Effects of Caustic Extraction on Properties of Viscose Grade Dissolving Pulp

Abstract

:1. Introduction

2. Materials and Methods

2.1. Alkaline Extraction

2.2. Bleaching

2.3. Pulp Characterisation

2.4. Design of Experiments

3. Results and Discussion

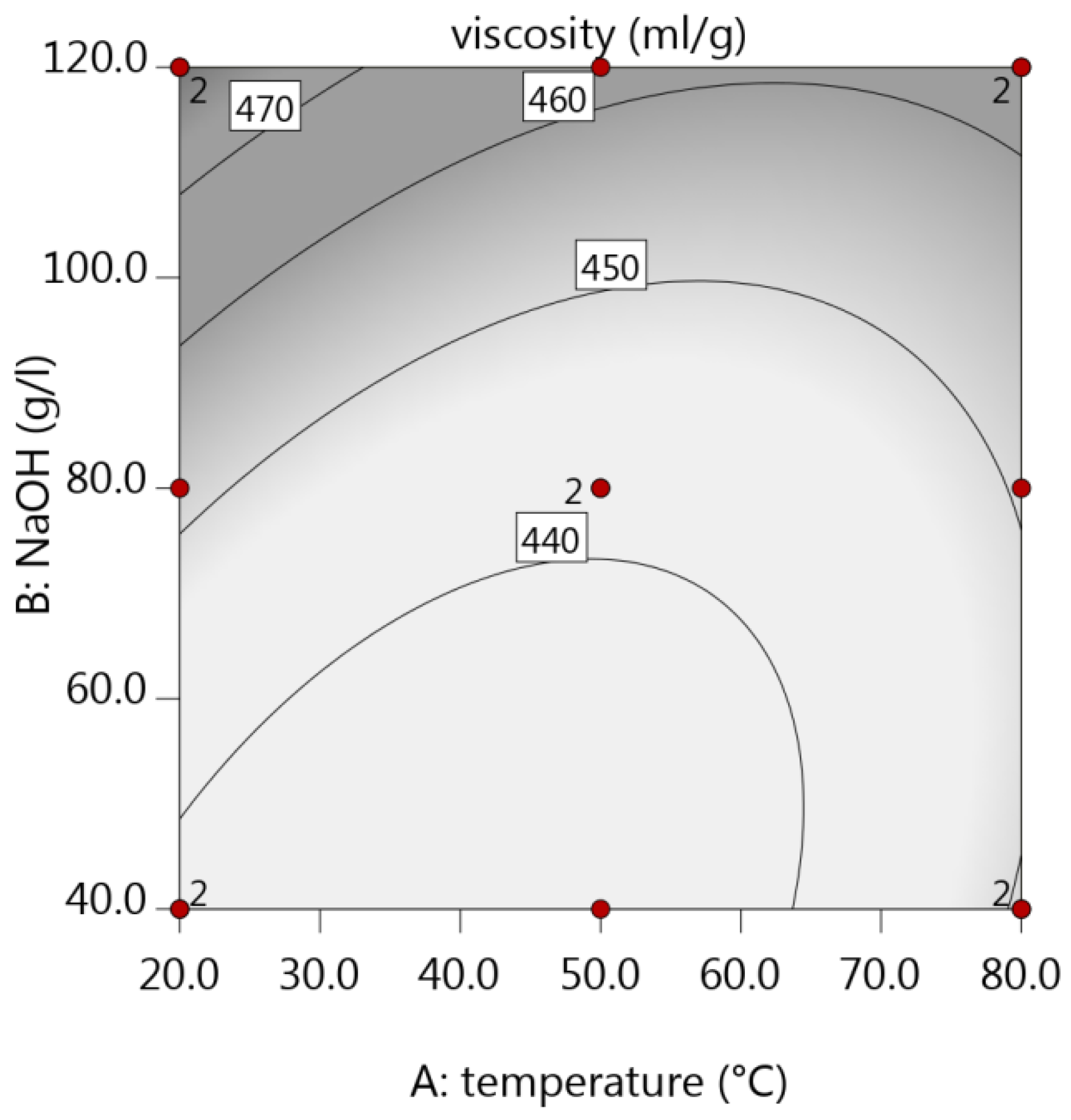

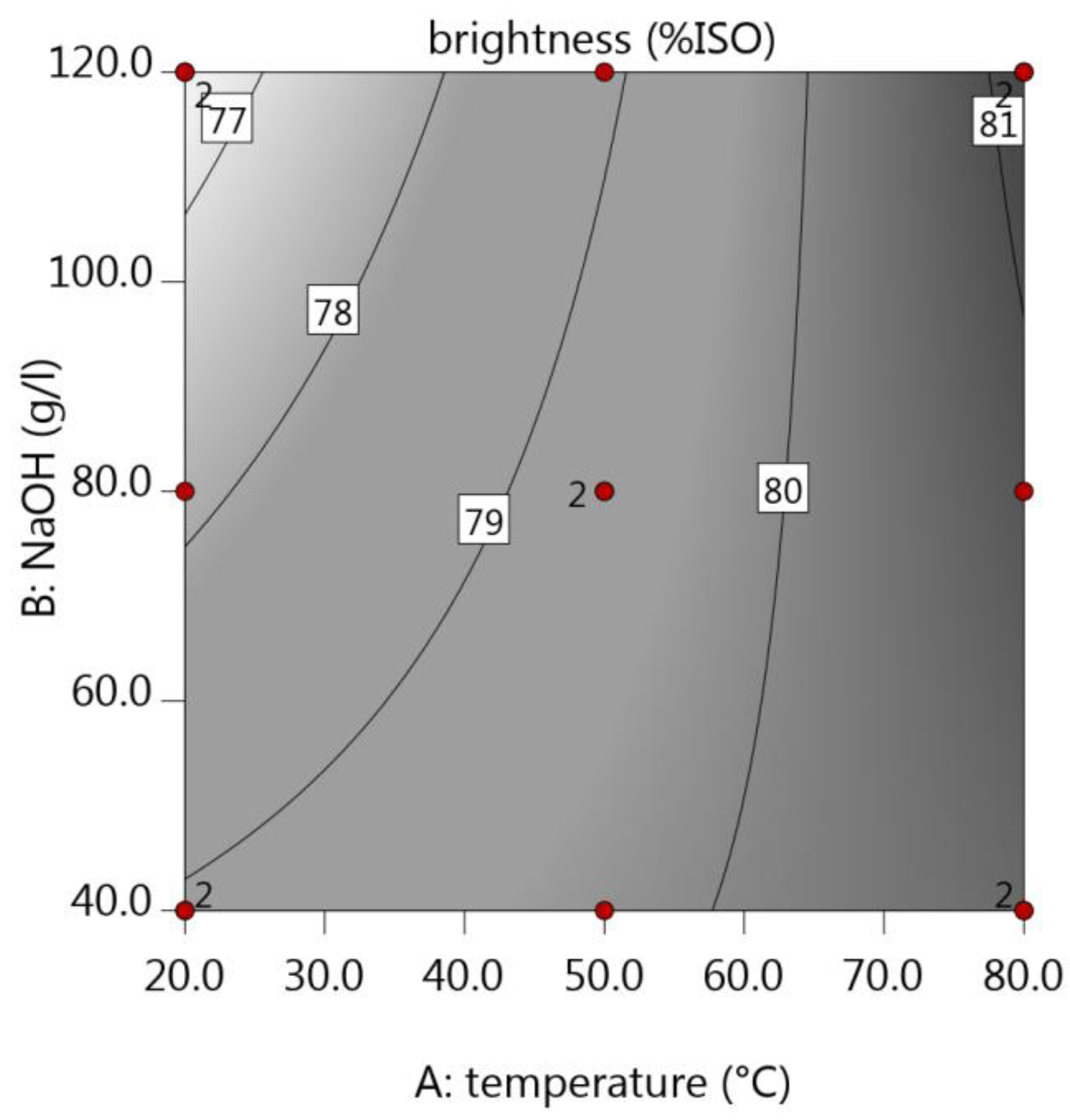

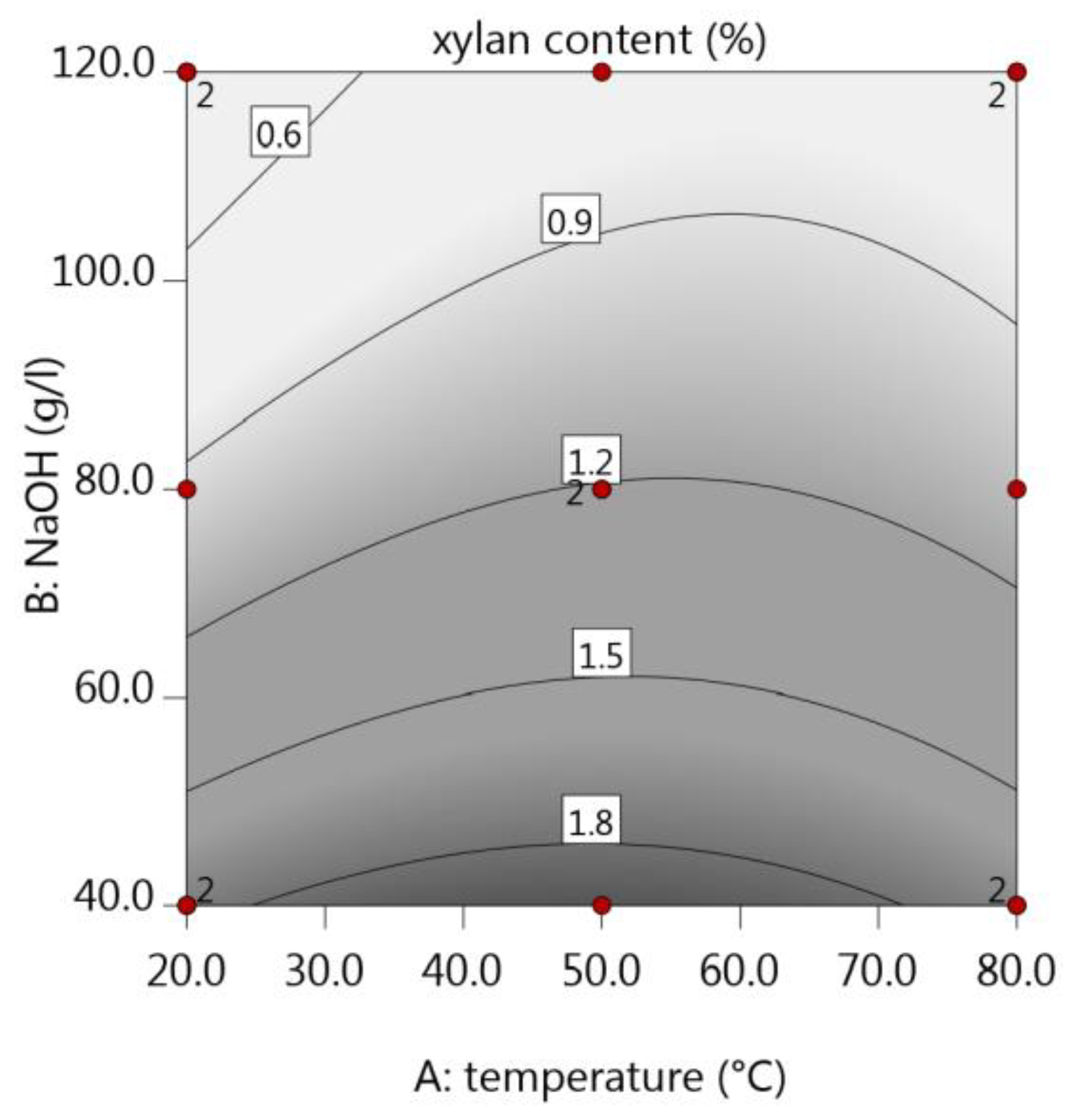

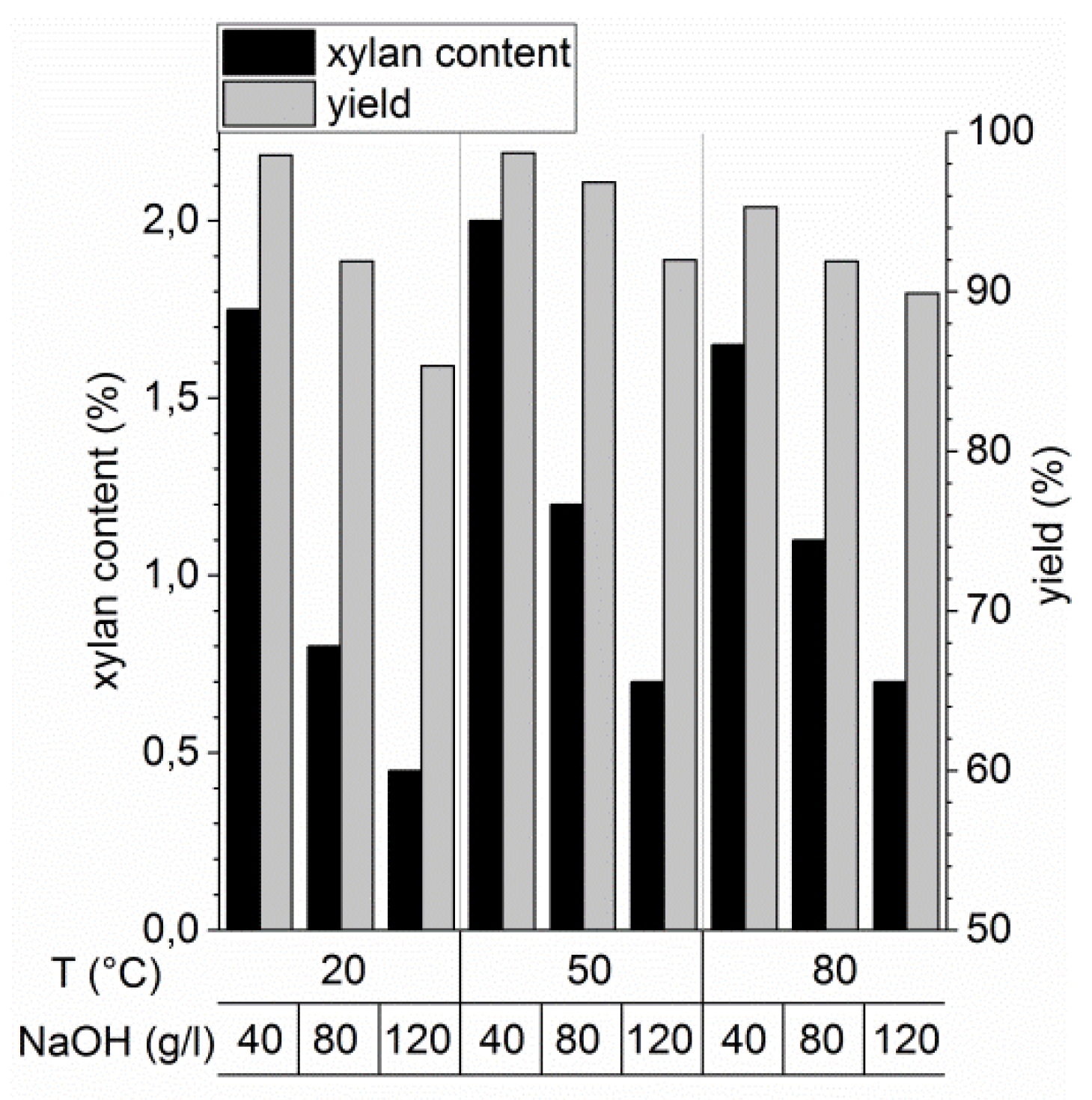

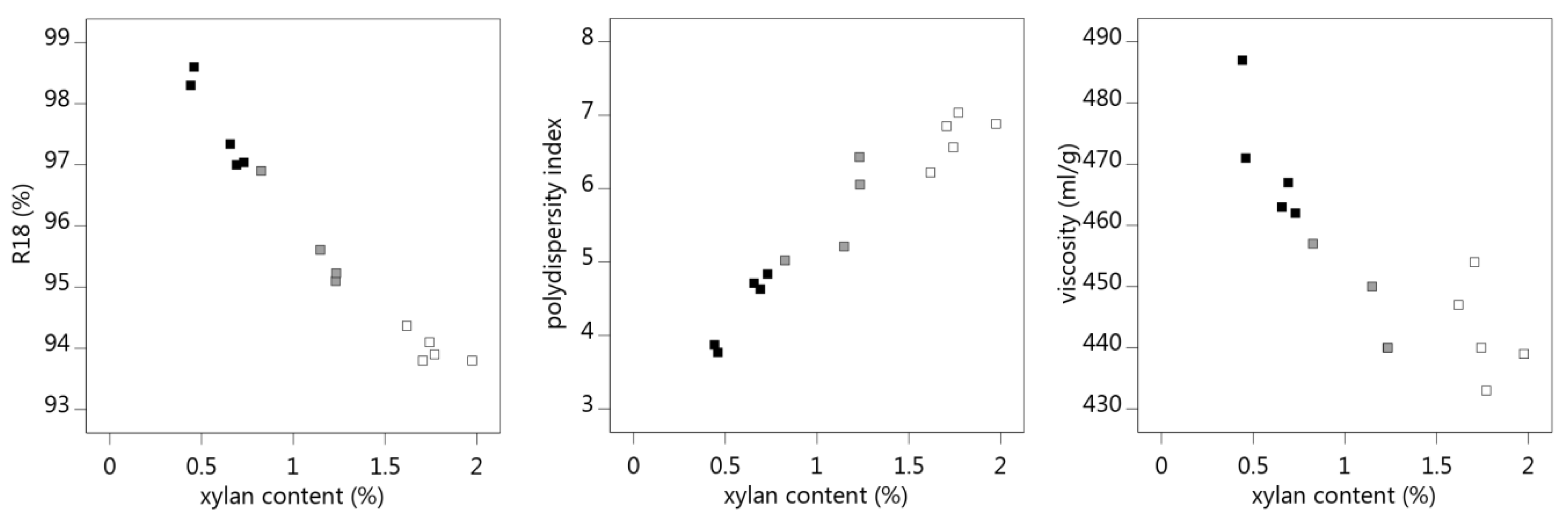

