Realizing Energy Savings in Integrated Process Planning and Scheduling

Abstract

:1. Introduction

2. Literature Review

3. Methodological Approach and Advantages

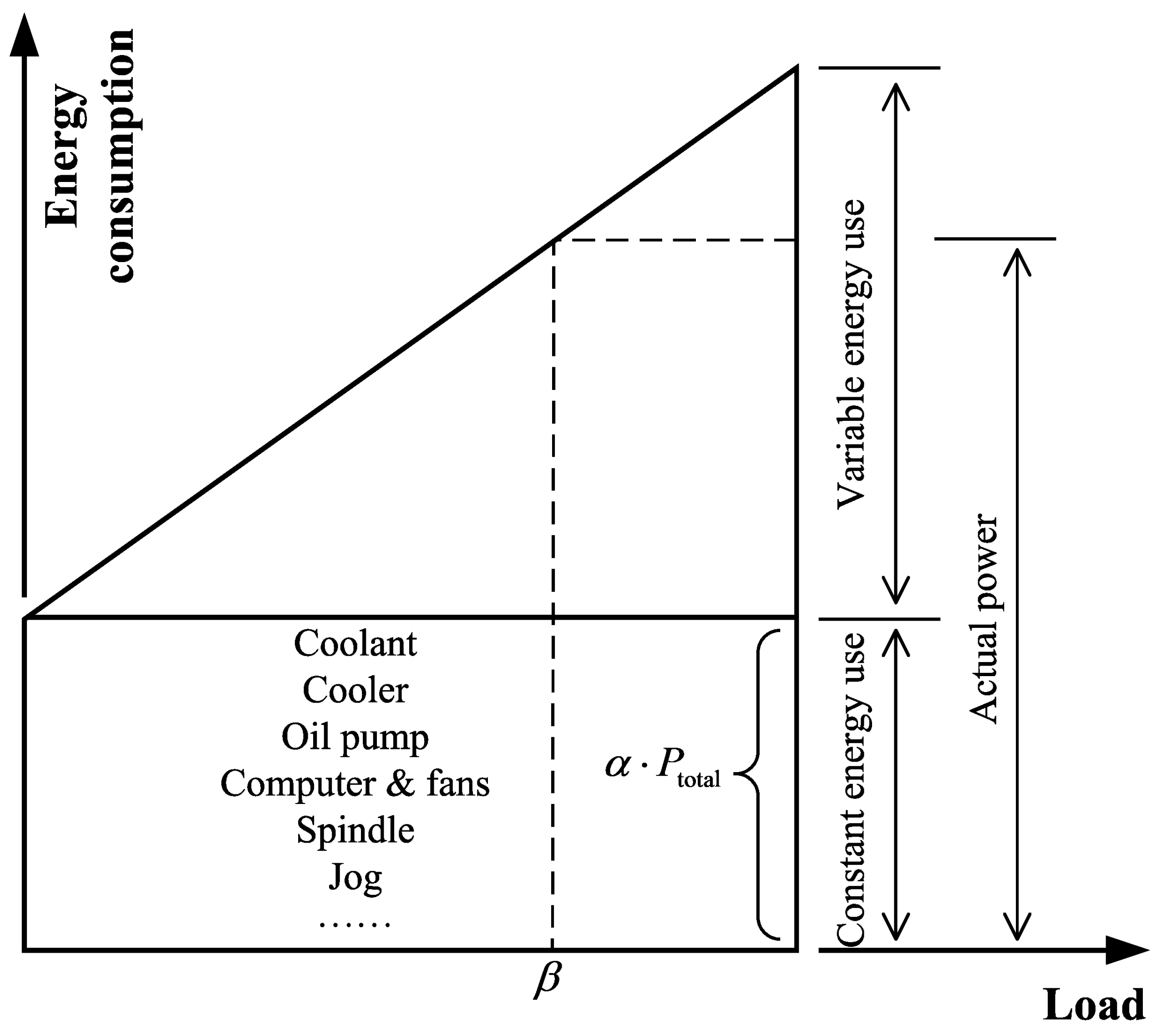

- In this research, frequent machine turning “ons” and “offs” as well as changeable processing times are not allowed to make the resultant scheduling scheme of the energy-efficient IPPS problem more practical. The energy consumption reduction of the IPPS problem is realized by the optimal scheduling scheme.

