Improving Recovery Mechanism Through Multi-Well Water and Gas Injection in Underground River Reservoirs

Abstract

1. Introduction

2. Experiments and Methods

2.1. Experimental Model and Materials

2.2. Experimental Scheme and Procedures

3. Results and Discussion

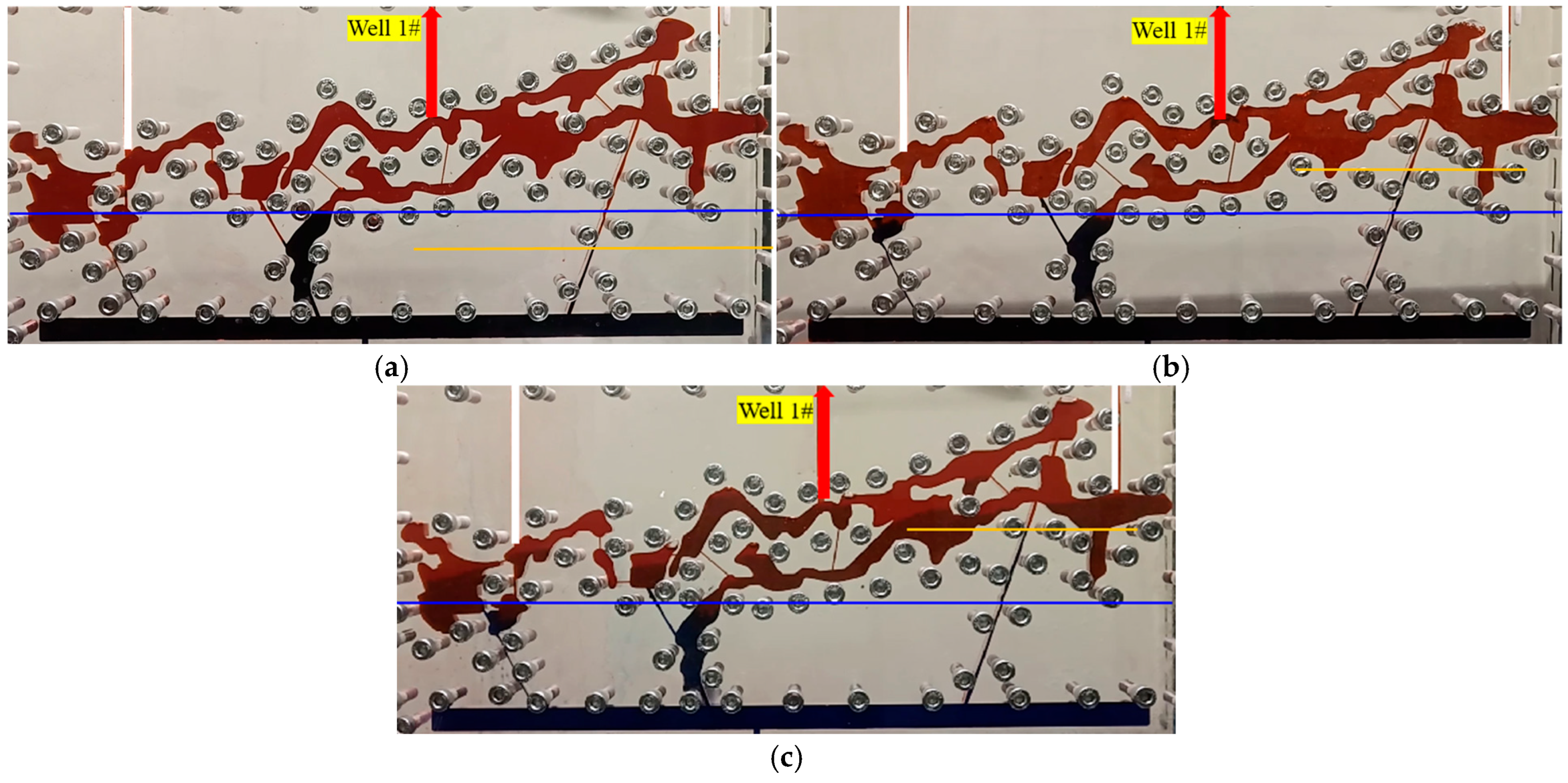

3.1. Bottom Water Flooding Pattern

3.1.1. Early Stage of Bottom Water Flooding

3.1.2. Late Stage of Bottom Water Flooding

3.2. Remaining Oil Distribution Pattern and Mechanism After Bottom Water Flooding

