Recent Advances in Green and Low-Carbon Energy Resources: Navigating the Climate-Friendly Microgrids for Decarbonized Power Generation

Abstract

1. Introduction

2. Recent Progress in Green Energy and Decarbonization Technology

2.1. Green Energy Technologies

2.2. Decarbonization Technologies

2.2.1. Power-to-X Technology

2.2.2. Power-to-Fuel

2.2.3. Carbon Sequestration

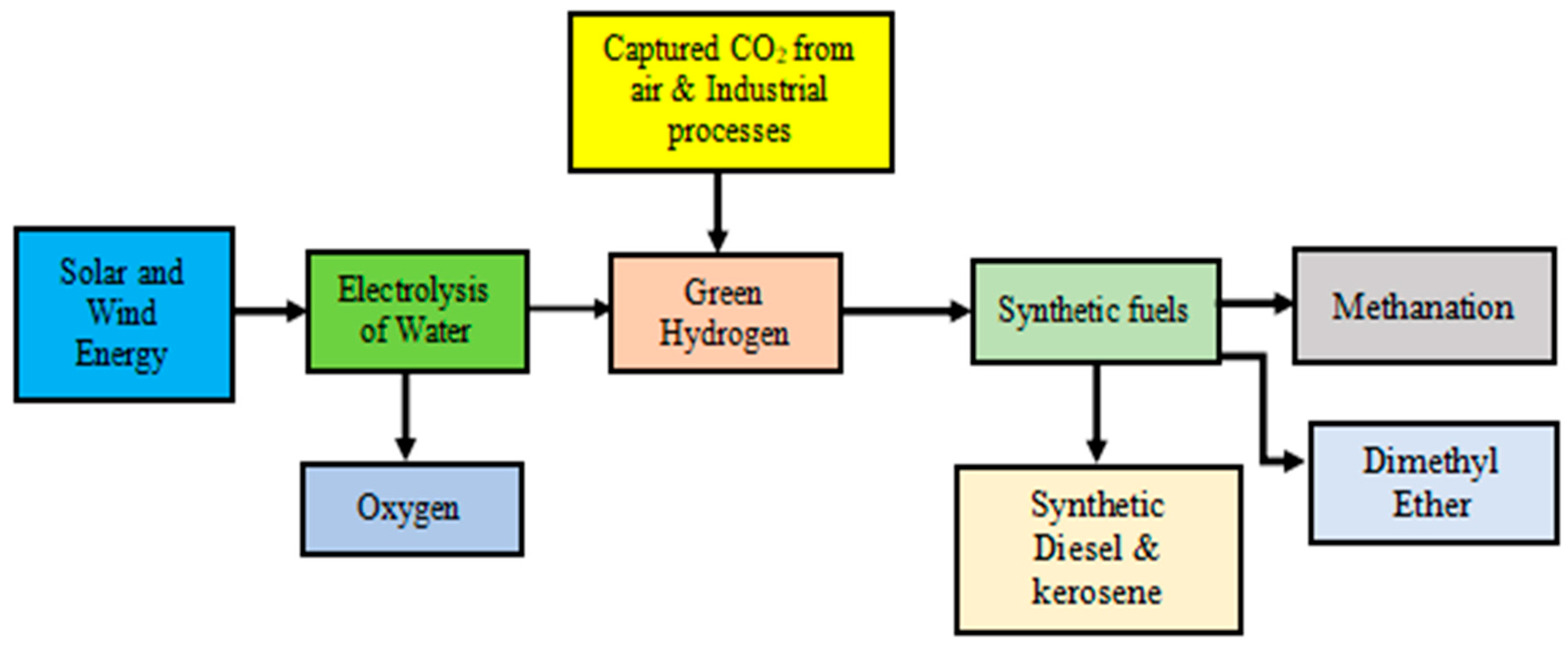

2.2.4. Electrofuel (E-Fuel)

3. Methods and Materials

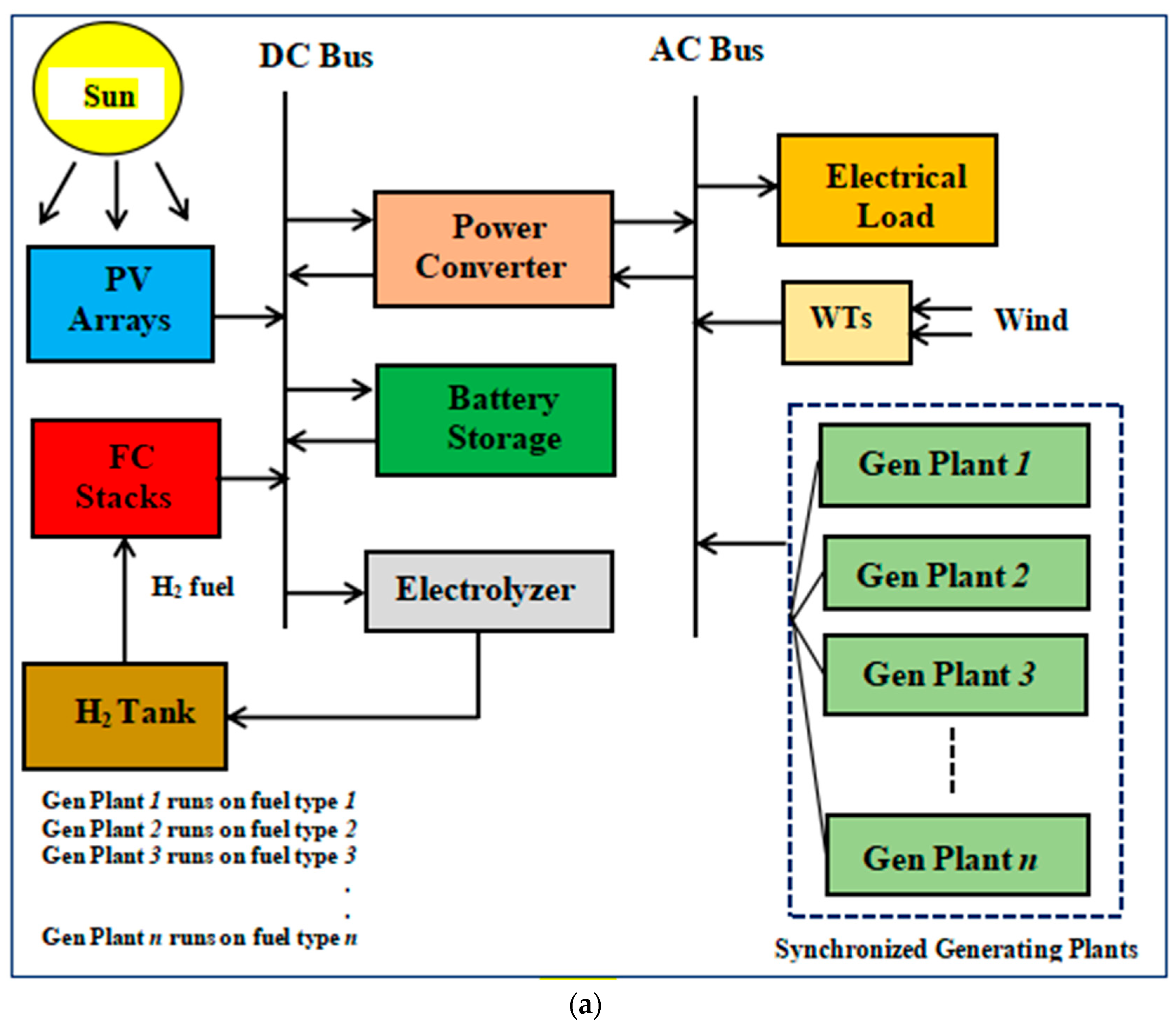

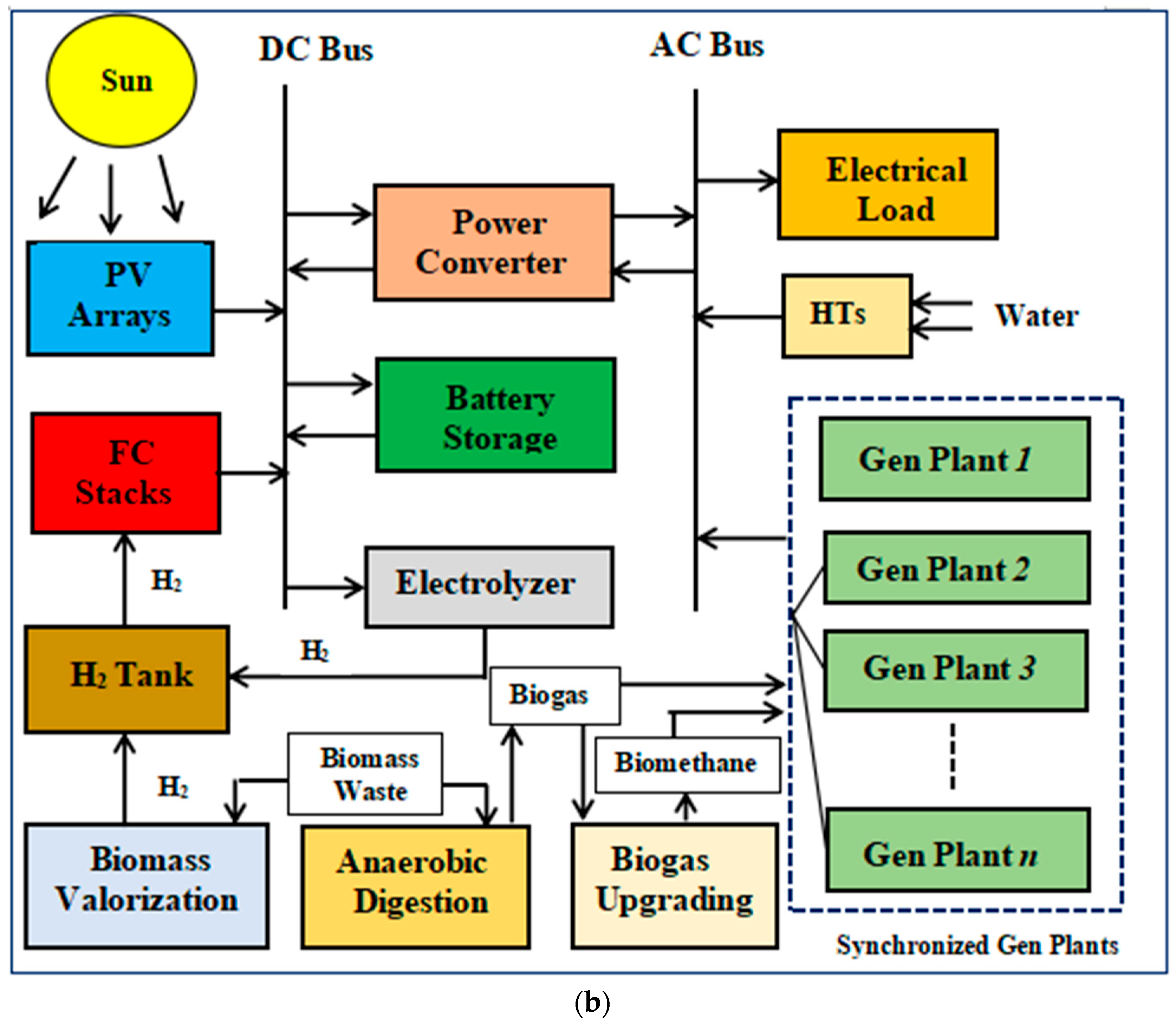

3.1. Utilization and Application of Green and Low-Carbon Fuels in Microgrids

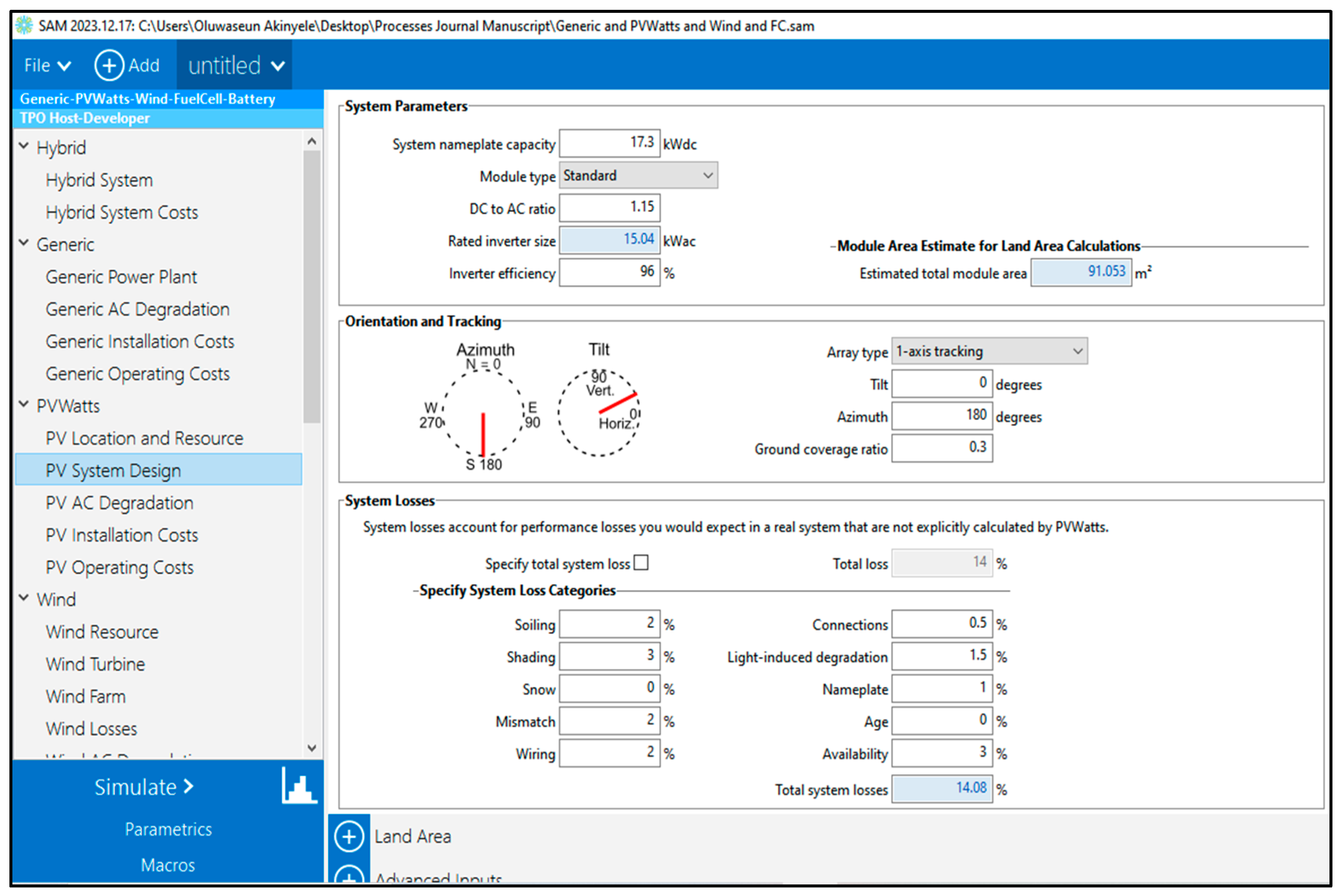

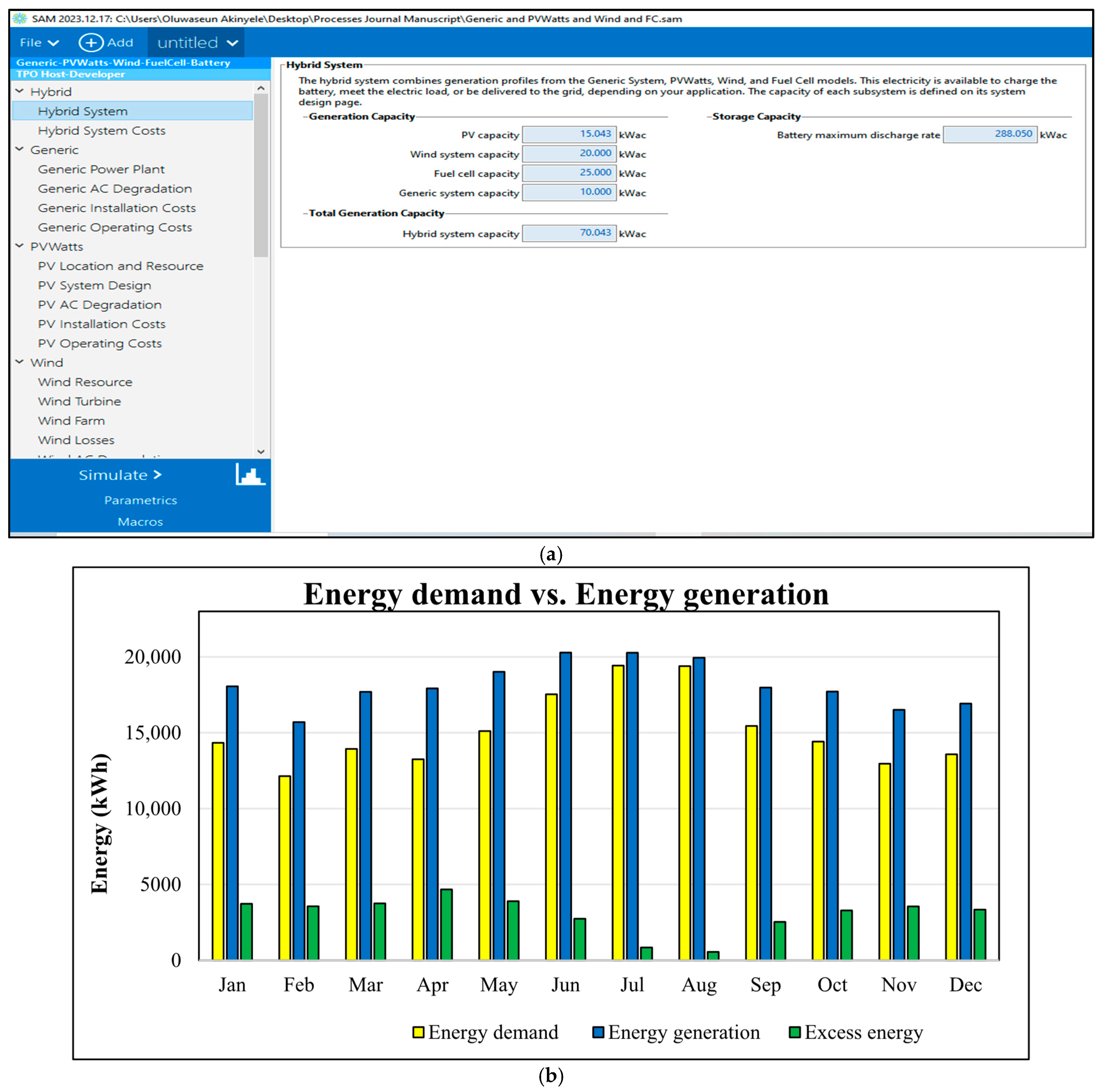

3.2. Approach to Multi-Energy Generation in Microgrids in the SAM Environment

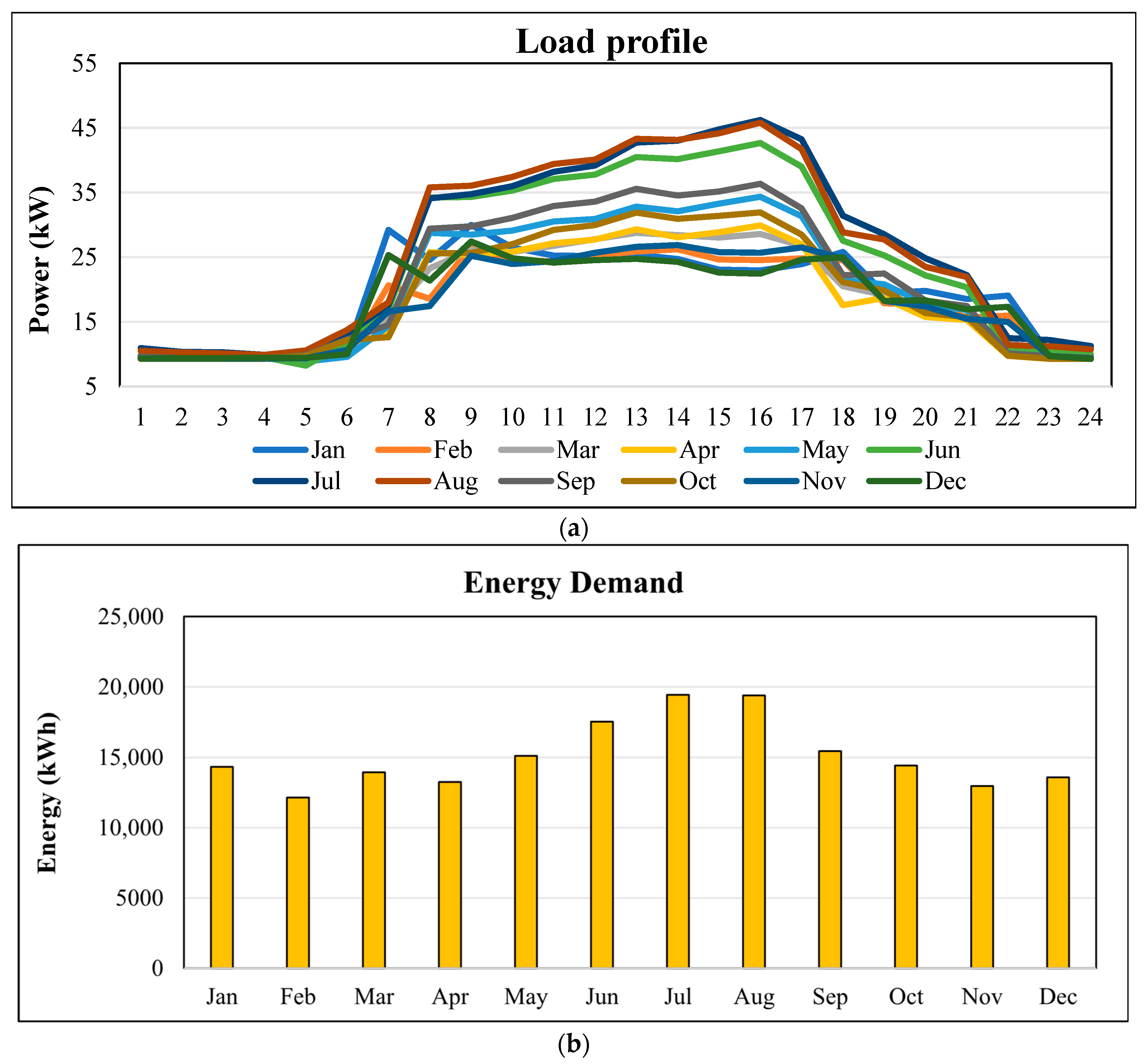

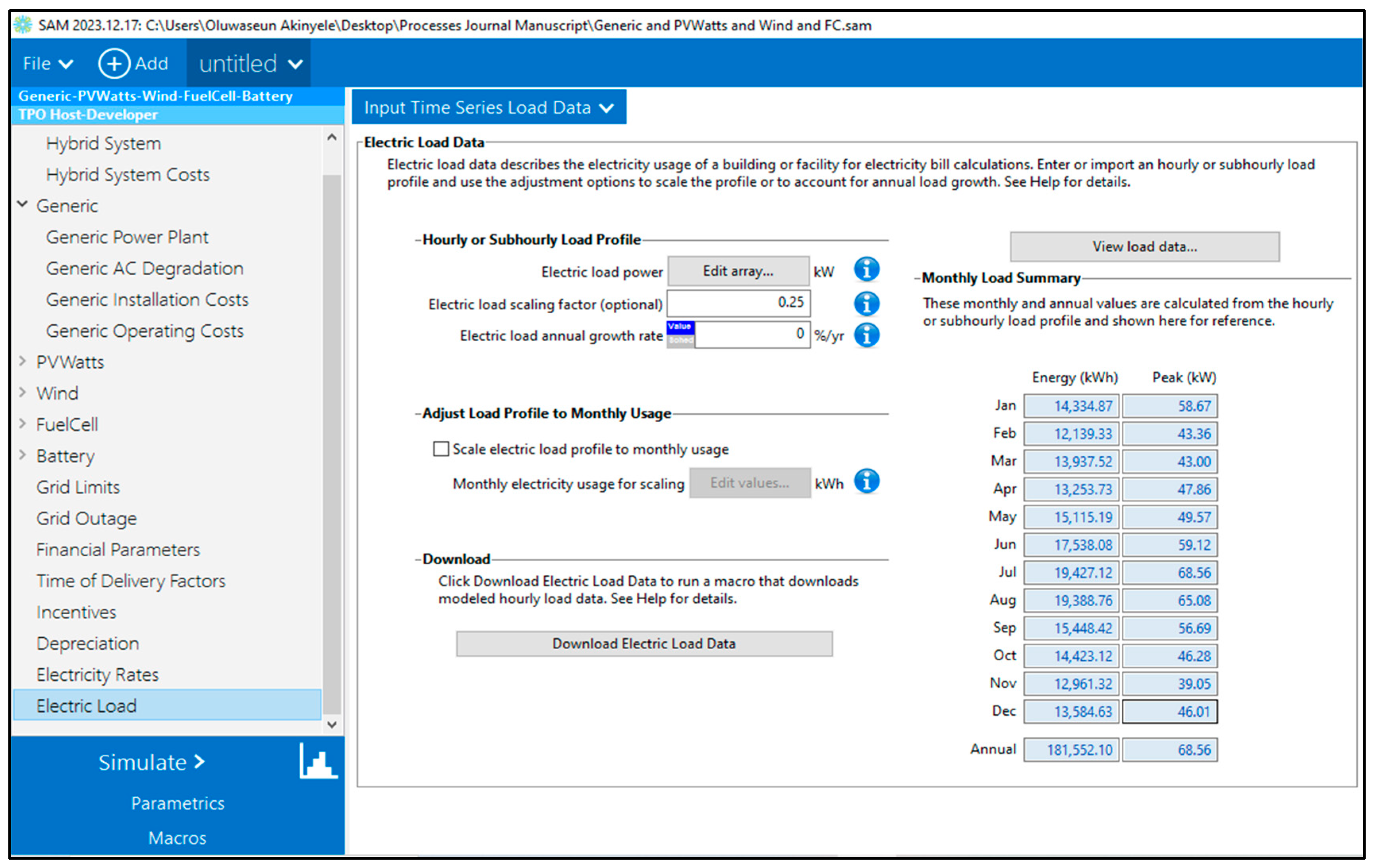

3.2.1. Commercial Load Demand Model

