Abstract

This study presents a comprehensive study integrating machine learning, life cycle assessment (LCA) and heuristic optimization to achieve a low-carbon medical waste (MW)-to fuel process. A detailed process simulation coupled with cradle to gate LCA is employed to generate a dataset covering diverse process operation conditions, embodied carbon of supplying H2 and the associated carbon emission factor of MW treatment (CEF). Four machine learning techniques, including support vector machine, artificial neural network, Gaussian process regression, and XGBoost, are trained, each achieving test R2 close to 0.90 and RMSE of ~0.26. These models are integrated with heuristic algorithms to optimize operating parameters under various green hydrogen mixes (20–80%). Our results show that machine learning models outperform the detailed process model (DPM), achieving a minimum CEF of ~1.3 to ~1.1 kg CO2-eq/kg MW with higher computational stabilities. Importantly, the optimization times dropped from hours (DPM) to seconds (machine learning models) and the combination of Gaussian process regression and particle swarm optimization is highlighted, with an optimization time under one second. The optimized process holds promise in carbon reduction compared to traditional MW disposal methods. These findings show machine learning can achieve high predictive accuracy while dramatically enhancing optimization speed and stability, providing a scalable framework for extensive scenario analysis during waste-to-energy process design and further real-time optimization application.

1. Introduction

Medical waste (MW) refers to waste materials generated during the diagnosis, treatment, or immunization of humans and animals [1]. Due to pandemics, the annual global production of related MW has climbed sharply, arriving at more than 2.9 million tonnes in 2022 alone [2]. Different from typical waste types, approximately 15% of MW is categorized by high toxicity, corrosivity, or pathogenicity [3]. Therefore, a rapid increase in MW presents both societal and environmental challenges, necessitating more urgent handling and disposal.

To date, most MW streams are first collected and sterilized, then either landfilled or incinerated [4,5]. Landfilling, while widely practiced, occupies extensive land, generates methane, and produces leachate that can contaminate soil and groundwater [6,7]. Incineration can effectively reduce waste volume and harnesses energy from thermal oxidation, but it also leads to significant emission of greenhouse gases (GHGs) and hazardous by-products (e.g., dioxins, furans) [8]. To mitigate the impact from MW treatment, policymakers and engineers worldwide are exploring more sustainable strategies. For example, the European Union is progressively reducing landfilling and incineration reliance by promoting adoption of green technologies and improving waste management regulations [9]. Likewise, Hong Kong’s Climate Action Plan 2050 prioritizes waste reduction and the expansion of waste-to-energy infrastructure [10]. Waste-to-energy conversion not only helps recover the energy content contained in waste but also offers economic benefits and opportunities for GHG mitigation.

Quite a few thermochemical methods have been investigated to recover energy from MW (mainly including incineration, pyrolysis, and gasification) since high energy output could be achieved compared to biochemical-based methods [11]. For instance, Chaiyat [12] developed a system integrating infectious medical waste incinerator with an organic Rankine cycle for power generation, reporting an energy efficiency of 0.91% and an exergy efficiency of 0.89%. It was also shown that waste-incineration-based fly ash can be used for preparing filling material [13]. In another study, Zhao et al. designed a pyrolysis-based process for disposable respirator treatment, achieving an internal rate of return of 21.5% and a seven-year payback [14]. To curb pollutant emissions inherent in incineration and pyrolysis, gasification has garnered attention as an attractive alternative [15]. Under oxygen-limited gasifying conditions, organic matters are converted into syngas mainly containing CO and H2, which can be tailored for diverse downstream products. In this way, subsequent purification like pressure swing adsorption (PSA) can be used for high-purity H2 production. And it was shown that H2 production through waste mask gasification held levelized emissions as low as 1.27 kg CO2-eq per kg treated waste [16]. Alternatively, the raw syngas can be catalytically upgraded into fuels and chemicals such as methanol [17] and dimethyl ether [18], contributing to flexible uses and economic value. An additional and practical source of uncertainty for MW-to-fuel systems is the carbon intensity and availability of hydrogen used for downstream upgrading or CO2 utilization, which should be explicitly considered when designing low-carbon waste-to-energy pathways.

