Edible Pouch Packaging for Food Applications—A Review

Abstract

1. Introduction

2. Biodegradable Films, Edible Coatings and Sachets

3. Different Aspects of Food Packaging

3.1. Social Impacts

3.2. Environmental Impacts

3.3. Economic Impacts

4. Legal Aspects and Regulations

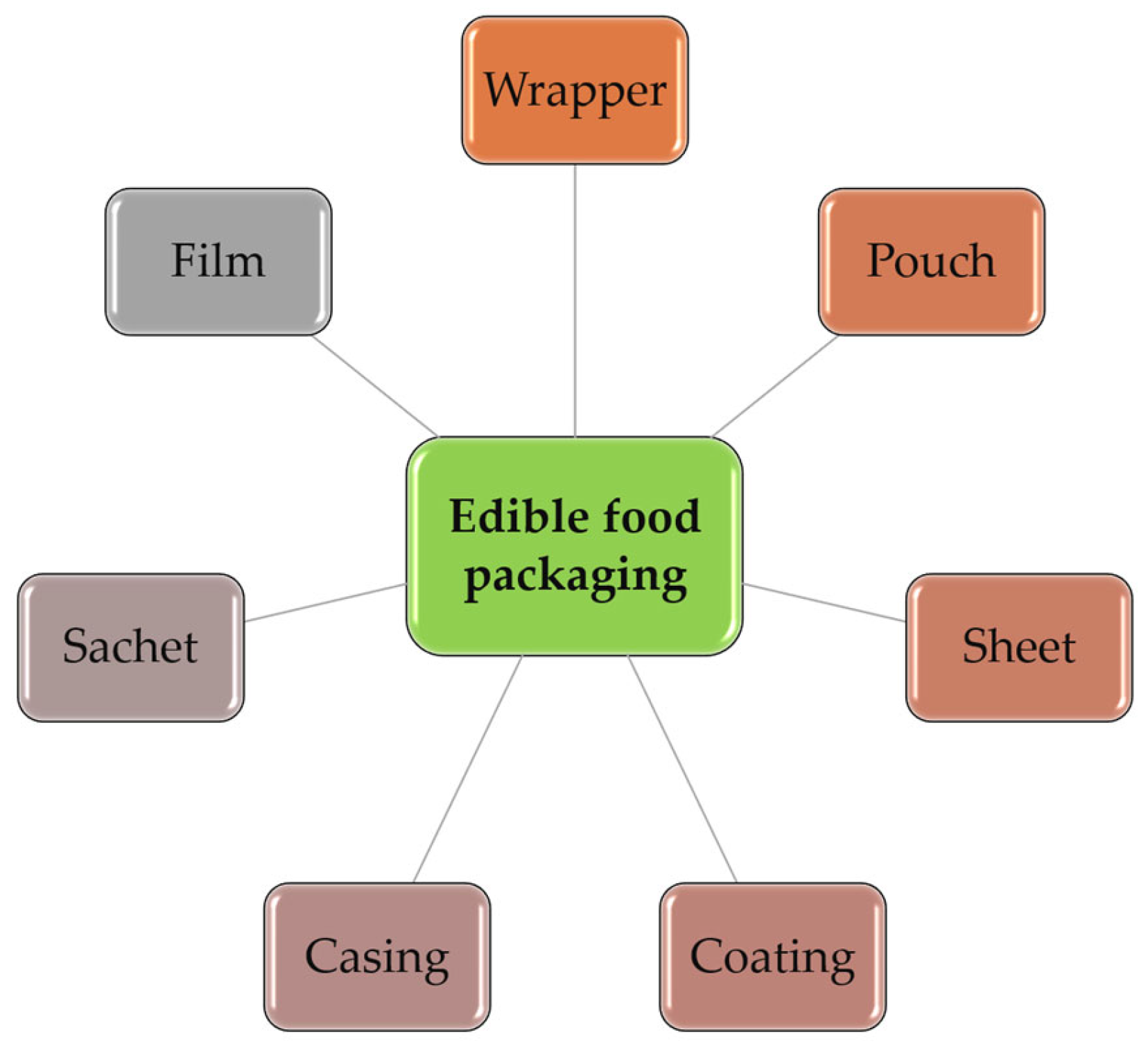

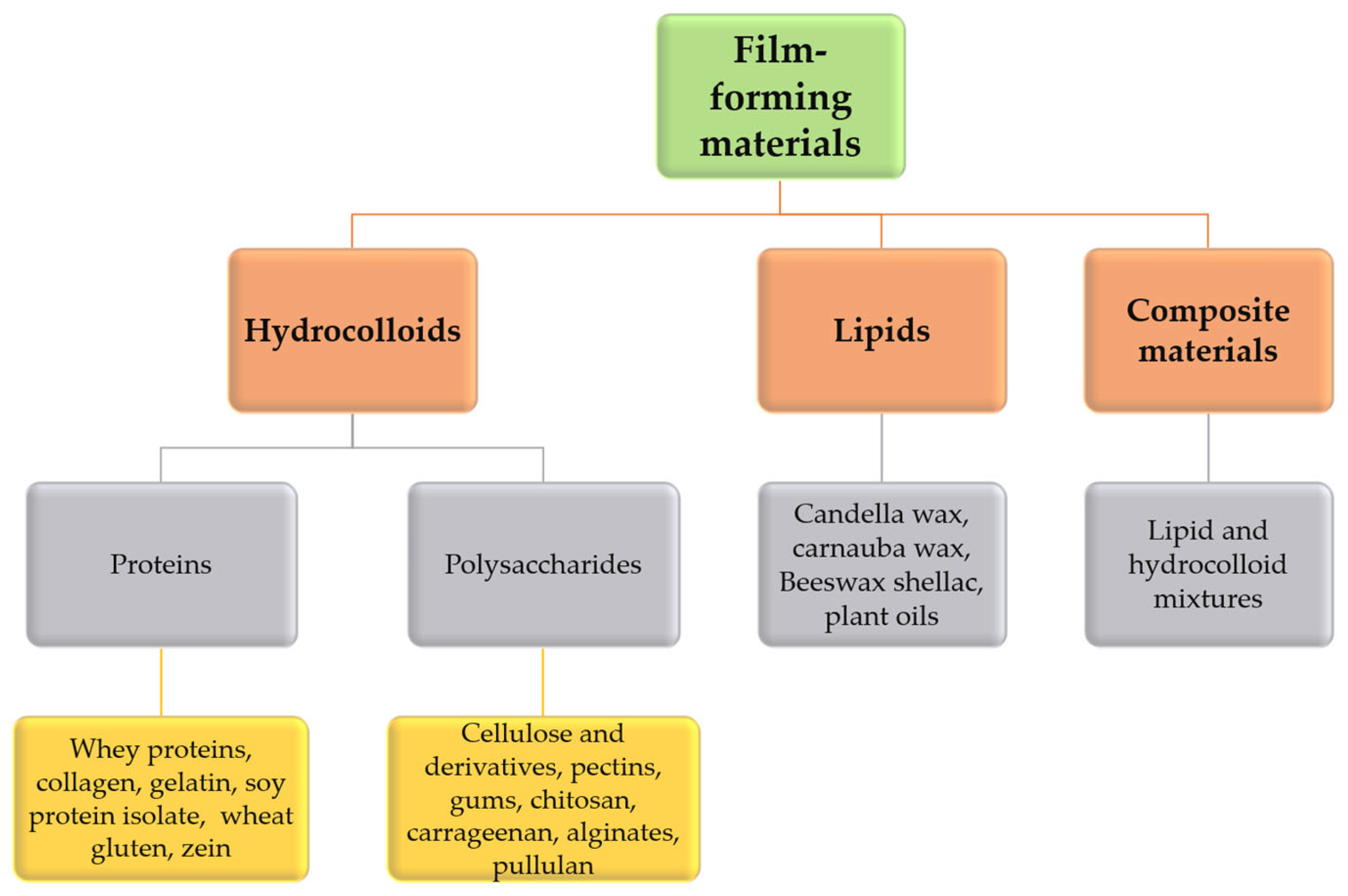

5. Biopolymer-Based Edible Food Packaging

5.1. Polysaccharides

5.2. Proteins

5.3. Lipids

5.4. Edible Films and Coatings from Food Waste

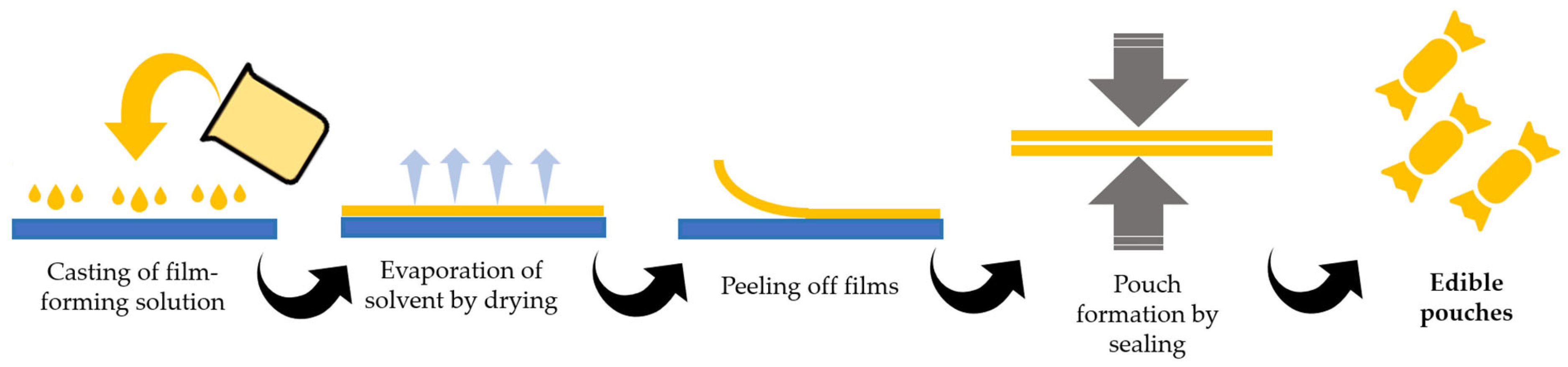

6. Preparation Methods for Biopolymer-Based Packaging

7. Fast-Dissolving Edible Pouches for Food Applications

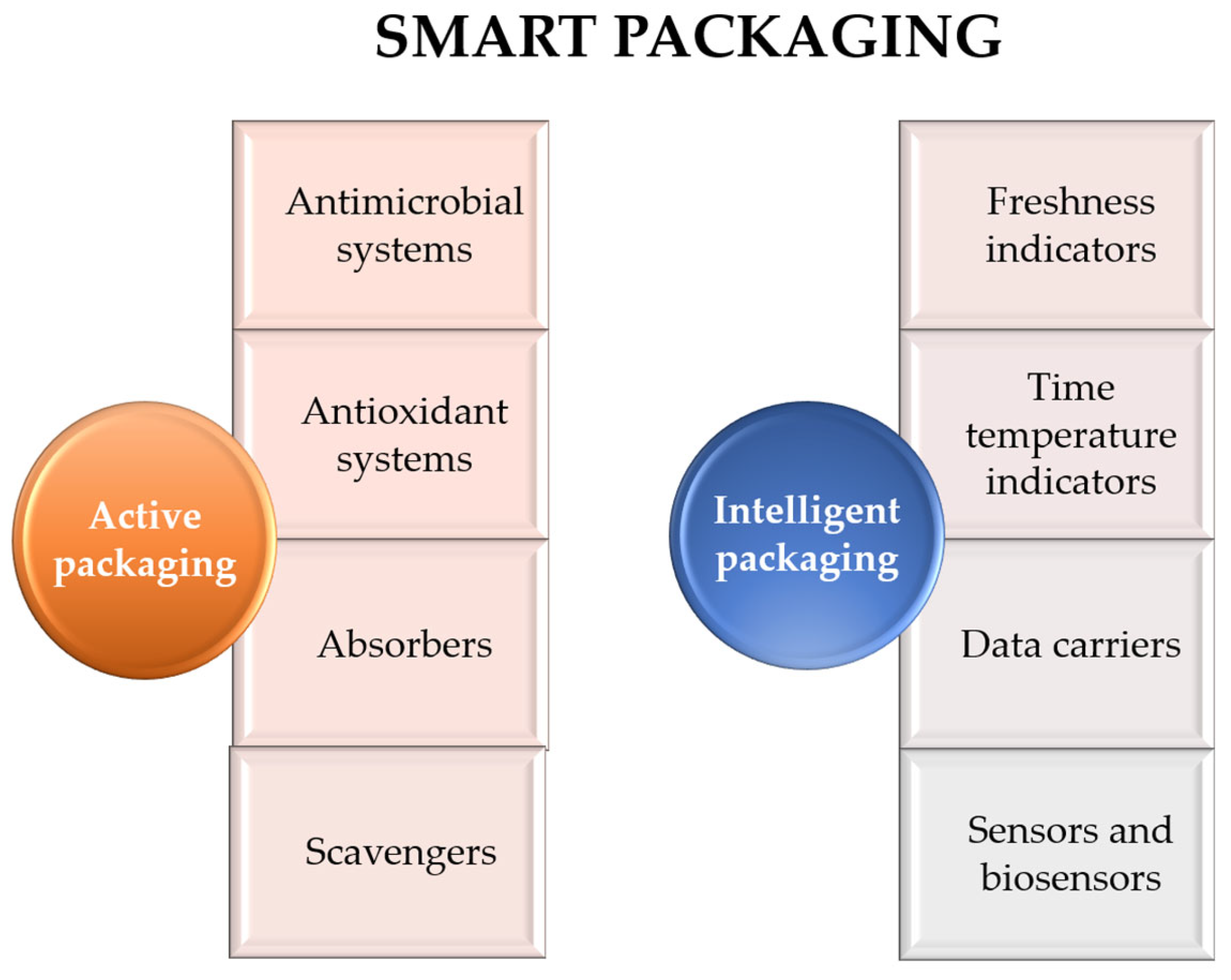

8. New Types of Food Packaging Systems

9. Future Trends and Perspectives

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mahmud, M.Z.A.; Mobarak, M.H.; Hossain, N. Emerging trends in biomaterials for sustainable food packaging: A comprehensive review. Heliyon 2024, 10, e24122. [Google Scholar] [CrossRef] [PubMed]

- Teixeira, S.C.; de Oliveira, T.V.; de Fátima Ferreira Soares, N.; Raymundo-Pereira, P.A. Sustainable and biodegradable polymer packaging: Perspectives, challenges, and opportunities. Food Chem. 2025, 470, 142652. [Google Scholar] [CrossRef] [PubMed]

- Meghwal, M.; Goyal, M. Food Process Engineering: Emerging Trends in Research and Their Applications; Apple Academic Press lnc.: Waretown, NJ, USA, 2016. [Google Scholar]

- Upadhyay, A.; Agbesi, P.; Arafat, K.M.Y.; Urdaneta, F.; Dey, M.; Basak, M.; Hong, S.; Umeileka, C.; Argyropoulos, D. Bio-based smart packaging: Fundamentals and functions in sustainable food systems. Trends Food Sci. Technol. 2024, 145, 104369. [Google Scholar] [CrossRef]