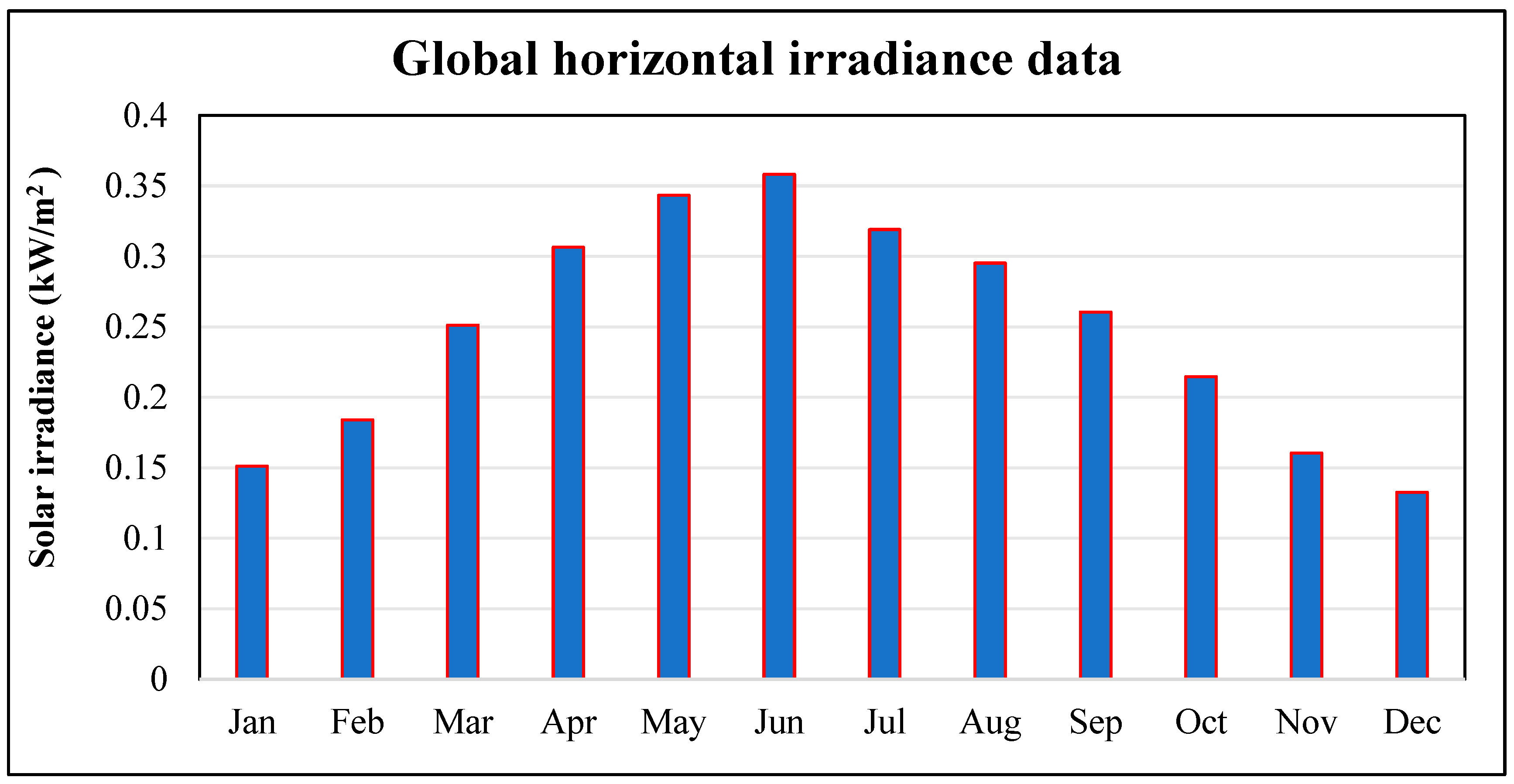

3.2.2. Solar Photovoltaic Power Simulation Methods

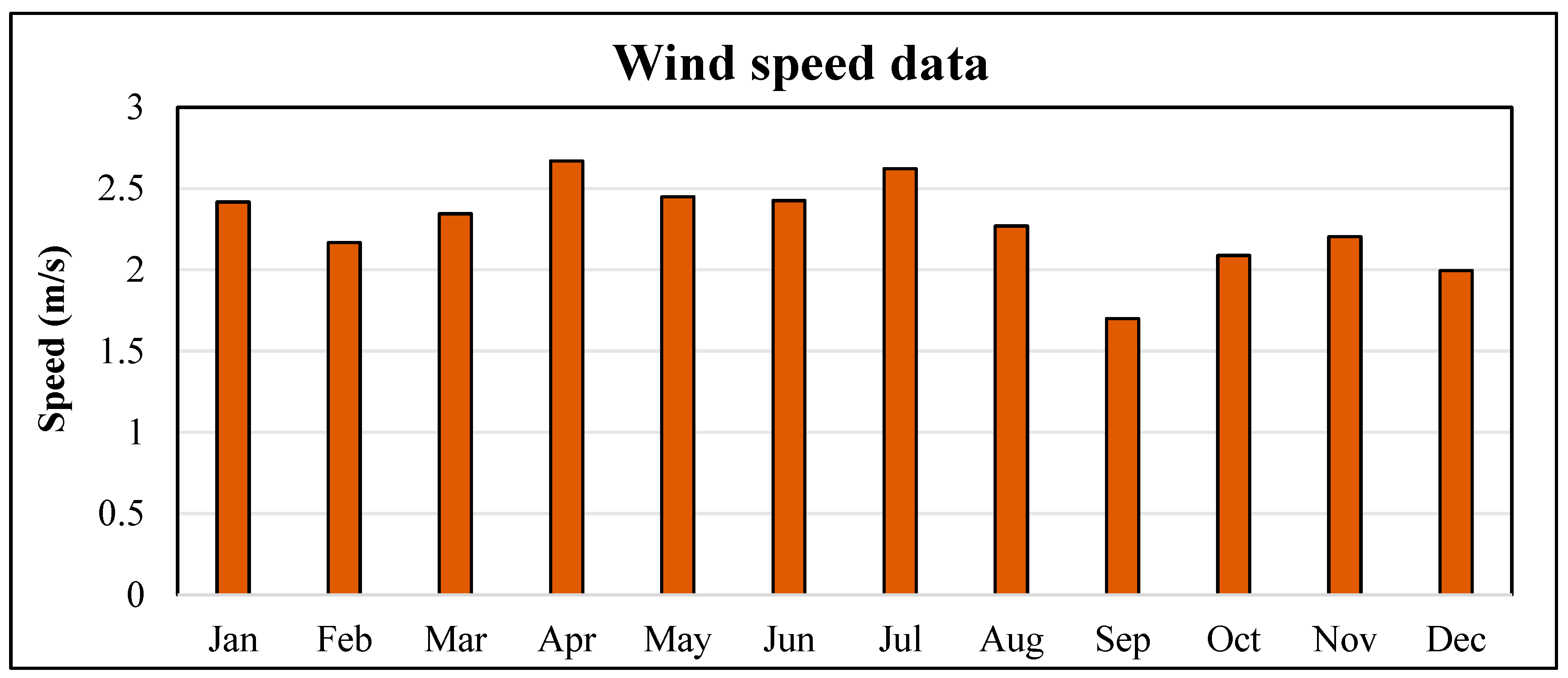

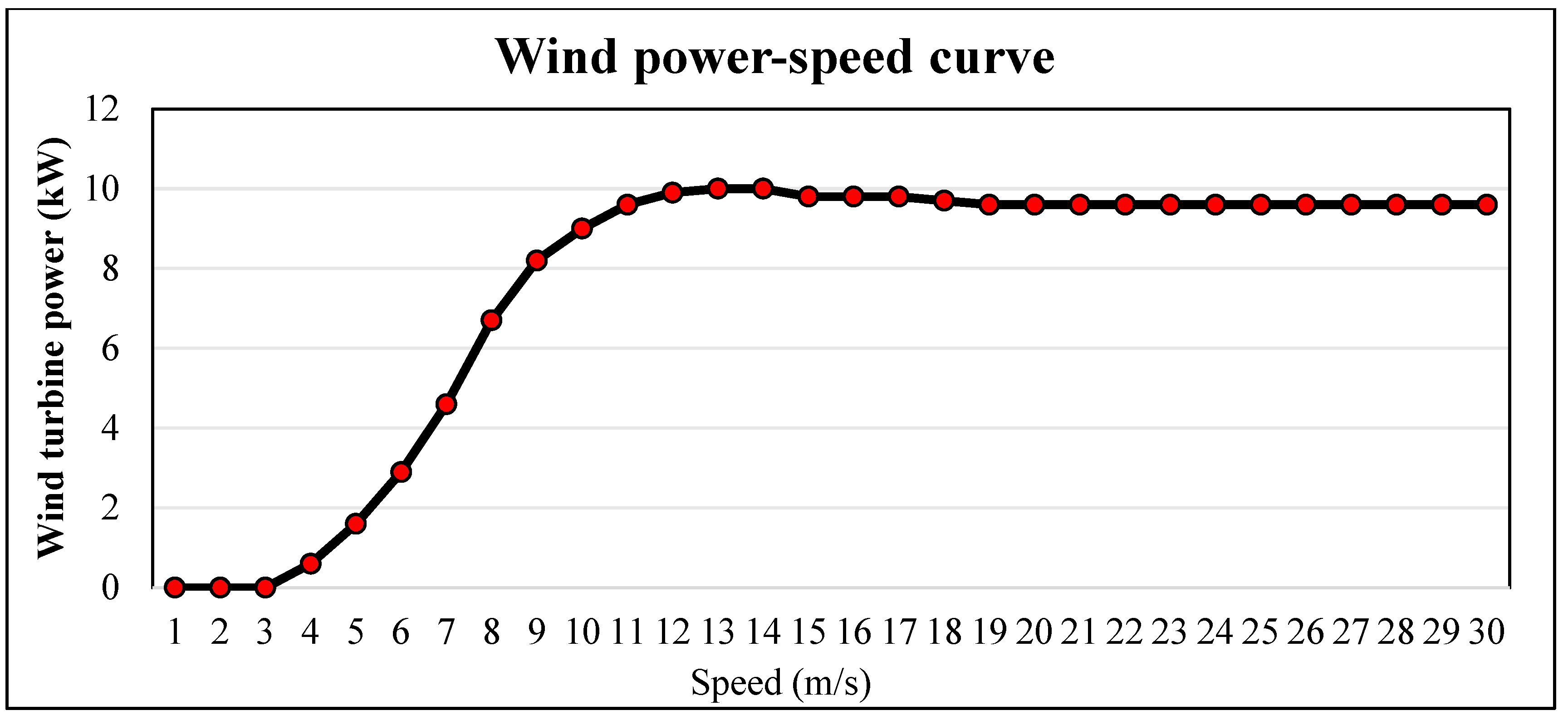

3.2.3. Wind Power Simulation Methods

3.2.4. Fuel Cells Power Simulation Methods

3.2.5. Battery Storage System Sizing

3.2.6. Generic Power Plant Simulation Methods

3.2.7. Total Performance and Reliability Analysis

3.2.8. Quantity of Fuel and Carbon Emissions Analyses

3.2.9. Project Cost Analyses

- -

- Reduction in installation and/or operating costs;

- -

- Increase in the level of incentives;

- -

- Increase in discount rate;

- -

- Increase in revenue (i.e., increase in PPA price, PPA price escalation, or decrease in IRR target) for PPA projects, e.g., PPA, merchant plant, third-party ownership, community solar PV system;

- -

- Increase in savings (i.e., adjust retail electricity rate or load) for distributed projects (e.g., residential and commercial).