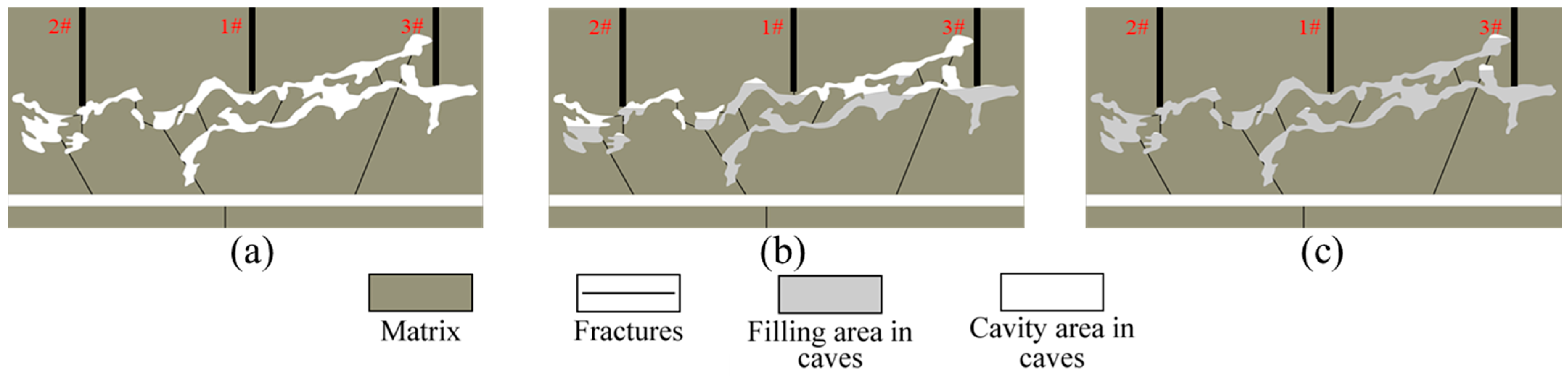

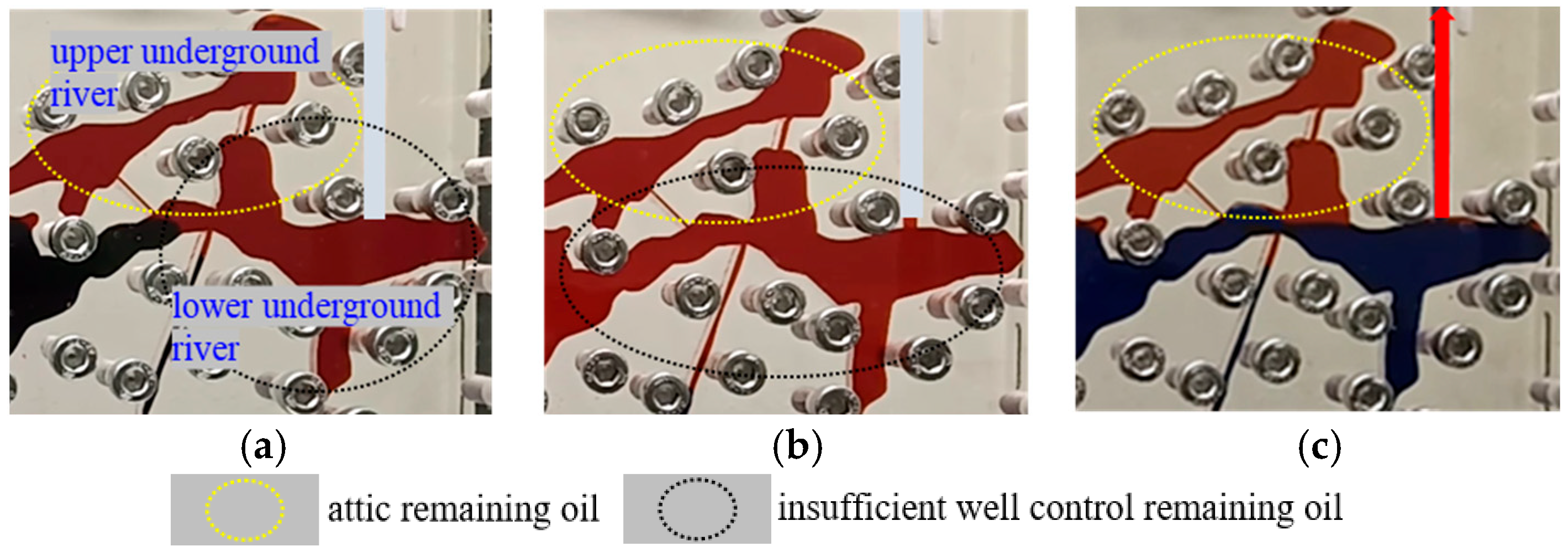

3.2.1. No Filling Media in the Caves

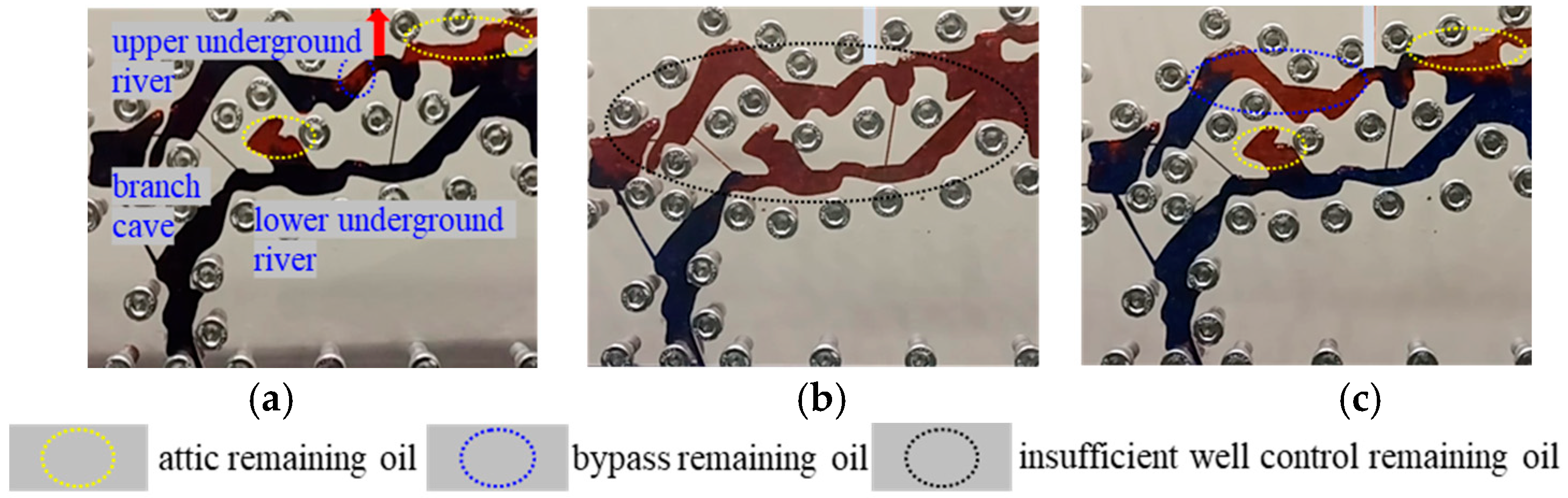

3.2.2. High Filling in the Caves

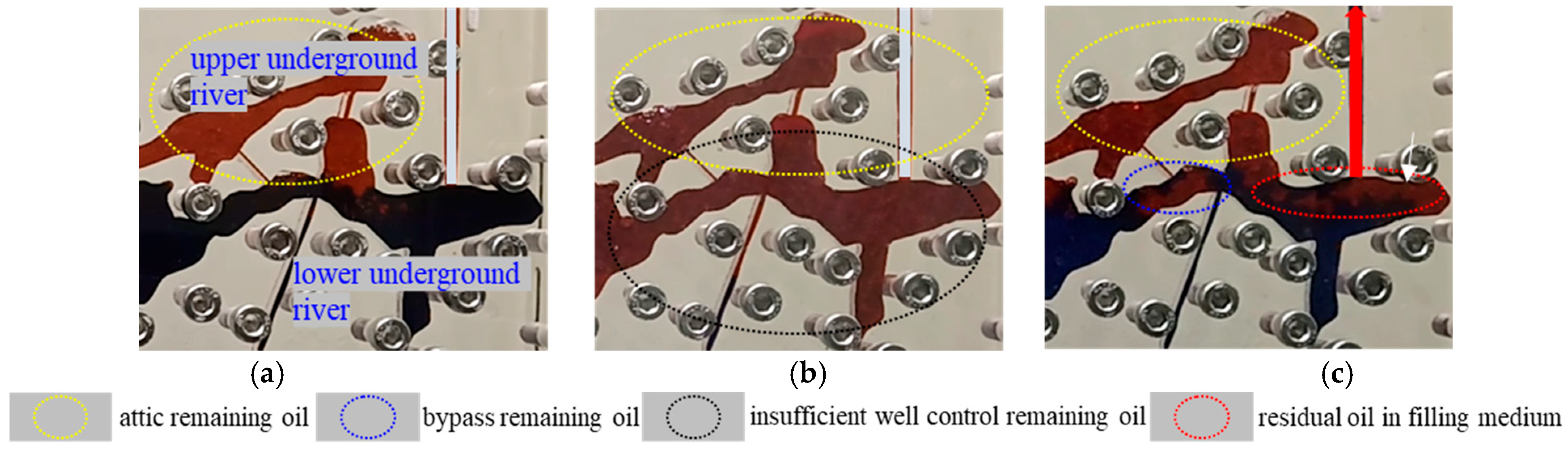

3.2.3. Partial Filling in the Caves

