Erosion Wear Characteristics of V-Shaped Elbow in Blooey Line

Abstract

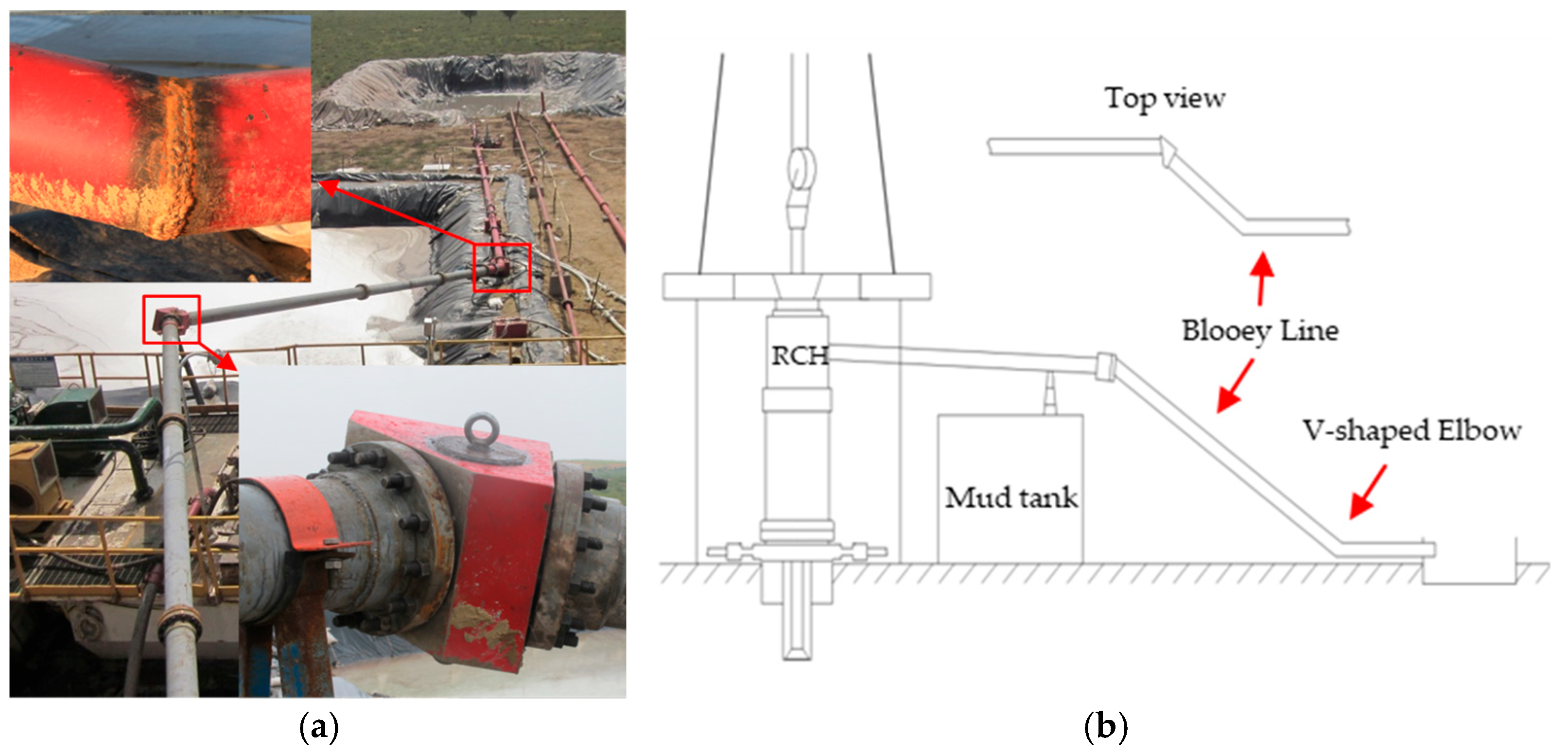

1. Introduction

2. Methods

2.1. Mathematical Model

2.1.1. Governing Equations for the Continuous Phase

2.1.2. Governing Equations for the Discrete Phase

2.1.3. Erosion Wear Equation