4. Results and Discussion

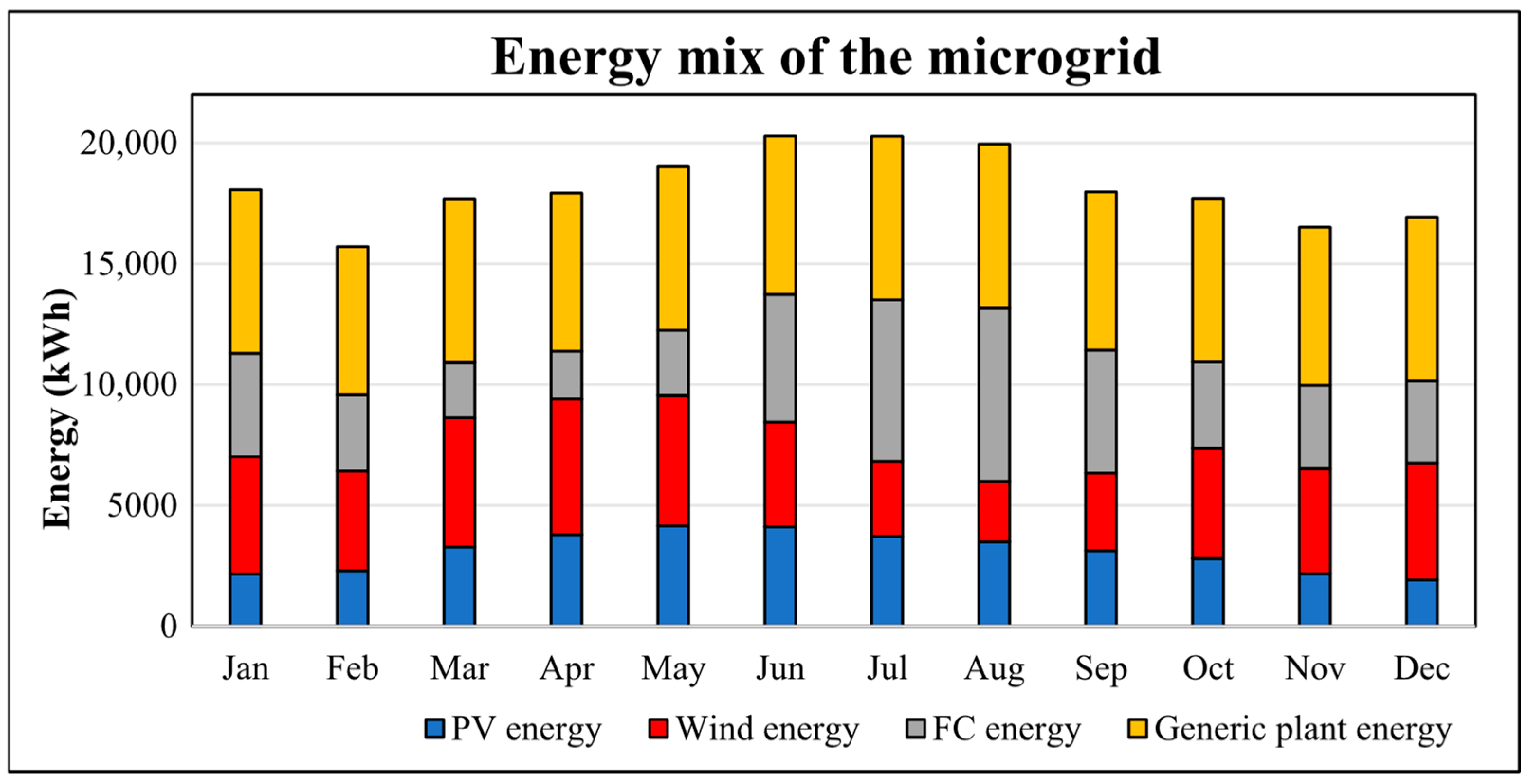

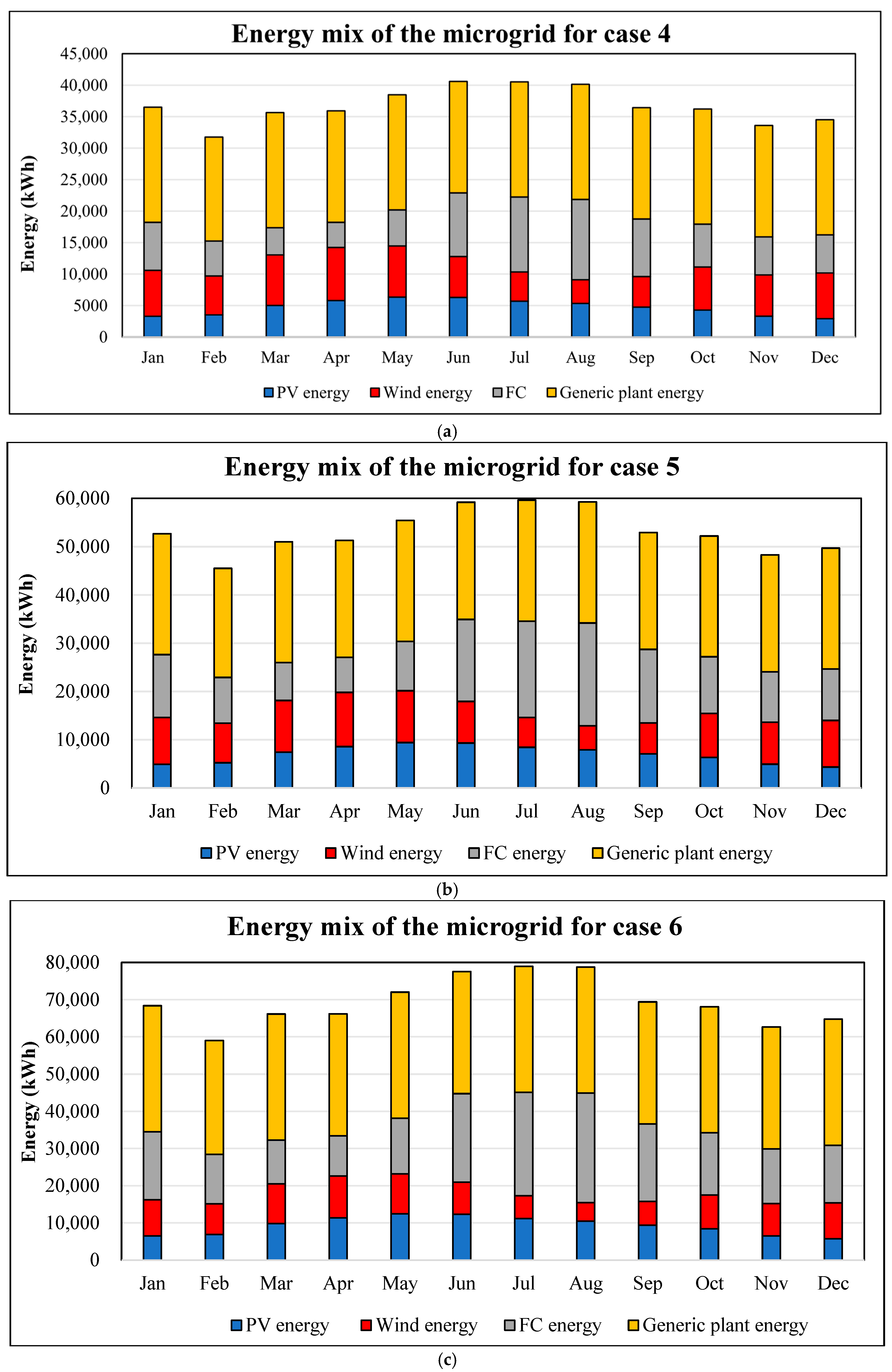

4.1. Energy Mix in the Microgrid

4.2. Sensitivity Analysis

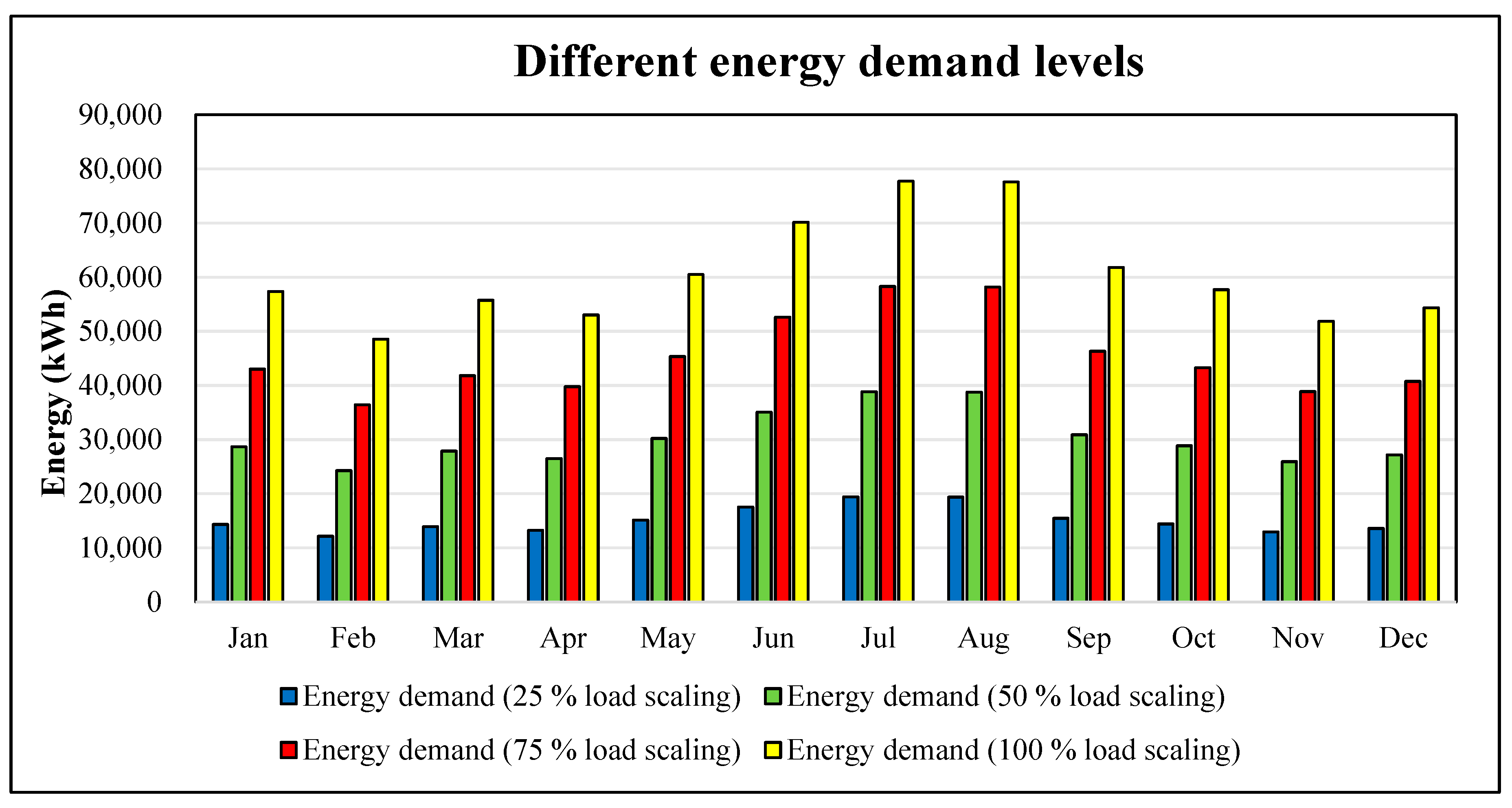

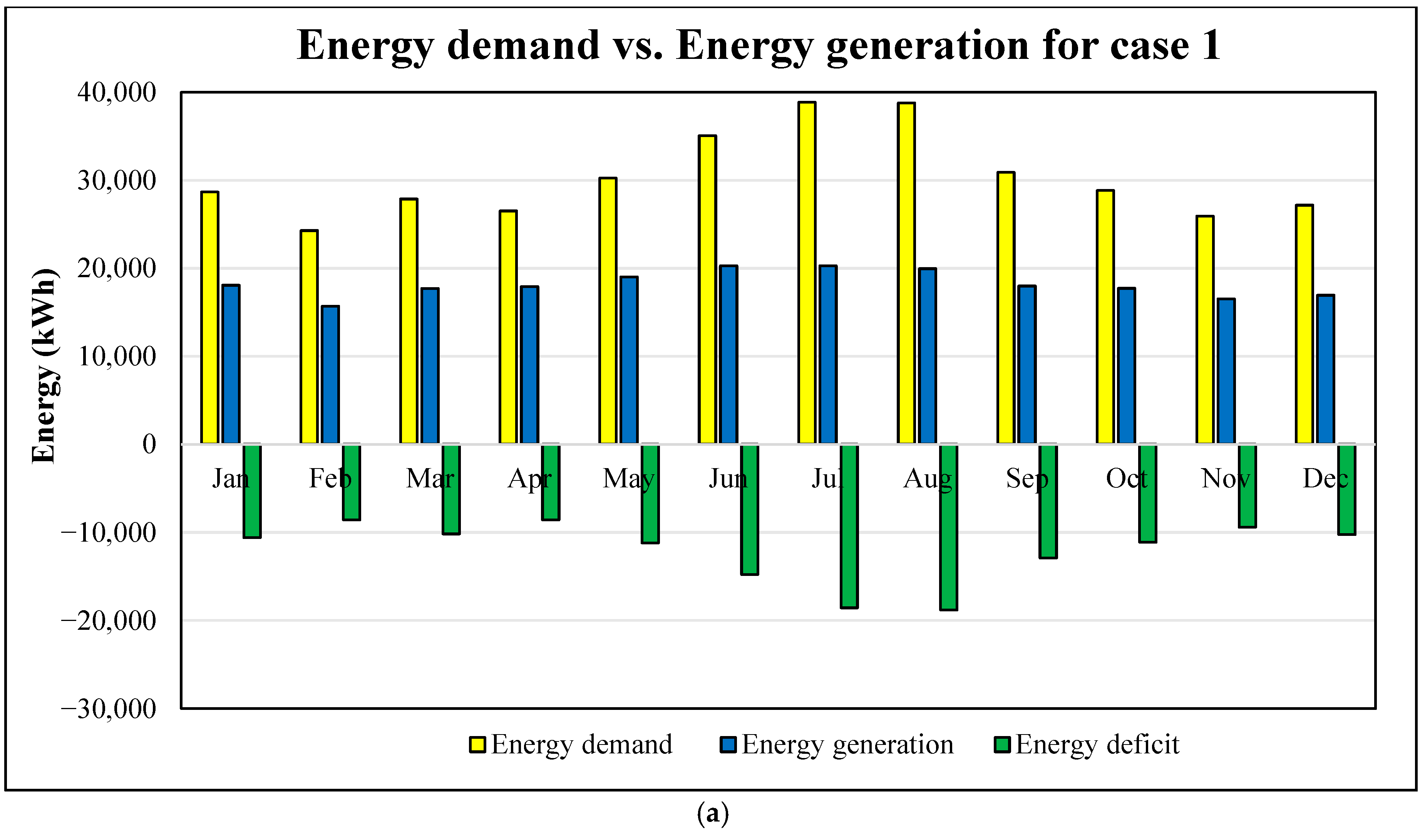

4.2.1. Impact of Load Growth

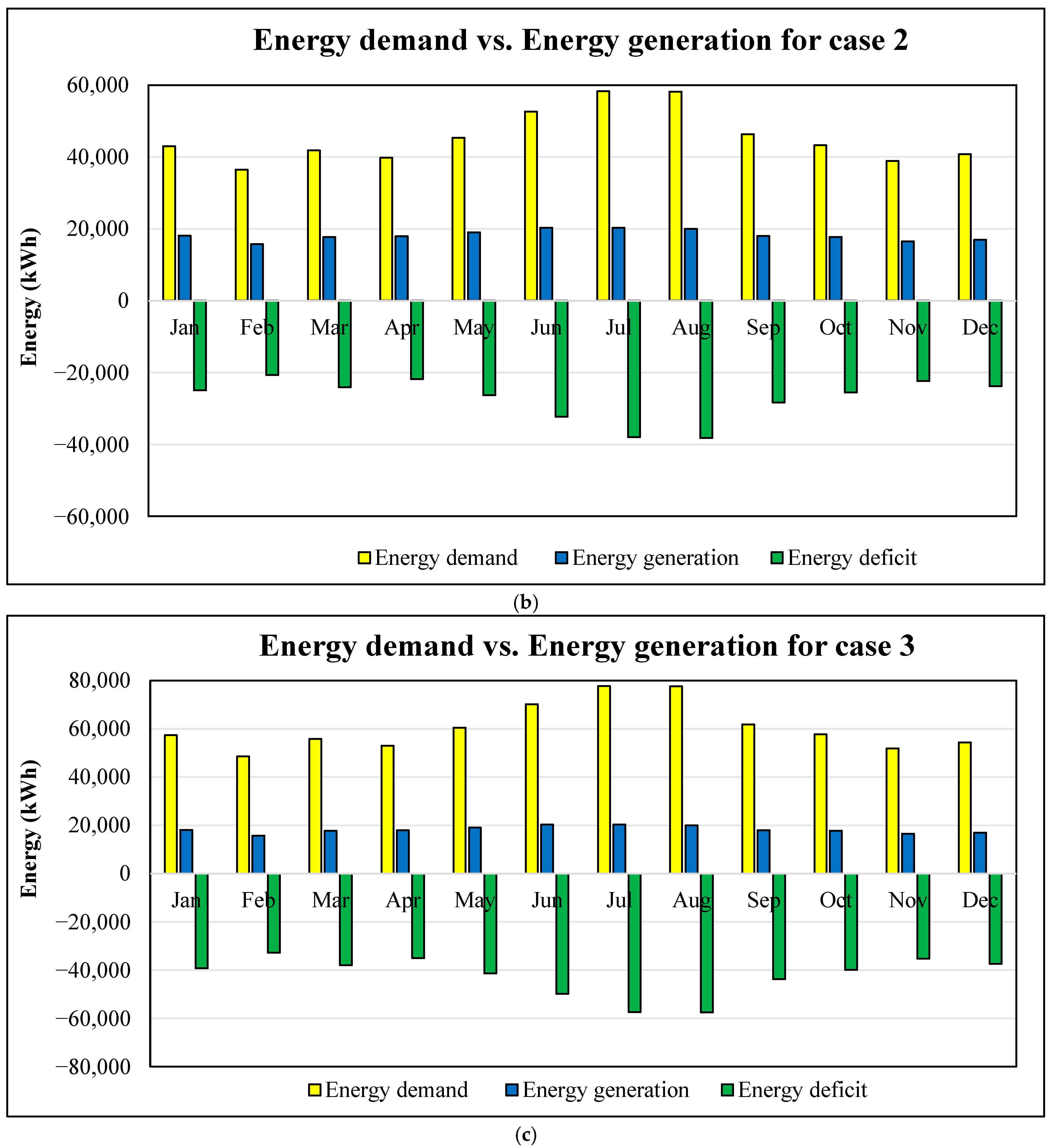

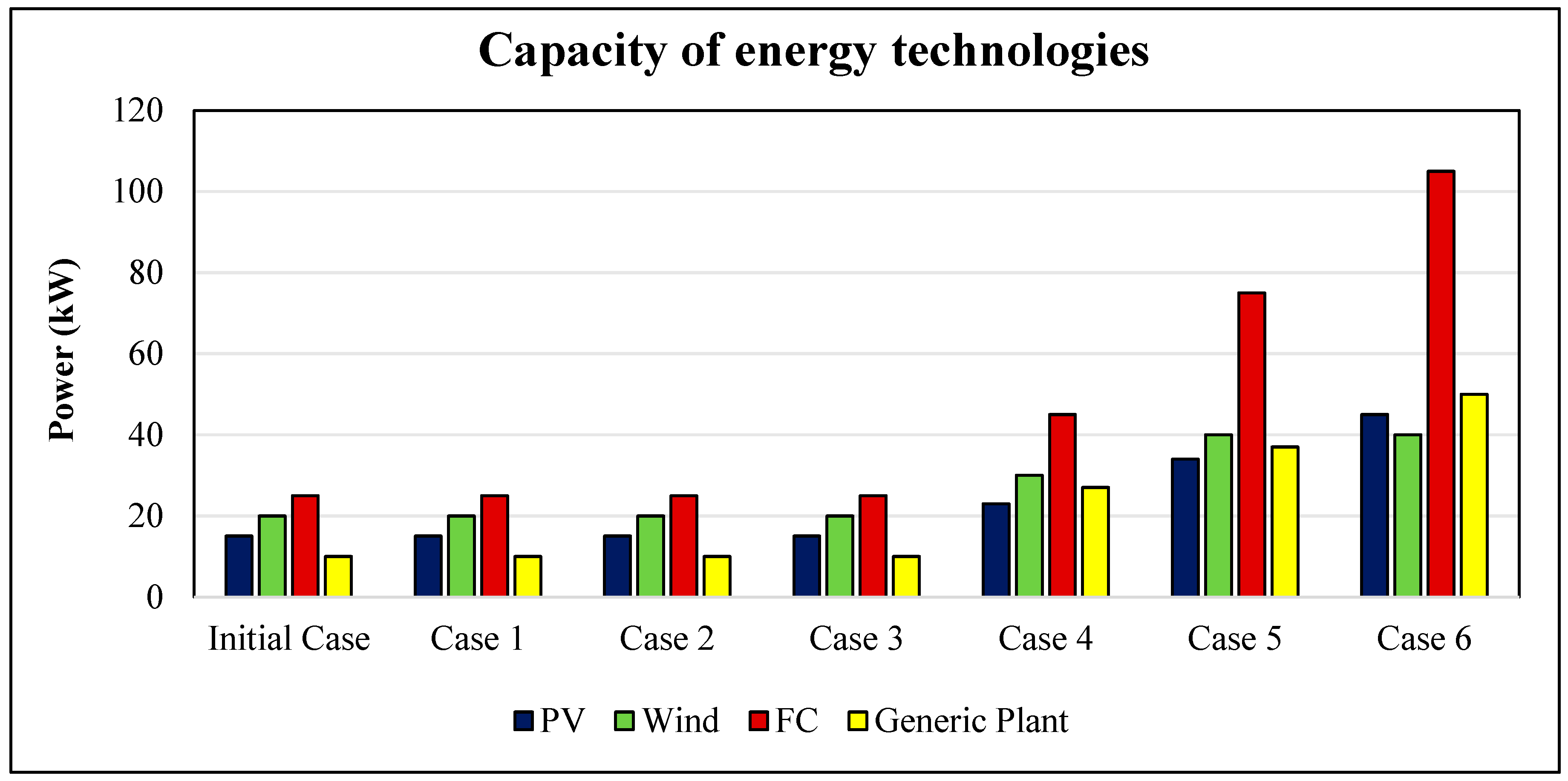

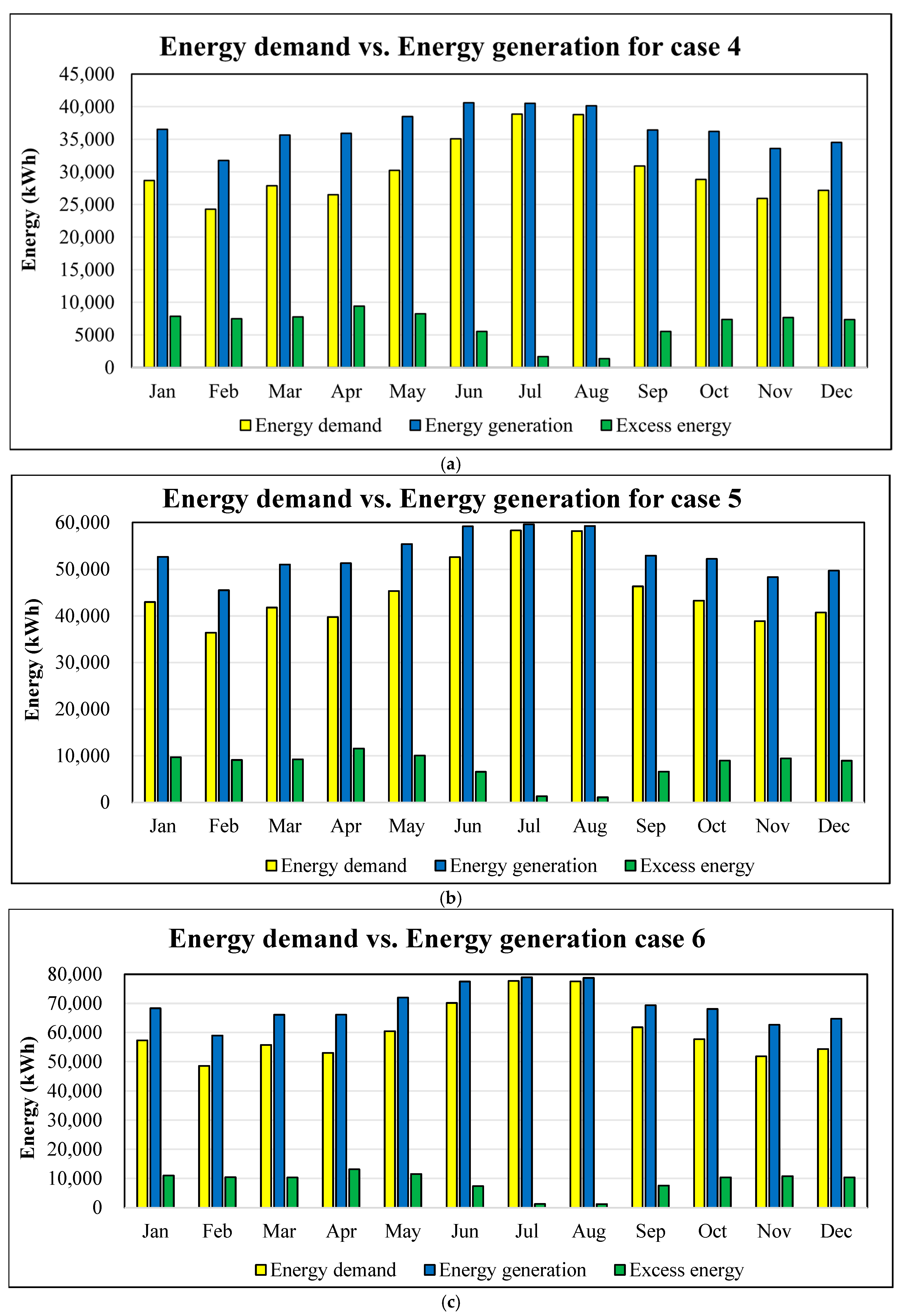

4.2.2. New Microgrid Capacities and Performance

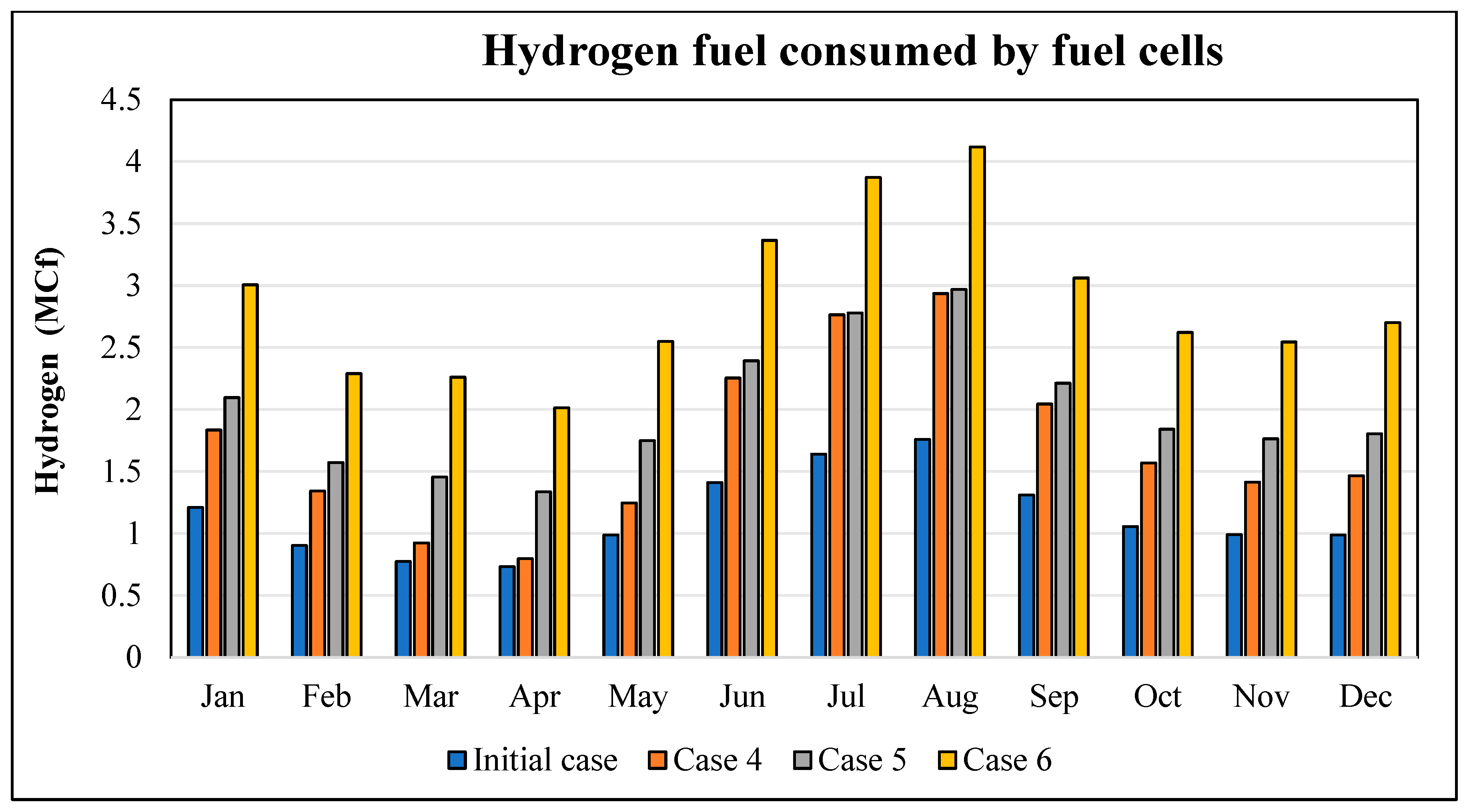

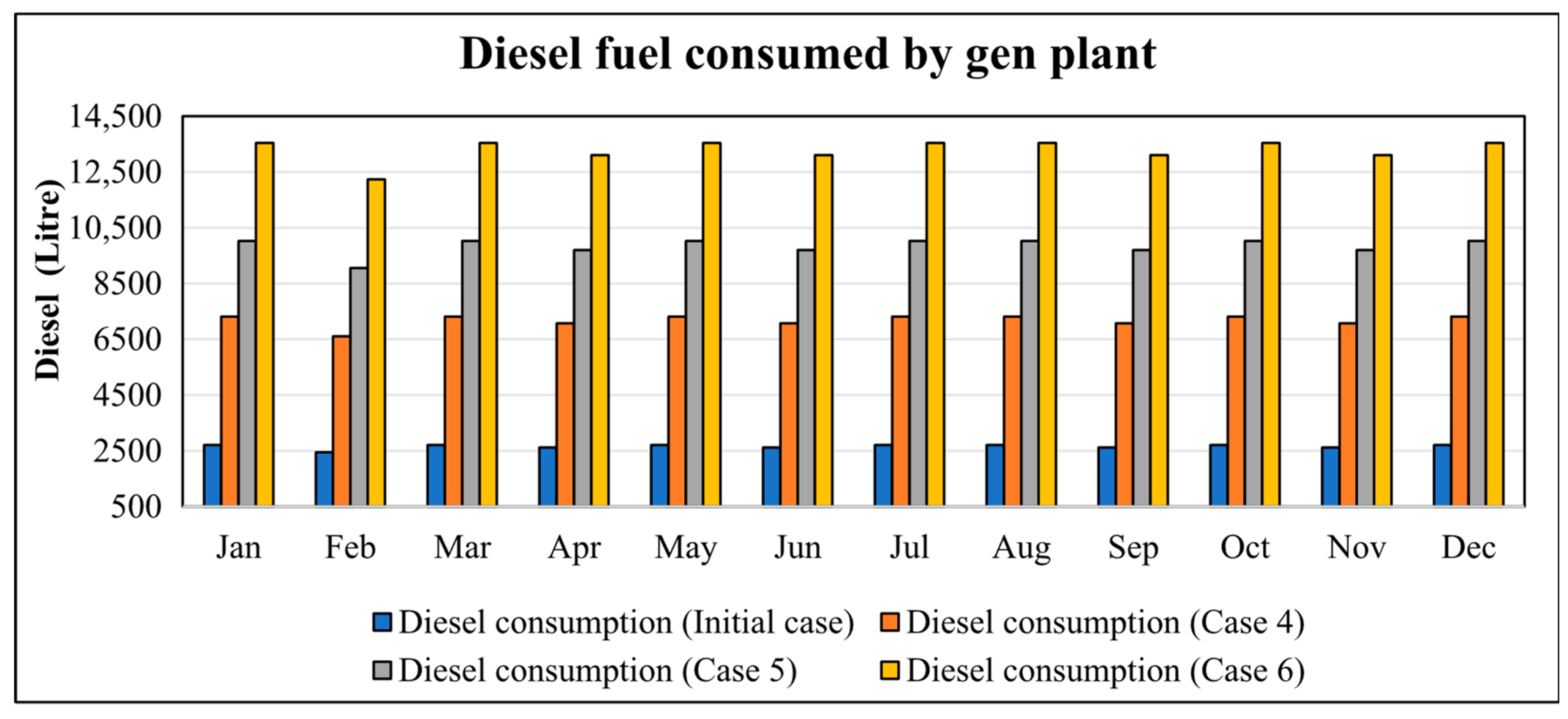

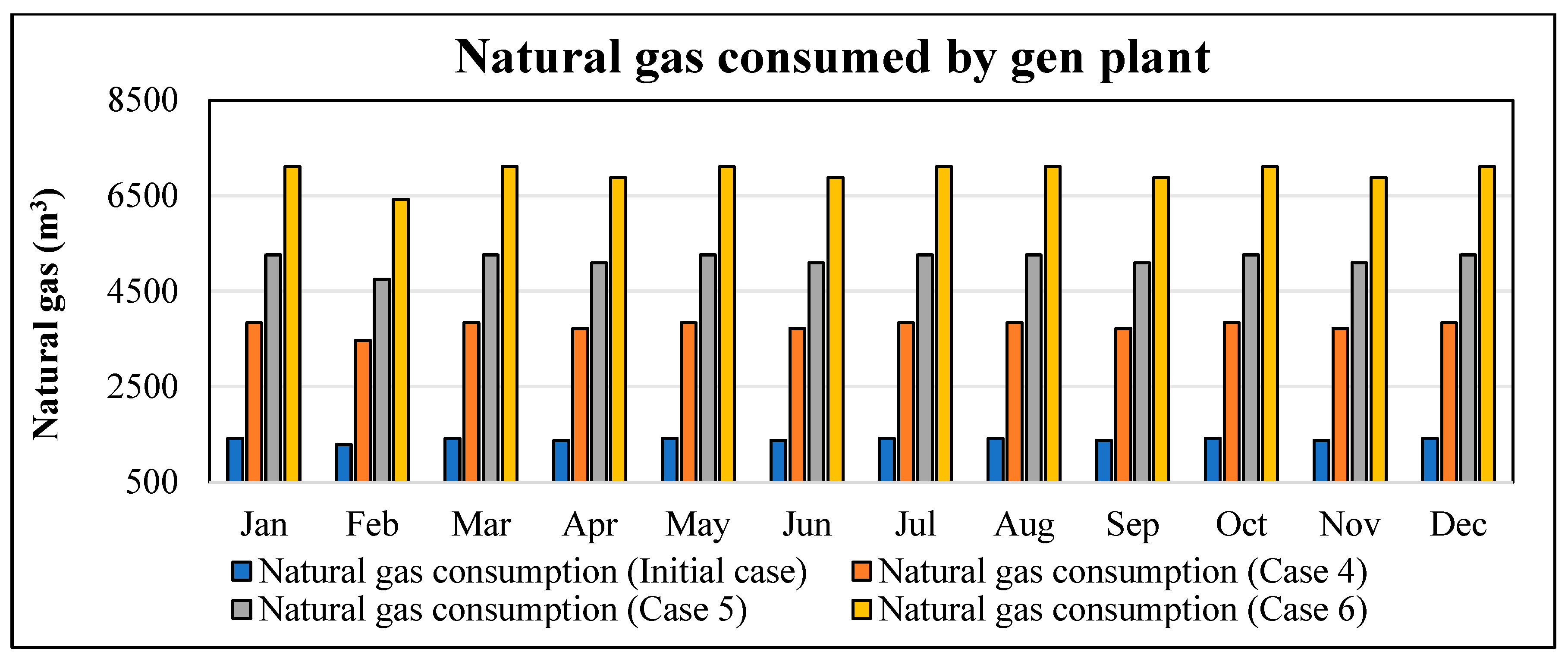

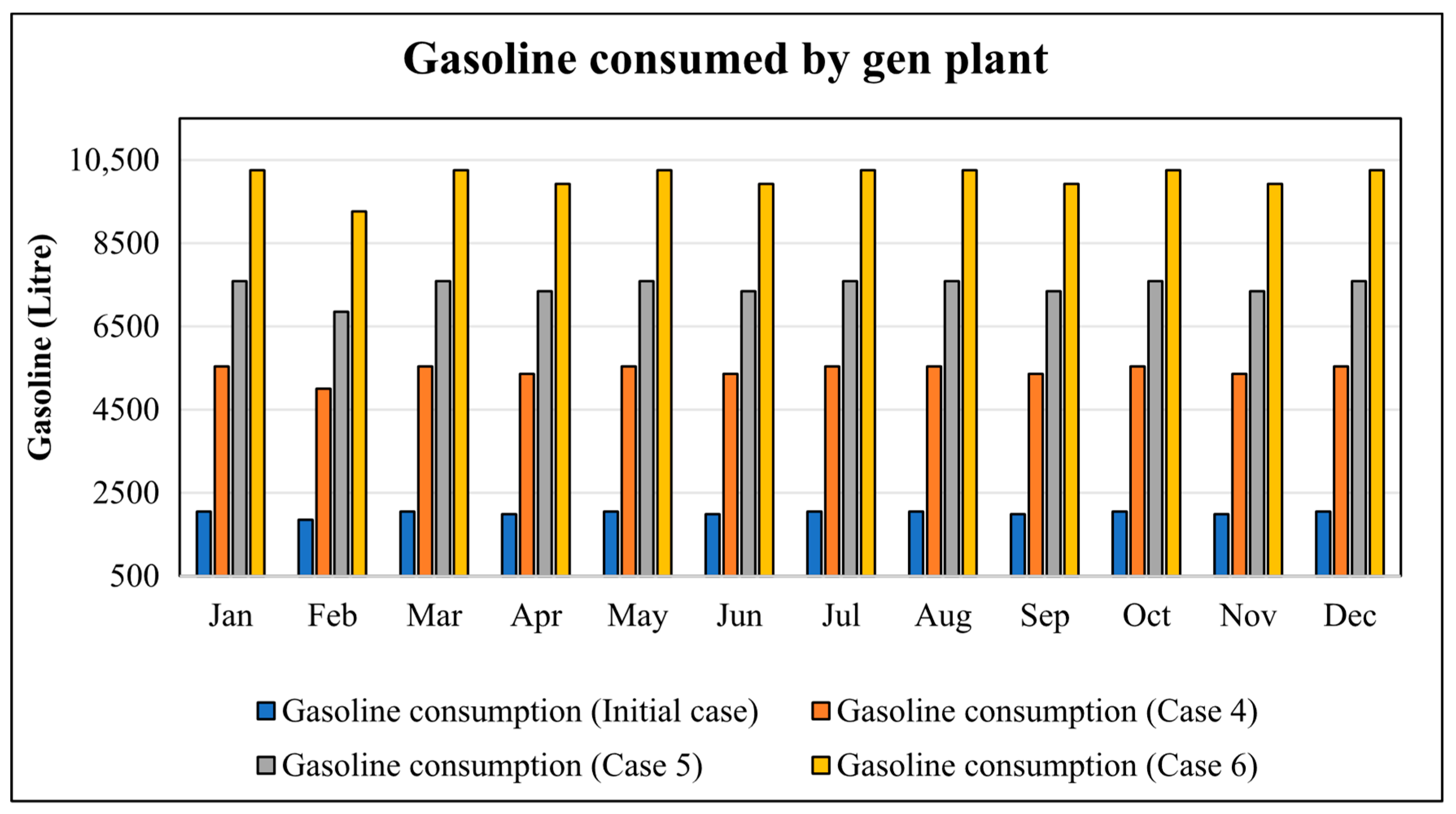

4.2.3. Fuel Consumption by FC and Generic Power Plant

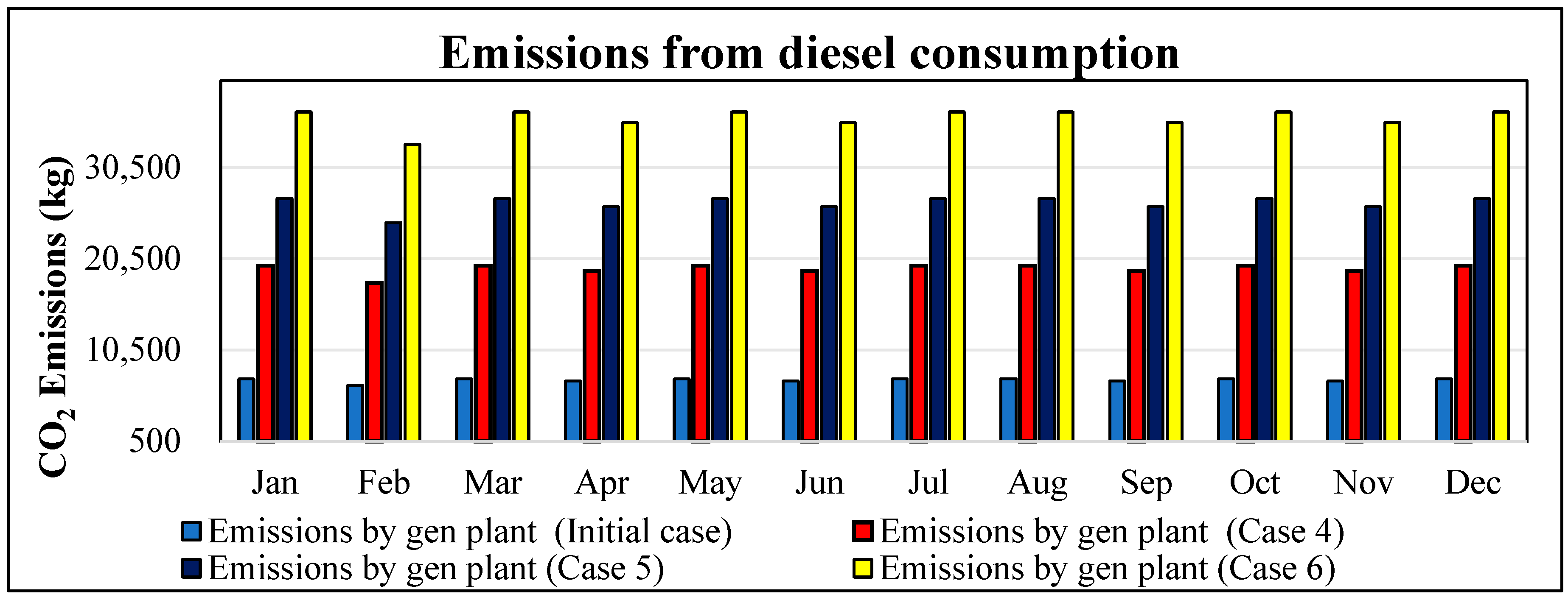

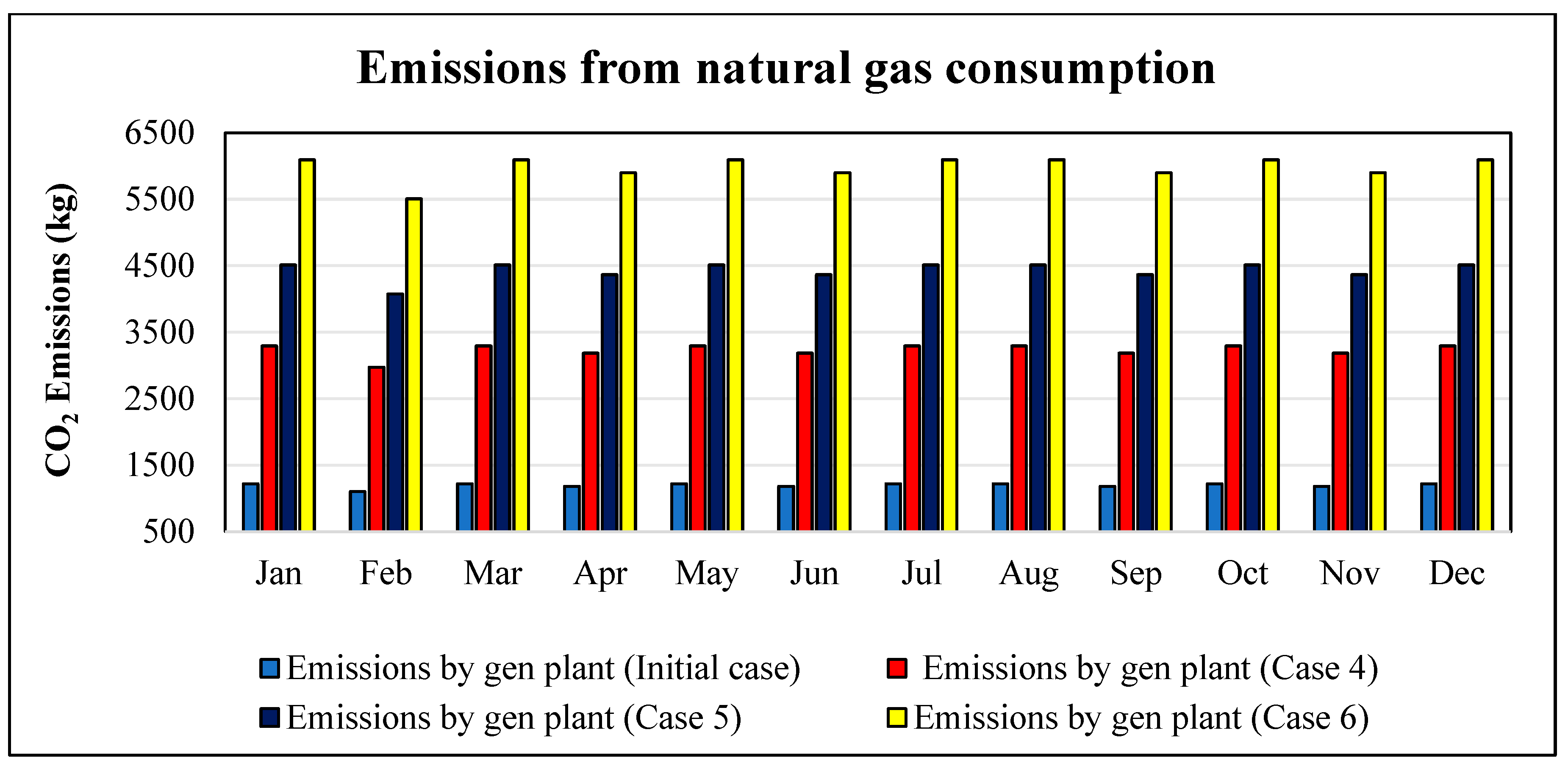

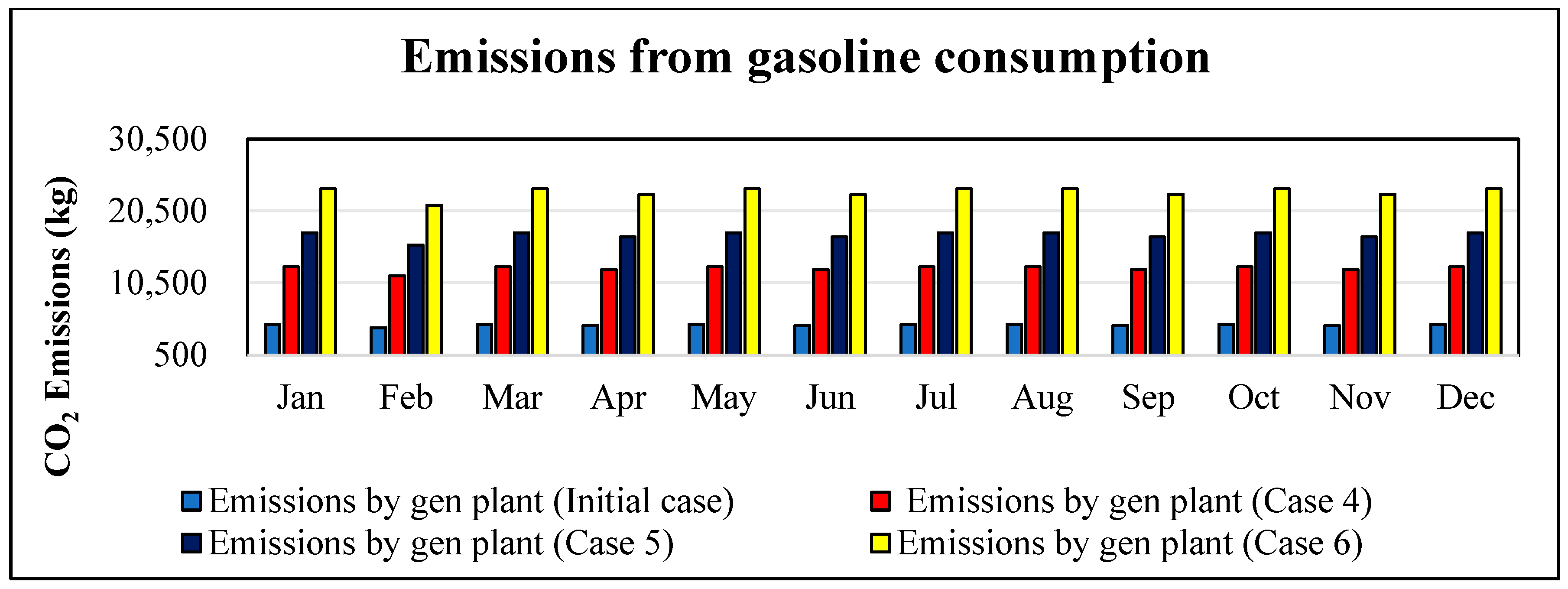

4.2.4. Emissions Analysis for Different Fuels

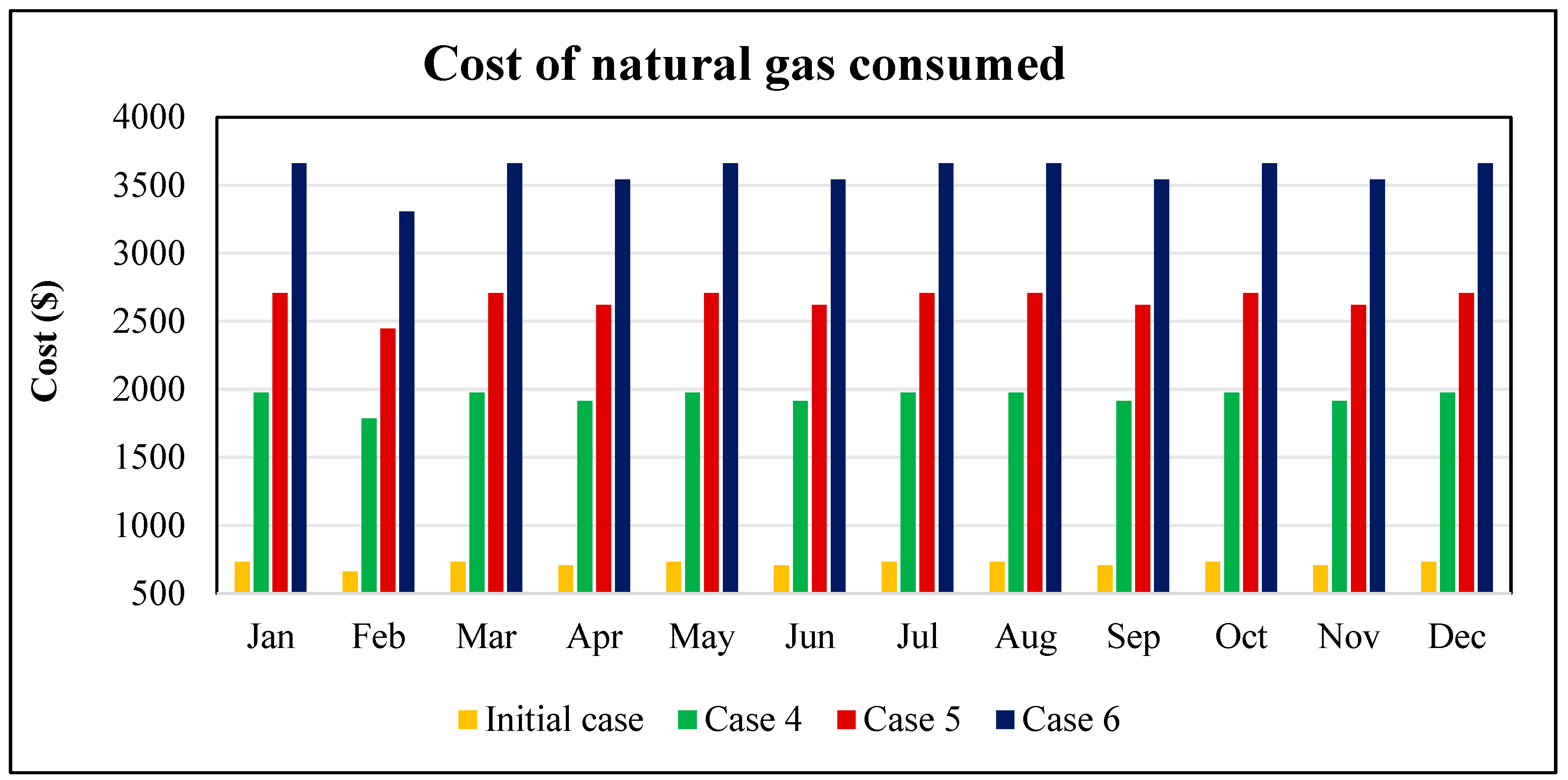

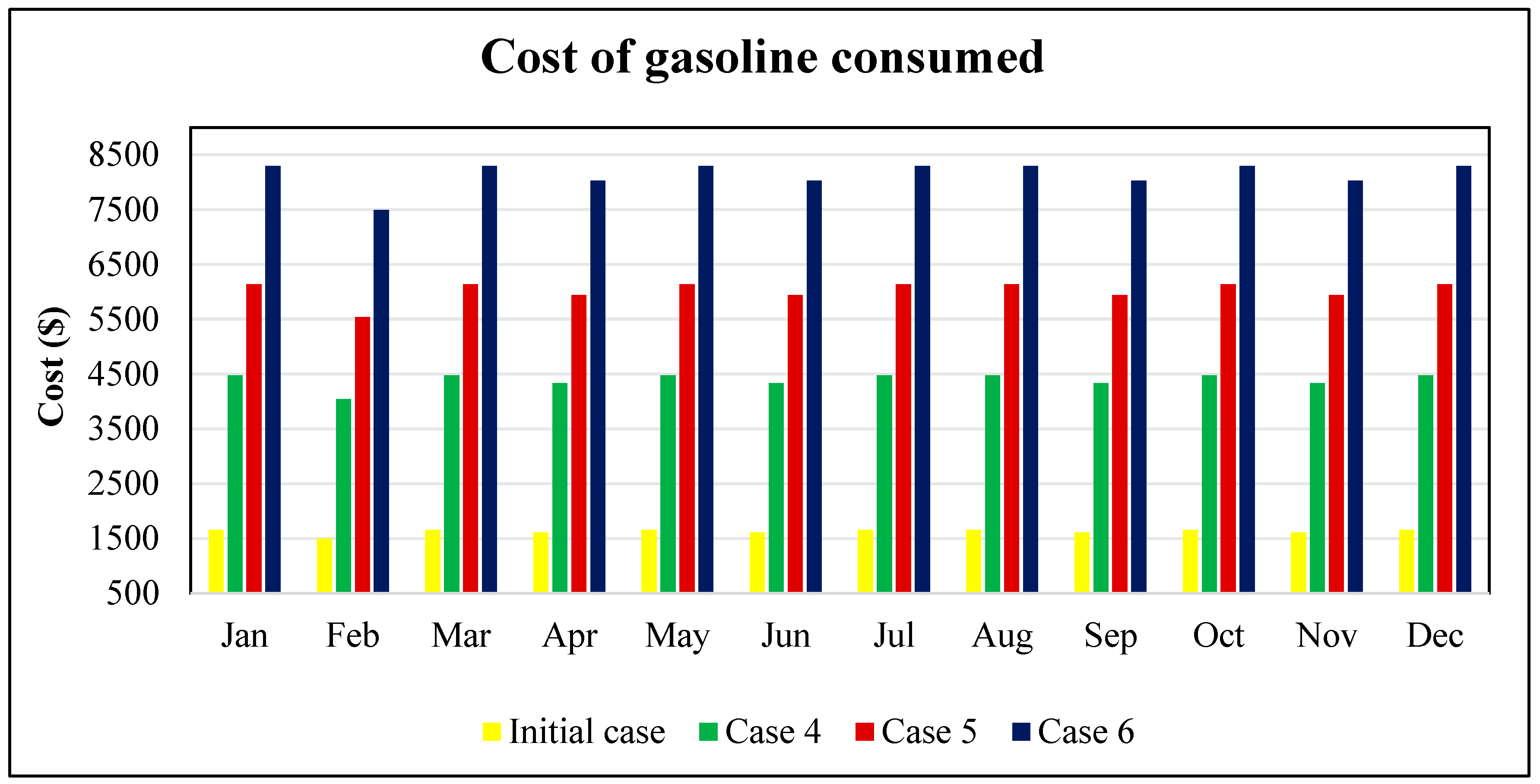

4.2.5. Cost of Fuels Consumed

4.2.6. Direct Capital Costs of Microgrid Subsystem

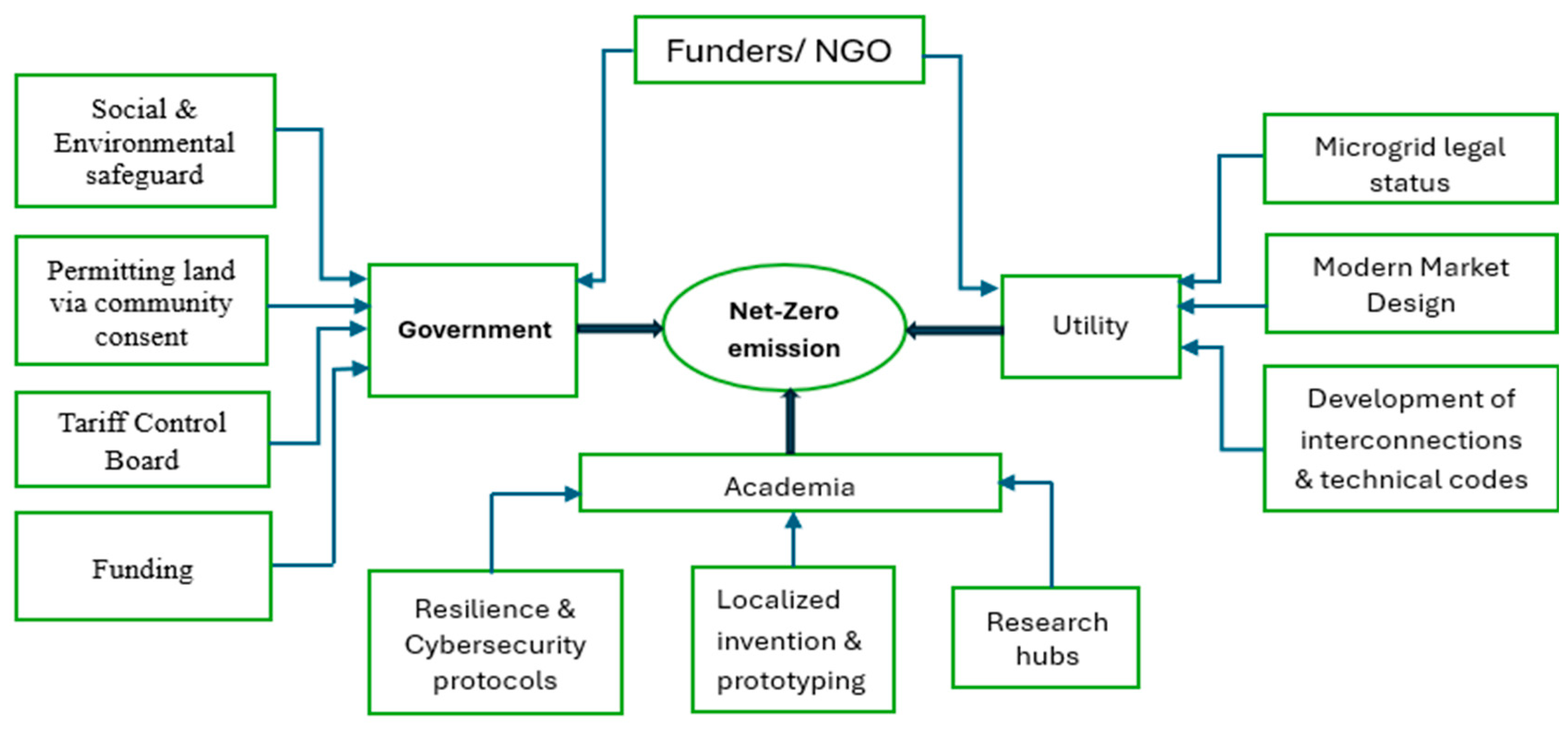

4.3. Proposed Policy Framework for the Multi-Energy-Based Microgrid

4.4. Limitations of the Analysis and Future Work

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FCs | Fuel Cells |

| gE | Green Energy |

| GHGs | Greenhouse Gases |

| gLE | Green Low-Carbon Energy |

| GRPC | Global Renewable Power Capacity |

| LE | Low-Carbon Energy |

| LOESP | Loss of Energy Supply Probability |

| m-grd | Microgrid |

| NREL | National Renewable Energy Laboratory |

| R and D | Research and Development |

| SAM | System Advisor Model |

| SaV | System Availability |

References

- Rozina Emmanuel, O.; Ahmad, M.; Duduyemi, A.; Ahmad, S.; Khan, A.; Esiaba, R.; Elekwachi, C. Valorization of waste seed oil from Cupressus macrocarpa L. for biodiesel production via green-synthesized iron oxide nanoparticles: A sustainable approach toward decarbonization. Next Energy 2025, 7, 100218. [Google Scholar] [CrossRef]

- Raman, A.; Altalbawy, F.M.A.; Ali, A.; Vora, T.; Alkhayyat, A.; Yogi, K.S.; Sapev, I.B.; Dhaliwal, A.S.; Singh, A.; Shafieezadeh, M.M. Enhancing net zero decarbonization strategies: A comparative analysis with the analytic hierarchy process. Int. J. Low-Carbon Technol. 2025, 20, 508–518. [Google Scholar] [CrossRef]

- Xu, X.; Wang, C.; Zhou, P. GVRP considered oil-gas recovery in refined oil distribution: Form an environmental perspective. Int. J. Prod. Econ. 2021, 235, 108078. [Google Scholar] [CrossRef]

- Gong, Q.; Wu, J.; Jiang, Z.; Hu, M.; Chen, J.; Cao, Z. An integrated design method for remanufacturing scheme considering carbon emission and customer demands. J. Clean. Prod. 2024, 476, 143681. [Google Scholar] [CrossRef]

- Xu, A.; Wang, W.; Zhu, Y. Does smart city pilot policy reduce CO2 emissions from industrial firms? Insights from China. J. Innov. Knowl. 2023, 8, 100367. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, Y.; Kong, H. In-depth review of key technologies and pathways to carbon neutrality: Classification and assessment of decarbonization technologies. Carbon Neutrality 2025, 4, 15. [Google Scholar] [CrossRef]

