Abstract

Process systems engineering (PSE), after being proposed by Sargent and contemporary researchers, has been fast developing in various domains and research communities around the world in the last couple of decades, with energy systems engineering featuring a typical yet still fast propagating domain, and the Chinese PSE community featuring a typical community with its own unique challenges for applying PSE theory and methods. In this paper, development of energy systems engineering and process systems engineering in China is discussed, and Sargent’s impacts on these two fields are the main focus. Pioneering work conducted by Sargent is firstly discussed. Then, a venation on how his work and thoughts have motivated later researchers and led to progressive advances is reviewed and analyzed. It shows that Sargent’s idea of optimum design and his work on nonlinear programming and superstructure modelling have resulted in well-known methods that are widely adopted in energy systems engineering and PSE applications in tackling problems in China. Following Sargent’s pioneering ideas and conceptual design of the PSE mansion, future development directions of energy systems engineering are also discussed.

1. Introduction

Process systems engineering (PSE) is an interdiscipline of chemical engineering and systems engineering. It aims at providing a systematic methodology for chemical engineering decisions [1,2]. Energy systems engineering (ESE) is a branch of PSE, applying theories from PSE to analyses of energy systems. Since the beginning of PSE and ESE, their application to the industry has produced significant benefits. Researchers are putting more and more emphasis on these two disciplines.

Professor Sargent is entitled the father of PSE, since he had made great contributions to design, boost, and lead the PSE field. His work and impact can almost be found in every corner of PSE, including process design, process control, and others. In addition, his thoughts have a leading role for the development of PSE. A tribute of Sargent, which summarized his important work and his impact had been written by Doherty et al. [3]. However, there seems to be a lack of review work on Sargent’s impact on ESE. Moreover, Sargent’s work has inspired many research communities around the world with their unique yet challenging PSE problems. Furthermore, a study on Sargent’s impact on the Chinese PSE development is chosen in this review.

The remaining part of the paper is organized as follows. Firstly, Sargent’s major contributions, especially those with direct impact with energy systems engineering and PSE applications in China, are discussed. Development of energy systems engineering, guided by the framework set by Sargent, and applications in solving local challenging problems of China, inspired by Sargent’s work, are then summarized. Last, future directions of energy systems engineering are proposed, following the PSE framework set up by Sargent, and based on characteristics of energy systems which are unique from a generic process system.

2. Contributions of Professor Sargent

Over his research career, Professor Sargent made tremendous contributions to the field of PSE. His work can be found in almost every discipline, including system decomposition, optimal design, process control, solution of nonlinear algebraic equations (NAE), differential algebraic equations (DAE), and others. In addition, it is more creditable that Professor Sargent does not only make great achievements in his own research, but also acts as a leader of PSE researchers, providing guiding light for the development of the whole field. In 1967, he published an inspiring and insightful article, pointing out possible directions for future research [4]. The most important one in this article might be the idea of integrated design, i.e., combining design and optimization instead of regarding them as two separate tasks. Sargent also pointed out the need for future work in better understanding of physical mechanisms of chemical process, in development of model simplification techniques, and in exploration of dynamic behaviour. In 1971, he presented another review article as a supplement of the former one [4], in which he pointed out that much work remained to be done in the solution of large-scale NAEs, stochastic optimal control, nonlinear filtering, and the automatic determination of model structure [5]. Those research directions he had mentioned have almost all become research frontends in the next few decades. With such significant contributions, Professor Sargent is regarded as the father of PSE. In this part, his contributions in several specific disciplines are discussed, whilst some of the significant work are further elaborated in the following sections.

In early years, Sargent had made much effort in system decomposition techniques. In 1964, Sargent and Westerberg developed two algorithms, one for decomposing a system into sequential groups, and the other for determining the computational order within a group, based on dynamic programming [6]. Later Sargent extended the research to systems of equations. In his article in 1977 [7], Sargent studied the connection between decomposition of systems of procedures and systems of equations, and extended Leigh’s algorithm [8] to recognizing linear subsets.

In terms of optimization, Sargent mainly focused on solution methods for nonlinear programming (NLP) problems. In 1969, based on the Davidon–Fletcher–Powell (DFP) method for unconstrained nonlinear optimization [9,10] and Rosen’s gradient projection method for dealing with constraints [11], Sargent and Murtagh developed the variable-metric projection (VMP) method for NLP [12]. In 1973, they further improved the VMP method in situations of nonlinear constraints [13]. Sargent also did much work to discuss the convergence property of the method, such as Sargent and Murtagh in 1970 [14], Sargent and Sebastian in 1973 [15], and Sargent in 1973 [16]. In 1978, Sargent proposed an efficient implementation of the Lemke algorithm, which could be used to solve quadratic programming (QP) problems [17]. Later this algorithm was used to derive an SQP algorithm in 2001 [18]. Sargent was also one of the first to study process design under uncertainty. In 1978, Grossmann and Sargent proposed an efficient method for NLP problems with uncertain parameters [19]. Their method aimed to design a plant that could meet the specifications over a bounded range of values of parameters, which was essentially the idea of robust optimization.

In process design, a proper representation of the model could make the analysis more convenient. Sargent had done much profound work in this area. In 1976, Sargent and Gaminibandara proposed the superstructure representation for synthesis of distillation columns [20]. In 1993, Sargent and his co-workers introduced the state-task-network (STN) representation for batch scheduling [21]. And in 1998, Sargent further applied the STN representation method to distillation systems [22].

The steady-state simulation of chemical processes usually involved the solution of large systems of NAEs. In 1980, Sargent presented a review of various methods for this problem, such as Newton’s method and least-change secant methods [23]. In addition, since solving the whole set of NAEs is rather difficult, development of equation-oriented decomposition techniques was motivated, as discussed above.

When it comes to dynamic simulation, the problem becomes the solution of large systems of DAEs. Sargent and co-workers had studied various solution methods, such as Cameron’s work on diagonally implicit Runge–Kutta (DIRK) methods and backward differentiation formulae (BDF) algorithms in 1981 [24]. In 1988, Sargent and his co-workers put this problem in a general mathematical formulation, and they used a BDF-based software to solve the problem of a plate distillation column described by index two DAEs [25].

3. Energy Systems Engineering

Energy systems engineering (ESE) is usually regarded as a branch of PSE, which aims to apply PSE methodologies to analyse energy systems. The concept of ESE was first proposed by Pistikopoulos and co-workers at the sixth European Congress of Chemical Engineering in 2007 [26]. According to their definition, energy systems engineering provides a methodological framework to address the complex energy and environmental problems by an integrated systematic approach, which accounts complexities of very different scales, ranging from technology, plant, to energy supply chain, and megasystem [27]. Typical methodologies include mixed integer programming (MIP), superstructure-based modelling, and others. In this chapter, the development of such techniques as related to Sargent’s ideas is discussed, and a venation on how researchers came to realize the usability and helpfulness of those PSE methods in energy systems research is given.

3.1. Development of Optimum Design and Synthesis

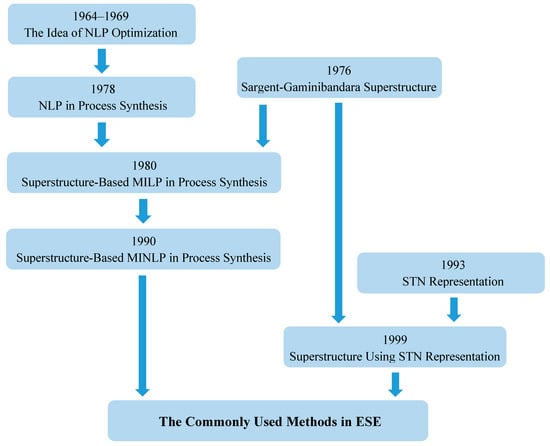

The venation on how Sargent’s original work in optimum design was gradually developed to commonly-used methods in ESE nowadays is illustrated in Figure 1. Detailed description of the relevant work is given in the following.

Figure 1.

The development of Sargent’s work in optimum design to methods used in energy systems engineering (ESE).

Professor Sargent was one of the first researchers to recognize the importance of optimization in PSE. Although his article in 1967 [4] was the most well-known for this idea, Sargent had actually come to it much earlier. In 1964, Sargent and Westerberg published an article describing their SPEED-UP program for analysis and design of chemical processes [6]. The main topic of the article is about decomposition techniques. However, it was mentioned that, at that time, design and optimization were usually treated as two separate tasks, which meant that a feasible design of the system would first be worked out, and then attempts would be made to change the parameters of the model for better performance, and that in optimization, no published work had discussed modifying plant structure to achieve optimum performance. Sargent and co-workers were attempting to develop a program called SPEED-UP, which could automatically make the optimum design of chemical systems, in which both the parameters and the structure would be modifiable. In the 1967 article [4], Sargent expressed this idea in more details. He defined process design as the determination of the fixed parameters for a process so that it meets the specifications as well as being optimum in some sense, and the criterion for being optimum is to maximize (or minimize) an objective function. In addition, he pointed out that it had become common practice to assume a fixed process flow diagram at the outset of design, but with the development of the computer it was hoped that the process structure could be decided automatically.