3.1. DoE Models, Effects of Alkaline Extraction on Pulp

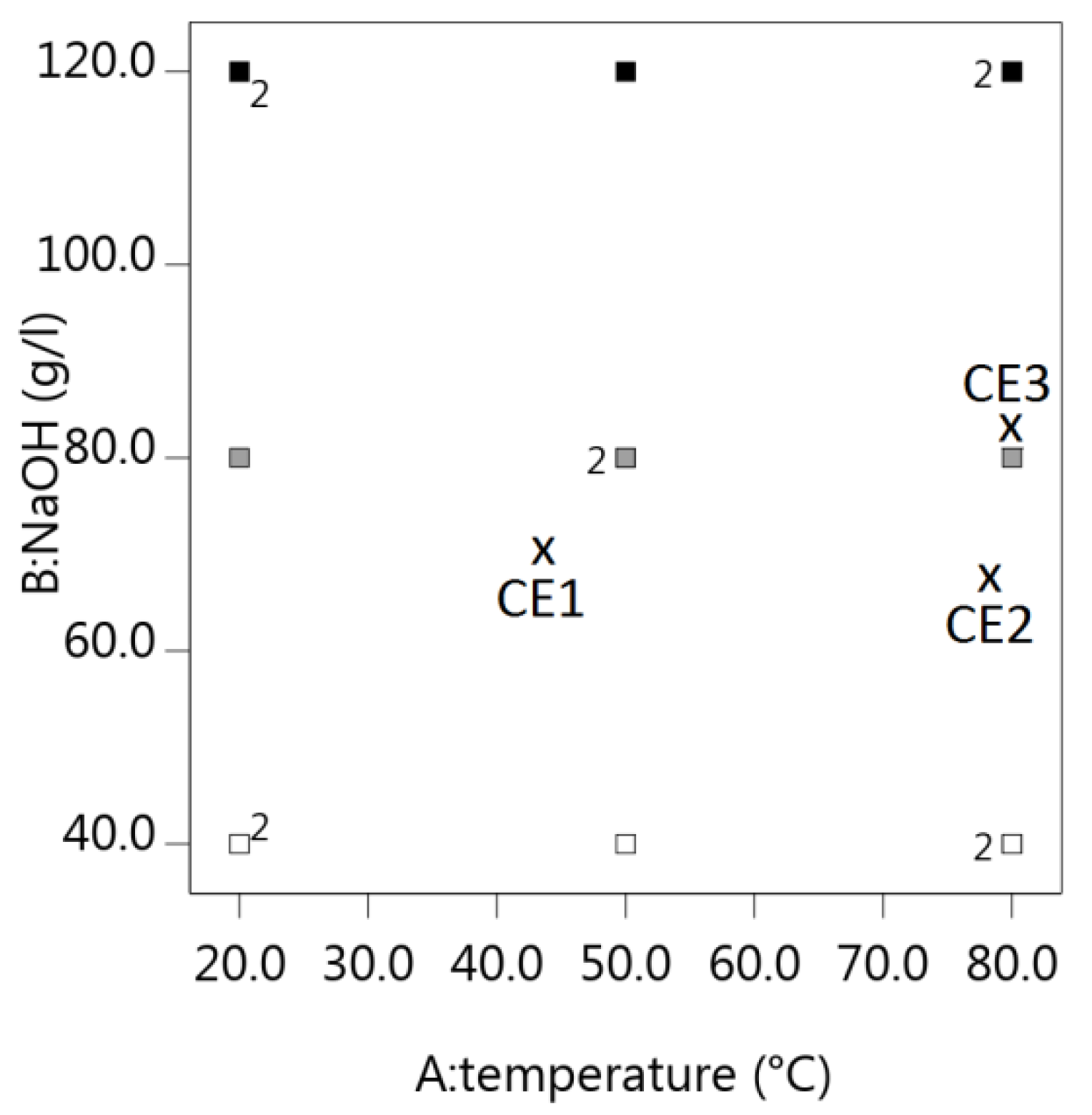

3.2. Targeted Extraction

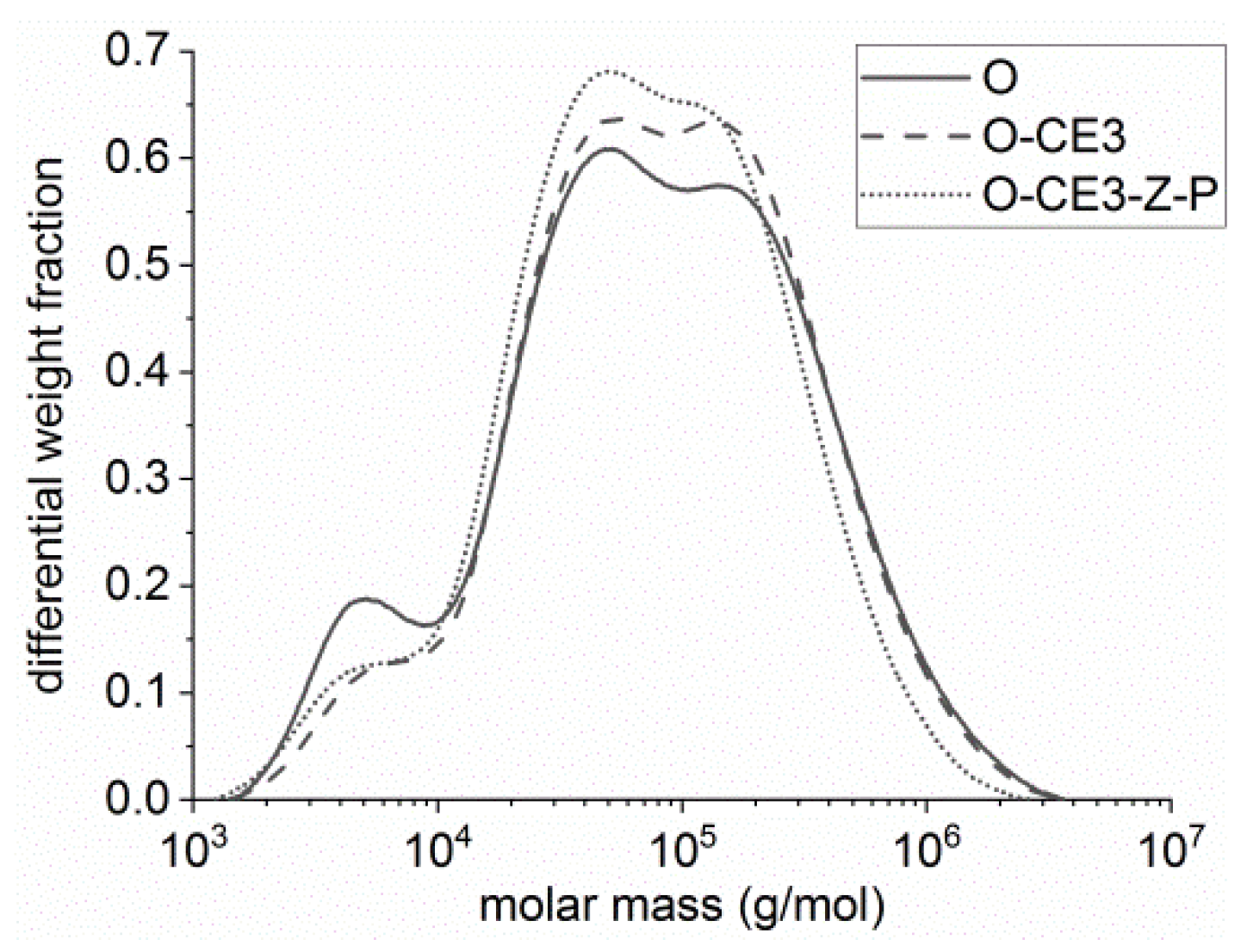

3.3. Bleaching and Viscose Testing

3.4. Process Viability

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Variables | Response | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| exp. number | design layout | temperature (°C) | NaOH (g/L) | kappa | brightness (%ISO) | viscosity (ml/g) | R10 (%) | R18 (%) | PDI | glucan (%) | xylan (%) | crystallinity index (%) | cellulose II (%) | yield (%) |

| 4 | -- | 20 | 40 | 0.84 | 78.3 | 433 | 85.4 | 93.9 | 7.0 | 96.5 | 1.8 | 54 | 8 | 98.6 |