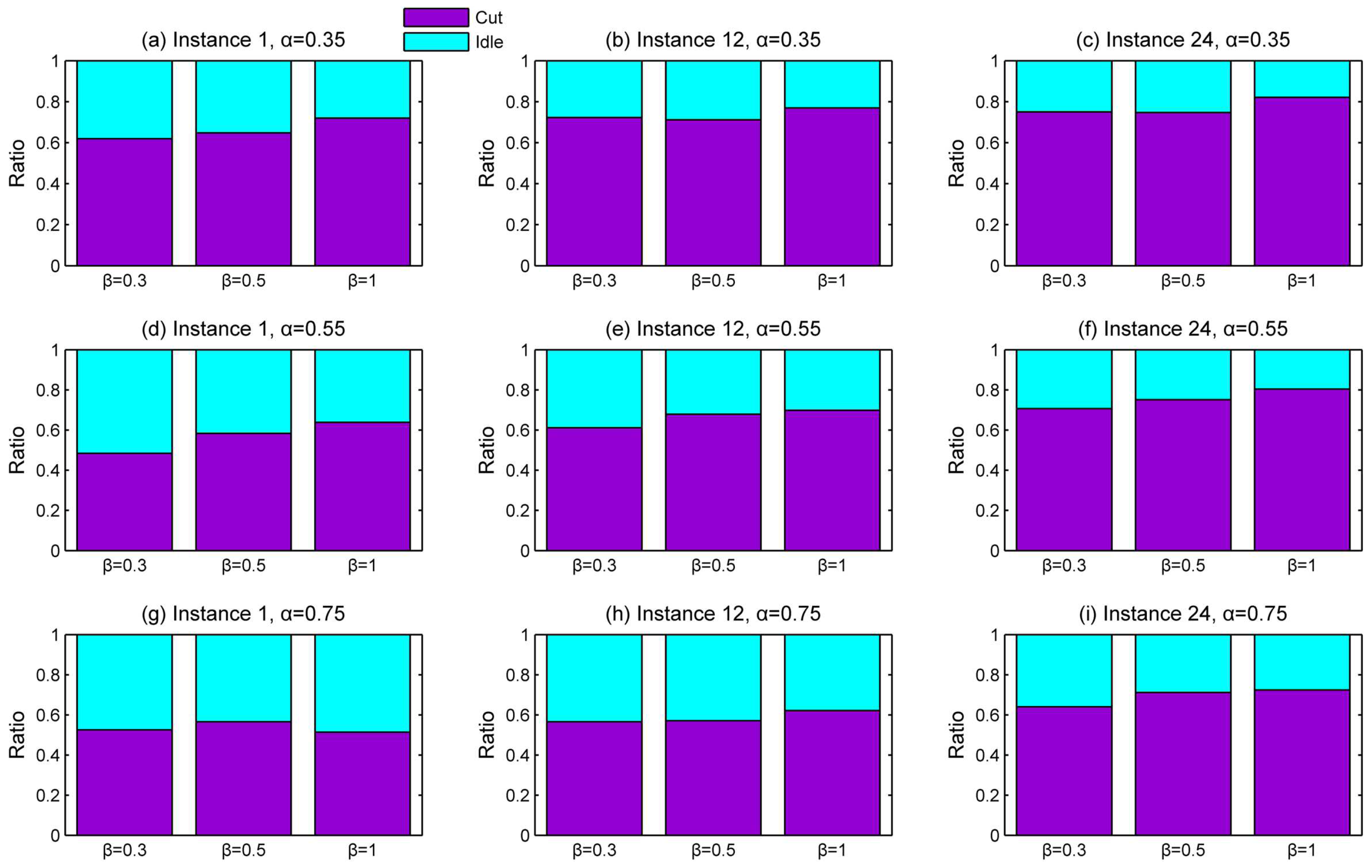

- Based on the two scenarios, we analyze the impacts of different machine automation levels (different types of machine tools, represented by the value in Figure 2) and different workloads (represented by the value in Figure 2) on the energy consumptions of IPPS instances. Before this research, the impacts of machine automation levels on the energy consumption reductions have seldom been discussed in energy-efficient production scheduling optimizations.

- There are two types of MILP models for the IPPS problem, and the Type-2 MILP model can realize a true integration of process planning and scheduling [2]. Based on our previous Type-2 MILP model [2], this research reports a novel multi-objective MILP model for the energy-efficient IPPS problem for the first time where the energy consumption criterion together with the makespan criterion is optimized simultaneously.