This idea was soon embodied in Sargent’s work. In 1969, Sargent and Murtagh described a program for performance calculation of distillation columns [28], and they pointed out that the program could be used in an integrated optimum design, forming an optimization problem where several degrees of freedom, such as the number of plates and the positions of the feeds, are to be fixed to minimize a specific objective function. This is a pioneering work in optimum design, and since it became necessary to solve optimization problems, usually NLP problems, Sargent began to conduct much research in this field. In 1969, Sargent and Murtagh developed the VMP method for solving NLP problems [12] and further developed it in 1973 [13]. The VMP method was one of the first algorithms for NLP that could handle both linear and nonlinear constraints. However, when applied to large-scale systems, it would show some shortcomings. Motivated by these deficiencies, in 1978, Murtagh and Saunders developed an algorithm for solving large-scale NLP problems with linear constraints, and a code was written based on it, which was now one of the widely used NLP solvers, MINOS [29].

For conventional design problems, the process flow diagram is fixed, and equations can be easily written according to the diagram. However, in optimum design, the structure and thus the flow diagram are modifiable, making it difficult for mathematical analysis. Drawing all functionally possible configurations and writing corresponding sets of equations is certainly an effective way, but such a combinatory problem requires too much effort and is of poor efficiency. Faced with this question, Sargent and Gaminibandara proposed the superstructure representation of the system in 1976 [20]. For the design of a separation system with multiple distillation columns, they concluded all possible configurations to one general system—superstructure, from which any particular configuration could be obtained by deleting some of the components in the system. Such deletions could be done through direct optimization of the superstructure, solving continuous NLP problems [30]. With Sargent’s idea of superstructure, tedious combinatory problems were avoided, and the optimum design problem could be solved using mathematical programming (MP).

In the meantime, research on the synthesis of heat exchanger network (HEN) emerged. HEN can be defined as a heat recovery system consisting of a set of heat exchangers [31]. By suitable arrangement of heat exchangers, the resulting HEN can have higher heat efficiency and make better use of thermal energy, leading to reduced energy consumption and costs. Around 1970, energy price became higher and higher, and thus researchers came to pay more attention to such a synthesis problem. The first one to tackle this problem was Rudd, who in 1967 presented an article discussing process synthesis with an example about the synthesis of a system of heat exchangers [32]. In addition since the HEN synthesis is for energy-saving purposes, Rudd’s work could also be regarded as the origin of ESE. In the current view, there are mainly two kinds of methods for the HEN synthesis problem, one based on thermodynamics and the other based on pure MP [33]. Rudd’s method [32] belongs to the latter, in which he formulated the problem as an unconstrained optimization problem. At first, Sargent did not pay much attention to this problem. However, his student Grossmann was obviously very interested in it. As was shown in Sargent’s retrospect [34], Grossmann obtained his Ph.D. at Imperial College in 1977, and during his doctoral research, he had involved Sargent in newer areas of the HEN synthesis, batch scheduling, and integer programming. Their cooperative work on optimum design of HEN was published in 1978 [35]. In addition, since Sargent had made great efforts in NLP-based process design, it is not surprising that in this paper NLP optimization was performed to solve the problem, which is a pioneering work in applying MP to the HEN synthesis. This work was also the first step into the MINLP-based HEN synthesis, as discrete variables were introduced to determine the configuration [36].

Since then Grossmann had been studying the solution of MINLP and its application. In 1979, Sargent and Grossmann considered the design of sequential multiproduct batch plants and formulated the problem as a mixed integer nonlinear programming (MINLP) one [37]. However, at that time no efficient methods for MINLP existed, so they used the VMP method to solve a relaxed NLP version of the problem, obtaining a practically satisfactory solution though it might be suboptimal rather than exactly optimal. Since MINLP was difficult to solve, in 1980, Grossmann and Santibanez suggested to reformulate those process synthesis problems as mixed integer linear programming (MILP) problems [38]. In 1983, Papoulias and Grossmann did so to the HEN problem and used the standard Branch & Bound (BB) technique to solve it [39].

The difficulty in MINLP has aroused much research interest. In 1986, Duran and Grossmann proposed the outer-approximation (OA) algorithm for solving MINLP [40]. Their algorithm was designed to solve MINLP problems in which integer variables are in linear form and the nonlinear functions are convex. In addition, on problems of this kind, OA would perform better than generalized benders decomposition (GBD) and BB, since it fully takes advantage of the problem structure. The requirements of OA are often satisfied in process synthesis problems. However, OA cannot explicitly handle nonlinear equality constraints. In the same year, Kocis and Grossmann developed an equality-relaxation (OA/ER) algorithm that could handle such constraints as well as preserve the advantages of OA [41]. In 1989, the two authors further wrote a computer code to implement OA/ER, and showed that it could solve MINLP problems efficiently [42]. Their code, DICOPT, has become one of the most commonly used solvers for MINLP nowadays. As efficient tools for MINLP had been well developed, the process synthesis problems were no longer restricted to MILP forms. In 1990, Grossmann reviewed the current MINLP strategies and algorithms, and illustrated their use in process synthesis [43].

The superstructure representation proposed by Sargent is naturally a method to formulate design problems as MINLP ones, since it covered all possible choices for equipment, pathways and others. As a result, with the rapid development of MINLP methodologies, superstructure-based modelling became more and more widely-known. Grossmann had made great contributions in spreading this method. In 1983, Papoulias and Grossmann proposed a superstructure for process synthesis problems of utility systems, which provide electricity, power and steam for the facilities in the plant [39]. What is worth mentioning is that their superstructure is a more detailed one than the Sargent–Gaminibandara superstructure [20], as the latter only included the possible configurations of the system, while theirs included the configurations as well as the available types of the equipment. However, at that time MINLP techniques were still immature, so the problem was in the form of MILP. In his 1990 paper [43], Grossmann gave a clear scheme for solving process synthesis problems, providing a systematic way to use superstructure representation and MINLP techniques in design problems. The scheme includes three steps, i.e., one should first postulate a superstructure involving all the feasible alternatives, then model the superstructure as an MINLP problem, and finally solve the problem to obtain the optimal design. Later this year, Yee et al. implemented this scheme in simultaneous synthesis of the process and its HEN [21]. Their work was ground-breaking, as it was the first time process synthesis problems were solved using superstructure-based MINLP modelling, showing the feasibility and usefulness of this method. In addition more importantly, as the HEN synthesis is to a large extent an energy problem, the work also showed the potential of this method in the field of ESE. After Sargent and his co-workers introduced the state-task-network (STN) representation for batch scheduling in 1993 [21], and for synthesis of distillation systems in 1998 [22], Yeomans and Grossmann presented a general framework of superstructure optimization in 1999 [44]. In their paper, two fundamental representations of superstructure, STN and its complementary, state-equipment-network (SEN), were given. Then they used generalized disjunctive programming (GDP) to model the superstructure, and reformulated the GDP problem as an MILP problem, which could be steadily solved. This systematic approach was widely adopted in Grossmann’s later research. Furthermore, the STN superstructure representation proposed in this paper, combined with Grossmann’s systematic scheme for design problems [43], became a commonly used method in ESE research. This method is especially useful in energy generating systems, as the production process of energy products is naturally in such a form, including states from feedstocks, intermediates to finals, and the technologies linking these states. Typical application will be discussed in the following sections.

3.2. Development of Environmentally Conscious Process Design

Pollution minimization is also an important topic in the field of ESE. As people were more aware of the importance of environmental protection and thus relevant regulations became stricter, the costs of pollution treatment to comply with these regulations were increasing rapidly [45]. These costs were so high that pollution prevention seemed to be a better way than pollution disposal. As many researchers had shown, reduction in pollution can lead to cost savings, and thus bring an increase in profits [46]. This led to a new objective in design problems, i.e., to minimize the wastes generated in the process. Furthermore, since there was no appropriate way to convert the amount of pollution to numerical values that were comparable with economic costs, it was infeasible to include pollution and costs in one objective function. Thus, environmentally conscious process design problems were inevitably multi-objective optimization problems.