- Davarpanah, A. Comparative evaluation of carbon capture, utilization, ans storage (CCUS) technologies using multi-criteria decision-making approaches. ACS Sustain. Chem. Eng. 2024, 12, 9498–9510. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Q.; Liu, J. Innovating sustainability: VQA-based AI for carbon neutrality challenges. J. Organ. End User Comput. 2024, 36, 1–22. [Google Scholar] [CrossRef]

- Li, T.; Yu, L.; Ma, Y.; Duan, T.; Huang, W.; Zhou, Y.; Jin, D.; Li, Y.; Jiang, T. Carbon emissions of 5G mobile networks in China. Nat. Sustain. 2023, 6, 1620–1631. [Google Scholar] [CrossRef]

- Al Khaffaf, I.; Tamimi, A.; Ahmed, V. Pathways to carbon neutrality: A review of strategies and technologies across sectors. Energies 2024, 17, 6129. [Google Scholar] [CrossRef]

- Wang, F.; Harindintwali, J.D.; Yuan, Z.; Wang, M.; Wang, F.; Li, S.; Yin, Z.; Huang, L.; Fu, Y.; Li, L.; et al. Technologies and perspectives for achieving carbon neutrality. Innovation 2021, 2, 100180. [Google Scholar] [CrossRef]

- Sharma, V.K.; Monteleone, G.; Braccio, G.; Anyanwu, C.N.; Aneke, N.N. A comprehensive review of green energy technologies: Towards sustainable clean energy transition and global net-zero carbon emissions. Processses 2024, 13, 69. [Google Scholar] [CrossRef]

- Ullah, M.; Gutierrez-Rojas, D.; Inkeri, E.; Tynjala, T.; Nardelli, P.H.J. Operation of power-to-X-related processes based on advanced data-driven methods: A comprehensive review. Energies 2022, 15, 8118. [Google Scholar] [CrossRef]

- Palys, M.J.; Daoutidis, P. Power-to-X: A review and perspective. Comput. Chem. Eng. 2022, 165, 107948. [Google Scholar] [CrossRef]

- Skaaret, A. Power-to-X: Challenges and Possibilities in Project Development. Available online: https://www.southernlights.io/industry/what-is-power-to-x/ (accessed on 12 July 2025).

- Ognonnaya, C.; Abeykoon, C.; Damo, U.M.; Turan, A. The current and emerging renewable energy technologies for power generation in Nigeria: A review. Therm. Sci. Eng. Process 2019, 13, 100390. [Google Scholar] [CrossRef]

- Ang, Z.; Salem, M.; Kamarol, M.; Das, H.S.; Nazari, M.A.; Prabaharan, N. A comprehensive study of renewable energy sources: Classifications, challenges and suggestions. Energy Strategy Rev. 2022, 43, 100939. [Google Scholar] [CrossRef]

- Maheshwar, S.; Manglam, M.K.; Sinha, R.K. Advancements in renewable energy harvesting technologies for sustainable power generation. Tuijin Jishu J. Propuls. Technol. 2023, 44, 1371–1377. [Google Scholar]

- Esan, O.C.; Anthony, E.; Obaseki, O. Utilization of renewable energy for improved power generation in Nigeria. J. Phys. Conf. Ser. 2019, 1299, 012026. [Google Scholar] [CrossRef]

