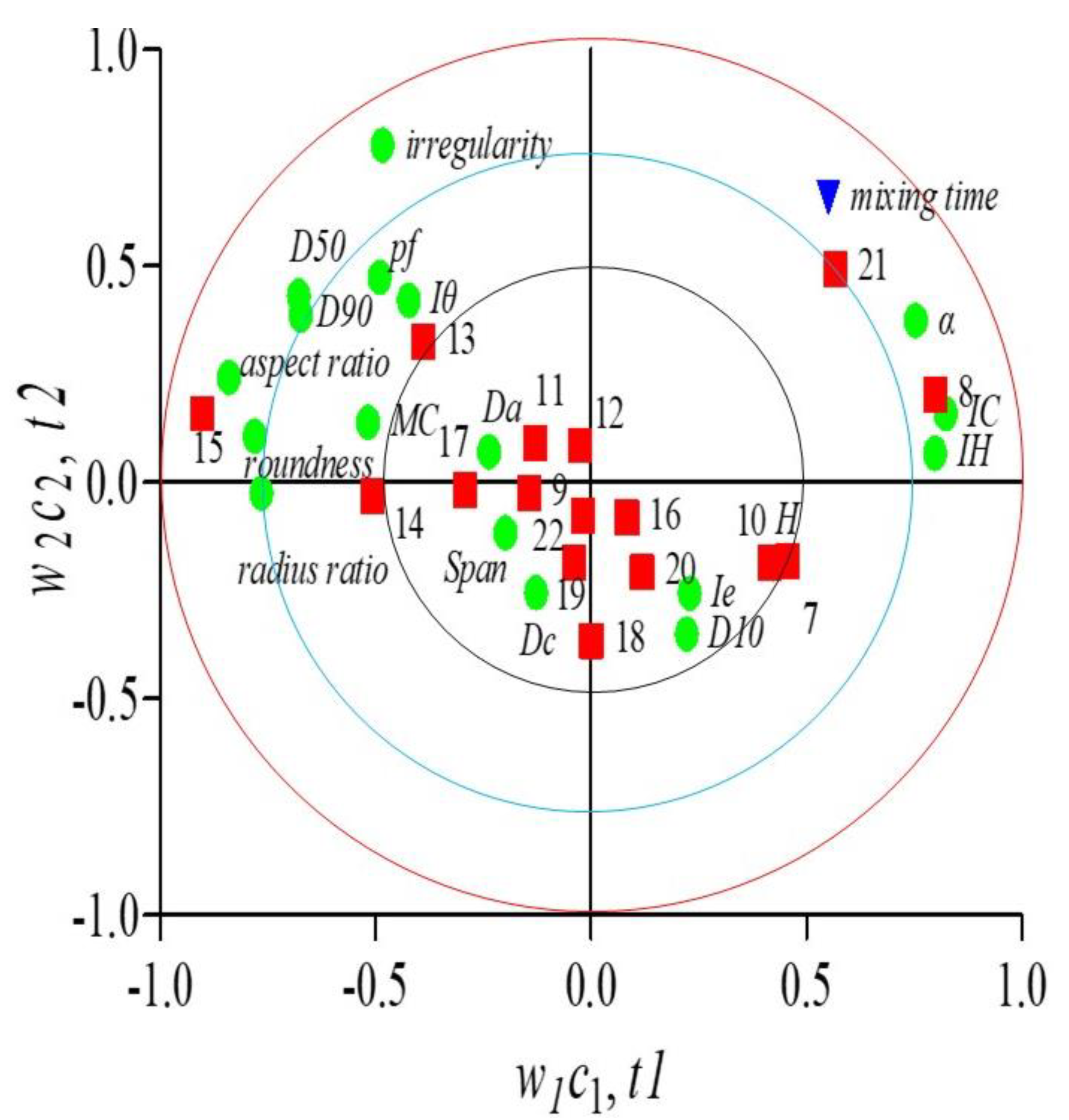

3.2. Principle Component Analysis of Physical Properties

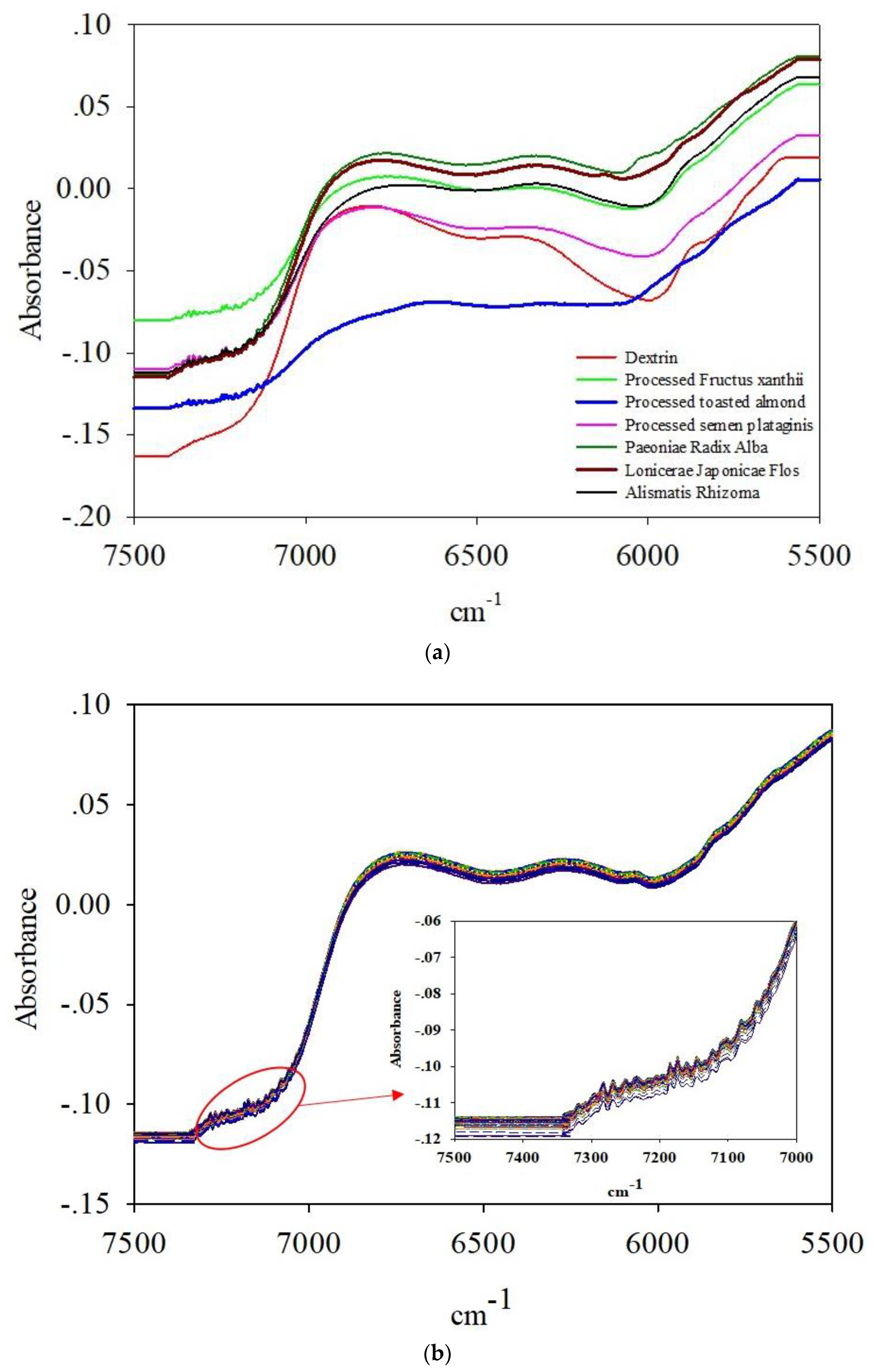

3.3. Pretreatment of NIR Spectra

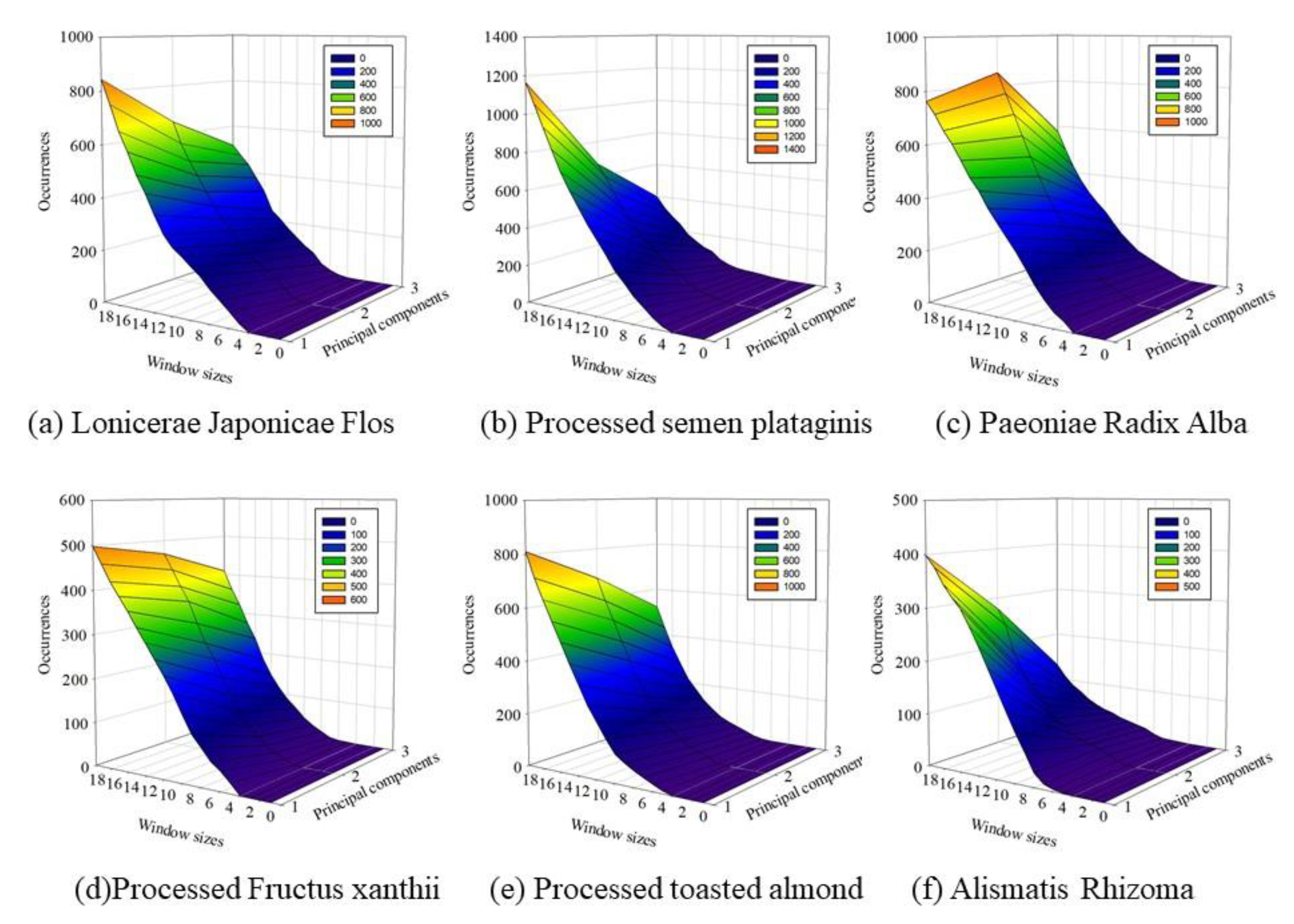

3.4. Parameters Optimization of the Adaptive Algorithm

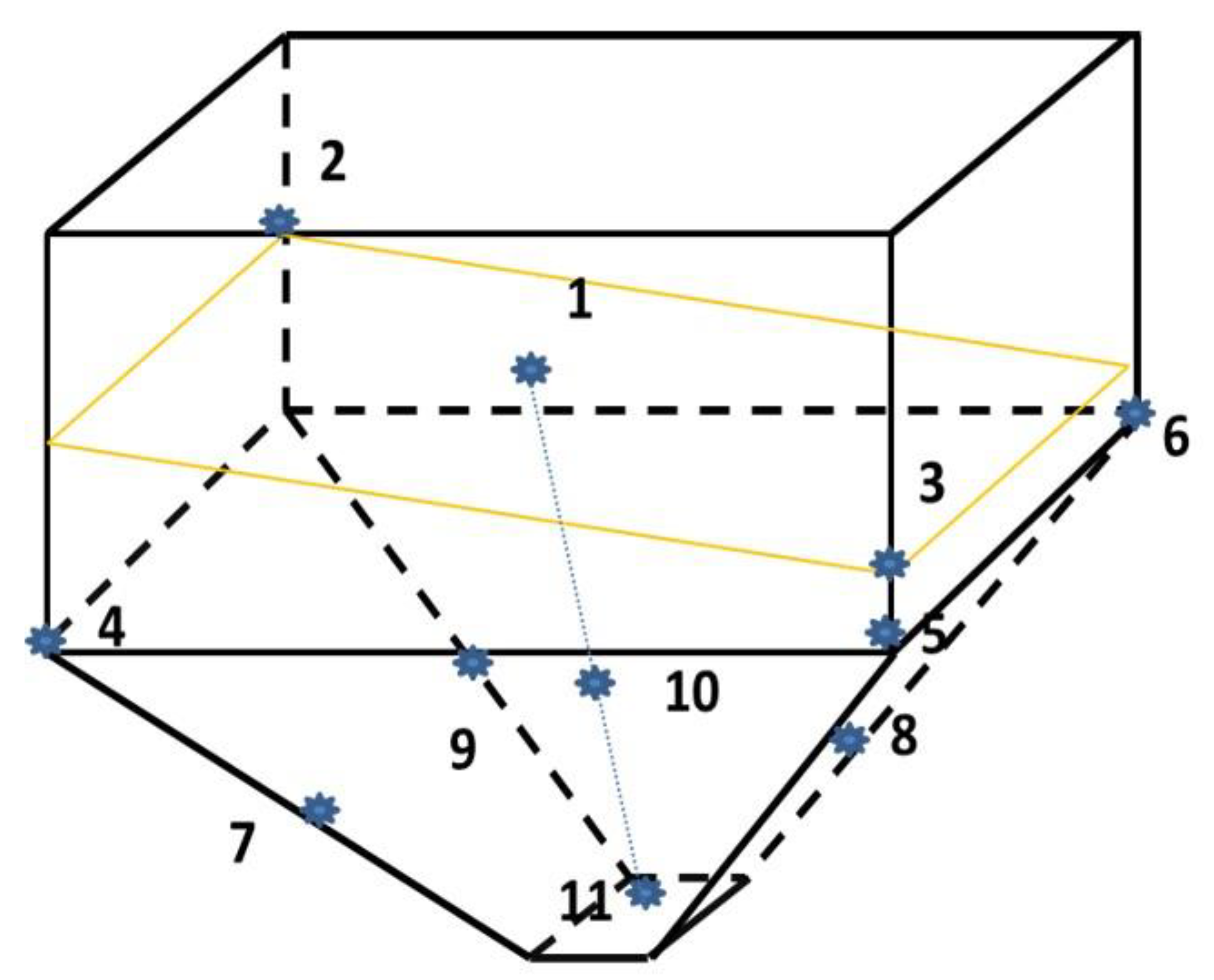

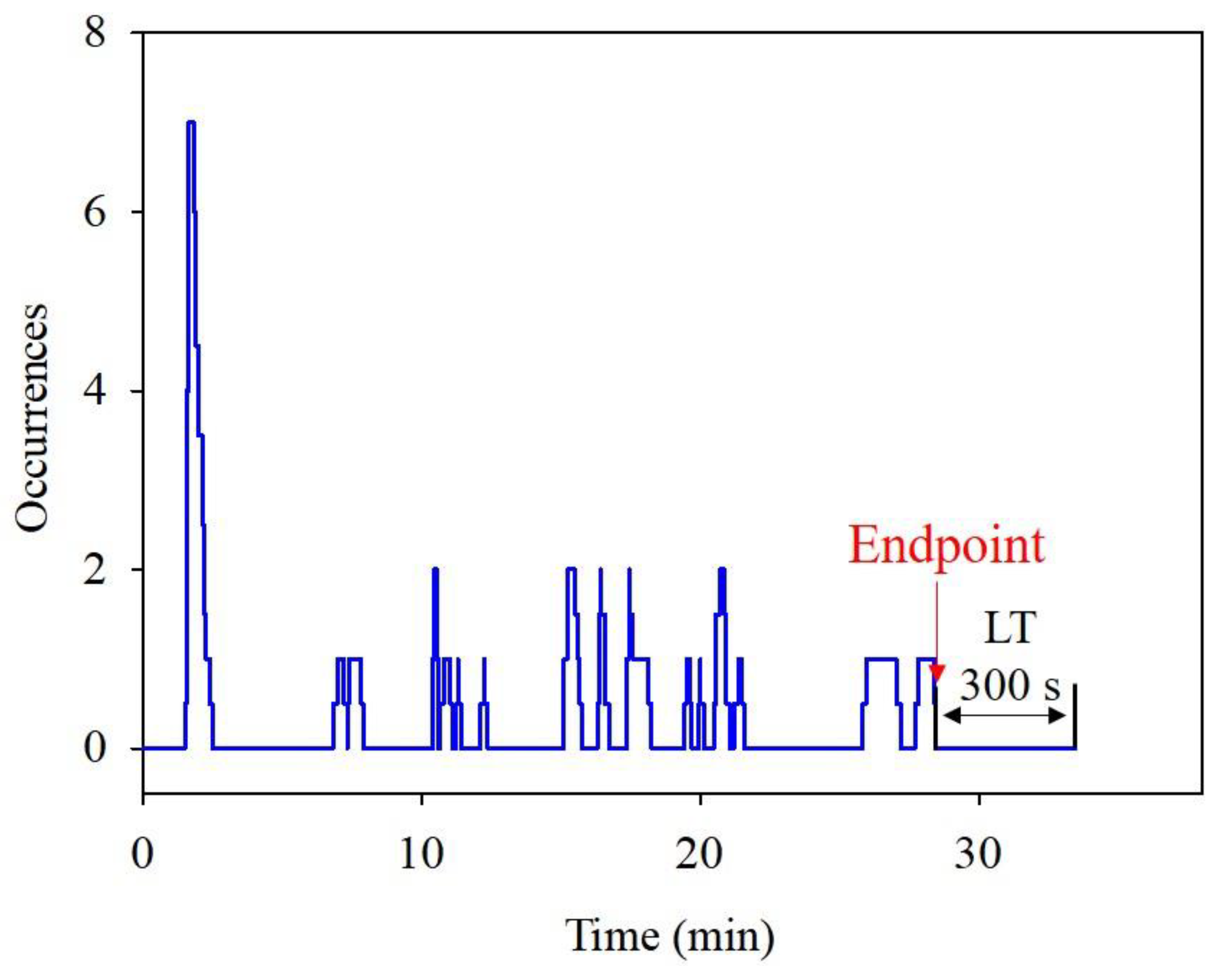

3.5. Real Time Detection of the Blending Homogeneity during Industrial Production

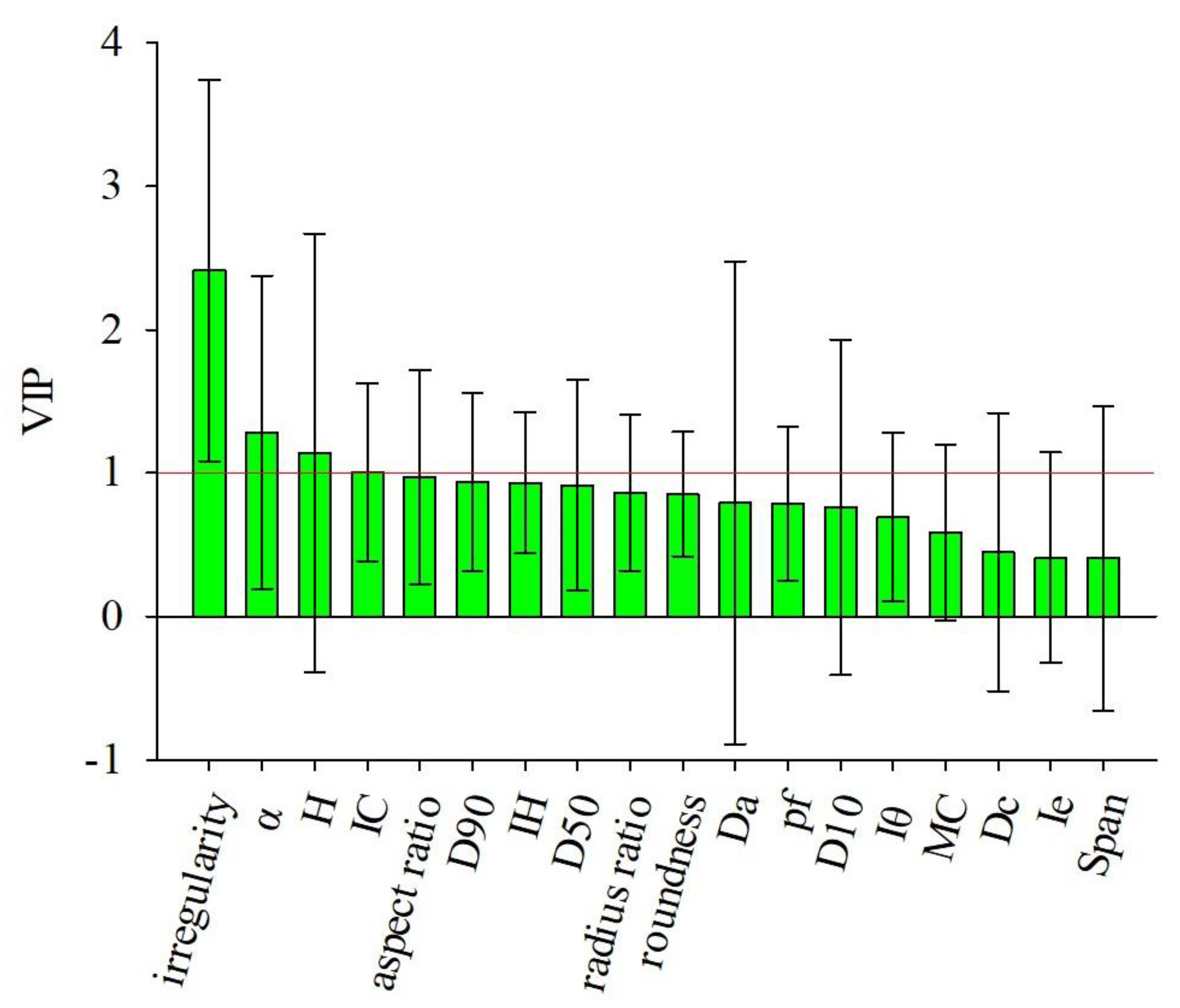

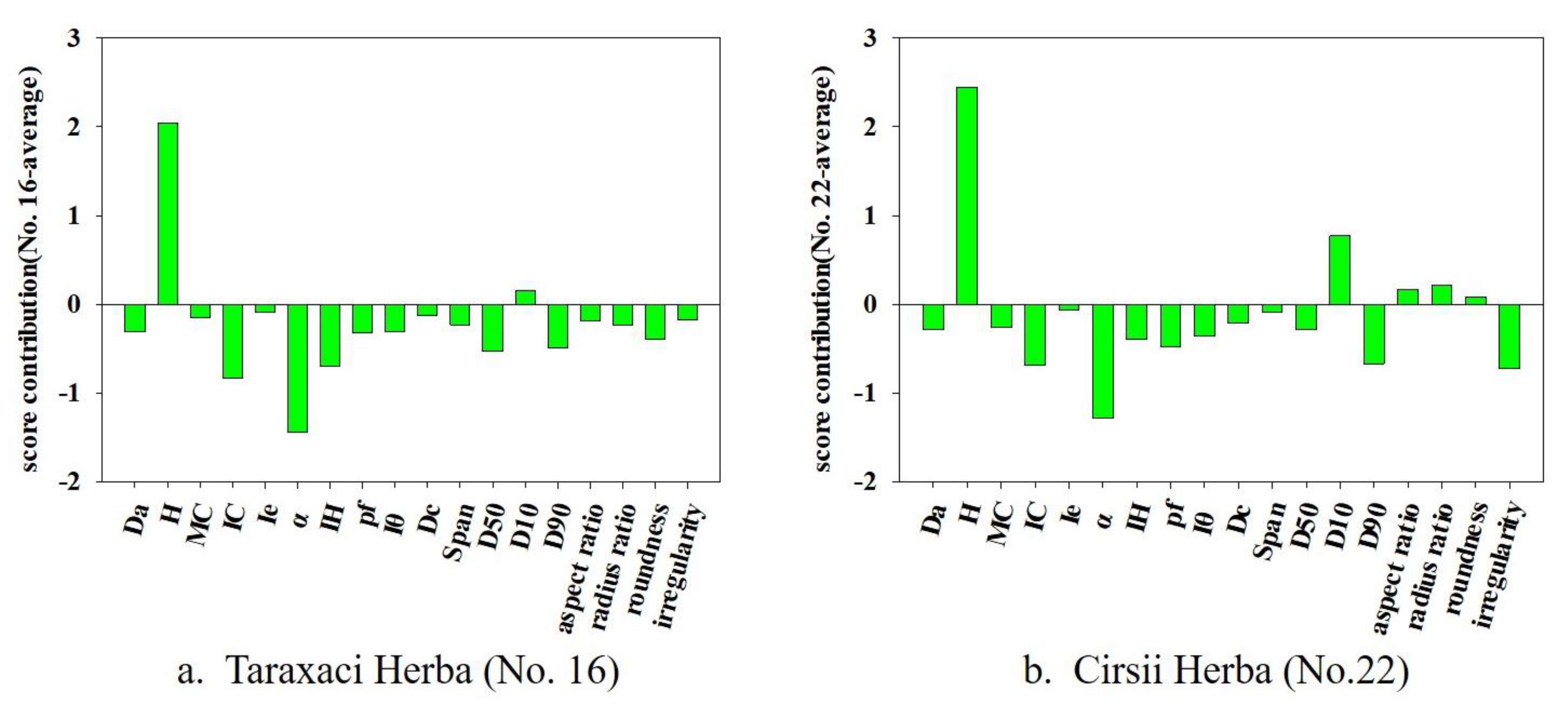

