Preparation and Performance Analysis of Graphite Additive/Paraffin Composite Phase Change Materials

Abstract

:1. Introduction

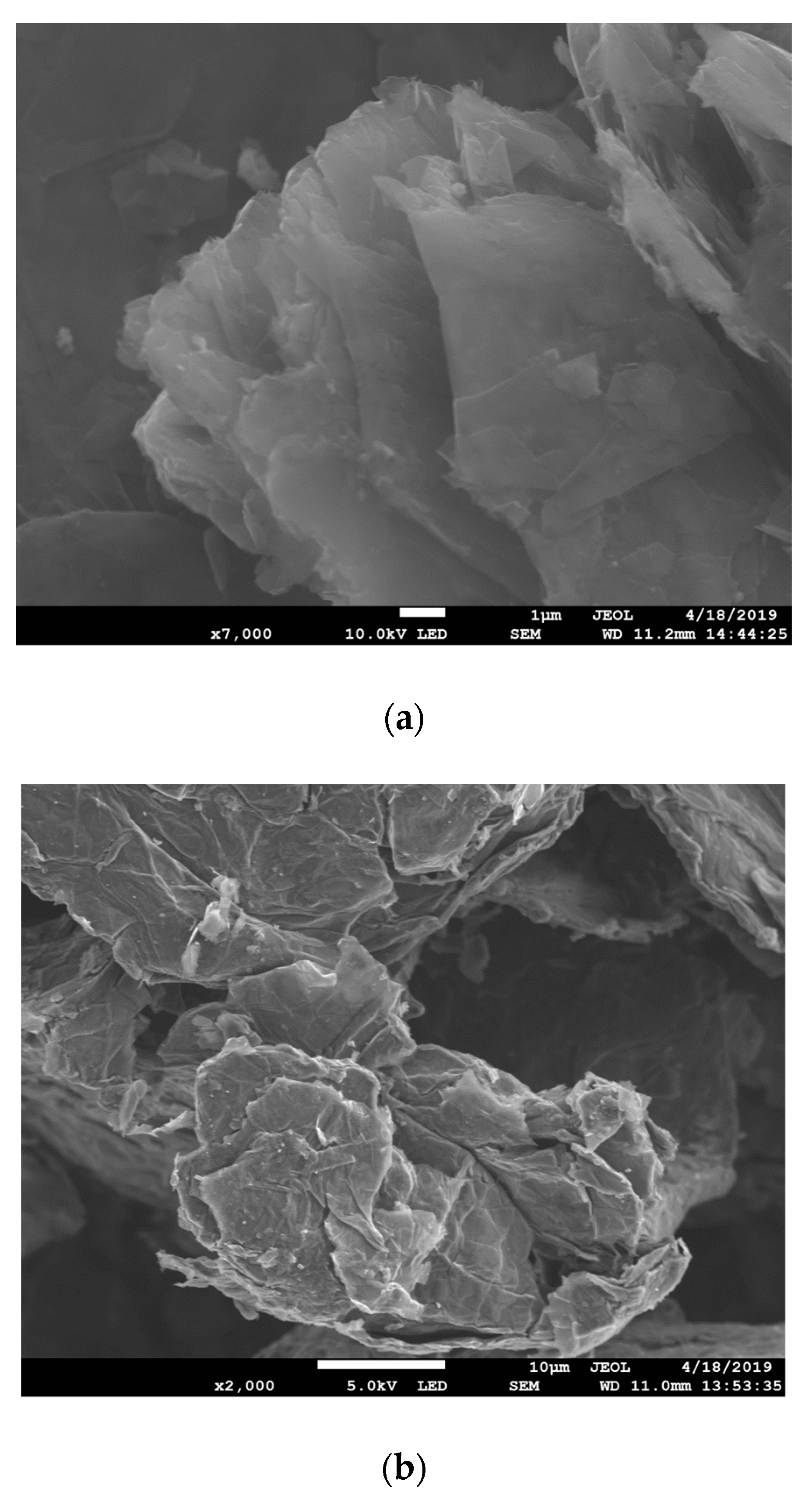