Although process simulations based on thermodynamics and kinetics have been widely used in waste-to-energy design and assessment [19,20], these models are usually complex and coupled with numerous nonlinear algebraic and differential equations, thus posing computational challenges in further process understanding and optimization [18]. This has motivated the exploration of data-driven surrogate models, which can approximate the behavior of these complex systems with far lower computational cost.

In recent years, machine learning approaches have revolutionized the modeling of waste-to-energy systems. Table 1 outlines recent studies on process modeling and optimization. Various machine learning techniques have been used. For example, Zhu et al. [21] applied random forest to predict the yield and carbon contents of biochar derived from biomass pyrolysis, with an R2 of nearly 0.85. Furthermore, Tang et al. [22] explored feature reduction in a support vector machine (SVM) and random forest, and the results showed that six features covering pyrolysis conditions and biomass properties were sufficient to accurately predict the pyrolytic gas yield with an RMSE of less than 5.7%. In another study, both gradient-boosted regression trees and artificial neural network (ANN) were trained to forecast syngas composition from waste gasification, reporting excellent predictive performance, and then the prediction models were integrated in process assessment with Aspen Plus [23]. Similarly, various machine learning models including random forest, SVM, MLP and gradient boosting have been used in wet organic waste gasification, with an R2 of >0.9 for each prediction achieved [24]. Although these proposed machine learning models have shown high accuracy in modeling waste-to-energy process, detailed and comprehensive study on revealing various machine learning’s performance across both surrogate-modeling accuracy and optimization efficiency, especially in MW-to-fuel applications, is still lacking, as presented in Table 1. Typically, real-time process optimization demands models that can be evaluated and optimized rapidly. Prior work in chemical process control has underscored the need for both precise prediction and efficient optimization [25,26]. In addition, early-stage process design accounts for numerous external uncertainties, often necessitating thousands of simulations for evaluation and comparison. Thus, efficient process optimization is important to enable thorough uncertainty analysis within practical time frames. Zhou et al. [16] have shown Gaussian process regression (GPR) is excellent in surrogating detailed gasification process models, markedly accelerating operation optimization to roughly four seconds per run. Despite these individual advances, systematic studies that benchmark diverse ML techniques are still underexplored. In particular, comprehensive head-to-head comparisons of how different algorithms perform when embedded within optimization are notably absent, yet critical for guiding future choices of machine learning in sustainable MW-to-energy process design.

Table 1.

Evaluation results of different models.

To address the above-mentioned limitations of existing machine-learning-based work on MW-to-energy systems, this study first establishes a conceptual process for converting MW into Fischer–Tropsch (FT) liquid fuels and evaluates its carbon footprint given the recent high concerns on carbon emission [27]. Then, a dataset of life-cycle emissions under varied operating and environmental conditions through high-fidelity simulation is generated. Four widely recognized machine learning techniques, including SVM, ANN, GPR, and extreme gradient boosting (XGBoost), are trained to construct computationally concise surrogate models. Finally, each surrogate is embedded within an optimization framework to rapidly identify optimal operating conditions, demonstrating how different ML approaches influence both the speed and the quality of process design. The main contributions of this study are as follows:

- (1)

- Developing and comparing four distinct machine learning models to predict environmental performance of a promising MW-to-FT process, providing clear guidance on their relative accuracy and generalizability.

- (2)

- Coupling each surrogate with different optimization algorithms to reveal model performance in the efficiency and robustness of process optimization, highlighting the importance of effective optimization in unlocking waste-to-energy process’s potential.

Overall, our systematic evaluation of machine-learning-driven modeling and optimization strategies offers a practical roadmap for selecting and deploying these AI tools in the design of next-generation waste-to-energy systems.