- Kiehbadroudinezhad, M.; Hosseinzadeh-Bandbafha, H.; Rosen, M.A.; Kumar, V. The role of energy security and resilience in the sustainability of green microgrids: Paving the way to sustainable and clean production. Sustain. Energy Technol. Assess. 2023, 60, 103485. [Google Scholar] [CrossRef]

- Tatar, M.; Akulker, H.; Sildir, H.; Aydin, E. Optimal design and operation of integrated microgrids under intermittent renewable energy sources coupled with green hydrogen and demand scenarios. Int. J. Hydrogen Energy 2022, 47, 27848–27865. [Google Scholar] [CrossRef]

- Mewafy, A.; Ismael, I.; Kaddah, S.S.; Hu, W.; Chen, Z.; Abulanwar, S. Optimal design of multiuse hybrid microgrids power by green hydrogen–ammonia. Renew. Sustain. Energy Rev. 2024, 192, 114174. [Google Scholar] [CrossRef]

- Ram, K.; Chand, S.S.; Prasad, R.; Mohammadi, A.; Cirrincione, M. Microgrids for green hydrogen production for fuel cell buses—A techno-economic analysis for Fiji. Energy Convers. Manag. 2024, 300, 117928. [Google Scholar] [CrossRef]

- Zhai, Y.; He, Y.; Shao, J.; Zhang, W.; Tong, X.; Wang, Z.; Weng, W. Review of hydrogen-driven power-to-X technology and application status in China. Processes 2024, 12, 1518. [Google Scholar] [CrossRef]

- Marvin, M.K.; Sarkinbaka, Z.M. A review of power-to-X and its prospects for integration in Nigeria’s energy transition plan. Sustain. Energy Res. 2024, 11, 34. [Google Scholar] [CrossRef]

- Kilic, H. Improving the performance of microgrid-based Power-to-X systems through optimization of renewable hydrogen generation. Int. J. Hydrogen Energy 2024, 75, 106–120. [Google Scholar] [CrossRef]

- Quizhpe, K.; Arevalo, P.; Ochoa-Correa, D.; Villa-Avila, E. Optimizing microgrid planning for renewable integration in power systems: A comprehensive review. Electronics 2024, 13, 3620. [Google Scholar] [CrossRef]

- Daiyan, R.; MacGill, I.; Amal, R. Opportunities and challenges of renewable power-to-X. ACS Energy Lett. 2020, 5, 3843–3847. [Google Scholar] [CrossRef]

- REN 21 Global Reneable Energy Status 2025. Available online: https://www.ren21.net/wp-content/uploads/2019/05/25-1395_GO_2025_Full_Report_13opt.pdf (accessed on 2 August 2025).

- Hassan, Q.; Viktor, P.; Al-Musawi, T.J.; Ai, B.M.; Algburi, S.; Alzoubi, H.M.; Al-Jiboory, A.K.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. The renewable energy role in the global energy transformations. Renew. Energy Focus 2024, 48, 100545. [Google Scholar] [CrossRef]

- Henrysson, M.; Swain, R.B.; Swain, A.; Nerini, F.F. Sustainable development goals and wellbeing for resilient societies: Shocks and recovery. Humanit. Soc. Sci. Commun. 2024, 11, 1513. [Google Scholar] [CrossRef]

- Jaysawal, R.K.; Chakraborty, S.; Elangovan, D.; Padmanaban, S. Concept of net zero energy buildings (NZEB)—A literature review. Clean. Eng. Technol. 2022, 11, 100582. [Google Scholar] [CrossRef]

- IEA. Net Zero by 2050: A Roadmap for the Global Energy Sector. Available online: https://www.iea.org/reports/net-zero-by-2050#overview (accessed on 26 June 2025).