3.6. Effect of Powder Properties on Mixing Process

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Scheibelhofer, O.; Balak, N.; Wahl, P.R.; Koller, D.M.; Glasser, B.J.; Khinast, J.G. Monitoring Blending of Pharmaceutical Powders with Multipoint NIR Spectroscopy. AAPS PharmSciTech 2013, 14, 234–244. [Google Scholar] [CrossRef] [PubMed]

- Maesschalck, R.D.; Sànchez, F.C. On-Line Monitoring of Powder Blending with Near-Infrared Spectroscopy. Appl. Spectrosc. 1998, 52, 725–731. [Google Scholar] [CrossRef]

- Hausman, D.S.; Cambron, R.T.; Sakr, A. Application of Raman spectroscopy for on-line monitoring of low dose blend uniformity. Int. J. Pharm. 2005, 298, 80–90. [Google Scholar] [CrossRef] [PubMed]

- Florian-Algarin, M.; Méndez, R. Effect of material properties and design parameters on the final blend uniformity using experimental and simulation results. Powder Technol. 2015, 276, 156–165. [Google Scholar] [CrossRef]

- Escotet-Espinoza, M.S.; Moghtadernejad, S.; Oka, S.; Wang, Y.; Roman-Ospino, A.; Schäfer, E.; Cappuyns, P.; Van Assche, I.; Futran, M.; Ierapetritou, M.; et al. Effect of tracer material properties on the residence time distribution (RTD) of continuous powder blending operations Part I of II: Experimental evaluation. Powder Technol. 2018, 342, 744–763. [Google Scholar] [CrossRef]

- US Department of Health and Human Services, Food and Drug Administration. Guidance for Industry PAT—A Framework for Innovative Pharmaceutical Development, Manufacturing and Quality Assurance. 2004. Available online: http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/ucm070305.pdf (accessed on 27 August 2019).

