1. Introduction

Currently, transportation is the largest generator of greenhouse gas (GHG) emissions and energy and consumption by this sector is estimated to increase 60% by 2030, in part due to global population growth [

1]. In this regard, bioethanol is considered a promising, environmentally friendly alternative for petroleum-based fuels. The most abundant feedstock for bioethanol production is in the form of lignocellulose (e.g., cellulosic biomass). Globally, the energy supply generated from cellulosic materials is estimated to be 60 EJ, accounting for greater than 10% of the total annual energy supply [

2].

Numerous types of cellulosic materials have been investigated as feedstocks for ethanol production, including crop residues (corn stover, sugarcane bagasse, wheat straw), herbaceous biomass (switchgrass, prairie cordgrass, hay), hardwood (poplar, pine) and municipal solid wastes (office paper). Generally, lignocellulose contains 55% to 75% carbohydrates (cellulose and hemicellulose) and 10% to 30% lignin. The complex plant cell wall structure is recalcitrant to extraction of carbohydrates and their depolymerization to monosaccharides, as is necessary for subsequent ethanol fermentation. Therefore, pretreatment is essential for enzymatic hydrolysis [

3]. Pretreatments are graded according to multiple targets, including degree of particle size reduction, fermentable sugar (hexose/pentose) recovery, inhibitor formation (e.g., “fermentability”), energy and water consumption, as well as operating cost and environmental footprint.

Dilute-acid pretreatment is one of the most effective methods to reduce biomass particle size and increase cellulose accessibility for cellulases. However, the use of harsh chemicals leads to sugar losses from degradation, formation of fermentation inhibitors, additional chemical usage for post-pretreatment pH adjustment, and corrosion of equipment, which increases operating costs and creates environmental concerns. On the other hand, mild pretreatments, such as liquid hot water (LHW), avoid the formation of excess inhibitors that would otherwise require conditioning hydrolysates prior to fermentation. The major disadvantage of pretreating with LHW is the low yield of sugars following enzymatic hydrolysis. One strategy is to combine LHW with disk refining. LHW followed by disc refining improved sugar yields compared to either pretreatment used alone in the case of herbaceous biomass; as demonstrated for: rice straw [

4], corn stover [

5] and sugarcane bagasse [

6]. However, adding a disc mill significantly inflates capital costs and pretreatment is already the single most expensive unit operation [

7]. Therefore, determining the full merits of LHW disc refining requires an economic analysis.

Numerous pretreatments have been researched over the past decades. The pretreatment technology chosen affects operating costs related to utility consumption (steam, electricity), labor and wastewater treatment. Feedstock and chemical costs are similar among various pretreatment options and these make up 60% of the total production costs [

8]. An economic comparison of leading pretreatment technologies, using the same process assumptions, found that LHW pretreatment has higher production cost than dilute acid and ammonia fiber expansion (AFEX) due to lower ethanol yields and higher energy inputs [

8,

9]. However, the pretreatment operating conditions play an important role in determining production cost, especially utility cost. As reported by da Silva (2016) the total energy usage of LHW pretreatment increased from 232.3 to 393.6 MW when pretreatment solids loading (SL) decreased from 20% to 13% [

10]. Heat accounts for over 70% of the total energy requirement in the LHW process because high temperatures are required to achieve targeted sugar yields. After feedstock, enzymes (e.g., cellulase) are the next largest material cost item (>20%) [

9,

11]. Onsite enzyme production is considered as a promising approach to reduce enzyme costs [

8], albeit an onsite enzyme production facility inflates fixed capital costs by 13%.

As reported by Kazi et al., (2010), the minimum ethanol selling price (MESP) ranges from

$2 to

$7/gal depending on pretreatment and fermentation strategies [

9]. Basic (mostly AFEX) and LHW (i.e., hydrothermal and liquid hot-water) pretreatments have higher MESP (

$3.69 to

$5.08/gal) than dilute acid pretreatments (

$3.40 to

$4.38/gal) [

9,

12]. However, there are other factors that could affect ethanol production costs, including solids content during hydrolysis and fermentation, fermentation technologies, material and equipment suppliers, and biorefinery site selection [

8]. Therefore, under a very conservative scenario, the MESP for dilute-acid pretreatment increased to

$7.08/gal [

9]. These results were for switchgrass, a report on ethanol production from sugarcane bagasse using dilute acid steam explosion pretreatment estimated the MESP as

$1.91 to

$2.37/gal [

13].