2.1.4. Service Life Before Leakage

2.2. Erosion Model Validation

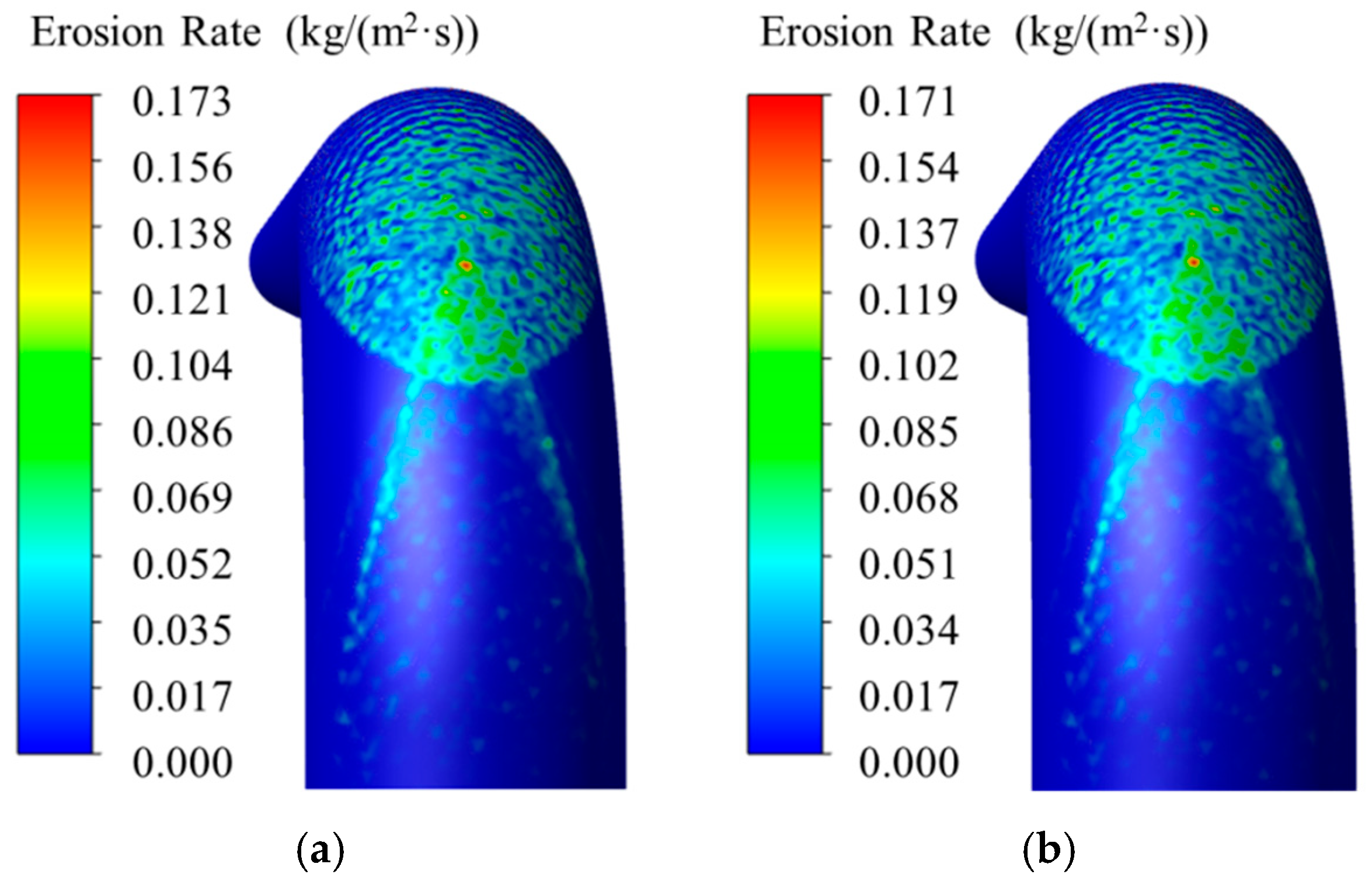

2.3. Particle Size Analysis of Rock Cuttings

3. Discussion of Results

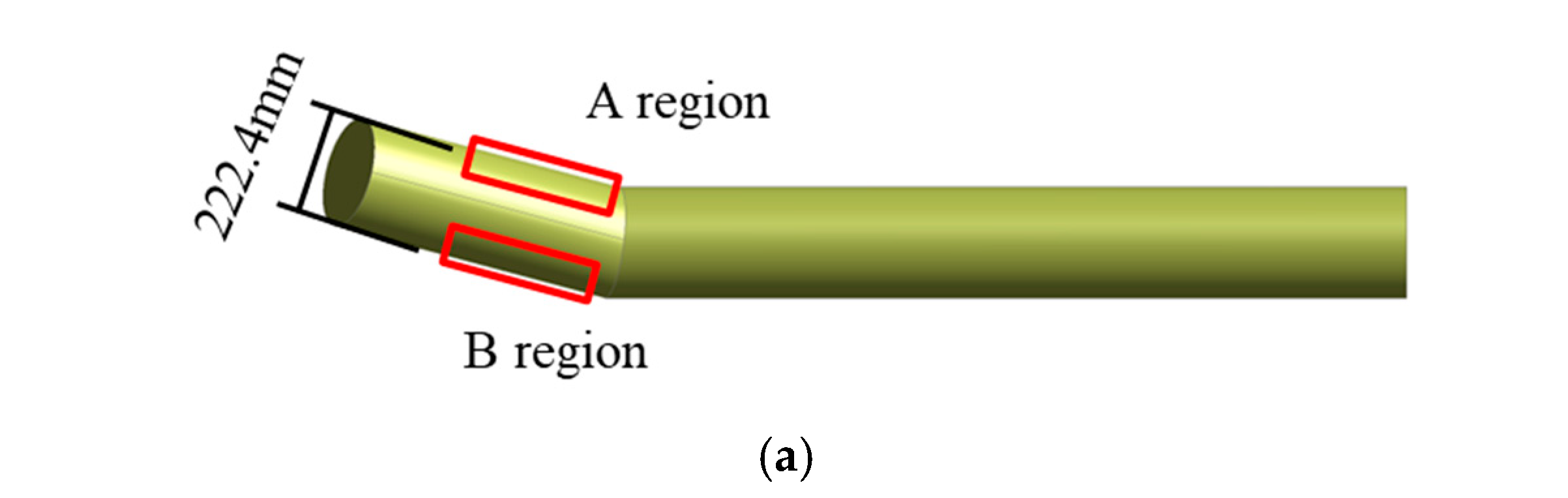

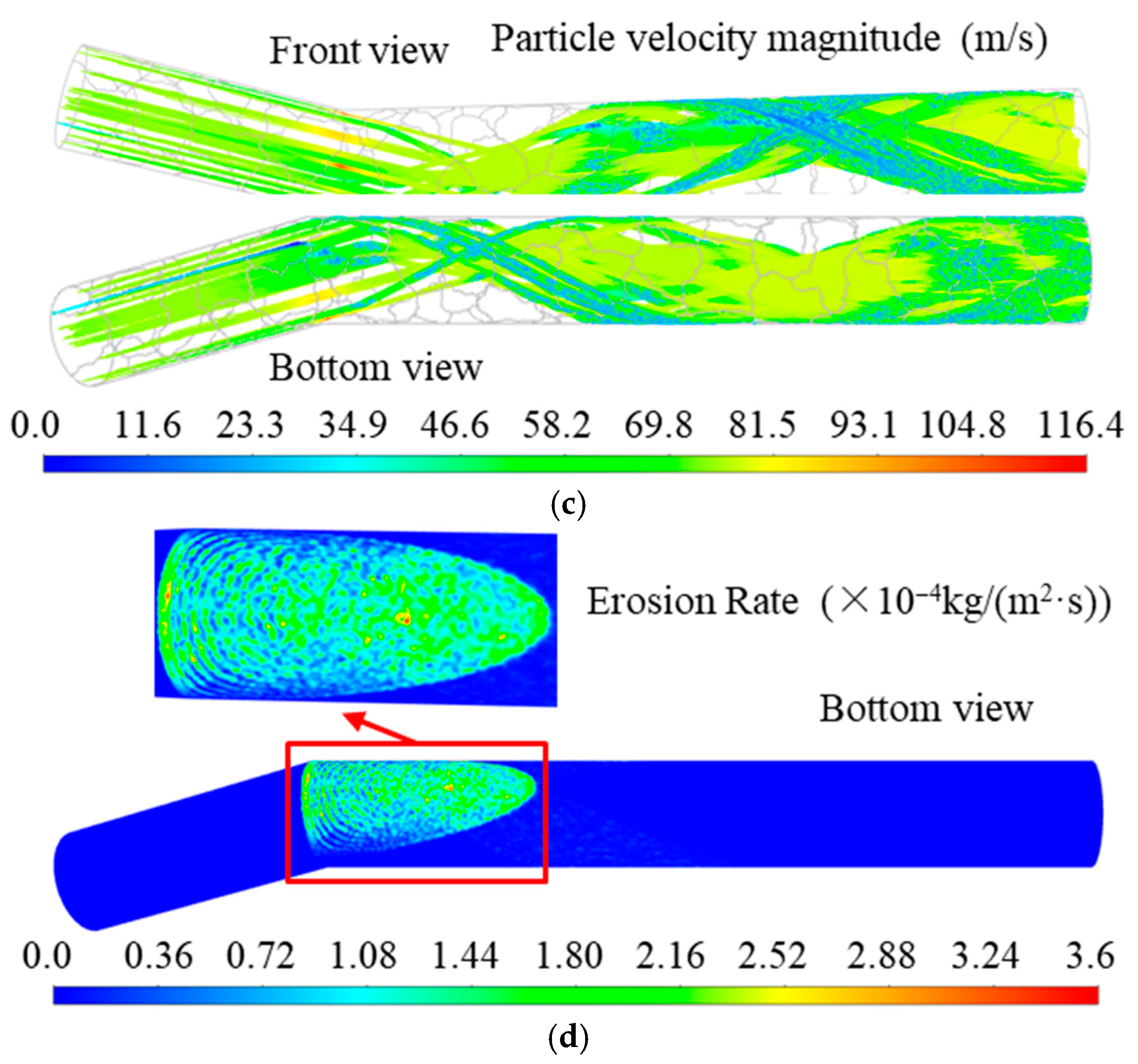

