Effect of Burial Depth, Cavern Shape, and Sealing Layer on the Mechanical Behaviour of Abandoned Mines for Compressed Air Energy Storage

Abstract

1. Introduction

2. Finite Element Analysis of CAES Cavern

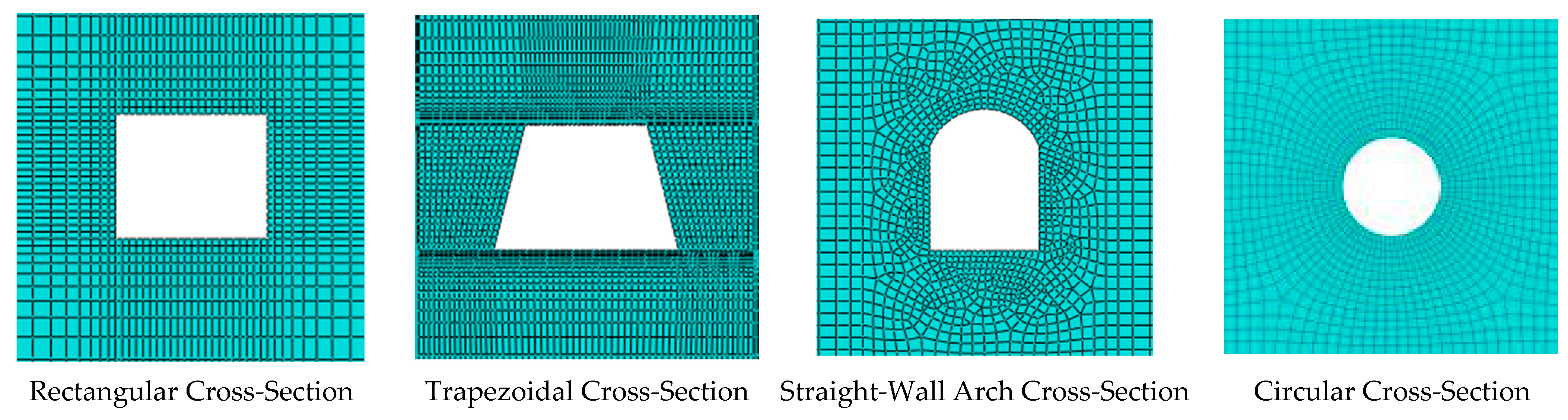

2.1. Cavern Shape of Abandoned Mines for CAES

2.2. CAES Cavern Dimensions

2.3. Numerical Simulation Schemes for CAES

2.4. Constitutive Model and Parameters of the CAES Cavern

3. Calculation Results and Discussion

3.1. Cavern Stability After Excavation and Lining Installation

3.1.1. Rectangular Cavern

3.1.2. Trapezoid Cavern

3.1.3. Straight-Wall Arch Cavern

3.1.4. Circular Cavern

3.2. Comparison of the Mechanical Properties of the Surrounding Rock After Excavation and Lining Construction

3.3. Post-Pressurization Cavern Stability and Deformation

3.3.1. Rectangular Cavern

3.3.2. Trapezoid Cavern

3.3.3. Straight-Wall Arch Cavern

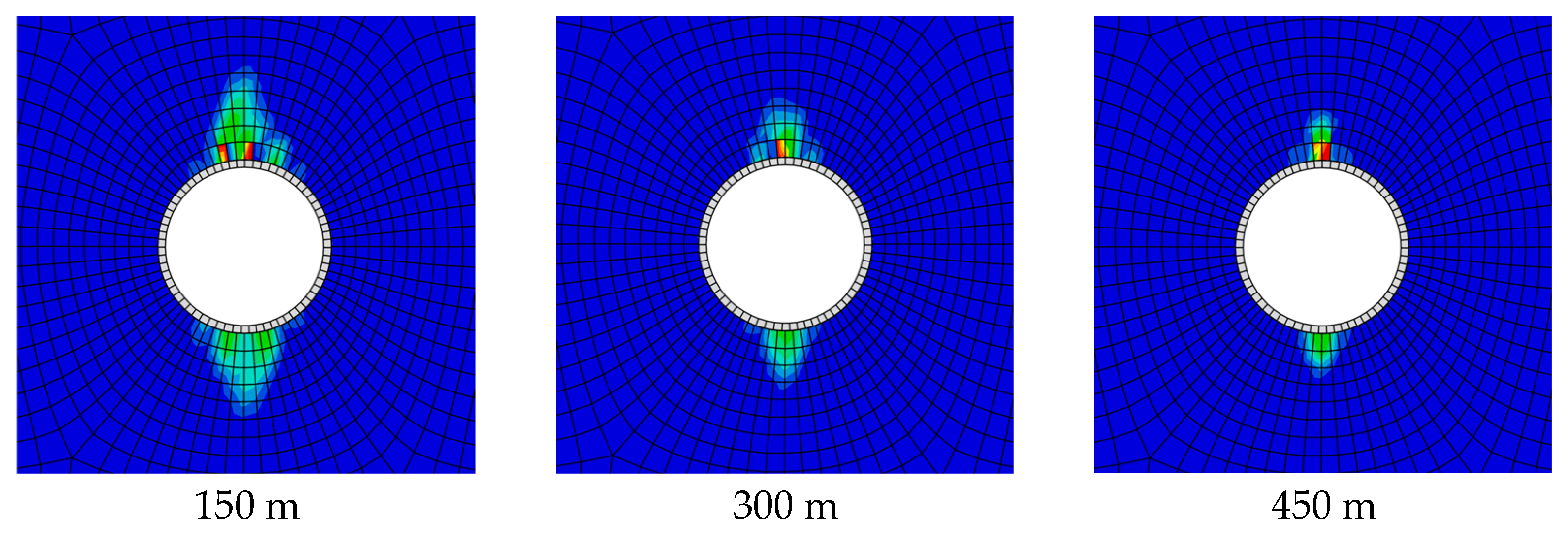

3.3.4. Circular Cavern

3.4. Comparison of Mechanical Properties of Surrounding Rock After Gas Compression

4. Influence of Sealing Layer

4.1. Steel Sealing Layer

4.2. Sealing Layer of Polymer Material

4.3. Analysis of Sealing Layer Effects

5. Conclusions

- (1)

- Burial depth has a greater influence on the stability of the cavern. When the burial depth is 150 m, the threat to the stability of the cavern caused by the gas pressure condition is greater than that after excavation and lining. When the burial depth is increased to 450 m, the stability is lower after excavation and lining. When the burial depth is 300 m, the degree of development of the plastic zone triggered by the two conditions of excavation and gas pressure is comparable, and the overall stability is better than that under the conditions of 150 m and 450 m burial depth, which shows a better safety. Overall, the stability of rectangular and