Chen (2015) [

14] reported a process that combined dilute alkaline deacetylation and disk refining (DDR) that achieved high sugars and ethanol titers. Economic analysis of the DDR process predicted a minimum ethanol selling price (MESP) of 2.24 to

$2.54/gal ethanol, for the case of enzymatic hydrolysis at 15% solids. The majority of cellulosic ethanol studies operated at low solids (5% to 10% w/w) saccharification and fermentation that favor high yields. However, realistically for distillation, ethanol concentrations should be greater than 4% [

15], which requires high solids (≥15% w/w) loading hydrolysis and fermentation [

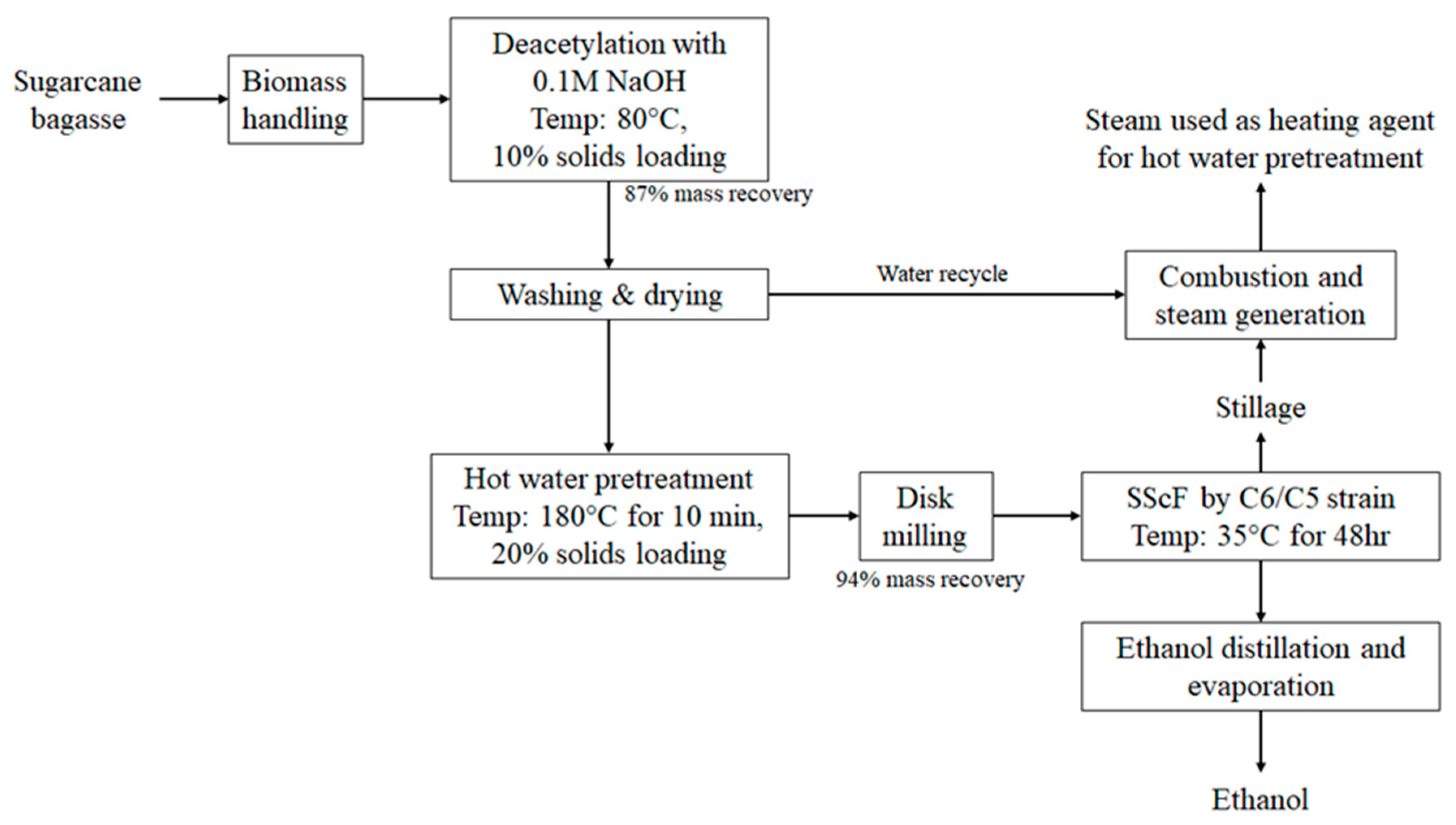

16]. The objective of this study was to evaluate the economics feasibility of a new cellulosic ethanol process that implements deacetylation followed by combined LHW-disc refining of sugarcane bagasse.

3. Results and Discussion

3.1. Fermentation Efficiecncy and Ethanol Yields

An economic analysis of sugarcane bagasse to ethanol was conducted using prior research results using the three-stage pretreatment and SScF process. The SScF was operated at 10% and 16% solids and all other operating parameters were kept constant. Fermentation results from these two processes are summarized in

Table 5. Low solids loading (10%) achieved the highest ethanol yield (0.33 g/g biomass) and conversion efficiency (94%). At 16% solids, the ethanol conversion efficiency was reduced to 91%. However, high solids loading is required for fermentation to achieve the minimum ethanol concentration needed for efficient distillation. Therefore, two ethanol efficiencies and responding solids loading (10% and 16%) were used to compare the effect of solids loading on the minimum ethanol selling price (MESP).