3.1. Flow Field Analysis of V-Shaped Elbow

3.2. Effect of Operation Parameters on Erosion

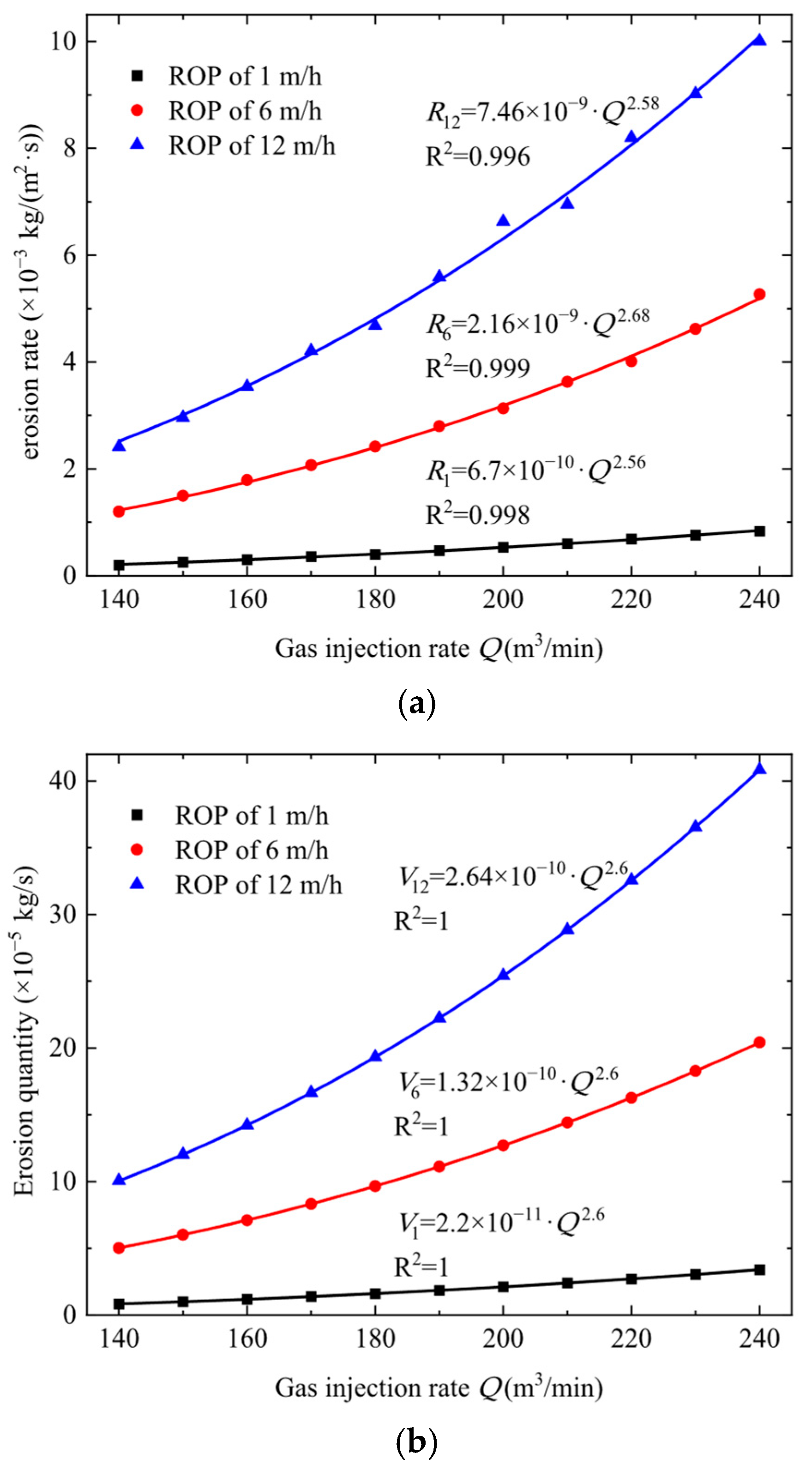

3.2.1. Influence of Gas Injection Rate on Erosion

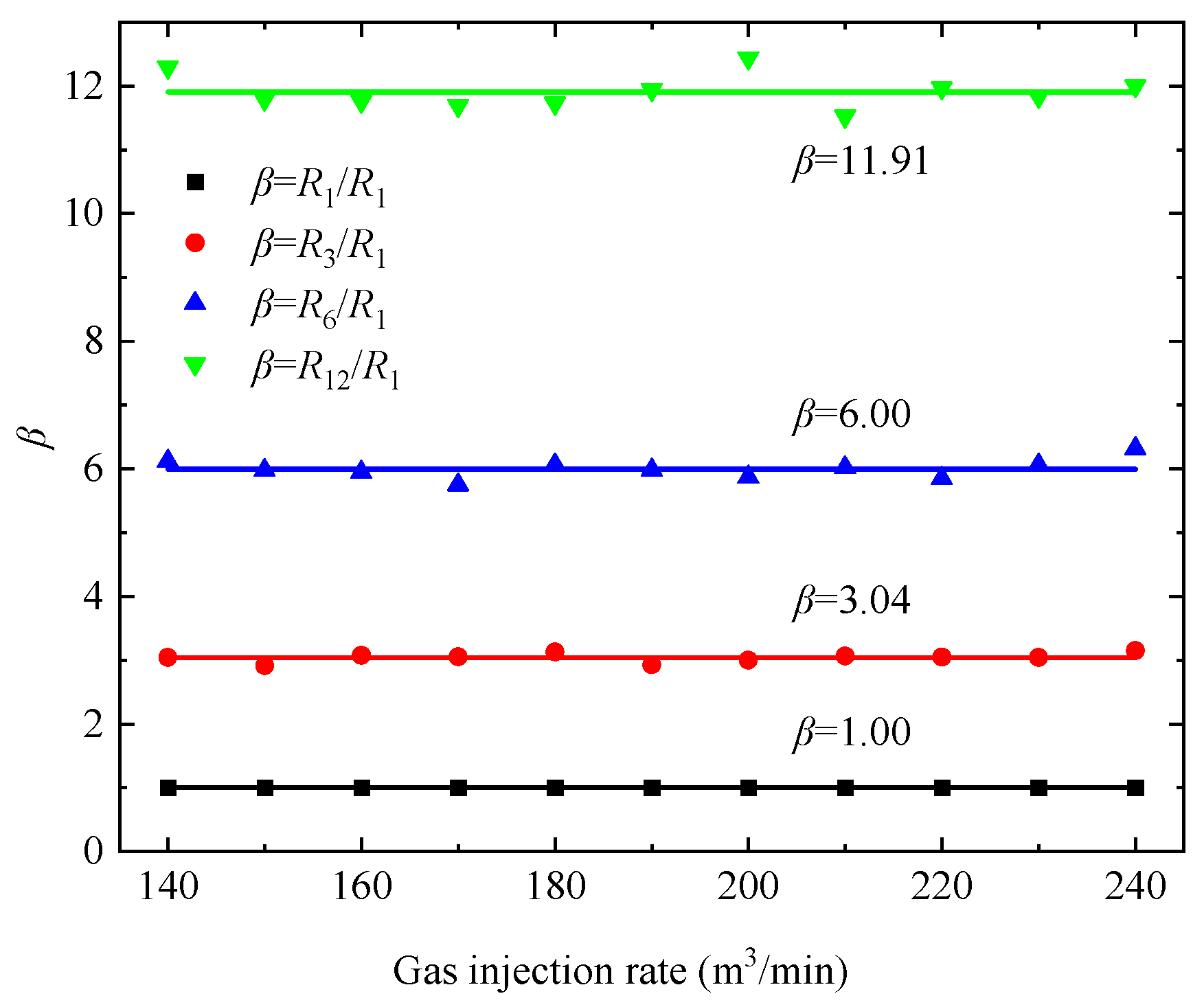

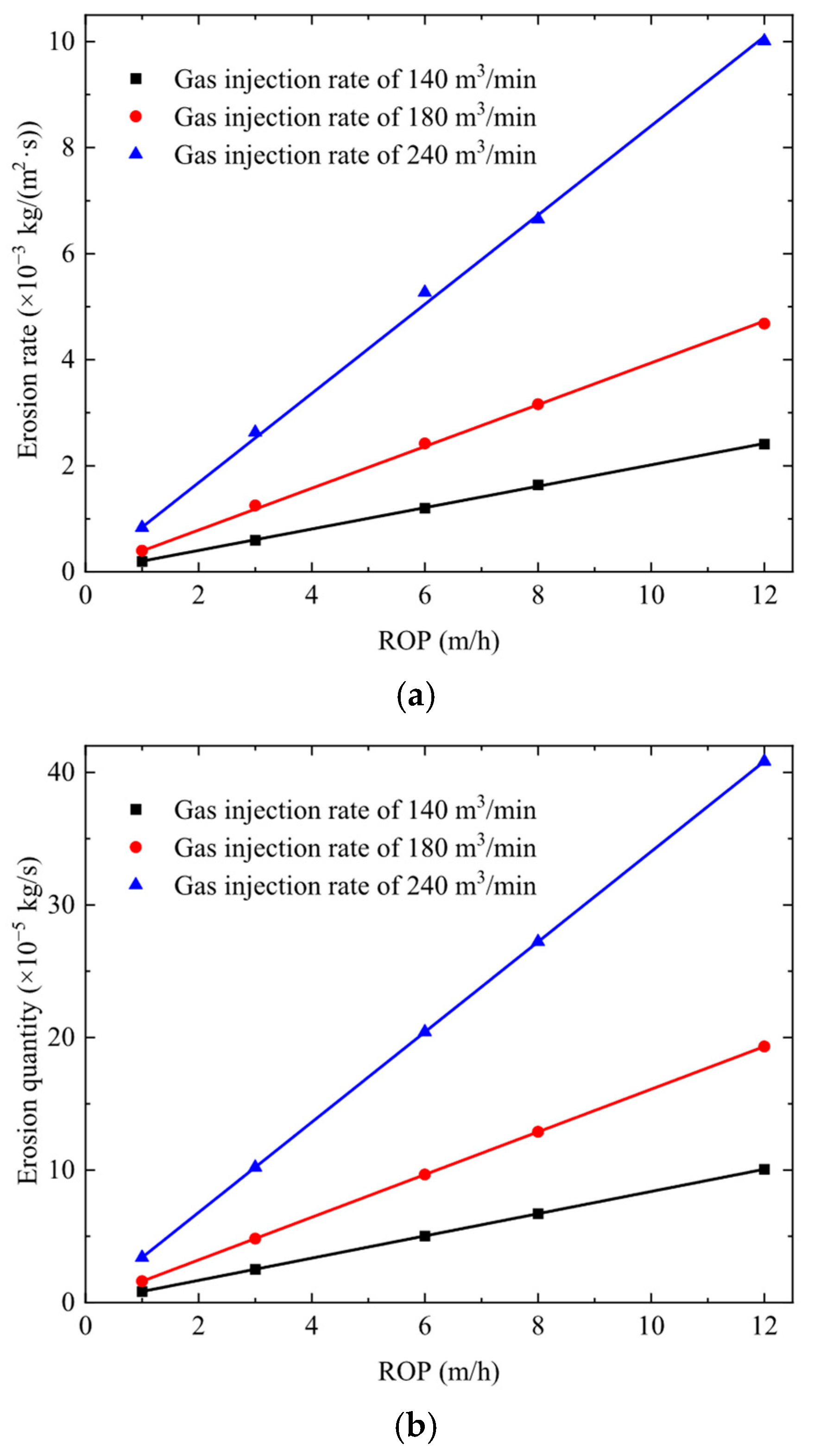

3.2.2. Influence of ROP on Erosion

