Abstract

The mechanical properties and seepage characteristics of gas-bearing coal evolve with changes in the loading pattern, which could reveal the evolution of permeability in a protected coal seam and allow gas extraction engineering work to be designed by using the effect of mining multiple protective seams. Tests on gas seepage in raw coal under three paths (stepped-cyclic, stepped-increasing-cyclic, and crossed-cyclic loading and unloading) were carried out with a seepage tester under triaxial stress conditions. The permeability was subjected to the dual influence of stress and damage accumulation. After being subjected to stress unloading and loading, the permeability of coal samples gradually decreased and the permeability did not increase before the stress exceeded the yield stage of the coal samples. The mining-enhanced permeability of the coal samples in the loading stage showed a three-phase increase with the growth of stress and the number of cycles and exhibited an N-shaped increase under the stepped-cyclic loading while it linearly increased under the other two paths in the unloading stage. With the increase of peak stress and the accumulation of damage in coal samples, the sensitivity of the permeability of coal samples to stress gradually declined. The relationship between the damage variable and the number of cycles conformed to the Boltzmann function.

1. Introduction

Coal seams in China are characterized by having a low permeability and a high gas content, which is an essential reason for the occurrence of coal and gas outbursts [1,2,3,4,5,6]. Permeability-enhancing measures must be taken and the gas content must be below the critical values specified by the related provisions before the mining of the coal seam that has an outburst risk [7,8,9,10,11,12]. The mining of multiple protective seams in coal seam groups is considered to be one of the more effective regional measures for preventing and controlling gas outbursts in protected seams [13,14,15,16]. In this process, the coal in a protected seam is subjected to cyclic loading–unloading effects, which significantly change the mechanical properties and seepage characteristics of the coal. Related research results show that gas has a significant influence on the mechanical properties and energy dissipation characteristics of coal [17,18,19,20,21,22,23,24]. Moreover, the mechanical properties and seepage characteristics of coal under different loading–unloading paths greatly differ from those under the conventional loading pattern. Therefore, it is necessary to investigate the mechanical properties and seepage characteristics of gas-containing coal under different loading–unloading paths. Various achievements have been made regarding the previously mentioned topics. An experimental investigation on the anisotropic permeability of coal under cyclic loading and unloading conditions was conducted and it was found that cyclic loading and unloading can induce an irreversible reduction of the permeability, which tends to be diminished with the increasing loading/unloading cycles [25]. The seepage properties, acoustic emission characteristics, and energy dissipation of coal under the tiered cyclic loading were also relatively revealed [26]. To analyze the spatial evolution characteristics of AE events and the failure process of coal samples, the single-link cluster method was used. Based on the microcrack density criterion, Zhang et al. proposed that the failure process of a coal sample involves the transformation from small-scale damage to large-scale damage, which results in changes in the spatial correlation length [27]. Afterward, multilevel cyclic loading tests on cylindrical coal specimens were performed by Yang et al. to investigate the fatigue failure of coal under uniaxial stress [28]. Furthermore, the relationship between electromagnetic radiation and the dissipated energy of coal during the cyclic loading process was elaborated by Song et al. [29]. Overall, the mechanical properties and seepage characteristics of coal have been shown to be closely related to the loading pattern. Investigating the mechanical properties and seepage characteristics of gas-containing coal under cyclic loading–unloading paths will provide more theoretical and practical guidance toward revealing the evolution of permeability in a protected coal seam and to design gas extraction engineering works under the effect of mining multiple protective seams. In addition, the damage evolution characteristics of gas-bearing coal under different cyclic loading–unloading stress paths have not been fully investigated.

In order to study the mechanical properties and seepage characteristics of gas-containing coal under complex mining stress, three different cyclic loading–unloading paths were designed. By analyzing stress–strain and stress–permeability curves, the deformation and seepage characteristics of gas-containing coal under different cyclic loading–unloading paths were revealed. By virtue of the theory of the loading–unloading response ratio (LURR), the damage evolution characteristics of coal under different cyclic loading–unloading paths were investigated. By applying a mining-enhanced permeability and a stress sensitivity coefficient of permeability, the characteristics of seepage evolution in gas-containing coal under different cyclic loading–unloading paths were quantified. The research results are expected to provide theoretical support to further reveal the mechanism of a permeability increase in coal seams under multiple protective seams.

2. Experimental Equipment and Test Scheme

2.1. Experimental Equipment

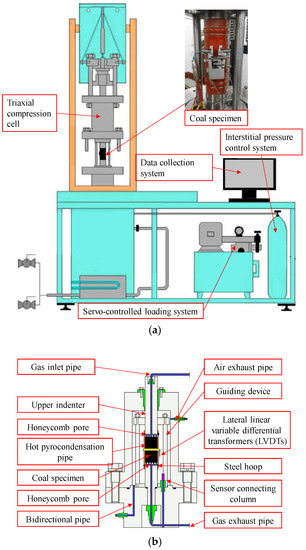

The experiment was carried out by using a triaxial seepage experiment device for heat–fluid–solid coupling in gas-containing coal made at the Chongqing University, China. The experimental device can be used in gas seepage experiments in coal under the effects of different stress regimes (including confining pressure and axial stress) and gas pressures. The experimental device and constituents of the experimental cavity are displayed in Figure 1.

Figure 1.

Triaxial seepage experimental device for the measurement of the heat–fluid–solid coupling property of gas-containing coal and the experimental chamber: (a) The whole experimental device and (b) the experimental chamber.

