Optimal Design of Off-Grid Wind–Solar–Hydrogen Integrated Energy System Considering Power and Hydrogen Storage: A General Method

Abstract

1. Introduction

- First, a novel superstructure-based MILP framework was developed for the simultaneous optimization of topology, technology selection, and capacity in off-grid WSH-IES.

- Second, a modular modeling approach was developed to enhance adaptability and interpretability across diverse application scenarios.

- Third, comprehensive case studies demonstrated the framework’s effectiveness for different demand profiles (electricity-only and combined electricity–hydrogen).

- Finally, economic and sensitivity analysis provide insights into optimal configurations under a range of constraints and boundary conditions.

2. Methods

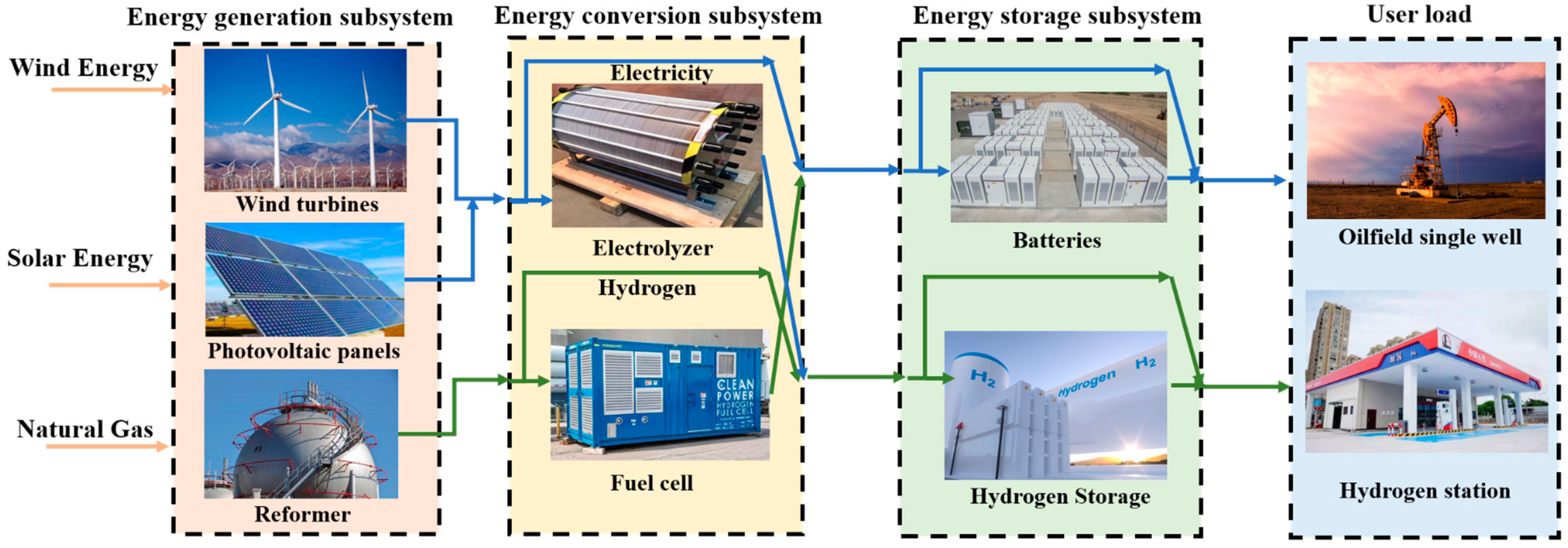

2.1. Superstructure and Modular Modeling Framework

2.2. Mathematical Model of Candidate Devices

2.3. Mixed-Integer Linear Programming Formulation

2.3.1. Decision Variables

2.3.2. Objective Function

2.3.3. Constraints

- Mutually Exclusive Selection

- Capacity-Selection Coupling (Big-M Logic)

- Generalized Output Limits (Generator & Converter)

- Input–Output Conversion Law (Coupling Physics)

- Storage State Dynamics

- Storage Technical Limits

- Energy balance constraints

- Off-grid Cyclic Stability

- Environmental Constraints (Optional)

2.3.4. Model Linear Strategy

- (a)

- Piecewise Linear Approximation (PWL): This method converts non-linear relationships into a set of linear constraints to ensure that the maximum approximation error remains below 1.5%.

- (b)

- Big-M Method: This is a standard reformulation technique in MILP that enforces conditional logic without introducing nonlinearity. It is used to precisely linearize the product of binary variables and continuous variables.