- Syarifuddin, A.; Muflih, M.H.; Izzah, N.; Fadillah, U.; Ainani, A.F.; Dirpan, A. Pectin-based edible films and coatings: From extraction to application on food packaging towards circular economy—A review. Carbohydr. Polym. Technol. Appl. 2025, 9, 100680. [Google Scholar] [CrossRef]

- Wang, C.; Mao, L.; Yao, J.; Zhu, H. Improving the active food packaging function of poly (lactic acid) film coated by poly (vinyl alcohol) based on proanthocyanidin functionalized layered clay. LWT 2023, 174, 114407. [Google Scholar] [CrossRef]

- Akhila, K.; Ramakanth, D.; Gaikwad, K.K. Development of novel gallic acid- and cellulose acetate-coated paper as pH-responsive oxygen indicator for intelligent food packaging. J. Coat. Technol. Res. 2022, 19, 1493–1506. [Google Scholar] [CrossRef]

- Bai, F.; Chen, G.; Hu, Y.; Liu, Y.; Yang, R.; Liu, J.; Hou, R.; Li, H.; Wan, X.; Cai, H. Understanding the effect of plastic food packaging materials on food flavor: A critical review. Trends Food Sci. Technol. 2024, 148, 104502. [Google Scholar] [CrossRef]

- Łęczycka-Wilk, K.; Kaczmarczyk, B.; Jakubowska, E.; Rolińska, K.; Janowicz, M.; Galus, S. Sustainable PVA Films Plasticized with Deep Eutectic Solvents for Active Packaging Applications. ACS Food Sci. Technol. 2025, 5, 2731–2742. [Google Scholar] [CrossRef]

- Majid, I.; Ahmad Nayik, G.; Mohammad Dar, S.; Nanda, V. Novel food packaging technologies: Innovations and future prospective. J. Saudi Soc. Agric. Sci. 2018, 17, 454–462. [Google Scholar] [CrossRef]