| 13 | -- | 20 | 40 | 0.99 | 79.2 | 440 | 85.8 | 94.1 | 6.6 | 97.8 | 1.7 | 54 | 8 | 98.5 |

| 14 | 0- | 50 | 40 | 0.95 | 79.9 | 439 | 85.7 | 93.8 | 6.9 | 95.5 | 2.0 | 54 | 9 | 98.7 |

| 1 | +- | 80 | 40 | 0.90 | 80.0 | 454 | 86.0 | 93.8 | 6.9 | 96.9 | 1.7 | 54 | 7 | 95.8 |

| 11 | +- | 80 | 40 | 0.91 | 80.8 | 447 | 86.5 | 94.4 | 6.2 | 96.7 | 1.6 | 54 | 10 | 94.8 |

| 12 | -0 | 20 | 80 | 0.90 | 78.8 | 457 | 90.2 | 96.9 | 5.0 | 96.8 | 0.8 | 52 | 14 | 91.9 |

| 5 | 00 | 50 | 80 | 0.85 | 79.7 | 440 | 86.3 | 95.1 | 6.4 | 98.1 | 1.2 | 55 | 6 | 96.9 |

| 7 | 00 | 50 | 80 | 0.94 | 80.1 | 440 | 86.6 | 95.2 | 6.1 | 96.8 | 1.2 | 54 | 8 | 96.8 |

| 9 | +0 | 80 | 80 | 0.90 | 80.7 | 450 | 87.4 | 95.6 | 5.2 | 96.9 | 1.1 | 53 | 9 | 91.9 |

| 3 | -+ | 20 | 120 | 0.85 | 76.5 | 487 | 96.5 | 98.3 | 3.9 | 99.0 | 0.4 | 46 | 75 | 85.5 |

| 6 | -+ | 20 | 120 | 0.91 | 75.2 | 471 | 96.9 | 98.6 | 3.8 | 96.7 | 0.5 | 45 | 79 | 85.2 |

| 10 | 0+ | 50 | 120 | 0.93 | 80.1 | 463 | 92.0 | 97.3 | 4.7 | 98.5 | 0.7 | 50 | 28 | 92.0 |

| 2 | ++ | 80 | 120 | 0.89 | 80.5 | 467 | 90.5 | 97.0 | 4.6 | 96.8 | 0.7 | 53 | 14 | 90.9 |

| 8 | ++ | 80 | 120 | 0.89 | 81.1 | 462 | 89.9 | 97.0 | 4.8 | 96.5 | 0.7 | 52 | 16 | 88.9 |

| Response | X | A | B | A·B | A2 | B2 | σ | R2 |

|---|---|---|---|---|---|---|---|---|

| brightness | +80.4069 | −0.0025 | −0.0448 | +0.0007 | 0.8031 | 0.8240 | ||

| viscosity | +445.1235 | −0.5816 | −0.0375 | −0.0059 | +0.0103 | +0.0042 | 5.52 | 0.9191 |

| R10 | +85.9130 | −0.0869 | +0.0186 | +0.0015 | +0.0016 | +0.0009 | 0.5617 | 0.9872 |

| R18 | +92.7577 | −0.0541 | +0.0616 | −0.0003 | +0.0007 | 0.2939 | 0.9796 | |

| PDI | +7.3807 | +0.0541 | −0.0416 | +0.0002 | −0.0007 | 0.3045 | 0.9498 | |

| xylan content | +2.5255 | +0.0185 | −0.0312 | +0.0001 | −0.0002 | +0.0001 | 0.0757 | 0.9875 |

| crystallinity index | +54.1866 | −0.0722 | +0.0579 | +0.0015 | −0.0012 | 0.9715 | 0.9282 | |

| cellulose II content | +8.8545 | +0.6078 | −0.5177 | −0.0130 | +0.0099 | 7.98 | 0.9256 | |

| yield | +100.1077 | +0.3114 | −0.1907 | +0.0016 | −0.0043 | 0.9180 | 0.9723 |

References

- Shen, L.; Worrell, E.; Patel, M.K. Environmental impact assessment of man-made cellulose fibres. Resour. Conserv. Recycl. 2010, 55, 260–274. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E.; Patel, M.K. Comparing life cycle energy and GHG emissions of bio-based PET, recycled PET, PLA, and man-made cellulosics. Biofuel Bioprod. Bior. 2012, 6, 625–639. [Google Scholar] [CrossRef]

- Kumar, H.; Christopher, L.P. Recent trends and developments in dissolving pulp production and application. Cellulose 2017, 24, 2347–2365. [Google Scholar] [CrossRef]

- Li, H.; Legere, S.; He, Z.; Zhang, H.; Li, J.; Yang, B.; Zhang, S.; Zhang, L.; Zheng, L.; Ni, Y. Methods to increase the reactivity of dissolving pulp in the viscose rayon production process: A review. Cellulose 2018, 25, 3733–3753. [Google Scholar] [CrossRef]

- Schlesinger, R.; Röder, T.; Götzinger, G.; Sixta, H.; Harasek, M.; Friedl, A. Influence of hemicellulose aggregate and gel layer formation on flux and retention during nanofiltration of alkaline solutions. Desalination 2005, 175, 121–134. [Google Scholar] [CrossRef]

