Remaining Oil Distribution Characteristics in Sandy Conglomerate Reservoirs During CO2-WAG Flooding: Insights from Nuclear Magnetic Resonance (NMR) Technology

Abstract

1. Introduction

2. Experiments

2.1. Experimental Materials

2.2. Experimental Setup and Procedure

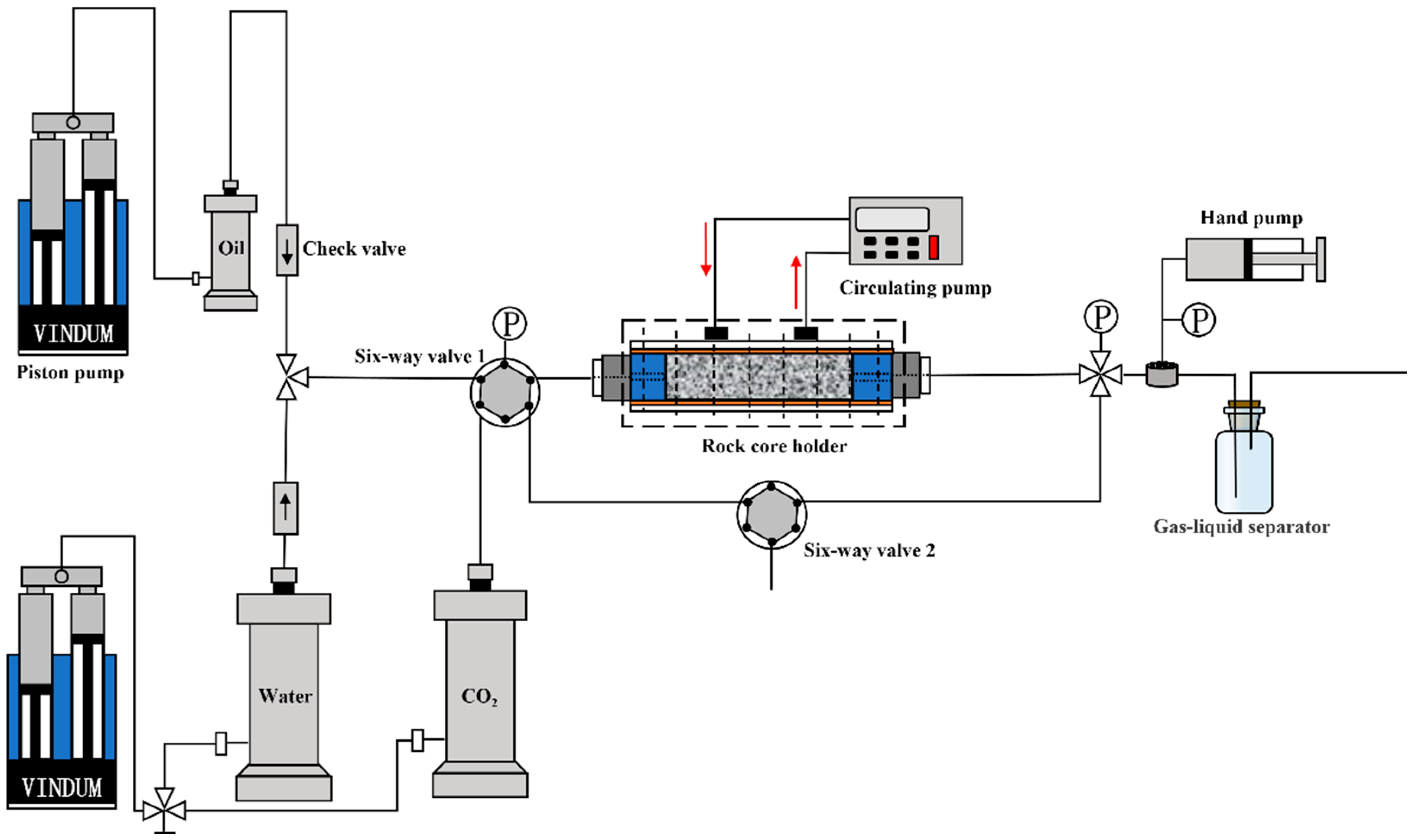

2.2.1. Experimental Setup

2.2.2. Experimental Procedure

- (1)

- Wash and dry the experimental core, measure the length and diameter of the core, and determine the porosity and permeability of the experimental core.

- (2)

- Each core was vacuumed and then saturated with water at a displacement rate of 0.05 mL/min. The volume of saturated water was measured, after which the core was saturated with oil until no water was produced at the outlet. The volume of saturated oil was then measured to determine the bound water saturation.

- (3)

- Before the experiment, anhydrous ethanol was used to clean the pipeline of the test system, and experimental water was used to continue washing after cleaning.

- (4)

- Leak detection of the experimental system was performed to ensure the airtightness of the test system, to ensure the accuracy of the experiment and facilitate the smooth conduct of subsequent experiments.

- (5)