- Lou, H.; Hsieh, S. Towards zero: A review on strategies in achieving net-zero-energy and net-zero-carbon buildings. Sustainability 2024, 16, 4735. [Google Scholar] [CrossRef]

- Zheng, X.; Streimikiene, D.; Balezentis, T.; Mardani, A.; Cavallaro, F.; Liao, H. A review of greenhouse gas emission profiles, dynamics, and climate change mitigation efforts across the key climate change players. J. Clean. Prod. 2019, 234, 1113–1133. [Google Scholar] [CrossRef]

- Cholewa, T.; Semmel, M.; Mantei, F.; Güttel, R.; Salem, Q. Process intensification strategies for power-to-x technologies. Chem. Eng. 2022, 6, 13. [Google Scholar] [CrossRef]

- Candelaresi, D.; Spazzafumo, G. The power-to-fuel concept. In Power to Fuel; Academic Press: Cambridge, MA, USA, 2021; pp. 1–15. [Google Scholar]

- Sterner, M.; Specht, M. Power-to-gas and power-to-x—The history and results of developing a new storage concept. Energies 2021, 14, 6594. [Google Scholar] [CrossRef]

- Davidson, F.T.; Nagasawa, K.; Webber, M.E. Electrofuel. Mech. Eng. 2017, 139, 30–35. [Google Scholar] [CrossRef]

- Cigolotti, V.; Genovese, M.; Fragiacomo, P. Comprehensive review on fuel cell technology for stationary applicationsas sustainable and efficient poly-generation energy systems. Energies 2021, 14, 4963. [Google Scholar] [CrossRef]

- Hank, C.; Sternberg, A.; Köppel, N.; Holst, M.; Smolinka, T.; Schaadt, A.; Hebling, C.; Henning, H.M. Energy efficiency and economic assessment of imported energy carriers based on renewable electricity. Sustain. Energy Fuels 2020, 4, 2256–2273. [Google Scholar] [CrossRef]

- Raji, A.A.; Adejumobi, I.A.; Orimolade, J.F.; Amusa, K.A.; Olabode, O.E. Effect of training overhead on the performance of millimeter wave channel estimation models. Univ. Pitesti Sci. Bull. Electron. Comput. Sci. 2024, 24, 1–10. [Google Scholar]

- Akinyele, D.O.; Rayudu, R.K. Review of energy storage technologies for sustainable power networks. Sustain. Energy Technol. Assess. 2014, 8, 74–91. [Google Scholar] [CrossRef]

- Akinyele, D.O.; Olabode, O.E.; Opeyemi, D.A. Modelling and simulation of microgrid system with photovoltaic and biogas co-fired power generating sources for commercial application. In Photovoltaic Materials: Synthesis, Characterizations, and Applications; CRC Press, Taylor and Francis: Boca Raton, FL, USA, 2025; In Press. [Google Scholar]

- Panchawadkar, D. Review of Opportunities to Valorise the Oxygen Generated from Water Electrolysis. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2024; pp. 1–58. [Google Scholar]

- Assessment of Green Hydrogen for Industrial Heat. 2023. Available online: https://www.renewablethermal.org/wp-content/uploads/2018/06/Assessment-of-Green-Hydrogen-for-Industrial-Heat.pdf (accessed on 7 July 2024).

- Power-to-X: Transforming Renewable Energy for a Sustainable Future. Available online: https://www.greengoenergy.com/power-to-x (accessed on 8 July 2025).