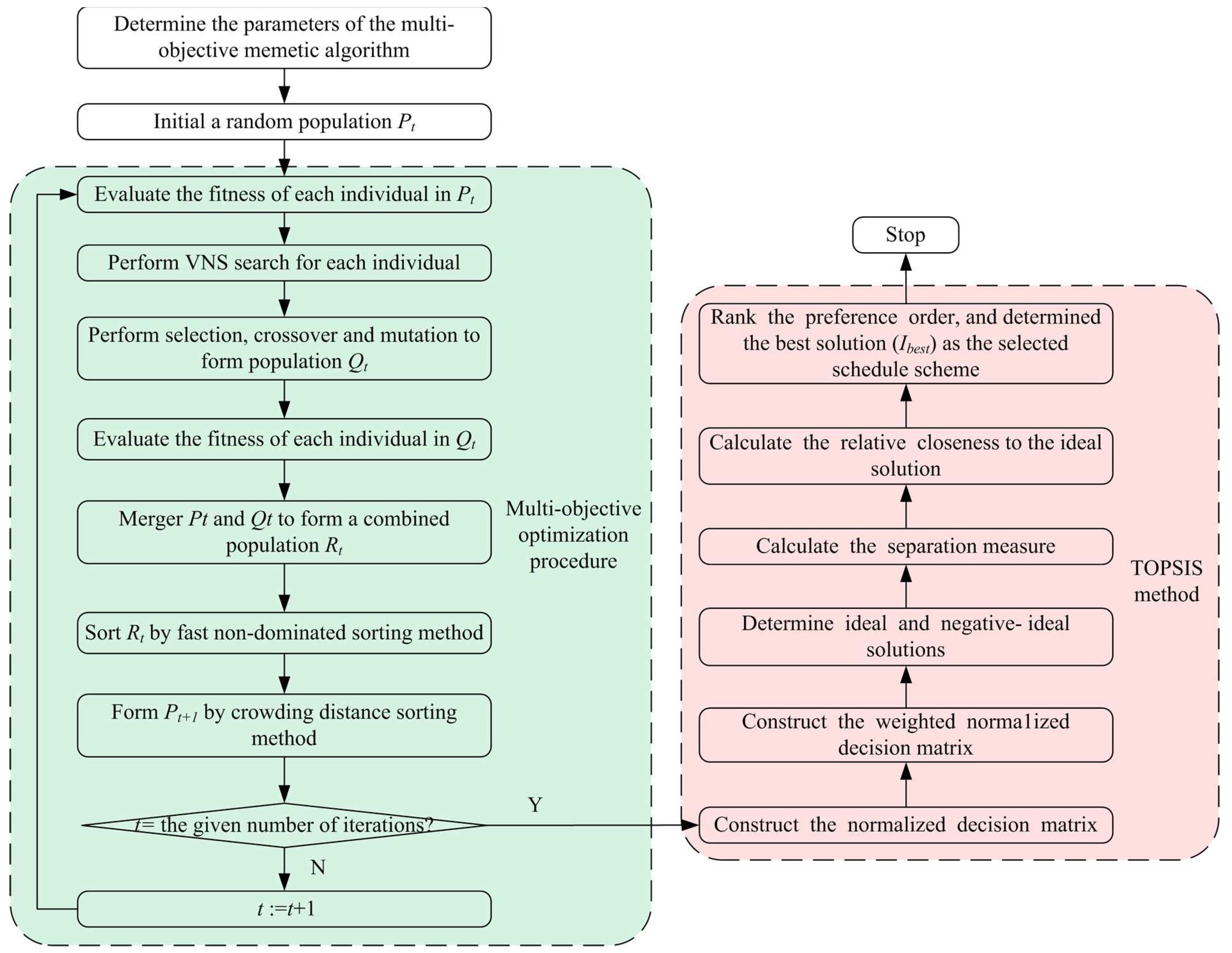

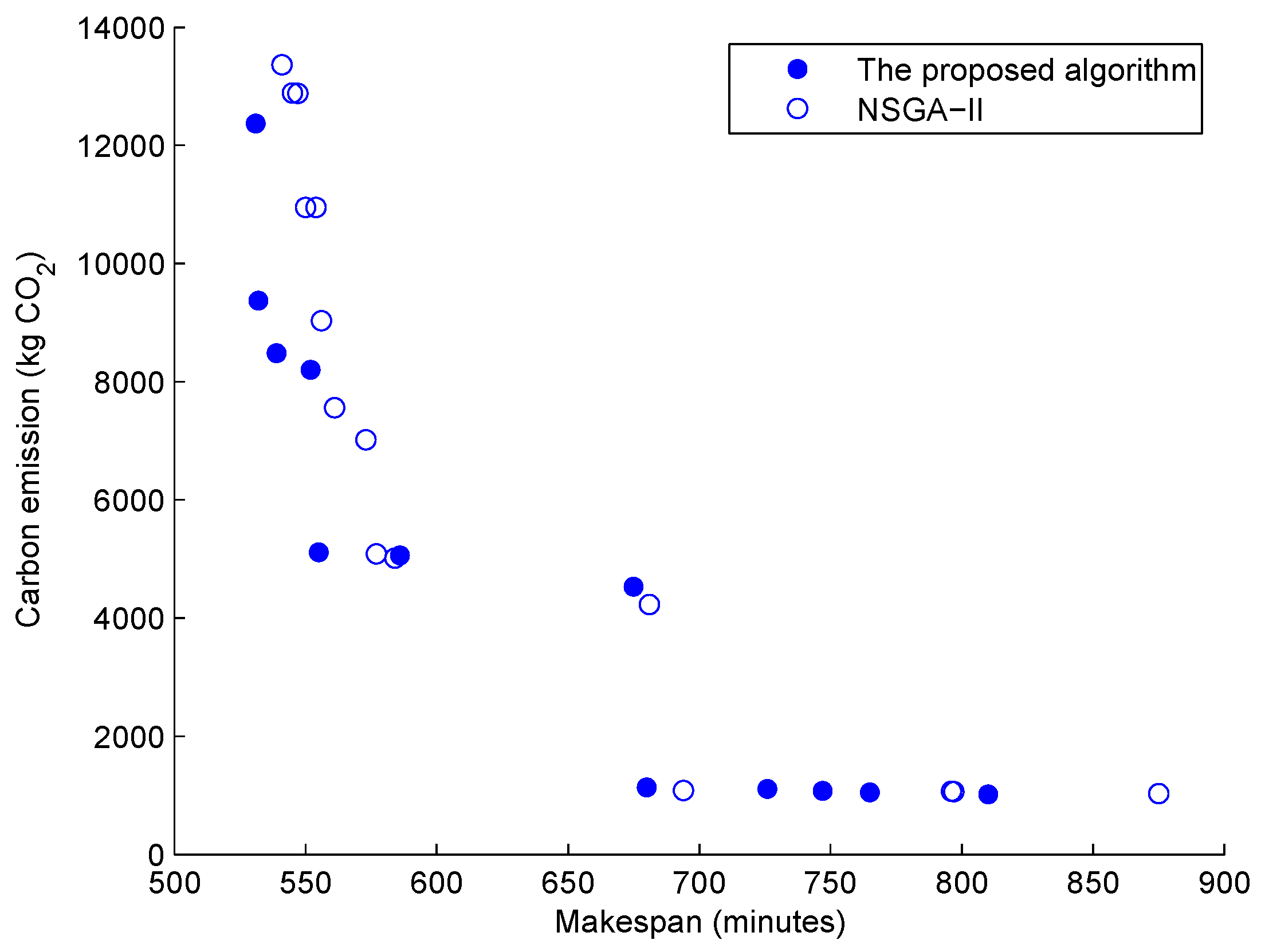

- Due to the complexity in solving the MILP model, a multi-objective memetic algorithm is developed to accommodate multi-objective optimization of the IPPS problem. In the proposed algorithm, the variable neighborhood search (VNS) is adopted to enhance the search ability of the algorithm. Instead of the abusive weighted sum method, the Pareto-based method [51] is adopted in the proposed memetic algorithm; this multi-objective optimization paradigm allows a set of non-dominated solutions for the decision maker. To determine the most promising scheduling scheme from the Pareto front, the TOPSIS decision method is adopted.

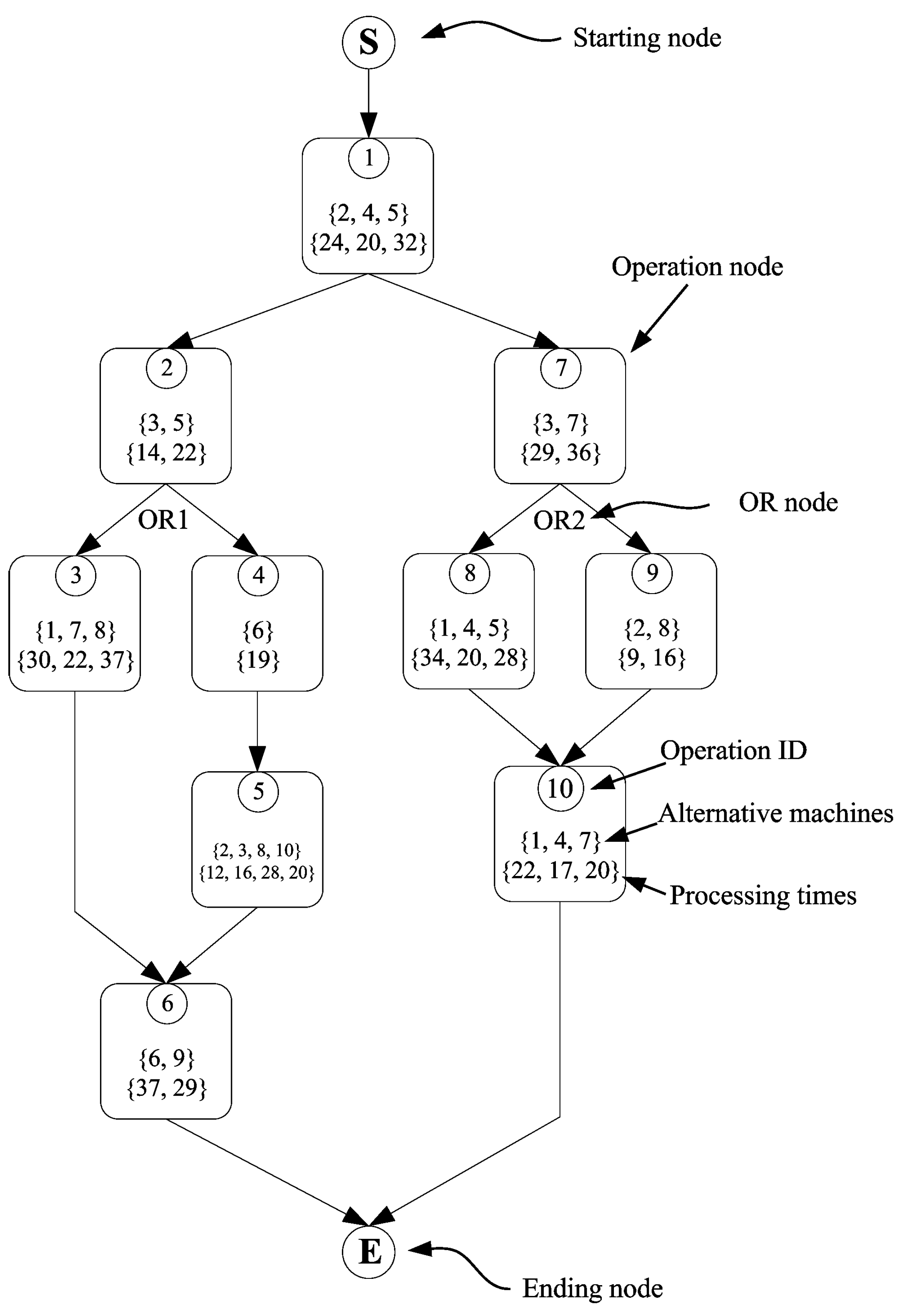

4. Mathematical Modelling

Subscripts and notations

| jobs, 1 , | |

| operations, , | |

| machines, | |

| h | combinations, |

| the j-th operation of job i, | |

| the j-th operation of job i using the h-th combination of that job. |

Sets and parameters

| A | a very large positive integer, |

| the processing time of on machine k, | |

| the set that contains the operations belonging to the h-th combination of job i, | |

| the set of combinations of job i, | |

| n | the set of all the jobs, |

| the set of all the operations in the network graph of job i, | |

| the set of available machines for , | |

| 1, if is to be processed before represented directly by the network graph; 0, otherwise, | |

| 1, should be processed directly or indirectly before ; 0, otherwise, | |

| the rated power of machine k, | |

| the cutting power of machine k, , | |

| the idle power of machine k, . |

Variables

| makespan, | |

| total energy consumption, | |

| 1, if the h-th combination of job i is selected; 0, otherwise, | |

| 1, if operation is processed on machine k; 0, otherwise, | |

| 1, if operation is processed directly or indirectly before ; 0, otherwise, | |

| the completion time of , | |

| 1, if is processed before on a machine; 0, otherwise, | |

| the completion time of the last operation on machine k, | |

| the total production time of the operations on machine k (the time in cutting on machine k). |