- Shi, Z.; Mcghehey, K.C.; Leavesley, I.M.; Manley, L.F. On-line monitoring of blend uniformity in continuous drug product manufacturing process—The impact of powder flow rate and the choice of spectrometer: Dispersive vs. FT. J. Pharm. Biomed. Anal. 2016, 118, 259–266. [Google Scholar] [CrossRef] [PubMed]

- Fonteyne, M.; Vercruysse, J.; De Leersnyder, F.; Besseling, R.; Gerich, A.; Oostra, W.; Remon, J.P.; Vervaet, C.; De Beer, T. Blend Uniformity Evaluation During Continuous Mixing in a Twin Screw Granulator by in-Line Nir Using a Moving F-Test. Anal. Chim. Acta 2016, 935, 213–223. [Google Scholar] [CrossRef] [PubMed]

- Hattori, Y.; Otsuka, M. ATR/FT-IR and NIR Auto-correlation Spectroscopic Analysis of Powder Blending Uniformity of Low-content Magnesium Stearate and Potato Starch. Anal. Sci. Int. J. Jpn. Soc. Anal. Chem. 2017, 33, 65–68. [Google Scholar] [CrossRef][Green Version]

- Corredor, C.C.; Lozano, R.; Bu, X.; McCann, R.; Dougherty, J.; Stevens, T.; Both, D.; Shah, P. Analytical Method Quality by Design for an On-Line Near-Infrared Method to Monitor Blend Potency and Uniformity. J. Pharm. Innov. 2015, 10, 47–55. [Google Scholar] [CrossRef]

- Wang, H.; Barona, D.; Oladepo, S.; Williams, L.; Hoe, S.; Lechuga-Ballesteros, D.; Vehring, R. Macro-Raman spectroscopy for bulk composition and homogeneity analysis of multi-component pharmaceutical powders. J. Pharm. Biomed. Anal. 2017, 141, 180–191. [Google Scholar] [CrossRef]

- Ma, H.; Anderson, C. Characterization of pharmaceutical powder blends by NIR chemical imaging. J. Pharm. Sci. 2008, 97, 3305–3320. [Google Scholar] [CrossRef] [PubMed]

- Osorio, J.G.; Stuessy, G.; Kemeny, G.J.; Muzzio, F.J. Characterization of pharmaceutical powder blends using in situ near-infrared chemical imaging. Chem. Eng. Sci. 2014, 108, 244–257. [Google Scholar] [CrossRef]

- Uchiyama, J.; Aoki, S.; Uemoto, Y. New approach to evaluate the lubrication process in various granule filling levels and rotating mixer sizes using a thermal effusivity sensor. Chem. Pharm. Bull. (Tokyo) 2015, 63, 164–179. [Google Scholar] [CrossRef] [PubMed]

- Roggo, Y.; Chalus, P.; Maurer, L.; Jent, N. A review of near infrared spectroscopy and chemometrics in pharmaceutical technologies. J. Pharm. Biomed. Anal. 2007, 44, 683–700. [Google Scholar] [CrossRef] [PubMed]

- Tewari, J.; Strong, R.; Boulas, P. At-line determination of pharmaceuticals small molecule’s blending end point using chemometric modeling combined with Fourier transform near infrared spectroscopy. Spectrochim. Acta A 2017, 17, 886–891. [Google Scholar] [CrossRef] [PubMed]

- Momose, W.; Imai, K.; Yokota, S.; Yonemochi, E.; Terada, K. Process analytical technology applied for end-point detection of pharmaceutical blending by combining two calibration-free methods: Simultaneously monitoring specific near-infrared peak intensity and moving block standard deviation. Powder Technol. 2011, 210, 122–131. [Google Scholar] [CrossRef]

- Vanarase, A.U.; Järvinen, M.; Paaso, J.; Muzzio, F.J. Development of a methodology to estimate error in the on-line measurements of blend uniformity in a continuous powder mixing process. Powder Technol. 2013, 241, 263–271. [Google Scholar] [CrossRef]

- Mukherjee, R.; Mao, C.; Chattoraj, S.; Chaudhuri, B. DEM based computational model to predict moisture induced cohesion in pharmaceutical powders. Int. J. Pharm. 2018, 536, 301–309. [Google Scholar] [CrossRef]

- Deng, X.; Scicolone, J.V.; Davé, R.N. Discrete element method simulation of cohesive particles mixing under magnetically assisted impaction. Powder Technol. 2013, 243, 96–109. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Cagatay, I.H.; Tokyay, M.; Emsen, E. The effect of particle size distribution on the properties of blended cements incorporating GGBFS and natural pozzolan (NP). Powder Technol. 2007, 177, 140–147. [Google Scholar] [CrossRef]

- Pingali, K.C.; Shinbrot, T.; Hammond, S.V.; Muzzio, F.J. An observed correlation between flow and electrical properties of pharmaceutical blends. Powder Technol. 2009, 192, 157–165. [Google Scholar] [CrossRef]

- Shenoy, P.; Viau, M.; Tammel, K.; Innings, F.; Fitzpatrick, J.; Ahrné, L. Effect of powder densities, particle size and shape on mixture quality of binary food powder mixtures. Powder Technol. 2015, 272, 165–172. [Google Scholar] [CrossRef]

- Liew, C.V.; Karande, A.D.; Heng, P.W.S. In-line quantification of drug and excipients in cohesive powder blends by near infrared spectroscopy. Int. J. Pharm. 2010, 386, 138–148. [Google Scholar] [CrossRef]

- Casian, T.; Iurian, S.; Gavan, A.; Revnic, C.; Porav, S.; Porfire, A.; Vlase, L.; Tomuță, I. Near Infra-Red spectroscopy for content uniformity of powder blends—Focus on calibration set development, orthogonality transfer and robustness testing. Talanta 2018, 188, 404–416. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Li, W.; Xu, J.; Boulas, P. Development of a NIR-based blend uniformity method for a drug product containing multiple structurally similar actives by using the quality by design principles. Int. J. Pharm. 2015, 488, 120–126. [Google Scholar] [CrossRef] [PubMed]

- Besseling, R.; Damen, M.; Tran, T.; Nguyen, T.; Dries, K.V.D.; Oostra, W.; Gerich, A. An efficient, maintenance free and approved method for spectroscopic control and monitoring of blend uniformity: The moving F-test. J. Pharm. Biomed. Anal. 2015, 114, 471–481. [Google Scholar] [CrossRef]