- Power-to-X: Bridging the Gap for a Sustainable Energy Future. Available online: https://www.powerpartners-awi.com/power-to-x-bridging-the-gap-for-a-sustainable-energy-future/ (accessed on 8 July 2025).

- Budt, M.; Wolf, D.; Span, R.; Yan, J. A review on compressed air energy storage: Basic principles, past milestones and recent developments. Appl. Energy 2016, 170, 250–268. [Google Scholar] [CrossRef]

- Mosca, L.; Palo, E.; Colozzi, M.; Iaquaniello, G.; Salladini, A.; Taraschi, S. Hydrogen in chemical and petrochemical industry. In Current Trends and Future Developments on (Bio-) Membranes; Elsevier: Amsterdam, The Netherlands, 2020; pp. 387–410. [Google Scholar]

- Olabode, O.E.; Ayantunji, O.D.; Nwagbara, V.U. Performance evaluation of reactive power compensation of tcsc and svc on voltage profile enhancement and power system loss minimization using firefly algorithm. Int. J. Sci. Eng. Res. 2017, 8, 1514–1519. [Google Scholar]

- Dahiru, A.R.; Vuokila, A.; Huuhtanen, M. Recent development in power-to-x: Part I—A review on techno-economic analysis. J. Energy Storage 2020, 56, 105861. [Google Scholar] [CrossRef]

- Glenk, G.; Reichelstein, S. Economics of converting renewable power to hydrogen. Nat. Energy 2019, 4, 216–222. [Google Scholar] [CrossRef]

- Li, Y.; Guan, B.; Guo, J.; Chen, Y.; Ma, Z.; Zhuang, Z.; Zhu, C.; Dang, H.; Chen, L.; Shu, K.; et al. Renewable synthetic fuels: Research progress and development trends. J. Clean. Prod. 2024, 450, 141849. [Google Scholar] [CrossRef]

- Doğan, A.; Yüksel, G.; Uğur, A.; Boy, M.; Kayabaş, E.; Demirsöz, R. Synthetic fuels as a cornerstone of net-zero emissions: A review of production methods and future prospects. DCE Doğa Bilimleri Dergisi 2025, 5, 113–131. [Google Scholar]

- Li, S.; Jin, H.; Gao, L.; Zhang, X.; Ji, X. Techno-economic performance and cost reduction potential for the substitute/synthetic natural gas and power cogeneration plant with CO2 capture. Energy Convers. Manag. 2014, 85, 875–887. [Google Scholar] [CrossRef]

- Audi E-Gas Project, Germany. Available online: https://www.power-technology.com/marketdata/audi-e-gas-project-germany/ (accessed on 29 July 2025).

- Norsk E-Fuel; Project Scaling Production to Make Aviation Sustainable. Available online: https://www.norsk-e-fuel.com/projects (accessed on 29 July 2025).

- Carlsson, I.Y. World’s First Commercial-Scale E-Methanol Plant Opens in Denmark. 2025. Available online: https://www.reuters.com/sustainability/climate-energy/worlds-first-commercial-scale-e-methanol-plant-opens-denmark-2025-05-13/ (accessed on 29 July 2025).

- Advances in Renewable Energy and the Rise of Green Hydrogen in Spain. Available online: https://www.moeveglobal.com/en/planet-energy/green-energy/spain-renewable-energy-transition-green-hydrogen (accessed on 29 July 2025).

- World’s First Commercial CO2 to Methanol Plant. Available online: https://repository.gatech.edu/entities/publication/57082baa-0389-433c-ad95-e2402d0f450e (accessed on 29 July 2025).

- Valluri, S.; Claremboux, V.; Kawatra, S. Opportunities and challenges in CO2 utilization. J. Environ. Sci. 2022, 113, 322–344. [Google Scholar] [CrossRef]

- Bridge, G.; Özkaynak, B.; Turhan, E. Energy infrastructure and the fate of the nation: Introduction to special issue. Energy Res. Soc. Sci. 2018, 41, 1–11. [Google Scholar] [CrossRef]

- Segovia-Hernández, J.G. Advancing E-fuels production through process intensification: Overcoming challenges and seizing opportunities for a sustainable energy future—A critical review. Chem. Eng. Process.-Process Intensif. 2025, 208, 110107. [Google Scholar] [CrossRef]

- Prajapati, S.K.; Choudhary, S.; Kumar, V.; Dayal, P.; Srivastava, R.; Gairola, A.; Borate, R.B. Carbon sequestration: A key strategy for climate change mitigation towards a sustainable future. Emerg. Trends Clim. Change 2023, 2, 1–14. [Google Scholar]

- Lønborg, C.; Carreira, C.; Jickells, T.; Álvarez-Salgado, X.A. Impacts of global change on ocean dissolved organic carbon (DOC)cycling. Front. Mar. Sci. 2020, 7, 466. [Google Scholar] [CrossRef]

- Ma, T.; Wang, T.; Yang, D.; Yang, S. Impacts of vegetation restoration on water resources and carbon sequestration in the mountainous area of Haihe Riverbasin, China. Sci. Total Environ. 2023, 869, 161724. [Google Scholar] [CrossRef]

- Zhang, Z.; Wan, X.; Sheng, K.; Sun, H.; Jia, L.; Peng, J. Impact of carbon sequestration by terrestrial vegetation on economic growth: Evidence from Chinese country satellite data. Sustainability 2023, 15, 1369. [Google Scholar] [CrossRef]

- Bai, Y.; Cotrufo, M.F. Grassland soil carbon sequestration: Current understanding, challenges, and solutions. Science 2022, 377, 603–608. [Google Scholar] [CrossRef]

- Jung, S.; Park, Y.; Kwon, E.E. Strategic use of biochar for CO2 capture and sequestration. J. CO2 Util. 2019, 32, 128–139. [Google Scholar] [CrossRef]

- Saraf, S.; Bera, A. Carbon dioxide injection for enhanced oil recovery and underground storage to reduce greenhouse gas. In Green Sustainable Process for Chemical and Environmental Engineering and Science; Elsevier: Amsterdam, The Netherlands, 2023; pp. 149–176. [Google Scholar]

- Raza, A.; Glatz, G.; Gholami, R.; Mahmoud, M.; Alafnan, S. Carbon mineralization and geological storage of CO2 in basalt: Mechanisms and technical challenges. Earth-Sci. Rev. 2022, 229, 104036. [Google Scholar] [CrossRef]

- Biochar: Essential in Carbon Dioxide Removal Portfolios. Available online: https://www.weforum.org/stories/2023/11/biochar-carbon-removals-jack-of-all-trades-for-immediate-climate-action/ (accessed on 29 July 2025).

- Sodiq, A.; Abdullatif, Y.; Aissa, B.; Ostovar, A.; Nassar, N.; El-Naas, M.; Amhamed, A. A review on progress made in direct air capture of CO2. Environ. Technol. Innov. 2023, 29, 102991. [Google Scholar] [CrossRef]

- Carbon Capture and Storage in the United States. Available online: https://www.cbo.gov (accessed on 30 July 2025).

- Australia’s Carbon Sequestration Potential. Available online: https://research.csiro.au/tnz/australias-carbon-sequestration-potential/ (accessed on 30 July 2025).

- Ababneh, H.; Hameed, B.H. Electrofuels as emerging new green alternative fuel: A review of recent literature. Energy Convers. Manag. 2022, 254, 115213. [Google Scholar] [CrossRef]

- Nemmour, A.; Inayat, A.; Janajreh, I.; Ghenai, C. Green hydrogen-based e-fuels (E-methane, E-methanol, E-ammonia) to support clean energy transition: A literature review. Int. J. Hydrogen Energy 2023, 48, 29011–29033. [Google Scholar] [CrossRef]

- E-Methanol: A Game Changer for Decarbonising Heavy Transport and Industry. Available online: https://europeanenergy.com/wp-content/uploads/2025/02/e-methanol-a-game-changer-for-decarbonising-heavy-transport-and-industry-2.pdf (accessed on 31 July 2025).

- Souissi, N. E-Diesel in the Shipping Sector: Prospects and Challenges. Master’s Thesis, Oxford Institute for Energy Studies, Oxford, UK, 2024; pp. 1–28. [Google Scholar]

- Okelola, M.O.; Olabode, O.E. Application of root mean square and adaptive neuro-fuzzy inference system for power quality events classification using electrical and electronics home appliances as case study. IOSR J. Electr. Electron. Eng. 2018, 13, 15–23. [Google Scholar]

- Ellis, T.; Gerrish, R.; Michel, G. E-fuels: A challenging journey to a low-carbon future. Available online: https://www.spglobal.com/ratings/en (accessed on 15 July 2024).

- Olabode, O.E.; Arowolo, O.A.; Arowolo, M.P. A comparative application of shunt capacitor and load tap—Changing transformer (LTCT) to the optimal economic dispatch of generation on Nigerian 330kV, 24-bus grid system. Int. J. Sci. Eng. Res. 2017, 8, 1017–1023. [Google Scholar]

- Winton, N. Germany Wins European E-Fuels Concession; Nothing Much Changes. 2023. Available online: https://www.forbes.com/sites/neilwinton/2023/03/30/germany-wins-european-e-fuels-concession-nothing-much-changes/ (accessed on 31 July 2025).

- E-Fuel Alliance: First Steps: German Government and EU Commission Agreed on eFuels for New Vehicles. Available online: https://www.efuel-alliance.eu/fileadmin/Downloads/Pressemitteilungen_2023/20230325_PM_eFuel_COM_Agreement_final_EN_JW.pdf (accessed on 31 July 2025).

- Driving the Transition to Renewable Aviation. Available online: https://www.norsk-e-fuel.com/ (accessed on 31 July 2025).

- Norwegian Becomes Co-Owner of Norsk E-Fuel. Available online: https://media.uk.norwegian.com/pressreleases/norwegian-becomes-co-owner-of-norsk-e-fuel-3297613 (accessed on 31 July 2025).

- eFuels Pilot Plant in Chile Officially Opened. Available online: https://newsroom.porsche.com/en/2022/company/porsche-highly-innovative-fuels-hif-opening-efuels-pilot-plant-haru-oni-chile-synthetic-fuels-30732.html (accessed on 31 July 2025).

- Japan’s Road Map for Fuel Ammonia. Available online: https://ammoniaenergy.org/articles/japans-road-map-for-fuel-ammonia/ (accessed on 31 July 2025).

- Jameel, M.K.; Mustafa, M.A.; Ahmed, A.S.; Mohammed, A.J.; Ghazy, H.; Shakir, M.N.; Lawas, A.M.; Mohammed, S.K.; Idan, A.H.; Mahmoud, Z.H.; et al. Biogas: Production, properties, applications, economic and challenges: A review. Results Chem. 2024, 7, 101549. [Google Scholar] [CrossRef]

- Silva, J.; Gonclaves, J.C.; Rocha, C.; Vilaca, J.; Madeira, L.M. Biometane production from biogas obtained in wastewater treatment plants: Process optimization and economic analysis. Renew. Energy 2024, 220, 119469. [Google Scholar] [CrossRef]

- Man Energy. Power-to-X Solutions. Available online: https://www.man-es.com (accessed on 30 June 2025).

- System Advisor Model. Available online: https://sam.nrel.gov/ (accessed on 24 June 2025).

- Dobos, A.P. PVWAtts Version 5 Manual; Technical Report: NREL/TP-6A20-62641; National Renewable Energy Laboratory: Golden, CO, USA, 2014. Available online: www.nrel.gov/publications (accessed on 30 November 2024).

- Fuentes, M.K. A Simplified Thermal Model for Flat-Plate Photovoltaic Arrays; SAND85-0330; Sandia National Laboraties: Albuquerque, NM, USA, 1987. [Google Scholar]

- Deshmukh, M.K.; Deshmukh, S.S. Modeling of hybrid renewable energy systems. Renew. Sustain. Energy Rev. 2008, 23, 5–249. [Google Scholar] [CrossRef]

- Diaf, S.; Belhamel, M.; Haddadi, M.; Louche, A. Technical and economic assessment of hybrid photovoltaic/wind system with battery storage in Corsica island. Energy Policy 2008, 36, 754. [Google Scholar] [CrossRef]

- Kaabeche, A.; Belhamel, M.; Ibtiouen, R. Techno-economic valuation and optimization of integrated photovoltaic/wind energy conversion system. Sol. Energy 2011, 85, 2407–2420. [Google Scholar] [CrossRef]

- Akinyele, D. Techno-economic design and performance analysis of nanogrid systems for households in energy-poor villages. Sustain. Cities Soc. 2017, 34, 335–357. [Google Scholar] [CrossRef]

- Freeman, J.; Gilman, P.; Jorgenson, J.; Ferguson, T. Reference Manual for the System Advisor Model’s Wind Performance Model; NREL/TP-6A20-60570; National Renewable Energy Laboratory: Golden, CO, USA, 2014. [Google Scholar]

- Ghenai, C.; Salameh, T.; Merabet, A. Techno-economic analysis of off-grid solar PV/fuel cell energy system for residential community in desert region. Int. J. Hydrogen Energy 2020, 45, 11460–11470. [Google Scholar] [CrossRef]

- Yuksel, O.; Blanco-Davis, E.; Spiteri, A.; Hitchmough, D.; Shagar, V.; Di Piazza, M.C.; Pucci, M.; Tsoulakos, N.; Armin, M.; Wang, J. Optimising the design of a hybrid fuel cell/battery and waste heat recovery system for retrofitting ship power generation. Energies 2025, 18, 288. [Google Scholar] [CrossRef]

- Akinyele, D.O.; Rayudu, R.K.; Nair, N.K.C. Grid-independent renewable energy solutions for residential use: The case of an off-grid house in wellington, New Zealand. In Proceedings of the IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Brisbane, QLD, Australia, 15–18 November 2015; pp. 1–5. [Google Scholar]

- Khatib, T.; Mohamed, A.; Sopina, K.; Mahmoud, M. A new approach for optimal sizing of stand-alone photovoltaic systems. Int. J. Photoenergy 2012, 2012, 391213. [Google Scholar] [CrossRef]

- Posadillo, R.; Lopez Luque, R. A sizing method for stand-alone PV installations with variable demand. Renew. Energy 2008, 33, 1049–1055. [Google Scholar] [CrossRef]

- Shen, W.X. Optimally sizing of solar array and battery in a stand-alone photovoltaic system in Malaysia. Renew. Energy 2009, 34, 348–352. [Google Scholar] [CrossRef]

- Short, W.; Packey, D.J.; Holt, T. Manual for the Economic Evalaution of Energy Efficiency and Renewable Energy Technologies; NREL/TP-462-5173; National Renewable Energy Laboratory: Golden, CO, USA, 1995; pp. 39–42. Available online: http://www.nrel.gov/docs/legosti/old/5173.pdf (accessed on 28 August 2025).

- Energy Education. Diesel Generator. Available online: https://energyeducation.ca/encyclopedia/Diesel_generator#:~:text=This%20mechanical%20energy%20then%20rotates,gasoline%2C%20wood%20gas%20and%20diesel (accessed on 29 June 2025).

- Paul, U.; Hasan, M.M.; Labib, L.; Roy, N.K. Optimal design of hybrid microgrids for readymade garments industry of Bangladesh: A case study. In Proceedings of the 3rd International Conference on Electrical Information and Communication Technology (EICT), Khulna, Bangladesh, 7–9 December 2017. [Google Scholar]

- EIA. How Much Coal, Natural Gas, or Petroleum Is Used to Generate a Kilowatthour of Electricity? Available online: https://eia.gov/tools/faqs/faq.php?id=667&t=6 (accessed on 2 July 2025).

- Emission Factor for Fuels. Available online: https://cultureforclimate.scot/services/environmental-reporting/guidance-for-reporting-organisations/emission-factors (accessed on 3 July 2025).

- Natural Resources Canada. Learn the Facts: Fuel Consumption and CO2. Available online: https://natural-resources.canada.ca (accessed on 3 July 2025).

- Green H2 to Undercut Gray Sibling by End of Decade. Available online: https://about.bnef.com/insights/clean-energy/green-hydrogen-to-undercut-gray-sibling-by-end-of-decade/ (accessed on 4 July 2025).

- DOE Sets Eyes on Cutting Clean Hydrogen Cost, $/kg by 2030. Available online: https://carboncredits.com/doe-sets-eyes-on-cutting-clean-hydrogen-cost-1-kilo-by-2031/ (accessed on 4 July 2025).

- Alternative Fuels Data, US DOE, Office of Energy Efficiency and Renewable Energy. Available online: https://afdc.energy.gov/fuels/prices.html (accessed on 4 July 2025).

- How Much Does Natural Gas Cost? Available online: https://www.chooseenergy.com/data-center/natural-gas-rates-by-state/ (accessed on 4 July 2025).

- Lee, Y.; Lee, M.C.; Kim, Y.J. Barriers and strategies of hydrogen fuel cell power generation based on expert survey in South Korea. Int. J. Hydrogen Energy 2022, 47, 5709–5719. [Google Scholar] [CrossRef]

- Castillo, O.; Alvarez, R.; Domingo, R. Opportunities and barriers of hydrogen-electric hybrid power-n-train vans: A systematic literature review. Processes 2020, 8, 1261. [Google Scholar] [CrossRef]

- Kumar, P.; Britter, R.; Gupta, N. Hydrogen fuel: Opportunities and barriers. J. Electrochem. Energy Convers. Storage 2009, 6, 021009. [Google Scholar] [CrossRef]

- US DOE. Cost of Solar Module. Available online: https://www.tesla.com/learn/solar-panel-cost-breakdown (accessed on 26 August 2025).

- Solar Inverter Cost. Available online: https://www.solarharmonics.com/solar-inverters-how-much-do-solar-inverters-cost/ (accessed on 26 August 2025).

- Fuel Cell Cost. Available online: https://www.horizoneducational.com (accessed on 26 August 2025).

- Generator Cost. Available online: https://www.absolutegenerators.com/american-built/watts/10-kw-15-kw?srsltid=AfmBOoq8X5utaxUn-9plwZBt4c0Drco2JDD3_z0CBmS_EYY8AwtTkGKu (accessed on 26 August 2025).

- Enspire Energy Conversion Calculator. Available online: https://www.enspireenergy.com (accessed on 27 August 2025).

- USEIA Btu. Available online: https://www.eia.gov (accessed on 27 August 2025).

- Gasoline Converter. MMBtu to Gasoline Liter. Available online: https://hextobinary.com (accessed on 27 August 2025).

- MMBtu Trade Remedies Service. Available online: https://www.trade-remedies.service.gov.uk (accessed on 29 August 2025).

