1. Introduction

At present, more than 60% of the traditional old machine tools have been used for more than 10 years in China. Eighty percent of the in-service construction machinery has exceeded their shelf life and about 800 million tons of solid waste are generated every year [

1]. Since remanufacturing can maximize the development and utilization of the value contained in waste resources and reduce the environmental hazards of plenty of scrapped products, it has aroused widespread concern in academia and relevant industry.

The traditional remanufacturing process was more concerned about whether the used components can produce more economic benefits through remanufacturing [

2,

3,

4,

5]. However, as the ecological problems become more and more serious in China, simply evaluating the remanufacturing process with the goal of economic benefits does not meet the requirements of ecological civilization construction. Although the literature [

6,

7,

8] achieved the goal of simultaneously optimizing the economic benefits and environmental benefits of remanufacturing through multi-objective optimization, they used the expert scoring method when dealing with multi-objective functions, which undoubtedly had a great impact on the objectivity of remanufacturing system. So is there a single goal of remanufacturing that can take into account both economic benefits and environmental impacts? The basic principle of remanufacturing ecological efficiency (EE) was to balance the economic benefits and environmental impacts, and effectively integrate the sustainable development goals on the macro scale into the development planning and management of micro (such as enterprises) and meso (such as industry) [

9]. Hence, if remanufacturing EE is set as the research goal, it can not only avoid the subjectivity of multi-objectives, but also consider remanufacturing economic and environmental benefits at the same time.

Based on the importance of remanufacturing EE research, many scholars have studied it at different levels. Literature [

10] found that the remanufacturing process was more eco-efficient than the manufacturing process; Huisman et al. proposed a newly developed concept of EE, which took into account a series of technical, logistics, economic and policy issues [

11]; Quariguasi-Frota-Neto et al. investigated whether remanufacturing will reduce environmental impact by analyzing the relative EE of the remanufacturing of personal computers and mobile phones [

12]. Deng et al. identified the key factors affecting the EE of remanufacturing based on the theory of fuzzy DEMATEL (decision making trial and evaluation laboratory) [

13]. Liu et al. established a competition decision model based on EE and considered that the remanufacturer, with a cost advantage, can enjoy a lower product price and a higher manufacturing profit [

14].

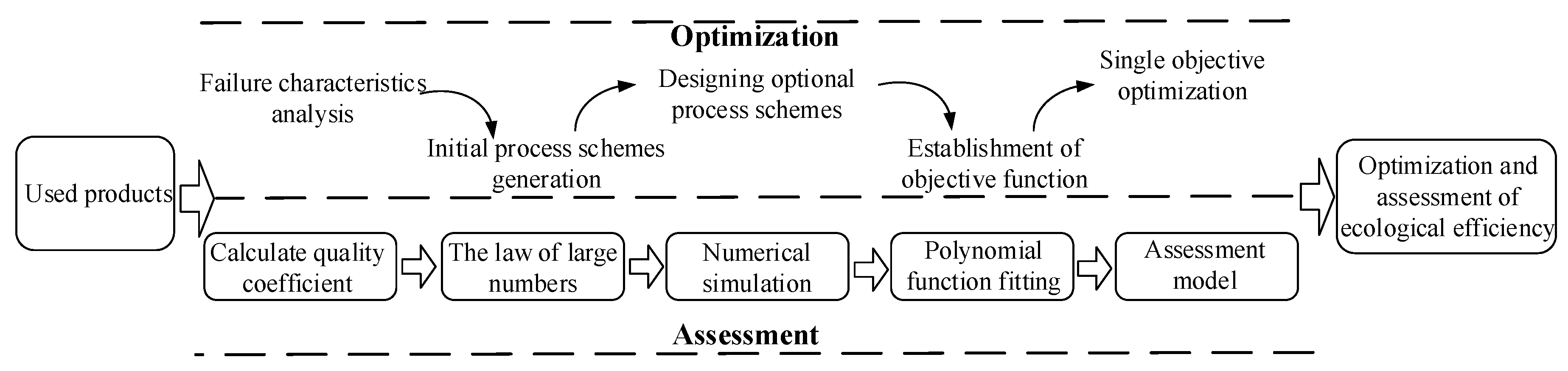

There was no doubt that these scholars have made useful attempts to study the EE of remanufacturing, such as the fuzzy DEMATEL theory, competitive decision model, etc. But the literature did not clearly define, quantify and evaluate the remanufacturing EE, nor use it as an evaluation index to guide the remanufacturing process schemes optimization. In fact, compared with the previous qualitative analysis of EE, the quantification, evaluation and optimization of EE play a decisive role in maximizing the EE of enterprises, because it directly affects the reconditioning process of remanufacturing. Based on this, the EE of the remanufacturing process is studied from two aspects of optimization and evaluation.