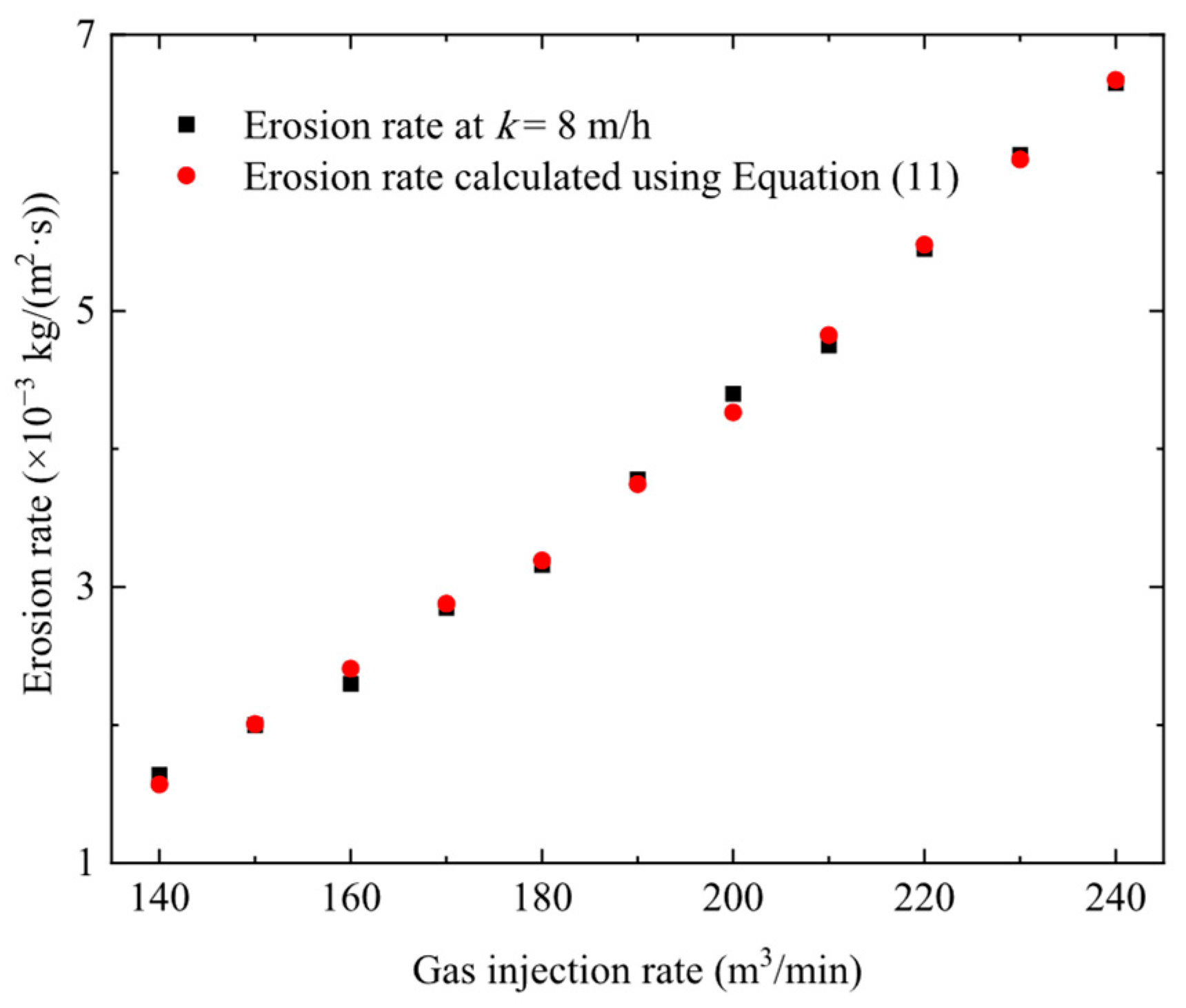

3.3. Prediction of Blooey Line Service Life

3.3.1. Calculation Method for Residual Wall Thickness

3.3.2. Calculation Method for Remaining Time to Leakage

4. Conclusions

- In the inclined V-shaped elbow of a blooey line, particles from the central region of the inlet pipe directly impact the outer wall of the outlet pipe opposite the inlet. Meanwhile, cutting particles near the pipe walls in regions further away from the inclined plane of the blooey line axis form helical flows along the outlet pipe after impacting its outer wall, resulting in the maximum erosion rate occurring at the intersection of these spiral flows. After four hours of actual drilling operation, the measured wall thickness at this location reduced to 9.92 mm, while the predicted residual thickness was 9.25 mm, showing a relative error of 6.8%.