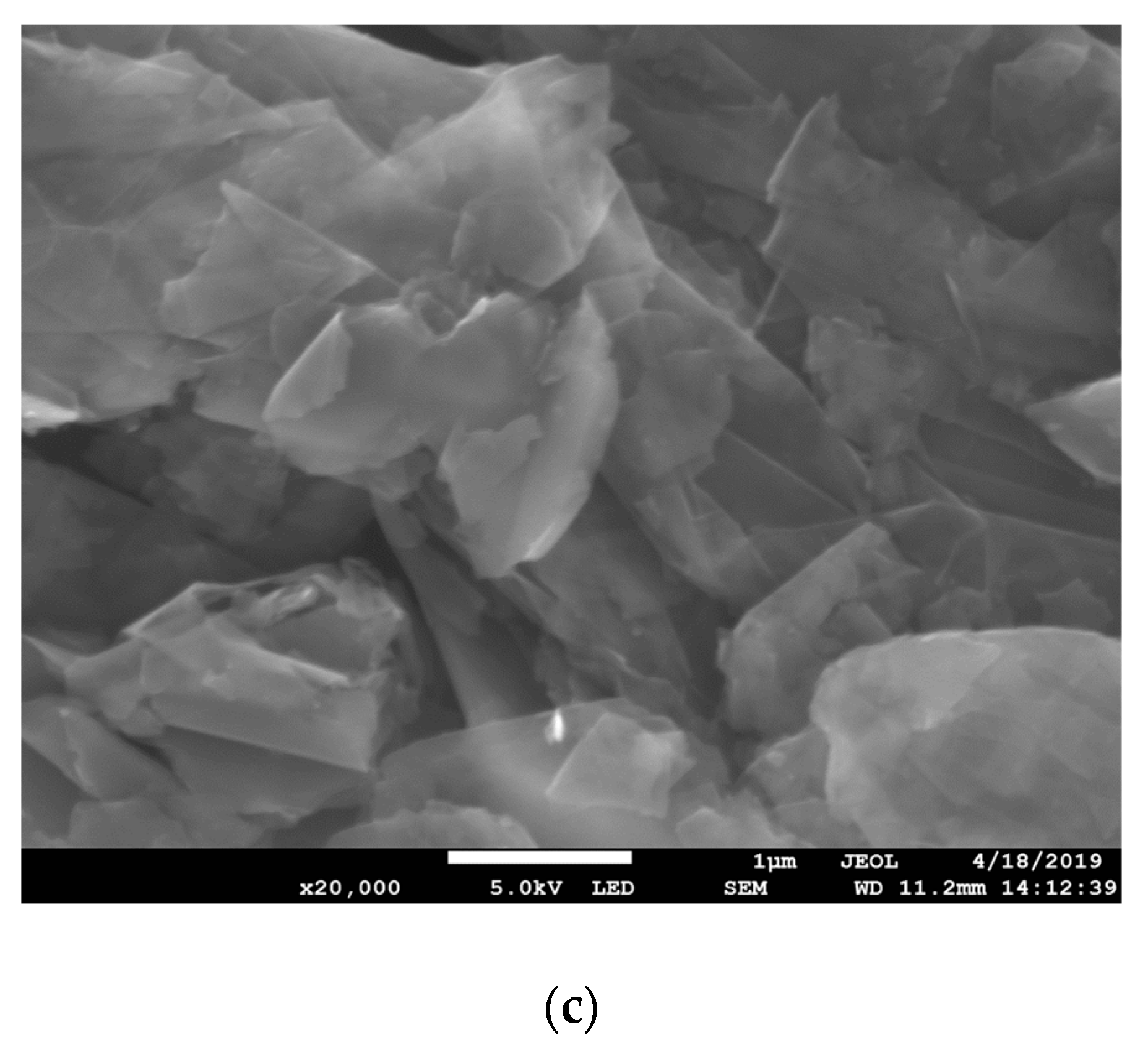

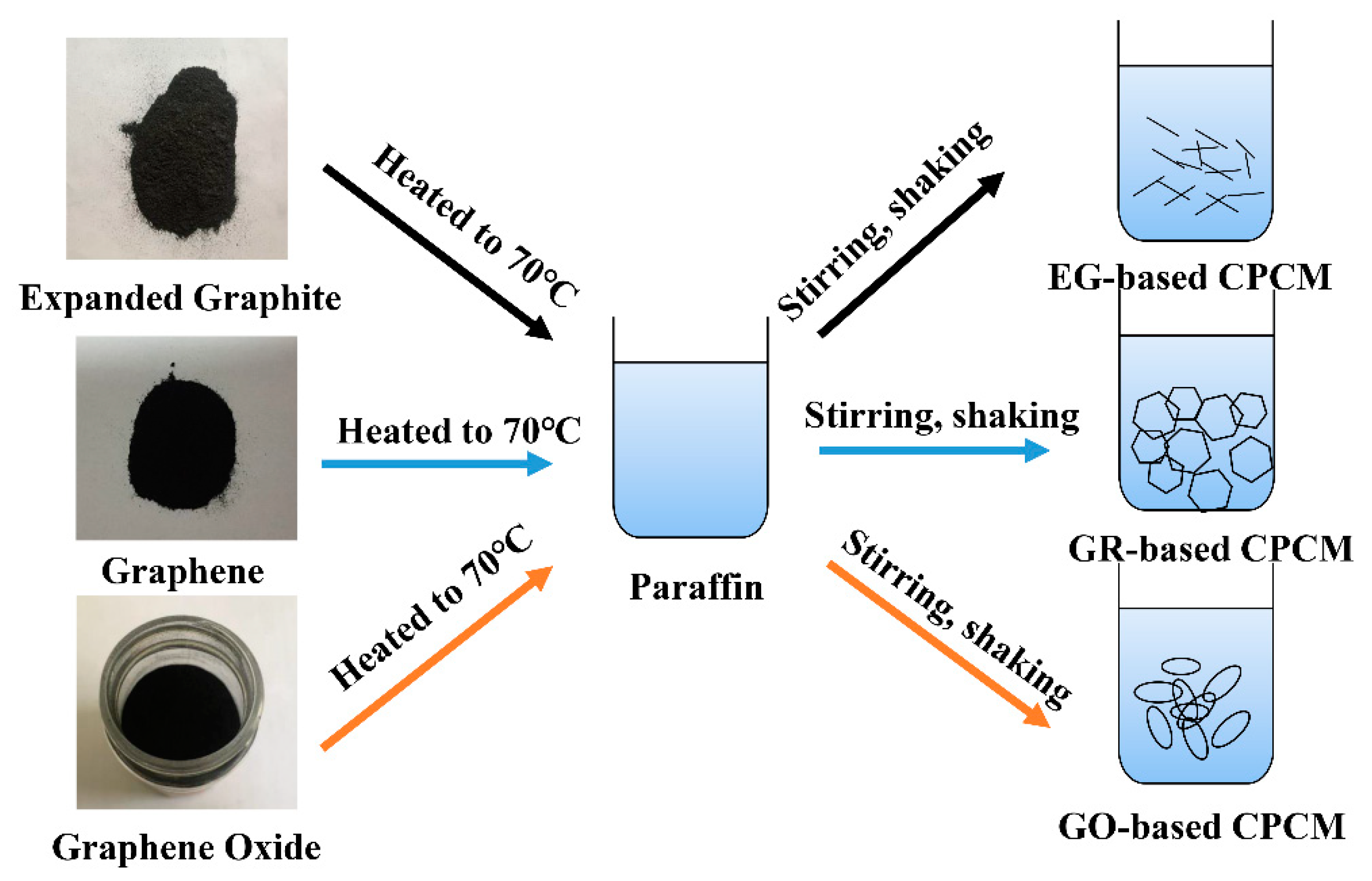

2. Materials and Experimental Methods