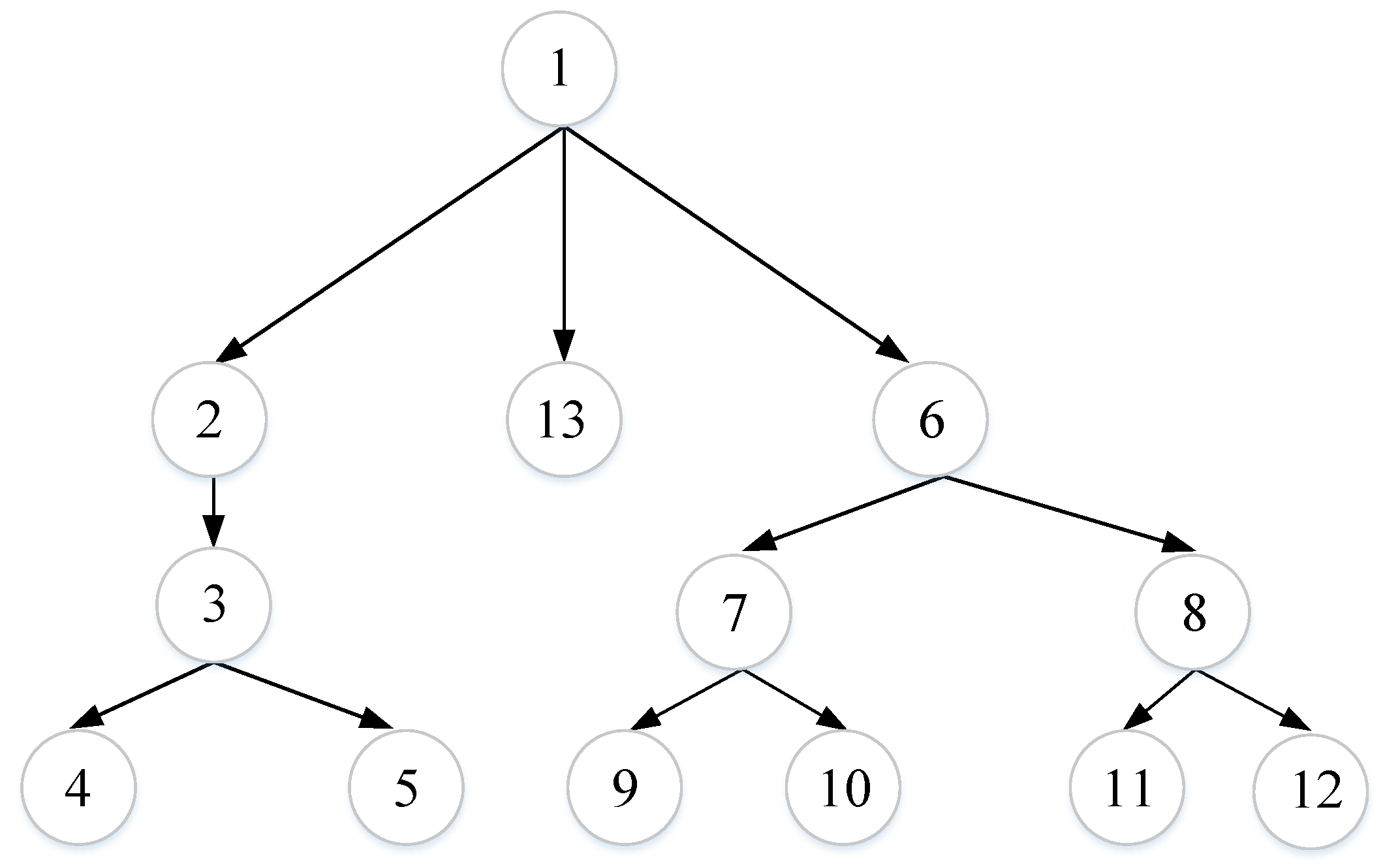

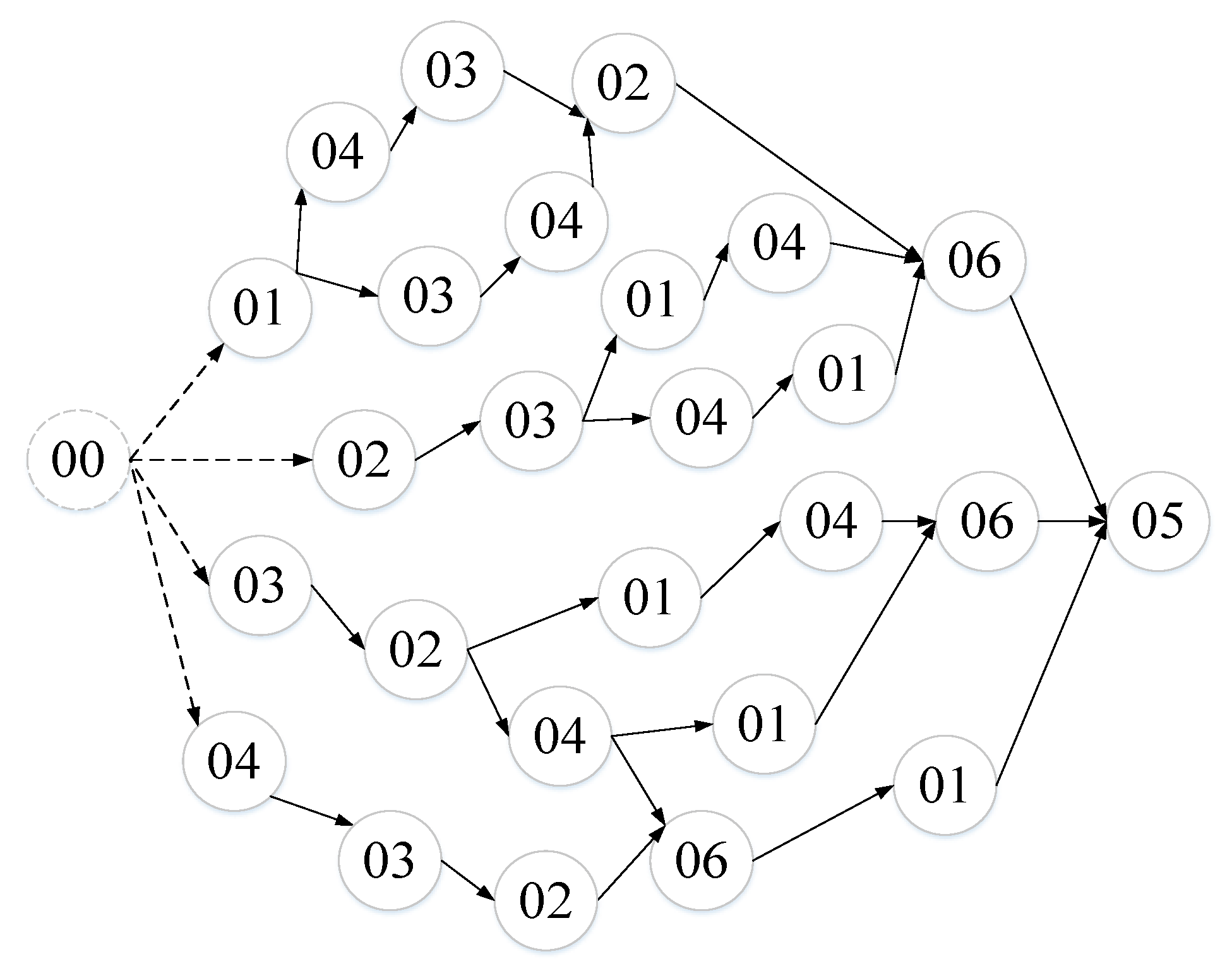

In the optimization stage, the EE of remanufacturing is defined and quantified firstly; secondly, the optional process schemes are designed by fault characteristics analysis and directed graph (DG), and then the process scheme with the optimal EE is obtained by using a suitable algorithm. At present, ant colony algorithm (ACO) is widely used in the remanufacturing process scheme optimization. Compared with other optimization algorithms, ACO has the advantages of self-organization, positive feedback and robustness. For example, in literature [

15], two ACOs were used to solve the displacement flow shop scheduling problem with the goal of minimizing the completion time. Su et al. used ACO to optimize the assembly model for the remanufacturing of construction machinery [

16]. Ma et al. used ACO to solve the problem of remanufacturing mixed economic batches with limited inventory capabilities [