- In gas drilling, the erosion rate and erosion quantity of the V-shaped elbow increase with the gas injection rate following a power function trend, and the rate of increase accelerates as the gas injection rate rises.

- Based on the established calculation formulas of the erosion rate and quantity under different working conditions (referencing the erosion rate at 1 m/h ROP), a computational method was developed for the real-time calculation of residual wall thickness and remaining service life in the V-shaped elbows of blooey lines. The method provides gas drilling engineers with a quick calculation formula to estimate the remaining service life and determine the proper replacement timing for these elbows.

- The methodology for calculating the residual wall thickness of a V-shaped elbow in a blooey line can be extended to other elbows and bends in blooey lines, providing a basis for their programmatic management.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Meng, Y.F.; Wu, S.J.; Chen, X.Y.; Zhang, Y.P.; Wang, Z.N.; Wang, X.H. Analysis on the nitrogen drilling accident of Well Qionglai 1 (I): Major inducement events of the accident. Nat. Gas Ind. 2016, 2, 548–564. [Google Scholar] [CrossRef][Green Version]

- Meng, Y.F.; Wu, S.J.; Chen, X.Y.; Zhang, Y.P.; Wang, Z.N.; Wang, X.H. Analysis on the nitrogen drilling accident of Well Qionglai 1 (II): Restoration of the accident process and lessons learned. Nat. Gas Ind. 2016, 2, 565–574. [Google Scholar] [CrossRef][Green Version]

- Reynolds, O. On the action of a blast of sand in cutting hard material. London Edinb. Dublin Philos. Mag. J. Sci. 1873, 46, 337–343. [Google Scholar] [CrossRef]

- Finnie, I. Erosion of surfaces by solid particles. Wear 1960, 3, 87–103. [Google Scholar] [CrossRef]

- Nesic, S.; Postlethwaite, J. Hydrodynamics of disturbed flow and erosion-corrosion. Part I: Single-phase flow study. Can. J. Chem. Eng. 1991, 69, 698–703. [Google Scholar] [CrossRef]

- Putra, I.W.E.; Chien, T.C.; Badaruddin, M.F.; Isa, M.H.; Hou, C.X.; Dongjie, L.; Sun, D. Sand erosion mitigation for offshore pipeline and riser—erosion prediction by computational fluid dynamic CFD analysis and experimental testing. In Proceedings of the Offshore Technology Conference Asia, Virtual and Kuala Lumpur, Malaysia, 22–25 March 2022. [Google Scholar]

- Alghurabi, A.; Mohyaldinn, M.; Jufar, S.; Younis, O.; Abduljabbar, A.; Azuwan, M. CFD numerical simulation of standalone sand screen erosion due to gas-sand flow. J. Nat. Gas Sci. Eng. 2021, 85, 103706. [Google Scholar] [CrossRef]

- Farokhipour, A.; Mansoori, Z.; Rasoulian, M.A.; Rasteh, A.; Saffar-Avval, M.; Ahmadi, G. Study of particle mass loading effects on sand erosion in a series of fittings. Powder Technol. 2020, 373, 118–141. [Google Scholar] [CrossRef]

- Farokhipour, A.; Mansoori, Z.; Rasteh, A.; Rasoulian, M.A.; Saffar-Avval, M.; Ahmadi, G. Study of erosion prediction of turbulent gas-solid flow in plugged tees via CFD-DEM. Powder Technol. 2019, 352, 136–150. [Google Scholar] [CrossRef]

- Khan, R.; Ya, H.H.; Pao, W.; Abd Majid, M.A.; Ahmed, T.; Ahmad, A.; Alam, M.A.; Azeem, M.; Iftikhar, H. Effect of sand fines concentration on the erosion-corrosion mechanism of carbon steel 90° elbow pipe in slug flow. Materials 2020, 13, 4601. [Google Scholar] [CrossRef] [PubMed]

- Haider, G.; Arabnejad, H.; Shirazi, S.A.; McLaury, B.S. A mechanistic model for stochastic rebound of solid particles with application to erosion predictions. Wear 2017, 376–377, 615–624. [Google Scholar] [CrossRef]

- Haider, G.; Othayq, M.; Zhang, J.; Vieira, R.E.; Shirazi, S.A. Effect of particle size on erosion measurements and predictions in annular flow for an elbow. Wear 2021, 476, 203579. [Google Scholar] [CrossRef]

- Liu, D.; Yang, P.; Deng, K.; Tian, S.; Yan, H.; Li, H. Dynamic response of aerodynamic flutter of blooie line during gas drilling in mountain areas. AIP Adv. 2025, 15, 015018. [Google Scholar] [CrossRef]

- Lian, Z.; Chen, X.; Lin, T.; Ming, X.; Zheng, J. Study on erosion mechanism of bending joint in blooey line. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2014, 36, 150–156. [Google Scholar]

- Zhang, Y.; Lian, Z.; Abdelal, G.F.; Lin, T. Numerical and experimental investigation on flow capacity and erosion wear of blooey line in gas drilling. J. Energy Resour. Technol. 2018, 140, 054501. [Google Scholar]