2.2. Coal Sample Preparation

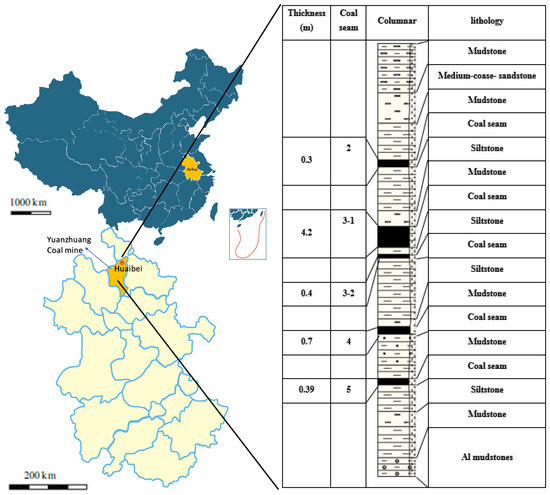

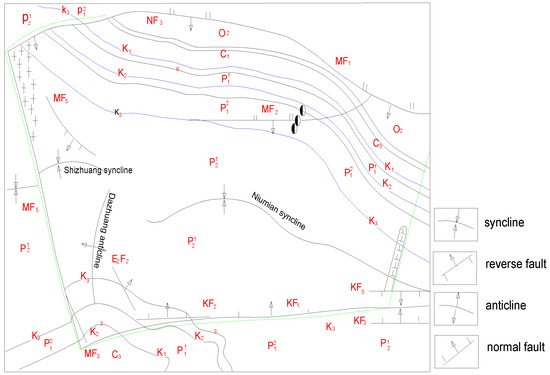

The coal samples used for the experiment were taken from the 3-1 coal seam of Yuanzhuang Coal Mine, Anhui Province, China, which is shown in Figure 2. The 3-1 coal seam is located in the Permian Lower Stone Box Group, which is shown in Figure 2. The coal type is low metamorphic gas coal. The average thickness is 4.2 m and the gas content is 3.45 m3/t. The main characteristics related to the coal’s quality are shown in Table 1. The coal field where the mine is located is affected by the Huaxia tectonic system and the construction line is dominated by North-northeast (NNE), which is shown in Figure 3. These coal samples were cored, cut, and ground to form standard cylindrical coal samples that were 50 mm in diameter and 100 mm in length.

Figure 2.

Location and geologic column of the Yuan Zhuang coal mine.

Table 1.

The main characteristics related to the coal’s quality.

Figure 3.

Geological structure outline map of the Yuan Zhuang coal mine.

2.3. Experimental Scheme

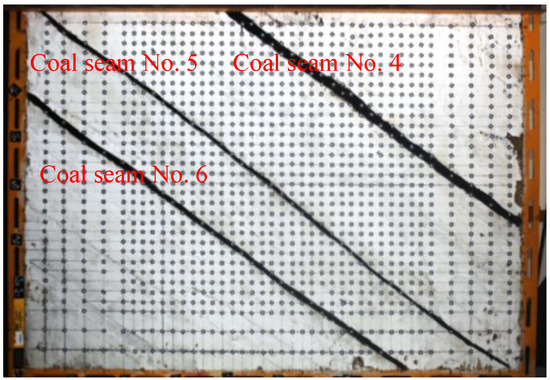

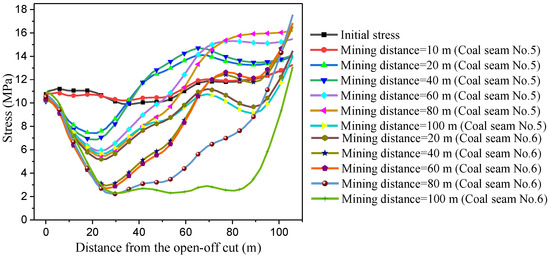

The authors carried out a similar simulation experiment involving the real-time monitoring of the stress state of a protected seam on the mining conditions of a coal seam group. The simulation experimental model is shown in Figure 4. During the experiment, under the conditions used to successively mine coal seams #5 and #6, the stress state of the coal seam #4 was monitored in real-time (Figure 5). Before coal seam #5 was mined for 80 m, the coal masses at the monitored point of the coal seam #4 were subjected to a significant concentration of stress. Furthermore, during the mining of coal seam #6, the coal masses at the monitored point of coal seam $4 underwent exposure to multiple stresses and stress relief.

Figure 4.

Similarity model for real-time monitoring of the stress state of the protected seam during the mining of multiple protective seams.

Figure 5.

The stress state in the protected seam after the mining of protective seams.

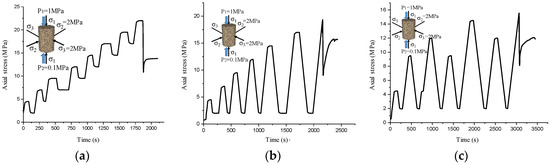

Based on the previously mentioned analysis, three simplified cyclic loading–unloading stress paths were designed, which is shown in Figure 6. The experimental steps were as follows: the axial stress and confining pressures were synchronously loaded to 2 MPa at a rate of 0.05 MPa/s. Then, gas was constantly injected under a pressure of 1 MPa with the gas concentration consisting of 99.99%. After holding for 24 h in this state, the coal samples reached adsorption saturation. If the confining pressure was unchanged, the axial stress continued to be loaded or unloaded at a rate of 0.05 MPa/s until the samples were damaged.

Figure 6.

Three cyclic loading–unloading stress paths. (a) Stress path 1: stepped-loading and unloading. (b) Stress path 2: stepped-increasing-loading and unloading. (c) Stress path 3: crossed-cyclic-loading and unloading.

3. Methods and Data

3.1. Permeability Calculation

It is presumed that the gas permeation process in raw coal is an isothermal process and this gas is considered to be an ideal gas. According to Darcy’s law, the permeability of coal is given by Reference [30].

where K is the permeability (m2), qv is the seepage velocity (m3/s) of gas in coal masses, Pa is the atmospheric pressure (Pa), A is the cross-sectional area (m2) of the specimen, L is the length (m) of the specimens, P1 is the gas pressure at the air inlet (Pa), P2 is the gas pressure at the air outlet (MPa), and μ is the gas viscosity (Pa·s).

During testing, the axial and lateral strains (ε1 and ε2) on the raw coal were monitored in real-time. Through the formula εv = ε1 + 2ε2, the volumetric strain (εv) in the raw coal was calculated. Based on the drawing, the axial stress–axial strain curve (σ1–ε1), axial stress–lateral strain curve (σ1–ε2), axial stress–volumetric strain curve (σ1–εv), and permeability–axial strain curve (K–ε1) of raw coal under different cyclic loading–unloading paths were obtained.

3.2. Permeability Ratio

Under cyclic loading–unloading paths 2 and 3, the ratio of the permeability at the end of unloading in each cycle to the permeability at the initial load is defined as the absolute recovery rate of permeability, which can be expressed in Formula (2) in percentage terms.

where χa and Ki refer to the absolute recovery rates of the permeability and the permeability (mD) when the axial stress applied to coal samples was unloaded to 2 MPa during the ith cycle, respectively. Additionally, K1 denotes the permeability (mD) of coal samples when the axial stress was loaded from 2 MPa during the first loading–unloading cycle.

The ratio of the permeability of coal samples after the stress unloading during each loading–unloading cycle to that in the loading process during this cycle is defined as the relative recovery rate of the permeability, which can be expressed as Formula (3) in percentage terms.

where χr and Ki+1 represent the relative recovery rates of the permeability and the permeability (mD) when the axial stress was unloaded to 2 MPa during the (i + 1)th loading–unloading cycle, respectively.