2.1. Material and Preparation

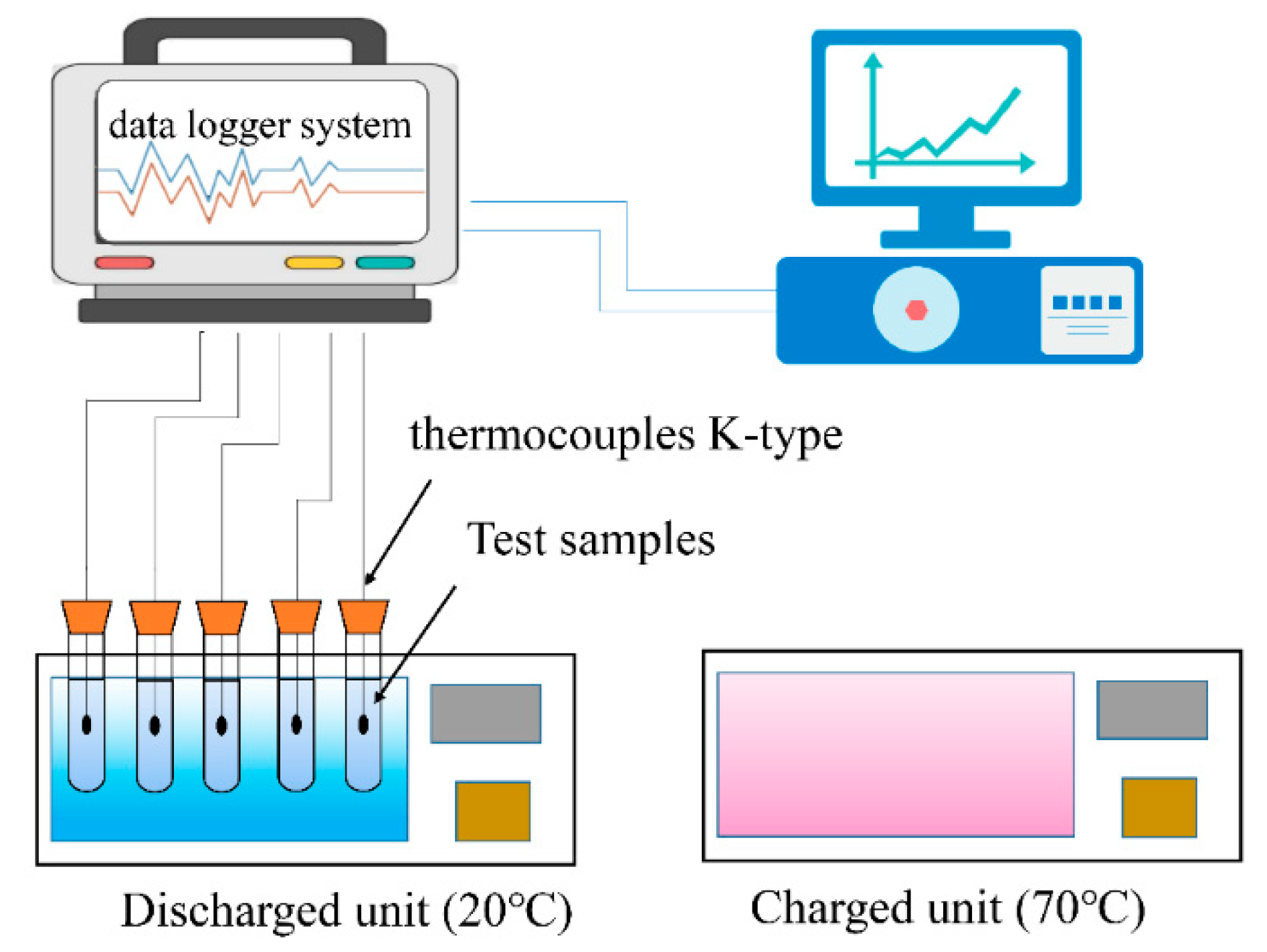

2.2. Test System of Heat Transfer Performance

2.3. Experimental Preparation

- (1)