Multi-objective optimization (MOO) was at first an economic problem, whose concept was proposed by Pareto in 1896. Several decades later, it became a popular topic in engineering. Methods for solving these problems were well developed, such as the ε-constrained method, which was proposed by Haimes et al. in 1971 [47], and the parametric programming method. However, it was not until 1980s that MOO was implemented in chemical engineering [48]. Additionally, as is stated above, such implementation could be attributed to the awareness of pollution reduction. One of the first attempts to include environmental considerations in design problems by MOO is the work by Grossmann and his co-workers in 1982 [49]. In their paper, the traditional optimal design framework was combined with the newly introduced environmental factors. To be specific, the considered type of pollution was the toxicity of the chemicals, and the two objectives were maximizing net present value (NPV) and minimizing a toxicity index. The ε-constrained method was adopted to solve this MOO problem. However, they only took into account the toxicity of material flows in the system, while ignoring the environmental impacts that had already been made before these materials flew into the system. This led to an unreasonable conclusion that the production of all intermediates should be carried out by suppliers [45].

Such a problem can be avoided by the life cycle assessment, also known as life cycle analysis (LCA), which is a methodology considering the environmental impact of a product in every stage of its life cycle. The first paper using LCA as a tool for process design was published in 1995 by Stefanis et al. [50]. They presented a method for minimizing environmental impact (MEI), which took advantage of LCA to give a systematic quantification of the wastes generated. Contrary to conventional design problems that only considered energy generation processes, in this method, the system boundary was expanded to include energy generation processes as well as raw material extraction processes, so that the pollution produced in the latter would not be neglected. Moreover through a case study, they found that minimizing pollution within the expanded system boundary led to lower operation costs than those obtained by minimizing pollution within the conventional boundary, which showed that LCA was a potentially useful tool in optimal design. One year later, Stefanis et al. applied this method of MEI in solvent design and reaction path synthesis problems [51]. This time they posed the problem in MOO, with a performance indicator and several environmental indices as the set of objective functions. In 1997, they extended this method to the optimal design and scheduling of batch processes, and similarly, formulated the problem as a MOO problem with economic costs and environmental criteria as two objectives [52]. The ε-constrained method was used to solve such problems, resulting in Pareto curves based on which compromise solutions could be obtained. Motivated by these researches, in 1999, Azapagic and Clift reviewed the application of LCA in process optimization [53]. In this article, they gave a formal definition of LCA and showed that MOO coupled with LCA could provide a powerful tool for balancing economic and environmental performance of a process from cradle to crave. Since then, MOO and LCA had become two common methodologies used for environmental problems in the field of ESE. These years, some software has also been developed to perform MOO and LCA in environmentally conscious process design, such as SustainPro [54] and LCSoft [55], both developed by Gani and co-workers. Although such software is still novel, it is believed that they will be put into wide use in the near future, bringing convenience to the implementation of sustainable design.

3.3. Other Techniques

Sargent has also made great contributions in many other fields of PSE, such as optimization under uncertainty, solution of NAEs and DAEs, optimal control, and others. In this part, his work on the former problems, which has been developed by later researchers to create widely-known algorithms or software nowadays, is given a detailed discussion.

When planning for a long future period, it is likely that changes will happen in the environment of the system. For example, the situation of the market might change for the better. Revolutions might happen in existing technologies. Such uncertainties should be involved in optimization, leading to a new field—optimization under uncertainty. One preferable approach to perform optimization under uncertainty is stochastic programming. In addition, Sargent was one of the first to propose a method of this kind. In 1978, Grossmann and Sargent proposed an efficient method for NLP problems with uncertain parameters [19]. In their work, the uncertainty was expressed by a bounded range of values of the parameters, and the objective of their method was to design the plants that could meet the specifications over such bounds, while obtaining the optimum value of a weighted cost function. Their model was a two-stage stochastic programming model, and the requirement that the process should be feasible under all possible realizations of the uncertain parameters was essentially the idea of robust optimization. In 1982, Halemane and Grossmann gave a new mathematical formulation of Sargent and Grossmann’s strategy so that the feasible operation under all possible situations could be rigorously ensured [56]. In 1985, Swaney and Grossmann considered another method to take into account uncertainty in their paper [57], in which an index of flexibility was proposed. Based on this work, in 1993, Straub and Grossmann proposed a method to maximize the stochastic flexibility [58]. Moreover, in this work, the uncertainty considered was in the form of probability distribution functions, rather than specific bounds. In 1995, Ierapetritou et al. proposed a combined multiperiod/stochastic programming formulation for optimization problems with uncertain parameters including both deterministic (expressed in bounded ranges) and stochastic (expressed in probability distribution functions) ones [59]. In the same year, Acevedo and Pistikopoulos gave several integration schemes for the approximation of the expected profit, which could be used in Ierapetritou et al.’s framework to find a trade-off between economic optimality and design flexibility [60]. These methods are widely applied to optimization problems under uncertainty.

Solution of systems of NAEs or DAEs is also a problem that frequently occurs in PSE research, and Sargent has made great contributions to this area. In terms of solution of NAEs, Sargent had presented a comprehensive article in 1980 [23], in which he discussed the existing solution methods of NAEs, the methods for ensuring global convergence, and the decomposition techniques for large problems. In addition, he also showed great interest in the way to facilitate the solution of NAEs through automatic algebraic manipulation. This idea was later further developed, giving rise to algorithms in the program developed by Sargent and his co-workers, SPEED-UP [3]. With regard to DAEs, Sargent and his co-workers were the first to point out the need for solving DAEs in PSE [61]. Since then Sargent and co-workers have made much effort to study available solution methods of DAEs [24] and to apply them to dynamic simulation of chemical processes [25]. Many of the algorithms they had developed were also incorporated in SPEED-UP. Around 1988, many researchers that had participated in the development of SPEED-UP started to design a new software, which is now one of the most frequently-used tools for process simulation, gPROMS [62]. This software is used in a large number of ESE studies, especially in modelling of energy-related devices. Typical applications include Kikkinides et al.’s work on hydrogen storage tanks [63], Kouramas and Pistikopoulos’s work on wind turbines [64], and others. There are also many other useful tools for dynamic simulation. In 1988, Cameron and Gani developed an adaptive Runge–Kutta algorithm for solution of ordinary differential equation systems [65]. This algorithm was incorporated in an equation-oriented dynamic simulator, DYNSIM, developed by Sorensen and co-workers in 1990 [66]. Later Gani et al. applied this software to solve simulation problems in the design and analysis of chemical processes [67].

3.4. Typical Work in ESE

In the above paragraphs, the development history of ESE has been combed, especially on how researchers came to apply PSE methods, including superstructure, MIP, LCA, MOO, optimization under uncertainty, and others, to dealing with energy and environmental problems. In this part, typical work in ESE will be listed. The work to be mentioned is only a little portion of the numerous volumes of ESE research, but it is possible to see from it the wide application of those methods that was developed from Sargent’s work or thoughts.

As mentioned above, energy problems and environmental problems are the two main questions in the field of ESE. These two kinds of problems are not separate problems. As many studies have already shown, the increase in energy efficiency has important impacts on the decrease in environmental pollution. As a result, the application of methods that can improve energy efficiency is paid much attention to.

One way to improve energy efficiency is to adopt co-generation. For processes that share the same intermediates, such as liquid fuel synthesis and combined cycle power generation, co-production can be made to achieve higher efficiency, which is the concept of polygeneration energy systems. In 2007, Liu et al. built a model for strategic decisions in the development progress of a polygeneration energy system [68]. The model was presented in a superstructure method, and the problem was first formulated as an MINLP one, while linearization techniques were adopted to convert it into an MILP one which could be solved more efficiently. The model was used to analyze the investment planning of polygeneration energy systems co-producing methanol and electricity in China between 2010 and 2035. In addition, it was shown that polygeneration technologies were indeed superior to stand-alone technologies. In 2009, based on the previous work, Liu et al. further studied the design optimization of polygeneration energy systems [69]. The problem was formulated as a superstructure-based non-convex MINLP problem. Moreover, the model was used for detailed analysis of a polygeneration plant for electricity and methanol. In 2010, Liu et al. presented a framework for optimal design of polygeneration energy systems under uncertainty [70]. They incorporated uncertainty in their previous model, leading to a two-stage stochastic programming program, which was then converted to a large-scale multiperiod MINLP problem through a decomposition-based strategy. A case study was conducted, in which uncertainty in the price of coal and the price and demand of methanol and electricity was considered. In 2011, Liu et al. studied the strategic planning of polygeneration energy systems in the supply chain level and conducted a case study for the UK [71].