2.4. Model Implementation, Solution and Validation

2.5. Boundary Conditions and Demonstrability Analysis

3. Case Study

3.1. Basic Data

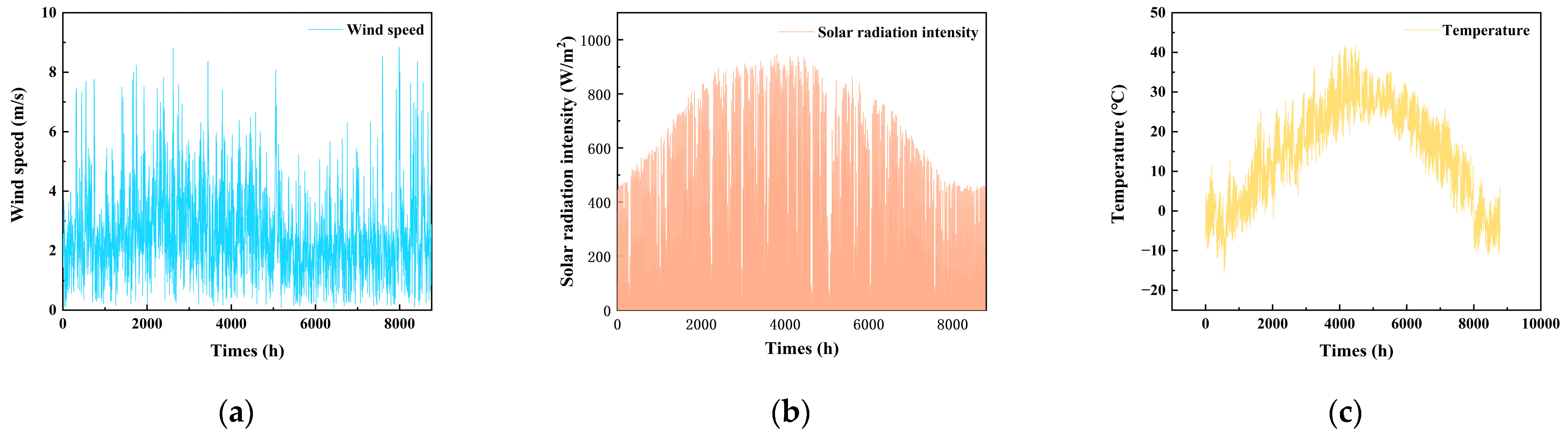

3.1.1. Meteorological Resource Data

3.1.2. Demands

3.1.3. Technological and Economic Data

3.2. Solving Strategy

- (a)

- Initialize necessary parameters, such as local meteorological parameters, techno-economic parameters of candidate equipment. Determine the electricity and hydrogen loads and the boundary condition.

- (b)

- Establish the mathematical model of the candidate equipment.

- (c)

- Establish the “structure-type-capacity” integrated design optimization model based on the unit models established in (b).

- (d)

- Solve the model established in (c) by Python and COPT.