2. Methodology

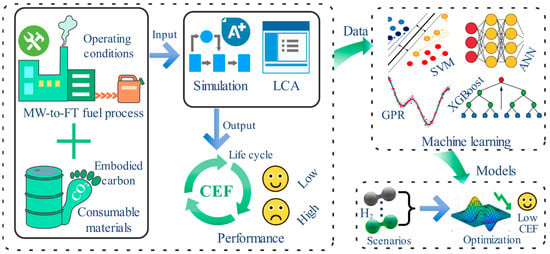

This study develops and compares machine learning models to predict and optimize the life cycle environmental performance of a MW-to-FT fuel process, as outlined in Figure 1. First, a detailed process model is developed by using the Aspen Plus simulation platform and its environmental impact is quantified via life cycle assessment (LCA), yielding a carbon emission factor of MW treatment (CEF) for each set of operating conditions and embodied carbon emissions of consumable materials. Second, a dataset is generated by systematically varying key operating parameters (e.g., reactor temperatures, embodied carbon of input materials), with each case providing simulation outputs and corresponding LCA results. Next, four distinct surrogate models (SVM, ANN, GPR and XGBoost) are trained to surrogate the high-fidelity simulation with low computational expense. Finally, each surrogate is integrated with heuristic optimization algorithms to identify operating conditions that minimize the CEF under multiple hydrogen-supply scenarios. All simulations and ML workflows are executed on a Windows 10 PC equipped with an AMD Ryzen 7 5800H (6 cores, 3.2 GHz) and 16 GB RAM.

Figure 1.

Workflow of this study.

2.1. Process Development

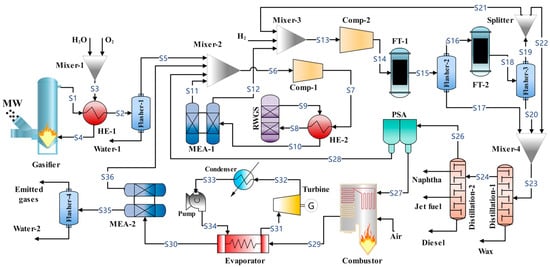

A comprehensive process incorporating plasma gasification, carbon capture, FT synthesis and combined heat and power generation is designed to convert MW into FT fuel, as shown in Figure 2. Plasma gasification is widely regarded as one of the most effective technologies for treating hazardous medical waste [28]. The extremely high operating temperatures (often reaching several thousand °C) achieved in plasma gasifiers are sufficient to completely destroy pathogens and organic contaminants, thereby eliminating the need for additional disinfection pretreatment [29]. In this study, a typical waste surgical mask was used as the feedstock for analysis and the proximate and ultimate analysis results of this MW sample is listed in Table A1, reflecting the sample’s chemical composition.

Figure 2.

Flowsheet of MW-to-FT fuel system.

The detailed process model (DPM) was then developed in a well-established process simulation platform, Aspen Plus, which has been widely used in waste-to-energy process design and assessment previously [19,20], demonstrating high feasibility to inform decision-making. For non-conventional components like MW, the HCOALGEN and DCOALIGT models were used to estimate the enthalpy and density [30]. For the conventional components, the Peng–Robinson/Boston–Mathias (PR-BM) equation of state was employed to estimate their thermodynamic parameters [31].

The gasification process comprises three zones, drying, pyrolysis and gasification, which are simulated by the “RStoic” model, the “RStoic” model and the “RGibbs” model, respectively [18]. As the primary unit within the process, the used gasification model has been validated in previous studies by using experimental data [32]. Here, pure oxygen and water are used as gasifying agents, following previous studies [16]. The inert and dense residue is removed from the bottom of gasifier, while the derived syngas is cooled and sent to a reactor for reverse water gas shift (RWGS) reaction () at 600 and 24.5 bar [33]. With supplemental H2 makeup, the upgraded syngas enters a two-stage FT synthesis unit (modeled by the “RStoic” model) to produce FT fuel, including naphtha, jet fuel, diesel and wax. The configuration of FT reactors can be found in our previous studies in detail [32]. The product distribution of FT synthesis is based on the widely accepted Anderson–Schulz–Flory distribution [34]. After separating the produced fuels (fractioned by carbon chain length [35]) via distillation, the remaining gases containing unreacted syngas and light hydrocarbon (C1–C4) are split: a portion is recycled back to the FT reactors, while the balance is directed to a PSA unit for H2 recovery. The captured H2 is returned to the RWGS step, and the PSA off-gas is used to drive a combined heat and power generation unit including fuel gas combustion and a steam cycle for power generation. To mitigate carbon emissions, both pre-combustion and post-combustion carbon capture are incorporated into the process through an monoethanolamine (MEA) scrubber (widely-used capture efficiency of 85% [36] and energy duty of 4 MJ per kg captured CO2 [37]), with the recovered CO2 looped back to the RWGS reactor. Waste heat from exothermic units is recovered for steam generation to enhance overall efficiency [16]. The key operating parameters involved in the process are outlined in Table A2 and the simulation results of a representative base case (where decision variables are fixed at the midpoint of their studied ranges) are presented in Table A3. The main assumptions in modeling include steady-state operation, no losses in piping, and complete tar conversion in the gasifier [16,38].