- Schild, G.; Sixta, H. Sulfur-free dissolving pulps and their application for viscose and lyocell. Cellulose 2011, 18, 1113–1128. [Google Scholar] [CrossRef]

- Sixta, H. Pulp Purification. In Handbook of Pulp; Sixta, H., Ed.; Wiley-VCH: Weinheim, Germany, 2006; pp. 933–966. [Google Scholar]

- Lai, Y.Z. Chemical Degradation. In Wood and Cellulose Chemistry; Hon, D.N.-S., Shiraishi, N., Eds.; Marcel Dekker Inc.: New York, NY, USA, 2001; pp. 443–512. [Google Scholar]

- Li, J.; Zhang, H.; Duan, C.; Liu, Y.; Ni, Y. Enhancing hemicelluloses removal from a softwood sulfite pulp. Bioresour. Technol. 2015, 192, 11–16. [Google Scholar] [CrossRef] [PubMed]

- Wennerström, M.; Bylund, S. Method for Controlling Viscosity in Dissolving Pulps. WO2017105322, 13 December 2017. [Google Scholar]

- Garrood, B.F.; Becker, E.S.; Sen, B. Pretreatment of Sulfite Pulp Before Bleaching with Oxygen Containing Chemicals. CA19942121969, 22 April 1994. [Google Scholar]

- Christov, L.P.; Prior, B.A. Xylan removal from dissolving pulp using enzymes of Aureobasidium pullulans. Biotechnol. Lett. 1993, 15, 1269–1274. [Google Scholar] [CrossRef]

- Gübitz, G.M.; Lischnig, T.; Stebbing, D.; Saddler, J.N. Enzymatic removal of hemicellulose from dissolving pulps. Biotechnol. Lett. 1997, 19, 491. [Google Scholar] [CrossRef]

- Hutterer, C. Enzymatic pulp upgrade for producing high-value cellulose out of a Kraft paper pulp. Enzyme Microb. Technol. 2017, 102, 67–73. [Google Scholar] [CrossRef] [PubMed]

- Quintana, E.; Valls, C.; Vidal, T.; Roncero, M.B. Comparative evaluation of the action of two different endoglucanases. Part I: On a fully bleached, commercial acid sulfite dissolving pulp. Cellulose 2015, 22, 2067–2079. [Google Scholar] [CrossRef]

- Österreichisches Normungsinstitut. ÖNORM EN 1484 Wasseranalytik—Anleitung zur Bestimmung des Gesamten Organischen Kohlenstoffs (TOC) und des Gelösten Organischen Kohlenstoffs (DOC); Österreichisches Normungsinstitut: Vienna, Austria, 1997. [Google Scholar]

- TAPPI. T236 cm-85 Kappa Number of Pulp; TAPPI: Atlanta, GA, USA, 1993. [Google Scholar]

- Scandinavian Pulp, Paper and Board Testing Committee. SCAN-CM 15:99 Viscosity in Cupriethylendiamine Solution; Scandinavian Pulp, Paper and Board Testing Committee: Stockholm, Sweden, 1999. [Google Scholar]

- ISO. Board and Pulps—Measurement of Diffuse Blue Reflectance Factor; ISO 2470-1 Paper; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- Deutsches Institut für Normung, e.V. In DIN 54355 Bestimmung der Beständigkeit von Zellstoff Gegen Natronlauge (Alkaliresistenz); Deutsches Institut für Normung e.V.: Berlin, Germany, 1977.

- Röder, T.; Moosbauer, J.; Fasching, M.; Bohn, A.; Fink, H.-P.; Baldinger, T.; Sixta, H. Crystallinity Determination of Native Cellulose—Comparison of Analytical Methods. Lenzing. Ber. 2006, 86, 85–89. [Google Scholar]

- Wright, P.J.; Wallis, A.F.A. Rapid determination of carbohydrates in hardwoods by high performance anion exchange chromatography. Holzforschung 1996, 50, 518–524. [Google Scholar] [CrossRef]

- Schelosky, N.; Röder, T.; Baldinger, T.; Milacher, W.; Morgenstern, B.; Sixta, H. Molecular mass distribution of cellulosic products by size exclusion chromatography in DMAc/LiCl. Das Pap. 1999, 12, 728–738. [Google Scholar]

- Huepfl, J.; Zauner, J. Prüfung von Chemiefaserzellstoffen an einer Viskose-Kleinstanlage. Das Pap. 1966, 20, 125–132. [Google Scholar]

- Treiber, E.; Rehnstroem, J.; Ameen, C.; Kolos, F. A small-scale laboratory viscose plant for testing rayon grade pulps. Das Pap. 1962, 16, 85–94. [Google Scholar]

- Sixta, H. Pulp Properties and Application. In Handbook of Pulp; Sixta, H., Ed.; Wiley-VCH: Weinheim, Germany, 2006; pp. 1009–1068. [Google Scholar]

- Rydholm, S.A. Preparation of Unbleached Pulp. In Pulping Processes; Robert E. Krieger Publishing: Malabar, FL, USA, 1965; pp. 255–835. [Google Scholar]

- Wayman, M.; Sherk, D.L. Caustic Extraction of Refined Sulphite Pulp. Tappi 1956, 39, 786–790. [Google Scholar]

- Saito, G.-I. The behaviour of cellulose in solutions of alkalies. I. Cross-sectional swelling of fibers of different celluloses in sodium hydroxide solutions at different temperatures. Kolloid-Beihefte 1939, 49, 367–387. [Google Scholar]