- Preparing stage: Number the test tubes filled with CPCM with different additives (GO, EG, and GR) and different loadings (0.5%, 1.0%, 1.5% and 2.0%). Put the test tubes into the low-temperature water bath for 2 h to unify their temperatures.

- (2)

- Charge stage: Transfer the test tubes to the high-temperature water bath. The charge processes and the temperature changes of the CPCM are recorded by the digital camera and the data acquisition system, respectively. When the temperatures collected by the thermocouples are stable at 70 °C, the charge stage is deemed to have been completed.

- (3)

- Discharge stage: After the charge stage, the test samples are rapidly transferred to the low-temperature water bath. The temperature changes of the CPCM are recorded by the data acquisition system until they are stable at 20 °C.

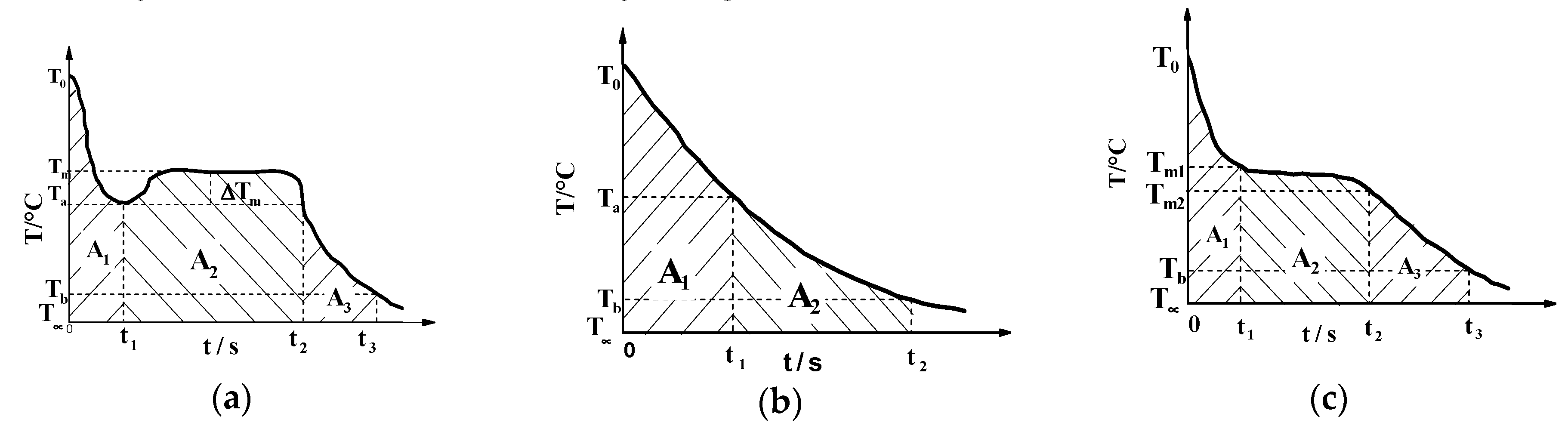

2.4. Measurements of the Thermophysical Properties

3. Results and Discussions

3.1. Compatibility of Composite PCM

3.2. Analysis of the Charge Process

3.3. Analysis of the Discharge Process

3.4. Thermophysical Properties

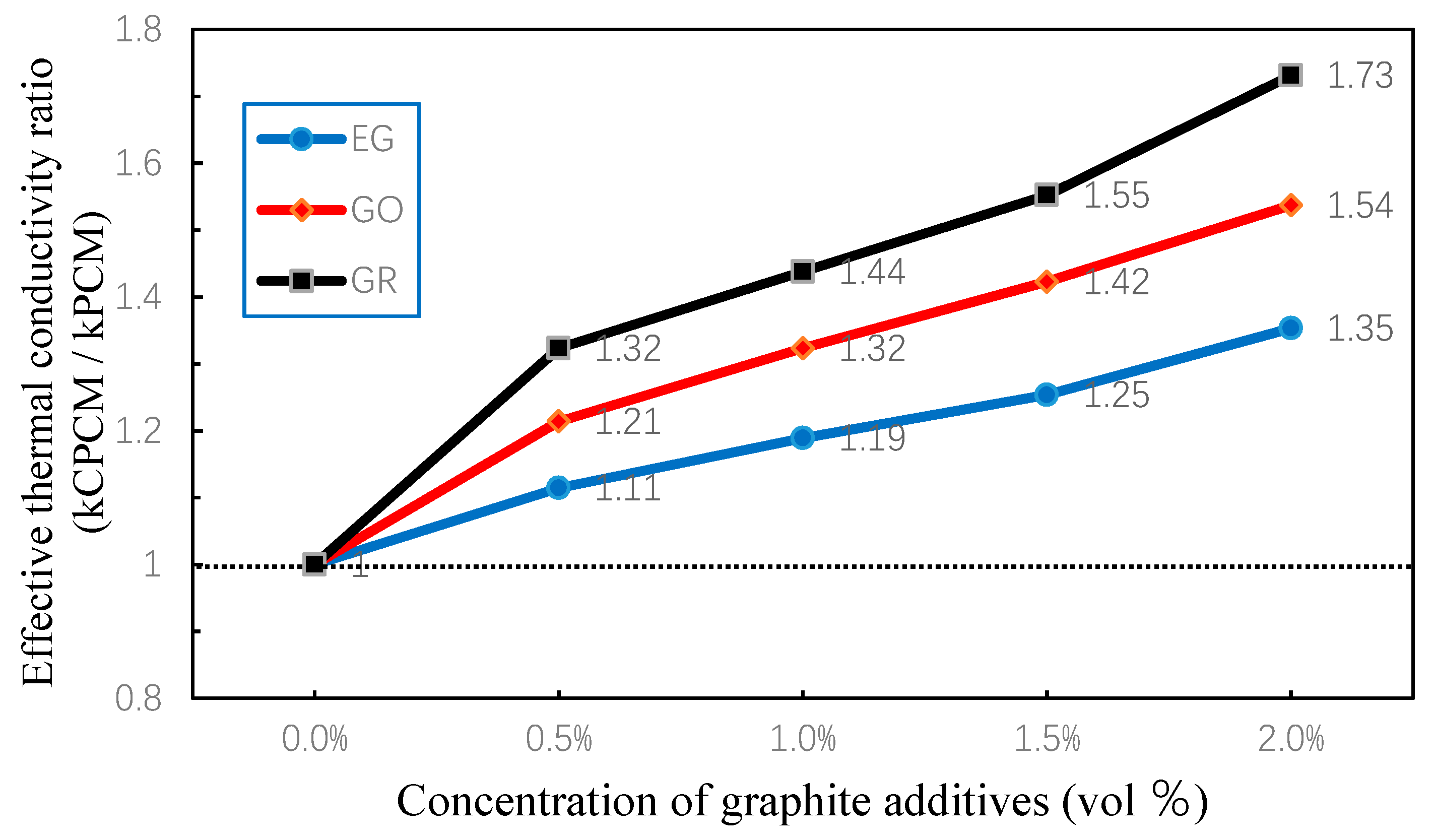

3.4.1. Thermal Conductivity

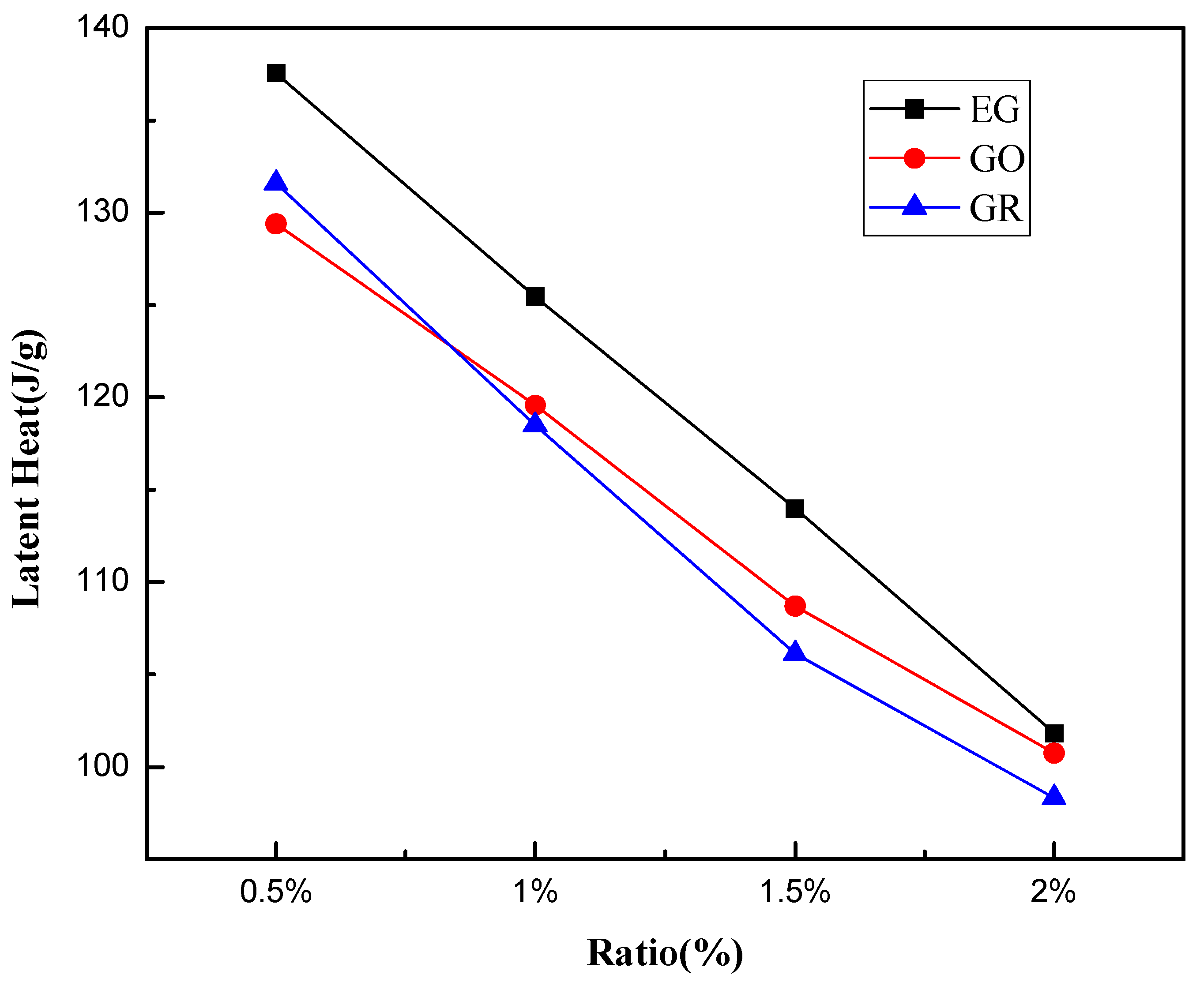

3.4.2. Latent Heat