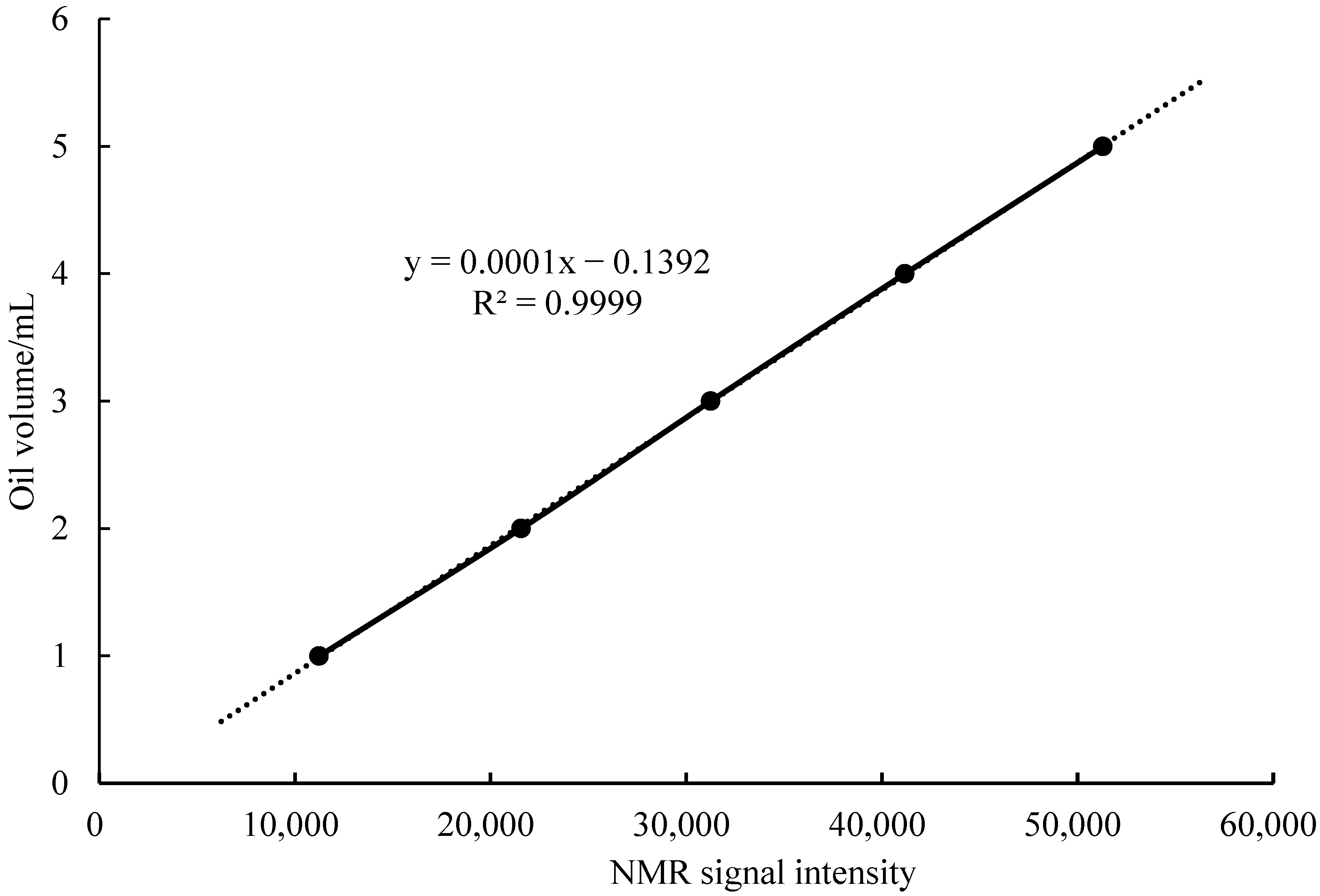

- Before displacement, the core was scanned with a NMR scanner to see the distribution of oil and water and calculate the porosity and permeability. The NMR-related parameters were set as follows: echo time of 0.1 ms; number of echoes of 25,000; and number of accumulations of 64.

- (6)

- The core was placed into the core holder, the instrument installed, and the switching of each valve checked, to prepare for the experiment.

- (7)

- Confining pressure and back pressure was added to the core according to the experimental scheme, the constant pressure and constant speed pump was opened, and the pump parameters adjusted according to the formulated experimental scheme.

- (8)

- Under the condition of keeping the pressure unchanged, the displacement was started. During the displacement process, the nuclear magnetic scanner was used to scan the core and observe the distribution of oil and water.

- (9)

- After displacement, the pressure in the experimental system was relieved, the desktop cleaned, and the experimental equipment organized.