2.2. Life Cycle Assessment

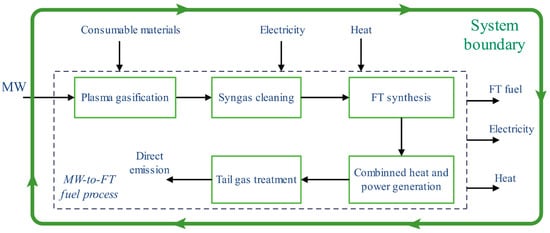

To evaluate the carbon footprint of the proposed MW-to-FT fuel system, a cradle-to-gate LCA is employed to calculate the CEF, reflecting the equivalent CO2 emission level per unit medical waste processed. The LCA boundary (see Figure 3) covers five core process stages: plasma gasification, syngas purification, FT synthesis, combined heat and power generation, and flue gas treatment. Emissions are classified into three categories: (1) on-site direct emission during process operation; (2) indirect emission associated with upstream production of consumable materials (e.g., catalysts, sorbents, process water); and (3) indirect emission from the generation of utilities (e.g., steam, cooling water, and electricity). Notably, following previous similar studies [14], the sorting and collection of waste are excluded from the system boundary in this study. Life cycle inventory data is sourced from the Ecoinvent database [39], and all GHG impacts are characterized using the IPCC 2013 climate change methodology [40]. To account for credit-worthy energy outputs including FT fuels, turbine electricity, and recovered heat, the avoided emissions are subtracted from the total. Thus, the overall CEF is calculated as in Equation (1).

where is the mass flowrate of processing and is the net carbon emission, including the direct emission (), indirect emission due to raw material acquisition () and utility generation (), as well as the avoided emission () from products, as calculated by Equation (2).

Figure 3.

System boundary of life cycle assessment.

2.3. Data Collection

Data is collected by performing detailed process simulation and LCA calculation. Through system analysis, five input features that most strongly influence the cradle-to-gate CEF are determined: gasifier temperature (GT), equivalence ratio (ER), steam-to-waste ratio (SWR), splitting ratio of light gases to the PSA unit (SRLG), and the levelized carbon emission of makeup H2 (LCEH). LCEH reflects market-driven variations in H2 sourcing (e.g., green, blue, or grey H2) and directly affects the overall emissions of the designed process, making it a critical factor. The ranges of these variables are summarized in Table A2, with GT, ER, SWR selected based on prior literature, SRLG determined from 0 to 1, and LCEH bounded by the emissions associated with photovoltaic (PV) electrolysis and steam methane reforming (SMR) [16]. Within these bounds, random sampling is employed to generate diverse scenarios, and each sampled point is evaluated through process simulation and LCA to produce a corresponding CEF. To approximate the real-world measurement and modeling uncertainty, Gaussian noise (5% standard deviation) is introduced on the collected data to test the performances of various machine learning algorithms under realistic data variability [41].