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zou, D.Q.; Ma, X.F.; Liu, X.S.; Zhang, P.J.J.; Hu, Y.P. Thermal performance enhancement of composite phase change materials (PCM) using graphene and carbon nanotubes as additives for the potential application in lithium-ion power battery. Int. J. Heat Mass Transf. 2018, 120, 33–41. [Google Scholar] [CrossRef]

- Zhang, H.L.; Fang, X.D.; Zhao, Y.J. Progress in Phase Change Materials and Technologies. Mater. Rev. 2014, 28, 26–32. [Google Scholar]

- Sheng, Q.Q.; Zhang, X.L. Research about the Wax Composite Phase Change Materials. Refrig. Air Cond. Electr. Power Mach. 2008, 2, 18–20, 31. [Google Scholar]

- Zhang, Z.G.; Wen, L.; Fang, X.M.; Shao, G.; Huang, Y.F. Research and Development on Composite Phase Change Thermal Energy Storage Materials. Chem. Ind. Eng. Prog. 2003, 05, 462–465. [Google Scholar]

- Zhang, P.; Meng, Z.N.; Zhu, H.; Wang, Y.L.; Peng, S.P. Melting heat transfer characteristics of a composite phase change material fabricated by paraffin and metal foam. Appl. Energy 2017, 195, 1971–1983. [Google Scholar] [CrossRef]

- Ji, J.; Zeng, T.; Zhang, X.L.; Ren, Y.L.; Chen, Y.F.; Gao, Y.H. Preparation and Properties of Water-based Nano-TiO2 Composite Phase Change Material. J. Refrig. 2018, 39, 90–97. [Google Scholar]