3.3. Mining-Enhanced Permeability

A method was proposed by Xie et al. [31] to reflect the permeability increasing effect of coal seams by considering the contribution of volumetric change of a coal mass to its permeability. The mining-enhanced permeability (χp) is defined as the variation in permeability under the change per unit volume of coal masses.

where k and εv represent the permeability (mD) of coal masses and the volumetric strain of damaged and fractured coal masses, respectively. The mining-enhanced permeability describes the permeability increase due to the fracturing of coal masses under the impact of mining and can allow the quantitative evaluation of the effect of permeability by increasing measures in coal seams.

3.4. Stress Sensitivity Coefficient of Permeability

To express the evolution of permeability, the dimensionless permeability (DP) was introduced, which is defined below [32].

where k and k0 refer to the permeability (mD) under different effective stresses and that under the initial effective stress, respectively.

The regression analysis showed that, during the loading and unloading of coal samples, the dimensionless permeability has a negative exponential relationship with the effective stress effect.

where αe, σe, and b separately denote the stress sensitivity coefficient (MPa−1) of the permeability, the effective stress (MPa), and the dimensionless coefficient influenced by the initial permeability. Additionally, the stress sensitivity coefficient of the permeability of coal samples can be defined by the equation below.

where Δk and Δσe refer to the variation in the permeability of coal samples and the variation in the effective stress, respectively.

3.5. Damage Variable of Coal

The LURR is a parameter that was proposed by Yin Xiangchu to quantify damage when relating the extent of damage in a material to change in a physical quantity [33]. The commonly used axial stress and strain properties are separately considered as the load variable and the corresponding response variable, which are taken as the parameters for describing the LURR. The LURR Y is defined by the equation below.

where X+ and X− separately refer to the responses during loading and unloading, respectively. and denote the increments corresponding to the stress load variable (P) and the strain response variable (R), respectively, which can be acquired according to the stress–strain curve under the effect of experimental cyclic loading. When the load (P) is low, rocks are in an elastic stage and a linear or quasi-linear relationship arises between P and R with X+ = X− and LURR Y = 1. When the load gradually increases, the damage increases, which shows that X+ > X− and, correspondingly, Y > 1. Moreover, with increased damage, Y also rises. When media are close to becoming damaged, Y reaches a maximum. Therefore, the damage to coal samples during cyclic loading can be characterized by using LURR Y.

The relationship between LURR YE and damage variable (D) based on the fact that the fracture limit of materials conforms to a Weibull distribution on a mesoscopic scale was established by Zhang et al. [34].

where represents the Weibull index, denotes the strain (), and refers to the strain at the breaking point where the correspondence to damage is denoted by ().

By transforming Formula (11), we get the equation below.

Formula (11) displays the relationship between D and LURR Y. By utilizing the LURR Y calculated using Formula (11) and curve fitting, the parameters of the stress–strain curve were transformed to D to acquire the relationship between D and cyclic loading–unloading stresses.

4. Results

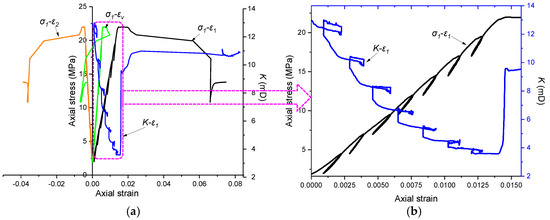

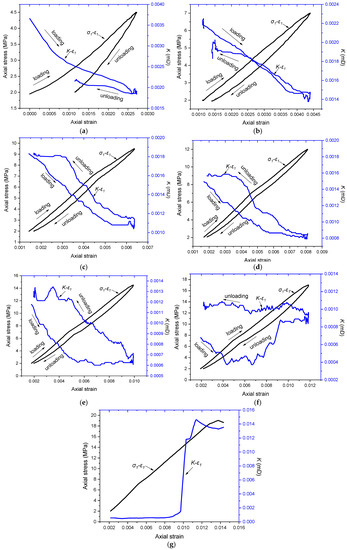

4.1. Characteristics of Deformation–Permeability of Gas-Containing Coal under Stress Path 1

The experimental results under stress path 1 are shown in Figure 7. Figure 7b presents the partially enlarged detail of the permeability–axial strain curve. As shown in the figure, during the stepped-cyclic loading–unloading experiment, the change in permeability of coal samples matched that of the axial stress–strain curve. The change in permeability of raw coal generally appeared as follows: with an increase in the number of cycles of loading and unloading, the permeability of the coal samples was significantly reduced during compaction, slowly declined in the elastic stage, and slowly rose in the yield stage. When coal samples were damaged, the permeability of the coal samples increased to a significant extent. The test results are described from two aspects below.

Figure 7.

The relationships among the stress, strain, and permeability of raw coal under stress path 1. (a) Stress–strain and permeability–strain curves. (b) Partial enlargement of the axial stress–strain curve and the permeability–axial strain curve.

First, the stress–strain relationship met the following rules: hysteresis loops were seen in the axial stress–strain curve reflecting the plasticity of the coal samples. With an increasing axial stress, the area of these hysteresis loops gradually decreased. The radial strain was low before reaching the yield stage and coal samples were mainly subjected to axial deformation, which indicated that the axial strain played a dominant role while radial deformation exhibited little influence.

Second, the permeability–strain relationship had the following results: as cyclic loads were applied to the coal samples, their permeability generally declined with increasing stress. A significant hysteresis loop appeared during the first cycle and hysteresis loops gradually reduced in magnitude during subsequent cycles. This implied that, with growing stress, the plasticity of the coal samples reduced while their elasticity increased. The influence of stress loading and unloading on the permeability of coal samples gradually diminished.

Additionally, under stress path 1, with an increasing number of cycles, the area enclosed by unloading and loading curves in the stress–strain space gradually declined and the elastic moduli gradually increased coinciding during the unloading and loading stages. In this case, the permeability of the coal samples in the loading stage gradually approximated that in the unloading stage and the hysteresis effect diminished. This indicated that, as cyclic loads were applied to the coal samples, their elasticity increased and the fracture deformation could be recovered to the greatest extent.

4.2. Characteristics of the Deformation–Permeability Curve of Gas-Containing Coal under Stress Path 2

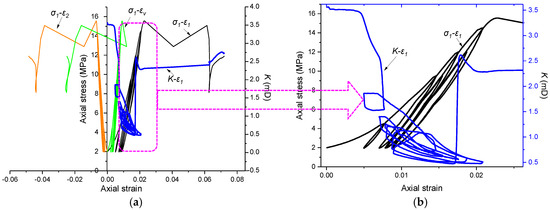

Figure 8 shows the relationship curve between the stress–strain and the permeability of raw coal under the effect of the stepped-increasing peak load in stress path 2. As shown in the figure, the envelope line between the axial peak stress and axial strain of raw coal under stress path 2 was similar to that under uniaxial loading, which shows that the coal samples showed a favorable mechanical memory performance. Similar to stress path 1, the radial deformation of raw coal was less significant than its axial deformation. With an increase in the number of cycles, the area of the hysteresis loops in the axial stress–strain curve gradually increased.