3.3. Setting of Scenarios

4. Results

4.1. Optimal System Configurations

4.1.1. Electricity-Only Load

4.1.2. Combined Electricity–Hydrogen Load

4.2. Economic Performance Analysis

4.2.1. Impact of Equipment Demonstrability

4.2.2. Impact of Electro-Hydrogen Coupling

4.2.3. Analysis of Key Cost Components

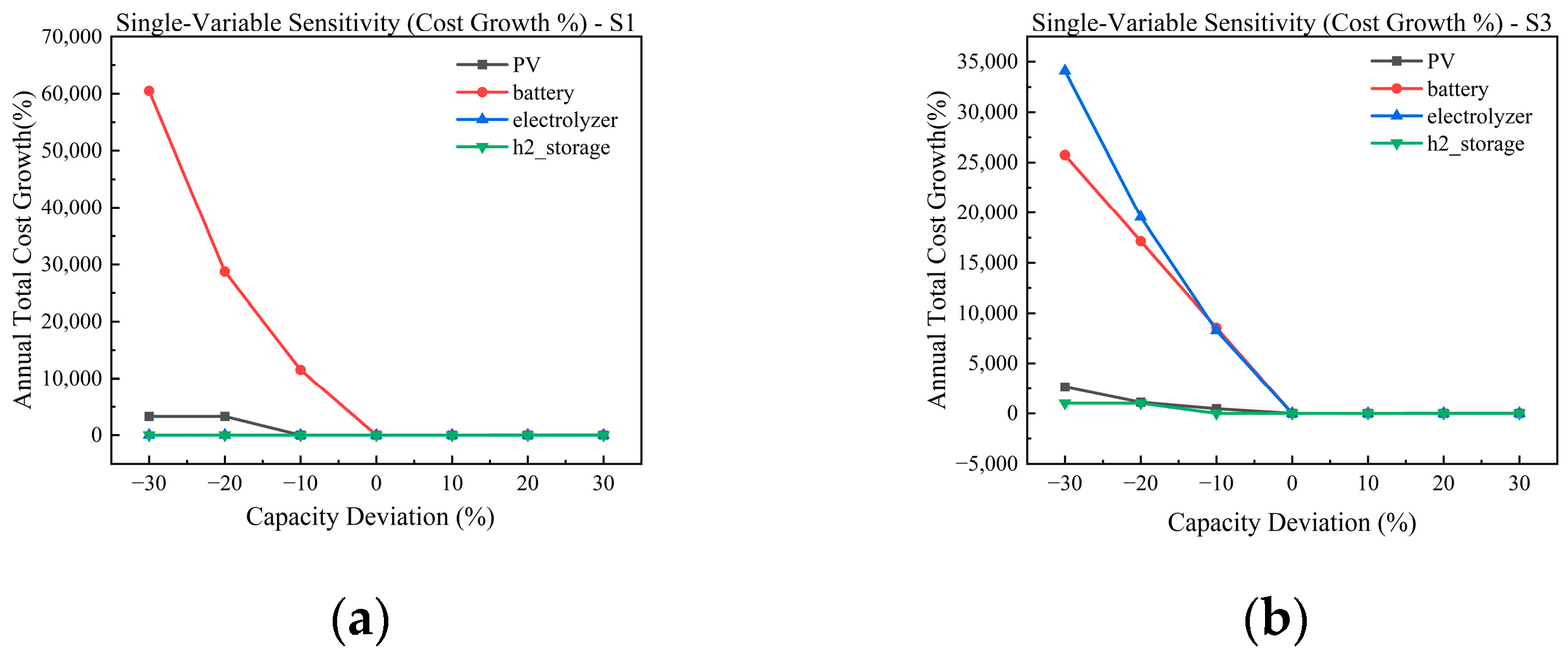

4.3. Sensitivity Analysis

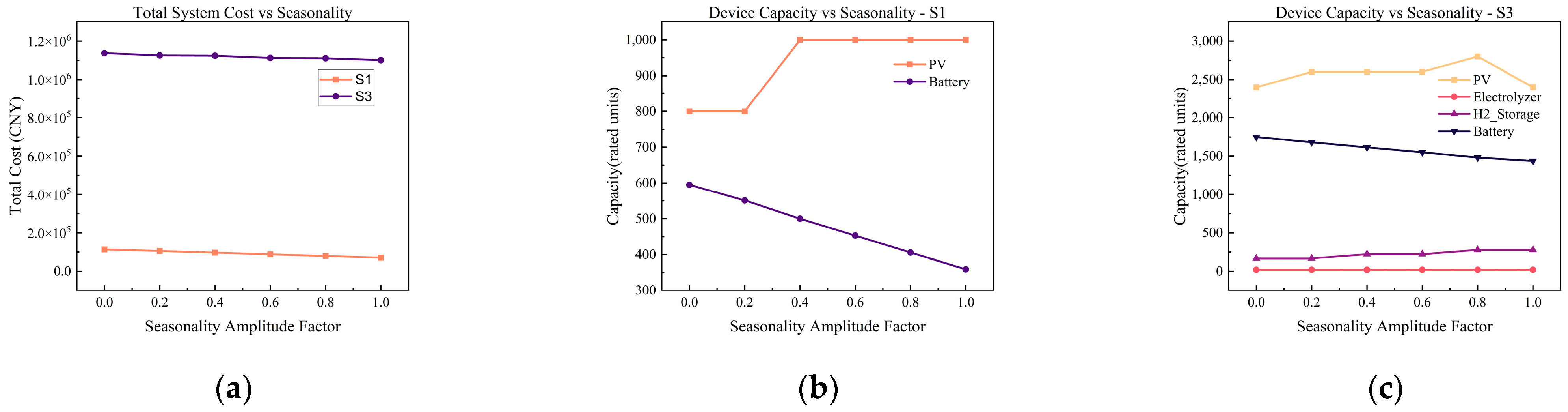

4.4. Seasonal Impact Analysis

4.5. Levelized Cost Analysis

4.5.1. Levelized Cost of Electricity (LCOE)

4.5.2. Levelized Hydrogen Cost (LCOH)

5. Discussion

5.1. Economic Deconstruction of System Architecture and Hydrogen’s Role

5.2. Value, Validation, and Limitations of the Methodological Framework

- Deterministic Optimization Framework. The model relies on deterministic typical-year meteorological data and load curves, neglecting the randomness of wind/solar resources and load uncertainty. Future work may employ stochastic or robust optimization methods to enable designs resilient to input fluctuations within defined ranges.