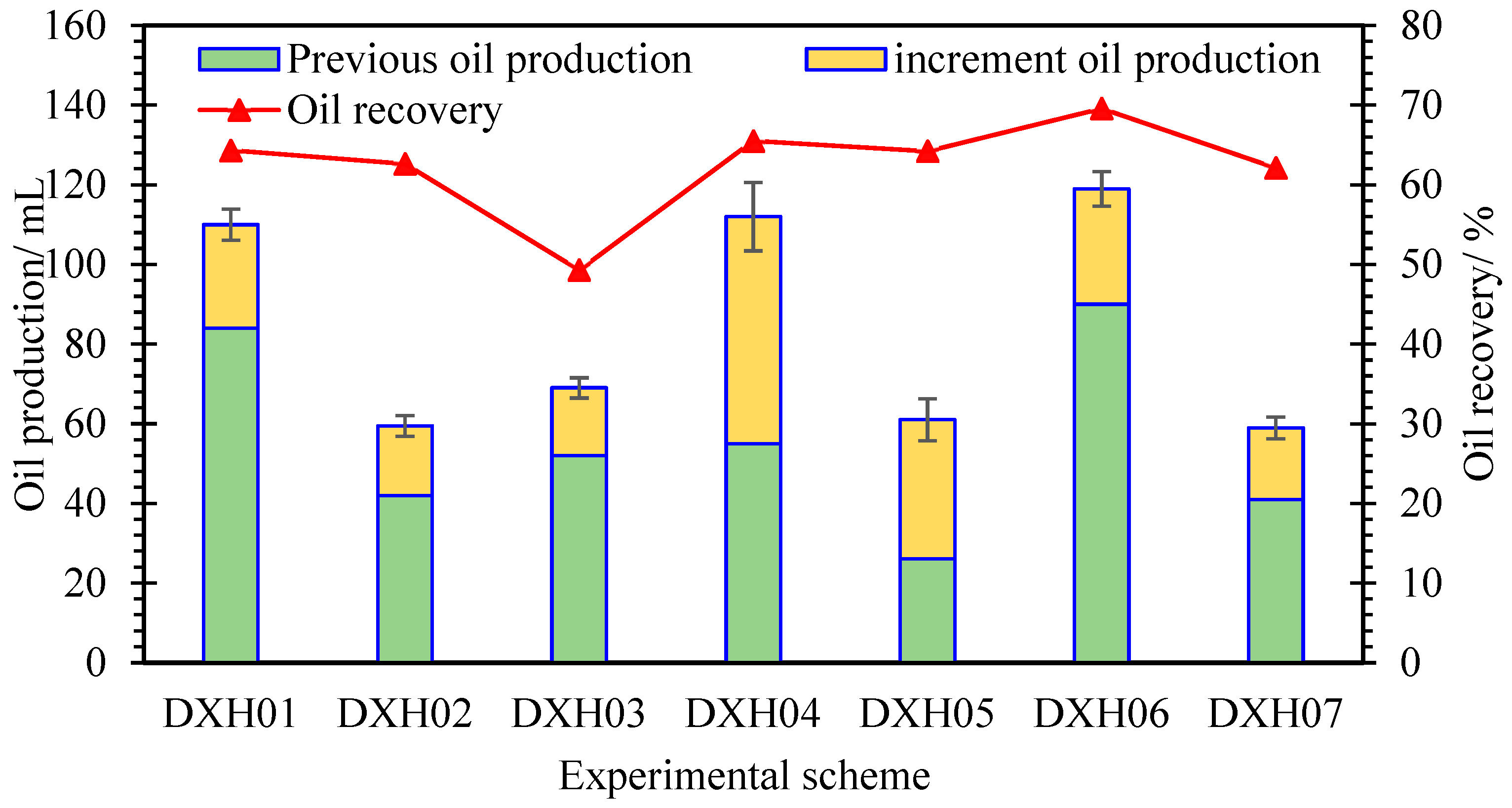

3.2.4. Comparison of Oil Production and Recovery

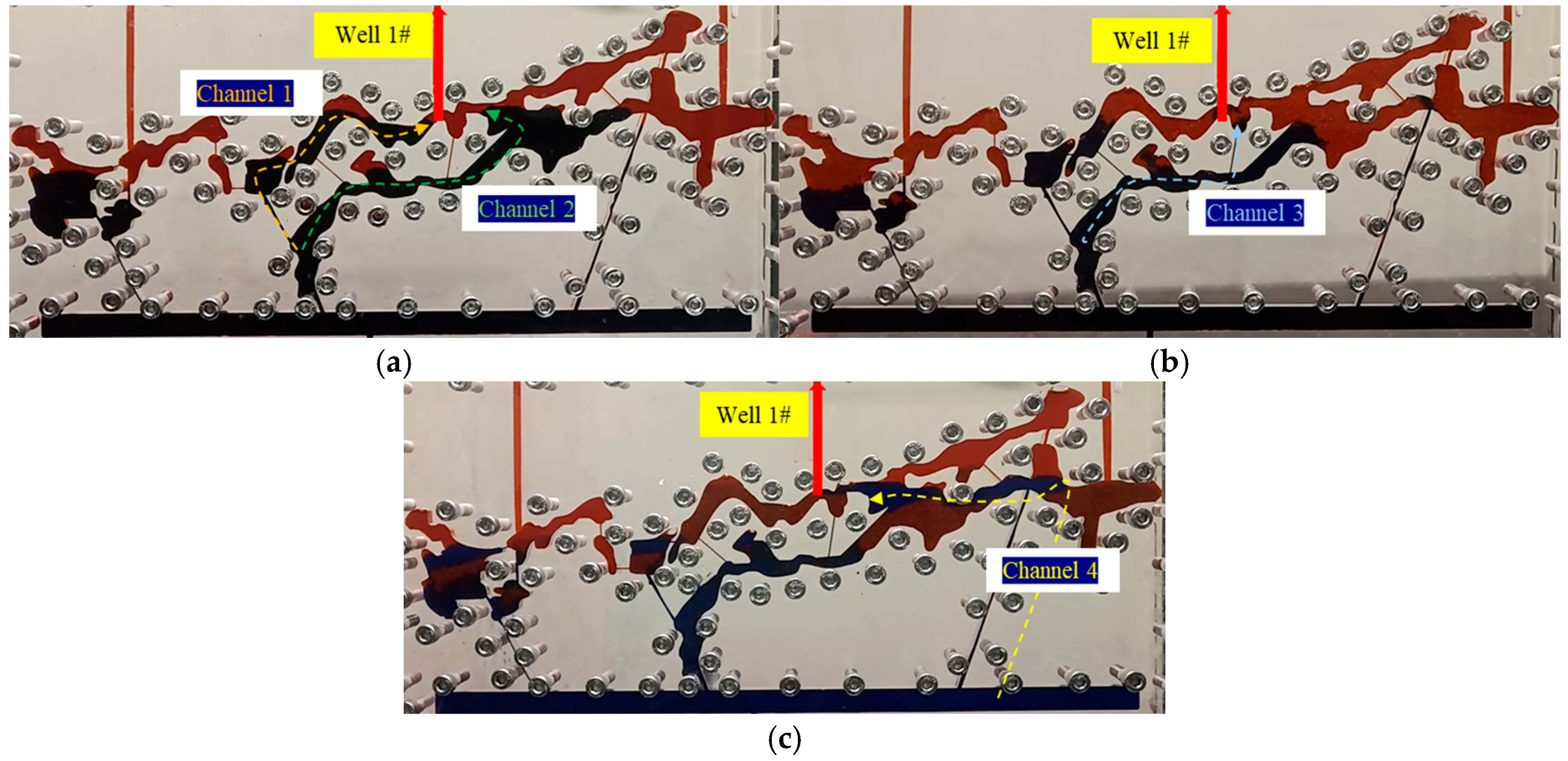

3.3. Mechanism of Improving Recovery by Multi-Well Alternating Water Flooding and Gas Injection

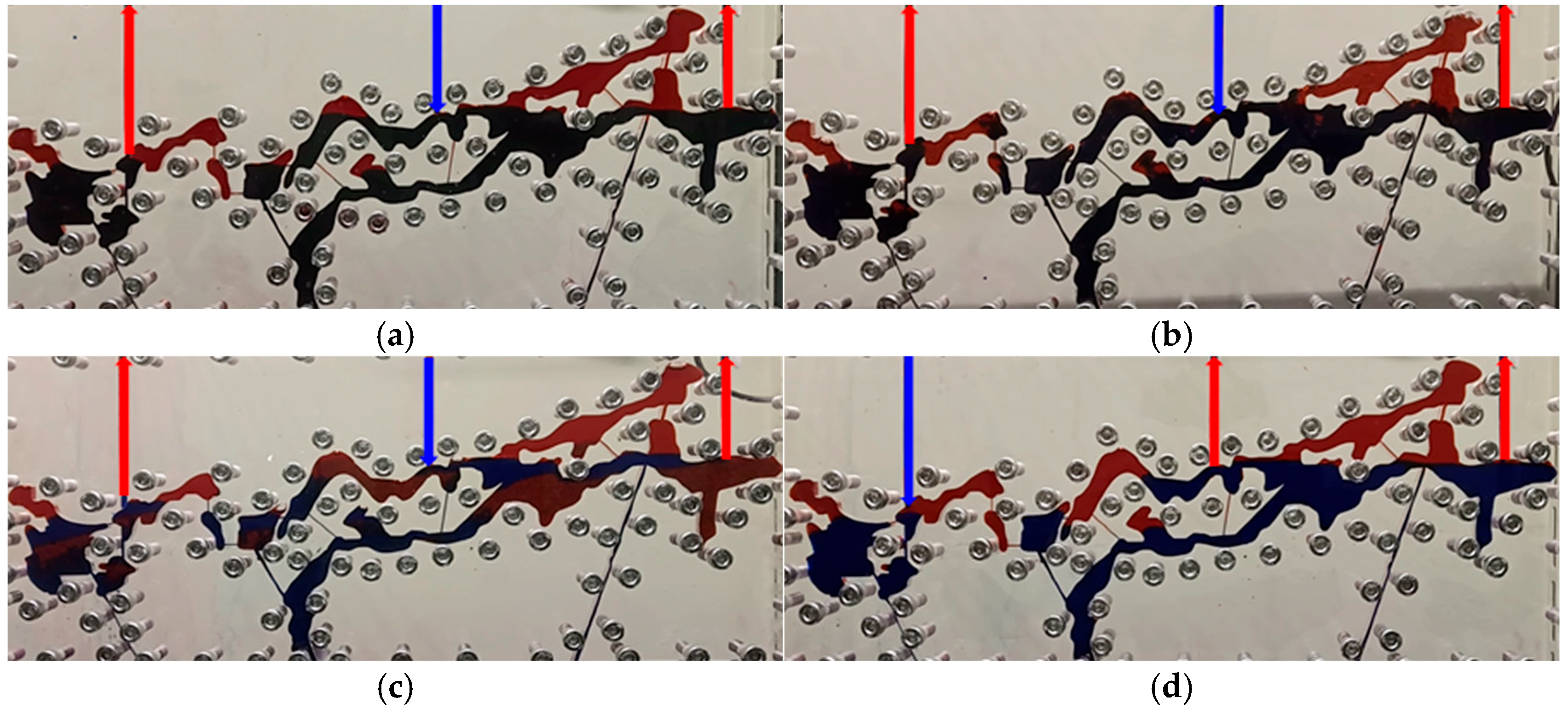