In power generation, some energy will be inevitably discarded as waste heat. Combined heat and power (CHP) system is a system that co-generates electricity and heat so that a portion of waste heat can be used for heat supply, thus leading to higher energy efficiency. Further development of CHP systems led to combined cooling, heat and power (CCHP) systems, which use the waste energy not only for heat supply, but also as the driving power for refrigerators to produce cooling. Since the produced heat or cooling cannot be transported for a long distance, CHP or CCHP systems are usually distributed energy systems (DES), with the consumption of energy close to the production. In 2007, Arcuri et al. studied the optimal design of the CCHP system in a hospital complex by performing MILP optimization [72]. Their model was rather simple, in which only the energy provided by fuel was taken into account. In 2010, Liu et al. used the ESE framework to deal with the optimal design of DES in a supermarket [73]. In their model, fuel as well as other available energy sources were considered, including wind, solar and biomass energy. In 2013, Zhou et al. proposed an even more elaborate model, including six types of energy resources and twenty types of equipment [74]. Their model was used for optimal design of DES for a hypothetic hotel in Beijing, and it was shown that the system described by their model did better than centralized systems and traditional, simpler CCHP systems. In 2013, Kopanos et al. considered uncertainty in the scheduling of household CHP (or called micro-CHP) systems, and used parametric programming methods for solution [75].

The use of clean energy, such as hydrogen, is also given serious attention to. Since hydrogen was a novel kind of energy, its whole supply chain was to be designed. In 2005, Hugo et al. performed superstructure-based multi-objective MILP to study the optimal design of hydrogen infrastructure [76]. In every stage of the infrastructure, including production, transmission, storage and others, various technological options were considered. Greenhouse gas (GHG) emissions were evaluated using LCA, and MOO was solved to find the set of optimal trade-off solutions between investment and environmental pollution. In 2008, Li et al. extended this model for application to case studies in China [77]. Due to high transportation costs of hydrogen, they put emphasis on methanol pathway, which means methanol was to be produced and delivered as an alternative energy carrier, and hydrogen would be produced onsite from it. They found that methanol pathway had great potential for future Chinese hydrogen economy. In 2018, Ogumerem et al. developed a model similar to that of Hugo et al. [76], and deployed it for a case study in the state of Texas [78]. A creative point of their work was that they considered the possibility to collect and sell oxygen as a source of revenue, which was a by-product from electrolysis. They found that the processing of oxygen for selling could make electrolysis a more economically viable choice for hydrogen production.

Improvement in technology will inevitably lead to the need to construct new power plants and decommission old ones. The scheduling of such tasks has received wide attention. In 2012, Zhang et al. studied the planning of China’s power sector with consideration of carbon dioxide (CO2) emission [79]. In their research, renewable energy was paid much attention to, and plants with application of integrated gasification combined cycle plants (IGCC) or carbon dioxide capture and sequestration (CCS) were considered. CO2 mitigation was considered by incorporating CO2 emission costs in the objective function, and the problem was solved through single objective optimization. One year later, Zhang et al. further studied the problem under uncertainty using the levelized optimization method [80]. However, in Zhang et al.’s research, the power system of China was considered as a whole, in which energy transmission was neglected. However, in reality, the transmission losses could lead to very high costs, especially when serious mismatches happened among the distribution of power generation and power demand. In 2014, Koltsaklis et al. developed a spatial MILP model for optimal planning of Greek’s power system [81]. The whole Greek was divided into five geographical zones, and energy transmission and resource transportation among zones were taken into account. In 2015, Cheng et al. also developed a multi-regional planning model for China’s power system [82], in which China was modelled as 10 regions. Additionally, as was in Zhang et al.’s research [79,80], their research featured the consideration of renewable energy as well as application of IGCC and CCS. Guo et al. further considered the transmission capacity between regions [83]. They also further divided China into seventeen regions [84]. Furthermore, in previous research electricity supply and demand were balanced on a yearly basis, while Guo et al. sub-divided one year into several time blocks so that variations in the availability of various energy resources could be considered [85].

The operation or scheduling problems of existing plants can also be tackled using MIP optimization. However, when developing the model of the plant, it is necessary to determine the design variables from the plant’s measurement data, and since given data are usually not satisfactory, data reconciliation techniques are usually adopted to improve their accuracy. One of the earliest works to use data reconciliation for modelling was conducted by Papalexandri et al. in 1996. They applied data reconciliation methods to the modeling of a steam production network, and performed multi-period MINLP optimization based on this model to get optimal operating schemes of the network under various demands. Such technologies are also widely studied and applied in ESE research. In 2014, Jiang et al. used the data reconciliation method for gross error detection in a real-life coal-fired power plant [86]. In 2016, Guo et al. proposed an inequality constrained nonlinear data reconciliation framework, applied it in real-life power plants, and found that their approach could lead to more accurate operational data and better estimates of parameters than the equality constrained approach [87]. In 2017, Li et al. [88] adopted Guo et al.’s data reconciliation method [87] to preprocess the operating data of a thermal power unit under various working conditions, and thus developed a mathematical model for the unit, after which operation optimization was performed.

4. Process Systems Engineering in China

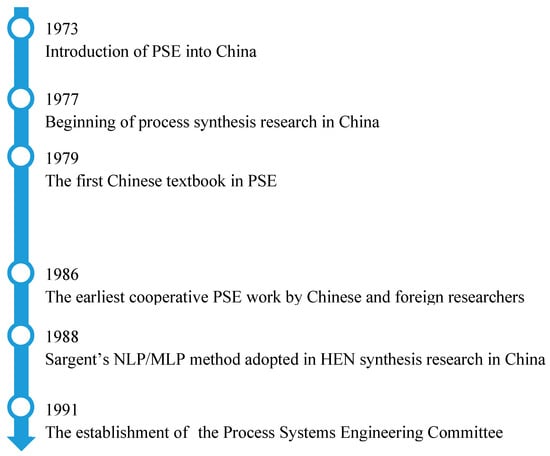

The development of PSE in China can be generally divided into three periods. From 1973 to 1980, the discipline was introduced into China, and much fundamental research was conducted. In early and middle 1980s, people came to pay more attention to this field, and began to explore more fields such as process synthesis. Since the late 1980s, Chinese researchers have strengthened their communication with researchers all over the world. In addition, Sargent’s idea of superstructure and NLP/MIP optimization has begun to be embodied in Chinese research. Some important events in the development of PSE in China are illustrated in Figure 2.

Figure 2.

Important event in the development of process systems engineering (PSE) in China.

4.1. Before and In 1970s: Origin of PSE in China

From an international perspective, process systems engineering (PSE) can be traced back to 1959, when Williams delivered his lecture at the University of Texas with the title, “Systems Engineering for the Process Industries” [89], marking the beginning of the application of systems engineering to chemical engineering. In 1963, the exact term “process systems engineering” first appeared, as the title of the CEP Symposium Series Volume 59 [90]. The first textbook in PSE was “Strategy of Process Engineering” by Rudd and Watson in 1968 [91]. Next year, Japanese scientists Yagi and Nishimura published another book, “chemical process engineering” [92]. These two earliest textbooks had a significant impact on the spread of PSE, and their appearance could be regarded as the beginning of PSE as a discipline.

China was also amongst the earliest communities to recognize the PSE discipline. In 1973, the Research Institute of Petroleum Processing of Ministry of Fuel and Chemical Industries published the paper “Mathematical Simulation of Chemical Engineering Processes—A Brief Introduction of Process Systems Engineering Methodology” on the Conference on Computer Applications in Chemical Refining held in Lanzhou, China [93,94]. In the first paragraph of this paper, it was stated that, mathematical simulation of chemical processes was a rapidly developing method which had already shown great impacts on the industry, for which a new discipline had been formed, which was called “process systems engineering” in western countries. This article marked the point at which PSE was first introduced to China. Furthermore, the main focus of this paper is the concept, method and application of mathematical simulation to the analysis of chemical processes. Though problems in optimal design and optimal control were touched upon, they were not paid much attention to. In addition, the content about optimal design in this article was mostly from the two early textbooks in PSE [91,92], while Sargent’s ideas were barely recognized. As a result, in the first few years after PSE was introduced in China, Chinese researchers were mainly conducting research in the field of process simulation, while little work in optimal design had been done, not to mention recognizing the importance of Sargent’s work and thoughts in this field.