Figure 8.

The relationships among the stress, strain, and permeability of raw coal under stress path 2.

Figure 9 shows the axial stress–axial strain and permeability–axial strain curves of raw coal in each cycle. As shown in the figure, with increasing axial stress, the permeability of raw coal declined. During the first two cycles, the permeability of raw coal in the unloading stage was lower than that in the loading stage. The reason for this was that, during the first two cycles, coal samples were compacted and, therefore, pores were smaller and subjected to irrecoverable deformation, which causes the permeability of the coal samples to fail to recover in the unloading stage after decreasing initially. From the third cycle to the failure stage, the permeability of the coal samples in the unloading stage was always greater than that in the loading stage during each cycle. The reason for this was due to the peak stress during each loading cycle damaging the coal samples, which resulted in increased fracturing and, thus, the permeability increased in the unloading stage. Eventually, the permeability rose dramatically in the yield stage and surpassed the initial permeability of the coal samples.

Figure 9.

The axial stress–axial strain and permeability–axial strain curves of raw coal during each cycle under stress path 2. (a) The first cycle. (b) The second cycle. (c) The third cycle. (d) The fourth cycle. (e) The fifth cycle. (f) The sixth cycle. (g) The seventh cycle.

4.3. Characteristics of the Deformation–Permeability Curve of Gas-Containing Coal under Stress Path 3

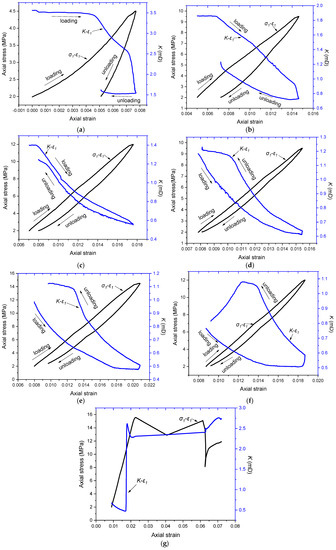

The experimental results under stress path 3 are shown in Figure 10. Figure 10b shows the partially enlarged details of the permeability–axial strain curve. It can be seen from the figure that, under the effect of the crossed-cyclic loading–unloading path (stress path 3), the stress at the fourth cycle was the same as that at the second cycle and it was the same as that in the third and sixth cycles. However, the stress curves at the same stress level did not coincide and strain accumulation was found subjected to the previous high stress level.

Figure 10.

The relationships among stress, strain, and permeability of raw coal under stress path 3. (a) Stress–strain and permeability–strain curves. (b) Partial enlargement.

Figure 11 shows the axial stress–axial strain and permeability–axial strain curves of raw coal in each cycle. As shown in the figure, during the first two cycles, the permeability in the unloading process was far lower than that in the loading process, which indicates that coal samples were still in a compaction and closure stage. In this case, the pores failed to recover completely after being compressed. In contrast, during the third cycle, the permeability of coal samples in the unloading process approximated this in the loading process, which implies that the coal was in an elastic deformation stage. During the fourth cycle, the stress level was the same as that during the second cycle. However, during unloading, the stress–strain hysteresis loop was significantly smaller than during the second cycle. The permeability of coal samples in the unloading stage was larger than that in the loading stage, which indicates that the coal samples had entered a yielding stage. During this stage, the cumulative damage caused by cyclic loading and unloading constantly increased and the pores expanded after unloading, which resulted in increased permeability of the coal samples. During the fifth cycle, the stress further increased while the permeability further increased after unloading. During the sixth cycle, the stress applied to the coal samples was the same as that during the third cycle while the permeability of the coal samples was greater in the unloading stage, which indicates that damage accumulated over time in the post-yield state.

Figure 11.

The axial stress–axial strain and permeability–axial strain curves of raw coal during each cycle under stress path 3. (a) The first cycle. (b) The second cycle. (c) The third cycle. (d) The fourth cycle. (e) The fifth cycle. (f) The sixth cycle. (g) The seventh cycle.

5. Discussion

5.1. Effects of the Loading–Unloading Processes on the Permeability of Gas-Containing Coal

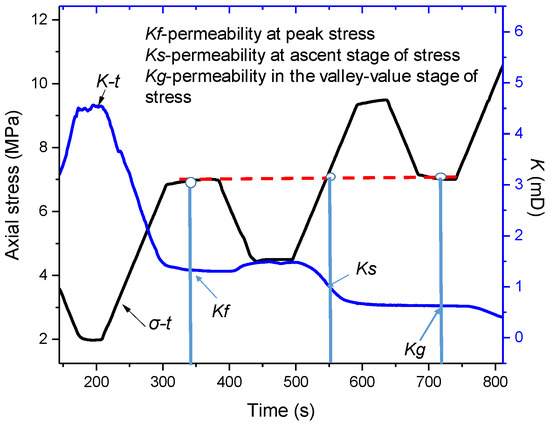

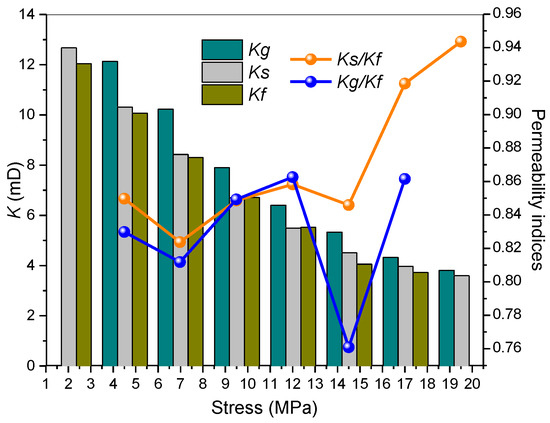

For a given stress level, the permeability when the peak stress was applied during the first cycle is defined as Kf. Similarly, Ks refers to the permeability during the ascending stage of stress application at the same stress level as Kf while the permeability in the stress valley is defined as Kg. Furthermore, Ks/Kf and Kg/Kf denote the recovery rates of permeability in the ascent and valley stages of stress relative to those under peak stress. The previously mentioned permeability levels of raw coal under the effect of stress path 1 are displayed in Figure 12.