- Static techno-economic parameters. The model ignores equipment performance degradation over time (e.g., electrolyzer efficiency decay, battery capacity reduction). Consequently, the current annual total costs and levelized costs (LCOE, LCOH) reflect early-stage project evaluations rather than precise full-lifecycle calculations. Integrating degradation models, such as those focusing on electrolyzer degradation dynamics [32], is a necessary step toward more comprehensive techno-economic analysis.

- Simplified operational dynamics. The model operates at hourly resolution and focuses on energy balance, neglecting sub-hourly power dynamics, grid stability issues (e.g., voltage control, frequency regulation, short-circuit currents), and hydrogen system pipeline pressure dynamics. At more detailed design stages, these dynamic constraints require consideration through hierarchical optimization or coupled simulation approaches.

- Preset Superstructure. Optimization results strictly depend on the predefined equipment library. If promising emerging technologies (e.g., novel energy storage or hydrogen production methods) are omitted from the library, the model cannot identify their potential value.

5.3. Implications for Future Research and Practice

6. Conclusions

- First, the system cost structure is fundamentally determined by load characteristics and profoundly impacts economic vulnerability. Pure electric systems use a “PV + battery” architecture that concentrates over 96% of costs and risks in energy storage batteries. Hybrid hydrogen systems use a “PV-based hydrogen production + hybrid storage” architecture, which distributes costs between batteries and electrolyzers. This diversified structure effectively mitigates the volatility of equipment prices.

- In off-grid systems, the hydrogen energy chain’s core value lies in providing medium- to long-term energy storage and time-shifting capabilities. By serving as a cross-day or even cross-seasonal energy storage medium, it effectively complements the limitations of battery storage, thereby optimizing the overall storage portfolio and dispersing system cost risks.

- Under current typical technical and economic parameters, real-time bidirectional coupling between electricity and hydrogen fails to demonstrate economic viability. Due to the relatively high cost of fuel cell power generation, the optimization model did not select hydrogen-based power generation for grid regulation, indicating that the cost competitiveness of this technology pathway still needs improvement.

- Non-economic design constraints incur quantifiable costs. For example, technology demonstration requirements increase the cost of small-scale pure electric systems by over 70%, providing a quantitative reference for policymakers balancing technology deployment goals with actual economic burdens.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WSH-IES | Wind–Solar–Hydrogen Integrated Energy Systems |

| EH | Energy Hub |

| HRES | Hybrid Renewable Energy System |

| PSO | Particle Swarm Optimization |

| GA | Genetic Algorithms |

| ATC | Annual Total Cost |

| LCOE | Levelized Cost of Electricity |

| LCOH | Levelized Cost of Hydrogen |

| MINLP | Mixed Integer Nonlinear Programming |

| MILP | Mixed Integer Linear Programming |

| SDG | Sustainable Development Goal |

| WT | Wind turbines |

| PV | Photovoltaic |

| RH | Reformer hydrogen plant |

| EL | Electrolyzer |

| FC | Fuel cell |

| BT | Lithium batteries |

| HS | Solid-state hydrogen |

| Wind turbine’s cut-in wind speed (m/s) | |

| Wind turbine’s cut-out wind speed (m/s) | |

| Wind turbine’s rated wind speed (m/s) | |

| Wind turbine’s rated power (kW) | |

| Photovoltaic Panel’s rated power (kW) | |

| Actual solar radiation intensity (kW/m2) | |

| Rated solar radiation intensity (kW/m2) | |

| The temperature corresponding to the standard conditions (°C) | |

| The volumetric flow rate of natural gas into the reformer (Nm3/h) | |

| Conversion efficiency of the reformer | |

| The hydrogen production power of the reformer (kW); | |

| The volumetric energy density of hydrogen at high calorific value (kWh/Nm3) | |

| The hydrogen production power of the alkaline electrolyzer (kW) | |

| Hydrogen production efficiency | |

| The electric power of the alkaline electrolyzer (kW) | |

| The system output of the fuel cell to convert hydrogen energy(kW) | |

| The input hydrogen power of the fuel cell (kW) | |

| The fuel cell conversion of hydrogen into usable energy system efficiency | |

| Electrical conversion efficiency of fuel cells | |

| Thermal production power of fuel cells (kW) | |

| t moment of power storage (kWh) | |

| The initial energy storage and energy storage capacity ratio | |

| The installation capacity of the electric storage (kWh) | |

| The charging and discharging efficiency of the electricity storage | |

| The charging and discharging power of the electricity storage equipment (kW) | |