3. Results and Discussion

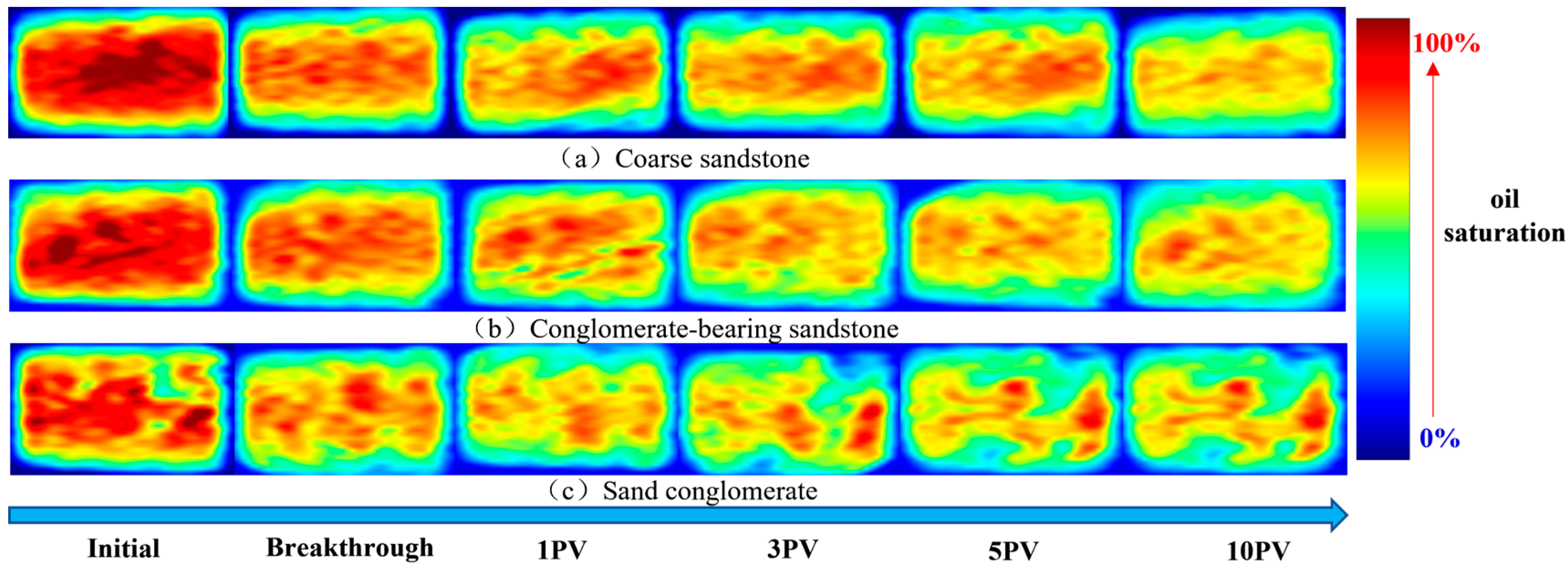

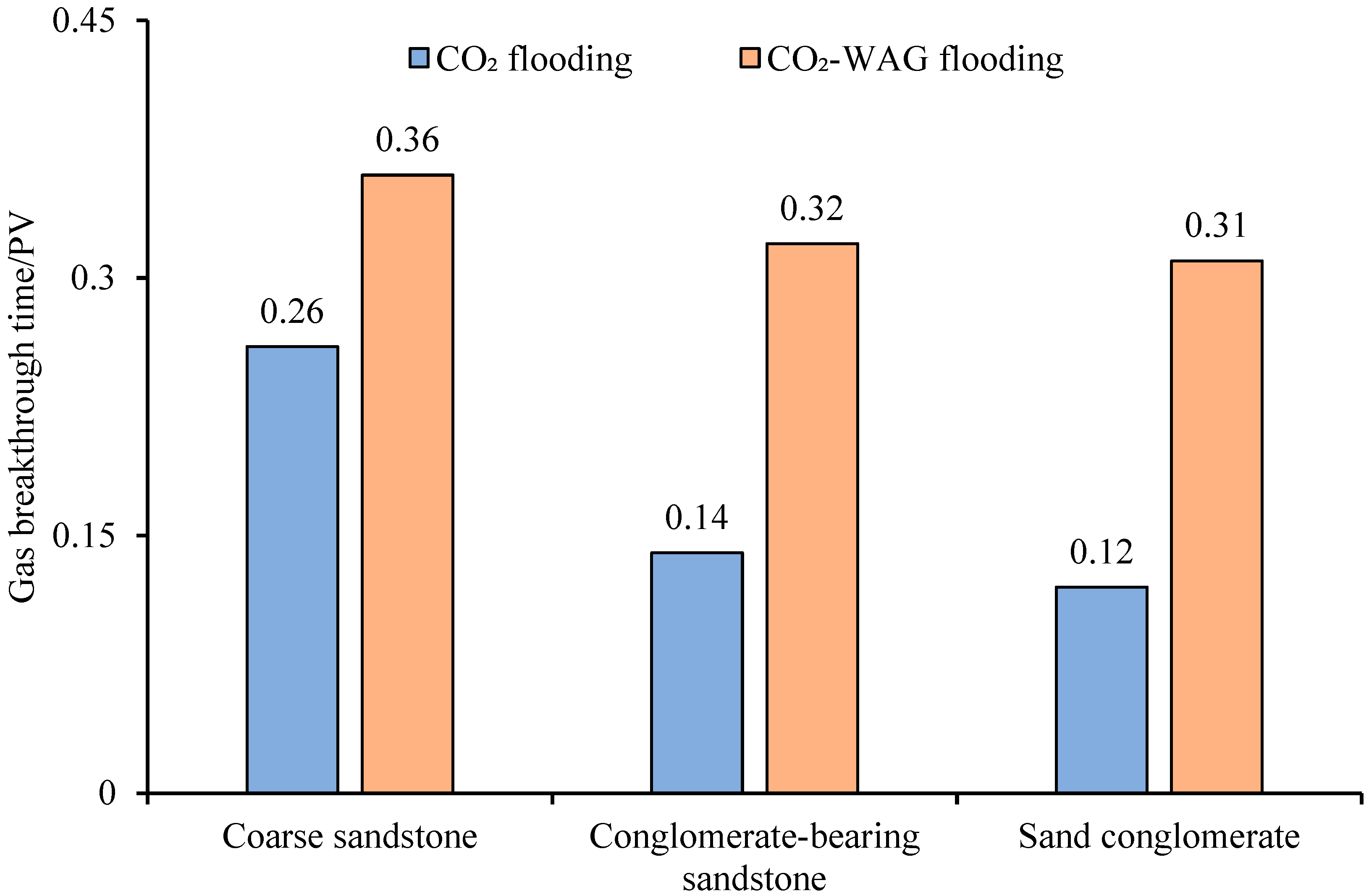

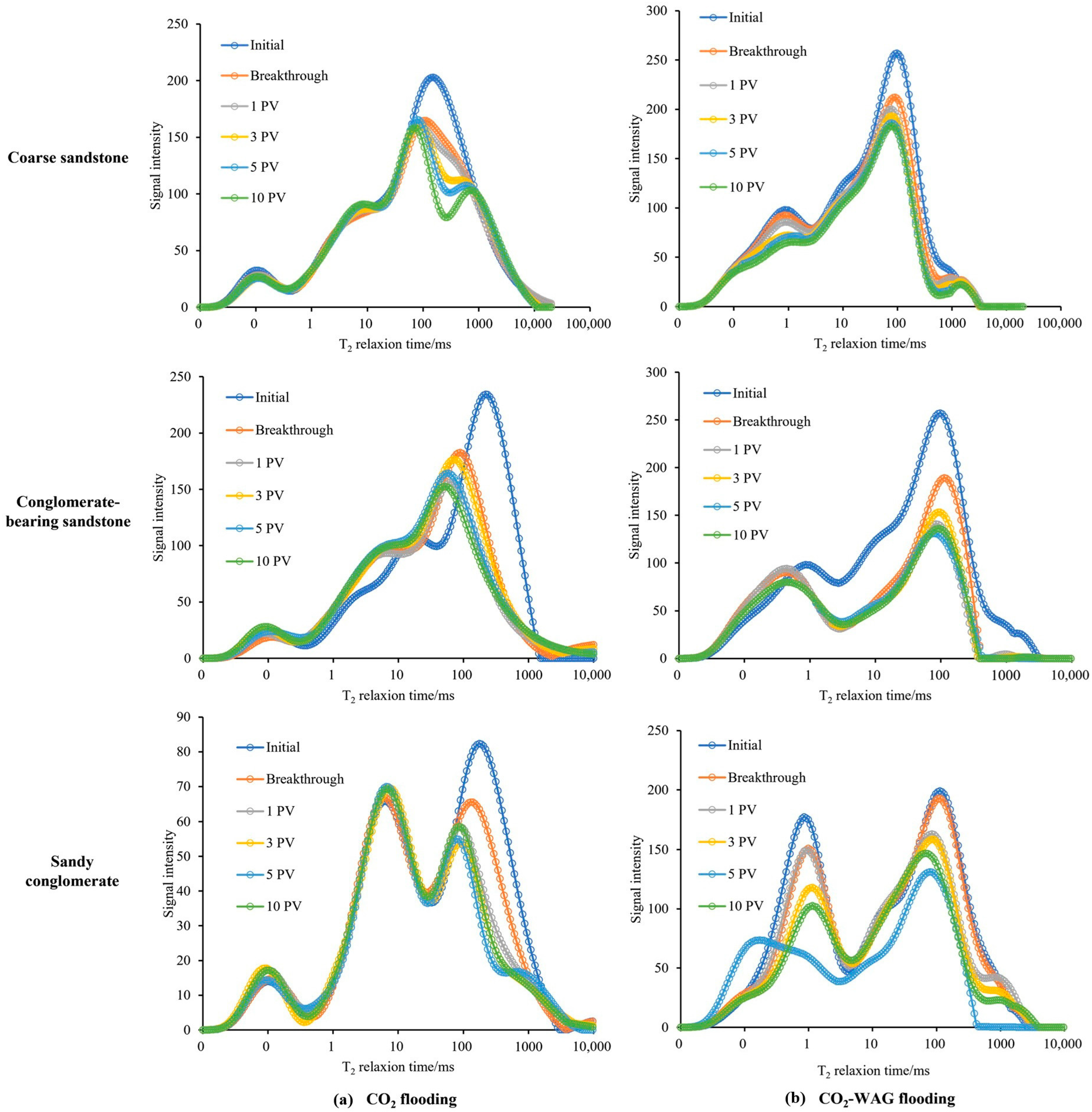

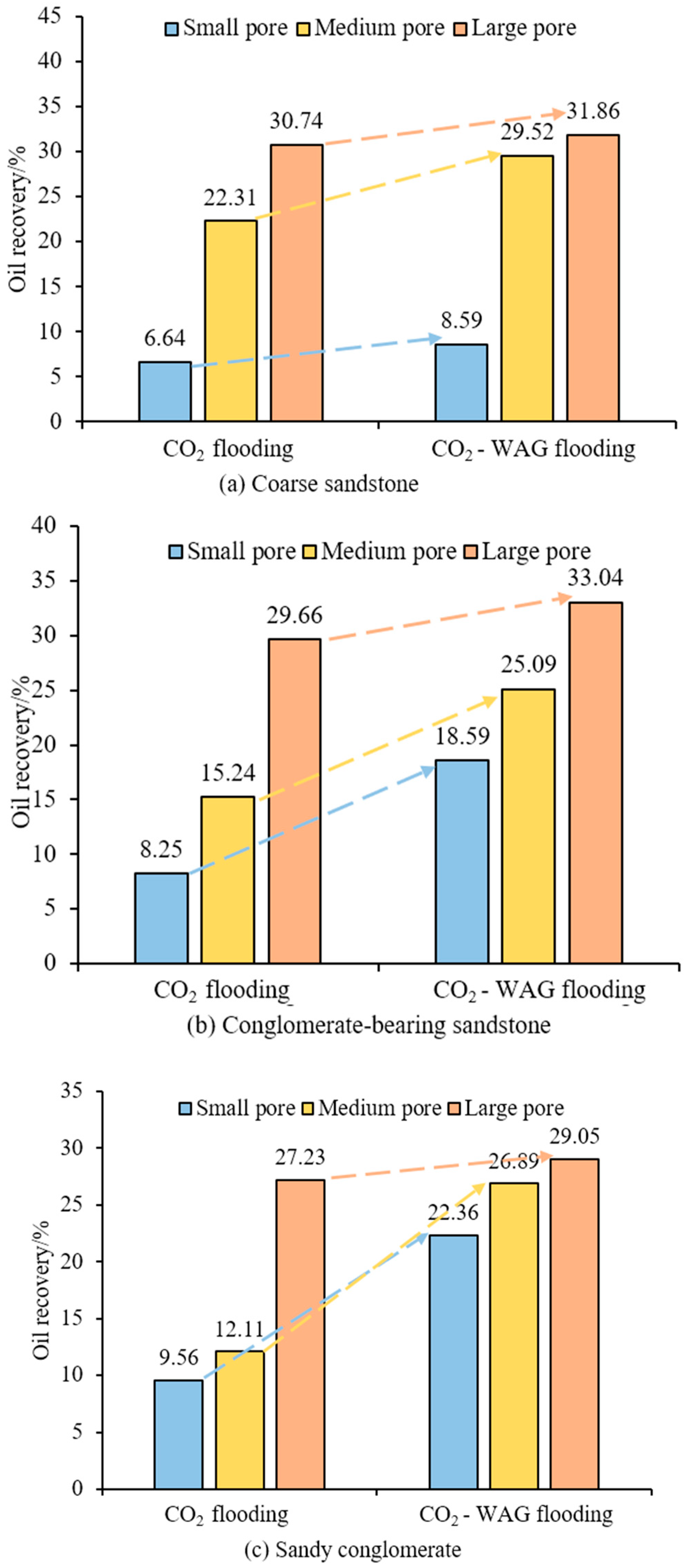

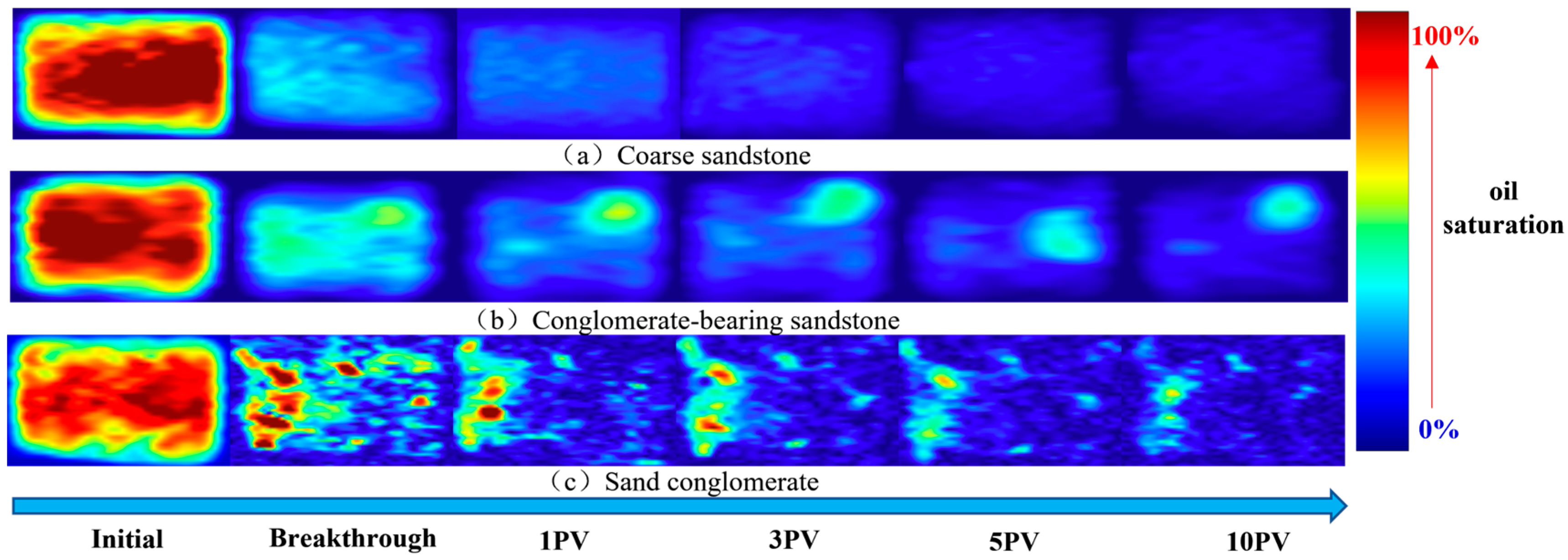

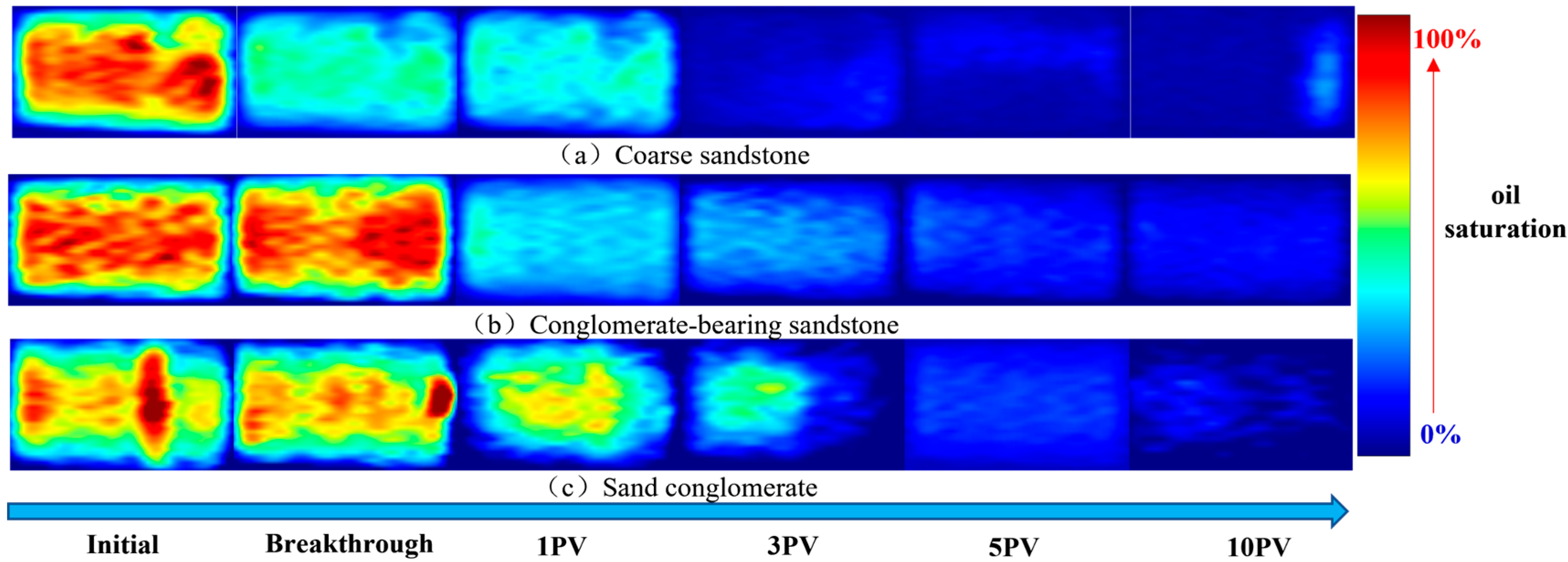

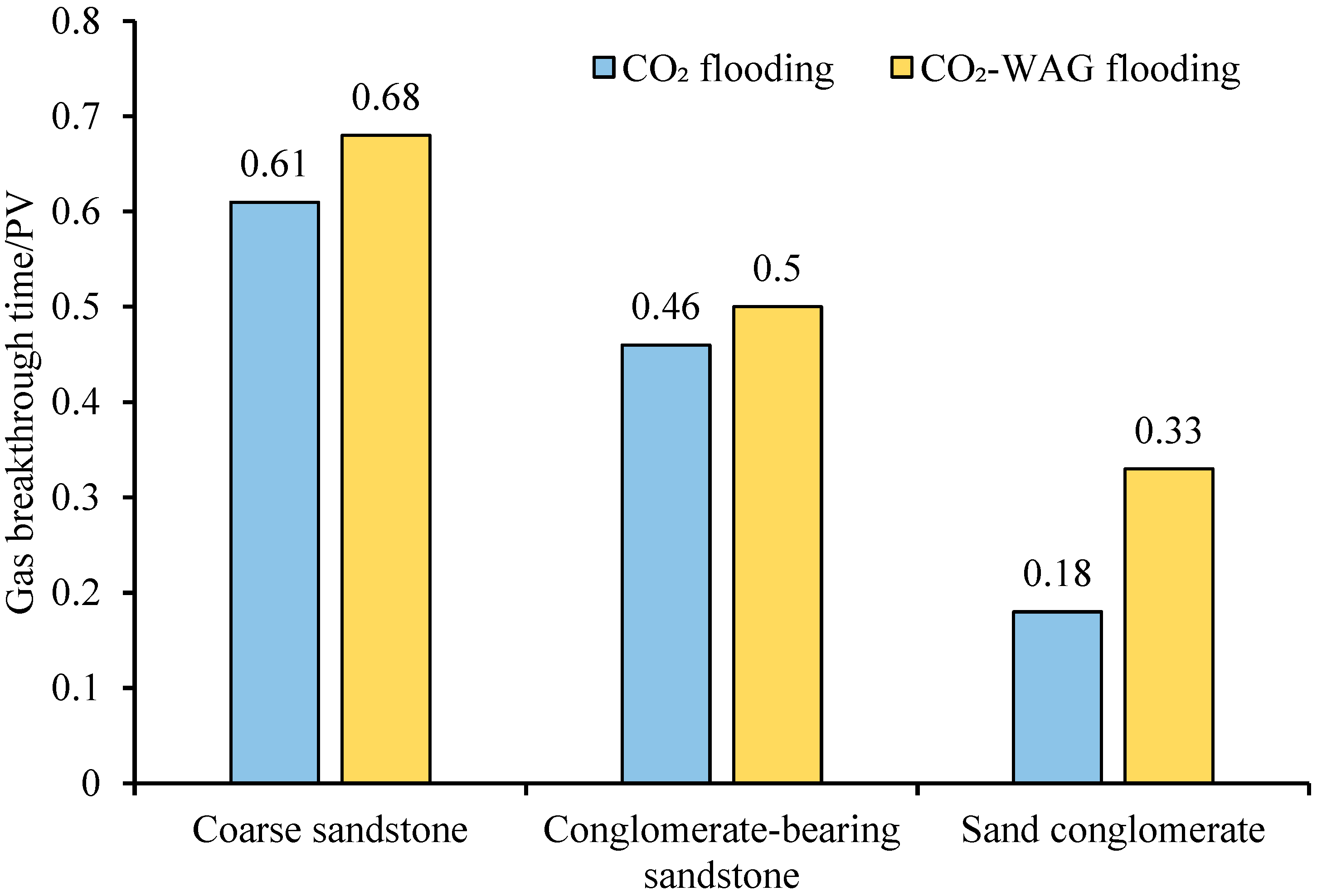

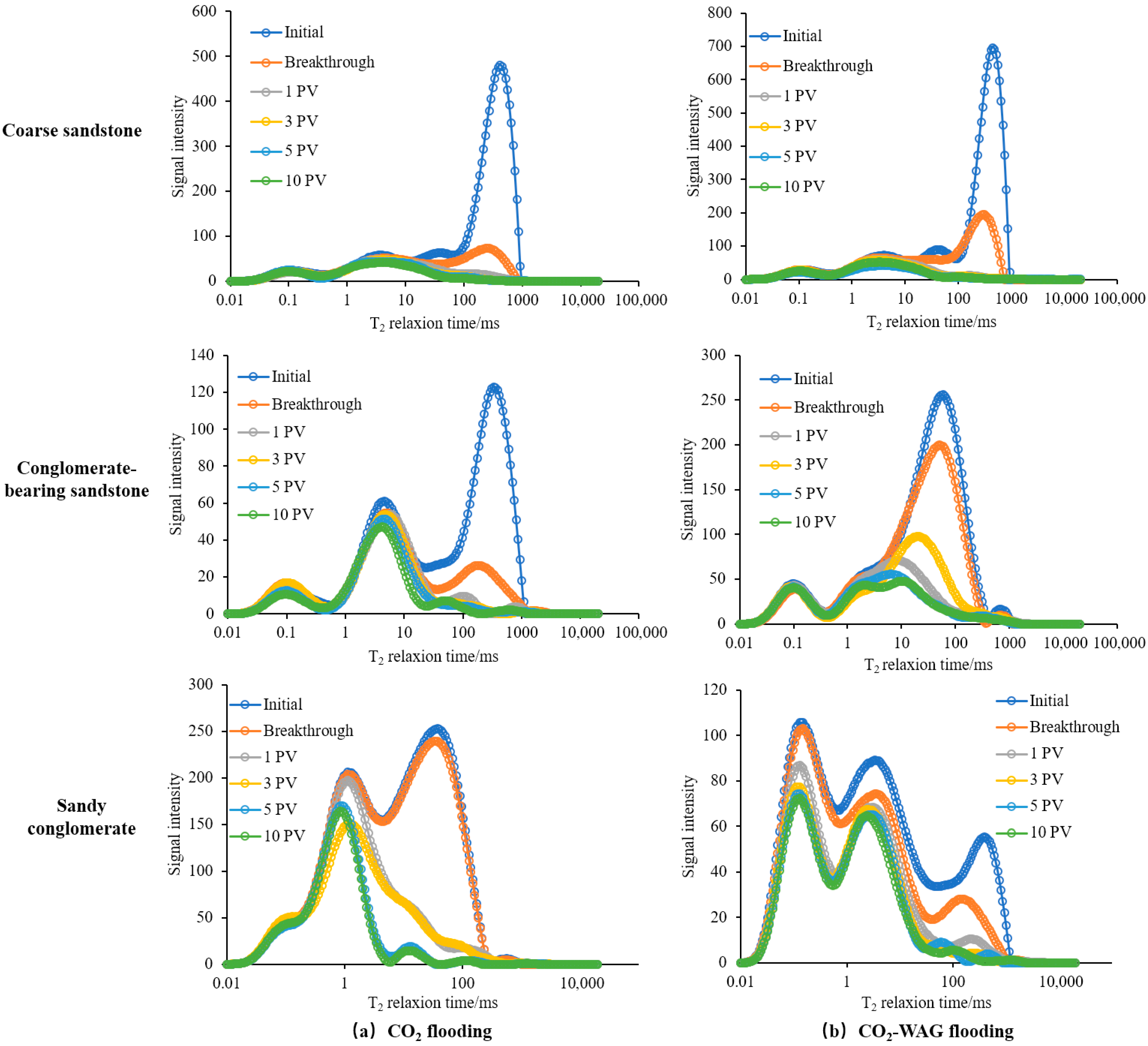

3.1. Immiscible Displacement Experiment

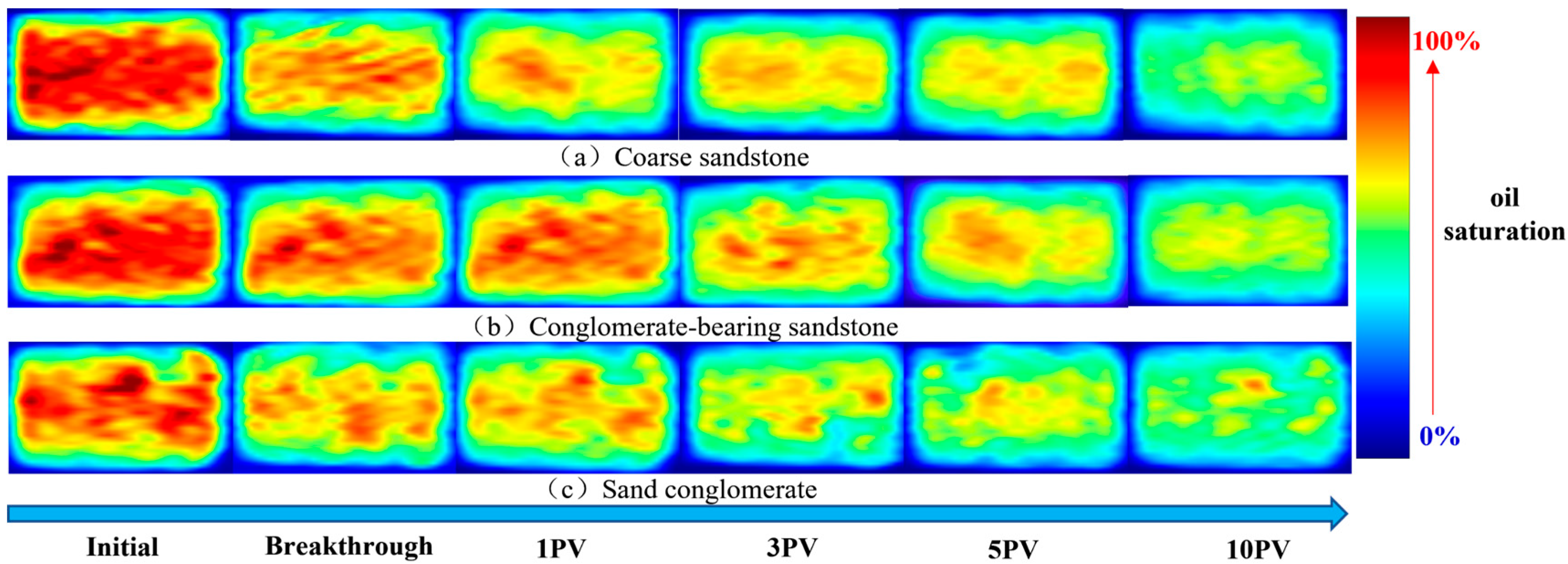