- Wilson, M.D.; Stanley, R.A.; Eyles, A.; Ross, T. Innovative processes and technologies for modified atmosphere packaging of fresh and fresh-cut fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2019, 59, 411–422. [Google Scholar] [CrossRef]

- Purushotam, K.; Ganguly, S. Role of vacuum packaging in increasing shelf life in fish processing technology: A Review. Asian J. Bio Sci. Hind Inst. Sci. Technol. Muzaff. India 2014, 9, 109–112. [Google Scholar]

- Götz, A.; Wani, A.A.; Langowski, H.C.; Wunderlich, J. Food Technologies: Aseptic Packaging. In Encyclopedia of Food Safety; Motarjemi, Y., Ed.; Academic Press: Waltham, MA, USA, 2014; pp. 124–134. [Google Scholar]

- Ribeiro, I.S.; Maciel, G.M.; Bortolini, D.G.; Fernandes, I.d.A.A.; Maroldi, W.V.; Pedro, A.C.; Rubio, F.T.V.; Haminiuk, C.W.I. Sustainable innovations in edible films and coatings: An overview. Trends Food Sci. Technol. 2024, 143, 104272. [Google Scholar] [CrossRef]

- Mikus, M.; Galus, S. Extending the Shelf Life of Apples After Harvest Using Edible Coatings as Active Packaging—A Review. Appl. Sci. 2025, 15, 767. [Google Scholar] [CrossRef]

- Yadav, A.; Kumar, N.; Upadhyay, A.; Pratibha; Anurag, R.K. Edible Packaging from Fruit Processing Waste: A Comprehensive Review. Food Rev. Int. 2023, 39, 2075–2106. [Google Scholar] [CrossRef]

- Hassan, B.; Chatha, S.A.S.; Hussain, A.I.; Zia, K.M.; Akhtar, N. Recent advances on polysaccharides, lipids and protein based edible films and coatings: A review. Int. J. Biol. Macromol. 2018, 109, 1095–1107. [Google Scholar] [CrossRef]