Objectives

Constraints

Constraints

5. Multi-Objective Memetic Algorithm

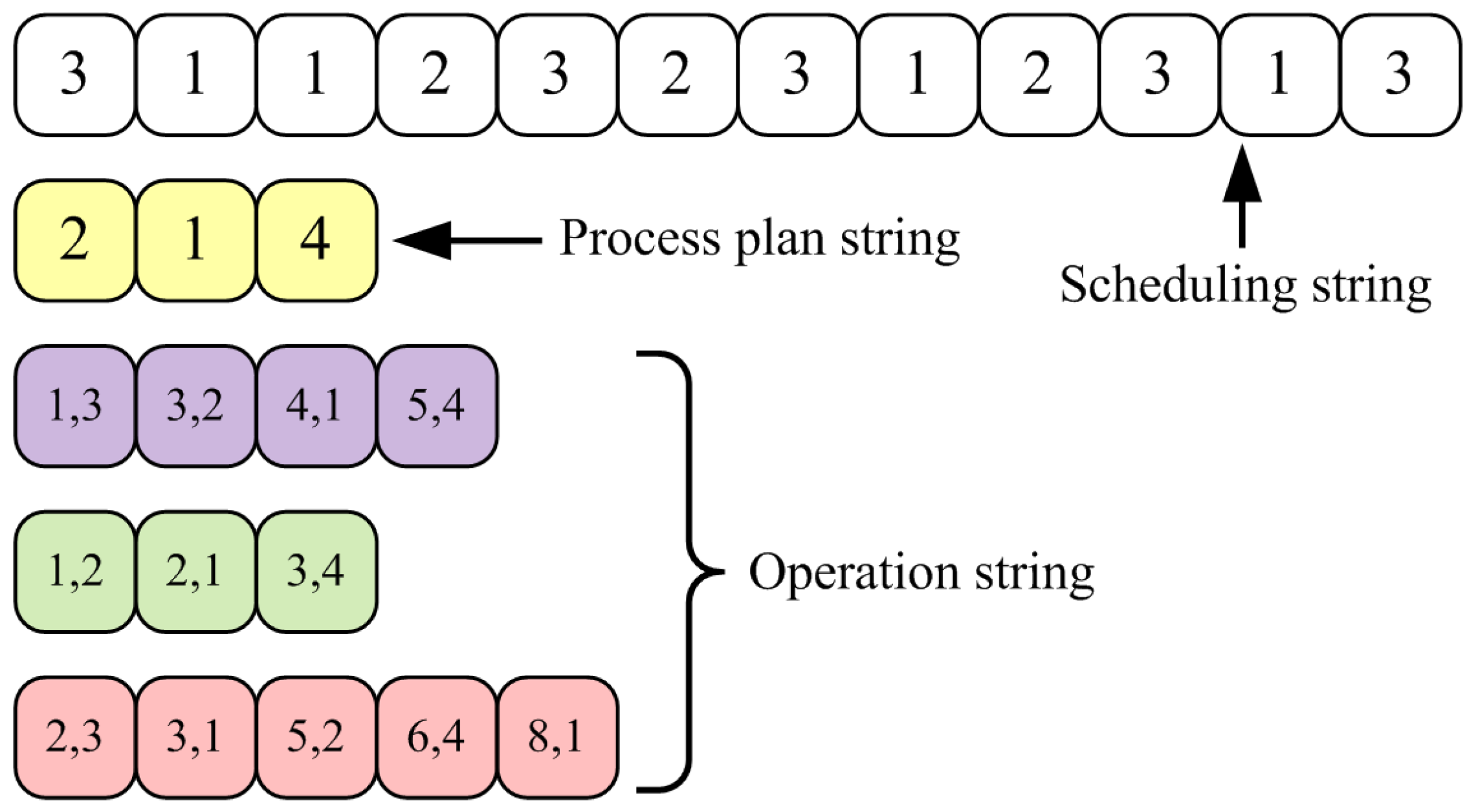

5.1. Encoding & Decoding

5.2. Crossover & Local Search

5.3. Multi-Objective Optimization

6. Experiments with Discussions

6.1. Experiment 1

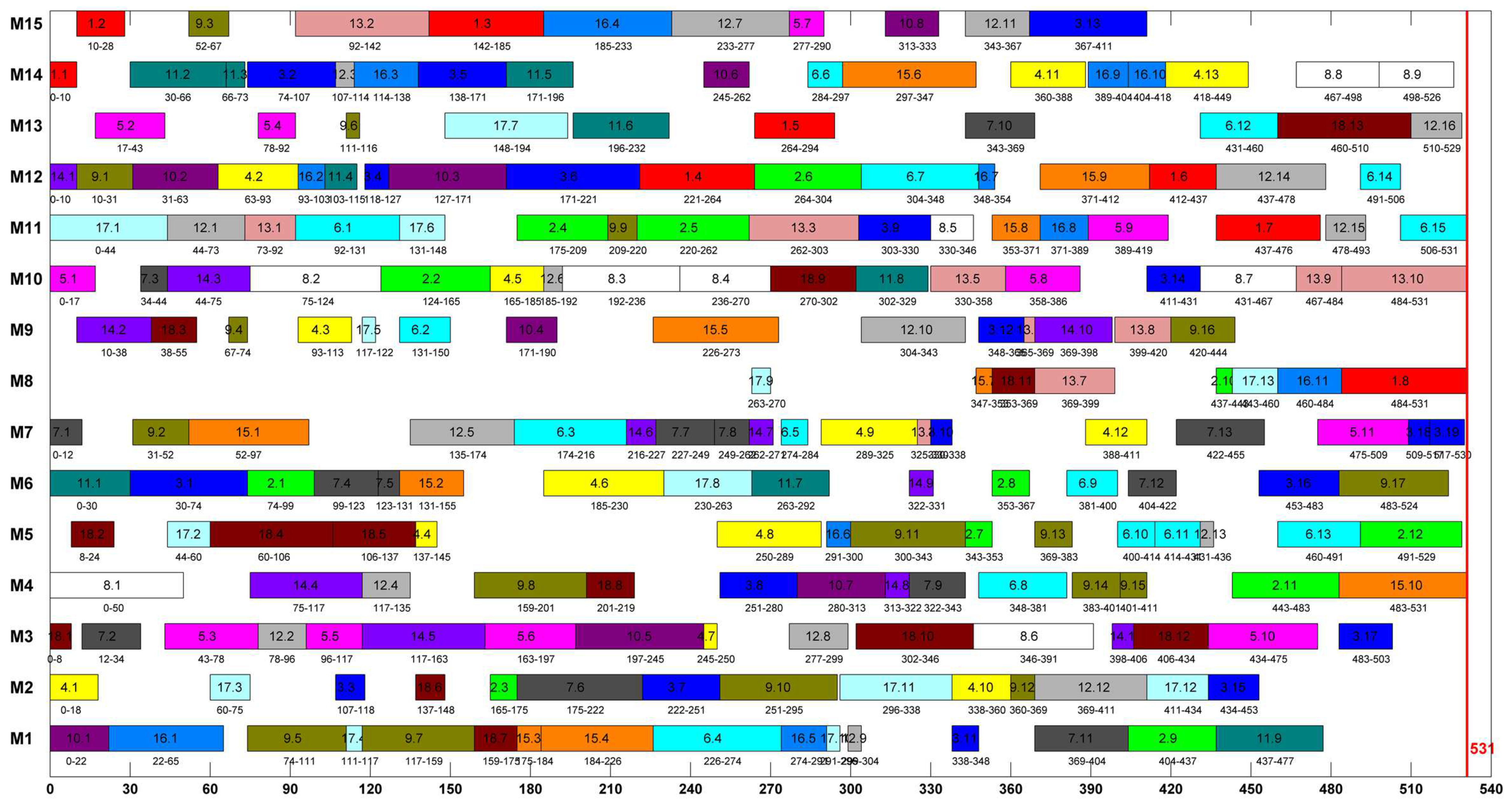

- Assign operations to the machines with low powers as much as possible. For example, the power values of machines 1, 3, 4, 6, 9, 10, 12, and 15 are larger than 15kw and only few operations are assigned to machines 1, 6, 9, and 10 according to Figure 8. In this way, the machine with low constant energy use will be assigned more operations to save energy; the negative effect is that the makespan criterion will deteriorate because more operations will accumulate and wait to be processed.

- Finish operation processing as early as possible on the machines with large powers. For example, operations processed by machines 1, 9, and 10 are sequenced compactly according to Figure 8 and the machines will be shut down once the machining procedures of the operations are finished; in this way, the idle energy consumptions on these machines can be reduced.

- From Figure 8, energy-efficient scheduling can also be realized by tight arrangements of operations on machines because this can edge out the idle time intervals on machines and therefore the idle energy consumption can be reduced.

