Effects of Drying Methods on Drying Characteristics and Physicochemical Quality of Turnip Slices (Brassica rapa L.)

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Drying Experiments

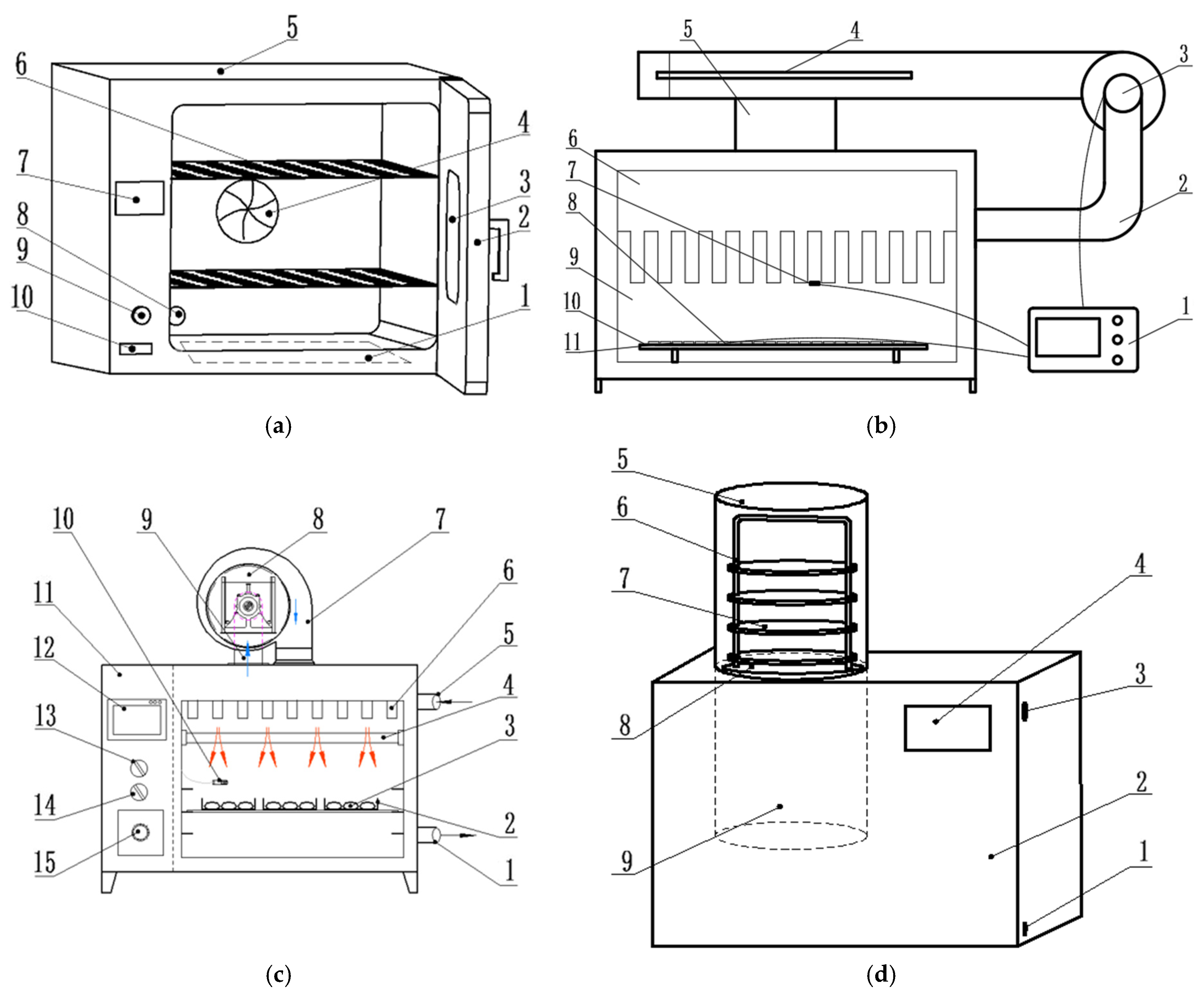

2.2.1. Hot Air Drying (HAD)

2.2.2. Air Impingement Drying (AID)

2.2.3. Infrared Heating-Assisted Hot Air-Drying (IR-HAD)

2.2.4. Vacuum-Freeze Drying (VFD)

2.3. Drying Characteristics

2.4. Texture

2.5. Rehydration Ratio (RR)

2.6. Microstructure Measurement

2.7. Color Measurement

2.8. Determination of Total Phenolic Content (TPC)

2.9. Antioxidant Capacity Determination

2.10. Statistical Data Analysis

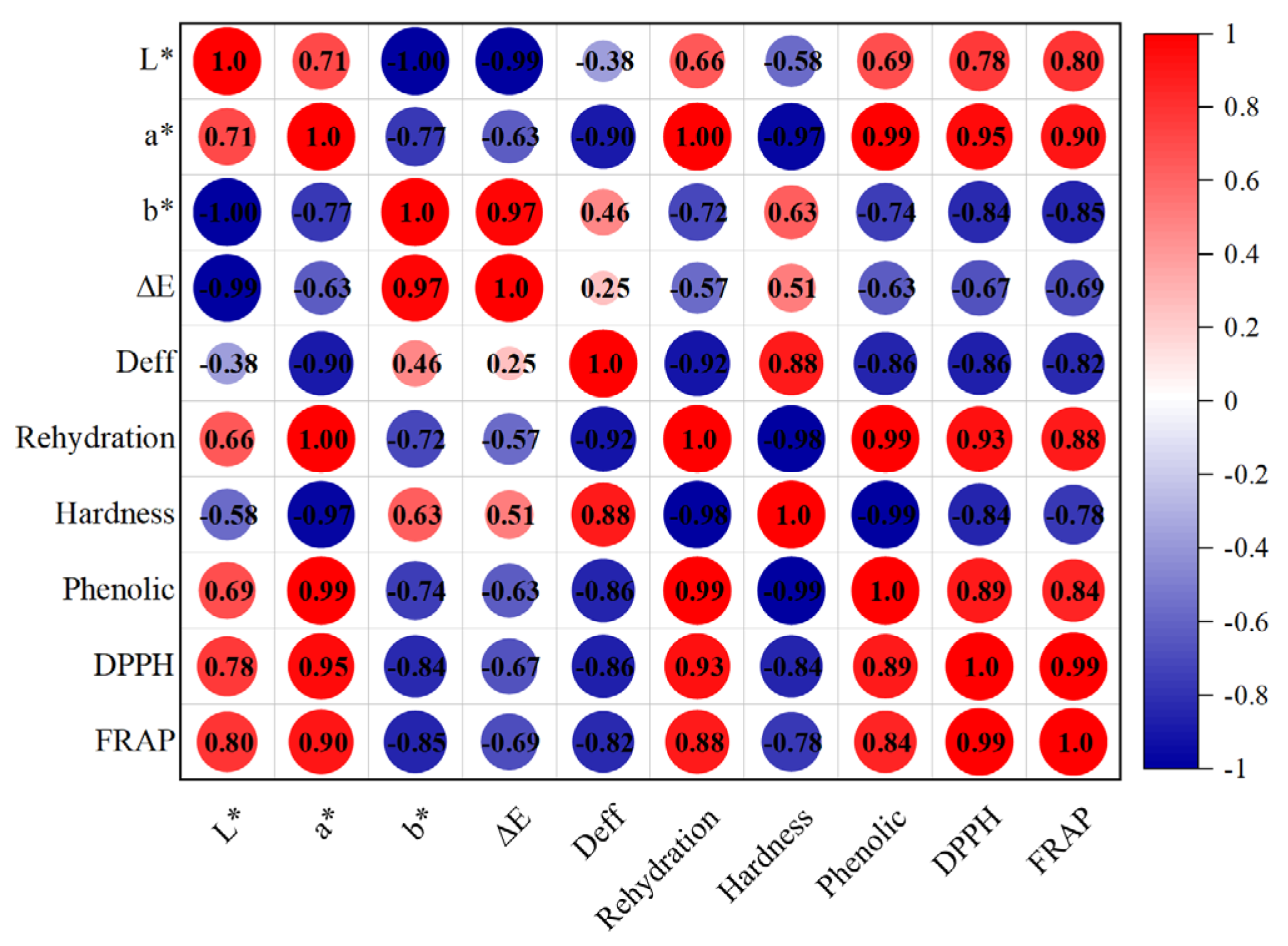

3. Results and Discussion

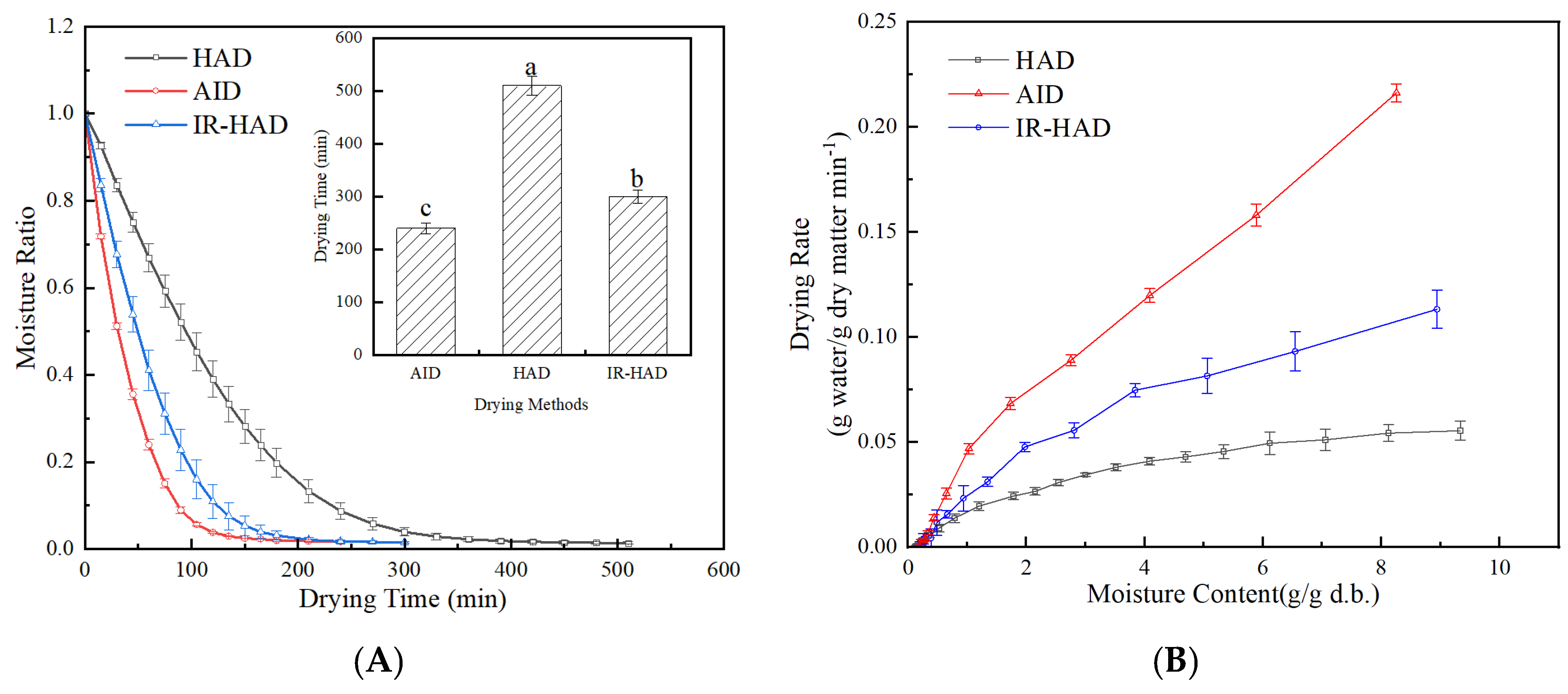

3.1. Drying Characteristics Analysis

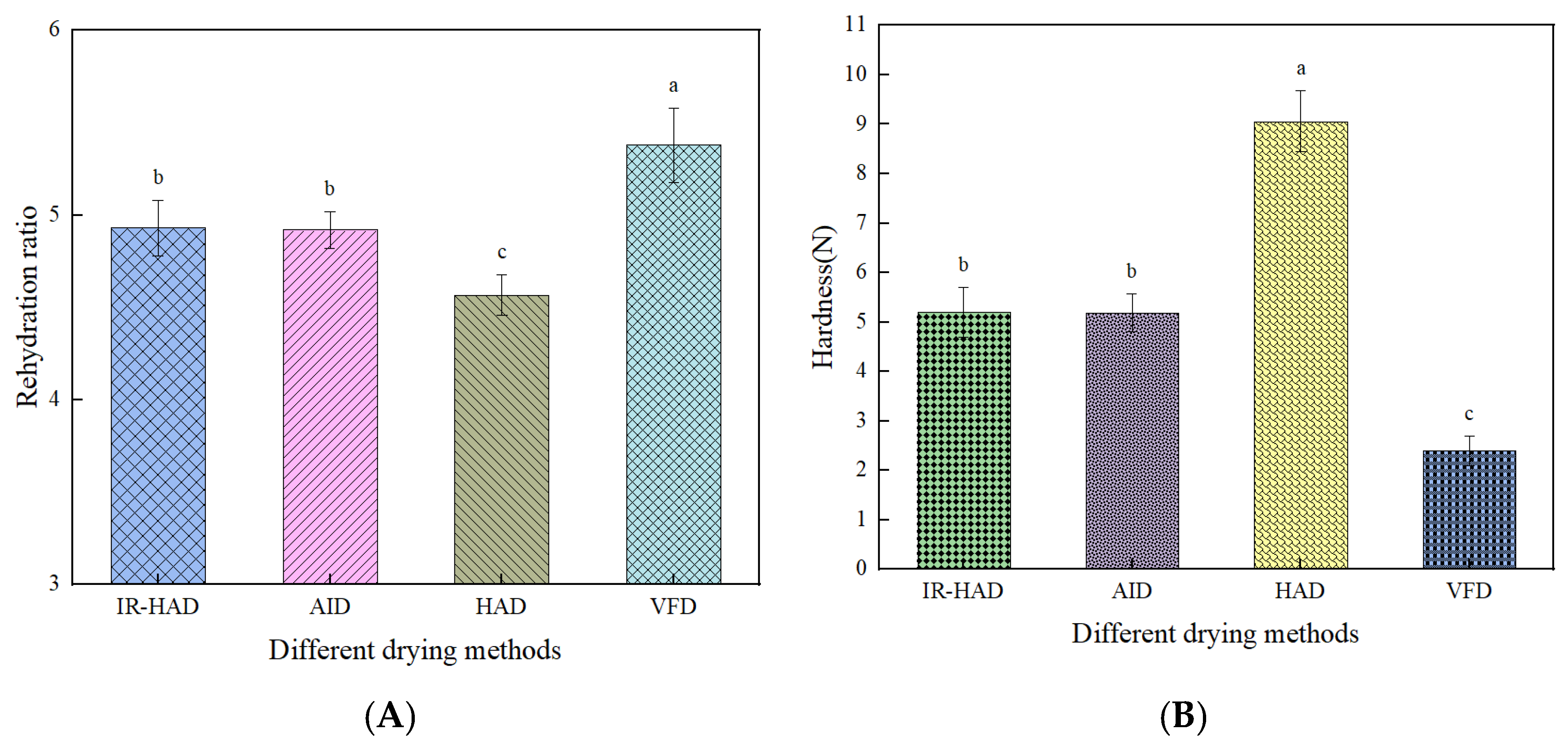