| The electricity storage and thermal storage of the self-loss factor. | |

| The amount of hydrogen storage at time t (Nm3) | |

| The ratio of the initial amount of hydrogen storage to the storage capacity | |

| Hydrogen storage tank’s hydrogen charge and discharge efficiency | |

| The installed capacity of hydrogen storage (Nm3) | |

| The annual equipment purchase and installation costs | |

| The annual operation and maintenance costs | |

| The annual natural gas expense | |

| The capital recovery factor | |

| The purchase cost of a single unit of equipment, CNY/unit | |

| The number of type j of equipment of category i | |

| 0–1 integer variable, the category and type of equipment are installed or not | |

| The discount rate of the equipment | |

| The life of the equipment model (years) | |

| The annual operation and maintenance cost of the system equipment, CNY/year | |

| The unit price of natural gas, CNY/Nm3 | |

| The power generation of the energy production system of the system at time t, kWh | |

| The electrical load demand of the scenario at time t, kWh | |

| The 0–1 variable indicating whether the system selects a certain type of power generator in the energy production system | |

| The power generation of the fuel cell in the system at time t | |

| The power consumption of the electrolyzer in the system at time t, kWh | |

| The power distribution coefficients of the electrolyzer and the fuel cells | |

| The amount of hydrogen produced by the hydrogen production equipment at time t, Nm3 | |

| The hydrogen load demand of the scenario at time t, Nm3 | |

| The installed capacity of the hydrogen reformer, Nm3/h | |

| The hydrogen production of the reformer hydrogen units at time t, Nm3/h | |

| The installed capacity of the fuel cell device, kW | |

| The power production of fuel cells at time t, kW | |

| The installed capacity of the electrolyzer unit, Nm3/h | |

| The installed capacity of the solid-state hydrogen storage unit, i.e., the rate of hydrogen production, Nm3 | |

| O&M | Operation and maintenance |

| PWL | Piecewise Linear Approximation |

| CNY | Chinese currency |

| The time period | |

| The set of technology types, the subscript represents the set of energy generation, conversion and storage devices | |

| The set of the candidate models | |

| The set of the energy carrier | |

| The value of load loss | |

| The unit price of fuel | |

| The normalized resource profile | |

| Charging/discharging efficiency | |

| The Depth of Discharge | |

| The incidence matrix mapping devices to buses. | |

| The self-discharge rate |

Appendix A

Appendix A.1. Wind Turbines

Appendix A.2. Photovoltaics

Appendix A.3. Hydrogen Production Reformer Devices

Appendix A.4. Electrolyzers

Appendix A.5. Fuel Cells

Appendix A.6. Electricity Storage

Appendix A.7. Hydrogen Storage

References

- Wu, D.; Han, Z.; Liu, Z.; Zhang, H. Study on configuration optimization and economic feasibility analysis for combined cooling, heating and power system. Energy Convers. Manag. 2019, 190, 91–104. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change, IPCC Chair’s Remarks at the High-Level Ministerial Roundtable on Pre-2030 Ambition. 2025. Available online: https://www.ipcc.ch/2024/11/18/ipcc-chairs-cop29-high-level-ministerial-roundtable-pre-2030-ambition/ (accessed on 18 March 2025).

- International Energy Agency. Clean Energy Transitions Programme 2023. Available online: https://www.iea.org/reports/clean-energy-transitions-programme-2023 (accessed on 18 March 2025).

- Hamedani, E.A.; Khodaparast, P.; Hosseini, E.; Mahmudy, T.; Yajloo, A.B. A mini-review of energy hub: Concept, components, classifications, and applications. Energy Rep. 2026, 15, 108886. [Google Scholar] [CrossRef]

- Ma, S.; Mi, Y.; Li, S.; Wang, X.; Li, D.; Wang, P. Bi-level operation model for energy hub based on energy-carbon coordination optimization framework. Energy 2025, 333, 137449. [Google Scholar] [CrossRef]

- Ning, X.; Wei, C.; Zhu, L.; Wang, Y.; Ji, Y.; Sun, L.; Zhang, L. A control strategy for a fully isolated universal DC bus-based AC/DC energy exchange system applicable in multiple scenarios. In Proceedings of the 2024 IEEE 2nd International Conference on Power Science and Technology (ICPST), Dali, China, 9–11 May 2024; pp. 848–853. [Google Scholar] [CrossRef]