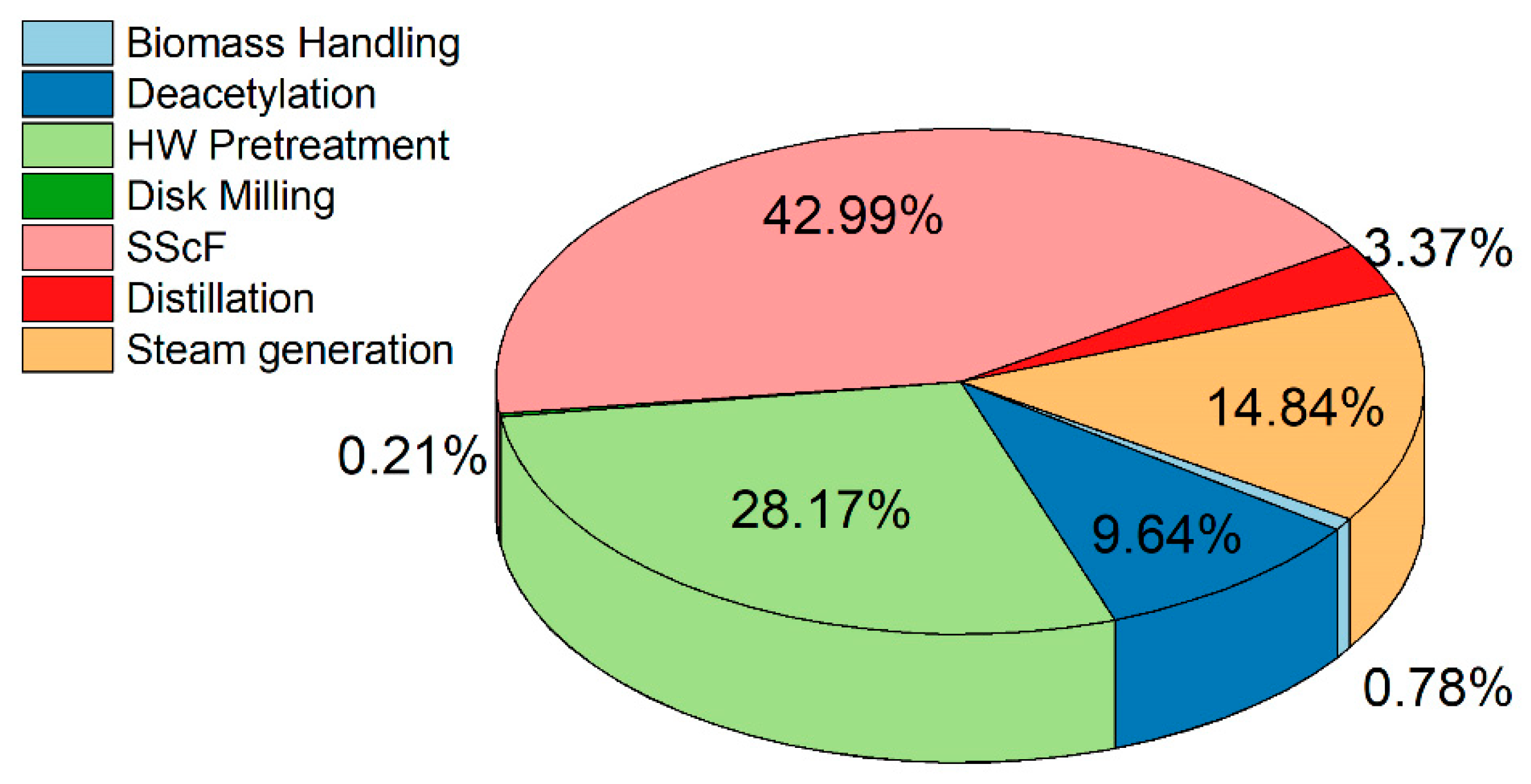

3.2. Fixed Capital Investment of Process Plant

Fixed capital cost for a plant with an annual capacity of 54.2 million gal was calculated to be

$398.94 million, where the majority of the investment comes from unit operations for (listed in order): SScF (42.99%), LHW pretreatment (28.17%), steam generation (14.84%), deacetyaltion (9.64%), distillation (3.37%), biomass handling (0.78%), and disk milling (0.21%) (

Figure 2).

Previous studies reported fixed capital costs for production of cellulosic ethanol are from

$185 to

$253 million [

9,

17,

26], which is lower than that for the three-stage pretreatment process plant. This increase in capital cost is expected because additional processing units were included in this model. The deacetylation and disk milling process increased total capital costs by 9.64% (

$35.05 million) and 0.21% (

$0.76 million), respectively. Chen et al. (2015) reported the additional high temperature pretreatment reactor increased the total capital investment by

$30.45 million (2017 dollars) [

14]. In this study, the cost of the high temperature pretreatment reactor was

$102 million.

The SScF included seed culturing for enzyme production and ethanol fermentation. In ethanol fermentation, 1000 m

3 fermenters are commonly used. Same size fermenters were used in this study, and there were 36 fermenters required. Additionally, the hot water pretreatment does not require extra costs for anti-corrosion, neutralization, and waste acid water compared to typical acid pretreatment. Therefore, SScF is the major contributor for the fixed capital investment. For distillation, the 3.37% of the total fixed capital investment is comparable to 3–4% of total fixed capital investment for cellulosic ethanol plant reported by Gregg et al., (1998) [

27] and 1% reported by Humbird et al., (2011) [

17].

The high-solids (HS) scenario, the biomass processing capacity is same as the base scenario (BS) and the major difference is the solids fermented and less water loadings in the bioreactor. Hence, the total fermentation volume of HS is smaller than BS resulting in $41.55 million lower in the fermentation section.