3.2. Rehydration Ratio and Texture

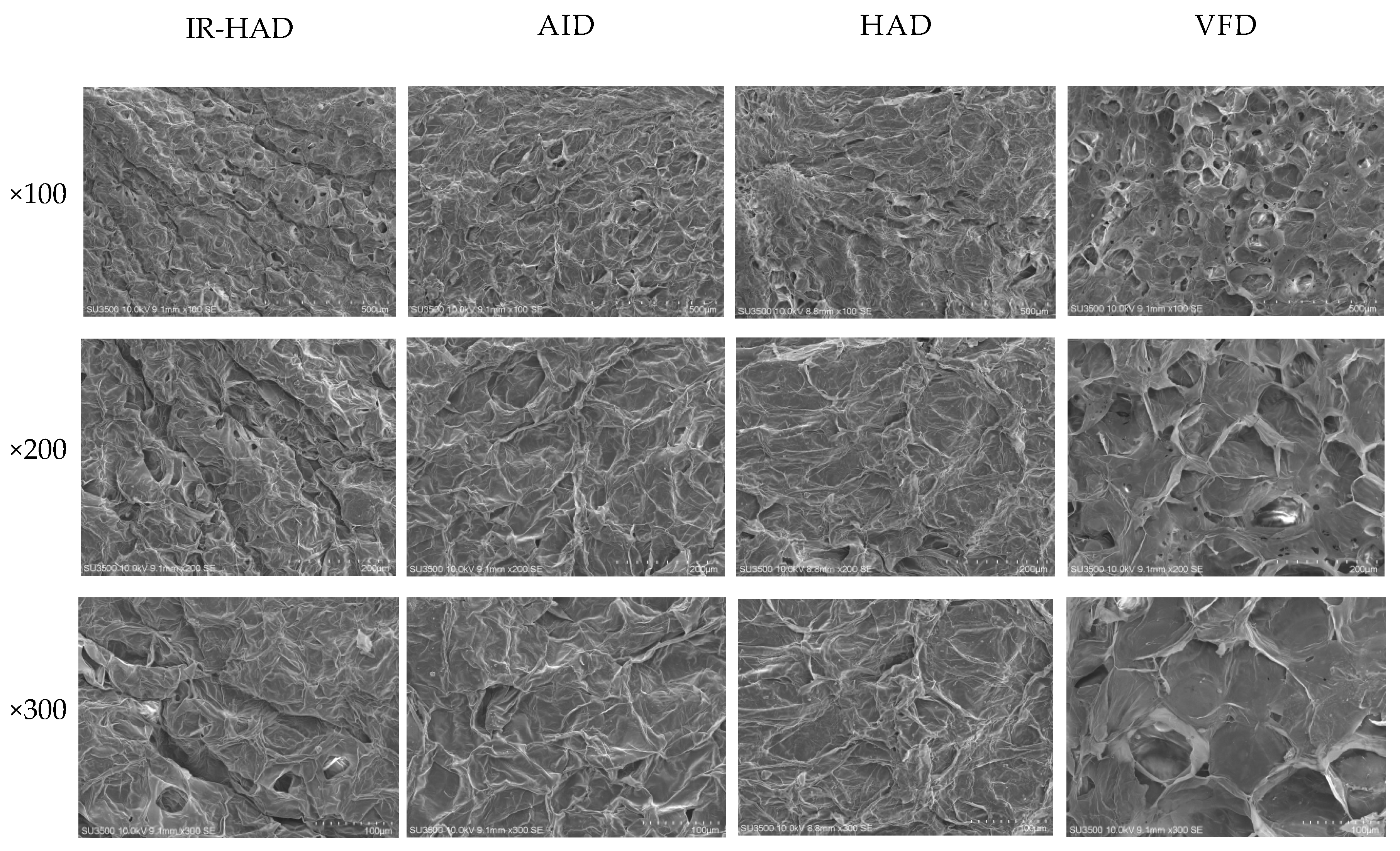

3.3. Microstructure by SEM

3.4. Color

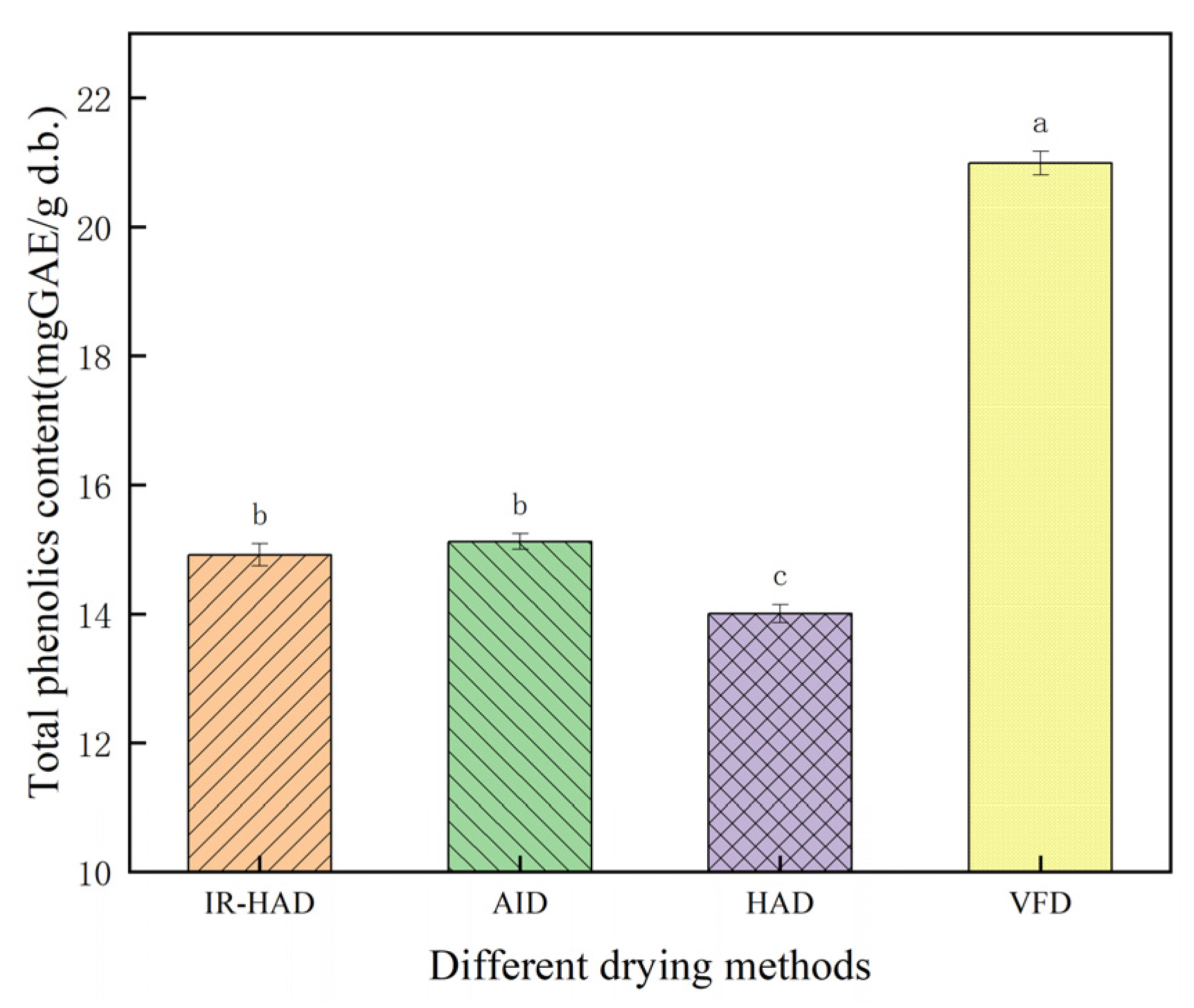

3.5. Total Phenolic Content

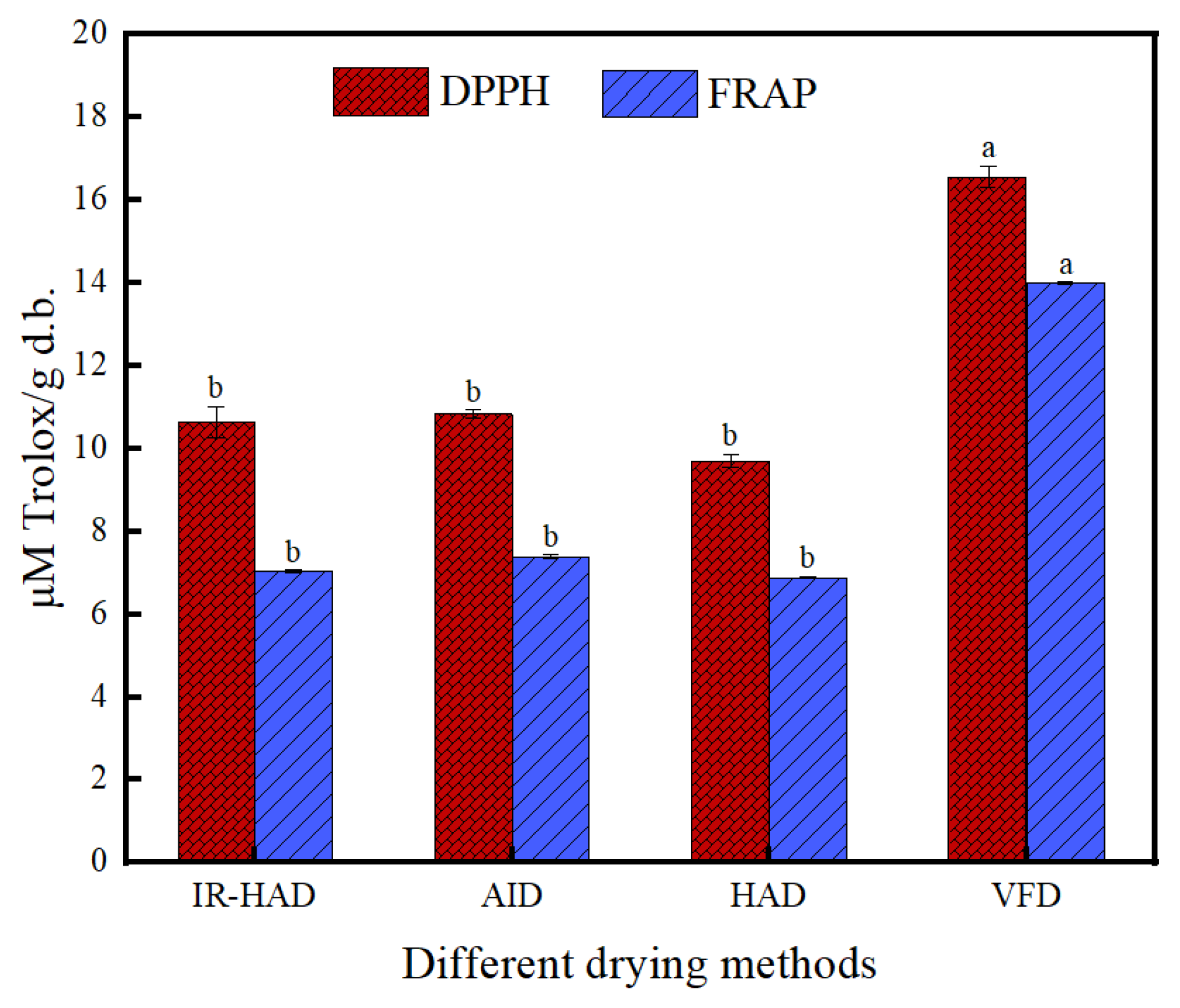

3.6. Antioxidant Activity In Vitro

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xue, Y.-L.; Chen, J.-N.; Han, H.-T.; Liu, C.-J.; Gao, Q.; Li, J.-H.; Li, D.-J.; Tanokura, M.; Liu, C.-Q. Multivariate analyses of the physicochemical properties of turnip (Brassica rapa L.) chips dried using different methods. Dry. Technol. 2019, 38, 411–419. [Google Scholar] [CrossRef]

- Yang, J.; Lou, J.; Zhong, W.; Li, Y.; He, Y.; Su, S.; Chen, X.; Zhu, B. Chemical Profile of Turnip According to the Plant Part and the Cultivar: A Multivariate Approach. Foods 2023, 12, 3195. [Google Scholar] [CrossRef]