- Przybyszewska, A.; Barbosa, C.H.; Pires, F.; Pires, J.R.A.; Rodrigues, C.; Galus, S.; Souza, V.G.L.; Alves, M.M.; Santos, C.F.; Coelhoso, I.; et al. Packaging of Fresh Poultry Meat with Innovative and Sustainable ZnO/Pectin Bionanocomposite Films—A Contribution to the Bio and Circular Economy. Coatings 2023, 13, 1208. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Mujumdar, A.; Wang, D.; Ma, Y. Novel multilayer chitosan/emulsion-loaded syringic acid grafted apple pectin film with sustained control release for active food packaging. Food Hydrocoll. 2023, 142, 108823. [Google Scholar] [CrossRef]

- Hussain, S.; Akhter, R.; Maktedar, S.S. Advancements in sustainable food packaging: From eco-friendly materials to innovative technologies. Sustain. Food Technol. 2024, 2, 1297–1364. [Google Scholar] [CrossRef]

- Trajkovska Petkoska, A.; Daniloski, D.; D’Cunha, N.M.; Naumovski, N.; Broach, A.T. Edible packaging: Sustainable solutions and novel trends in food packaging. Food Res. Int. 2021, 140, 109981. [Google Scholar] [CrossRef]

- Galus, S.; Arik Kibar, E.A.; Gniewosz, M.; Kraśniewska, K. Novel Materials in the Preparation of Edible Films and Coatings—A Review. Coatings 2020, 10, 674. [Google Scholar] [CrossRef]

- Mohamed, S.A.A.; El-Sakhawy, M.; El-Sakhawy, M.A. Polysaccharides, Protein and Lipid -Based Natural Edible Films in Food Packaging: A Review. Carbohydr. Polym. 2020, 238, 116178. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, L.; Fan, K. Recent advances in polysaccharide-based edible coatings for preservation of fruits and vegetables: A review. Crit. Rev. Food Sci. Nutr. 2024, 64, 3823–3838. [Google Scholar] [CrossRef] [PubMed]

- Kowalska, H.; Marzec, A.; Domian, E.; Kowalska, J.; Ciurzyńska, A.; Galus, S. Edible coatings as osmotic dehydration pretreatment in nutrient-enhanced fruit or vegetable snacks development: A review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 5641–5674. [Google Scholar] [CrossRef] [PubMed]

- Gamboni, J.E.; Bonfiglio, G.V.; Slavutsky, A.M.; Bertuzzi, M.A. Evaluation of edible films as single-serve pouches for a sustainable packaging system. Food Chem. Adv. 2023, 3, 100547. [Google Scholar] [CrossRef]

- Janjarasskul, T.; Tananuwong, K.; Phupoksakul, T.; Thaiphanit, S. Fast dissolving, hermetically sealable, edible whey protein isolate-based films for instant food and/or dry ingredient pouches. LWT 2020, 134, 110102. [Google Scholar] [CrossRef]

- Liu, C.; Huang, J.; Zheng, X.; Liu, S.; Lu, K.; Tang, K.; Liu, J. Heat sealable soluble soybean polysaccharide/gelatin blend edible films for food packaging applications. Food Packag. Shelf Life 2020, 24, 100485. [Google Scholar] [CrossRef]

- Ryu, S.Y.; Koh, K.H.; Son, S.M.; Oh, M.S.; Yoon, J.R.; Lee, W.J.; Kim, S.S. Physical and microbiological changes of sliced process cheese packaged in edible pouches during storage. Food Sci. Biotechnol. 2005, 14, 694–697. [Google Scholar]

- Cho, S.Y.; Lee, S.Y.; Rhee, C. Edible oxygen barrier bilayer film pouches from corn zein and soy protein isolate for olive oil packaging. LWT-Food Sci. Technol. 2010, 43, 1234–1239. [Google Scholar] [CrossRef]

- Hromiš, N.; Lazic, V.; Popovic, S.; Suput, D.; Bulut, S.; Kravic, S.; Romanic, R. The possible application of edible pumpkin oil cake film as pouches for flaxseed oil protection. Food Chem. 2022, 371, 131197. [Google Scholar] [CrossRef]

- Rosenbloom, R.A.; Zhao, Y. Hydroxypropyl methylcellulose or soy protein isolate-based edible, water-soluble, and antioxidant films for safflower oil packaging. J. Food Sci. 2021, 86, 129–139. [Google Scholar] [CrossRef]

- Quilez-Molina, A.I.; Mazzon, G.; Athanassiou, A.; Perotto, G. A novel approach to fabricate edible and heat sealable bio-based films from vegetable biomass rich in pectin. Mater. Today Commun. 2022, 32, 103871. [Google Scholar] [CrossRef]

- Tagrida, M.; Gulzar, S.; Nilsuwan, K.; Prodpran, T.; Ma, L.; Benjakul, S. Properties of gelatin/chitosan blend films incorporated with betel leaf ethanolic extract loaded in liposomes and their use as pouches for shrimp oil packaging. Int. J. Food Sci. Tech. 2023, 58, 1108–1119. [Google Scholar] [CrossRef]

- Nilsuwan, K.; Benjakul, S.; Prodpran, T.; de la Caba, K. Fish gelatin monolayer and bilayer films incorporated with epigallocatechin gallate: Properties and their use as pouches for storage of chicken skin oil. Food Hydrocoll. 2019, 89, 783–791. [Google Scholar] [CrossRef]

- Galus, S.; Karwacka, M.; Ciurzyńska, A.; Janowicz, M. Effect of Drying Conditions and Jojoba Oil Incorporation on the Selected Physical Properties of Hydrogel Whey Protein-Based Edible Films. Gels 2024, 10, 340. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Wang, J.; Cheng, Y.; Wang, C.; Liu, H.; Bian, H.; Pan, Y.; Sun, J.; Han, W. Application of Protein-Based Films and Coatings for Food Packaging: A Review. Polymers 2019, 11, 2039. [Google Scholar] [CrossRef]

- Galus, S.; Kadzińska, J. Food applications of emulsion-based edible films and coatings. Trends Food Sci. Technol. 2015, 45, 273–283. [Google Scholar] [CrossRef]

- Jurić, M.; Maslov Bandić, L.; Carullo, D.; Jurić, S. Technological advancements in edible coatings: Emerging trends and applications in sustainable food preservation. Food Biosci. 2024, 58, 103835. [Google Scholar] [CrossRef]

- Bodbodak, S.; Rafiee, Z. Recent trends in active packaging in fruits and vegetables. In Eco-Friendly Technology for Postharvest Produce Quality; Siddiqui, M.W., Ed.; Academic Press: Waltham, MA, USA, 2016; pp. 77–125. [Google Scholar]