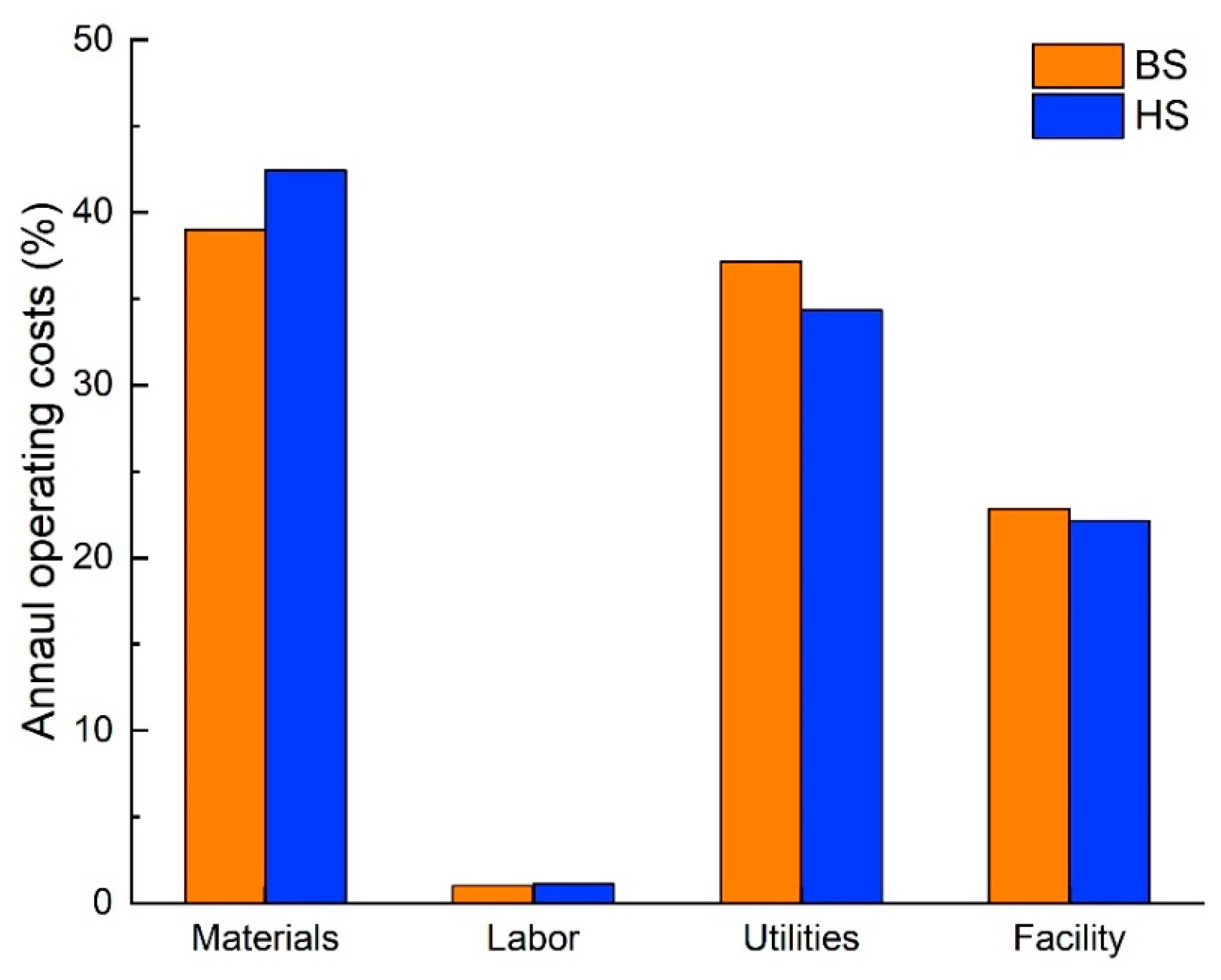

3.3. Operating Costs

Annual operating cost was estimated to be

$243.89 million and

$220.75 million for BS and HS, respectively; these costs are broken down in

Figure 3. Materials and utilities are the largest operating costs, accounting for 80% of the total.

Among the material costs, feedstock bagasse and the seed culturing/fermentation medium account for 35% and 45% of material costs, respectively, for both scenarios. Feedstock is typically the largest cost [

8]. However, this process used an engineered glucose and xylose co-fermenting

Saccharomyces yeast strain and refined/expensive medium was used to propagate the seed culture. For the HS scenario, higher material costs were associated with preparing the inoculum because fermenting a higher concentration of solids requires lager amounts of enzyme and yeast than the BS.

The utility costs were

$90.63 and

$75.75 million contributing 37.16% and 34.32% of operating cost for BS and HS, respectively, which included normal pressure steam (153 °C, 4.43 bar), cooling water, electricity and high pressure (242 °C, 13.17 bar) steam. Utility costs are itemized in

Table 6. Running the LHW pretreatment cost the most (in terms of utilities) followed by distillation and disk milling. The main utility cost associated with LHW pretreatment is high pressure steam, which is the heating agent for the pretreatment reactor. Additionally, after pretreatment, the pretreated biomass needs to be cooled to 100 °C before entering the disk mill. Hence, combined heating and cooling make LHW pretreatment a utility intensive process. Following fermentation, distillation and evaporation require large amounts of steam and cooling water for ethanol recovery.