- Hamidi Moghaddam, R.; Mansouripour, S.; Soltani, M. Functional Set-Type Yogurt Prepared Using Turnip Extract (Brassica Rapa L.): Physicochemical, Antioxidant, Microbiological, Rheological, Microstructural, and Sensory Characteristics. J. Food Meas. Charact. 2023, 18, 1204–1217. [Google Scholar] [CrossRef]

- Kong, D.; Wang, Y.; Li, M.; Liu, X.; Huang, M.; Li, X. Analysis of drying kinetics, energy and microstructural properties of turnips using a solar drying system. Sol. Energy 2021, 230, 721–731. [Google Scholar] [CrossRef]

- Cao, Q.; Wang, G.; Peng, Y. A critical review on phytochemical profile and biological effects of turnip (Brassica rapa L.). Front. Nutr. 2021, 8, 721733. [Google Scholar] [CrossRef]

- Paul, S.; Geng, C.A.; Yang, T.H.; Yang, Y.P.; Chen, J.J. Phytochemical and Health-Beneficial Progress of Turnip (Brassica rapa). J. Food Sci. 2018, 84, 19–30. [Google Scholar] [CrossRef] [PubMed]

- Taghinezhad, E.; Kaveh, M.; Szumny, A. Optimization and Prediction of the Drying and Quality of Turnip Slices by Convective-Infrared Dryer under Various Pretreatments by RSM and ANFIS Methods. Foods 2021, 10, 284. [Google Scholar] [CrossRef]

- Khalil, M.N.A.; Afifi, S.M.; Eltanany, B.M.; Pont, L.; Benavente, F.; El-Sonbaty, S.M.; Sedeek, M.S. Assessment of the effect of drying on Brassica greens via a multiplex approach based on LC-QTOF-MS/MS. molecular networking, and chemometrics along with their antioxidant and anticancer activities. Food Res. Int. 2024, 180, 114053. [Google Scholar] [CrossRef] [PubMed]

- Gao, Q.; Zhou, X.J.; Ma, R.; Lin, H.; Wu, J.L.; Peng, X.; Tanokura, M.; Xue, Y.L. Hydrogen peroxide modification affects the structure and physicochemical properties of dietary fibers from white turnip (Brassica Rapa L.). Sci Rep. 2021, 11, 1024. [Google Scholar] [CrossRef]

- Xue, Y.-l.; Han, H.-t.; Liu, C.-j.; Gao, Q.; Li, J.-h.; Zhang, J.-h.; Li, D.-J.; Liu, C.-q. Multivariate analyses of the volatile components in fresh and dried turnip (Brassica rapa L.) chips via HS-SPME–GC–MS. J. Food Sci. Technol. 2020, 57, 3390–3399. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, Z. Anti-fatigue activities and phytochemical compositions of turnip (Brassica rapa L.) extracts. Phcog. Mag. 2021, 17, 857–864. [Google Scholar] [CrossRef]

- Hamed, Y.S.; Ahsan, H.M.; Hussain, M.; Ahmad, I.; Tian, B.; Wang, J.; Zou, X.G.; Bu, T.; Ming, C.; Rayan, A.M.; et al. Polysaccharides from Brassica rapa root: Extraction, purification, structural features, and biological activities. A review. Int. J. Biol. Macromol. 2024, 254 Pt 3, 128023. [Google Scholar] [CrossRef]