- Wang, Y.Q. Preparation of Paraffin/Nano-SiO2 Composite Phase Change Material and Its Performance of Electronic Thermal Protection. Master’s Thesis, South China University of Technology, Guang Zhou, China, 2016. [Google Scholar]

- Zhang, P.; Meng, Z.N.; Zhu, H.; Wang, Y.L.; Peng, S.P. Experimental and Numerical Study of Heat Transfer Characteristics of a Paraffin/Metal Foam Composite PCM. Energy Procedia 2015, 75, 3091–3097. [Google Scholar] [CrossRef] [Green Version]

- Elbahjaoui, R.; Qarnia, H.E. Transient behavior analysis of the melting of nanoparticle-enhanced phase change material inside a rectangular latent heat storage unit. Appl. Therm. Eng. 2016, 112, 720–738. [Google Scholar] [CrossRef]

- Yu, H.; Liu, F.; Meng, E.L.; Yao, X.L. Heat Transfer Characteristics of the Melting Process of the Metal Foam/Paraffin Compound Material. J. Civ. Archit. Environ. Eng. 2011, 33, 112–116. [Google Scholar]

- Lu, W.; Wu, Y.W. Preparation and Study on the Performance of the Nano-Aluminum/Paraffin/Expanded Graphite Phase Change Composites. J. Eng. Therm. Energy Power 2017, 32, 101–105, 140–141. [Google Scholar]

- Kibria, M.A.; Anisur, M.R.; Mahfuz, M.H.; Saidur, R.; Metselaar, I.H.S.C. A review on thermophysical properties of nanoparticle dispersed phase change materials. Energy Convers. Manag. 2015, 95, 69–89. [Google Scholar] [CrossRef] [Green Version]