Electricity is used for grinding, milling, mixing, pumping, and agitation. From the model results, the disk refining consumed over 62% of total electricity followed by saccharification and cofermentation and distillation operations. Disk refining applies shear force (mechanical approach) to defibrillate the biomass at the microscope level; therefore, it consumes large amounts of energy. For SScF and distillation, the electricity is consumed by bioreactor agitators and by pumps that transfer biomass and products between unit operations.

Distillation was the major contributor to cooling water cost, accounting for 75.47% and 64.% in BS and HS, respectively. In this model, pretreated biomass was cooled to 100 °C before disk refining by using a heat exchanger, which would save cooling water in the pretreatment section. The distillation process consisted of beer distillation, ethanol rectification and stripping. Cooling water was required to recover the purified ethanol, which leads to the higher cost. However, the multiple stage pretreatment process accounted for over 75% the total utility cost, arising primarily from steam heating.

Comparing BS scenario and HS scenario, HS has 15.6% ($14 million/year) lower utility costs than BS. Due to the same plant and processing capacity, both scenarios share the same utility costs from biomass handling, deacetylation, hot water pretreatment, and the disk-milling process. In seed culturing and SScF process, HS scenario required more electricity for production of enzymes and yeast. However, the higher ethanol concentration lowers the utility costs associated with ethanol distillation. Therefore, operating at higher solids (HS) lowers the utility costs by 40% (electricity and steam) for distillation, which is the reason that operating at high solids is favored by industry.

3.4. Production Cost and the Minimum Ethanol Selling Price (MESP)

For BS, a yield of 205.06 million L (54.17 million gal) is produced yearly from 2000 MT of dry sugarcane bagasse using this multiple-stage pretreatment process. The 10% solid loading was the baseline for estimating the production cost and the MESP of the ethanol from sugarcane bagasse. The gross production cost was calculated by dividing annual operating costs by ethanol production, which for BS was $4.48/gal ethanol.

Typically, excess heat (generated from combustion of lignin enriched residues) and process waste-water are expected to be used for cogeneration of electricity at cellulosic ethanol plants. In this three-stage pretreatment scenario, the water used in the deacetylation and washing steps was reused for steam generation. However, the steam generated from the steam boiler (650,214 MT high pressure steam/year) cannot satisfy the total steam consumed (1,648,250 MT high pressure steam/year) in the HW pretreatment (180 °C for 10 min), resulting in no surplus energy left for electrical cogeneration. The steam generation and recycled water save operating costs, and net production cost is calculated by subtracting savings from total operation costs. Therefore, the net production cost was $4.16/gal ethanol and the MESP was estimated as $4.90/gal ethanol.

Cost and MESP associated with the HS scenario (16% solids in fermentation) are listed in

Table 7. Though the ethanol yield from 16% solid loading in fermentation was lower than the 10% solid loading, total operating costs were decreased by over

$23 million/year. The largest cost savings was for utilities, which were reduced by 15% (from

$90.7 million/year to

$76.5 million/year). This utility cost reduction was mainly from the distillation process due to the high ethanol titer of the beer. Thus, the net production cost of ethanol from 16% solid loading in the fermentation was

$3.83/gal ethanol and its MESP was

$4.23/gal ethanol. MESP was determined when net profit value equals to zero at the internal rate of 10%. Regardless of solids loading, the payback time is 8.91 years.

The MESP of cellulosic ethanol was estimated from

$2.38 to

$5.15/gal ethanol in 2017 dollars from various feedstocks and pretreatment technologies [

9,

28,

29]. A similar analysis for a multiple-step pretreatment approach was investigated by Chen et al., (2015) [

14]. Deacetylation of the same treatment condition combined with the disk-refining process yield from 77 to 89 gal ethanol/MT corn stover, oven dry basis, and the MESP was from

$2.24 to

$2.54/gal ethanol. The costs from LHW pretreatment and the distillation process resulted in a higher MESP in our study. Although the ethanol yield was increased by 5% compared to the Chen et al. study (2015) [

14], the steam and cooling costs were higher because of the pretreatment and distillation processes. Hence, utilities is an important area to target to reduce costs.