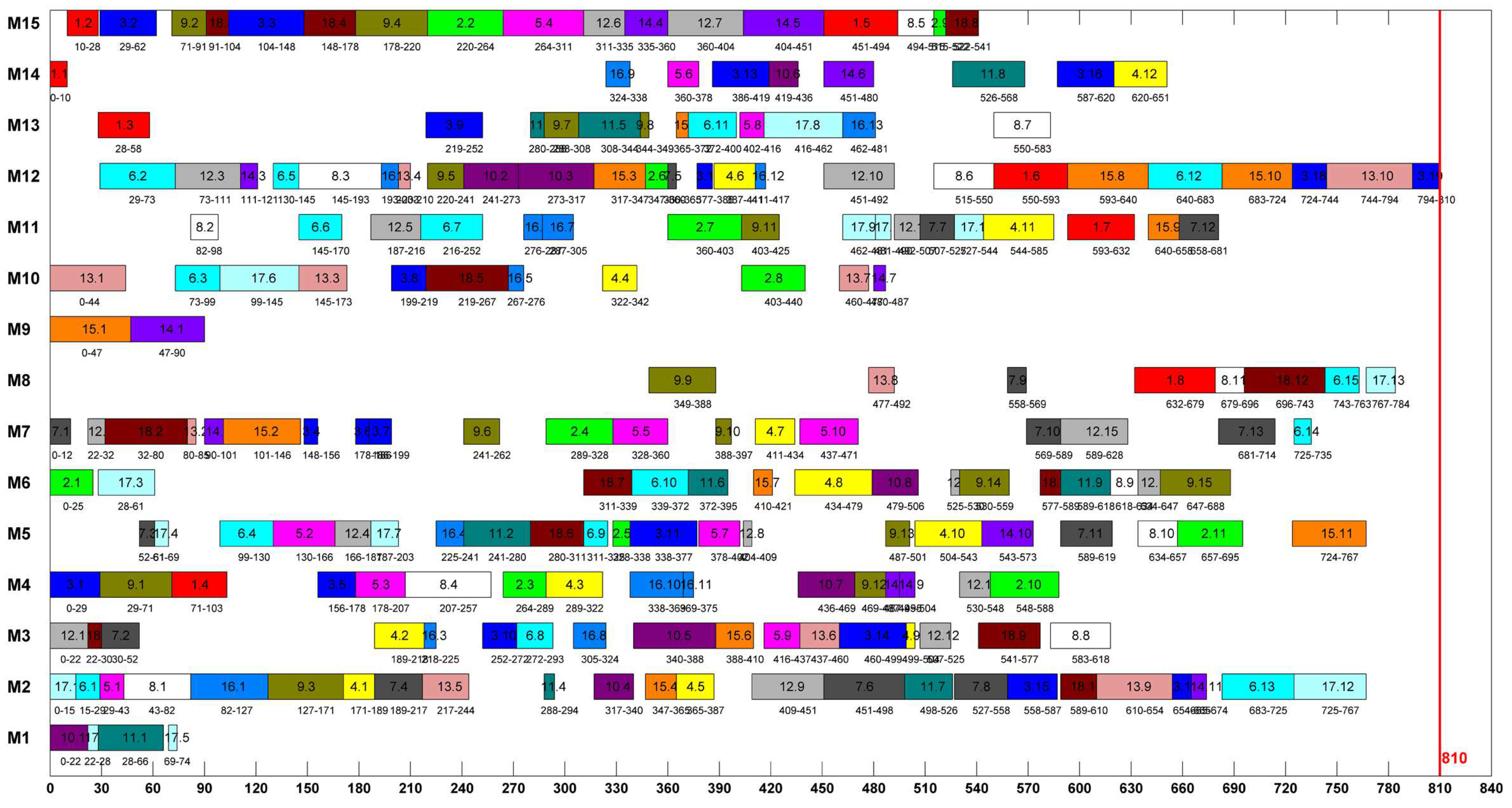

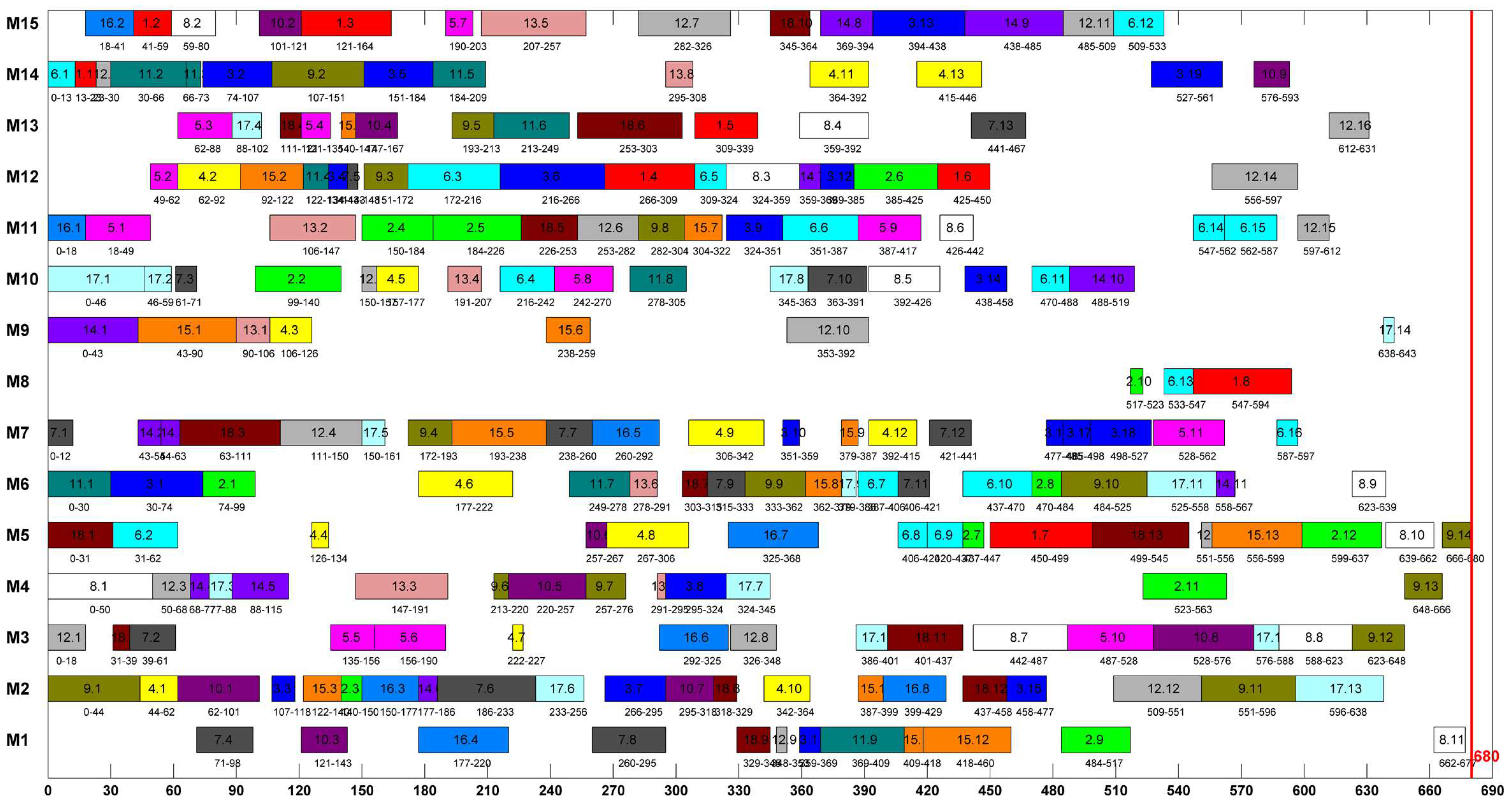

6.2. Experiment 2

7. Conclusions

- Due to low constant energy use of machines with low automation levels, operations are suggested to be processed by machines with low automation levels. In such a case, the idle energy consumption can be reduced. This strategy can be applied to the cases where only few operations to be processed because there will be many idle time intervals.

- Increasing the number of operations or jobs is another way to improve energy use rate; there will be no idle time intervals between two operations on a machine and therefore, the idle energy consumption can be reduced.

Author Contributions

Funding

Conflicts of Interest

References

- Jin, L.; Zhang, C.; Shao, X.; Yang, X.; Tian, G. A multi-objective memetic algorithm for integrated process planning and scheduling. Int. J. Adv. Manuf. Technol. 2016, 85, 1513–1528. [Google Scholar] [CrossRef]

- Jin, L.; Tang, Q.; Zhang, C.; Shao, X.; Tian, G. More MILP models for integrated process planning and scheduling. Int. J. Prod. Res. 2016, 54, 4387–4402. [Google Scholar] [CrossRef]

- Mohammadi, G.; Karampourhaghghi, A.; Samaei, F. A multi-objective optimisation model to integrating flexible process planning and scheduling based on hybrid multi-objective simulated annealing. Int. J. Prod. Res. 2012, 50, 5063–5076. [Google Scholar] [CrossRef]

- Lv, S.; Qiao, L. A cross-entropy-based approach for the optimization of flexible process planning. Int. J. Adv. Manuf. Technol. 2013, 68, 2099–2110. [Google Scholar] [CrossRef]

- Zhang, L.; Wong, T. An object-coding genetic algorithm for integrated process planning and scheduling. Eur. J. Oper. Res. 2015, 244, 434–444. [Google Scholar] [CrossRef]

- Lian, K.; Zhang, C.; Gao, L.; Li, X. Integrated process planning and scheduling using an imperialist competitive algorithm. Int. J. Prod. Res. 2012, 50, 4326–4343. [Google Scholar] [CrossRef]

- Li, X.; Gao, L.; Shao, X. An active learning genetic algorithm for integrated process planning and scheduling. Expert Syst. Appl. 2012, 39, 6683–6691. [Google Scholar] [CrossRef]

- Kim, Y.K.; Park, K.; Ko, J. A symbiotic evolutionary algorithm for the integration of process planning and job shop scheduling. Comput. Oper. Res. 2003, 30, 1151–1171. [Google Scholar] [CrossRef]

- Li, X.; Gao, L.; Shao, X.; Zhang, C.; Wang, C. Mathematical modeling and evolutionary algorithm-based approach for integrated process planning and scheduling. Comput. Oper. Res. 2010, 37, 656–667. [Google Scholar] [CrossRef]

- Doh, H.H.; Yu, J.M.; Kim, J.S.; Lee, D.H.; Nam, S.H. A priority scheduling approach for flexible job shops with multiple process plans. Int. J. Prod. Res. 2013, 51, 3748–3764. [Google Scholar] [CrossRef]

- Haddadzade, M.; Razfar, M.R.; Zarandi, M.H.F. Integration of process planning and job shop scheduling with stochastic processing time. Int. J. Adv. Manuf. Technol. 2014, 71, 241–252. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, C.; Shao, X. An effective hybrid honey bee mating optimization algorithm for integrated process planning and scheduling problems. Int. J. Adv. Manuf. Technol. 2015, 80, 1253–1264. [Google Scholar] [CrossRef]

- Kumar, M.; Rajotia, S. Integration of process planning and scheduling in a job shop environment. Int. J. Adv. Manuf. Technol. 2006, 28, 109–116. [Google Scholar] [CrossRef]

- Shukla, S.K.; Tiwari, M.K.; Son, Y.J. Bidding-based multi-agent system for integrated process planning and scheduling: A data-mining and hybrid tabu-SA algorithm-oriented approach. Int. J. Adv. Manuf. Technol. 2007, 38, 163. [Google Scholar] [CrossRef]

- Özgüven, C.; Özbakır, L.; Yavuz, Y. Mathematical models for job-shop scheduling problems with routing and process plan flexibility. Appl. Math. Model. 2010, 34, 1539–1548. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, C.; Shao, X.; Tian, G. Mathematical modeling and a memetic algorithm for the integration of process planning and scheduling considering uncertain processing times. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 1272–1283. [Google Scholar] [CrossRef]