- Modu, B.; Abdullah, M.P.; Bukar, A.L.; Hamza, M.F. A systematic review of hybrid renewable energy systems with hydrogen storage: Sizing, optimization, and energy management strategy. Int. J. Hydrogen Energy 2023, 48, 38354–38373. [Google Scholar] [CrossRef]

- Thirunavukkarasu, M.; Sawle, Y.; Lala, H. A comprehensive review on optimization of hybrid renewable energy systems using various optimization techniques. Renew. Sustain. Energy Rev. 2023, 176, 113192. [Google Scholar] [CrossRef]

- Assaf, J.; Shabani, B. A novel hybrid renewable solar energy solution for continuous heat and power supply to standalone-alone applications with ultimate reliability and cost effectiveness. Renew. Energy 2019, 138, 509–520. [Google Scholar] [CrossRef]

- Jamshidi, M.; Askarzadeh, A. Techno-economic analysis and size optimization of an off-grid hybrid photovoltaic, fuel cell and diesel generator system. Sustain. Cities Soc. 2019, 44, 310–320. [Google Scholar] [CrossRef]

- Anoune, K.; Laknizi, A.; Bouya, M.; Astito, A.; Abdellah, A.B. Sizing a PV-wind based hybrid system using deterministic approach. Energy Convers. Manag. 2018, 169, 137–148. [Google Scholar] [CrossRef]

- Das, M.; Singh, M.A.K.; Biswas, A. Techno-economic optimization of an off-grid hybrid renewable energy system using metaheuristic optimization approaches—Case of a radio transmitter station in India. Energy Convers. Manag. 2019, 185, 339–352. [Google Scholar] [CrossRef]

- Wang, M.; Zheng, J.H.; Li, Z.; Wu, Q.H. Multi-attribute decision analysis for optimal design of park-level integrated energy systems based on load characteristics. Energy 2022, 254, 124379. [Google Scholar] [CrossRef]

- Mokhtara, C.; Negrou, B.; Bouferrouk, A.; Yao, Y.; Settou, N.; Ramadan, M. Integrated supply–demand energy management for optimal design of off-grid hybrid renewable energy systems for residential electrification in arid climates. Energy Convers. Manag. 2020, 221, 113192. [Google Scholar] [CrossRef]

- Alhamami, A.H.; Abba, S.I.; Musa, B.; Dodo, Y.A.; Salami, B.A.; Dodo, U.A.; Alyami, S.H. Off-grid multi-region energy system design based on energy load demand estimation using hybrid nature-inspired optimization algorithms. Energy Convers. Manag. 2024, 315, 118766. [Google Scholar] [CrossRef]

- Marocco, P.; Ferrero, D.; Lanzini, A.; Santarelli, M. The role of hydrogen in the optimal design of off-grid hybrid renewable energy systems. J. Energy Storage 2022, 46, 103893. [Google Scholar] [CrossRef]

- Koholé, Y.W.; Ngouleu, C.A.W.; Fohagui, F.C.V.; Tchuen, G. Quantitative techno-economic comparison of a photovoltaic/wind hybrid power system with different energy storage technologies for electrification of three remote areas in cameroon using cuckoo search algorithm. J. Energy Storage 2023, 68, 107783. [Google Scholar] [CrossRef]

- Li, J.; Liu, P.; Li, Z. Optimal design and techno-economic analysis of a hybrid renewable energy system for off-grid power supply and hydrogen production: A case study of west China. Chem. Eng. Res. Des. 2022, 177, 604–614. [Google Scholar] [CrossRef]

- He, B.; Ismail, N.; Leng, K.K.K.; Chen, G. Techno-economic analysis of an HRES with fuel cells, solar panels, and wind turbines using an improved al-biruni algorithm. Heliyon 2023, 9, e22828. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Hao, N.; Li, X.; Alshahrani, M.Y. AI-enabled sports-system peer-to-peer energy exchange network for remote areas in the digital economy. Heliyon 2024, 10, e35890. [Google Scholar] [CrossRef] [PubMed]

- Nordin, N.D.; Rahman, H.A. Comparison of optimum design, sizing, and economic analysis of standalone photovoltaic/battery without and with hydrogen production systems. Renew. Energy 2019, 141, 107–123. [Google Scholar] [CrossRef]

- Ahmadi, S.; Abdi, S. Application of the hybrid big bang–big crunch algorithm for optimal sizing of a stand-alone hybrid PV/wind/battery system. Sol. Energy 2016, 134, 366–374. [Google Scholar] [CrossRef]