3.5. Energy Efficiency

Steam and electricity are main energy used to convert biomass to ethanol. The net energy input (NEI) indicates the energy input required in the process to produce ethanol, and it is defined in Equation (2), where E

p, E

s, E

hs and E

e indicate the energy content of ethanol product, steam, high pressure steam and electricity, respectively. Additionally, the energy ratio (Equation (3)) represents the energy efficiency of converting biomass to ethanol. It is measured by dividing NEI by the energy content of sugarcane bagasse (15.6 MJ/kg) [

30]. An energy ratio greater than one means more energy inputs, higher than biomass energy content, are required for the process to produce ethanol.

Table 8 lists the net energy and energy ratio derived from BS and HS scenarios. BS has higher total energy input than HS in steam and electricity, which were from distillation process. Though BS has higher ethanol conversion rate, the lower ethanol titer resulted in higher energy consumption in the ethanol recovery. For net energy and energy ratio, HS is about 17% lower than BS. However, the energy ratios are 0.95 and 0.78 for BS and HS, respectively, which are higher than 0.61 reported by NREL of ethanol production from corn stover using dilute acid pretreatment [

17]. From the results, the high pressure steam, used in LHW pretreatment, is the major contributor to the total energy consumption. Therefore, improving energy efficiency is the main challenge for applying this multistep pretreatment in industrial applications.