2.4. Machine Learning Techniques

Four representative supervised learning techniques were selected for surrogate model development, including SVM, ANN, GPR and XGBoost, covering connectionist, kernel-based, probabilistic, and ensemble learning paradigms, respectively. SVMs leverage the kernel trick to learn nonlinear decision functions from relatively small datasets [42] while providing strong regularization against overfitting. ANNs are highly flexible function approximators that capture complex, high-dimensional nonlinear mappings and interactions. GPR offers a probabilistic surrogate that provides principled predictive uncertainty (predictive mean and variance), which is useful for uncertainty-aware optimization and for guiding further sampling. XGBoost is a tree-based ensemble that excels on tabular data, often achieving strong predictive performance with fast training, built-in regularization, and interpretable feature-importance measures. By using these models, the strengths and trade-offs across approaches commonly used for complex process systems can be evaluated. All models are developed in the MATLAB 2021a platform. Below, the mathematics of these machine learning methods and the used evaluation metrics are briefly summarized.

2.4.1. Support Vector Machine (SVM)

SVM is a machine learning technique that is particularly well suited for tasks with limited training data [42] and has been successfully used in solving regression problems such as yield forecasting [43] and material property estimation [44]. The goal of SVM regression is to determine a function that maps input vectors to the targeted output by fitting a hyperplane in feature space. This hyperplane is determined by minimizing prediction error while maximizing the margin, i.e., the distance between the plane and the closest data points [45].

In linear SVM regression, is formulated as Equation (3), determined by solving an optimization problem that balances margin width against regression loss [46].

where , (the introduced nonnegative multipliers) and are the parameters to determine the optimal hyperplane, which can be obtained by training. denotes the dot product of the input vectors and . Here, the support vectors are those training samples corresponding to nonzero coefficients or . Thus, the prediction is completely determined by the support vectors.

In nonlinear SVM regression, the input vectors are projected into a high-dimensional space via a kernel function , which can effectively separate the data points and capture complex relationships. The resulting regression function is then expressed in terms of support vectors and the chosen kernel, as given in Equation (4) [42].

Typical nonlinear kernel function includes polynomial and Gaussian kernels as calculated by Equations (5) and (6) [42,47].

where d is the degree of polynomial expression; second degree (polynomial2) or third degree (polynomial3) are usually selected.

2.4.2. Artificial Neural Network (ANN)

An ANN typically consists of an ordered sequence of layers, an input layer, one or more hidden layers, and an output layer, where each layer k contains a set of neurons whose outputs depend on the previous layer’s activations. Between layer k − 1 and k, each neuron j computes a weighted sum of its inputs plus a bias and is then activated by a nonlinear function. Formally, the value of neuron j in layer k () is calculated by Equation (7) [48].

where is the weight connecting i-th neuron in k − 1-th layer and j-th node in k-th layer, is the bias term for j-th neuron in k-th layer, and n is the number of neurons in k − 1 layer. f is the activation function that introduces nonlinearity. In this work, a Rectified Linear Unit (ReLU), as shown in Equation (8), is employed due to its ability in modeling chemical systems [49].

2.4.3. Gaussian Process Regression (GPR)

A Gaussian process defines a distribution over functions such that any finite collection of function values has a joint Gaussian distribution. In regression settings, one places a Gaussian process prior on the unknown function, as expressed by Equation (9) [50].

where the mean function represents the expected output at a given input (Equation (10)) and is a co-variance function, reflecting how the dependence between the function values at different inputs and co-varies (Equation (11)) [50].

where is commonly called the kernel function of Gaussian process. To achieve various fitting tasks, different kernel functions have been proposed and developed, mainly including radial basic function (RBF) kernel, Matern 3/2 kernel, rational quadratic (RQ) kernel and automatic relevance determination squared exponential (ARDSE) kernel, as calculated by Equations (12)–(15) [51,52,53], respectively.

where is the signal standard deviation, and is the characteristic length scale. r is the Euclidean distance between and , as calculated by Equation (16). is a positive-valued scale-mixture parameter and is a parameterization vector. is a separate length scale for each predictor ().