In reality, before 1973, a few companies had already been contacting PSE theories from abroad, compiling internal documentation. However, it was since 1973 that PSE gradually became well-known among Chinese universities and companies, in which researchers started to pay attention to the field of PSE. In the 1970s, much work had been done. Chinese researchers introduced advanced process flowsheeting systems from foreign countries and reviewed the development of PSE theories. For example, the research institute of Nanjing Chemical Industries Company introduced the GIPS synthetic ammonia simulation system from Denmark [93]. Li reviewed the methods for synthesis of heat exchanger networks [95]. Creative work had also been conducted in both application and theoretical areas. The designing institute of Lanzhou Chemical Industries Company invented the process flowsheeting system for petroleum gas compression separation, which is the first chemical process flowsheeting system independently developed by China [96]. Researchers from Shanghai Research Institute of Chemical Industry and East China Institute of Chemical Engineering (now named East China University of Science and Technology) cooperated to apply the theory of PSE to the simulation and analysis of combined production of synthetic ammonia and urea [97]. Chen and Chen conducted research in process decomposition, studying the criterion of optimal tearing [98]. The country was putting more and more emphasis on this discipline. In 1979, receiving the commission from Bureau of Science and Technology of Ministry of Chemical Industry, Tsinghua University held the first “chemical systems engineering course”, and compiled the first Chinese textbook in PSE [99]. This decade witnessed the introduction of PSE in China and its application in Chinese industry. However, during this period, consensus understanding on this new discipline was not reached. In the 1978–1985 development layout for chemical engineering, PSE was placed as a subtitle under “chemical engineering dynamics and optimal process control” [93], which showed that the importance of PSE had still not been fully recognized in China.

Furthermore, in terms of Sargent’s impact, although his research on optimal design was barely recognized, his work in other fields was gradually inspiring Chinese researchers. A typical example was Chen and Chen’s research in process decomposition in 1979 [98]. In the field of system decomposition, one of the first research results is Sargent and Westerberg’s tearing method based on dynamic programming, which was proposed in 1964 [6]. However, their method had the deficiency that it aimed at breaking the recycle streams with the minimum number of variables, but as some variables might have poorer convergence properties than others, such an approach didn’t necessarily result in a minimum iteration time. Motivated by such shortcomings, in 1975, Upadhye and Grens developed a method for selecting the set of torn streams that could lead to a minimum number of iterations [100]. They found that multi-tearing a stream would lead to degradation of the convergence rate, so their method aimed to minimize the number of tearing that was made. Chen and Chen carefully studied this criterion and thought that it didn’t take into account the convergence properties of the loops. They formulated a generalized expression of the eigen-polynomial of the iteration equations, and derived a new criterion for optimal tearing. They found that Upadhye and Gren’s criterion was only a special case of their criterion. Later in 1983, Zhang et al. adopted their method to propose a new plate-to-plate method for calculating distillation processes [101].

4.2. In 1980s: Rapid Development of PSE in China

The 1980s saw the rapid development of PSE in China. Chinese universities began to set up courses on PSE, and pioneer institutes such as Tsinghua University and Tianjin University, founded their teaching and research group on PSE [102]. The first generation of Chinese PSE experts made great efforts to enlighten students on this subject. Famous textbooks, such as Yagi and Nishimura’s “Chemical Process Engineering” [92] and Takamatsu’s “Chemical Process Systems Engineering” [103], were translated into Chinese. Various textbooks compiled by Chinese researchers were also published, such as Zhang’s “Process Systems Engineering” [104] and Yang’s “Practical Process Systems Engineering” [105].

Before 1980, the research on PSE in China was mainly about the simulation of chemical processes. Since 1980, Chinese researchers had paid attention to new problems, such as process synthesis. As in western countries, the earliest studies in this field dealt with the synthesis problem of HEN. The first work in China was made in 1977 by researchers from Institute of Computing Technology of Chinese Academy of Sciences and Technical Laboratory of Design Institute of Beijing General Petrochemical Plant [106]. As mentioned above, there were generally two types of methods for the HEN synthesis, one using pure MP, another based on thermodynamics. Their work belongs to the former, in which they put the problem into an assignment problem, which was a special case of MILP, and solved it using Munkres assignment algorithm. In 1980s, Chen et al. conducted another pioneering study in the HEN synthesis [107]. They adopted a method based on thermodynamics, instead of MILP-based methods as in the previous work [106], which was because they thought that using MP to solve this problem required complicated computation and could be very different from reality. A worth mentioning point is that, since China put much emphasis on energy saving, Chen et al. formulated the problem as a multi-objective one, using energy consumption and equipment investment as two objectives, so that the weight on energy consumption could be adjusted according to China’s energy policies. However, at that time, when foreign researchers studied this problem, they usually just added together the costs of energy and the investment on equipment to obtain a total cost which was to be minimized, which meant that they put equal weight on energy and other costs. Back to Chen et al.’s work, they used the linear combination method, i.e., adding the two objective functions together with respective weighting factors. However, this aggregate objective function was not to be minimized directly. According to thermodynamic analysis, they required that heat flows and cold flows should exchange their heat in a countercurrent way. So under any specific value of energy consumption, they designed the optimal structure of HEN based on this requirement, and calculated the corresponding value of the objective function. Then they changed the value of energy consumption, designed the structure and calculated the function value time and again, until they found the minimum objective function value. In their method, the optimization problem was not solved on a mathematical basis, but through making thermodynamic analyses in trial and error. Two years later, Chen et al. further studied this problem, and this time they required low sensibility of the HEN [108]. As in the earlier research, the problem was a multi-objective one, and requirements based on thermodynamics were put forward. Furthermore, to achieve low sensibility, they concluded some empirical requirements from several examples, and added them to the original thermodynamic ones. Then the design process could be done in a similar way. Their research was applied to improve the HEN structures of oil refining plants in China. Meanwhile, as problems were usually formulated as MOO ones in China, strategies for solving these problems were studied. Shen et al. discussed the MOO methods, which could be used in optimal scheduling of oil refining plants [109]. In this problem, the two objectives were maximizing profits and minimizing energy consumption. Motivated by various deficiencies in traditional methods for MOO, Shen et al. proposed a new method, in which they used two parameters to represent the difference between the energy consumption or the profit under any feasible solution and the minimum energy consumption or the maximum profit. The sum of the two parameters was the final objective function, and its value closer to zero, the system closer to the optimum. This method was later used in a computer software designed for optimal management of oil refining plants.

As mentioned above, during this period Sargent was also conducting much research in process synthesis. Grossmann and his work in 1978 [35] had already taken the first step into MINLP-based process synthesis, in which both the structure and the parameters could be decided through one pure MP problem, though computational techniques were still immature for solution. However, in China, such methods were regarded as impractical, and thus didn’t receive much attention. Actually, it was not until Grossmann and his co-workers successfully solved process synthesis problems using MIP that Chinese researchers started to lay emphasis on MP-based design, which will be discussed in the following section.

4.3. Since Late-1980s: Sargent’s Ideas Integrated into Development of PSE in China

Since 1980, a large number of international conferences had been held, strengthening the communication between researchers from different countries. In 1982, the first International Symposia on PSE was held in Kyoto, Japan. From then on it was held every three years. In addition, it was recorded that one of the pioneering institute in China PSE, Tsinghua University, began to attend this series of conferences in 1988, when the 3rd International Symposia on PSE was held. Furthermore, through a literature search, which might be not that sufficient, it seemed that the first cooperative work by Chinese and foreign researchers is that published in 1986 by Chen and Westerberg [110]. As a result, although it is hard to identify the exact point at which Chinese researchers began to have extensive contact with foreign researchers, the approximate time should be in middle or late 1980s. Back to Chen and Westerberg’s paper, they studied the structural flexibility of heat integrated distillation processes. Flexibility is the property that the system be able to work properly when variations in parameters occur. As in the article by Grossmann et al. in 1987 [111], one way to introduce flexibility is to design the process for a number of different operating conditions, for which a pioneering work was done by Grossmann and Sargent in 1979 [37], or to design under uncertainty, which was explored by Grossmann and Sargent in 1978 [19]. Another way is to derive an index of flexibility, such as in Swaney and Grossmann’s work in 1985 [57], and this idea served as the motivation for Chen and Westerberg’s research. More importantly, Papoulias and Grossmann’s success in using superstructure-based mixed-integer optimization in the design of utility systems [39] inspired Chinese researchers to pay more attention to MP methods for optimal design. In 1988, researchers in Tsinghua University combined such MP-based methods with the thermodynamic method they had developed before, and managed to apply it to the optimization of the operation of Jinxi Oil Refining Plant [99]. Under the above facts, it is reasonable to say that the integration of Sargent’s idea of optimal design into China PSE research did occur in late 1980s.