straight-wall arch caverns with a burial depth of 450m and 300m is relatively high. Compared with other cavern shapes, the circular cavern shows better applicability in compressed air energy storage underground engineering, and thus is more suitable as the choice of cavern shape for energy storage.

- (2)

- Cavern shape is one of the important factors controlling the strain level of rock around the cavern. Among all the calculated cavern shapes, the trapezoidal cavern has the highest maximum peri-cavity strain value (1.60 × 10−3~1.93 × 10−3), followed by the rectangular cavern (1.08 × 10−3~1.18 × 10−3). The straight-wall arch-shaped cavern is slightly lower than the rectangular cavern (1.05 × 10−3~1.15 × 10−3), and the circular cavern has the smallest peri-cavity strain (8.01 × 10−4~9.91 × 10−4).

- (3)

- In this study, it was found that the shape of the cavern and the burial depth were the main influencing factors of the surrounding rock strain. The surrounding rock strains are different for different cavern shapes. When the sectional area and burial depth are the same, the maximum strains around the hole of the rectangular, trapezoidal, straight-wall arch and circular caverns are not much different. While the stability of the circular cavern is the best, the cave modification can be closer to the circular cavern to meet the requirements of different geological conditions.

- (4)

- Different sealing conditions have a certain impact on the stability of the compressed air energy storage cavern. The steel sealing layer can enhance the stability of the cavern after compressed air storage, while polymer material as a sealing layer is corrosion-resistant in comparison, and the stability of the cavern is similar to that of the sealing layer, so that the appropriate sealing material can be selected according to the actual working conditions.