- Feng, Y.; Xu, B.; ElGasim, A.; Yagoub, A.; Ma, H.; Sun, Y.; Xu, X.; Yu, X.; Zhou, C. Role of Drying Techniques on Physical, Rehydration, Flavor, Bioactive Compounds and Antioxidant Characteristics of Garlic. Food Chem. 2021, 343, 128404. [Google Scholar] [CrossRef]

- Chen, Y.N.; Li, M.; Dharmasiri, T.S.K.; Song, X.Y.; Liu, F.; Wang, X. Novel ultrasonic-assisted vacuum drying technique for dehydrating garlic slices and predicting the quality properties by low field nuclear magnetic resonance. Food Chem. 2020, 306, 125625. [Google Scholar] [CrossRef]

- Thuwapanichayanan, R.; Prachayawarakorn, S.; Kunwisawa, J.; Soponronnarit, S. Determination of effective moisture diffusivity and assessment of quality attributes of banana slices during drying. LWT-Food Sci. Technol. 2011, 44, 1502–1510. [Google Scholar] [CrossRef]

- Ju, H.Y.; El-Mashad, H.M.; Fang, X.M.; Pan, Z.; Xiao, H.W.; Liu, Y.H.; Gao, Z.J. Drying Characteristics and Modeling of Yam Slices under Different Relative Humidity Conditions. Dry. Technol. 2016, 34, 296–306. [Google Scholar] [CrossRef]

- Rojas, M.L.; Augusto, P.E. Ethanol and Ultrasound Pre-Treatments to Improve Infrared Drying of Potato Slices. Innov. Food Sci. Emerg. Technol. 2018, 49, 65–75. [Google Scholar] [CrossRef]

- Pawar, S.B.; Pratape, V.M. Fundamentals of Infrared Heating and Its Application in Drying of Food Materials: A Review. J. Food Process Eng. 2017, 40, 12308. [Google Scholar] [CrossRef]

- Deng, L.Z.; Yang, X.H.; Mujumdar, A.S.; Zhao, J.H.; Wang, D.; Zhang, Q.; Wang, J.; Gao, Z.J.; Xiao, H.W. Red Pepper (Capsicum annuum L.) Drying: Effects of Different Drying Methods on Drying Kinetics, Physicochemical Properties, Antioxidant Capacity, and Microstructure. Dry. Technol. 2018, 36, 893–907. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, X.; Xiao, H.; Li, Y.; Yang, T. Effect of Combined Infrared Hot Air Drying on Yam Slices: Drying Kinetics, Energy Consumption, Microstructure, and Nutrient Composition. Foods 2023, 12, 3048. [Google Scholar] [CrossRef]

- Boy, V.; Ben Khalifa, W.; Drevillon, L.; Lemee, Y.; Lendormi, T.; Lanoiselle, J.L. Air impingement and intermittent drying: Application to apple and to mango. Can. J. Chem. Eng. 2021, 99, 120–134. [Google Scholar] [CrossRef]

- Jiang, D.L.; Wang, Q.H.; Huang, C.; Sutar, P.P.; Lin, Y.W.; Okaiyeto, S.A.; Lin, Z.F.; Wu, Y.T.; Ma, W.M.; Xiao, H.W. Effect of various different pretreatment methods on infrared combined hot air impingement drying behavior and physicochemical properties of strawberry slices. Food Chem. X 2024, 22, 101299. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Ai, Z.; Xiao, H.; Mowafy, S.; Pei, Y.; Liu, Y. Improvement of drying efficiency and physicochemical quality of kiwifruit slices using infrared-assisted tilted tray air impingement drying. Dry. Technol. 2023, 41, 1159–1170. [Google Scholar] [CrossRef]

- Wang, D.; Dai, J.W.; Ju, H.Y.; Xie, L.; Xiao, H.W.; Liu, Y.H.; Gao, Z.J. Drying Kinetics of American Ginseng Slices in Thin-Layer Air Impingement Dryer. Int. J. Food Eng. 2015, 11, 701–711. [Google Scholar] [CrossRef]

- Ma, Y.; Yi, J.; Jin, X.; Li, X.; Feng, S.; Bi, J. Freeze-Drying of Fruits and Vegetables in Food Industry: Effects on Phytochemicals and Bioactive Properties Attributes—A Comprehensive Review. Food Rev. Int. 2022, 39, 6611–6629. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, D.; Li, M.; Zheng, J.; Jiang, L.; Li, R.; Wang, S. Developing a two-stage strategy in the dehydration treatment of fresh apple slices: Combined freeze and radio frequency-vacuum drying. Innov. Food Sci. Emerg. Technol. 2024, 92, 103596. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Y.; Nian, R.; Li, Q.; Zhu, D.; Cao, X. Effects of ultrasonic pretreatment on drying characteristics and water migration characteristics of freeze-dried strawberry. Food Chem. 2024, 450, 139267. [Google Scholar] [CrossRef]

- Fan, D.; Chitrakar, B.; Ju, R.; Zhang, M. Effect of ultrasonic pretreatment on the properties of freeze-dried carrot slices by traditional and infrared freeze-drying technologies. Dry. Technol. 2020, 39, 1176–1183. [Google Scholar] [CrossRef]

- Wang, J.-R.; Wu, X.-Y.; Cui, C.-B.; Bi, J.-F. Effect of osmotic dehydration combined with vacuum freeze-drying treatment on characteristic aroma components of peach slices. Food Chem. X 2024, 22, 101337. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 15th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- Li, C.; Ren, G.; Zhang, L.; Duan, X.; Wang, Z.; Ren, X.; Chu, Q.; He, T. Effects of different drying methods on the drying characteristics and drying quality of Cistanche deserticola. LWT-Food Sci. Technol. 2023, 184, 115000. [Google Scholar] [CrossRef]

- Liu, Z.L.; Bai, J.W.; Wang, S.X.; Meng, J.S.; Wang, H.; Yu, X.L.; Gao, Z.J.; Xiao, H.W. Prediction of energy and exergy of mushroom slices drying in hot air impingement dryer by artificial neural network. Dry. Technol. 2020, 38, 1959–1970. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, G.; Li, X.; Zhao, Y.; Lei, D.; Ding, G.; Ambrose, K.; Liu, Y. Combined medium- and short-wave infrared and hot air impingement drying of sponge gourd (Luffa cylindrical) slices. J. Food Eng. 2020, 284, 110043. [Google Scholar] [CrossRef]