With more and more successful application of PSE in industry, the importance of this discipline became widely recognized in China. In 1991, affiliated to the Systems Engineering Society of China, the Process Systems Engineering Committee was established, which greatly strengthened exchanges in China and cooperation between Chinese and foreign researchers [112]. Since the beginning of the 1990s decade, Sargent’s work had affected Chinese researchers much, embodied in the fact that the methods derived from his ideas began to be widely adopted and developed. In process design, Sargent was one of the first to recognize the importance of optimization in process engineering, and he had conducted significant work on NLP and superstructure. This research was further developed by his descendants, giving rise to systematic process synthesis methods combining superstructure-based modelling with NLP/MIP optimization. Such technologies were widely applied in China. One traditional as well as popular problem in process design is the synthesis of HEN. Chinese researchers have made great efforts for more efficient and reliable solution of such problems. In 1995, Yin et al. proposed a superstructure-based MINLP model, through which multiple objectives could be optimized, such as utility cost, exchanger areas and number of units [113]. In 1999, Wang et al. [114] proposed a new superstructure-based MINLP model for synthesis of large-scale HEN without stream splitting, and adopted the improved genetic algorithm (GA) they developed earlier [115] for solution. In 2000, Li et al. formed a superstructure representation of HEN with stream splitting based on expert systems and presented the corresponding MINLP model [116]. In 2004, Wei et al. proposed a hybrid method of GA and simulated annealing algorithm (SA) to solve the MINLP problem in the HEN synthesis [117]. In 2008, Ma et al. [118] used the MINLP model for multi-period synthesis of multi-stream HEN and adopted the GA/SA algorithm developed by Wei et al. [117] for solution. In 2015, Peng et al. developed a two-level method for simultaneous HEN synthesis using SA mechanism [119].

Similar methods can also be found in research on design of chemical processes or their operating units. In 1995, Wang et al. studied the optimization of operation for multipurpose batch chemical plants with multiple production routes. In their work, a MILP model for production plan was proposed [120]. In 2011, Jiao et al. presented a multi-objective superstructure-based model for design of hydrogen network in refineries [121]. In 2012, Jin et al. proposed a double-level optimization method for superstructure-based synthesis of reactor network composed of continuous stirred-tank reactors and plug flow reactors [122]. In 2017, Cui et al. developed a superstructure of 4-column methanol distillation systems (MDSs), based on which they performed simultaneous MINLP optimization for the system as well as its HEN and work exchanger network (WEN) [123]. Qian et al. used superstructure and NLP to deal with the synthesis of a reactor system composed of rotating packed bed reactors and traditional packed bed reactors, and demonstrated their method through a case study on the desulfurization process for crack gas in refineries [124]. In 2018, Zhang et al. proposed a method combining superstructure-based modelling and the GDP optimization method, developed by Grossmann and co-workers [44], for design of reaction and separation processes [125]. In addition, they applied the method to two important chemical industrial processes—cyclohexane oxidation process and benzene chlorination process. Furthermore, the idea of superstructure and MIP is also embodied in other fields, such as biology, pharmacy and others. In 2000, Hou et al. performed NLP optimization for the leaching process of angelica, showing that a 20% increase in profit could be achieved [126]. The authors commented that PSE methodology was useful in herb leaching processes, encouraging the modernization of traditional Chinese medicine production. In 2015, Du et al. adopted superstructure-based MINLP optimization for optimal synthesis of reverse osmosis networks with split partial second pass design for seawater desalination [127]. In 2016, Yan et al. proposed a superstructure representation of biomass to biomethane system through digestion and formed a multi-objective MINLP problem, which was solved using the nondominated sorting genetic algorithm (NSGA-II) [128]. Additionally, they concluded that the superstructure optimization method they proposed could be a useful tool for improving the performance of biomethane production process.

Moreover, ESE was also developing fast. As is mentioned above, as soon as PSE was introduced into China, Chinese researchers began to use its methodology to solve problems considering the costs (or profits) as well as the energy consumption of the system. As a result, the origin of China ESE was almost at the same time of the origin of China PSE. Since 1980, much research had been done on the modelling of energy systems in the scope of plants, districts and the whole country, amongst which many of the results were used for making energy policies [129]. For example, Li et al. proposed a combined approach of thermodynamic analysis and MILP for optimal design of steam-power energy system in 1992 [130]. They set up the superstructure of system by thermodynamic rules, formulated the problem as MILP one, and solved it using the BB method. Since the concept of ESE was formally proposed in 2007 [26], Chinese researchers have made significant contributions in this field, conducting a great amount of pioneering work to apply the systematic methodology from PSE to the research of various energy systems. Typical work in polygeneration energy systems [68,69,70,71], CHP/CCHP systems [73,74], hydrogen infrastructure [77], power systems [79,80,81,82,83,84,85] and data reconciliation [86,87,88] has already been mentioned in Section 3.4.

5. Industrial Applications of PSE and ESE Methods

The PSE and ESE methods mentioned above have also been widely applied to the chemical industry and led to significant economic and environmental contributions. In this part, some representative industrial practices are presented, showing the feasibility and helpfulness of PSE and ESE theories in real-life industries.

As is mentioned above, Sargent’s work has led to tools that are widely used in the industry. Based on Sargent’s work on NLP/MIP optimization, researchers developed the NLP solver, MINOS [29], and the MINLP solver, DICOPT [42], both of which can now be founded in GAMS. In addition, Sargent and his co-workers in Imperial College developed the SPEED-UP software, in which many algorithms they had proposed were incorporated, such as the decomposition techniques and the solution methods for DAEs. Many of these developers later participated in the research and development of gPROMS [62]. In addition, they founded PSE Limited with gPROMS as a major product. gPROMS is undoubtedly a huge success, which is used for design and optimization tasks in a large number of universities and companies all over the world [131].

In addition to those commercialized packages, some theoretical methodologies, which were originally proposed in academic research, have been popularized and applied in real-life projects. In 1996, Siirola [132] pointed out that the systematic process synthesis technologies, such as the superstructure-based MIP approach developed by Sargent, Grossmann and others and the pinch analysis method proposed by Linnhoff and colleagues, had been put into industrial practice and achieved great success. Typically, the application of these technologies could lead to a 50% saving of energy and a 35% reduction in costs. In their paper in 2003, Dunn and El-Halwagi also presented many industrial applications of those process synthesis methods, including projects on energy conservation, optimization of utility systems, and others [133].

Applications of PSE and ESE methods in China have also achieved great success. In 2008, Gao et al. proposed a hybrid MOO method combining SQP and NSGA-II for the periodic operation of the naphtha pyrolysis process [134]. Their algorithm was incorporated in a new software for simulation and optimization of ethylene cracking furnace, which was developed by researchers from Tsinghua University, PetroChina Research Institute of Petrochemical Technology and Lanzhou Petrochemical Company. This software, EPSOS, was used in a 240 kt/a ethylene plant of the Lanzhou Petrochemical Company and resulted in a 1.08% increase in production [135]. According to Wang’s paper in 2009 [136], petrochemical companies in China have been positively applying PSE technologies, including modern control, process synthesis and others, to the restructuring of the plants and facilities and have made great progress. From 2005 to 2009, the two leading petrochemical enterprises in China, Sinopec and PetroChina, had on average achieved a 12.5% reduction in the energy consumption of their oil refining processes. In addition, Sinopec’s overall energy consumption had decreased by 15.4% in this period. In the field of ESE, the monitoring and optimization methods for power units via data reconciliation, developed by researchers from Tsinghua University [86,87,88], have been applied to several Chinese power plants, making contributions to their energy saving. Furthermore, much of the strategic research on development strategies of China’s power sector has been incorporated into the National Energy Development Strategy by 2030, whose effects will be seen with the restructuring of China’s energy system in the future.

6. Conclusions

In his research career, Professor Sargent had made great contributions to the field of PSE, and his work surely took a guiding role in the development of ESE and China PSE. Sargent is one of the first to recognize the importance of optimization in process design. His attempts to apply optimization in chemical engineering and to develop computational techniques for NLP problems, have led to a combined superstructure representation and MIP modelling framework for design problems, which is widely applied in ESE. With people becoming more conscious of environmental protection, pollution minimization was regarded as an important objective by more researchers, giving rise to much work on MOO and LCA, which are now common methods in ESE research. Sargent and co-workers’ work in other fields, such as optimization under uncertainty and solution of DAEs and NAEs, have also led to useful algorithms and software that are frequently adopted in the field of ESE.