- Cai, W.; Lai, K.; Liu, C.; Wei, F.; Ma, M.; Jia, S.; Jiang, Z.; Lv, L. Promoting sustainability of manufacturing industry through the lean energy-saving and emission-reduction strategy. Sci. Total Environ. 2019, 665, 23–32. [Google Scholar] [CrossRef] [PubMed]

- Demichela, M.; Baldissone, G.; Darabnia, B. Using Field Data for Energy Efficiency Based on Maintenance and Operational Optimisation. A Step towards PHM in Process Plants. Processes 2018, 6, 25. [Google Scholar] [CrossRef]

- Tian, G.; Zhang, H.; Feng, Y.; Jia, H.; Zhang, C.; Jiang, Z.; Li, Z.; Li, P. Operation patterns analysis of automotive components remanufacturing industry development in China. J. Clean. Prod. 2017, 164, 1363–1375. [Google Scholar] [CrossRef]

- Li, S.; Mirlekar, G.; Ruiz-Mercado, G.J.; Lima, F.V. Development of Chemical Process Design and Control for Sustainability. Processes 2016, 4. [Google Scholar] [CrossRef]

- Cai, W.; Liu, C.; Zhang, C.; Ma, M.; Rao, W.; Li, W.; He, K.; Gao, M. Developing the ecological compensation criterion of industrial solid waste based on emergy for sustainable development. Energy 2018, 157, 940–948. [Google Scholar] [CrossRef]

- Li, C.; Xiao, Q.; Tang, Y.; Li, L. A method integrating Taguchi, RSM and MOPSO to CNC machining parameters optimization for energy saving. J. Clean. Prod. 2016, 135, 263–275. [Google Scholar] [CrossRef]

- Tan, W.; Khoshnevis, B. A linearized polynomial mixed integer programming model for the integration of process planning and scheduling. J. Intell. Manuf. 2004, 15, 593–605. [Google Scholar] [CrossRef]

- Li, X.; Shao, X.; Gao, L.; Qian, W. An effective hybrid algorithm for integrated process planning and scheduling. Int. J. Prod. Econ. 2010, 126, 289–298. [Google Scholar] [CrossRef]

- Guo, Y.; Li, W.; Mileham, A.; Owen, G. Optimisation of integrated process planning and scheduling using a particle swarm optimisation approach. Int. J. Prod. Res. 2009, 47, 3775–3796. [Google Scholar] [CrossRef]

- Guo, Y.; Li, W.; Mileham, A.; Owen, G. Applications of particle swarm optimisation in integrated process planning and scheduling. Robot. Comput. Integr. Manuf. 2009, 25, 280–288. [Google Scholar] [CrossRef]

- Zhang, S.; Wong, T.N. Integrated process planning and scheduling: An enhanced ant colony optimization heuristic with parameter tuning. J. Intell. Manuf. 2018, 29, 585–601. [Google Scholar] [CrossRef]

- Zhao, B.; Gao, J.; Chen, K.; Guo, K. Two-generation Pareto ant colony algorithm for multi-objective job shop scheduling problem with alternative process plans and unrelated parallel machines. J. Intell. Manuf. 2018, 29, 93–108. [Google Scholar] [CrossRef]

- Liu, M.; Yi, S.; Wen, P. Quantum-inspired hybrid algorithm for integrated process planning and scheduling. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 1105–1122. [Google Scholar] [CrossRef]

- Wong, T.; Zhang, S.; Wang, G.; Zhang, L. Integrated process planning and scheduling—Multi-agent system with two-stage ant colony optimisation algorithm. Int. J. Prod. Res. 2012, 50, 6188–6201. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, S. Flexible Assembly Job-Shop Scheduling With Sequence-Dependent Setup Times and Part Sharing in a Dynamic Environment: Constraint Programming Model, Mixed-Integer Programming Model, and Dispatching Rules. IEEE Trans. Eng. Manag. 2018, 65, 487–504. [Google Scholar] [CrossRef]

- Lu, C.; Gao, L.; Li, X.; Chen, P. Energy-efficient multi-pass turning operation using multi-objective backtracking search algorithm. J. Clean. Prod. 2016, 137, 1516–1531. [Google Scholar] [CrossRef]

- Dornfeld, D.A. Moving towards green and sustainable manufacturing. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 63–66. [Google Scholar] [CrossRef]

- He, Y.; Li, Y.; Wu, T.; Sutherland, J.W. An energy-responsive optimization method for machine tool selection and operation sequence in flexible machining job shops. J. Clean. Prod. 2015, 87, 245–254. [Google Scholar] [CrossRef]

- May, G.; Stahl, B.; Taisch, M.; Prabhu, V. Multi-objective genetic algorithm for energy-efficient job shop scheduling. Int. J. Prod. Res. 2015, 53, 7071–7089. [Google Scholar] [CrossRef]

- Lin, W.; Yu, D.; Zhang, C.; Liu, X.; Zhang, S.; Tian, Y.; Liu, S.; Xie, Z. A multi-objective teaching learning based optimization algorithm to scheduling in turning processes for minimizing makespan and carbon footprint. J. Clean. Prod. 2015, 101, 337–347. [Google Scholar] [CrossRef]

- Mouzon, G.; Yildirim, M.B.; Twomey, J. Operational methods for minimization of energy consumption of manufacturing equipment. Int. J. Prod. Res. 2007, 45, 4247–4271. [Google Scholar] [CrossRef]

- Dai, M.; Tang, D.; Giret, A.; Salido, M.A.; Li, W. Energy-efficient scheduling for a flexible flow shop using an improved genetic-simulated annealing algorithm. Robot. Comput. Integr. Manuf. 2013, 29, 418–429. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Shao, X.; Ren, Y.; Ren, C. Mathematical modelling and optimisation of energy-conscious hybrid flow shop scheduling problem with unrelated parallel machines. Int. J. Prod. Res. 2018, 1–27. [Google Scholar] [CrossRef]

- Zhang, R.; Chiong, R. Solving the energy-efficient job shop scheduling problem: A multi-objective genetic algorithm with enhanced local search for minimizing the total weighted tardiness and total energy consumption. J. Clean. Prod. 2016, 112, 3361–3375. [Google Scholar] [CrossRef]

- Fang, K.; Uhan, N.A.; Zhao, F.; Sutherland, J.W. Flow shop scheduling with peak power consumption constraints. Ann. Oper. Res. 2013, 206, 115–145. [Google Scholar] [CrossRef]

- Lei, D.; Zheng, Y.; Guo, X. A shuffled frog-leaping algorithm for flexible job shop scheduling with the consideration of energy consumption. Int. J. Prod. Res. 2017, 55, 3126–3140. [Google Scholar] [CrossRef]

- Wu, X.; Sun, Y. A green scheduling algorithm for flexible job shop with energy-saving measures. J. Clean. Prod. 2018, 172, 3249–3264. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, Z.; Wang, Y.; Zhang, H.; Wang, Y. A two-stage optimization method for energy-saving flexible job-shop scheduling based on energy dynamic characterization. J. Clean. Prod. 2018, 188, 575–588. [Google Scholar] [CrossRef]