In regression, the prior distribution of outputs (y) can be expressed by Equation (17) [16].

where denotes the multivariate normal distribution. is the variance in the observation noise. is an identity matrix. Assuming the joint distribution over the testing set and training set , the combined vector of observed outputs and predicted outputs follows [54]:

2.4.4. Extreme Gradient Boosting (XGBoost)

XGBoost is an emerging machine learning algorithm proposed in 2016 [55]. Based on a gradient boosting framework, the model’s prediction for sample i is the sum of the outputs from K individual weak learners (decision trees), as shown in Equation (19) [56].

where represents the prediction of learner k for sample i. The performance is influenced by the tree’s structure, like the maximum depth of tree [57]. During training, XGBoost sequentially adds new trees to correct the errors of the existing ensemble, optimizing an objective that combines a differentiable loss function , as shown in Equation (20) [58].

where is the loss function, which is determined by the actual value and predicted value and mean squared error is one of the most frequently used regression loss function [56]. represents the complexity of k-th tree, which is a penalty function used to prevent overfitting. At iteration t, the prediction is updated as Equation (21) [59].

where is the prediction of the t-th iteration and thus the loss function in t-th iteration is expressed as in Equation (22) [58].

The corresponding objective is approximated using a second-order Taylor expansion for efficient computation [58]. Key strengths of XGBoost include built-in regularization to reduce overfitting, robust handling of missing values, and parallelized tree construction, making it both accurate and scalable in different tasks [60].

2.4.5. Evaluation Metrics

To comprehensively evaluate the developed machine learning models, several metrics, including the coefficient of determination (R2), the root mean square error (RMSE), mean absolute error (MAE) and mean relative error (MRE), are used in this work, as calculated by Equations (23)–(26) [49,61], respectively.

2.5. Process Optimization

This study aims to determine the best operating parameters for the minimum CEF of the developed process with the constraint of market LECH. The optimization problem can be formulated as in Equation (27).

where is the i-th operating condition, is the mapping function, represents the LECH under j-th scenario, and and are the lower and upper bounds of , respectively.

To compare surrogate-based optimization with the high-fidelity process model, this study defines four hydrogen-supply scenarios by blending green H2 (with LECH of 0.37 kg CO2-eq/kg H2 [62], from PV-driven water electrolysis) with SMR-derived H2 (8.43 kg CO2-eq/kg H2 [16]), at green H2 fractions of 20% (S-0.2), 40% (S-0.4), 60% (S-0.6), and 80% (S-0.8). These mixes reflect evolving low-carbon hydrogen pathways and market share.

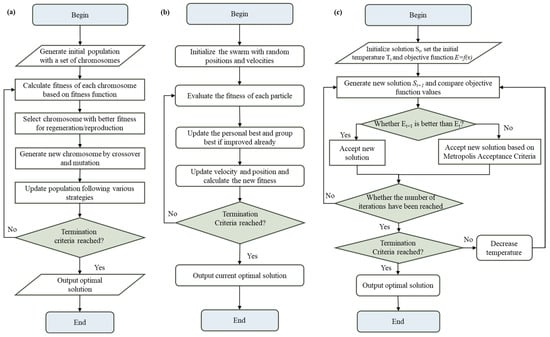

Because different mathematical expressions are involved in the mapping function (machine learning models and DPM), heuristic optimizers excel at exploring complex search spaces without requiring gradient information [63]. Specifically, well-established genetic algorithms (GA), particle swarm optimization (PSO), and simulated annealing algorithm (SA) are used to solve the optimization problems of complex waste-to-energy processes. The brief introduction of these algorithms is shown below, and Figure 4 demonstrates the core procedures.

Figure 4.

The general operation procedures of (a) GA; (b) PSO; and (c) SA.

2.5.1. Genetic Algorithms (GAs)

GAs are a series of optimization algorithms inspired by the evolution process. The behaviors of a chromosome during its generation process, such as selection, crossover, and mutation, are simulated to obtain the optimal solution with best fitness. The general operation procedures are shown in Figure 4a [64]. The population is initialized at the beginning to obtain a series of random solutions. Then, after evaluation based on fitness function, the individuals with superior fitness will be selected to generate a new population after crossover and mutation. Roulette wheel selection is a commonly used selection method, which is conducted based on the fitness value of each individual. The selection probability of individual can be calculated using Equation (28) [65]. If the termination conditions have been satisfied, the process will end. If not, the process will go back to evaluation step and repeat the former steps.

where the is the selection probability, is the fitness value of individual , and is the population number.