- Yee, T.F.; Grossmann, I.E. Simultaneous optimization models for heat integration—II. Heat exchanger network synthesis. Comput. Chem. Eng. 1990, 14, 1165–1184. [Google Scholar] [CrossRef]

- Wu, D.; Han, S.; Wang, L.; Li, G.; Guo, J. Multi-parameter optimization design method for energy system in low-carbon park with integrated hybrid energy storage. Energy Convers. Manag. 2023, 291, 117265. [Google Scholar] [CrossRef]

- Jia, J.; Li, H.; Wu, D.; Guo, J.; Jiang, L.; Fan, Z. Multi-objective optimization study of regional integrated energy systems coupled with renewable energy, energy storage, and inter-station energy sharing. Renew. Energy 2024, 225, 120328. [Google Scholar] [CrossRef]

- Carrara, A.; Perdichizzi, A.; Barigozzi, G. Simulation of an hydrogen production steam reforming industrial plant for energetic performance prediction. Int. J. Hydrogen Energy 2010, 35, 3499–3508. [Google Scholar] [CrossRef]

- Sharshir, S.W.; Joseph, A.; Elsayad, M.M.; Tareemi, A.A.; Kandeal, A.W.; Elkadeem, M.R. A review of recent advances in alkaline electrolyzer for green hydrogen production: Performance improvement and applications. Int. J. Hydrogen Energy 2024, 49, 458–488. [Google Scholar] [CrossRef]

- Sazali, N.; Salleh, W.N.W.; Jamaludin, A.S.; Razali, M.N.M. New perspectives on fuel cell technology: A brief review. Membranes 2020, 10, 99. [Google Scholar] [CrossRef]

- Stecca, M.; Elizondo, L.R.; Soeiro, T.B.; Bauer, P.; Palensky, P. A comprehensive review of the integration of battery energy storage systems into distribution networks. IEEE Open J. Ind. Electron. Soc. 2020, 1, 46–65. [Google Scholar] [CrossRef]

- Rajanna, S.; Saini, R.P. Development of optimal integrated renewable energy model with battery storage for a remote Indian area. Energy 2016, 111, 803–817. [Google Scholar] [CrossRef]

- Ruiming, F. Multi-objective optimized operation of integrated energy system with hydrogen storage. Int. J. Hydrogen Energy 2019, 44, 29409–29417. [Google Scholar] [CrossRef]

- Valedsaravi, S.; Vegelin, R.; Olveira, A. Operational framework for large-scale power-to-X plants fed by renewable energies incorporating BESS and electrolyzer degradation. IEEE Access 2025, 13, 215994–216012. [Google Scholar] [CrossRef]

| Technologies | Type * | Investment Cost, CNY/Unit | O&M Cost, CNY/Unit | Capacity, kW (or Nm3/h) | Lifetime, Year | Tech-Specific Parameter 1 | Tech-Specific Parameter 2 | Tech-Specific Parameter 3 |

|---|---|---|---|---|---|---|---|---|

| WT | a | 55,800 | 750 | 5 | 25 | 11 m/s | 2.5 m/s | 25 m/s |

| b | 97,400 | 750 | 10 | 25 | 11 m/s | 2.5 m/s | 25 m/s | |

| c | 194,500 | 750 | 20 | 25 | 11 m/s | 2.5 m/s | 25 m/s | |

| PV | a | 750 | 50 | 0.55 | 25 | 1000 W/m2 | β: 0.0045 K−1 | 25 °C |

| b | 5600 | 370 | 200 | 25 | 1000 W/m2 | β: 0.0045 K−1 | 25 °C | |

| RH | a | 50,000 | 10,000 | 1 | 10 | Efficiency: 0.98 | Water consumption: 0.9 L/Nm3 |

| Technologies | Type | Investment Cost, CNY/Unit | O&M Cost, CNY/Unit | Capacity, kW (or Nm3/h) | Lifetime, Year | Efficiency | ||

|---|---|---|---|---|---|---|---|---|

| EL | a | 450,000 | 10,000 | 2 | 10 | 0.85 | 0.9 | 4.8 |

| FC | a | 50,000 | 3333 | 5 | 10 | 0.55 | - | - |

| Technologies | Type | Investment Cost, CNY/Unit | O&M Cost, CNY/Unit | Capacity, kW (or Nm3/h) | Lifetime, Year | Efficiency |