3.3.1. Early Water Injection Period

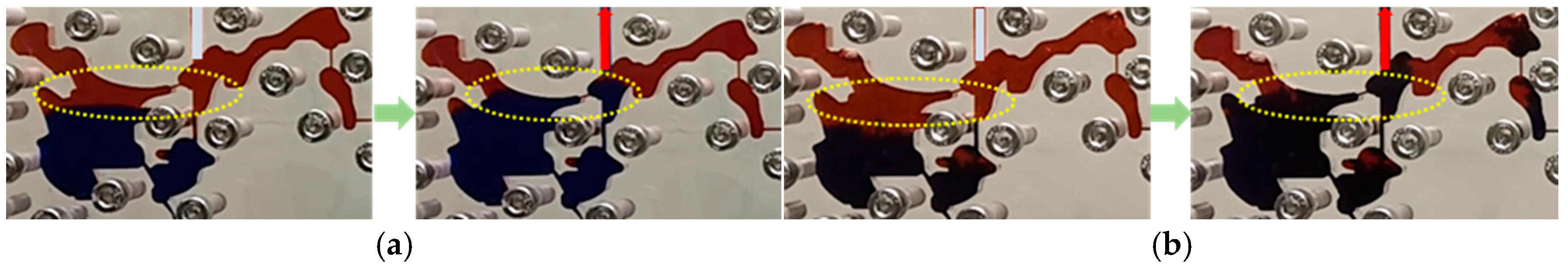

Recovering “Insufficient Well Control Remaining Oil”

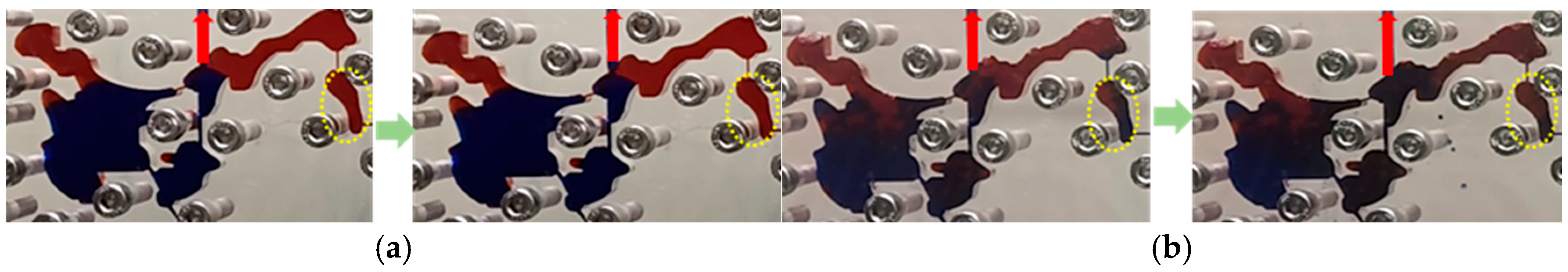

Recovering “Bypass Remaining Oil”

Recovering “Residual Oil in Filling Medium”