2.5.2. Particle Swarm Optimization (PSO)

PSO is inspired by the teaming behaviors in nature, such as bird flocks or fish schools, modeling the process of searching for optimal solution or near-optimal regions by sharing group information among individuals, which will allow the swarm to converge toward optimal solutions or near-optimal solutions. At the beginning of a general PSO process, the population with N particles is initialized, and each particle i has its own position (x) and velocity vector (v); then, fitness is evaluated based on the fitness function (objective function) and the current position will be updated based on the inertia, as well as the individual optimal value () and global optimal value (), as shown in Equations (29) and (30) [66]. After updating individual and global optimal values, the stopping condition will be checked. If it is satisfied, the final optimal solution can be obtained, which is also the global best position.

where and denote the position and the instantaneous velocity of the particle i in iteration k. is the inertia weight, c1 and c2 are the acceleration coefficient, and are random scalars that introduce stochasticity.

2.5.3. Simulated Annealing Algorithm (SA)

An SA is a probabilistic global optimization algorithm inspired by the solid annealing process, which has a better performance in avoiding local optima since worse solutions can be accepted with certain probability. Based on the Metropolis acceptance criterion [67], the probability of acceptance will be higher when the temperature (T) is higher at the initial stage. As time passes, the temperature will decrease; so, the probability of acceptance for the poor solution will also decrease [68]. Equation (2), representing the time for probability of acceptance, is shown below:

where the is the probability of acceptance, t is the current temperature, and the E is the fitness value at corresponding temperature.

To balance solution quality with computational cost, the maximum stable evolution step is used as the stopping criteria [49], or when the elapsed runtime reaches one hour, whichever comes first. The other parameters involved in these algorithms follow default settings recommended by MATLAB.

3. Results and Discussion

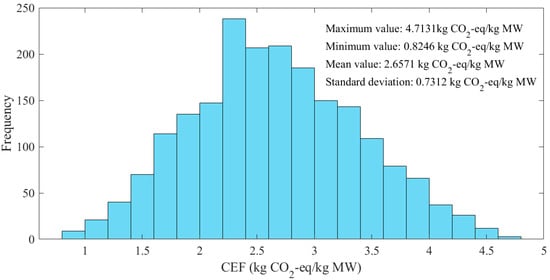

Within the design space, the five input variables were sampled randomly and each sample was evaluated via the detailed process simulation and LCA calculation to yield the corresponding CEF. In total, 2000 data points were generated. As depicted in Figure 5, the CEF values ranged from 0.8246 to 4.7131 kg CO2-eq per kg MW, with a mean value of 2.6571 kg CO2-eq/kg MW and a standard deviation of 0.7312 kg CO2-eq/kg MW. This wide dispersion shows the strong sensitivity of process emissions to operating conditions and LCEH. Given that the average CEF remains relatively high, optimization is essential to identify operating conditions that substantially lower lifecycle emissions and improve the environmental performance of the WM-to-FT fuel process.

Figure 5.

CEF distribution of the collected data.