17]. Undoubtedly, these studies have made valuable attempts to apply ACO to single-objective optimization, but as a global optimization algorithm, ACO also has some shortcomings, such as long search time, being trapped in a local optimum and the stagnation phenomenon. In order to overcome these shortcomings, elite ant strategy is introduced to form a new algorithm (ES-ACO). ES-ACO introduces elite ant strategy in the update pheromone phase of ACO. This strategy can adjust the pheromone concentration of the algorithm to enhance the global search ability of the algorithm, which makes the algorithm more advantageous in solving quality and iteration speed, such as shortening the search time, effectively avoiding the occurrence of local optimum and stagnation. In view of these theoretical merits of ES-ACO, ES-ACO is applied as the algorithm for the process scheme optimization. At the same time, in order to demonstrate the advantages of ES-ACO, ACO is set as a comparison algorithm to detect the performance of ES-ACO.

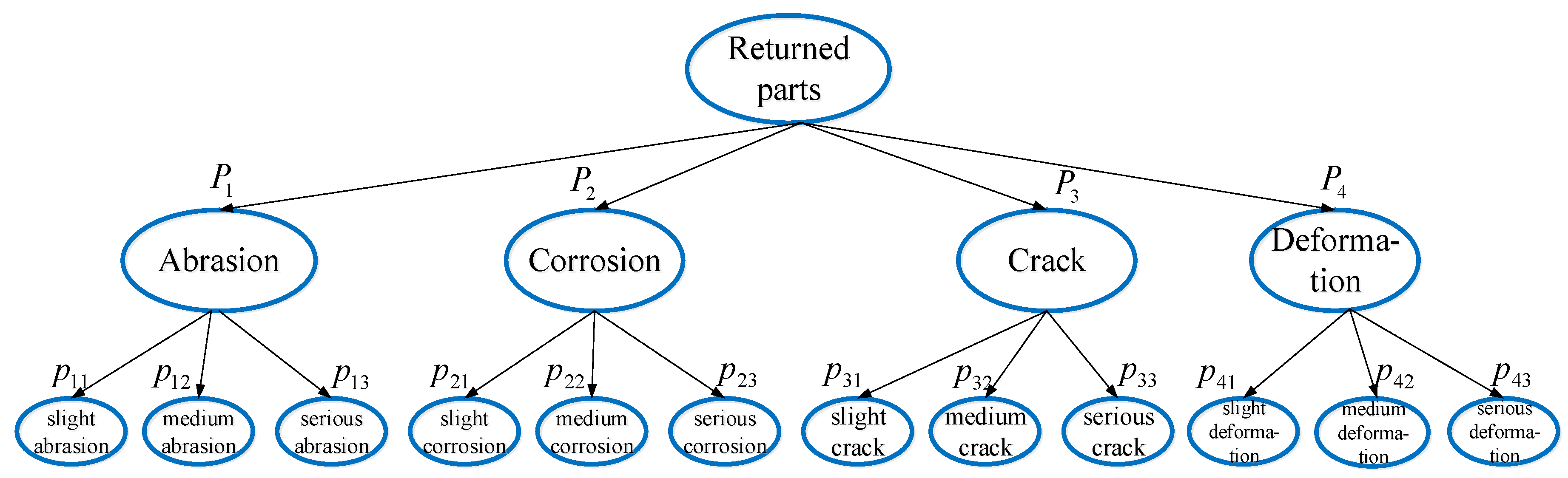

In the evaluation stage, the quality coefficient of the used components is calculated based on the fault characteristics information, and then the evaluation model of the optimized EE oriented to the quality coefficient is constructed by numerical simulations (NS) and polynomial function fitting (PFF). At the same time, the cost factor is considered to obtain the quality range of the used components that can be remanufactured.

From the previous studies, it can be found that one of the difficulties in the study of the EE of the remanufacturing process is the lack of a reasonable method, which can optimize and evaluate EE. There are four following innovations in this paper: (1) Designing alternative process schemes. The initial process sub-schemes are generated based on the fault characteristics, and then a set of process schemes are integrated by DG. (2) Using ES-ACO to optimize single objective function. The objective function of EE is established, and then ES-ACO is used to find the process scheme with the optimal EE. (3) Correlation analysis. The correlation between quality coefficient and the optimized EE is analyzed by using NS. (4) Polynomial function fitting. The functional relationship between the quality coefficient and the optimized EE is established, and then the quality range of used components suitable for remanufacturing under cost constraints is determined.