- (5)

- This study is derived from simulations conducted under Class II surrounding rock conditions. There are still some disadvantages. In weaker rock masses, and commonly in such cases as Class III–IV conditions, the optimal cavern geometry may vary. Moreover, the effects of thermal fields under cyclic charge–discharge conditions also were not considered. Future work will include systematically mechanical behaviour and sensitivity analyses in the light of varying rock mass and temperature parameters to assess the performance of different cavern geometries under a wider range of geological conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Luo, X.; Wang, J.; Dooner, M.; Clarke, J. Overview of current development in electrical energy storage technologies and the application potential in power system operation. Appl. Energy 2015, 137, 511–536. [Google Scholar] [CrossRef]

- Succar, S.; Williams, R.H. Compressed air energy storage: Theory, resources, and applications for wind power. Princet. Environ. Inst. Rep. 2008, 8, 81. [Google Scholar]

- Olabi, A.G.; Tabbi-Wilberforce, T.; Ramadan, M.; Abdelkareem, M.A.; Alami, A.H. Compressed air energy storage systems: Components and operating parameters—A review. J. Energy Storage 2021, 34, 102000. [Google Scholar] [CrossRef]

- Xu, Y.; Zhou, S.; Xia, C.; Zhao, H.; Xue, X. Three-dimensional thermo-mechanical analysis of abandoned mine drifts for underground compressed air energy storage: A comparative study of two construction and plugging schemes. J. Energy Storage 2021, 39, 102696. [Google Scholar] [CrossRef]

- Waniczek, S.; Ochmann, J.; Bartela, L.; Rulik, S.; Lutyński, M.; Brzuszkiewicz, M.; Kołodziej, K.; Smolnik, G.; Jurczyk, M.; Lipka, M. Design and construction challenges for a hybrid air and thermal energy storage system built in the post-mining shaft. J. Therm. Sci. 2022, 31, 1302–1317. [Google Scholar] [CrossRef]

- Li, F.; Li, F.; Sun, R.; Zheng, J.; Li, X.; Shen, L.; Sun, Q.; Liu, Y.; Ji, Y.; Duan, Y. A study on the transient response of compressed air energy storage in the interaction between gas storage chambers and horseshoe-shaped tunnels in an abandoned coal mine. Energies 2024, 17, 953. [Google Scholar] [CrossRef]

- Komba, N.A.; Haisong, C.; Liwoko, B.B.; Mwakipunda, G.C. A comprehensive review on compressed air energy storage in geological formation: Experiments, simulations, and field applications. J. Energy Storage 2025, 114, 115795. [Google Scholar] [CrossRef]

- Sciacovelli, A.; Li, Y.; Chen, H.; Wu, Y.; Wang, J.; Garvey, S.; Ding, Y. Dynamic simulation of Adiabatic Compressed Air Energy Storage (A-CAES) plant with integrated thermal storage—Link between components performance and plant performance. Appl. Energy 2017, 185, 16–28. [Google Scholar] [CrossRef]

- Ye, B.; Cheng, Z.; Ye, W.; Peng, Y. An analytical solution for analyzing the sealing-efficiency of compressed air energy storage caverns. KSCE J. Civ. Eng. 2019, 23, 2025–2035. [Google Scholar] [CrossRef]

- Zhou, Y.; Xia, C.; Zhao, H.; Wang, X.; Mei, S.; Zhou, S. A method for estimating air leakage through inner seals and mechanical responses of the surrounding rock of lined rock caverns for compressed air energy storage. Chin. J. Rock Mech. Eng. 2017, 36, 297–309. [Google Scholar]

- Xia, C.; Zhang, P.; Zhou, S.; Zhou, Y.; Wang, R. Stability and tangential strain analysis of large-scale compressed air energy storage cavern. Rock Soil Mech. 2014, 35, 1391–1398. [Google Scholar]

- Li, W.; Ma, H.; Zhao, K.; Li, H.; Zeng, Z.; Wang, X.; Liang, R.; Yang, C. Stability and settlement analysis of salt cavern groups for compressed air energy storage: A case study in China. J. Energy Storage 2025, 122, 116626. [Google Scholar] [CrossRef]