The beginning of the discipline of PSE in China was not much later than that in other countries. However, during the initial period, Sargent’s idea of optimal design did not receive much attention in China. In early research on HEN synthesis problems, Chinese researchers preferred thermodynamic methods, while regarding MP methods as infeasible. However, Sargent’s work in other aspects was gradually inspiring Chinese researchers, such as in system decomposition. It was in late 1980s that Sargent’s ideas became integrated to China PSE research. Since then, methods developed under his leadership have been widely studied and applied in the industry. Chinese researchers also paid much attention to the field of ESE, resulting in advanced achievements.

Looking forward to the future, the pioneering concepts and methodological contributions of Sargent are still inspiring new research directions. Taking energy systems for instance, operation at a more intermittent mode, in a much wider range, and with more severe pollutants and greenhouse-gas emissions constraints, pose great challenges for design and operation of these systems. However, increasing availability of operational data, improving data quality, and higher computational capability, when integrated with mathematical programming, provide opportunities to tackle these challenges, giving rise to a merging research direction of integrated mathematical programming and data analytics. This fits well with the idea of using increasingly powerful mathematical and computational methods to tackle unprecedented problems with process design and operation, originally proposed by Sargent and developed by his co-workers and followers.

Author Contributions

Conceptualization, W.Q., P.L. and Z.L.; Methodology, P.L.; Resources: W.Q.; Writing-Original Draft Preparation, W.Q.; Writing-Review & Editing, P.L.; Supervision, P.L.

Funding

This research was funded by the National Key Research and Development Program of China (2018YFB0604301), National Natural Science Foundation of China (71690245), and the Phase III Collaboration between BP and Tsinghua University.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sargent, R.W.H. Process Systems Engineering: A Retrospective View with Questions for the Future. Comput. Chem. Eng. 2005, 29, 1237–1241. [Google Scholar] [CrossRef]

- Glavic, P. Thirty Years of International Symposia on Process Systems Engineering. Curr. Opin. Chem. Eng. 2012, 1, 421–429. [Google Scholar] [CrossRef]

- Doherty, M.F.; Grossmann, I.E.; Pantelides, C.C. A Tribute to Professor Roger Sargent: Intellectual Leader of Process Systems Engineering. AIChE J. 2016, 62, 2951–2958. [Google Scholar] [CrossRef]

- Sargent, R.W.H. Integrated Design and Optimization of Processes. Chem. Eng. Prog. 1967, 63, 71–78. [Google Scholar]

- Sargent, R.W.H. Forecasts and Trends in Systems Engineering. In Proceedings of the Annual Meeting of Israel Institute of Chemical Engineers, Haifa, Israel, 29 August–2 September 1971. [Google Scholar]

- Sargent, R.W.H.; Westerberg, A.W. SPEED-UP in Chemical Engineering Design. Trans. Inst. Chem. Eng. 1964, 42, T190–T197. [Google Scholar]

- Sargent, R.W.H. The Decomposition of Systems of Procedures and Algebraic Equations. In Numerical Analysis, Proceedings of the Biennial Conference, Dundee, UK; Springer: Berlin/Heidelberg, Germany, 1978. [Google Scholar]

- Leigh, M.J. A Computer Flowsheeting Programme Incorporating Algebraic Analysis of the Problem Structure. Ph.D. Thesis, University of London, London, UK, 1973. [Google Scholar]

- Davidon, W.C. Variable Metric Method for Minimization. SIAM J. Optim. 1991, 1, 1–17. [Google Scholar] [CrossRef]

- Fletcher, R.; Powell, M.J.D. A Rapidly Convergent Descent Method for Minimization. Comput. J. 1963, 6, 163–168. [Google Scholar] [CrossRef]

- Rosen, J.B. The Gradient Projection Method for Nonlinear Programming. Part I. Linear Constraints. J. Soc. Ind. Appl. Math. 1960, 8, 181–217. [Google Scholar] [CrossRef]

- Murtagh, B.A.; Sargent, R.W.H. A Constrained Minimization Method with Quadratic Convergence. In Optimization; Academic Press: London, UK, 1965; pp. 215–245. [Google Scholar]

- Sargent, R.W.H.; Murtagh, B.A. Projection Methods for Non-linear Programming. Math. Program. 1973, 4, 245–268. [Google Scholar] [CrossRef]

- Murtagh, B.A.; Sargent, R.W.H. Computational Experience with Quadratically Convergent Minimisation Methods. Comput. J. 1970, 13, 185–194. [Google Scholar] [CrossRef]

- Sargent, R.W.H.; Sebastian, D.J. On the Convergence of Sequential Minimization Algorithms. J. Optim. Theory Appl. 1973, 12, 567–575. [Google Scholar] [CrossRef]

- Sargent, R.W.H. Convergence Properties of Projection Methods for Nonlinear Programming. In Proceedings of the 8th International Symposium on Mathematical Programming, Stanford, CA, USA, 26–31 August 1973. [Google Scholar]

- Sargent, R.W.H. An Efficient Implementation of the Lemke Algorithm and Its Extension to Deal with Upper and Lower Bounds. Math. Program Stud. 1978, 7, 36–54. [Google Scholar]

- Sargent, R.W.H.; Ding, M. A New SQP Algorithm for Large-scale Nonlinear Programming. SIAM J. Optim. 2001, 11, 716–747. [Google Scholar] [CrossRef]

- Grossmann, I.E.; Sargent, R.W.H. Optimum Design of Chemical-Plants with Uncertain Parameters. AIChE J. 1978, 24, 1021–1028. [Google Scholar] [CrossRef]

- Sargent, R.W.H.; Gaminibandara, K. Optimum design of plate distillation columns. In Optimization in Action; Dixon, L.C.W., Ed.; Academic Press: London, UK, 1976; pp. 267–314. [Google Scholar]

- Yee, T.F.; Grossmann, I.E.; Kravanja, Z. Simultaneous Optimization Models for Heat Integration. III. Process and Heat Exchanger Network Optimization. Comput. Chem. Eng. 1990, 14, 1185–1200. [Google Scholar] [CrossRef]

- Sargent, R.W.H. A Functional Approach to Process Synthesis and Its Application to Distillation Systems. Comput. Chem. Eng. 1998, 22, 31–45. [Google Scholar] [CrossRef]

- Sargent, R.W.H. A Review of Methods for Solving Nonlinear Algebraic Equations. In Proceedings of the Engineering Foundation Conference, Henniker, NH, USA, 3–8 August 1980. [Google Scholar]

- Cameron, I.T. Numerical Solution of Differential-Algebraic Systems in Process Dynamics. Ph.D. Thesis, University of London, London, UK, 1981. [Google Scholar]

- Gritsis, D.; Pantelides, C.C.; Sargent, R.W.H. The Dynamic Simulation of Transient Systems Described by Index Two Differential Algebraic Equations. In Proceedings of the PSE’88 The Third International Symposium on Process Systems Engineering, Sydney, Australia, 28 August–2 September 1988. [Google Scholar]

- Pistikopoulos, E.N. Energy Systems Engineering—An Integrated Approach for the Energy Systems of the Future. In Proceedings of the European Congress of Chemical Engineering—6, Copenhagen, Denmark, 16–20 September 2007. [Google Scholar]

- Liu, P.; Georgiadis, M.C.; Pistikopoulos, E.N. Advances in Energy Systems Engineering. Ind. Eng. Chem. Res. 2011, 50, 4915–4926. [Google Scholar] [CrossRef]

- Sargent, R.W.H.; Murtahg, B.A. Design of Plate Distillation Columns for Multicomponent Mixtures. Trans. Inst. Chem. Eng. 1969, 47, T85–T94. [Google Scholar]

- Murtagh, B.A.; Saunders, M.A. Large-Scale Linearly Constrained Optimization. Math. Program. 1978, 14, 41–72. [Google Scholar] [CrossRef]

- Sargent, R.W.H.; Ming, D. A Modified Sargent-Gaminibandara Superstructure for Synthesis of Distillation Sequences; Report No. A94-23; Centre for Process Systems Engineering, Imperial College: London, UK, 1994. [Google Scholar]

- El-Temtamy, S.A.; Hamid, I.; Gabr, E.M.; Sayed, A.E.-R. The Use of Pinch Technology to Reduce Utility Consumption in a Natural Gas Processing Plant. Petrol. Sci. Technol. 2010, 28, 1316–1330. [Google Scholar] [CrossRef]

- Rudd, D.F. Synthesis of System Designs. I. Elementary Decomposition Theory. AIChE J. 1968, 14, 343–349. [Google Scholar] [CrossRef]

- Gundersen, T.; Naess, L. The Synthesis of Cost Optimal Heat Exchanger Networks—An Industrial Review of the State of the Art. Comput. Chem. Eng. 1988, 12, 503–530. [Google Scholar] [CrossRef]