- Jia, Z.; Liu, Y.; Xiao, H. Deep Learning Prediction of Moisture and Color Kinetics of Apple Slices by Long Short-Term Memory as Affected by Blanching and Hot-Air Drying Conditions. Processes 2024, 12, 1724. [Google Scholar] [CrossRef]

- Ju, H.-Y.; Vidyarthi, S.K.; Karim, M.A.; Yu, X.-L.; Zhang, W.-P.; Xiao, H.-W. Drying quality and energy consumption efficient improvements in hot air drying of papaya slices by step-down relative humidity based on heat and mass transfer characteristics and 3D simulation. Dry. Technol. 2022, 41, 460–476. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.-L.; Vidyarthi, S.K.; Wang, Q.-H.; Gao, L.; Li, B.-R.; Wei, Q.; Liu, Y.-H.; Xiao, H.-W. Effects of different drying methods on drying kinetics, physicochemical properties, microstructure, and energy consumption of potato (Solanum tuberosum L.) cubes. Dry. Technol. 2020, 39, 418–431. [Google Scholar] [CrossRef]

- Sun, W.; Li, M.; Zhang, Y.; Ai, Z.; Lei, D.; Pei, Y.; Liu, Y. Effect of different drying techniques on drying characteristics, physical quality, and active components of Citri reticulatae pericarpium, and the correlation between physiochemical quality. Ind. Crops Prod. 2023, 204 Pt B, 117350. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Pei, Y.P.; Sutar, P.P.; Liu, D.H.; Deng, L.Z.; Duan, X.; Liu, Z.L.; Xiao, H.W. Pulsed vacuum drying of banana: Effects of ripeness on drying kinetics and physicochemical properties and related mechanism. LWT-Food Sci. Technol. 2022, 161, 113362. [Google Scholar] [CrossRef]

- Aradwad, P.P.; Thirumani Venkatesh, A.K.; Mani, I. Infrared Drying of Apple (Malus Domestica) Slices: Effect on Drying and Color Kinetics, Texture, Rehydration, and Microstructure. J Food Process Eng. 2023, 46, e14218. [Google Scholar] [CrossRef]

- Guo, X.; Hao, Q.; Qiao, X.; Li, M.; Qiu, Z.; Zheng, Z.; Zhang, B. An Evaluation of Different Pretreatment Methods of Hot-Air Drying of Garlic: Drying Characteristics, Energy Consumption and Quality Properties. LWT-Food Sci. Technol. 2023, 180, 114685. [Google Scholar] [CrossRef]

- Deng, L.-Z.; Xiong, C.-H.; Pei, Y.-P.; Zhu, Z.-Q.; Zheng, X.; Zhang, Y.; Yang, X.-H.; Liu, Z.-L.; Xiao, H.-W. Effects of various storage conditions on total phenolic, carotenoids, antioxidant capacity, and color of dried apricots. Food Control 2022, 136, 108846. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Benzie, I.F.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Ai, Z.; Mowafy, S.; Liu, Y. Comparative analyses of five drying techniques on drying attributes, physicochemical aspects, and flavor components of Amomum villosum fruits. LWT-Food Sci. Technol. 2022, 154, 112879. [Google Scholar] [CrossRef]

- Xu, H.; Wu, M.; Wang, Y.; Wei, W.; Sun, D.; Li, D.; Zheng, Z.; Gao, F. Effect of combined infrared and hot air drying strategies on the quality of Chrysanthemum (Chrysanthemum morifolium Ramat.) cakes: Drying behavior, aroma profiles and phenolic compounds. Foods 2022, 11, 2240. [Google Scholar] [CrossRef]

- Marques, L.G.; Prado, M.M.; Freire, J.T. Rehydration characteristics of freeze-dried tropical fruits. LWT-Food Sci. Technol. 2009, 42, 1232–1237. [Google Scholar] [CrossRef]

- Xiao, H.W.; Bai, J.W.; Xie, L.; Sun, D.W.; Gao, Z.J. Thin-Layer Air Impingement Drying Enhances Drying Rate of American Ginseng (Panax quinquefolium L.) Slices with Quality Attributes Considered. Food. Bioprod. Process 2015, 94, 581–591. [Google Scholar] [CrossRef]

- Geng, Z.; Zhu, L.; Wang, J.; Yu, X.; Li, M.; Yang, W.; Hu, B.; Zhang, Q.; Yang, X. Drying sea buckthorn berries (Hippophae rhamnoides L.): Effects of different drying methods on drying kinetics, physicochemical properties, and microstructure. Front. Nutr. 2023, 10, 1106009. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Sun, P.; Chen, B.; Sajjad, U.; Yan, W. Influence of the process parameters on the energy conservation and quality of the kiwi fruit subjected to vacuum freeze drying. Case Stud. Therm. Eng. 2022, 33, 101935. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Y.; Zhang, Y.; Liu, Y.; Gao, Z.; Zhu, G. Relative humidity control during shiitake mushroom (Lentinus edodes) hot air drying based on appearance quality. J. Food Eng. 2022, 315, 110814. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, L.U.; Al-Said, F. Colour Measurement and Analysis in Fresh and Processed Foods. Food Bioprocess Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Xiao, H.W.; Law, C.L.; Sun, D.W.; Gao, Z.J. Color Change Kinetics of American Ginseng (Panax quinquefolium) Slices during Air Impingement Drying. Dry. Technol. 2014, 32, 418–427. [Google Scholar] [CrossRef]

- Zheng, Z.-A.; Wang, S.-Y.; Wang, H.; Xiao, H.; Liu, Z.-L.; Pan, Y.-H.; Gao, L. Comparative Study on the Influence of Various Drying Techniques on Drying Characteristics and Physicochemical Quality of Garlic Slices. Foods 2023, 12, 1314. [Google Scholar] [CrossRef]

- Bondaruk, J.; Markowski, M.; Aszczak, W. Effect of drying conditions on the quality of vacuum-microwave dried potato cubes. J. Food Eng. 2007, 81, 306–312. [Google Scholar] [CrossRef]

- Du, Y. Intervention mechanisms of cold plasma pretreatment on the quality, antioxidants and reactive oxygen metabolism of fresh wolfberries during storage. Food Chem. 2024, 431, 137106. [Google Scholar] [CrossRef]