Figure 12.

The definitions of permeability indices under stress path 1.

Figure 13 shows the changes in permeability of raw coal and its recovery rate at different stress levels under stress path 1. It can be seen from Figure 13 that, as the cyclic loads were applied and axial stress increased, the permeability decreased. Ks/Kf and Kg/Kf declined at first and then increased with increasing axial stress. At the same stress level, the permeability of coal samples after being subjected to unloading–loading decreased while their relative recovery rates fell at first and then rose with growing axial stress. The pore structure of coal samples before entering the yield stage showed plasticity under the effect of changing stress and, therefore, the loading–unloading effects were able to decrease the permeability of such coal samples.

Figure 13.

Changes in permeability of raw coal and its recovery rate at different stress levels under stress path 1.

5.2. Changes in the Relative and Absolute Recovery Rates of Permeability under Different Cyclic Loading–Unloading Paths

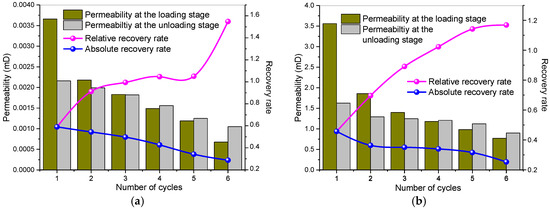

Figure 14 shows the changes in the relative and absolute recovery rates of the permeability of raw coal under stress paths 2 and 3. It can be seen from the figure that the evolution of the permeability of coal samples under stress paths 2 and 3 was similar. As cyclic loads were applied, the permeability in the loading and unloading processes declined and the permeability after loading showed a more rapid rate of reduction than that in the unloading stage. Under stress path 2, the relative recovery rate exhibited a three-phase characteristic—a rapid, then slow, and finally rapid increase—and, in contrast, the absolute recovery rate linearly decreased. Under stress path 3, the relative recovery rate rapidly, slowly, and steadily rose (a three-phase increase) while the rate of reduction of the absolute recovery was lower than that under stress path 2. Under stress path 2, the pores in coal samples, as gas seepage passages, were gradually compressed with the growth in the number of cycles. In the first two cycles, the permeability of the coal samples after stress relief failed to recover to the level before stress loading. However, the relative recovery rate during the second cycle was far larger than that during the first cycle, which implies that the recovery rate of pores from deformation increased. From the third to the fifth cycles, the increment of the recovery rate of permeability was low, which indicates that the seepage pores in coal samples were further compressed under the effect of cyclic loading and damage to the coal samples due to increasing peak stress made an insignificant contribution to changes in the permeability. During the sixth cycle, the relative recovery rate rose dramatically, which suggests that the coal samples entered the yield deformation stage. The stress cycle-induced damage to coal samples resulted in an increase in their permeability. Under stress path 3, from the first to the third cycles, the relative recovery rate of the permeability rose rapidly. Due to the stress level during the fourth cycle being the same as that during the second cycle, the stress-induced damage to coal samples was alleviated and the rate of increase in the recovery of the permeability decreased. Similarly, the stress during the sixth cycle was equivalent to that during the third cycle. As a result, the recovery rate of the permeability was basically the same as that during the fifth cycle and the change in the permeability was near-zero. Through the previously mentioned analysis, it can be seen that cyclic loading and unloading caused certain levels of damage to the coal samples, which shows a negative influence on the permeability of coal samples. Cyclic loading and unloading failed to increase the permeability before the stress exceeded the yield stress of the coal samples.

Figure 14.

Changes in the absolute and relative recovery rates of the permeability of raw coal under cyclic loading–unloading paths 2 and 3. (a) Stress path 2. (b) Stress path 3.

5.3. Evolution of Mining-Enhanced Permeability of Gas-Containing Coal under Different Cyclic Loading–Unloading Paths

Under the effect of mining-induced disturbance, the equilibrium state of in situ stress on deep underground coal and rock masses was disturbed and the stress state continuously changed. The structures of the coal masses also underwent continuous change with fracture initiation, fracture propagation, cracking, and rupture of coal masses. Mining-induced damage, fractures, and rupture of coal masses caused fundamental changes in the permeability of such coal masses, which also affected the extraction of gas. The permeability of coal masses reflects the number of pores in and connectivity of the material’s structure and the change in the permeability of coal mass is closely related to volumetric changes in the coal mass.

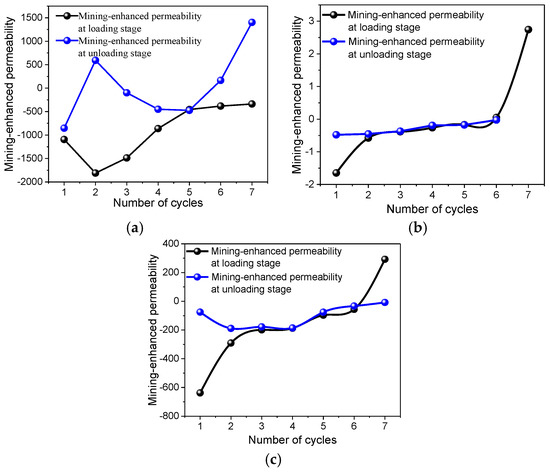

The change law of the mining-enhanced permeability of coal mass under three paths was calculated by using Formula (4), as shown in Figure 15. It can be seen from the figure that, under stress path 1, the permeability of the coal samples declined with increasing axial stress so that the calculated mining-enhanced permeability in the loading was negative and gradually rose. This indicates that loading during cyclic loading increased the permeability of the samples. Furthermore, during loading, the mining-enhanced permeability fell at first, then rapidly rose, and increased slowly with a rise in stress. In contrast, the mining-enhanced permeability in the unloading stage first increased, then decreased, and, finally, rose to a positive value with increasing axial stress, which implies that the growth in volumetric strain during unloading resulted in the increase, reduction and growth in permeability of the coal samples. The increase in volume was not the only cause of the increase in permeability. Under stress path 2, with an increasing number of cycles, a three-phase change was seen in the mining-enhanced permeability in the loading stage, which is a rapid increase in the first two cycles. Then there was slow growth from the third to the sixth cycles and a rapid increase during the seventh cycle. This indicates that, with an increasing number of cycles, the mining-enhanced permeability rises and the increment of permeability under per unit volumetric strain is different. The mining-enhanced permeability and the number of cycles increased linearly during unloading. Under stress path 3, the change in mining-enhanced permeability under loading during different cycles was similar to that under stress path 2. The difference was that the increments of mining-enhanced permeability during the fourth and sixth cycles were lower than those during the corresponding previous cycles due to the stress levels during the fourth and sixth cycles being the same as those during the second and third cycles. In a similar way, the mining-enhanced permeability in the unloading also deviated from the predicted linear increase.