- Han, J.-W.; Ruiz-Garcia, L.; Qian, J.-P.; Yang, X.-T. Food Packaging: A Comprehensive Review and Future Trends. Compr. Rev. Food Sci. Food Saf. 2018, 17, 860–877. [Google Scholar] [CrossRef]

- Braga, L.R.; Peres, L. New Trends in Packaging For Foods: A Review. Bol. Cent. Pesqui. Process. Aliment. 2010, 28, 69–84. [Google Scholar]

- Napper, I.E.; Thompson, R.C. Chapter 22—Marine Plastic Pollution: Other Than Microplastic. In Waste, 2nd ed.; Letcher, T.M., Vallero, D.A., Eds.; Academic Press: Waltham, MA, USA, 2019; pp. 425–442. [Google Scholar]

- Mellinas, C.; Valdés, A.; Ramos, M.; Burgos, N.; Garrigós, M.d.C.; Jiménez, A. Active edible films: Current state and future trends. J. Appl. Polym. Sci. 2016, 133, 42631. [Google Scholar] [CrossRef]

- Yun, D.; Liu, J. Recent advances on the development of food packaging films based on citrus processing wastes: A review. J. Agric. Food Res. 2022, 9, 100316. [Google Scholar] [CrossRef]

- Falleh, H.; Ben Jemaa, M.; Saada, M.; Ksouri, R. Essential oils: A promising eco-friendly food preservative. Food Chem. 2020, 330, 127268. [Google Scholar] [CrossRef]

- Ortiz, C.; Vicente, A.; Mauri, A. Combined use of physical treatments and edible coatings in fresh produce: Moving beyond. Stewart Postharvest Rev. 2014, 10, 1–6. [Google Scholar]

- Motelica, L.; Ficai, D.; Oprea, O.C.; Ficai, A.; Andronescu, E. Smart Food Packaging Designed by Nanotechnological and Drug Delivery Approaches. Coatings 2020, 10, 806. [Google Scholar] [CrossRef]

- European Commission. Regulation (EC) No 1935/2004 of the European Parliament and of the Council of 27 October 2004 on Materials and Articles Intended to Come into Contact with Food and Repealing Directives 80/590/EEC and 89/109/EEC; European Commission: Brussels, Belgium, 2004. [Google Scholar]

- Liegeard, J.; Manning, L. Use of intelligent applications to reduce household food waste. Crit. Rev. Food Sci. Nutr. 2020, 60, 1048–1061. [Google Scholar] [CrossRef] [PubMed]

- Juikar, S.K.; Warkar, S.G. Biopolymers for packaging applications: An overview. Packag. Technol. Sci. 2023, 36, 229–251. [Google Scholar] [CrossRef]

- Gupta, V.; Biswas, D.; Roy, S. A Comprehensive Review of Biodegradable Polymer-Based Films and Coatings and Their Food Packaging Applications. Materials 2022, 15, 5899. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Iacovidou, E.; Gerassimidou, S. Plastic waste in a circular economy. In Plastic Waste and Recycling; Letcher, T.M., Ed.; Academic Press: Waltham, MA, USA, 2020; pp. 481–512. [Google Scholar]

- European Commission. Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Plastic Products on the Environment (Text with EEA Relevance); European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. Commission Regulation (EC) No 450/2009 of 29 May 2009 on Active and Intelligent Materials and Articles Intended to Come into Contact with Food (Text with EEA Relevance); European Commission: Brussels, Belgium, 2009. [Google Scholar]

- Amin, U.; Khan, M.U.; Majeed, Y.; Rebezov, M.; Khayrullin, M.; Bobkova, E.; Shariati, M.A.; Chung, I.M.; Thiruvengadam, M. Potentials of polysaccharides, lipids and proteins in biodegradable food packaging applications. Int. J. Biol. Macromol. 2021, 183, 2184–2198. [Google Scholar] [CrossRef]

- Cheng, J.; Gao, R.; Zhu, Y.; Lin, Q. Applications of biodegradable materials in food packaging: A review. Alex. Eng. J. 2024, 91, 70–83. [Google Scholar] [CrossRef]

- EN 13432:2000; Packaging—Requirements for Packaging Recoverable Through Composting and Biodegradation—Test Scheme and Evaluation Criteria for the Final Acceptance of Packaging. European Committee for Standardization: Brussels, Belgium, 2020.

- ASTM D6400; Standard Specification for Labeling of Plastics Designed to be Aerobically Composted in Municipal or Industrial Facilities. ASTM International: West Conshohocken, PA, USA, 2022.

- Salgado, P.R.; Ortiz, C.M.; Musso, Y.S.; Di Giorgio, L.; Mauri, A.N. Edible films and coatings containing bioactives. Curr. Opin. Food Sci. 2015, 5, 86–92. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Kamalesh, R.; Senthil Kumar, P.; Saravanan, A.; Vijayasri, K.; Rangasamy, G. Recent advances in edible coatings and their application in food packaging. Food Res. Int. 2023, 173, 113366. [Google Scholar] [CrossRef]

- Arruda, T.R.; Machado, G.d.O.; Marques, C.S.; Souza, A.L.d.; Pelissari, F.M.; Oliveira, T.V.d.; Silva, R.R.A. An Overview of Starch-Based Materials for Sustainable Food Packaging: Recent Advances, Limitations, and Perspectives. Macromol 2025, 5, 19. [Google Scholar] [CrossRef]

- Dutta, D.; Sit, N. Comprehensive review on developments in starch-based films along with active ingredients for sustainable food packaging. Sustain. Chem. Pharm. 2024, 39, 101534. [Google Scholar] [CrossRef]

- Pei, J.; Chella Perumal, D.P.; Srinivasan, G.P.; Panagal, M.; Dhilip Kumar, S.S.; Mironescu, M. A comprehensive review on starch-based sustainable edible films loaded with bioactive components for food packaging. Int. J. Biol. Macromol. 2024, 274, 133332. [Google Scholar] [CrossRef] [PubMed]

- Hui, C.; Jiang, H.; Liu, B.; Wei, R.; Zhang, Y.; Zhang, Q.; Liang, Y.; Zhao, Y. Chitin degradation and the temporary response of bacterial chitinolytic communities to chitin amendment in soil under different fertilization regimes. Sci. Total Environ. 2020, 705, 136003. [Google Scholar] [CrossRef] [PubMed]