4. Conclusions

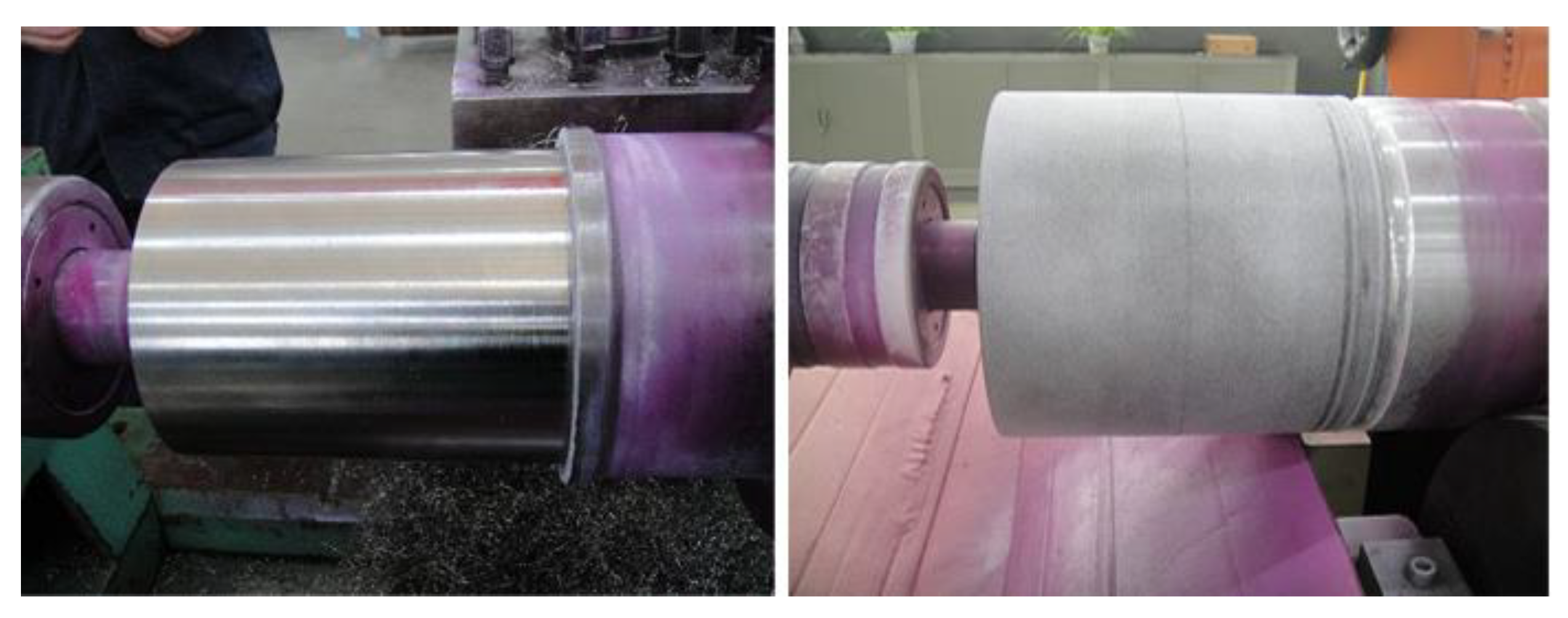

A research method of remanufacturing process EE considering optimization and evaluation is proposed. In this method, firstly, a process scheme with the optimal EE is obtained by failure characteristics analysis, DG and ES-ACO. After that, the evaluation model of the optimized EE is obtained by calculating the quality coefficient, correlation analysis and PFF. Meanwhile, the quality range of used components suitable for remanufacturing is calculated under cost constraints. Finally, the validity of the proposed method is validated by the example of the remanufacturing of commonly used lathe spindles.

Generally, studying the remanufacturing EE can better reflect the production demands of enterprises than other indicators (such as cost and time). For the used components to be remanufactured, the evaluation method proposed in this paper can be used to evaluate the optimal remanufacturing EE value; based on this value, the company can theoretically make decisions on whether or not to remanufacture these used components. Then, once the used components for remanufacturing have been identified, the optimization method proposed in this paper can be applied to optimize the remanufacturing process to achieve the best EE. At the same time, in order to avoid excessive pursuit of EE and neglect the profit of remanufacturing, the quality range of used components suitable for remanufacturing is theoretically screened from the perspective of cost constraints. However, other process attributes of used components (except for failure characteristics), such as material features and surface hardness, will also affect EE of remanufacturing process. How to comprehensively consider these process attributes to analyze EE should be the attention of future research.