- Giglio, D.; Paolucci, M.; Roshani, A. Integrated lot sizing and energy-efficient job shop scheduling problem in manufacturing/remanufacturing systems. J. Clean. Prod. 2017, 148, 624–641. [Google Scholar] [CrossRef]

- Mikhaylidi, Y.; Naseraldin, H.; Yedidsion, L. Operations scheduling under electricity time-varying prices. Int. J. Prod. Res. 2015, 53, 7136–7157. [Google Scholar] [CrossRef]

- Zhou, S.; Li, X.; Du, N.; Pang, Y.; Chen, H. A multi-objective differential evolution algorithm for parallel batch processing machine scheduling considering electricity consumption cost. Comput. Oper. Res. 2018, 96, 55–68. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, R.; Peng, T.; Tao, L.; Jia, S. A method for minimizing the energy consumption of machining system: integration of process planning and scheduling. J. Clean. Prod. 2016, 137, 1647–1662. [Google Scholar] [CrossRef]

- Dahmus, J.B.; Gutowski, T.G. An environmental analysis of machining. In Proceedings of the ASME 2004 International Mechanical Engineering Congress and Exposition, Anaheim, CA, USA, 13–19 November 2004; pp. 643–652. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Shao, X.; Ren, Y. MILP models for energy-aware flexible job shop scheduling problem. J. Clean. Prod. 2019, 210, 710–723. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evolut. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Manne, A.S. On the Job-Shop Scheduling Problem. Oper. Res. 1960, 8, 219–223. [Google Scholar] [CrossRef]

- Bierwirth, C. A generalized permutation approach to job shop scheduling with genetic algorithms. Oper. Res. Spektrum 1995, 17, 87–92. [Google Scholar] [CrossRef]

- Bierwirth, C.; Mattfeld, D.C. Production scheduling and rescheduling with genetic algorithms. Evolut. Comput. 2014, 7, 1–17. [Google Scholar] [CrossRef]

- Cheng, R.; Gen, M.; Tsujimura, Y. A tutorial survey of job-shop scheduling problems using genetic algorithms—I. representation. Comput. Ind. Eng. 1996, 30, 983–997. [Google Scholar] [CrossRef]

- Nowicki, E.; Smutnicki, C. A Fast Taboo Search Algorithm for the Job Shop Problem. Manag. Sci. 1996, 42, 797–813. [Google Scholar] [CrossRef]

- Gao, J.; Sun, L.; Gen, M. A hybrid genetic and variable neighborhood descent algorithm for flexible job shop scheduling problems. Comput. Oper. Res. 2008, 35, 2892–2907. [Google Scholar] [CrossRef]

- Jin, H.; Jin, L.; Zhang, C. Mathematical Modeling and a Hybrid NSGA-II Algorithm for Process Planning Problem Considering Machining Cost and Carbon Emission. Sustainability 2017, 9, 1769. [Google Scholar]

- Tian, G.; Zhou, M.; Li, P. Disassembly Sequence Planning Considering Fuzzy Component Quality and Varying Operational Cost. IEEE Trans. Autom. Sci. Eng. 2018, 15, 748–760. [Google Scholar] [CrossRef]

| Names | Number of Positions | Purpose |

|---|---|---|

| Scheduling string | at most | Operations belonging to different jobs will be processed sequentially according to the sequence in this string. |

| Process plan string | Indicate which operation combination will be adopted for each job. | |

| Operation string | There are operation strings; each has positions at most | The operation IDs and machine IDs of the corresponding operations are specified in each position; each operation string stands for an operation combination. |

| Number | Jobs | Job ID | Operations |

|---|---|---|---|

| 1 | 6 | 1, 2, 3, 10, 11, 12 | 79 |

| 2 | 6 | 4, 5, 6, 13, 14, 15 | 100 |

| 3 | 6 | 7, 8, 9, 16, 17, 18 | 121 |

| 4 | 6 | 1, 4, 7, 10, 13, 16 | 95 |

| 5 | 6 | 2, 5, 8, 11, 14, 17 | 96 |

| 6 | 6 | 3, 6, 9, 12, 15, 18 | 109 |

| 7 | 6 | 1, 4, 8, 12, 15, 17 | 99 |

| 8 | 6 | 2, 6, 7, 10, 14, 18 | 96 |

| 9 | 6 | 3, 5, 9, 11, 13, 16 | 105 |

| 10 | 9 | 1, 2, 3, 5, 6, 10, 11, 12, 15 | 132 |

| 11 | 9 | 4, 7, 8, 9, 13, 14, 16, 17, 18 | 168 |

| 12 | 9 | 1, 4, 5, 7, 8, 10, 13, 14, 16 | 146 |

| 13 | 9 | 2, 3, 6, 9, 11, 12, 15, 17, 18 | 154 |

| 14 | 9 | 1, 2, 4, 7, 8, 12, 15, 17, 18 | 151 |

| 15 | 9 | 3, 5, 6, 9, 10, 11, 13, 14, 16 | 149 |

| 16 | 12 | 1, 2, 3, 4, 5, 6, 10, 11, 12, 13, 14, 15 | 179 |

| 17 | 12 | 4, 5, 6, 7, 8, 9, 13, 14, 15, 16, 17, 18 | 221 |

| 18 | 12 | 1, 2, 4, 5, 7, 8, 10, 11, 13, 14, 16, 17 | 191 |

| 19 | 12 | 2, 3, 5, 6, 8, 9, 11, 12, 14, 15, 17, 18 | 205 |

| 20 | 12 | 1, 2, 4, 6, 7, 8, 10, 12, 14, 15, 17, 18 | 195 |

| 21 | 12 | 2, 3, 5, 6, 7, 9, 10, 11, 13, 14, 16, 18 | 201 |

| 22 | 15 | 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 16, 17, 18 | 256 |

| 23 | 15 | 1, 4, 5, 6, 7, 8, 9, 11, 12, 13, 14, 15, 16, 17, 18 | 256 |

| 24 | 18 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 300 |

| Machine ID | Power (kW) | Machine ID | Power (kW) | Machine ID | Power (kW) |

|---|---|---|---|---|---|

| 1 | 25 | 6 | 19 | 11 | 7 |

| 2 | 12 | 7 | 7 | 12 | 21 |

| 3 | 17 | 8 | 5 | 13 | 9 |

| 4 | 18 | 9 | 23 | 14 | 13 |

| 5 | 12 | 10 | 16 | 15 | 28 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, L.; Zhang, C.; Fei, X. Realizing Energy Savings in Integrated Process Planning and Scheduling. Processes 2019, 7, 120. https://doi.org/10.3390/pr7030120

Jin L, Zhang C, Fei X. Realizing Energy Savings in Integrated Process Planning and Scheduling. Processes. 2019; 7(3):120. https://doi.org/10.3390/pr7030120

Chicago/Turabian StyleJin, Liangliang, Chaoyong Zhang, and Xinjiang Fei. 2019. "Realizing Energy Savings in Integrated Process Planning and Scheduling" Processes 7, no. 3: 120. https://doi.org/10.3390/pr7030120

APA StyleJin, L., Zhang, C., & Fei, X. (2019). Realizing Energy Savings in Integrated Process Planning and Scheduling. Processes, 7(3), 120. https://doi.org/10.3390/pr7030120