- Parlak, M.; Kurtuluş, S.; Temel, U.N.; Yapici, K. Thermal property investigation of multi walled carbon nanotubes (MWCNTs) embedded Phase Change Materials (PCMs). In Proceedings of the Thermal and Thermomechanical Phenomena in Electronic Systems, IEEE, Las Vegas, NV, USA, 31 May–3 June 2016; pp. 639–644. [Google Scholar]

- Wang, X.; Ding, Q.; Yao, X.L.; Fang, X.; Xu, X.; Yu, Z.T.; Hu, Y.C. Thermophysical properties of paraffin-based composite phase change materials filled with carbon nanotubes. J. Therm. Sci. Technol. 2013, 12, 124–130. [Google Scholar]

- Teng, T.P.; Cheng, C.M.; Cheng, C.P. Performance assessment of heat storage by phase change materials containing MWCNTs and graphite. Appl. Therm. Eng. 2013, 50, 637–644. [Google Scholar] [CrossRef]

- Wang, Y.M.; Ding, Y.F.; Wu, H.J. Performance of paraffin/carbon nanotube composite phase change material. Mod. Chem. Ind. 2015, 35, 130–134. [Google Scholar]

- Mo, Y.B.; YU, H.Q.; Liao, Y.F.; Zhou, H. Review of paraffin wax phase change materials for thermal energy storage. Mod. Chem. Ind. 2016, 36, 50–54. [Google Scholar]

- Mehrali, M.; Latibari, S.T.; Mehrali, M.; Metselaar, H.S.C.; Silakhori, M. Shape-stabilized phase change materials with high thermal conductivity based on paraffin/graphene oxide composite. Energy Convers. Manag. 2013, 67, 275–282. [Google Scholar] [CrossRef]

- Xiao, X.; Zhang, P. Thermal Characterization of Graphite Foam/Paraffin Composite Phase Change Material. J. Eng. Thermophys. 2013, 34, 530–533. [Google Scholar]

- Xia, L.; Zhang, P.; Wang, R.Z. Preparation and thermal characterization of expanded graphite/paraffin composite phase change material. Carbon 2010, 48, 2538–2548. [Google Scholar] [CrossRef]

- Chen, J.J.; Xu, T.; Fang, X.M.; Gao, X.N. Performance Study on Expanded Graphite Based Dodecane Composite Phase Change Material for Cold Thermal Energy Storage. J. Eng. Thermophys. 2015, 36, 1307–1310. [Google Scholar]

- Kant, K.; Shukla, A.; Sharma, A.; Biwole, P.H. Heat transfer study of phase change materials with graphene nano particle for thermal energy storage. Sol. Energy 2017, 146, 453–463. [Google Scholar] [CrossRef]

- Da, H.C.; Lee, J.; Hong, H.; Kang, Y.T. Thermal conductivity and heat transfer performance enhancement of phase change materials (PCM) containing carbon additives for heat storage application. Int. J. Refrig. 2014, 42, 112–120. [Google Scholar]

- Zhang, Y.P.; Jiang, Y. A simple method, the T-history method, of determining the heat of fusion, specific heat and thermal conductivity of phase-change materials. Meas. Sci. Technol. 1999, 10, 201. [Google Scholar]

- Fan, L.W.; Zhu, Z.Q.; Zeng, Y.; Lu, Q.; Yu, Z.T. Heat transfer during melting of graphene-based composite phase change materials heated from below. Int. J. Heat Mass Transf. 2014, 79, 94–104. [Google Scholar] [CrossRef]

- Venkata Sastry, N.N.; Bhunia, A.; Sundararajan, T.; Das, S.K. Predicting the effective thermal conductivity of carbon nanotube based nanofluids. Nanotechnology 2008, 19, 055704. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Hecht, D.S.; Grüner, G. Percolation in Transparent and Conducting Carbon Nanotube Networks. Nano Lett. 2014, 4, 2513–2517. [Google Scholar] [CrossRef]