- Yuan, G.; Chen, X.; Li, D. Chitosan films and coatings containing essential oils: The antioxidant and antimicrobial activity, and application in food systems. Food Res. Int. 2016, 89, 117–128. [Google Scholar] [CrossRef]

- Pavinatto, A.; de Almeida Mattos, A.V.; Malpass, A.C.G.; Okura, M.H.; Balogh, D.T.; Sanfelice, R.C. Coating with chitosan-based edible films for mechanical/biological protection of strawberries. Int. J. Biol. Macromol. 2020, 151, 1004–1011. [Google Scholar] [CrossRef]

- Cazon, P.; Vázquez, M. Bacterial cellulose as a biodegradable food packaging material: A review. Food Hydrocoll. 2021, 113, 106530. [Google Scholar] [CrossRef]

- Hoque, M.; Hossain, M.; Hasan, A.; Jubayer, M.; Aktaruzzaman, M. Investigating the characteristics of carboxymethyl cellulose film as a possible material for green packaging. GSC Biol. Pharm. Sci. 2023, 24, 193–201. [Google Scholar] [CrossRef]

- Pakulska, A.; Kawecka, L.; Galus, S. Physical Properties of Selected Fruit Fibre and Pomace in the Context of Their Sustainable Use for Food Applications. Appl. Sci. 2024, 14, 9051. [Google Scholar] [CrossRef]

- Mikus, M.; Galus, S. The Effect of Phenolic Acids on the Sorption and Wetting Properties of Apple Pectin-Based Packaging Films. Molecules 2025, 30, 1960. [Google Scholar] [CrossRef]

- Ribeiro, A.J.; de Souza, F.R.L.; Bezerra, J.; Oliveira, C.; Nadvorny, D.; de La Roca Soares, M.F.; Nunes, L.C.C.; Silva-Filho, E.C.; Veiga, F.; Soares Sobrinho, J.L. Gums’ based delivery systems: Review on cashew gum and its derivatives. Carbohydr. Polym. 2016, 147, 188–200. [Google Scholar] [CrossRef] [PubMed]

- Elnour, A.; Mirghani, M.; Kabbashi, N.; Alam, M.; Musa, K.H. Study of Antioxidant and Anti-Inflammatory Crude Methanol Extract and Fractions of Acacia seyal Gum. Am. J. Pharmacol. Pharmacother. 2018, 5, 3. [Google Scholar] [CrossRef]

- Bashir, M.; Usmani, T.; Haripriya, S.; Ahmed, T. Biological and textural properties of underutilized exudate gums of Jammu and Kashmir, India. Int. J. Biol. Macromol. 2018, 109, 847–854. [Google Scholar] [CrossRef] [PubMed]

- Galus, S.; Kowalska, H.; Ignaczak, A.; Kowalska, J.; Karwacka, M.; Ciurzyńska, A.; Janowicz, M. Effects of Polysaccharide-Based Edible Coatings on the Quality of Fresh-Cut Beetroot (Beta vulgaris L.) During Cold Storage. Coatings 2025, 15, 583. [Google Scholar] [CrossRef]

- Tavassoli-Kafrani, E.; Shekarchizadeh, H.; Masoudpour-Behabadi, M. Development of edible films and coatings from alginates and carrageenans. Carbohydr. Polym. 2016, 137, 360–374. [Google Scholar] [CrossRef]

- Chen, J.; Wu, A.; Yang, M.; Ge, Y.; Pristijono, P.; Li, J.; Xu, B.; Mi, H. Characterization of sodium alginate-based films incorporated with thymol for fresh-cut apple packaging. Food Control 2021, 126, 108063. [Google Scholar] [CrossRef]

- Zhu, D.; Guo, R.; Li, W.; Song, J.; Cheng, F. Improved Postharvest Preservation Effects of Pholiota nameko Mushroom by Sodium Alginate–Based Edible Composite Coating. Food Bioprocess. Technol. 2019, 12, 587–598. [Google Scholar] [CrossRef]

- Li, X.-y.; Du, X.-l.; Liu, Y.; Tong, L.-j.; Wang, Q.; Li, J.-l. Rhubarb extract incorporated into an alginate-based edible coating for peach preservation. Sci. Hortic. 2019, 257, 108685. [Google Scholar] [CrossRef]

- Sarengaowa; Hu, W.; Feng, K.; Xiu, Z.; Jiang, A.; Lao, Y. Thyme oil alginate-based edible coatings inhibit growth of pathogenic microorganisms spoiling fresh-cut cantaloupe. Food Biosci. 2019, 32, 100467. [Google Scholar] [CrossRef]

- Calva-Estrada, S.J.; Jiménez-Fernández, M.; Lugo-Cervantes, E. Protein-Based Films: Advances in the Development of Biomaterials Applicable to Food Packaging. Food Eng. Rev. 2019, 11, 78–92. [Google Scholar] [CrossRef]

- Khan, M.R.; Volpe, S.; Valentino, M.; Miele, N.A.; Cavella, S.; Torrieri, E. Active Casein Coatings and Films for Perishable Foods: Structural Properties and Shelf-Life Extension. Coatings 2021, 11, 899. [Google Scholar] [CrossRef]

- Bonnaillie, L.M.; Zhang, H.; Akkurt, S.; Yam, K.L.; Tomasula, P.M. Casein Films: The Effects of Formulation, Environmental Conditions and the Addition of Citric Pectin on the Structure and Mechanical Properties. Polymers 2014, 6, 2018–2036. [Google Scholar] [CrossRef]

- Picchio, M.L.; Linck, Y.G.; Monti, G.A.; Gugliotta, L.M.; Minari, R.J.; Alvarez Igarzabal, C.I. Casein films crosslinked by tannic acid for food packaging applications. Food Hydrocoll. 2018, 84, 424–434. [Google Scholar] [CrossRef]

- Zhu, Q.; Lu, H.; Zhu, J.; Zhang, M.; Yin, L. Development and characterization of pickering emulsion stabilized by zein/corn fiber gum (CFG) complex colloidal particles. Food Hydrocoll. 2019, 91, 204–213. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z.; Wang, X.; Dong, S.; Sun, Y.; Zhao, Z. The properties of chitosan/zein blend film and effect of film on quality of mushroom (Agaricus bisporus). Postharvest Biol. Technol. 2019, 155, 47–56. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Janowicz, M.; Karwacka, M.; Nowacka, M.; Galus, S. Development and Characteristics of Protein Edible Film Derived from Pork Gelatin and Beef Broth. Polymers 2024, 16, 1009. [Google Scholar] [CrossRef]