- Brogdon, B.N. Caustic Extraction in Elemental Chlorine-free Bleaching Sequences for Soft-wood Kraft Pulps: A Fundamental Review and Analysis. In Proceedings of the Engineering, Pulping and Environmental Conference, Portland, OR, USA, 24–27 August 2008; TAPPI Press: Peachtree Corners, GA, USA, 2008. [Google Scholar]

- Patt, R.; Kockmann, C.; Kordsachia, O.; Geisenheiner, A. Pulping of Beech Wood Using Different Acid and Alkaline Pulping Processes—A Comparison. Das Pap. 2004, 1, 41–46. [Google Scholar]

- Fengel, D.; Wegener, G. Reactions in Acidic Medium. In Wood—Chemistry, Ultrastructure, Reactions; Walter de Gruyter & Co.: Berlin, Germany, 1989; pp. 268–295. [Google Scholar]

- Götze, K. Die Technologie des Viskoseverfahrens. In Chemiefasern nach dem Viskoseverfahren; Springer: Berlin/Heidelberg, Germany, 1967; pp. 779–991. [Google Scholar]

- Nascimento Marcos, V.; Manrich, A.; Tardioli Waldir, P.; de Campos Giordano, R.; Jackson de Moraes Rocha, G.; de Lima Camargo Giordano, R. Alkaline pretreatment for practicable production of ethanol and xylooligosaccharides. Bioethanol 2016, 2, 112–125. [Google Scholar] [CrossRef]

- Lin, S.H.; Chou, L.M.; Chien, Y.W.; Chang, J.S.; Lin, C.I. Prebiotic Effects of Xylooligosaccharides on the Improvement of Microbiota Balance in Human Subjects. Gastroent. Res. Pract. 2016, 2016, 1–6. [Google Scholar] [CrossRef] [PubMed]

| Experimental Goal | NaOH (g/L) | Temperature (°C) | |

|---|---|---|---|

| CE1 | high yield, high R18 | 70 | 44 |

| CE2 | high temperature, high R18 | 66 | 78 |

| CE3 | high temperature, low PDI | 82 | 80 |

| Bleaching Sequence | O | O-CE | O-CE | O-CE-Z-P | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CE1 | CE2 | CE3 | σ | CE1 | CE2 | CE3 | CE1 | CE2 | CE3 | ||

| parameter | calculated | observed | observed | ||||||||

| kappa number | 1.2 | 0.9 | 0.9 | 0.9 | 0.04 | 0.9 | 0.9 | 0.9 | 0.1 | 0.1 | 0.1 |

| brightness (%ISO) | 75.7 | 79.2 | 80.7 | 80.9 | 0.8 | 78.5 | 80.0 | 81.0 | 91.8 | 93.0 | 93.6 |

| viscosity (ml/g) | 435 | 440 | 450 | 455 | 6 | 445 | 455 | 460 | 405 | 400 | 400 |

| R10 (%) | 84.7 | 86.4 | 86.3 | 87.0 | 0.6 | 86.2 | 86.8 | 87.7 | 84.8 | 85.6 | 86.2 |

| R18 (%) | 92.7 | 95.0 | 95.0 | 95.6 | 0.3 | 94.8 | 94.9 | 95.8 | 94.7 | 94.8 | 95.8 |

| PDI | 7.1 | 6.3 | 5.9 | 5.5 | 0.3 | 5.9 | 6.0 | 5.5 | 5.8 | 5.4 | 5.0 |

| xylan (%) | 2.4 | 1.3 | 1.4 | 1.1 | 0.1 | 1.4 | 1.4 | 1.1 | 1.4 | 1.3 | 1.1 |

| crystallinity index (%) | 55 | 54 | 55 | 55 | 1 | 53 | 53 | 53 | 53 | 54 | 53 |

| cellulose II (%) | 4 | 8 | 6 | 6 | 8 | 13 | 12 | 12 | 12 | 12 | 13 |

| yield DOC (%) | 95.7 | 97.0 | 93.8 | 92.3 | 0.9 | 97.3 | 94.0 | 89.1 | 99.4 | 99.4 | 99.5 |

| particles (ppm) | 7.1 | 4.4 | 4.4 | ||||||||

| filtration value (g/cm2) | 390 | 400 | 421 | ||||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Friebel, C.; Bischof, R.H.; Schild, G.; Fackler, K.; Gebauer, I. Effects of Caustic Extraction on Properties of Viscose Grade Dissolving Pulp. Processes 2019, 7, 122. https://doi.org/10.3390/pr7030122

Friebel C, Bischof RH, Schild G, Fackler K, Gebauer I. Effects of Caustic Extraction on Properties of Viscose Grade Dissolving Pulp. Processes. 2019; 7(3):122. https://doi.org/10.3390/pr7030122

Chicago/Turabian StyleFriebel, Cindy, Robert H. Bischof, Gabriele Schild, Karin Fackler, and Ireen Gebauer. 2019. "Effects of Caustic Extraction on Properties of Viscose Grade Dissolving Pulp" Processes 7, no. 3: 122. https://doi.org/10.3390/pr7030122

APA StyleFriebel, C., Bischof, R. H., Schild, G., Fackler, K., & Gebauer, I. (2019). Effects of Caustic Extraction on Properties of Viscose Grade Dissolving Pulp. Processes, 7(3), 122. https://doi.org/10.3390/pr7030122