|---|---|---|---|---|---|---|

| BT | a | 1200 | 6 | 1 | 10 | 0.9 |

| HS | a | 50,000 | 3333 | 5 | 10 | 3 |

| Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | Scenario 5 | Scenario 6 | |

|---|---|---|---|---|---|---|

| Cases | 1 | 1 | 2 | 2 | 2 | 2 |

| Electro-hydrogen coupling | √ * | √ | √ | √ | - | - |

| Boundary conditions | - * | √ | - | √ | - | √ |

| Devices | Scenario 1 | Scenario 2 | ||||

|---|---|---|---|---|---|---|

| Type | Units | Capacities * | Type | Units | Capacities | |

| WT (kW) | - | 0 | 0 | a | 1 | 5 |

| PV (kW) | b | 4 | 800 | a | b | 1000 |

| RH () | - | 0 | 0 | - | 0 | 0 |

| EL () | - | 0 | 0 | a | 1 | 2 |

| FC (kW) | - | 0 | 0 | a | 1 | 5 |

| BT (kWh) | a | 595 | 595 | a | 467 | 467 |

| HS () | - | - | - | a | 1 | 55.617 |

| Annual total cost (CNY) | 113,555.46 | 195,856.7 | ||||

| Devices | Scenario 3 | Scenario 4 | ||||

|---|---|---|---|---|---|---|

| Type | Units | Capacities | Type | Units | Capacities | |

| WT (kW) | - | 0 | 0 | a | 1 | 5 |

| PV (kW) | b | 12 | 2400 | b | 12 | 2400 |

| RH () | - | 0 | 0 | - | 0 | 0 |

| EL () | a | 10 | 20 | a | 10 | 20 |

| FC (kW) | - | 0 | 0 | a | 1 | 5 |

| BT (kWh) | a | 1750 | 1750 | a | 1747 | 1747 |

| HS () | a | 3 | 166.85 | a | 3 | 166.85 |

| Annual total cost (CNY) | 1,137,183.26 | 1,153,846.58 | ||||

| Devices | Scenario 5 | Scenario 6 | ||||

|---|---|---|---|---|---|---|

| Type | Units | Capacities | Type | Units | Capacities | |

| WT (kW) | - | 0 | 0 | a | 1 | 5 |

| PV (kW) | b | 12 | 2400 | b | 12 | 2400 |

| RH () | - | 0 | 0 | - | 0 | 0 |

| EL () | a | 10 | 20 | a | 10 | 20 |

| FC (kW) | - | 0 | 0 | - | 0 | 0 |

| BT (kWh) | a | 1750 | 1750 | a | 1747 | 1747 |

| HS () | a | 3 | 166.85 | a | 3 | 166.85 |

| Annual total cost (CNY) | 1,137,183.26 | 1,143,062.11 | ||||

| Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | Scenario 5 | Scenario 6 | |

|---|---|---|---|---|---|---|

| ATC (CNY) | 113,555.46 | 195,856.70 | 1,137,183.26 | 1,153,846.58 | 1,137,183.26 | 1,143,062.11 |

| LCOE (CNY/kWh) | 1.13 | 1.94 | 11.07 | 11.23 | 11.07 | 11.12 |

| LCOH (CNY/kg) | 0 | 0 | 78.38 | 79.53 | 78.38 | 78.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Lin, L.; Gao, X.; Zuo, X.; Bu, Z.; Li, J.; Tan, C. Optimal Design of Off-Grid Wind–Solar–Hydrogen Integrated Energy System Considering Power and Hydrogen Storage: A General Method. Processes 2026, 14, 154. https://doi.org/10.3390/pr14010154

Lin L, Gao X, Zuo X, Bu Z, Li J, Tan C. Optimal Design of Off-Grid Wind–Solar–Hydrogen Integrated Energy System Considering Power and Hydrogen Storage: A General Method. Processes. 2026; 14(1):154. https://doi.org/10.3390/pr14010154

Chicago/Turabian StyleLin, Lihua, Xiaoyong Gao, Xin Zuo, Zhijun Bu, Jian Li, and Chaodong Tan. 2026. "Optimal Design of Off-Grid Wind–Solar–Hydrogen Integrated Energy System Considering Power and Hydrogen Storage: A General Method" Processes 14, no. 1: 154. https://doi.org/10.3390/pr14010154

APA StyleLin, L., Gao, X., Zuo, X., Bu, Z., Li, J., & Tan, C. (2026). Optimal Design of Off-Grid Wind–Solar–Hydrogen Integrated Energy System Considering Power and Hydrogen Storage: A General Method. Processes, 14(1), 154. https://doi.org/10.3390/pr14010154