- Łupina, K.; Kowalczyk, D.; Zięba, E.; Kazimierczak, W.; Mężyńska, M.; Basiura-Cembala, M.; Wiącek, A.E. Edible films made from blends of gelatin and polysaccharide-based emulsifiers—A comparative study. Food Hydrocoll. 2019, 96, 555–567. [Google Scholar] [CrossRef]

- Shankar, S.; Wang, L.-F.; Rhim, J.-W. Effect of melanin nanoparticles on the mechanical, water vapor barrier, and antioxidant properties of gelatin-based films for food packaging application. Food Packag. Shelf Life 2019, 21, 100363. [Google Scholar] [CrossRef]

- Galus, S. Soy Protein Edible Films with Improved Properties Through the Blending Process. In Soy-Based Bioplastics; Vijay Kumar Thakur, M.K.T., Michael, R., Kessler, Eds.; Smithers Rapra: Akron, OH, USA, 2017; pp. 151–166. [Google Scholar]

- Galus, S. Functional properties of soy protein isolate edible films as affected by rapeseed oil concentration. Food Hydrocoll. 2018, 85, 233–241. [Google Scholar] [CrossRef]

- Thakur, R.; Pristijono, P.; Golding, J.B.; Stathopoulos, C.E.; Scarlett, C.J.; Bowyer, M.; Singh, S.P.; Vuong, Q.V. Amylose-lipid complex as a measure of variations in physical, mechanical and barrier attributes of rice starch- ι -carrageenan biodegradable edible film. Food Packag. Shelf Life 2017, 14, 108–115. [Google Scholar] [CrossRef]

- Goslinska, M.; Heinrich, S. Characterization of waxes as possible coating material for organic aerogels. Powder Technol. 2019, 357, 223–231. [Google Scholar] [CrossRef]

- Susmita Devi, L.; Kalita, S.; Mukherjee, A.; Kumar, S. Carnauba wax-based composite films and coatings: Recent advancement in prolonging postharvest shelf-life of fruits and vegetables. Trends Food Sci. Technol. 2022, 129, 296–305. [Google Scholar] [CrossRef]

- Formiga, A.S.; Pinsetta, J.S.; Pereira, E.M.; Cordeiro, I.N.F.; Mattiuz, B.-H. Use of edible coatings based on hydroxypropyl methylcellulose and beeswax in the conservation of red guava ‘Pedro Sato’. Food Chem. 2019, 290, 144–151. [Google Scholar] [CrossRef]

- Galus, S.; Gaouditz, M.; Kowalska, H.; Debeaufort, F. Effects of Candelilla and Carnauba Wax Incorporation on the Functional Properties of Edible Sodium Caseinate Films. Int. J. Mol. Sci. 2020, 21, 9349. [Google Scholar] [CrossRef] [PubMed]

- Oregel-Zamudio, E.; Angoa-Pérez, M.V.; Oyoque-Salcedo, G.; Aguilar-González, C.N.; Mena-Violante, H.G. Effect of candelilla wax edible coatings combined with biocontrol bacteria on strawberry quality during the shelf-life. Sci. Hortic. 2017, 214, 273–279. [Google Scholar] [CrossRef]

- Kurek, M.; Garofulić, I.E.; Bakić, M.T.; Ščetar, M.; Uzelac, V.D.; Galić, K. Development and evaluation of a novel antioxidant and pH indicator film based on chitosan and food waste sources of antioxidants. Food Hydrocoll. 2018, 84, 238–246. [Google Scholar] [CrossRef]

- Cristofoli, N.L.; Lima, A.R.; Tchonkouang, R.D.N.; Quintino, A.C.; Vieira, M.C. Advances in the Food Packaging Production from Agri-Food Waste and By-Products: Market Trends for a Sustainable Development. Sustainability 2023, 15, 6153. [Google Scholar] [CrossRef]

- Pandey, A.K.; Thakur, S.; Mehra, R.; Kaler, R.S.S.; Paul, M.; Kumar, A. Transforming Agri-food waste: Innovative pathways toward a zero-waste circular economy. Food Chem. X 2025, 28, 102604. [Google Scholar] [CrossRef]

- Xu, K.; Xiao, X.; Wang, L.; Lou, M.; Wang, F.; Li, C.; Ren, H.; Wang, X.; Chang, K. Data-Driven Materials Research and Development for Functional Coatings. Adv. Sci. 2024, 11, 2405262. [Google Scholar] [CrossRef]

- Shafiq, M.; Anjum, S.; Hano, C.; Anjum, I.; Abbasi, B.H. An Overview of the Applications of Nanomaterials and Nanodevices in the Food Industry. Foods 2020, 9, 148. [Google Scholar] [CrossRef]

- Donsì, F.; Annunziata, M.; Sessa, M.; Ferrari, G. Nanoencapsulation of essential oils to enhance their antimicrobial activity in foods. LWT Food Sci. Technol. 2011, 44, 1908–1914. [Google Scholar] [CrossRef]

- Ceylan, Z.; Unal Sengor, G.F.; Yilmaz, M.T. Nanoencapsulation of liquid smoke/thymol combination in chitosan nanofibers to delay microbiological spoilage of sea bass (Dicentrarchus labrax) fillets. J. Food Eng. 2018, 229, 43–49. [Google Scholar] [CrossRef]

- Singh, S.P. A Review On Fast Dissolving Formulation Technologies. World J. Pharm. Pharm. Sci. 2015, 4, 574–585. [Google Scholar]

- Ali, M.S.; Choppari, V. Formulation and Evaluation of Fast Dissolving Oral Films of Diazepam. J. Pharmacovigil. 2016, 4, 210. [Google Scholar] [CrossRef]

- Hemavathy, S.; Sinha, P.; Ubaidulla, U.; Rathnam, G. A Detailed Account On Novel Oral Fast Dissolving Strips: Application And Future Prospects. Int. J. Creat. Res. Thoughts 2022, 10, 773–787. [Google Scholar]

- Thakur, N.; Bansal, M.; Sharma, N.; Yadav, G.; Khare, P. Overview A Novel Approach of Fast Dissolving Films and Their Patients. Adv. Biol. Res. 2013, 7, 50–58. [Google Scholar]

- Bala, R.; Pawar, P.; Khanna, S.; Arora, S. Orally dissolving strips: A new approach to oral drug delivery system. Int. J. Pharm. Investig. 2013, 3, 67–76. [Google Scholar] [CrossRef] [PubMed]