- Sibik, J.; Chalus, P.; Maurer, L.; Murthy, A.; Krimmer, S. Mechanistic approach in powder blending PAT: Bi-layer mixing and asymptotic end point prediction. Powder Technol. 2017, 308, 306–317. [Google Scholar] [CrossRef]

- Flåten, G.R.; Belchamber, R.; Collins, M.; Walmsley, A.D. Caterpillar—An adaptive algorithm for detecting process changes from acoustic emission signals. Anal. Chim. Acta 2005, 544, 280–291. [Google Scholar] [CrossRef]

- Flåten, G.R.; Ferreira, A.P.; Bellamy, L.; Frake, P. PAT within the QbD Framework: Real-Time End Point Detection for Powder Blends in a Compliant Environment. J. Pharm. Innov. 2012, 7, 38–45. [Google Scholar] [CrossRef]

- Geldart, D. Types of gas fluidization. Powder Technol. 1973, 7, 285–292. [Google Scholar] [CrossRef]

- Capece, M.; Huang, Z.; To, D.; Aloia, M.; Muchira, C.; Dave, R.; Yu, A. Prediction of porosity from particle scale interactions: Surface modification of fine cohesive powders. Powder Technol. 2014, 254, 103–113. [Google Scholar] [CrossRef]

- Wu, H.; White, M.; Khan, M. An Integrated Process Analytical Technology (PAT) Approach for Process Dynamics-Related Measurement Error Evaluation and Process Design Space Development of a Pharmaceutical Powder Blending Bed. Org. Process Res. Dev. 2015, 19, 215–226. [Google Scholar] [CrossRef]

- Osorio, J.G.; Stuessy, G.; Kemeny, G.J.; Muzzio, F.J. Micro-mixing dynamics of active pharmaceutical ingredients in bin-blending. Chem. Eng. Process. 2016, 102, 141–155. [Google Scholar] [CrossRef]

- Kirchler, C.G.; Pezzei, C.K.; Beć, K.B.; Mayr, S.; Ozaki, Y.; Huck, C.W.; Ishigaki, M. Critical evaluation of spectral information of benchtop vs. portable near-infrared spectrometers: Quantum chemistry and two-dimensional correlation spectroscopy for a better understanding of PLS regression models of the rosmarinic acid content in Rosmarini folium. Analyst 2017, 142, 455–464. [Google Scholar] [CrossRef]

- Peter, J.; Brush, A.; Alexander, W. Using MEMS to Control Blending at AstraZeneca. 2006. Available online: https://www.pharmamanufacturing.com/articles/2006/149/ (accessed on 21 August 2006).

- Chen, Y.; Yang, J.; Dave, R.N.; Pfeffer, R. Fluidization of coated group C powders. AIChE J. 2010, 54, 104–121. [Google Scholar] [CrossRef]

- Shi, W.; Galella, E.; Sprockel, O. Macro-and micro-mixing of a cohesive pharmaceutical powder during scale up. Powder Technol. 2015, 274, 319–323. [Google Scholar] [CrossRef]

- Mangal, S.; Gengenbach, T.; Millington-Smith, D.; Armstrong, B.; Morton, D.A.; Larson, I. Relationship between the cohesion of guest particles on the flow behaviour of interactive mixtures. Eur. J. Pharm. Biopharm. 2016, 102, 168–177. [Google Scholar] [CrossRef]

- Xu, B.; Lin, Z.; Wu, Z.; Shi, X.; Qiao, Y.; Luo, G. Target-oriented Overall Process Optimization (TOPO) for Reducing Variability in the Quality of Herbal Medicine Products. Chemom. Intell. Lab. Syst. 2013, 128, 144–152. [Google Scholar] [CrossRef]

- Xiong, H.; Lawrence, X.Y.; Qu, H. Batch-to-batch quality consistency evaluation of botanical drug products using multivariate statistical analysis of the chromatographic fingerprint. AAPS PharmSciTech 2013, 14, 802–810. [Google Scholar] [CrossRef]

- Dai, S.; Xu, B.; Shi, G.; Liu, J.; Zhang, Z.; Shi, X.; Qiao, Y. SeDeM expert system for directly compressed tablet formulation: A review and new perspectives. Powder Technol. 2019, 342, 517–527. [Google Scholar] [CrossRef]

- Jys, T.; Liew, C.V.; Pws, H. Powder Flow Testing: Judicious Choice of Test Methods. AAPS PharmSciTech 2017, 18, 1843–1854. [Google Scholar] [CrossRef]

- Geldart, D.; Harnby, N.; Wong, A.C. Fluidization of cohesive powders. Powder Technol. 1984, 37, 25–37. [Google Scholar] [CrossRef]

- Capece, M.; Ho, R.; Strong, J.; Gao, P. Prediction of powder flow performance using a multi-component granular Bond number. Powder Technol. 2015, 286, 561–571. [Google Scholar] [CrossRef]

- Capece, M.; Silva, K.R.; Sunkara, D.; Strong, J.; Gao, P. On the Relationship of Inter-particle Cohesiveness and Bulk Powder Behavior: Flowability of Pharmaceutical Powders. Int. J. Pharm. 2016, 511, 178–189. [Google Scholar] [CrossRef]

- Legoix, L.; Gatumel, C.; Milhe, M.; Berthiaux, H. Rheology of cohesive powders in a pilot scale planetary blender. Powder Technol. 2017, 305, 609–619. [Google Scholar] [CrossRef]

- Van Snick, B.; Dhondt, J.; Pandelaere, K.; Bertels, J.; Mertens, R.; Klingeleers, D.; Di Pretoro, G.; Remon, J.P.; Vervaet, C.; De Beer, T.; et al. A multivariate raw material property database to facilitate drug product development and enable in-silico design of pharmaceutical dry powder processes. Int. J. Pharm. 2018, 549, 415–435. [Google Scholar] [CrossRef]

- Schiller, M.; Von Der Heydt, H.; März, F.; Schmidt, P.C. Quantification of sugars and organic acids in hygroscopic pharmaceutical herbal dry extracts. J. Chromatogr. A 2002, 968, 101–111. [Google Scholar] [CrossRef]

- Igne, B.; Talwar, S.; Drennen, J.K.; Anderson, C.A. Online Monitoring of Pharmaceutical Materials Using Multiple NIR Sensors—Part II: Blend End-point Determination. J. Pharm. Innov. 2013, 8, 45–55. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, J.; Zhou, J.; Li, S.; Feng, J. Enhancing mixing of cohesive particles by baffles in a rotary drum. Particuology 2016, 25, 104–110. [Google Scholar] [CrossRef]

- Fu, X.; Huck, D.; Makein, L.; Armstrong, B.; Willen, U.; Freeman, T. Effect of particle shape and size on flow properties of lactose powders. Particuology 2012, 10, 203–208. [Google Scholar] [CrossRef]

- Abhaykumar, B. Correlation between Physical Properties and Flowability Indicators for Fine Powders. Master’s Thesis, Department of Chemical Engineering, University of Saskatchewan, Saskatoon, SK, Canada, 2006. [Google Scholar]