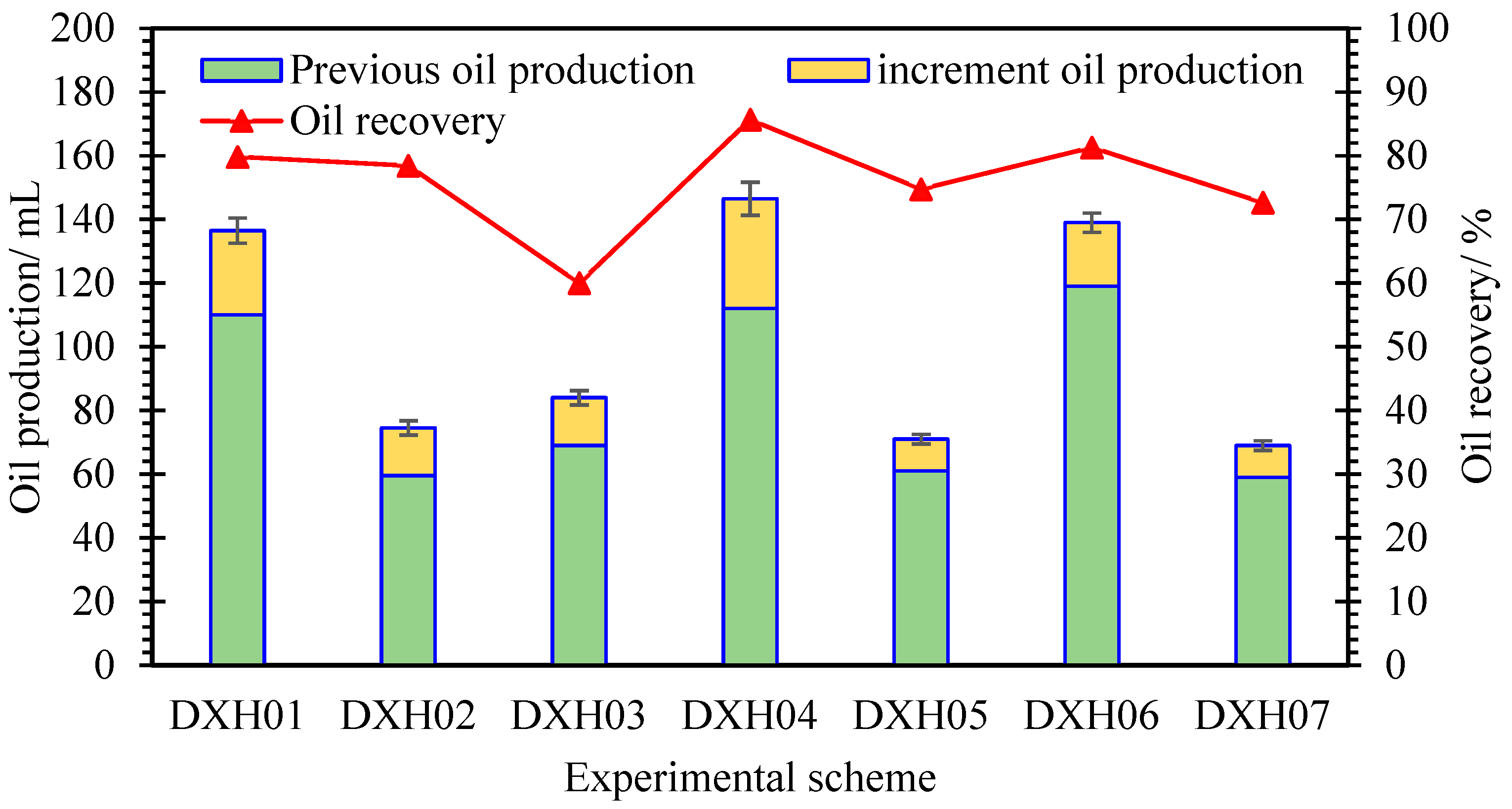

Comparison of Oil Production and Recovery

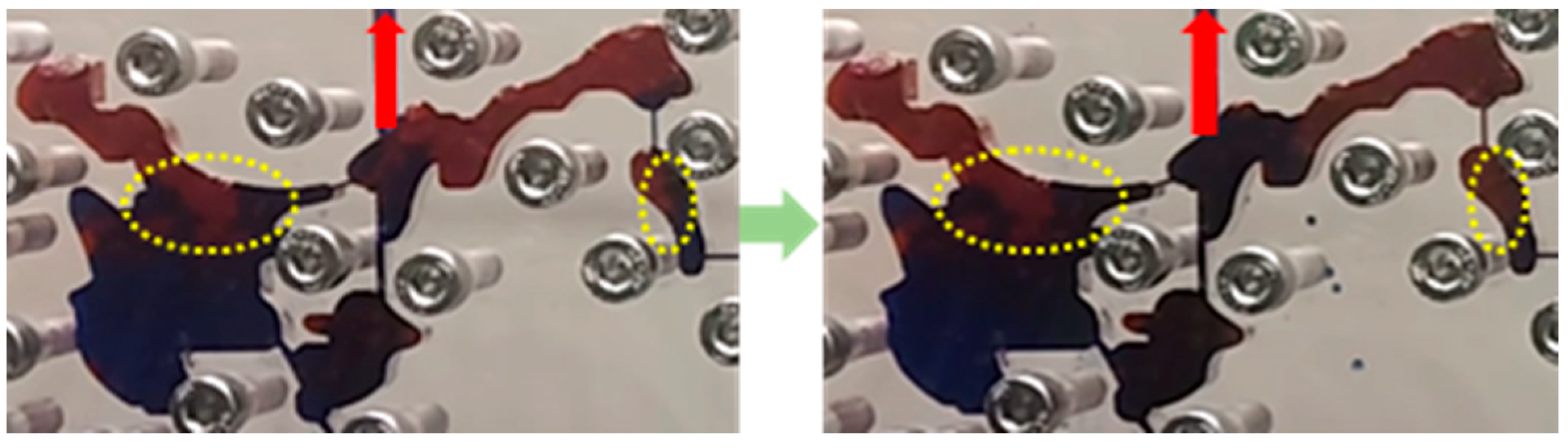

3.3.2. Middle Gas Injection Period

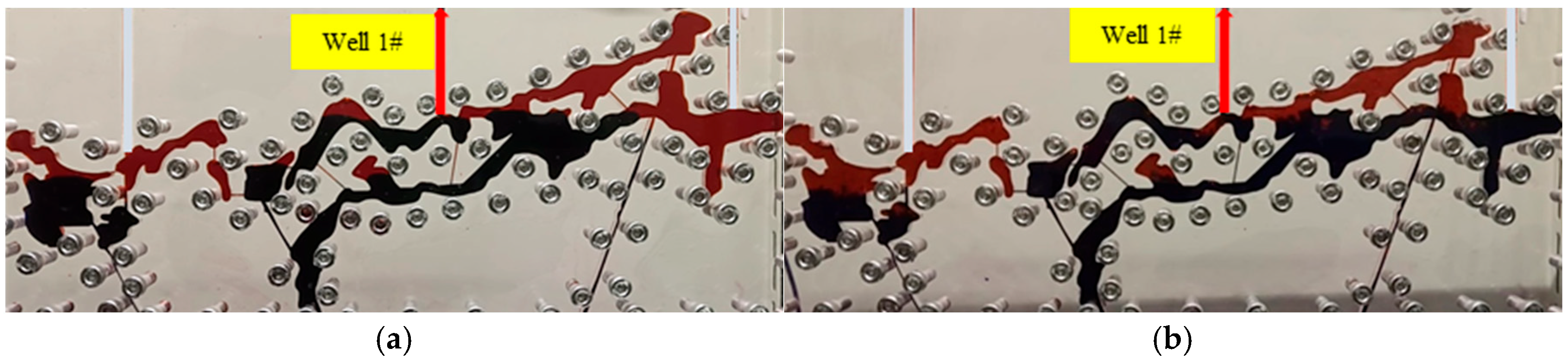

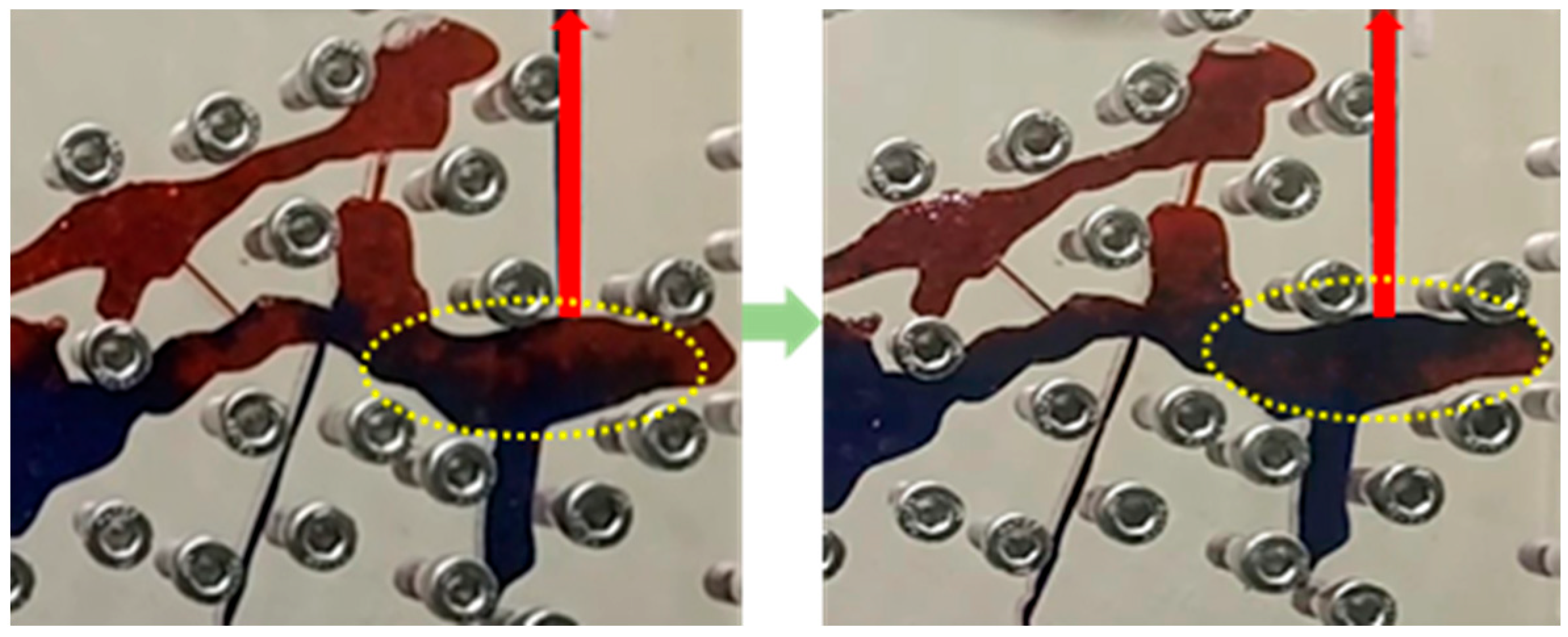

3.3.3. Late Water Injection Period

4. Conclusions

- The remaining oil after bottom water flooding can be divided into the following five types: “insufficient well control remaining oil”, “attic remaining oil”, “bypass remaining oil”, “residual oil in filling medium”, and “shielded oil in filling medium”. The distribution is greatly affected by filling modes and well locations. The highest recovery after bottom water flooding was 83.7% (DXH01), while partially filled caves averaged at only 37.1%

- Early water injection can effectively recover “insufficient well control remaining oil”, “bypass remaining oil”, and “residual oil in filling medium”. Gas injection is favorable for recovering “attic remaining oil”. Late water injections can further improve recovery.

- When the cave is partially filled, there exists a large amount of “shielded oil in filling medium” that is difficult to recover by multi-well water and gas injection.

- This study has clarified the remaining oil distribution laws and water–gas flooding mechanisms for underground river reservoirs under different conditions, providing guidance for efficient development.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sagbana, P.I.; Sarkodie, K.; Nkrumah, W.A. A critical review of carbonate reservoir wettability modification during low salinity waterflooding. Petroleum 2023, 9, 317–330. [Google Scholar] [CrossRef]

- Li, Y.; Kang, Z.; Xue, Z.; Zheng, S. Theories and practices of carbonate reservoirs development in China. Pet. Explor. Dev. 2018, 45, 712–722. [Google Scholar] [CrossRef]