- Kanavouras, A.; Hernandez-Munoz, P.; Coutelieris, F.A. Packaging of Olive Oil: Quality Issues and Shelf Life Predictions. Food Rev. Int. 2006, 22, 381–404. [Google Scholar] [CrossRef]

- Lee, Y.S.; Shin, H.-S.; Han, J.-K.; Lee, M.; Giacin, J.R. Effectiveness of antioxidant-impregnated film in retarding lipid oxidation. J. Sci. Food Agr. 2004, 84, 993–1000. [Google Scholar] [CrossRef]

- Giménez, B.; Gómez-Estaca, J.; Alemán, A.; Gómez-Guillén, M.C.; Montero, M.P. Improvement of the antioxidant properties of squid skin gelatin films by the addition of hydrolysates from squid gelatin. Food Hydrocoll. 2009, 23, 1322–1327. [Google Scholar] [CrossRef]

- Guo, M.; Jin, T.Z.; Wang, L.; Scullen, O.J.; Sommers, C.H. Antimicrobial films and coatings for inactivation of Listeria innocua on ready-to-eat deli turkey meat. Food Control 2014, 40, 64–70. [Google Scholar] [CrossRef]

- Mathew, S.; Snigdha, S.; Mathew, J.; E.K, R. Biodegradable and active nanocomposite pouches reinforced with silver nanoparticles for improved packaging of chicken sausages. Food Packag. Shelf Life 2019, 19, 155–166. [Google Scholar] [CrossRef]

- Díaz, P.; Garrido, M.D.; Bañón, S. The effects of packaging method (vacuum pouch vs. plastic tray) on spoilage in a cook-chill pork-based dish kept under refrigeration. Meat Sci. 2010, 84, 538–544. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Xue, R. Nanostructured materials for smart food packaging: Integrating preservation and antimicrobial properties. Alex. Eng. J. 2025, 124, 446–461. [Google Scholar] [CrossRef]

- Chaari, M.; Elhadef, K.; Akermi, S.; Ben Akacha, B.; Fourati, M.; Chakchouk Mtibaa, A.; Ennouri, M.; Sarkar, T.; Shariati, M.A.; Rebezov, M.; et al. Novel Active Food Packaging Films Based on Gelatin-Sodium Alginate Containing Beetroot Peel Extract. Antioxidants 2022, 11, 2095. [Google Scholar] [CrossRef]

- Kozakiewicz, G.; Małajowicz, J.; Szulc, K.; Karwacka, M.; Ciurzyńska, A.; Żelazko, A.; Janowicz, M.; Galus, S. The Effect of a Pectin Coating with Gamma-Decalactone on Selected Quality Attributes of Strawberries During Refrigerated Storage. Coatings 2025, 15, 903. [Google Scholar] [CrossRef]

- Soltani Firouz, M.; Mohi-Alden, K.; Omid, M. A critical review on intelligent and active packaging in the food industry: Research and development. Food Res. Int. 2021, 141, 110113. [Google Scholar] [CrossRef]

- Ahmed, M.W.; Haque, M.A.; Mohibbullah, M.; Khan, M.S.I.; Islam, M.A.; Mondal, M.H.T.; Ahmmed, R. A review on active packaging for quality and safety of foods: Current trends, applications, prospects and challenges. Food Packag. Shelf Life 2022, 33, 100913. [Google Scholar] [CrossRef]

- Mikus, M.; Galus, S. Biopolymer active materials for food. Food Sci. Technol. Qual. 2023, 30, 18–32. [Google Scholar] [CrossRef]

- Salama, H.E.; Abdel Aziz, M.S.; Sabaa, M.W. Development of antibacterial carboxymethyl cellulose/chitosan biguanidine hydrochloride edible films activated with frankincense essential oil. Int. J. Biol. Macromol. 2019, 139, 1162–1167. [Google Scholar] [CrossRef]

- Heydari-Majd, M.; Ghanbarzadeh, B.; Shahidi-Noghabi, M.; Najafi, M.A.; Hosseini, M. A new active nanocomposite film based on PLA/ZnO nanoparticle/essential oils for the preservation of refrigerated Otolithes ruber fillets. Food Packag. Shelf Life 2019, 19, 94–103. [Google Scholar] [CrossRef]

- Moghimi, R.; Aliahmadi, A.; Rafati, H. Antibacterial hydroxypropyl methyl cellulose edible films containing nanoemulsions of Thymus daenensis essential oil for food packaging. Carbohydr. Polym. 2017, 175, 241–248. [Google Scholar] [CrossRef]

- Hashemi, S.M.B.; Mousavi Khaneghah, A. Characterization of novel basil-seed gum active edible films and coatings containing oregano essential oil. Prog. Org. Coat. 2017, 110, 35–41. [Google Scholar] [CrossRef]

| Pouch Main Components | Food Application | Effect | References |

|---|---|---|---|

| Corn zein | Cheese | Maintain the cheese qualities proved by the physical and microbiological changes over 28 days at 5 °C | [29] |

| Corn zein and soy protein isolate | Olive oil | Reducing the increase in peroxide values during 120 days of storage (enhanced the oxidative stability) | [30] |

| Soybean polysaccharide and pork gelatin | Instant coffee, coconut powder | Dissolving in water in less than 30 s; no tests on the product | [28] |

| Whey protein isolate | Instant coffee; salad dressing | Dissolving (completely or partially) in hot water (90 °C); no tests on the product | [27] |

| Corn starch, low methoxyl pectin and bovine gelatin and carboxymethylcellulose | Instant coffee | Preservation of quality characteristics | [26] |

| Orange peels, calcium salts and citric acid | Herbs | No tests on the product | [33] |

| Gelatin and chitosan | Shrimp oil | Enhanced the oxidative stability | [34] |

| Fish gelatin | Chicken skin oil | Enhanced the oxidative stability | [35] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Omid Jeivan, A.; Galus, S. Edible Pouch Packaging for Food Applications—A Review. Processes 2025, 13, 2910. https://doi.org/10.3390/pr13092910

Omid Jeivan A, Galus S. Edible Pouch Packaging for Food Applications—A Review. Processes. 2025; 13(9):2910. https://doi.org/10.3390/pr13092910

Chicago/Turabian StyleOmid Jeivan, Azin, and Sabina Galus. 2025. "Edible Pouch Packaging for Food Applications—A Review" Processes 13, no. 9: 2910. https://doi.org/10.3390/pr13092910

APA StyleOmid Jeivan, A., & Galus, S. (2025). Edible Pouch Packaging for Food Applications—A Review. Processes, 13(9), 2910. https://doi.org/10.3390/pr13092910