Figure 15.

Changes in the mining-enhanced permeability of coal samples under different cyclic loading–unloading paths. (a) Stress path 1. (b) Stress path 2. (c) Stress path 3.

5.4. Stress Sensitivity of the Permeability of Gas-Containing Coal under Different Cyclic Loading–Unloading Paths

The large value of in Formula (7) implies that the permeability of coal samples is more sensitive to changes in the effective stress and the permeability of coal samples changes more significantly under changes in the effective stresses when the amplitude of variation is kept constant. On the contrary, a small value of indicates that the permeability of coal samples is less sensitive to changes in the effective stress and the permeability of coal samples changes less significantly with changes in the effective stress.

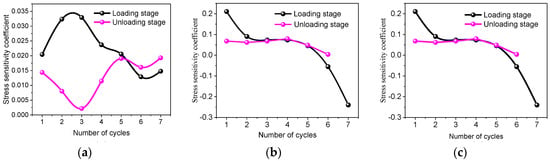

The stress sensitivity coefficients of the permeability of coal samples under three stress paths were calculated by using the above formula, as shown in Figure 16. It can be seen from the figure that, under stress path 1, the stress sensitivity coefficient of the permeability of coal samples in the loading stage varied with the growth in effective stress in the following manner. With an increase in the effective stress, the stress sensitivity coefficient of the permeability of coal samples rose at first and then reduced and, finally, it fluctuated to some extent. However, the stress sensitivity coefficient of the permeability of coal samples during unloading showed the opposite trend, which indicates that, during stepped-cyclic loading, when the stress applied on the coal samples was less than 10 MPa, the level of permeability was sensitive to stress but not to stress unloading. This occurs because the pores in the coal samples were subjected to plastic deformation and failed to recover after stress unloading. When the stress was greater than 10 MPa, the pores in the coal samples shrank under load and recovered upon unloading to some extent, which showed that the permeability became less sensitive to stress loading but more sensitive to stress unloading. Under stress path 2, the stress sensitivity coefficient of permeability under load declined with an increasing number of cycles and this can be divided into three phases: rapid reduction during the first two cycles, a slow decrease from the third to the fifth cycle, and rapid reduction during the last two cycles. This indicates that, with an increase in peak stress and the accumulation of damage, the sensitivity of the permeability to stress gradually decreased. The stress sensitivity coefficient of the permeability during unloading slowly increased and then linearly decreased with an increasing number of cycles, which implied that, as stress was applied, the influence of stress unloading on the permeability of coal samples was strengthened at first and then weakened. Under stress path 3, the change in the stress sensitivity coefficient of permeability with the number of cycles was similar to that under stress path 2. The difference was that the stress levels during the fourth and sixth cycles were, respectively, the same as those during the second and third cycles so that the stress sensitivity coefficients of permeability were, respectively, equivalent to those during the third and fifth cycles. The change in the stress sensitivity coefficient of permeability shows that the increase in effective stress caused the reduction in the stress sensitivity coefficient of permeability. The growth in the number of cyclic loading and unloading events also resulted in the decrease of the stress sensitivity coefficient of the permeability of such coal samples.

Figure 16.

The changes in the stress sensitivity coefficient of the permeability of coal samples under different cyclic loading–unloading paths. (a) Stress path 1. (b) Stress path 2. (c) Stress path 3.

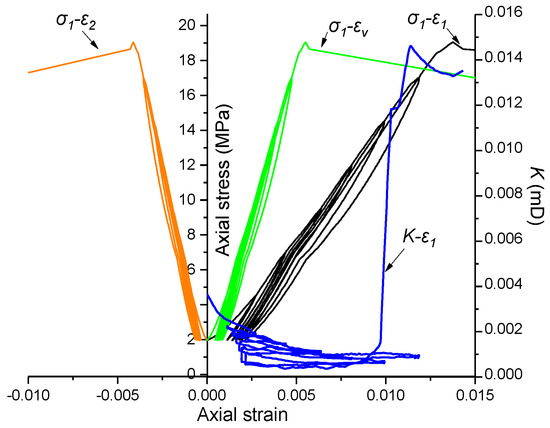

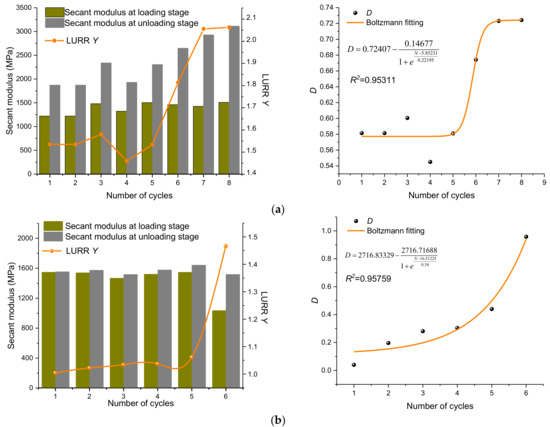

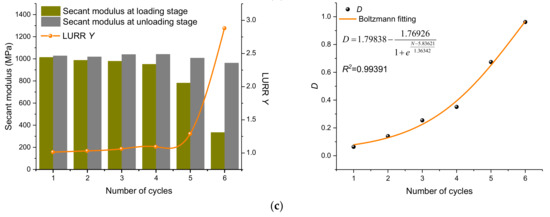

5.5. Damage Evolution Characteristics of Gas-Containing Coal under Different Cyclic Loading–Unloading Paths

Figure 17 shows the change in LURR Y and D of raw coal with stress under different cyclic loading–unloading paths. It can be seen from Figure 16 that, under stress path 1, with increasing axial stress, the LURR Y rose slowly at first, then rapidly increased, and. finally, increased in a quasi-linear manner. However, the curve relating to the damage suffered by coal samples exhibited a three-phase characteristic: a slow increase, rapid growth, and finally, a slow increase. It can be seen from the figure that the elastic modulus during loading was lower than that during unloading, which implies that damage accumulated in coal samples under load. The LURR gradually increased. When the stress reached a certain level, the elastic modulus under loading was further decreased and the LURR rose suddenly, which indicated that coal samples were about to be damaged and, therefore, they entered a yielding stage. This is consistent with the previously mentioned result in which the recovery rate of the permeability of coal samples rose dramatically. The change in D with the number of cycles obtained through Formula (11) was fitted by using the Boltzmann formula and the goodness of fit reached 0.95. The Boltzmann formula can be used as an empirical formula for damage prediction. Under the effects of stress paths 2 and 3, the elastic modulus under load remained unchanged with an increasing number of cycles in the initial stage while it suddenly reduced in the later stages of testing. In contrast, the elastic modulus remained unchanged during unloading. In terms of LURR Y, it rose slowly at the start and suddenly increased later. This indicated that coal samples underwent yield and failure, which agrees with the observed evolution of the recovery rate of the permeability mentioned above. Correspondingly, D, calculated through the Y value, also showed a similar trend and can be fitted by applying the Boltzmann formula [35].