| Paraffin | Thermal conductivity (W/m·K) | 0.2 |

| Melting point (°C) | 52 | |

| Density (kg/m3) | 800 | |

| Latent heat (J/g) | 160.8 | |

| Expanded graphite | Carbon content (%) | ≥99.5 |

| Particle size (mesh) | 325 | |

| Expansion ratio (times) | 40~425 | |

| Graphene | Thickness (nm) | 0.55~3.8 |

| Specific surface area (m2/g) | 50~100 | |

| Thermal conductivity (W/m·K)) | ~5000 | |

| Graphene oxide | Purity (%) | 95~99 |

| Thickness (nm) | 0.8~1.2 |

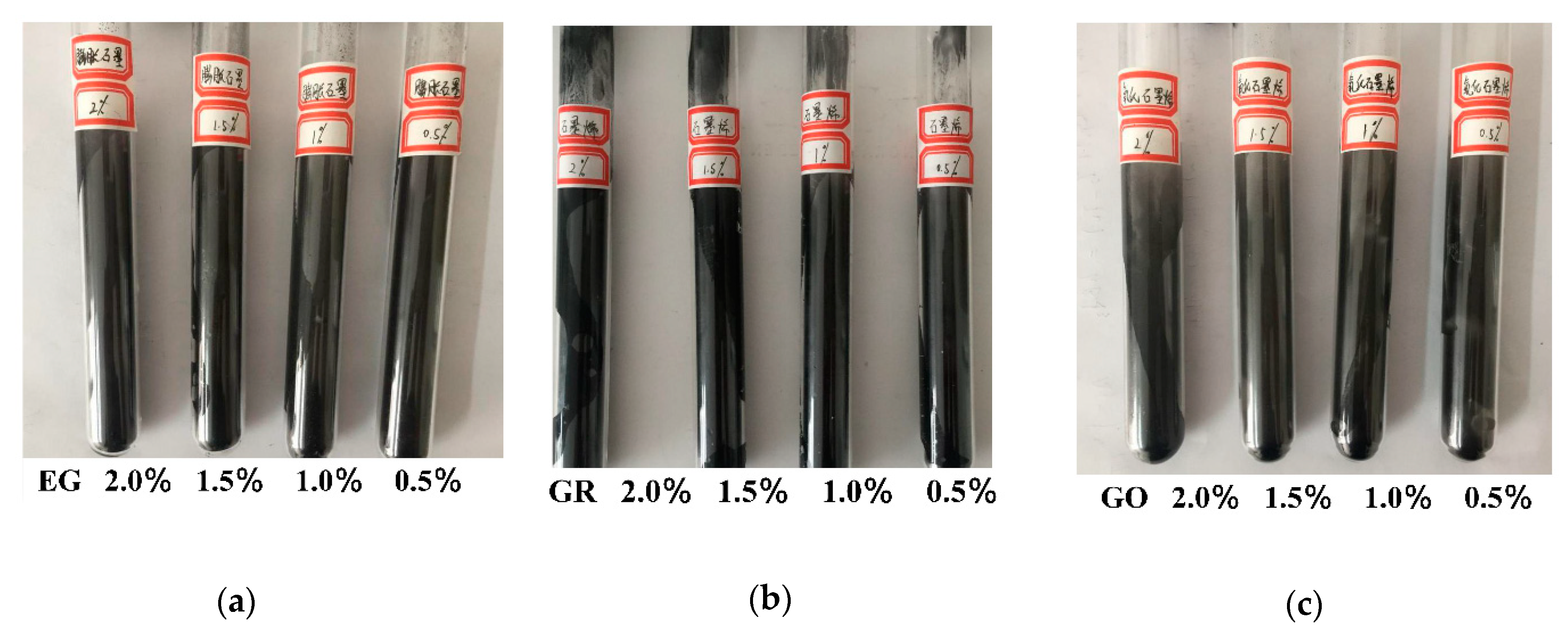

| CPCM | Melting Point (°C) | Latent Heat (J/g) | Liquid Specific Heat Capacity (J/kg·K) | Solid Specific Heat Capacity (J/kg·K) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|---|

| Pure paraffin | 52°C | 146.97 | 2773.758 | 3886.135 | 0.201 |

| 0.5% EG | 51°C | 137.56 | 2683.367 | 3623.256 | 0.224 |

| 1.0% EG | 51°C | 125.47 | 2522.432 | 3418.309 | 0.239 |

| 1.5% EG | 52°C | 113.98 | 2384.305 | 3178.919 | 0.252 |

| 2.0% EG | 53°C | 101.84 | 2240.271 | 3085.336 | 0.272 |

| 0.5% GO | 51°C | 129.41 | 2632.573 | 3609.049 | 0.244 |

| 1.0% GO | 51°C | 119.57 | 2338.629 | 3240.265 | 0.266 |

| 1.5% GO | 52°C | 108.69 | 2215.676 | 3189.368 | 0.286 |

| 2.0% GO | 55°C | 100.76 | 2102.365 | 3055.634 | 0.309 |

| 0.5% GR | 52°C | 131.60 | 2409.717 | 3224.259 | 0.266 |

| 1.0% GR | 52°C | 118.51 | 2144.818 | 3153.062 | 0.289 |

| 1.5% GR | 55°C | 106.12 | 2031.645 | 3021.319 | 0.312 |

| 2.0% GR | 56°C | 98.33 | 1931.629 | 3010.212 | 0.348 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Dong, Y.; Zhang, X.; Liu, X. Preparation and Performance Analysis of Graphite Additive/Paraffin Composite Phase Change Materials. Processes 2019, 7, 447. https://doi.org/10.3390/pr7070447

Li W, Dong Y, Zhang X, Liu X. Preparation and Performance Analysis of Graphite Additive/Paraffin Composite Phase Change Materials. Processes. 2019; 7(7):447. https://doi.org/10.3390/pr7070447

Chicago/Turabian StyleLi, Wei, Yan Dong, Xu Zhang, and Xueling Liu. 2019. "Preparation and Performance Analysis of Graphite Additive/Paraffin Composite Phase Change Materials" Processes 7, no. 7: 447. https://doi.org/10.3390/pr7070447

APA StyleLi, W., Dong, Y., Zhang, X., & Liu, X. (2019). Preparation and Performance Analysis of Graphite Additive/Paraffin Composite Phase Change Materials. Processes, 7(7), 447. https://doi.org/10.3390/pr7070447