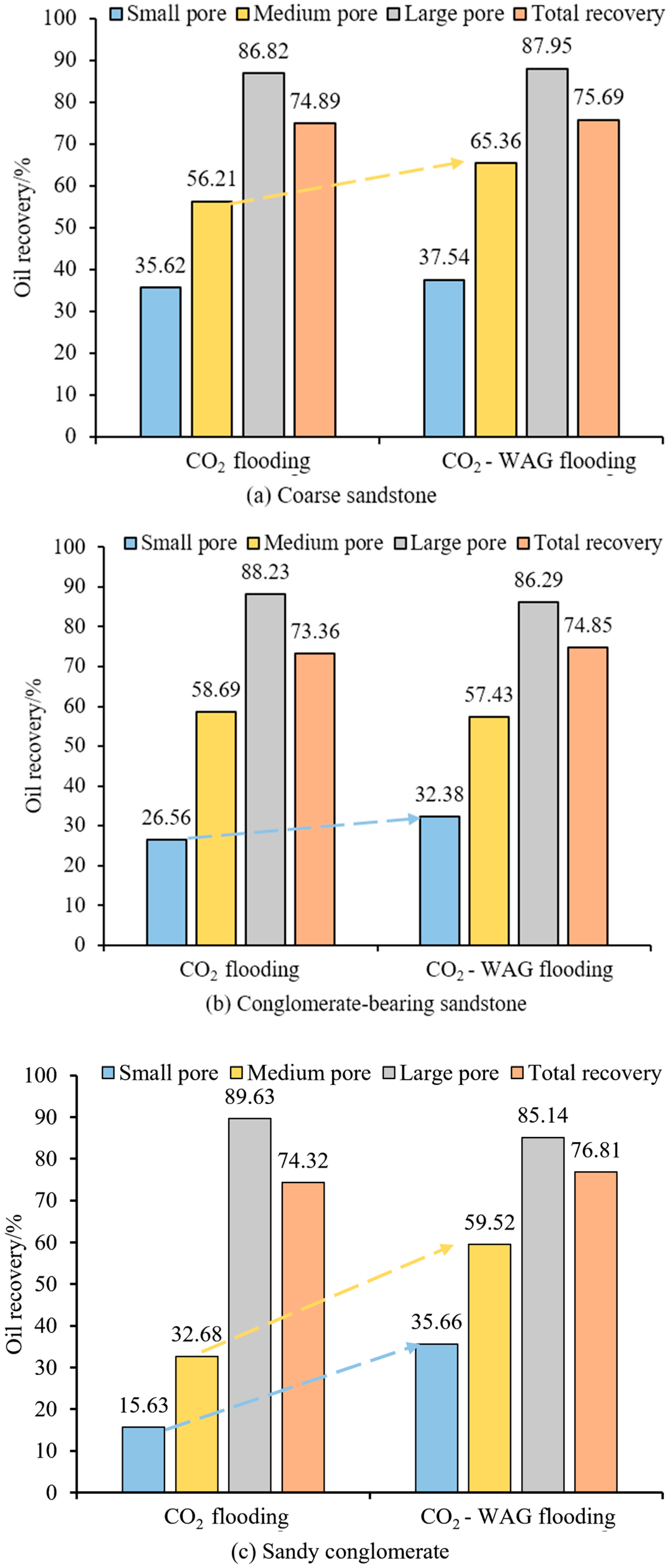

3.2. Miscible Displacement Experiment

4. Conclusions

- (1)

- Pore heterogeneity affects the NMR displacement trend through the dual effects of preferential channel development and fluid production uniformity. Immiscible CO2 flooding mainly recovers crude oil from macropores, while crude oil in micropores and mesopores is difficult to recover. After gas channeling, large-scale residual oil aggregates still remain in the core, resulting in low recovery efficiency. Compared with coarse sandstone, the strong heterogeneity of sandy conglomerate leads to faster gas breakthrough in gas flooding and low recovery rate.

- (2)

- Compared with CO2 flooding, CO2-water alternating gas (WAG) flooding can balance the microscopic oil displacement effect between micropores and macropores, and significantly increase oil production from micropores and medium pores. The core mechanism by which CO2-WAG flooding improves crude oil recovery in micropores lies in the aqueous phase’s ‘profile control’ effect in micropores, which blocks preferential channeling paths. This not only delays gas channeling during immiscible CO2 flooding and enhances core oil recovery but also exhibits a more pronounced improvement effect for sandy conglomerates with strong heterogeneity.