Figure 17.

The changes in LURR and D of raw coal with stress under different cyclic loading–unloading paths. (a) Stress path 1. (b) Stress path 2. (c) Stress path 3.

6. Conclusions

The mechanical properties and seepage characteristics of gas-bearing coal evolve with changes in the loading pattern, which could reveal the evolution of permeability in a protected coal seam and allow gas extraction engineering works to be designed using the effect of mining multiple protective seams. Based on the results of the similarity experiments on the stress state of protected seam during mining of a coal seam group, the seepage and damage evolution characteristics of gas-containing coal under cyclic loading–unloading effects were explored by conducting fluid–solid–coupling tests on the coal under three simplified stress paths. On this basis, the influence of mining multiple protective seams for pressure relief on the seepage characteristics of gas-containing coal in a protected seam was investigated.

Unloading and loading stress exerted different influences on the permeability and a dual influence of stress and damage accumulation was seen on coal permeability. The pores in coal samples, before entering their yield stage, exhibited a plastic structure due to the effects of changing stress and the loading–unloading effect can reduce the permeability. Cyclic loading and unloading resulted in damage to coal samples while having a negative influence on the permeability. The permeability of coal samples cannot increase before the stress exceeds the yield stress of the coal samples. The stress paths also affect the mining-enhanced permeability of coal. The mining-enhanced permeability of coal samples in the loading stage showed a three-phase increasing trend with growing stress and number of cycles. The mining-enhanced permeability caused by the change per unit volume increased, the mining-enhanced permeability in the unloading stage showed an N-shaped growth trend during stepped-cyclic loading while growing linearly under the other two paths, and the permeability increasing effect under the cyclic loading became better with an increasing number of cycles.

Furthermore, during the stepped-cyclic loading and unloading, when the stress was less than 10 MPa, the permeability of these coal samples was sensitive to the stress loading while it was insensitive to stress unloading, which indicates that plastic deformation occurred in the pores in the coal mass. This could not be recovered after stress unloading. When the stress exceeded 10 MPa, the pores in these coal samples were compressed under load while they recovered to some degree upon unloading. This behavior indicated that the sensitivity to loading stress was reduced while indicating that the sensitivity to the unloading stress increased. With increasing peak stress and damage accumulation in the coal samples, the sensitivity of the permeability to stress gradually decreased. As loads were applied to the coal samples, the influence of stress unloading on their permeability was first strengthened and then reduced. By calculating the LURRs at various stages of cyclic loading, the evolution of D of the coal samples was obtained. Through regression analysis, it can be seen that the relationship between D and the number of cycles can be characterized by applying the Boltzmann function. The function can be used as an empirical formula for damage prediction.

These conclusions validate the observed evolution of the permeability of gas-containing coal in protected seams at different stages of the mining of multiple protective seams during the mining of a coal seam group. On this basis, the results can be used to guide the design of engineering operations such as gas extraction in protected seams (e.g., setting a borehole, extracting gas from stress unloading zones, and avoiding stress concentration zones) and the prevention and control of gas disasters.

Author Contributions

Q.L. and Y.L. conceived and designed the experiments. Q.L. and Q.Z. performed the experiments. Q.L. analyzed the data. Q.L. and Q.Z. wrote the paper.

Funding

This work is financially supported by the State Key Research Development Program of China (2017YFC0804206 and 2016YFC0801404), the National Natural Science Foundation of China (51674050 and 51704046), the National Science and Technology Major Project of China (2016ZX05043005), the Fundamental Research Funds for the Central Universities (2018CDQYZH0001 and 106112017CDJXY240001), and the Open Fund Research Project of State Key Laboratory Breeding Base for Mining Disaster Prevention and Control (MDPC201710).

Acknowledgments

The authors thank the editor and anonymous reviewers for their valuable advice.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dou, L.; He, X.; Ren, T.; He, J.; Wang, Z. Mechanism of coal-gas dynamic disasters caused by thesuperposition of static and dynamic loads and its control technology. J. China Univ. Min. Tech. 2018, 47, 48–59. [Google Scholar] [CrossRef]

- Lin, B.; Liu, T.; Yang, W. Solid-gas coupling model for coalseams based on dynamic diffusion and its application. J. China Univ. Min. Tech. 2018, 47, 32–39. [Google Scholar] [CrossRef]

- Mark, C. Coal bursts that occur during development: A rock mechanics enigma. Int. J. Min. Sci. Tech. 2018, 28, 35–42. [Google Scholar] [CrossRef]

- Zhou, A.; Wang, K.; Fan, L.; Kiryaeva, T.A. Gas-solid coupling laws for deep high-gas coal seams. Int. J. Min. Sci. Tech. 2017, 27, 675–679. [Google Scholar] [CrossRef]

- Zhou, P.; Zhang, Y.; Huang, Z.A.; Gao, Y.; Wang, H.; Luo, Q. Coal and gas outburst prevention using new high water content cement slurry for injection into the coal seam. Int. J. Min. Sci. Tech. 2017, 27, 669–673. [Google Scholar] [CrossRef]

- Zou, Q.; Lin, B. Fluid–solid coupling characteristics of gas-bearing coal subjected to hydraulic slotting: An experimental investigation. Energ. Fuels 2018, 32, 1047–1060. [Google Scholar] [CrossRef]

- Ni, G.; Li, Z.; Xie, H. The mechanism and relief method of the coal seam water blocking effect (WBE) based on the surfactants. Powder Technol. 2018, 323, 60–68. [Google Scholar] [CrossRef]

- Xu, J.; Zhai, C.; Liu, S.; Qin, L.; Dong, R. Investigation of temperature effects from LCO 2 with different cycle parameters on the coal pore variation based on infrared thermal imagery and low-field nuclear magnetic resonance. Fuel 2018, 215, 528–540. [Google Scholar] [CrossRef]

- Ye, Q.; Jia, Z.; Zheng, C. Study on hydraulic-controlled blasting technology for pressure relief and permeability improvement in a deep hole. J. Petrol. Sci. Eng. 2017, 159, 433–442. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, H.; Guo, H. A case study of gas drainage to low permeability coal seam. Int. J. Min. Sci. Tech. 2017, 27, 687–692. [Google Scholar] [CrossRef]