- Sargent, R.W.H. Introduction: 25 Years of Progress in Process Systems Engineering. Comput. Chem. Eng. 2004, 28, 437–439. [Google Scholar] [CrossRef]

- Grossmann, I.E.; Sargent, R.W.H. Optimum Design of Heat-Exchanger Networks. Comput. Chem. Eng. 1978, 2, 1–7. [Google Scholar] [CrossRef]

- Vázquez-Román, R.; Inchaurregui-Méndez, J.A.; Ponce-Ortega, J.M.; Mannan, M.S. A Heat Exchanger Networks Synthesis Approach Based on Inherent Safety. J. Chem. Eng. Res. Update 2015, 2, 22–29. [Google Scholar] [CrossRef]

- Grossmann, I.E.; Sargent, R.W.H. Optimum Design of Multipurpose Chemical Plants. Ind. Eng. Chem. Proc. Des. Dev. 1979, 18, 343–348. [Google Scholar] [CrossRef]

- Grossmann, I.E.; Santibanez, J. Applications of Mixed-Integer Linear-Programming in Process Synthesis. Comput. Chem. Eng. 1980, 4, 205–214. [Google Scholar] [CrossRef]

- Papoulias, S.A.; Grossmann, I.E. A Structural Optimization Approach in Process Synthesis. Part 1. Utility Systems. Comput. Chem. Eng. 1983, 7, 695–706. [Google Scholar] [CrossRef]

- Duran, M.A.; Grossmann, I.E. An Outer-Approximation Algorithm for A Class of Mixed-Integer Nonlinear Programs. Math. Program. 1986, 36, 307–339. [Google Scholar] [CrossRef]

- Kocis, G.R.; Grossmann, I.E. Relaxation Strategy for the Structural Optimization of Process Flowsheets. Ind. Eng. Chem. Res. 1987, 26, 1869–1880. [Google Scholar] [CrossRef]

- Kocis, G.R.; Grossmann, I.E. Computational Experience with DICOPT Solving MINLP Problems in Process Systems Engineering. Comput. Chem. Eng. 1989, 13, 307–315. [Google Scholar] [CrossRef]

- Grossmann, I.E. MINLP Optimization Algorithms and Strategies for Process Synthesis. In Proceedings of the FOCAPD’89, Snowmass Village, CO, USA, 9–14 July 1989. [Google Scholar]

- Yeomans, H.; Grossmann, I.E. A Systematic Modeling Framework of Superstructure Optimization in Process Synthesis. Comput. Chem. Eng. 1999, 23, 709–731. [Google Scholar] [CrossRef]

- Cano-Ruiz, J.A.; McRae, G.J. Environmentally Conscious Chemical Process Design. Annu. Rev. Energy Environ. 1998, 23, 499–536. [Google Scholar] [CrossRef]

- Douglas, J.M. Process Synthesis for Waste Minimization. Ind. Eng. Chem. Res. 1992, 31, 238–243. [Google Scholar] [CrossRef]

- Haimes, Y.Y.; Ladson, L.S.; Wismer, D.A. Bicriterion Formulation of Problems of Integrated System Identification and System Optimization. IEEE Trans. Syst. Man Cybern. 1971, SMC1, 296–297. [Google Scholar]

- Bhaskar, V. Application of Multi-Objective Optimization in Chemical Engineering. Rev. Chem. Eng. 2000, 16. [Google Scholar] [CrossRef]

- Grossmann, I.E.; Drabbant, R.; Jain, R.K. Incorporating Toxicology in the Synthesis of Industrial Chemical Complexes. Chem. Eng. Commun. 1982, 17, 151–170. [Google Scholar] [CrossRef]

- Stefanis, S.K.; Livingston, A.G.; Pistikopoulos, E.N. Minimizing the Environmental Impact of Process Plants—A Process Systems Methodology. Comput. Chem. Eng. 1995, 19, S39–S44. [Google Scholar] [CrossRef]

- Stefanis, S.K.; Buxton, A.; Livingston, A.G.; Pistikopoulos, E.N. A Methodology for Environmental Impact Minimization: Solvent Design and Reaction Path Synthesis Issues. Comput. Chem. Eng. 1996, 20, S1419–S1424. [Google Scholar] [CrossRef]

- Stefanis, S.K.; Livingston, A.G.; Pistikopoulos, E.N. Environmental Impact Considerations in the Optimal Design and Scheduling of Batch Processes. Comput. Chem. Eng. 1997, 21, 1073–1094. [Google Scholar] [CrossRef]

- Azapagic, A.; Clift, R. The Application of Life Cycle Assessment to Process Optimisation. Comput. Chem. Eng. 1999, 23, 1509–1526. [Google Scholar] [CrossRef]

- Carvalho, A.; Matos, H.A.; Gani, R. SustainPro—A Tool for Systematic Process Analysis, Generation and Evaluation of Sustainable Design Alternatives. Comput. Chem. Eng. 2013, 50, 8–27. [Google Scholar] [CrossRef]

- Kalakul, S.; Malakul, P.; Siemanond, K.; Gani, R. Integration of Life Cycle Assessment Software with Tools for Economic and Sustainability Analyses and Process Simulation for Sustainable Process Design. J. Clean. Prod. 2014, 71, 98–109. [Google Scholar] [CrossRef]

- Halemane, K.P.; Grossmann, I.E. Optimal Process Design under Uncertainty. AIChE J. 1983, 29, 425–433. [Google Scholar] [CrossRef]

- Swaney, R.E.; Grossmann, I.E. An Index for Operational Flexibility in Chemical Process Design. Part I. Formulation and Theory. AIChE J. 1985, 31, 621–630. [Google Scholar] [CrossRef]

- Straub, D.A.; Grossmann, I.E. Design Optimization of Stochastic Flexibility. Comput. Chem. Eng. 1993, 17, 339–354. [Google Scholar] [CrossRef]

- Ierapetritou, M.G.; Acevedo, J.; Pistikopoulos, E.N. An Optimization Approach for Process Engineering Problems under Uncertainty. Comput. Chem. Eng. 1996, 20, 703–709. [Google Scholar] [CrossRef]

- Acevedo, J.; Pistikopoulos, E.N. Computational Studies of Stochastic Optimization Algorithms for Process Synthesis under Uncertainty. Comput. Chem. Eng. 1996, 20, S1–S6. [Google Scholar] [CrossRef]

- Mah, R.S.H.; Michaelson, S.; Sargent, R.W.H. Dynamic Behaviour of Multi-Component Multi-Stage Systems—Numerical Methods for the Solution. Chem. Eng. Sci. 1962, 17, 619–639. [Google Scholar] [CrossRef]

- Pantelides, C.C.; Barton, P.I. Equation-Oriented Dynamic Simulation Current Status and Future Perspectives. Comput. Chem. Eng. 1993, 17, S263–S285. [Google Scholar] [CrossRef]

- Kikkinides, E.S.; Georgiadis, M.C.; Stubos, A.K. On the Optimization of Hydrogen Storage in Metal Hydride Beds. Int. J. Hydrog. Energy 2006, 31, 737–751. [Google Scholar] [CrossRef]

- Kouramas, K.; Pistikopoulos, E.N. Wind Turbines Modeling and Control. In Process Systems Engineering: Volume 5: Energy Systems Engineering; Georgiadis, M.C., Kikkinides, E.S., Pistikopoulos, E.N., Eds.; Wiley-VCH: Weinheim, Germany, 2011; pp. 195–214. [Google Scholar]

- Cameron, I.T.; Gani, R. Adaptive Runge-Kutta Algorithms for Dynamic Simulation. Comput. Chem. Eng. 1988, 7, 705–717. [Google Scholar] [CrossRef]

- Sorensen, E.L.; Johansen, H.; Gani, R.; Fredenslund, A. A Dynamic Simulator for Design and Analysis of Chemical Processes. In Process Technology Proceedings; Bussemaker, H.T., Iedema, P.D., Eds.; Elsivier: Amsterdam, The Netherlands, 1990; Volume 9, pp. 13–18. [Google Scholar]

- Gani, R.; Sorensen, E.L.; Perregaard, J. Design and Analysis of Chemical Processes Through DYNSIM. Ind. Eng. Chem. Res. 1992, 31, 244–254. [Google Scholar] [CrossRef]

- Liu, P.; Gerogiorgis, D.I.; Pistikopoulos, E.N. Modeling and Optimization of Polygeneration Energy Systems. Catal. Today 2007, 127, 347–359. [Google Scholar] [CrossRef]