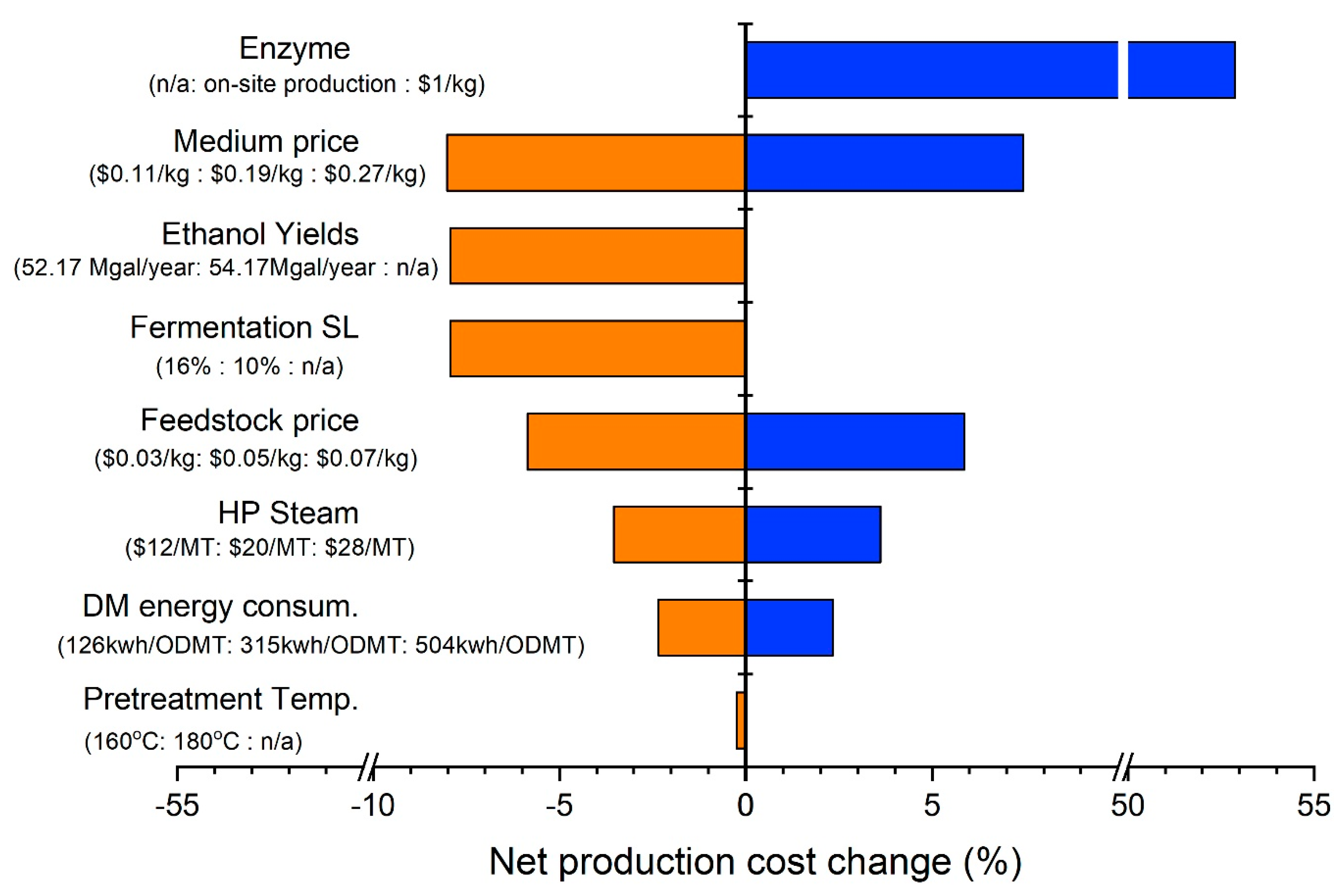

3.6. Sensitivity Analysis

Sensitivity analyses were performed based on BS to identify the variables that would most affect bioethanol production costs (

Figure 4). Among all the factors analyzed, enzyme costs had the largest effect. The net cost of producing ethanol increased to

$6.36/gal (53% increase in ethanol unit production cost and 48% in total operating costs) if the cellulase was purchased from the market for

$1/kg. However, the enzyme price (

$1/kg enzyme) was also an estimated value; therefore, the 53% increase in the ethanol unit production cost is an approximation, which is 18% higher and 10% lower than the base and pessimistic scenarios reported by Kazi et al., (2010) [

9], respectively. From this result, minimizing enzyme costs is critical for cellulosic ethanol plants, which favors on-site enzyme production.

Product cost was most sensitive to the costs for fermentation solids loading, medium (to grow the yeast inoculum) and feedstock. Production costs varied −8.02% to +7.45% when the unit cost of medium ranged from

$0.11 to

$0.27/kg (

$0.19/kg in BS). However, it was reported that there was alternative yeast medium with lower cost that had a similar performance on poplar SScF [

31]. Increasing fermentation solids loading had negative effect on conversion efficiency but increased efficiencies for downstream distillation and evaporation processes. The ethanol yield decreases about 2 million gal/year when increasing solids loading from 10% (54.17 million gal/year) to 16% (52.22 million gal/year). However, higher ethanol titer from 16% solids loading reduced about 42% utility cost in the distillation process which decreased net ethanol production cost from