- Lin, Y.; Huang, G.; Deng, K.; Liu, B.; Zhang, X.; Mei, Z. Simulation Study on Gas-solid Erosion of 90° Elbow Based on Full-sized Physical Experiment. J. Saf. Environ. 2023, 23, 4325–4334. [Google Scholar]

- Liu, H.; Mou, H.; Liu, S.; Zhang, Y. Study on erosion of vulnerable section of blooey line in gas drilling. Lubr. Eng. 2019, 44, 81–88. [Google Scholar]

- Ming, X. Research and Safety Evaluation on Ultimate Discharge Capability of Blooey Line Used in High Production Gas Well. Ph.D. Thesis, Southwest Petroleum University, Chengdu, China, 2014. [Google Scholar]

- Feng, G. Analysis of Erosion Failure and Deformation of Blooey Line in Gas Drilling. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2014. [Google Scholar]

- Wen, S. Study on Erosion Mechanism of Wellhead Equipment in Gas Drilling. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2015. [Google Scholar]

- Chen, W. Study on Erosion and Vibration Characteristics of Sand Discharge Manifold of Gas Drilling Under Extreme Working Conditions in Mountainous Environment. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2023. [Google Scholar]

- Sun, L. ANSYS Fluent 2020 Engineering Case Studies; Peking University Press: Beijing, China, 2021; pp. 146–169. [Google Scholar]

- Bourgoyne, A.T. Experimental study of erosion in diverter systems due to sand production. In Proceedings of the SPE/IADC Drilling Conference, New Orleans, LA, USA, 6–9 March 1989. [Google Scholar]

- Chen, X.; McLaury, B.S.; Shirazi, S.A. Application and experimental validation of a computational fluid dynamics (CFD)-based erosion prediction model in elbows and plugged tees. Comput. Fluids 2004, 33, 1251–1272. [Google Scholar] [CrossRef]

- Lin, J.; Shen, T. Discussion on relation between boundary layer and erosion by striking of particles. J. Hydrodyn. 1991, 1, 72–76. [Google Scholar]

- Zhao, X.; Cao, X.; Xie, Z.; Cao, H.; Wu, C. Numerical study on the particle erosion of elbows mounted in series in the gas-solid flow. J. Nat. Gas Sci. Eng. 2022, 104, 104423. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Pipe diameter | 235 mm |

| Curvature radius | 352.5 mm |

| Wall thickness | 9.525 mm |

| Gas velocity | 185 m/s |

| Elbow pressure | 483 kPa |

| Sand flow rate | 0.001 m3/s |

| Sand density | 2650 kg/m3 |

| Steel density | 7850 kg/m3 |

| Particle counts | 50,000; 60,000 |

| Particle size (mm) | 0.0424 | 0.1270 | 0.2434 | 0.3704 | 0.4939 | 0.7056 | 0.9525 | 1.2347 |

| Mass fraction (%) | 19.44 | 13.62 | 6.98 | 2.17 | 4.65 | 3.37 | 3.65 | 7.26 |

| k (m/h) | 1 | 3 | 6 | 12 |

| β | 1.00 | 3.04 | 6.00 | 11.91 |

| Gas Injection Rate (m3/min) | 140 | 150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 | 230 | 240 |

| Numerical Calculation (×10−4 kg/(m2·s)) | 1.64 | 2.00 | 2.30 | 2.85 | 3.16 | 3.78 | 4.40 | 4.75 | 5.45 | 6.13 | 6.65 |

| Equation (11) (×10−4 kg/(m2·s)) | 1.57 | 2.01 | 2.41 | 2.88 | 3.19 | 3.74 | 4.26 | 4.82 | 5.48 | 6.10 | 6.67 |

| Error (%) | 4.3 | 0.5 | 4.8 | 1.1 | 0.9 | 1.1 | 3.2 | 1.5 | 0.6 | 0.5 | 0.3 |

| Gas Injection Rate (m3/min) | 140 | 150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 | 230 | 240 |

| Remaining Time t1 (h) | 122.9 | 96 | 80.1 | 66.9 | 60.4 | 51.5 | 45.2 | 40 | 35.2 | 31.6 | 28.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Chen, X.; Wang, Q.; Lin, T.; Sun, W.; Wei, C. Erosion Wear Characteristics of V-Shaped Elbow in Blooey Line. Processes 2025, 13, 2694. https://doi.org/10.3390/pr13092694

Guo Y, Chen X, Wang Q, Lin T, Sun W, Wei C. Erosion Wear Characteristics of V-Shaped Elbow in Blooey Line. Processes. 2025; 13(9):2694. https://doi.org/10.3390/pr13092694

Chicago/Turabian StyleGuo, Yanru, Xiaokun Chen, Qiuhong Wang, Tiejun Lin, Wantong Sun, and Chenxing Wei. 2025. "Erosion Wear Characteristics of V-Shaped Elbow in Blooey Line" Processes 13, no. 9: 2694. https://doi.org/10.3390/pr13092694

APA StyleGuo, Y., Chen, X., Wang, Q., Lin, T., Sun, W., & Wei, C. (2025). Erosion Wear Characteristics of V-Shaped Elbow in Blooey Line. Processes, 13(9), 2694. https://doi.org/10.3390/pr13092694