- Juarez-Enriquez, E.; Olivas, G.I.; Zamudio-Flores, P.B.; Ortega-Rivas, E.; Perez-Vega, S.; Sepulveda, D.R. Effect of water content on the flowability of hygroscopic powders. Int. Food Eng. 2017, 205, 12–17. [Google Scholar] [CrossRef]

| Material No. | NPP Powder (Lot Number) | Reference Substance for HPLC (Lot Number) | Proportion of Dextrin Added (%) |

|---|---|---|---|

| 1 | Paeoniae Radix Alba (J1600160) | Paeoniflorin (110736–201438) | 3.75 |

| 2 | Processed Fructus xanthii (J1600481) | Chlorogenic acid (110753–201415) | 10.02 |

| 3 | Processed toasted almond (J1502067) | Amygdalin (J1502067) | 1.60 |

| 4 | Lonicerae Japonicae Flos (J1600420) | Chlorogenic acid (110753–201415) | 2.50 |

| 5 | Processed semen plataginis (J1600260) | Geniposide (J1600260) | 6.89 |

| 6 | Alismatis Rhizoma (J1502050) | 23-Acetyl-Alismol (111846–201504) | 13.78 |

| 7 | Lonicerae Japonicae Flos (J1601959) | Chlorogenic acid (110753–201415) | 5.72 |

| 8 | Ecliptae Herba (J1601771) | Wedelolactone (110773–201313) | 10.59 |

| 9 | Cibotii Rhizoma (J1601774) | Protocatechuic Acid (110809–200604) | 3.34 |

| 10 | Glycyrrhizae radix et rhizome Praeparata cum melle (J1601741) | Liquiritin (111610–201106) | 12.14 |

| 11 | Alismatis Rhizoma (J1601527) | 23-Acetyl-Alismol (111846–201504) | 21.96 |

| 12 | Belamcandae Rhizoma (J1601762) | Irigenin (111557–200602) | 5.56 |

| 13 | Radix Paeoniae Rubra (J1601588) | Paeoniflorin (110736–201640) | 4.13 |

| 14 | Scrophulariae Radix (J1601477) | Harpagoside (111730–201307) | 12.40 |

| 15 | Chuanxiong Rhizoma (J1601790) | Ferulic Acid (110773–201313) | 10.21 |

| 16 | Taraxaci Herba (J1601803) | Caffeic Acid (110885–200102) | 10.58 |

| 17 | Processed Radix Polygalae (J1601902) | 3,6-Disinapoylsucrose (J1601902) | 2.98 |

| 18 | Rhei Radix Et Rhizoma (J1601751) | Aloe-Emodine (110795–201308) | 7.86 |

| 19 | Angelica sinensis (J1601665) | Ferulic Acid (1110773–201313) | 4.80 |

| 20 | Dipsaci Radix (J1601913) | Asperosaponin (111685–201304) | 20.00 |

| 21 | Mume Fructus (J1601679) | Citric Acid (110773–201313) | 4.30 |

| 22 | Cirsii Herba (J1601841) | Linarin (111528–201308) | 2.67 |

| Number | Da | H | MC | Ic | Ie | α | IH | pf | Iθ | Dc | Span | t | D10 | D50 | D90 | Aspect Ratio | Radius Ratio | Roundness | Irregularity |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.47 | 16.23 | 6.70 | 31.60 | 0.67 | 43.83 | 1.46 | 52.04 | 0.002296 | 0.69 | 2.93 | +∞ | 4.746 | 18.950 | 60.30 | 1.21 | 1.44 | 1.04 | 2.89 |

| 2 | 0.44 | 21.42 | 4.71 | 18.69 | 0.42 | 33.05 | 1.23 | 55.13 | 0.001938 | 0.54 | 2.88 | +∞ | 4.425 | 17.243 | 54.00 | 1.25 | 1.66 | 1.19 | 3.10 |

| 3 | 0.13 | 23.22 | 7.04 | 39.47 | 2.92 | 49.95 | 1.65 | 68.86 | 0.000786 | 0.22 | 4.08 | +∞ | 3.564 | 12.663 | 55.69 | 1.26 | 1.74 | 1.09 | 2.89 |

| 4 | 0.39 | 19.90 | 7.36 | 34.50 | 0.89 | 42.66 | 1.53 | 49.35 | 0.002340 | 0.59 | 3.49 | +∞ | 4.945 | 20.337 | 75.88 | 1.34 | 2.79 | 1.29 | 2.93 |

| 5 | 0.37 | 17.79 | 3.41 | 30.16 | 0.81 | 36.31 | 1.43 | 75.41 | 0.000664 | 0.53 | 2.59 | +∞ | 3.670 | 11.647 | 33.88 | 1.33 | 1.95 | 1.16 | 2.91 |

| 6 | 0.51 | 20.62 | 8.39 | 31.16 | 0.61 | 38.29 | 1.45 | 42.78 | 0.003321 | 0.75 | 2.85 | +∞ | 4.787 | 24.477 | 74.48 | 1.48 | 1.98 | 1.22 | 2.81 |

| 7 | 0.44 | 24.54 | 5.36 | 21.86 | 0.50 | 39.31 | 1.28 | 74.73 | 0.000455 | 0.56 | 2.24 | +∞ | 4.746 | 12.037 | 30.68 | 1.30 | 1.67 | 1.08 | 2.88 |

| 8 | 0.43 | 39.07 | 7.52 | 19.82 | 0.47 | 38.60 | 1.25 | 78.60 | 0.000264 | 0.53 | 2.29 | +∞ | 4.425 | 10.987 | 28.70 | 1.22 | 1.55 | 1.07 | 2.95 |

| 9 | 0.35 | 23.66 | 5.64 | 29.44 | 0.84 | 59.08 | 1.42 | 49.41 | 0.002416 | 0.50 | 2.29 | +∞ | 3.564 | 24.167 | 62.29 | 1.36 | 1.85 | 1.20 | 2.98 |

| 10 | 0.44 | 21.07 | 5.77 | 21.09 | 0.48 | 39.62 | 1.27 | 56.19 | 0.002065 | 0.56 | 3.84 | 29.47 | 4.945 | 13.437 | 55.16 | 1.24 | 1.42 | 1.02 | 2.88 |

| 11 | 0.33 | 30.63 | 8.89 | 42.93 | 1.29 | 50.61 | 1.75 | 71.36 | 0.000390 | 0.58 | 2.21 | +∞ | 3.670 | 13.017 | 32.36 | 1.63 | 2.32 | 1.27 | 2.77 |

| 12 | 0.55 | 25.19 | 7.53 | 31.75 | 0.58 | 44.72 | 1.47 | 45.25 | 0.002769 | 0.81 | 2.57 | +∞ | 4.787 | 22.367 | 63.13 | 1.45 | 1.93 | 1.15 | 2.81 |

| 13 | 0.64 | 16.86 | 3.10 | 35.00 | 0.55 | 45.29 | 1.54 | 43.12 | 0.002651 | 0.98 | 3.90 | +∞ | 3.602 | 25.040 | 103.13 | 1.57 | 1.99 | 1.22 | 2.71 |