- Tan, Y.; Li, Q.; Xu, L.; Ghaffar, A.; Zhou, X.; Li, P. A critical review of carbon dioxide enhanced oil recovery in carbonate reservoirs. Fuel 2022, 328, 125256. [Google Scholar] [CrossRef]

- Moore, C.H.; Wade, W.J. Chapter 11—Natural Fracturing in Carbonate Reservoirs. In Developments in Sedimentology; Moore, C.H., Wade, W.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 285–300. [Google Scholar]

- Chen, S.; Wang, Y.; Guo, J.; He, Q.; Yin, X. Multi-scale evaluation of fractured carbonate reservoir and its implication to sweet-spot optimization: A case study of Tazhong oilfield, Central Tarim Basin, China. Energy Rep. 2021, 7, 2976–2988. [Google Scholar] [CrossRef]

- Lei, G.; Liao, Q.; Zhang, D. A new analytical model for flow in acidized fractured-vuggy porous media. Sci. Rep. 2019, 9, 8293. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Tan, X.; Wang, F.; Lian, P.; Gao, W.; Li, Y. Fracture and vug characterization and carbonate rock type automatic classification using X-ray CT images. J. Pet. Sci. Eng. 2017, 153, 88–96. [Google Scholar] [CrossRef]

- Liu, B.; Jin, Y.; Chen, M. Influence of vugs in fractured-vuggy carbonate reservoirs on hydraulic fracture propagation based on laboratory experiments. J. Struct. Geol. 2019, 124, 143–150. [Google Scholar] [CrossRef]

- Pirayesh, E.; Jamali, A.; Soliman, M.Y. Enhancing volumetric sweep efficiency in waterfloods using in-situ non-conductive barrier fractures. J. Pet. Sci. Eng. 2014, 122, 119–133. [Google Scholar] [CrossRef]

- He, J.; Liu, X.; Zhu, X.; Jiang, T.; He, H.; Zhou, L.; Liu, Q.; Zhu, Y.; Liu, L. Water-flooding characteristics of lithologic reservoir in Ordos basin. Sci. Rep. 2021, 11, 2503. [Google Scholar] [CrossRef] [PubMed]