- (3)

- Miscible CO2 flooding can effectively extract the oil in the mesopores and micropores that is difficult to displace using immiscible CO2 flooding. Also, the gas breakthrough is slower, and the recovery rate is much higher in miscible CO2-WAG flooding than that of immiscible one. Therefore, ensuring that the formation pressure is higher than the minimum pressure to achieve miscible flooding is the key to reservoir stimulation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tao, S.; Ju, W.; Chen, S.; Zhang, Z.; Han, J. Exploration and Development of Unconventional Oil and Gas Resources: Latest Advances and Prospects; MDPI AG: Basel, Switzerland, 2024. [Google Scholar]

- Alvarado, V.; Manrique, E. Enhanced oil recovery: An update review. Energies 2010, 3, 1529–1575. [Google Scholar] [CrossRef]

- Pradhan, A.; Al-Mayyan, H.; Malallah, M.; Al-Mutairi, F.; Ziyab, K.; Nurafza, P.; Srivastava, A.; Mishra, S.; Faulkner, T. First Miscible Gas Injection EOR Pilot in Kuwait: Integrated Reservoir Modelling Challenges & its Implications for Full Field CO2 EOR Development. In Proceedings of the ADIPEC, Abu Dhabi, United Arab Emirates, 4–7 November 2024; OnePetro: Richardson, TX, USA, 2024. [Google Scholar]

- Xu, S.; BinAmro, A.A.; Al Keebali, A.K.; Baslaib, M.; Masalmeh, S. Miscible Gas Injection EOR Complex Challenges–A CCUS Hub Approach to Unlock Value for a Multi Reservoir Onshore Field. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 15–18 November 2021; SPE: Richardson, TX, USA, 2021. [Google Scholar]

- Muggeridge, A.; Cockin, A.; Webb, K.; Frampton, H.; Collins, I.; Moulds, T.; Salino, P. Recovery rates, enhanced oil recovery and technological limits. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20120320. [Google Scholar] [CrossRef]

- Yang, W.; Peng, B.; Liu, Q.; Wang, S.; Dong, Y.; Lai, Y. Evaluation of CO2 enhanced oil recovery and CO2 storage potential in oil reservoirs of Bohai Bay Basin, China. Int. J. Greenh. Gas Control 2017, 65, 86–98. [Google Scholar] [CrossRef]

- Godec, M.; Kuuskraa, V.; Van Leeuwen, T.; Melzer, L.S.; Wildgust, N. CO2 storage in depleted oil fields: The worldwide potential for carbon dioxide enhanced oil recovery. Energy Procedia 2011, 4, 2162–2169. [Google Scholar] [CrossRef]

- Tan, Y.; Li, Q.; Xu, L.; Ghaffar, A.; Zhou, X.; Li, P. A critical review of carbon dioxide enhanced oil recovery in carbonate reservoirs. Fuel 2022, 328, 125256. [Google Scholar] [CrossRef]

- Liu, X.; Chen, H.; Li, Y.; Zhu, Y.; Liao, H.; Zhao, Q.; Zhou, X.; Zeng, H. Oil production characteristics and CO2 storage mechanisms of CO2 flooding in ultra-low permeability sandstone oil reservoirs. Pet. Explor. Dev. 2025, 52, 174–184. [Google Scholar] [CrossRef]

- Wan, T.; Zhang, J.; Dong, Y. Microscopic Oil Mobility in Tight Conglomerate Reservoirs Under Different Development Modes, Mahu Sag. Xinjiang Pet. Geol. 2024, 45, 327–333. [Google Scholar]

- Zhang, L.; Yue, X.; Yang, Z. Immiscible water-alternating-gas experiments in high-temperature heterogeneous reservoir. Fault-Block Oil Gas Field 2015, 22, 776–780. [Google Scholar]

- Wang, Q.; Yang, S.; Lorinczi, P.; Glover, P.W.; Lei, H. Experimental investigation of oil recovery performance and permeability damage in multilayer reservoirs after CO2 and water–alternating-CO2 (CO2–WAG) flooding at miscible pressures. Energy Fuels 2019, 34, 624–636. [Google Scholar] [CrossRef]

- Chen, H. New progress of CO2 displacement and storage technology. Pet. Geol. Recovery Effic. 2023, 30, 18–26. [Google Scholar]

- Gong, Y.; Gu, Y. Miscible CO2 simultaneous water-and-gas (CO2-SWAG) injection in the Bakken formation. In Proceedings of the SPE/CSUR Unconventional Resources Conference, Calgary, AB, Canada, 20–22 October 2015; SPE: Richardson, TX, USA, 2015. [Google Scholar]

- Chen, X.; Zhang, Q.; Trivedi, J.; Li, Y.; Liu, J.; Liu, Z.; Liu, S. Investigation on Enhanced Oil Recovery and CO2 Storage Efficiency of Temperature-Resistant CO2 Foam Flooding. Fuel 2024, 364, 130870. [Google Scholar] [CrossRef]

- Talebian, S.H.; Masoudi, R.; Tan, I.M.; Zitha, P.L.J. Foam Assisted CO2-EOR: A Review of Concept, Challenges, and Future Prospects. J. Pet. Sci. Eng. 2014, 120, 202–215. [Google Scholar] [CrossRef]

- Tang, Y.; Hou, C.; He, Y.; Tang, J.; Wang, Y.; Qin, J. Microscopic Flow Characteristics of Immiscible CO2 Flooding and CO2 Foam Flooding after Water Flooding in Fractured Porous Media: A Visual Investigation. Transp. Porous Media 2023, 149, 117–145. [Google Scholar] [CrossRef]

- Yang, Y. Research and practice of CO2 flooding technology for ultra-low permeability reservoirs in Shengli Oilfield. Pet. Geol. Recovery Effic. 2020, 27, 11–19. [Google Scholar]

- Tang, Y.; Hou, C.; He, Y.; Wang, Y.; Chen, Y.; Rui, Z. Review on pore structure characterization and microscopic flow mechanism of CO2 flooding in porous media. Energy Technol. 2021, 9, 2000787. [Google Scholar] [CrossRef]

- Chen, Z.; Li, R.; Du, Y.; Ma, S.; Zhang, X.; Shi, J. Effect of Confinement on the Vapor-Liquid-Liquid Three-Phase Equilibrium during CO2 Utilization and Sequestration in Shale Reservoirs. Adv. Geo-Energy Res. 2025, 16, 199–210. [Google Scholar] [CrossRef]

- Yang, G.; Fan, Z.; Li, X. Determination of Confined Fluid Phase Behavior Using Extended Peng-Robinson Equation of State. Chem. Eng. J. 2019, 378, 122032. [Google Scholar] [CrossRef]

- Chen, X.; Yu, H.; Cao, A.; Yang, Z.; Li, W.; Niu, Z.; Chang, Y.; Du, M. Study on enhanced oil recovery mechanism of CO2 miscible flooding in heterogeneous reservoirs under different injection methods. ACS Omega 2023, 8, 24663–24672. [Google Scholar] [CrossRef]

- Cui, M.; Wang, R.; Lun, Z.; Lv, C. Characteristics of water alternating CO2 injection in low-permeability beach-bar sand reservoirs. Energy Geosci. 2022, 5, 100119. [Google Scholar] [CrossRef]

- Nezhad, S.A.T.; Mojarad, M.R.R.; Paitakhti, S.J.; Moghadas, J.S.; Farahmand, D.R. Experimental study on applicability of water-alternating-CO2 injection in the secondary and tertiary recovery. In Proceedings of the International Oil Conference and Exhibition in Mexico, Cancun, Mexico, 2 September 2006; SPE-103988-MS. SPE: Richardson, TX, USA, 2006. [Google Scholar]

- Rahimi, V.; Bidarigh, M.; Bahrami, P. Experimental study and performance investigation of miscible water-alternating-CO2 flooding for enhancing oil recovery in the Sarvak formation. Oil Gas Sci. Technol.–Rev. D’ifp Energ. Nouv. 2017, 72, 35. [Google Scholar] [CrossRef]

- Yu, C.; Xia, Z.; Ren, W.; Sun, J.; Yin, C. Study on the law of CO2-water alternate flooding in ultra-low permeability reservoir. Petrochem. Ind. Appl. 2023, 42, 37–41. [Google Scholar]