- Qin, L.; Wang, H.; Zhang, W.; Pan, M.; Xie, H.; Guo, X. Effects of different drying methods on phenolic substances and antioxidant activities of seedless raisins. LWT-Food Sci. Technol. 2020, 131, 109807. [Google Scholar] [CrossRef]

- Ghafoor, K.; Al Juhaimi, F.; Özcan, M.M.; Uslu, N.; Babiker, E.E.; Ahmed, I.A.M. Total phenolics, total carotenoids, individual phenolics and antioxidant activity of ginger (Zingiber officinale) rhizome as affected by drying methods. LWT-Food Sci. Technol. 2020, 126, 109354. [Google Scholar] [CrossRef]

- Vega-Gálvez, A.; Ah-Hen, K.; Chacana, M.; Vergara, J.; Martínez-Monzó, J.; García-Segovia, P.; Lemus-Mondaca, R.; Di Scala, K. Effect of temperature and air velocity on drying kinetics, antioxidant capacity, total phenolic content, colour, texture and microstructure of apple (var. Granny Smith) slices. Food Chem. 2012, 132, 51–59. [Google Scholar] [CrossRef] [PubMed]

- Betoret, E.; Netoret, N.; Rocculi, P.; Rosa, M.D. Strategies to improve food functionality: Structure-property relationships on high pressures homogenization, vacuum impregnation and drying technologies. Trends Food Sci. Technol. 2015, 46, 1–12. [Google Scholar] [CrossRef]

- Akther, S.; Jothi, J.S.; Badsha, R.; Rahman, M.; Das, G.B.; Alim, A. Drying methods effect on bioactive compounds, phenolic profile, and antioxidant capacity of mango powder. J. King Saud Univ.-Sci. 2023, 35, 102370. [Google Scholar] [CrossRef]

- Zhang, A.A.; Xie, L.; Wang, Q.H.; Xu, M.Q.; Pan, Y.; Zheng, Z.A.; Lv, W.Q.; Xiao, H.W. Effect of the ripening stage on the pulsed vacuum drying behavior of goji berry (Lycium barbarum L.): Ultrastructure, drying characteristics, and browning mechanism. Food Chem. 2024, 442, 138489. [Google Scholar] [CrossRef]

- Liu, Z.L.; Xie, L.; Zielinska, M.; Pan, Z.; Deng, L.Z.; Zhang, J.S.; Gao, L.; Wang, S.Y.; Zheng, Z.A.; Xiao, H.W. Improvement of drying efficiency and quality attributes of blueberries using innovative far-infrared radiation heating assisted pulsed vacuum drying (FIR-PVD). Innov. Food Sci. Emerg. Technol. 2022, 77, 102948. [Google Scholar] [CrossRef]

| Models | Drying Method | Parameters | |||||

|---|---|---|---|---|---|---|---|

| α | β | χ2/(×10−4) | R2 | RMSE | Deff/(10−8, m2·s−1) | ||

| Weibull | HAD | 124.03565 ± 0.660 | 1.26917 ± 0.0137 | 0.5954 | 0.9994 | 0.0013 | 2.467 |

| AID | 42.61838 ± 0.53255 | 1.09985 ± 0.02323 | 0.1084 | 0.9988 | 0.0014 | 4.863 | |

| IR-HAD | 65.0599 ± 0.52267 | 1.23456 ± 0.01873 | 0.7852 | 0.9992 | 0.0011 | 4.068 | |

| k | n | χ2/(×10−4) | R2 | RMSE | Deff/(10−8, m2·s−1) | ||

| Page | HAD | 0.00221 ± 0.00016 | 1.26819 ± 0.015 | 0.5956 | 0.9994 | 0.0013 | 2.467 |

| AID | 0.01612 ± 0.00156 | 1.10004 ± 0.02455 | 1.0844 | 0.9988 | 0.0014 | 4.863 | |

| IR-HAD | 0.00579 ± 0.00050 | 1.23399 ± 0.02014 | 0.7852 | 0.9992 | 0.0011 | 4.068 | |

| Fresh | IR-HAD | AID | HAD | VFD | |

|---|---|---|---|---|---|

| Image |  |  |  |  |  |

| 93.53 ± 0.36 a | 85.24 ± 1.18 d | 91.58 ± 0.28 b | 88.39 ± 0.99 c | 94.67 ± 0.40 a | |

| −3.82 ± 0.30 b | −3.72 ± 0.91 b | −3.55 ± 0.35 b | −5.21 ± 0.44 c | −1.34 ± 0.10 a | |

| 2.80 ± 0.08 d | 15.22 ± 0.69 a | 7.33 ± 0.55 c | 11.54 ± 0.34 b | 1.88 ± 0.18 d | |

| — | 14.98 ± 0.64 a | 4.96 ± 0.43 c | 10.24 ± 0.83 b | 2.88 ± 0.26 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, F.; Zhang, J.; Mujumdar, A.S.; Sutar, P.P.; Yi, X.; Wang, X.; Hu, C.; Ni, J.; Xiao, H. Effects of Drying Methods on Drying Characteristics and Physicochemical Quality of Turnip Slices (Brassica rapa L.). Processes 2025, 13, 2773. https://doi.org/10.3390/pr13092773

Yang F, Zhang J, Mujumdar AS, Sutar PP, Yi X, Wang X, Hu C, Ni J, Xiao H. Effects of Drying Methods on Drying Characteristics and Physicochemical Quality of Turnip Slices (Brassica rapa L.). Processes. 2025; 13(9):2773. https://doi.org/10.3390/pr13092773

Chicago/Turabian StyleYang, Fan, Jingshou Zhang, Arun S. Mujumdar, Parag Prakash Sutar, Xiaokang Yi, Xufeng Wang, Can Hu, Jiabao Ni, and Hongwei Xiao. 2025. "Effects of Drying Methods on Drying Characteristics and Physicochemical Quality of Turnip Slices (Brassica rapa L.)" Processes 13, no. 9: 2773. https://doi.org/10.3390/pr13092773

APA StyleYang, F., Zhang, J., Mujumdar, A. S., Sutar, P. P., Yi, X., Wang, X., Hu, C., Ni, J., & Xiao, H. (2025). Effects of Drying Methods on Drying Characteristics and Physicochemical Quality of Turnip Slices (Brassica rapa L.). Processes, 13(9), 2773. https://doi.org/10.3390/pr13092773