- Yan, L.; Liu, Q.; Liu, X. Research on 3D geological modeling of fractured-vuggy carbonate reservoirs. Energy Rep. 2022, 8, 491–500. [Google Scholar] [CrossRef]

- Cao, N.; Lei, G.; Su, Y.; Li, H.; Zhang, J.; Zhang, C. A New Model for Predicting Flow in Fractured-Vuggy Carbonate Reservoirs under Pseudosteady State Condition. Geofluids 2021, 2021, 5613966. [Google Scholar] [CrossRef]

- Bin, L.; Zhengyu, L.; Shucai, L.; Lichao, N.; Maoxin, S.; Huaifeng, S.; Kerui, F.; Xinxin, Z.; Yonghao, P. Comprehensive surface geophysical investigation of karst caves ahead of the tunnel face: A case study in the Xiaoheyan section of the water supply project from Songhua River, Jilin, China. J. Appl. Geophys. 2017, 144, 37–49. [Google Scholar] [CrossRef]

- Wang, J.; Liu, H.; Xu, J.; Hongfang, Z. Formation mechanism and distribution law of remaining oil in fracture-cavity reservoir. Pet. Explor. Dev. 2012, 39, 624–629. [Google Scholar] [CrossRef]

- Li, W.; Hou, J.; Ding, G.; Li, H.; Zhang, L. Remaining oil types and influence factors for fractured-vuggy carbonate reservoir. Fault-Block Oil Gas. Field 2013, 20, 458–461. [Google Scholar]

- Yuan, D.; Hou, J.; Song, Z.; Wang, Y.; Luo, M.; Zheng, Z. Residual oil distribution characteristic of fractured-cavity carbonate reservoir after water flooding and enhanced oil recovery by N2 flooding of fractured-cavity carbonate reservoir. J. Pet. Sci. Eng. 2015, 129, 15–22. [Google Scholar] [CrossRef]

- Lu, G.; Zhang, L.; Liu, Q.; Xu, Q.; Zhao, Y.; Li, X.; Deng, G.; Wang, Y. Experiment analysis of remaining oil distribution and potential tapping for fractured-vuggy reservoir. J. Pet. Sci. Eng. 2022, 208, 109544. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, Z.; Lei, Q.; Yao, J.; Gong, L.; Sun, S.; Li, Y. Connectivity, permeability and flow channelization in fractured karst reservoirs: A numerical investigation based on a two-dimensional discrete fracture-cave network model. Adv. Water Resour. 2022, 161, 104142. [Google Scholar] [CrossRef]

- Yang, M.; Zhong, H.; Li, Y. Research on fluid flow mechanism of fracture-cave carbonate reservoirs based on fluid mechanics. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 47, 1051–1069. [Google Scholar] [CrossRef]

- Li, Y.; Sun, J.; Hou, J.; Tang, L. Characterization of underground river reservoirs in Tahe Oilfield, Tarim Basin, China. Arab. J. Geosci. 2022, 15, 1687. [Google Scholar] [CrossRef]

- Zheng, S.; Yang, M.; Kang, Z.; Liu, Z.; Long, X.; Liu, K.; Li, X.; Zhang, S. Controlling factors of remaining oil distribution after water flooding and enhanced oil recovery methods for fracture-cavity carbonate reservoirs in Tahe Oilfield. Pet. Explor. Dev. 2019, 46, 786–795. [Google Scholar] [CrossRef]

- Zhang, S.; Jin, Q.; Cheng, F.; Sun, J.; Wei, H.; Zhang, X. Genesis relation of surface and underground rivers and reservoir characteristics in paleokarst drainage systems: A case study of Ordovician karst in the Tahe oilfield. Carsologica Sin. 2020, 39, 900–910. [Google Scholar]

| N.O. | Production Well | Filling Mode |

|---|---|---|

| DXH01 | The middle well (Well 1#) | No filling media in the caves |

| DXH02 | The middle well (Well 1#) | High filling in the caves |

| DXH03 | The middle well (Well 1#) | Partial filling in the caves |

| DXH04 | The left well (Well 2#) | No filling media in the caves |

| DXH05 | The left well (Well 2#) | High filling in the caves |

| DXH06 | The right well (w ell 3#) | No filling media in the caves |

| DXH07 | The right well (Well 3#) | High filling in the caves |

| N.O. | Well Arrangement | Bottom Water Flooding Period | Early Water Injection Period | Middle Gas Injection Period | Late Water Injection Period | ||

|---|---|---|---|---|---|---|---|

| Stage 1 | Stage 2 | Stage 3 | Stage 4 | Stage 5 | Stage 6 | ||

| DXH01, DXH02, DXH03 | Injection well | / | Well 1# | Well 2# | Well 2# | Well 3# | Well 1# |

| Production well | well 1# | Well 2# | Well 3# | Well 3# | Well 1# | Well 2# | |

| DXH04, DXH05 | Injection well | / | Well 2# | Well 1# | Well 3# | Well 2# | Well 1# |

| Production well | well 2# | Well 1# | Well 3# | Well 2# | Well 1# | Well 3# | |

| DXH06, DXH07 | Injection well | / | Well 3# | Well 1# | Well 2# | Well 3# | Well 1# |

| Production well | well 3# | Well 1# | Well 2# | Well 3# | Well 1# | Well 2# | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yue, S.; Guo, W.; Ding, M.; Li, A. Improving Recovery Mechanism Through Multi-Well Water and Gas Injection in Underground River Reservoirs. Processes 2025, 13, 2743. https://doi.org/10.3390/pr13092743

Yue S, Guo W, Ding M, Li A. Improving Recovery Mechanism Through Multi-Well Water and Gas Injection in Underground River Reservoirs. Processes. 2025; 13(9):2743. https://doi.org/10.3390/pr13092743

Chicago/Turabian StyleYue, Shenghui, Wanjiang Guo, Mingshan Ding, and Aifen Li. 2025. "Improving Recovery Mechanism Through Multi-Well Water and Gas Injection in Underground River Reservoirs" Processes 13, no. 9: 2743. https://doi.org/10.3390/pr13092743

APA StyleYue, S., Guo, W., Ding, M., & Li, A. (2025). Improving Recovery Mechanism Through Multi-Well Water and Gas Injection in Underground River Reservoirs. Processes, 13(9), 2743. https://doi.org/10.3390/pr13092743