- Li, J.; Yao, J.; Huang, Z.; Wang, W.; Wu, Y.-S. An efficient numerical simulation of coupled thermo-hydro-mechanical processes in deep shale gas reservoirs. Phys. Fluids 2023, 35, 123112. [Google Scholar] [CrossRef]

- Hu, C.; Li, X.; Jia, B.; He, L.; Zhang, K. Thermo-Mechanical Behavior of Polymer-Sealed Dual-Cavern Hydrogen Storage in Heterogeneous Rock Masses. Energies 2025, 18, 3739. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, D. Study on Long-Term Stability of Lined Rock Cavern for Compressed Air Energy Storage. Energies 2024, 17, 5908. [Google Scholar] [CrossRef]

- Kuperman, A.M.; SergeevDeng, A.Y. Influence of a Sealing Layer on the Physical and Mechanical Properties of the Shell of a High-Pressure Vessel for Hydrogen Storage. Chem. Phys. Polym. Mater. 2022, 16, 1172–1179. [Google Scholar] [CrossRef]

- Kim, H.M.; Lettry, Y.; Park, D.; Ryu, D.-W.; Choi, B.-H.; Song, W.-K. Field evaluation of permeability of concrete linings and rock masses around underground lined rock caverns by a novel in-situ measurement system. Eng. Geol. 2012, 137–138, 97–106. [Google Scholar] [CrossRef]

- Huang, D.; Ma, Y.; Rao, Q.; Yi, W.; Yang, W.-T.; Li, P. A new multi-objective optimization model of multi-layer prestressed lining cavern for compressed air energy storage. J. Cent. South Univ. 2023, 30, 3855–3866. [Google Scholar] [CrossRef]

- Jiang, Z.; Gan, L.; Zhang, D.; Xiao, Z.; Liao, J. Distribution characteristics and evolution laws of liner cracks in underground caverns for compressed air energy storage. Chin. J. Geotech. Eng. 2024, 46, 110–119. [Google Scholar]

- Cui, L.; Ye, W.; Wang, Q.; Chen, Y.-G.; Cui, Y.-J.A. A model for describing advective and diffusive gas transport through initially saturated bentonite with consideration of temperature. Eng. Geol. 2023, 323, 107215. [Google Scholar] [CrossRef]

- Cui, L.; Ye, W.; Ji, Y.; Xu, L.; Ye, G.; Ye, B.; Chen, B.; Cui, Y.; Zhang, F. A new apparatus for investigating gas transport property in geomaterials with ultralow permeability. Constr. Build. Mater. 2023, 385, 131523. [Google Scholar] [CrossRef]

- Cui, L.; Ye, W.; Wang, Q.; Chen, Y.-G.; Cui, Y.-J. Investigation on successive gas breakthroughs behavior of saturated GMZ bentonite under rigid boundary conditions. Acta Geotech. 2024, 19, 6773–6786. [Google Scholar] [CrossRef]

- Cui, L.; Ye, W.; Wang, Q.; Chen, Y.-G.; Chen, B.; Cui, Y.-J. Experimental investigation on swelling and gas breakthrough properties of GMZ bentonite considering alkaline solution effects. Eng. Geol. 2025, 347, 107933. [Google Scholar] [CrossRef]

- Li, H.; Ma, H.; Zhu, S.; Liu, J.; Zhao, K.; Zheng, Z.; Zeng, Z.; Yang, C. Large-scale CAES in bedded rock salt: A case study in Jiangsu Province, China. Energy 2023, 281, 128271. [Google Scholar] [CrossRef]

- Jiang, Z.; Qin, S.; Tang, D. Numerical study on accumulative damage characteristics of underground rock caverns for compressed air energy storage. Chin. J. Geotech. Eng. 2020, 42, 230–238. [Google Scholar]

- Wang, Z.; Wang, L. Calculation of section area of arbitrary three-centered arch type and circular arch type headings. Met. Mine Des. Constr. 1995, 5, 25–26. [Google Scholar]