| 14 | 0.65 | 20.23 | 3.39 | 35.76 | 0.55 | 47.80 | 1.56 | 32.88 | 0.003975 | 1.01 | 2.68 | +∞ | 3.292 | 39.083 | 108.83 | 1.43 | 1.84 | 1.20 | 2.84 |

| 15 | 0.52 | 15.68 | 5.45 | 40.89 | 0.78 | 55.25 | 1.69 | 25.97 | 0.003418 | 0.88 | 2.48 | +∞ | 6.822 | 48.543 | 127.80 | 1.73 | 2.76 | 1.37 | 2.74 |

| 16 | 0.37 | 37.27 | 8.53 | 36.06 | 0.97 | 51.35 | 1.56 | 75.44 | 0.000492 | 0.58 | 2.44 | +∞ | 3.487 | 11.483 | 31.60 | 1.36 | 1.79 | 1.09 | 2.82 |

| 17 | 0.44 | 22.40 | 2.29 | 41.36 | 0.94 | 59.02 | 1.71 | 56.54 | 0.002176 | 0.75 | 3.86 | +∞ | 3.557 | 15.827 | 60.96 | 1.48 | 2.30 | 1.10 | 2.76 |

| 18 | 0.27 | 22.08 | 7.79 | 44.07 | 1.62 | 59.14 | 1.79 | 73.24 | 0.000951 | 0.49 | 3.87 | +∞ | 5.181 | 9.632 | 40.87 | 1.32 | 1.74 | 1.11 | 2.88 |

| 19 | 0.53 | 23.65 | 7.50 | 31.22 | 0.59 | 47.44 | 1.45 | 43.90 | 0.003109 | 0.77 | 2.56 | +∞ | 3.517 | 23.407 | 65.26 | 1.32 | 1.78 | 1.10 | 2.88 |

| 20 | 0.15 | 27.51 | 6.72 | 47.75 | 3.15 | 58.23 | 1.91 | 99.71 | 0.000000 | 0.29 | 1.64 | +∞ | 4.349 | 6.113 | 12.56 | 1.37 | 2.29 | 1.24 | 2.91 |

| 21 | 0.62 | 17.61 | 7.03 | 19.28 | 0.31 | 34.97 | 1.24 | 35.17 | 0.003842 | 0.76 | 2.30 | +∞ | 7.529 | 27.903 | 71.75 | 1.15 | 1.32 | 1.04 | 3.00 |

| 22 | 0.53 | 39.57 | 7.54 | 37.42 | 0.71 | 51.05 | 1.60 | 88.27 | 0.000000 | 0.84 | 2.62 | 6.83 | 3.489 | 7.460 | 21.25 | 1.49 | 2.12 | 1.20 | 2.83 |

| 23 | 0.45 | 6.05 | 7.44 | 38.04 | 0.85 | 54.31 | 1.61 | 98.10 | 0.000000 | 0.72 | 0.88 | +∞ | 6.476 | 11.723 | 16.85 | 1.21 | 1.27 | 1.03 | 2.89 |

| Material No. | Formula Granule | Time of Endpoint (min) | Mean Square (Between Group) | Mean Square (Within Group) | p Value |

|---|---|---|---|---|---|

| 7 | Lonicerae Japonicae Flos | 2.77 | 0.51 | 0.55 | 0.53 |

| 8 | Ecliptae Herba | 36.07 | 4.2 × 10−4 | 7.0 × 10−5 | 2.0 × 10−4 |

| 9 | Cibotii Rhizoma | 2.60 | 1.4 × 10−4 | 2.7 × 10−4 | 0.86 |

| 10 | Glycyrrhizae radix et rhizome Praeparata cum melle | 4.33 | 2.9 | 2.0 | 0.23 |

| 11 | Alismatis Rhizoma | 9.77 | 1.8 × 10−4 | 9.7 × 10−5 | 0.11 |

| 12 | Belamcandae Rhizoma | 8.83 | 2.0 × 10−4 | 1.0 × 10−4 | 0.081 |

| 13 | Radix Paeoniae Rubra | 17.87 | 1.3 | 1.5 | 0.56 |

| 14 | Scrophulariae Radix | 4.57 | 7.6 × 10−5 | 5.2 × 10−5 | 0.22 |

| 15 | Chuanxiong Rhizoma | 3.20 | 3.3 × 10−5 | 2.1 × 10−5 | 0.18 |

| 16 | Taraxaci Herba | 13.30 | 2.0 × 10−4 | 3.3 × 10−5 | 2.0 × 10−4 |

| 17 | Processed Radix Polygalae | 9.03 | 0.028 | 0.023 | 0.34 |

| 18 | Rhei Radix Et Rhizoma | 4.77 | 0.011 | 0.0077 | 0.24 |

| 19 | Angelica sinensis | 6.33 | 0.019 | 0.023 | 0.62 |

| 20 | Dipsaci Radix | 10.53 | 4.9 | 2.7 | 0.12 |

| 21 | Mume Fructus | 28.47 | 4.2 | 47 | 0.99 |

| 22 | Cirsii Herba | 12.47 | 3.4 × 10−3 | 7.2 × 10−3 | 0.89 |

| Components | R2xcum (%) | R2Ycum (%) | Q2Ycum (%) |

|---|---|---|---|

| 1 | 33.4 | 30.4 | −4.49 × 10−2 |

| 2 | 44 | 73.8 | 10.6 |

| 3 | 64.1 | 83.9 | 30.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, G.; Xu, B.; Zhang, Z.; Yang, C.; Dai, S.; Lin, Z.; Shi, X.; Fu, J.; Qiao, Y. Raw Material Variability and Its Impact on the Online Adaptive Control of Cohesive Powder Blend Homogeneity Using NIR Spectroscopy. Processes 2019, 7, 568. https://doi.org/10.3390/pr7090568

Shi G, Xu B, Zhang Z, Yang C, Dai S, Lin Z, Shi X, Fu J, Qiao Y. Raw Material Variability and Its Impact on the Online Adaptive Control of Cohesive Powder Blend Homogeneity Using NIR Spectroscopy. Processes. 2019; 7(9):568. https://doi.org/10.3390/pr7090568

Chicago/Turabian StyleShi, Guolin, Bing Xu, Zhiqiang Zhang, Chan Yang, Shengyun Dai, Zhaozhou Lin, Xinyuan Shi, Jing Fu, and Yanjiang Qiao. 2019. "Raw Material Variability and Its Impact on the Online Adaptive Control of Cohesive Powder Blend Homogeneity Using NIR Spectroscopy" Processes 7, no. 9: 568. https://doi.org/10.3390/pr7090568

APA StyleShi, G., Xu, B., Zhang, Z., Yang, C., Dai, S., Lin, Z., Shi, X., Fu, J., & Qiao, Y. (2019). Raw Material Variability and Its Impact on the Online Adaptive Control of Cohesive Powder Blend Homogeneity Using NIR Spectroscopy. Processes, 7(9), 568. https://doi.org/10.3390/pr7090568