- Zou, Q.; Lin, B.; Zheng, C.; Hao, Z.; Zhai, C.; Liu, T.; Liang, J.; Yan, F.; Yang, W.; Zhu, C. Novel integrated techniques of drilling–slotting–separation-sealing for enhanced coal bed methane recovery in underground coal mines. J. Nat. Gas Sci. Eng. 2015, 26, 960–973. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.Q.; Yang, W. Impact of matrix-fracture interactions on coal permeability: Model development and analysis. Fuel 2017, 207, 522–532. [Google Scholar] [CrossRef]

- Wu, Y.; Pan, Z.; Zhang, D.; Lu, Z.; Connell, L.D. Evaluation of gas production from multiple coal seams: A simulation study and economics. Int. J. Min. Sci. Tech. 2018, 28, 359–371. [Google Scholar] [CrossRef]

- Chang, X.; Tian, H. Technical scheme and application of pressure-relief gas extraction in multi-coal seam mining region. Int. J. Min. Sci. Tech. 2018, 28, 483–489. [Google Scholar] [CrossRef]

- Ye, Q.; Wang, G.; Jia, Z.; Zheng, C.; Wang, W. Similarity simulation of mining-crack-evolution characteristics of overburden strata in deep coal mining with large dip. J. Petrol. Sci. Eng. 2018, 165, 477–487. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.Q.; Yang, W.; Zou, Q.L.; Kong, J.; Yan, F.Z. Cracking Process and Stress Field Evolution in Specimen Containing Combined Flaw Under Uniaxial Compression. Rock Mech. Rock Eng. 2016, 49, 3095–3113. [Google Scholar] [CrossRef]

- Du, W.; Zhang, Y.; Meng, X.; Zhang, X.; Li, W. Deformation and seepage characteristics of gas-containing coal under true triaxial stress. Arab. J. Geosci. 2018, 11, 1–13. [Google Scholar] [CrossRef]

- Danesh, N.; Chen, Z.; Connell, L.D.; Kizil, M.S.; Pan, Z.; Aminossadati, S.M. Characterisation of creep in coal and its impact on permeability: An experimental study. Int. J. Coal Geol. 2017, 173, 200–211. [Google Scholar] [CrossRef]

- Peng, S.J.; Xu, J.; Yang, H.W.; Liu, D. Experimental study on the influence mechanism of gas seepage on coal and gas outburst disaster. Saf. Sci. 2012, 50, 816–821. [Google Scholar] [CrossRef]

- Tang, Y.; Okubo, S.; Xu, J.; Peng, S. Study on the Progressive Failure Characteristics of Coal in Uniaxial and Triaxial Compression Conditions Using 3D-Digital Image Correlation. Energies 2018, 11, 1215. [Google Scholar] [CrossRef]

- Yin, G.; Jiang, C.; Wang, J.G.; Xu, J. Geomechanical and flow properties of coal from loading axial stress and unloading confining pressure tests. Int. J. Rock Mech. Min. Sci. 2015, 76, 155–161. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, Y.; Chu, Y.; Zhang, X.; Xue, Y. Influence of loading and unloading velocity of confining pressure on strength and permeability characteristics of crystalline sandstone. Results Phys. 2018, 9, 1363–1370. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, P.; Dai, F.; Li, X.; Zhao, Y.; Liu, Y. Behavior and Modeling of Fiber-Reinforced Clay under Triaxial Compression by Combining the Superposition Method with the Energy-Based Homogenization Technique. Int. J. Geomech. 2018, 18, 04018172. [Google Scholar] [CrossRef]

- Wu, F.; Chen, J.; Zou, Q. A nonlinear creep damage model for salt rock. Int. J. Damage Mech. 2018. [Google Scholar] [CrossRef]

- Yang, D.S.; Qi, X.Y.; Chen, W.Z.; Wang, S.G.; Yang, J.P. Anisotropic Permeability of Coal Subjected to Cyclic Loading and Unloading. Int. J. Geomech. 2018, 18, 04018093. [Google Scholar] [CrossRef]

- Jiang, C.; Duan, M.; Yin, G.; Wang, J.G.; Lu, T.; Xu, J.; Zhang, D.; Huang, G. Experimental study on seepage properties, AE characteristics and energy dissipation of coal under tiered cyclic loading. Eng. Geol. 2017, 221, 114–123. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, E.; Li, N.; Li, X.; Wang, X.; Li, Z. Damage evolution analysis of coal samples under cyclic loading based on single-link cluster method. J. Appl. Geophys. 2018, 152, 56–64. [Google Scholar] [CrossRef]

- Yang, Y.J.; Duan, H.Q.; Xing, L.Y.; Deng, L. Fatigue Characteristics of Coal Specimens under Cyclic Uniaxial Loading. Geotech. Test. J. 2019, 42, 20170263. [Google Scholar] [CrossRef]

- Song, D.; Wang, E.; Liu, J. Relationship between EMR and dissipated energy of coal rock mass during cyclic loading process. Saf. Sci. 2012, 50, 751–760. [Google Scholar] [CrossRef]

- Ye, Z.; Zhang, L.; Hao, D.; Zhang, C.; Wang, C. Experimental study on the response characteristics of coal permeability to pore pressure under loading and unloading conditions. J. Geophys. Eng. 2017, 14, 1020–1031. [Google Scholar] [CrossRef]

- Xie, H.; Gao, F.; Zhou, H.; Cheng, H.; Zhou, F. On theoretical and modeling approach to mining-enhanced permeability for simultaneous exploitation of coal and gas. J. China Coal Soc. 2013, 38, 1101–1108. [Google Scholar] [CrossRef]

- Meng, Z.; Li, G. Experimental research on the permeability of high-rank coal under a varying stress and its influencing factors. Eng. Geol. 2013, 162, 108–117. [Google Scholar] [CrossRef]

- Yin, X.; Yin, C. Precursor and Earthquake Prediction of Nonlinear System Instability—Response Ratio Theory and Its Application. Sci. China Ser. B 1991, 5, 55–60. [Google Scholar]

- Zhang, L.; Yin, X.; Liang, N. Study on relation between load/unload response ratio and damage variable. Chin. J. Rock Mech. Eng. 2008, 27, 1874–1881. [Google Scholar]

- Wu, L.; White, C.; Scanlon, T.J.; Reese, J.M.; Zhang, Y. Deterministic numerical solutions of the Boltzmann equation using the fast spectral method. J. Comput. Phys. 2013, 250, 27–52. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).