- Fu, D.; Hu, X.; Wu, H.; Li, P.; Liu, Z. Characteristics of Nonlinear Mechanical Response of Sealing Steel Lining in Underground High Pressure Air Storage Caverns. Water Power 2024, 50, 38–44. [Google Scholar]

- Wang, Z.; Li, J.; Hao, X.; Li, M.; Zhang, W.; Liu, J. A review of several issues for compressed gas energy storage in lined rock cavern. Hazard Control Tunn. Undergr. Eng. 2024, 6, 1–13. [Google Scholar]

- Wang, Q.; Zhang, B.; Wang, H.; Li, Y.; Hu, Z.; Lang, B. Optimization and stability analysis of layout parameters of lined high-pressure gas storage caverns. J. Eng. Geol. 2020, 28, 1123–1131. [Google Scholar]

- JTG D70-2004; Code for Design of Road Tunnel. Ministry of Transport of the People’s Republic of China: Chongqin, China, 2004.

- DL/T 5195-2004; Specification for design of hydraulic tunnel. National Development and Reform Commission of the People’s Republic of China: Beijing, China, 2004.

- Xia, C.; Qin, S.; Zhao, H.; Xue, X.; Zhou, Y. Fatigue durability of steel lining in compressed air energy storage caverns under cyclic thermomechanical effects. J. Tongji Univ. 2023, 51, 1564–1573. [Google Scholar]

- Zhou, Y.; Xia, C.; Zhou, S.; Zhang, P. Air tightness and mechanical characteristics of polymeric seals in lined rock caverns(LRCs) for compressed air energy storage (CAES). Chin. J. Rock Mech. Eng. 2018, 37, 2685–2696. [Google Scholar]

| Surrounding Rock Classification | Unit Weight γ/kN/m3 | Elastic Modulus E/GPa | Poisson’s Ratio μ | Internal Friction Angle φ/° | Cohesion c/MPa | Tensile Strength σₜ/MPa |

|---|---|---|---|---|---|---|

| II | 25 | 30 | 0.2 | 60 | 2.0 | 2 |

| Concrete Strength | Lining Thickness/cm | Unit Weight γ/kN/m3 | Elastic Modulus E/GPa | Poisson’s Ratio μ |

|---|---|---|---|---|

| C30 | 25 | 25 | 30 | 0.167 |

| Sealing Type | Density ρ/kg/m3 | Elastic Modulus E/GPa | Poisson’s Ratio μ | Coefficient of Thermal Expansion α | Thermal Conductivity λ/W/(m·K) |

|---|---|---|---|---|---|

| Steel Lining | 7800 | 2 × 105 | 0.3 | 1.7 × 10−5 | 45 |

| Polymer Materials | 920 | 1.5 | 0.5 | 4.8 × 10−4 | 0.091 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, L.; Yan, S.; Zhao, F.; Bai, X.; Zhang, Y.; Qin, P. Effect of Burial Depth, Cavern Shape, and Sealing Layer on the Mechanical Behaviour of Abandoned Mines for Compressed Air Energy Storage. Processes 2025, 13, 2737. https://doi.org/10.3390/pr13092737

Niu L, Yan S, Zhao F, Bai X, Zhang Y, Qin P. Effect of Burial Depth, Cavern Shape, and Sealing Layer on the Mechanical Behaviour of Abandoned Mines for Compressed Air Energy Storage. Processes. 2025; 13(9):2737. https://doi.org/10.3390/pr13092737

Chicago/Turabian StyleNiu, Lihui, Shiji Yan, Fuchao Zhao, Xinchun Bai, Yaosheng Zhang, and Pengju Qin. 2025. "Effect of Burial Depth, Cavern Shape, and Sealing Layer on the Mechanical Behaviour of Abandoned Mines for Compressed Air Energy Storage" Processes 13, no. 9: 2737. https://doi.org/10.3390/pr13092737

APA StyleNiu, L., Yan, S., Zhao, F., Bai, X., Zhang, Y., & Qin, P. (2025). Effect of Burial Depth, Cavern Shape, and Sealing Layer on the Mechanical Behaviour of Abandoned Mines for Compressed Air Energy Storage. Processes, 13(9), 2737. https://doi.org/10.3390/pr13092737