- Sohrabi, M.; Jamiolahmady, M.; Al Quraini, A. Heavy oil recovery by liquid CO2/water injection. In Proceedings of the EUROPEC/EAGE Conference and Exhibition, London, UK, 11–14 June 2007; OnePetro: Richardson, TX, USA, 2007. [Google Scholar]

- Zheng, S.; Yang, D. Pressure maintenance and improving oil recovery by means of immiscible water-alternating-CO2 processes in thin heavy-oil reservoirs. SPE Reserv. Eval. Eng. 2013, 16, 60–71. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Dong, M.; Wang, J.; Jing, W.; Yao, J.; Zhang, K.; Sun, H.; Zhong, J.; Zhang, L.; et al. Micro-scale experimental investigations of CO2-WAG injection and Ostwald ripening analysis in carbonate rocks with different pore structures. Geoenergy Sci. Eng. 2024, 241, 213092. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, B.; You, Q.; Lin, B.; Sun, D.; Jin, Y. Micro-experimental study of residual oil in low permeability reservoirs in Jiangsu by NMR. Complex Oil Gas Reserv. 2023, 16, 199–203. [Google Scholar]

- Chen, X.; Yang, Z.; Yu, H.; Niu, Z.; Li, W.; Jia, N.; Wang, W.; Zhang, Y.; Li, H.; Chang, Y. Enhancing Oil Recovery in Low Permeability Reservoirs through CO2 Miscible Flooding: Mechanisms and Dynamics. ACS Omega 2024, 9, 49336–49347. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Li, H.; Liu, S.; Xu, J.; Wang, X.; Tan, Q. Investigating the Impact of Aqueous Phase on CO2 Huff ‘n’Puff in Tight Oil Reservoirs Using Nuclear Magnetic Resonance Technology: Stimulation Measures and Mechanisms. SPE J. 2023, 28, 3324–3340. [Google Scholar] [CrossRef]

- Xu, T.; Wang, J.; Lu, Y.; Wang, D.; Yu, L.; Tian, Y. Exploring pore-scale production characteristics of oil shale after CO2 huff ‘n’puff in fractured shale with varied permeability. Int. J. Coal Sci. Technol. 2024, 11, 12. [Google Scholar] [CrossRef]

- Wang, Y.F.; Li, Z.Y.; Zhang, S.M.; Liu, D.X.; Ding, M.C. Remaining oil distribution in models with different heterogeneities after CO2 WAG injection: Visual research by nuclear magnetic resonance technique. J. Cent. South Univ. 2021, 28, 1412–1421. [Google Scholar] [CrossRef]

- Sun, C. Displacement characteristics and remaining oil startup mechanism of WAG after CO2 flooding. Pet. Geol. Oilfield Dev. Daqing 2024, 43, 52–58. [Google Scholar] [CrossRef]

- Qian, K.; Yang, S.L.; Dou, H.E.; Zhang, J. Microscopic oil displacement characteristics of different CO2 injection methods in ultra-low permeability reservoirs. Xinjiang Pet. Geol. 2020, 41, 204–208. [Google Scholar]

- Song, G.; Meng, Y.; Zhang, C.; Zhao, Z.; Yang, Q. Comprehensive Review of the Determination and Reduction of the Minimum Miscibility Pressure during CO2 Flooding. ACS Omega 2024, 9, 14747–14765. [Google Scholar] [CrossRef] [PubMed]

- Almobarak, M.; Wu, Z.; Zhou, D.; Fan, K.; Liu, Y.; Xie, Q. A Review of Chemical-Assisted Minimum Miscibility Pressure Reduction in CO2 Injection for Enhanced Oil Recovery. Petroleum 2021, 7, 245–253. [Google Scholar] [CrossRef]

| Number | Core Type | Length, cm | Diameter, cm | Porosity, % | Permeability, mD |

|---|---|---|---|---|---|

| 1 | Sandy conglomerate | 4.812 | 2.515 | 16.13 | 130.22 |

| 2 | Sandy conglomerate | 4.856 | 2.503 | 13.41 | 119.35 |

| 3 | Sandy conglomerate | 4.897 | 2.529 | 13.12 | 120.28 |

| 4 | Sandy conglomerate | 4.916 | 2.536 | 16.34 | 139.63 |

| 5 | Sandy conglomerate | 4.899 | 2.369 | 13.51 | 140.59 |

| 6 | Conglomerate-bearing sandstone | 4.939 | 2.489 | 10.54 | 29.66 |

| 7 | Conglomerate-bearing sandstone | 4.955 | 2.499 | 10.03 | 19.68 |

| 8 | Conglomerate-bearing sandstone | 5.112 | 2.521 | 10.42 | 15.56 |

| 9 | Coarse sandstone | 5.088 | 2.506 | 8.26 | 1.26 |

| Number | Core Type | Flooding Mode | Production Pressure/MPa | Injection Rate/(mL·min−1) | Gas–Water Ratio |

|---|---|---|---|---|---|

| 1 | Coarse sandstone | CO2 flooding | 20 | 2 | / |

| 2 | Conglomerate-bearing sandstone | CO2 flooding | 20 | 2 | / |

| 3 | Sandy conglomerate | CO2 flooding | 20 | 2 | / |

| 4 | Coarse sandstone | CO2-WAG flooding | 20 | 2 | 1:1 |

| 5 | Conglomerate-bearing sandstone | CO2-WAG flooding | 20 | 2 | 1:1 |

| 6 | Sandy conglomerate | CO2-WAG flooding | 20 | 2 | 1:1 |

| 7 | Coarse sandstone | CO2 flooding | 27 | 2 | / |

| 8 | Conglomerate-bearing sandstone | CO2 flooding | 27 | 2 | / |

| 9 | Sandy conglomerate | CO2 flooding | 27 | 2 | / |

| 10 | Coarse sandstone | CO2-WAG flooding | 27 | 2 | 1:1 |

| 11 | Conglomerate-bearing sandstone | CO2-WAG flooding | 27 | 2 | 1:1 |

| 12 | Sandy conglomerate | CO2-WAG flooding | 27 | 2 | 1:1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Chang, T.; Zhou, J.; Wu, J.; Liu, S. Remaining Oil Distribution Characteristics in Sandy Conglomerate Reservoirs During CO2-WAG Flooding: Insights from Nuclear Magnetic Resonance (NMR) Technology. Processes 2025, 13, 2872. https://doi.org/10.3390/pr13092872

Wang Y, Chang T, Zhou J, Wu J, Liu S. Remaining Oil Distribution Characteristics in Sandy Conglomerate Reservoirs During CO2-WAG Flooding: Insights from Nuclear Magnetic Resonance (NMR) Technology. Processes. 2025; 13(9):2872. https://doi.org/10.3390/pr13092872

Chicago/Turabian StyleWang, Yue, Tao Chang, Junliang Zhou, Junda Wu, and Shuyang Liu. 2025. "Remaining Oil Distribution Characteristics in Sandy Conglomerate Reservoirs During CO2-WAG Flooding: Insights from Nuclear Magnetic Resonance (NMR) Technology" Processes 13, no. 9: 2872. https://doi.org/10.3390/pr13092872

APA StyleWang, Y., Chang, T., Zhou, J., Wu, J., & Liu, S. (2025). Remaining Oil Distribution Characteristics in Sandy Conglomerate Reservoirs During CO2-WAG Flooding: Insights from Nuclear Magnetic Resonance (NMR) Technology. Processes, 13(9), 2872. https://doi.org/10.3390/pr13092872