$4.16/gal to

$3.83/gal and lowered the MESP from

$4.90/gal to

$4.52/gal. This indicated that high solids saccharification and fermentation are economically preferred for industrial scale production. We also varied the cost of sugarcane bagasse. The cost of bagasse for the base case is

$0.05/kg and varied between

$0.03/kg (

$30/MT) and

$0.07/kg (

$70/MT). These changes resulted in cellulosic ethanol net production costs of

$3.92 to 4.40/gal.

In addition, the price of high-pressure (HP) steam played an essential role in determining ethanol production costs because of the large amount consumed by this pretreatment process. However, when the unit price of HP stream varied from

$12 to 28/MT, the ethanol net production cost changed ±3.6%. Also, energy consumption for disk refining was adjusted ±60% [

14]. The ethanol net production cost changed by ±2.33%. Pretreatment temperature was also varied but it had little effect on ethanol production cost. Based on the results, utility cost is higher for this three-stage pretreatment process. For lowering the utility costs, higher solids loading (~50%) in the hot water pretreatment process could be an alternative to improve the energy efficiency. Cheng et al.’s (2019) [

32] reported that high solids loading (50%) pretreatment at 180 to 190 °C resulted in increasing biomass surface area by 65% which facilitates the following disk-milling process and increases the sugar yields. Hence, the higher solids loading in hot water pretreatment is expected to lower the total operating cost and MESP.