- Saddari, N.; Derkyi, N.S.A.; Peprah, F.; Gyamfi, S.; Donkor, G.K. Techno-economic and environmental assessment of grid and solar photovoltaic microgrid supply options for isolated off-grid rural communities toward sustainable and affordable electricity in Nkoranza South, Bono East, Ghana. Results Eng. 2025, 25, 103915. [Google Scholar] [CrossRef]

- Zaidi, S.S.; Zaidi, S.S.H.; Khan, B.M.; Moin, L. Optimal designing of grid-connected microgrid systems for residential and commercial applications in Pakistan. Helyon 2023, 9, e17990. [Google Scholar] [CrossRef]

- Savas, A.; Sener, R.; Uslu, S.; Der, O. Experimental study on performance and emission optimization of MgO nanoparticle-enriched 2nd generation biodiesel: A method for employing nanoparticles to improve cleaner diesel combustion. J. Energy Inst. 2025, 120, 102024. [Google Scholar] [CrossRef]

- Aikhuele, D.O.; Ighravwe, D.E.; Akinyele, D. Evaluation of renewable energy technology based on reliability attributes using hybrid fuzzy dynamic decision-making model. Technol. Econ. Smart Grids Sustain. Energy 2019, 4, 16. [Google Scholar] [CrossRef]

- Monyei, C.G.; Viriri, S.; Adewumi, A.; Davidson, I.; Akinyele, D. A smart grid framework for optimally integrating supply-side, demand-side and transmission line management systems. Energies 2018, 11, 1038. [Google Scholar] [CrossRef]

- Aikhuele, D.O.; Ighravwe, D.E.; Akinyele, D.O. Hybrid fuzzy dynamic model for the evaluation of energy aggregation strategy. Process Integr. Optim. Sustain. 2022, 6, 931–941. [Google Scholar] [CrossRef]

| S/No. | Forms of Power-to-X Technology | Principle Involved | By-Products | Areas of Application | Roles in Power Transition and Environmental Sustainability |

|---|---|---|---|---|---|

| 1. | Power-to-Gas | Electrolysis of water powered by renewable energy to produce hydrogen. | Methane, syngas | Carbon-neutral fuel for transportation | (i). Clean energy transition (ii). Industrial heating applications |

| 2. | Power-to-Liquids | Production of green hydrogen via electrolysis. Production of carbon feedstock from captured and stored CO2, synthesis of green hydrogen to produce liquid fuels. | E-diesel, e-kerosene, methanol | Aviation, shipping, and heavy transport | Alternative fuel to decarbonize transportation industries |

| 3. | Power-to-Heat | Renewable energy resources such as solar and wind are employed to generate heat from water. | Heat energy | (i). Decarbonization of the industrial heating process (ii). Energy transition | |

| 4. | Power-to-Chemicals | The green hydrogen produced during electrolysis is synthesized with captured CO2, which is consequently fed into the chemical process. | Fertilizers, plastics | (i). Production of ammonia for fertilizer development (ii). Ammonia salt for industrial processes | (i). Expanded use of renewable energy (ii). Industrial application |

| S/No. | Parameter | Initial Case | Case 4 | Case 5 | Case 6 |

|---|---|---|---|---|---|

| 1 | PV capacity (kWdc) | 17.3 | 26.4 | 39.1 | 51.8 |

| 2 | Array cost ($) | 47,374.60 | 72,473 | 107,134 | 141,795 |

| 3 | Inverter cost ($) | 3112.20 | 4761 | 6120 | 8100 |

| 4 | Balance of system equipment cost ($) | 9474.92 | 44,494.60 | 21,426.8 | 28,359 |

| 5 | Installation labor cost ($) | 4737.46 | 7247.30 | 10,713.40 | 14,179.5 |

| 6 | Installer margin and overhead cost ($) | 2368.73 | 3623.65 | 5356.70 | 7089.75 |

| 7 | Subtotal ($) | 67,067.91 | 102,599.55 | 150,750.90 | 199,523.25 |

| 8 | Contingency ($) | 3353.46 | 5129.98 | 7537.55 | 9976.16 |

| 9 | Total direct cost ($) | 70,421.31 | 107,729.53 | 158,288.45 | 209,499.41 |

| 10 | Total installed cost of PV power subsystem ($) | 70,421.31 | 107,729.53 | 158,288.45 | 209,499.41 |

| 11 | Total installed cost per capacity ($/Wdc) | 4.07 | 4.05 | ||

| S/No. | O and M Cost Parameters | Initial Case | Case 4 | Case 5 | Case 6 |

| 1 | Fixed annual cost ($/yr) | 10 | |||

| 2 | Fixed cost by capacity ($/kW-yr) | 22 | |||

| 3 | Inflation/escalation rate (%) | 5 | |||

| S/No. | Direct Cost Parameters | Initial Case | Case 4 | Case 5 | Case 6 |

|---|---|---|---|---|---|

| 1 | Wind farm power capacity (kW) | 20 | 30 | 40 | 40 |

| 2 | Number of turbines in the farm | 2 | 3 | 4 | 4 |

| 3 | Turbine cost ($/kW) | 2781 | 2781 | 2781 | 2781 |

| 4 | Balance of system cost ($/kW) | 3633 | 3633 | 3633 | 3633 |

| 5 | Total turbine cost ($) | 55,620 | 83,430 | 111,240 | 111,240 |

| 6 | Total balance of system cost ($) | 72,660 | 108,990 | 145,320 | 145,320 |

| 7 | Total direct cost ($) | 128,280 | 192,420 | 256,560 | 256,560 |

| 8 | Total installed cost of wind power subsystem ($) | 128,280 | 192,420 | 256,560 | 256,560 |

| 9 | Total installed cost per capacity ($/W) | 6.41 | |||

| S/No. | O and M Cost Parameters | Initial Case | Case 4 | Case 5 | Case 6 |

| 1 | Fixed annual cost ($/yr) | 18 | |||

| 2. | Fixed cost by capacity ($/kW-yr) | 39 | |||

| 3 | Inflation/escalation rate (%) | 5 | |||

| S/No. | Direct Cost Parameters | Initial Case | Case 4 | Case 5 | Case 6 |

|---|---|---|---|---|---|

| 1 | Fuel cell power capacity (kW) | 25 | 45 | 75 | 105 |

| 2 | Fuel cell stack cost ($/kWac) | 1500 | 1500 | 1500 | 1500 |

| 3 | Total cost of fuel cell stacks ($) | 37,500 | 67, 500 | 112, 500 | 157,500 |

| 3 | Balance of system cost ($/kW) | 7500 | 13,500 | 22,500 | 31,500 |

| 4 | Installation labor cost ($) | 3750 | 6750 | 11,250 | 15,750 |

| 5 | Installer margin and overhead cost ($) | 1875 | 3375 | 5625 | 7875 |

| 6 | Subtotal ($) | 50,625 | 91,125 | 151,875 | 212,625 |

| 7 | Contingency ($) | 656.25 | 1181.25 | 1968.75 | 2756.25 |

| 8 | Total direct cost ($) | 51,281.25 | 92,306. 25 | 153,843.75 | 215,381.25 |

| 9 | Total installed cost of wind power subsystem ($) | 51,281.25 | 92,306.25 | 153,843.75 | 215,381.25 |

| 10 | Total installed cost per capacity ($/Wac) | 2.05 | |||

| S/No. | O and M Cost Parameters | Initial Case | Case 4 | Case 5 | Case 6 |

| 1 | Fixed annual cost ($/yr) | 20 | |||

| 2 | Operating cost by capacity ($/kW-yr) | 27 | |||

| 3 | Fuel cost ($/MCf) | 11.82 | |||

| 4 | Inflation/escalation rate | 5 | |||

| S/No. | Direct Cost Parameters | Initial Case | Case 4 | Case 5 | Case 6 |

|---|---|---|---|---|---|

| 1 | Battery pack capacity (kWh) | 1096.7 | 2193.5 | 3291.3 | 4338.1 |

| 2 | Battery power (kW) | 104 | 208.3 | 312.5 | 416.7 |

| 3 | Battery cost/capacity ($/kWdc) | 184 | 184 | 184 | 184 |

| 4 | Battery cost/kW ($/kWdc) | 667 | 667 | 667 | 667 |

| 5 | Battery direct cost ($) | 271,150.92 | 542,524.12 | 814,065.25 | 1,085,327.31 |

| 6 | Contingency ($) | 13,557.55 | 27,126.2 | 40,703.26 | 54,266.37 |

| 8 | Total direct cost ($) | 284,708.46 | 569,650.32 | 854,768.51 | 1,139,593.67 |

| 9 | Total installed cost of battery storage subsystem ($) | 284,708.46 | 569,650.32 | 854,768.51 | 1,139,593.67 |

| 10 | Total installed cost per capacity ($/Wac) | 2.85 | |||

| S/No. | O and M Cost Parameters | Initial Case | Case 4 | Case 5 | Case 6 |

| 1 | Fixed annual cost ($/yr) | 20 | |||

| 2 | Fixed cost by capacity ($/kWac) | 5.25 | |||

| 3 | Replacement cost ($/kWac) | 280 | |||

| 4 | Inflation/escalation rate | 5 | |||

| S/No. | Direct Cost Parameters | Initial Case | Case 4 | Case 5 | Case 6 |

|---|---|---|---|---|---|

| 1 | Nameplate capacity (kW) | 10 | 27 | 37 | 50 |

| 2 | Generating plant cost ($) | 4500 | 12, 150 | 16, 650 | 22,500 |

| 3 | BOS and other costs ($) | 1575 | 4320 | 5827.5 | 7875 |

| 4 | Plant cost per capacity ($/Wac) | 0.61 | 0.61 | 0.61 | 0.61 |

| 5 | Direct plant cost ($) | 6100 | 16, 470 | 22,570 | 30,500 |

| 6 | Contingency ($) | 530 | 1431 | 1961 | 2650 |

| 8 | Total direct cost ($) | 11,130 | 30,051 | 41,181 | 55,650 |

| 9 | Total installed cost of generic power subsystem ($) | 11,130 | 30,051 | 41,181 | 55,650 |

| 10 | Total installed cost per capacity ($/Wac) | 1.11 | 1.11 | 1.11 | 1.11 |

| S/No. | O and M Cost Parameters | Initial Case | Case 4 | Case 5 | Case 6 |

| 1 | Fixed operating cost ($/yr) | 50 | |||

| 2 | Fixed cost by capacity ($/kWac) | 43 | |||

| 3 | Fossil fuel cost ($/MMBtu) | 48.28 (Diesel), 14.55 (Natural gas), 24.94 (Gasoline) | |||

| 4 | Inflation/escalation rate | 5 | |||

| (a) | ||||

|---|---|---|---|---|

| S/No. | Parameters (Initial Case) | PV, WT, FC, and Gen Running on Diesel | PV, WT, FC, and Gen Running on Gasoline | PV, WT, FC, and Gen Running on Natural Gas |

| 1 | LCOE (nominal) (cents/kWh) | 58.82 | 45.97 | 40.25 |

| 2 | LCOE (real) (cents/kWh) | 47.75 | 37.32 | 32.67 |

| 3 | Hybrid total installed cost ($) | 545,821.02 | 545,821.02 | 545,821.02 |

| 4 | Developer NPV ($) | 22,595 | 25,653 | 27,014 |

| 5 | Host NPV ($) | −833,575 | −597,702 | −492,701 |

| 6 | Equity ($) | 259,349 | 263,670 | 265,593 |

| 7 | Size of debt ($) | 338,711 | 324,703 | 318,467 |

| 8 | Debt (%) | 56.63 | 55.19 | 54.53 |

| S/No. | Parameters (Case 4) | PV, WT, FC, and Gen Running on Diesel | PV, WT, FC, and Gen Running on Gasoline | PV, WT, FC, and Gen Running on Natural Gas |

| 1 | LCOE (nominal) (cents/kWh) | 62.96 | 46.02 | 38.48 |

| 2 | LCOE (real) (cents/kWh) | 50.97 | 37.25 | 31.15 |

| 3 | Hybrid total installed cost ($) | 992,157.10 | 992,157.10 | 992,157.10 |

| 4 | Developer NPV ($) | 38,856 | 46,385 | 49,737 |

| 5 | Host NPV ($) | −1,863,092 | −1,226,850 | −943,621 |

| 6 | Equity ($) | 466,968 | 477,864 | 482,715 |

| 7 | Size of debt ($) | 636,658 | 599,625 | 583,140 |

| 8 | Debt (%) | 57.69 | 55.65 | 54.71 |

| (b) | ||||

| S/No. | Parameters (Case 5) | PV, WT, FC, and Gen Running on Diesel | PV, WT, FC, and Gen Running on Gasoline | PV, WT, FC, and Gen Running on Natural Gas |

| 1 | LCOE (nominal) (cents/kWh) | 63.53 | 48.37 | 41.62 |

| 2 | LCOE (real) (cents/kWh) | 52.36 | 39.86 | 34.30 |

| 3 | Hybrid total installed cost ($) | 1,464,641.71 | 1,464,641.71 | 1,464,641.71 |

| 4 | Developer NPV ($) | 31,198 | 47,187 | 54,304 |

| 5 | Host NPV ($) | −3,001,516 | −2,121,294 | −1,729,455 |

| 6 | Equity ($) | 655,127 | 677,383 | 687,290 |

| 7 | Size of debt ($) | 981,532 | 923,252 | 897,308 |

| 8 | Debt (%) | 59.97 | 57.68 | 56.63 |

| S/No. | Parameters (Case 6) | PV, WT, FC, and Gen Running on Diesel | PV, WT, FC, and Gen Running on Gasoline | PV, WT, FC, and Gen Running on Natural Gas |

| 1 | LCOE (nominal) (cents/kWh) | 66.65 | 49.30 | 41.57 |

| 2 | LCOE (real) (cents/kWh) | 54.25 | 40.13 | 33.84 |

| 3 | Hybrid total installed cost ($) | 1,876,684.34 | 1,876,684.34 | 1,876,684.34 |

| 4 | Developer NPV ($) | 63,100 | 79,599 | 86,943 |

| 5 | Host NPV ($) | −3,714,372 | −2,533,170 | −2,007,348 |

| 6 | Equity ($) | 870,494 | 893,679 | 904,000 |

| 7 | Size of debt ($) | 1,219,436 | 1,147,766 | 1,115,862 |

| 8 | Debt (%) | 58.35 | 56.22 | 55.24 |

| (a) | ||||

|---|---|---|---|---|

| S/No. | Parameters (New Initial Case) | PV, WT, FC, and Gen Running on Diesel | PV, WT, FC, and Gen Running on Gasoline | PV, WT, FC, and Gen Running on Natural Gas |

| 1 | LCOE (nominal) (cents/kWh) | 49.46 | 36.44 | 30.65 |

| 2 | LCOE (real) (cents/kWh) | 40.14 | 29.58 | 24.88 |

| 3 | Hybrid total installed cost ($) | 545,821.02 | 545,821.02 | 545,821.02 |

| 4 | Developer NPV ($) | 319,838 | 246,732 | 214,188 |

| 5 | Host NPV ($) | −335,883 | −221,496 | −170,575 |

| 6 | Equity ($) | 436,018 | 432,036 | 430,263 |

| 7 | Size of debt ($) | 157,047 | 151,575 | 149,139 |

| 8 | Debt (%) | 26.48 | 25.97 | 25.74 |

| S/No. | Parameters (New Case 4) | PV, WT, FC, and Gen Running on Diesel | PV, WT, FC, and Gen Running on Gasoline | PV, WT, FC, and Gen Running on Natural Gas |

| 1 | LCOE (nominal) (cents/kWh) | 61.50 | 44.32 | 36.67 |

| 2 | LCOE (real) (cents/kWh) | 49.79 | 35.88 | 29.69 |

| 3 | Hybrid total installed cost ($) | 992,157.20 | 992,157.10 | 992,157.10 |

| 4 | Developer NPV ($) | 824,664 | 624,987 | 536,099 |

| 5 | Host NPV ($) | −823,879 | −516,442 | −379,584 |

| 6 | Equity ($) | 603,665 | 592,595 | 587,667 |

| 7 | Size of debt ($) | 496,095 | 481,650 | 475,220 |

| 8 | Debt (%) | 45.11 | 44.84 | 44.71 |

| (b) | ||||

| S/No. | Parameters (New Case 5) | PV, WT, FC, and Gen Running on Diesel | PV, WT, FC, and Gen Running on Gasoline | PV, WT, FC, and Gen Running on Natural Gas |

| 1 | LCOE (nominal) (cents/kWh) | 61.50 | 46.28 | 39.50 |

| 2 | LCOE (real) (cents/kWh) | 50.69 | 38.14 | 32.55 |

| 3 | Hybrid total installed cost ($) | 1,464,641.71 | 1,464,641.71 | 1,464,641.71 |

| 4 | Developer NPV ($) | 1,205,193 | 946,570 | 831,442 |

| 5 | Host NPV ($) | −1,377,642 | −941,146 | −746,836 |

| 6 | Equity ($) | 881,104 | 868,992 | 863,601 |

| 7 | Size of debt ($) | 749,165 | 726,225 | 716,013 |

| 8 | Debt (%) | 45.95 | 45.53 | 45.33 |

| S/No. | Parameters (New Case 6) | PV, WT, FC, and Gen Running on Diesel | PV, WT, FC, and Gen Running on Gasoline | PV, WT, FC, and Gen Running on Natural Gas |

| 1 | LCOE (nominal) (cents/kWh) | 64.92 | 47.38 | 39.57 |

| 2 | LCOE (real) (cents/kWh) | 52.85 | 38.56 | 32.21 |

| 3 | Hybrid total installed cost ($) | 1,876,684.34 | 1,876,684.34 | 1,876,684.34 |

| 4 | Developer NPV ($) | 1,549,801 | 1,187,082 | 1,025,615 |

| 5 | Host NPV ($) | −1,661,779 | −1,086,422 | −830,297 |

| 6 | Equity ($) | 1,137,652 | 1,118,420 | 1,109,858 |

| 7 | Size of debt ($) | 944,724 | 916,671 | 904,183 |

| 8 | Debt (%) | 45.37 | 45.04% | 44.89% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akinyele, D.; Olabode, O. Recent Advances in Green and Low-Carbon Energy Resources: Navigating the Climate-Friendly Microgrids for Decarbonized Power Generation. Processes 2025, 13, 3028. https://doi.org/10.3390/pr13093028

Akinyele D, Olabode O. Recent Advances in Green and Low-Carbon Energy Resources: Navigating the Climate-Friendly Microgrids for Decarbonized Power Generation. Processes. 2025; 13(9):3028. https://doi.org/10.3390/pr13093028

Chicago/Turabian StyleAkinyele, Daniel, and Olakunle Olabode. 2025. "Recent Advances in Green and Low-Carbon Energy Resources: Navigating the Climate-Friendly Microgrids for Decarbonized Power Generation" Processes 13, no. 9: 3028. https://doi.org/10.3390/pr13093028

APA StyleAkinyele, D., & Olabode, O. (2025). Recent Advances in Green and Low-Carbon Energy Resources: Navigating the Climate-Friendly Microgrids for Decarbonized Power Generation. Processes, 13(9), 3028. https://doi.org/10.3390/pr13093028