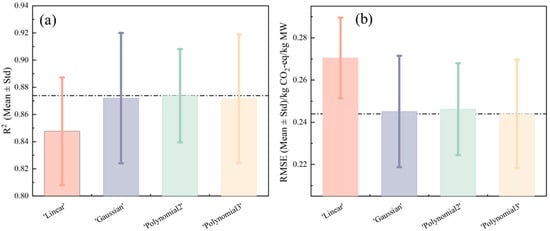

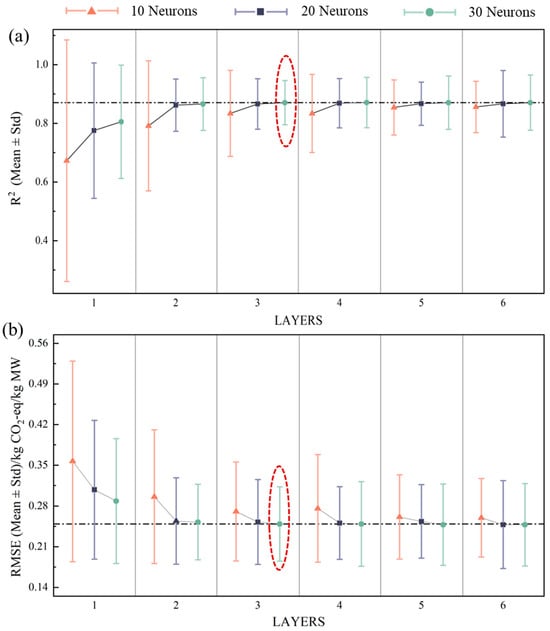

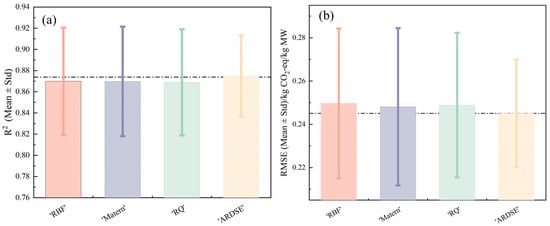

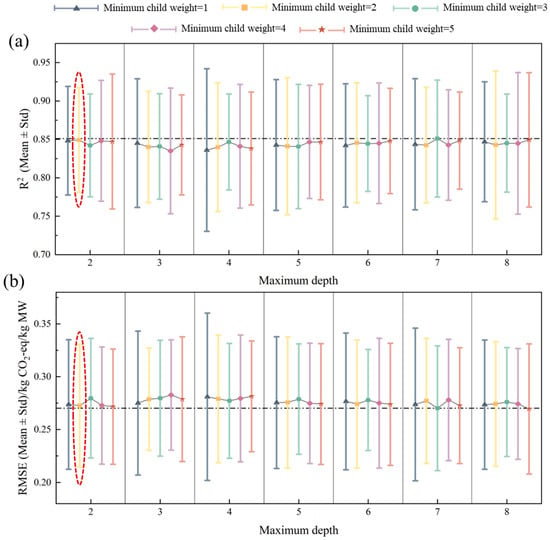

Since the machine learning techniques used involve quite a few hyperparameters which make a difference in model performance, the main parameters were tuned using five-fold cross-validation during model development for improving model’s robustness. At the same time, in order to more comprehensively test the effects of machine learning, each algorithm’s sensitivity was further assessed according to the size of the training dataset by varying the number of samples from 200 to 2000 (in increments of 300). This range was selected to balance both data-scarce (200 samples) and well-sampled (2000 samples) regimes while maintaining computational feasibility across the studied model complexities. A step size of 300 is sufficient to reveal the impact of dataset size, and the cross-validation standard deviation (Std) is plotted as error bars. With similar accuracies, the model with a compact structure would be determined in parameter selection for reducing the computational effort. In SVM, the performances of several common kernel functions, as introduced in Section 2, were compared. The results are shown in Figure 6. It can be clearly seen that nonlinear kernels consistently outperform the linear kernel (with an R2 over 0.87 and an RMSE below 0.25 kg CO2-eq/kg MW). This reflects the nonlinear characteristics underlying the dataset. Considering both predictive accuracy and stability across sample sizes, a polynomial kernel of degree 2 (polynomial2) was selected for subsequent optimization. In ANN, neural networks with identical widths per hidden layer but varying depths (1–6 layers) and widths (10–30 neurons) were evaluated, as shown in Figure A1. Essentially, deeper architectures improve performance stability across datasets, while wider layers (more neurons within a layer) are beneficial for average accuracy. However, marginal gains diminished beyond increasing layers or increasing neurons per layer, with an R2 approaching 0.9 and an RMSE approaching 0.245 kg CO2-eq/kg MW. Consequently, a 3-layer network with 30 neurons each (circled in red shown in Figure A1) was adopted due to its satisfactory performance in both accuracy and stability. In GPR, the performances of RBF, Matern 3/2, rational quadratic (RQ), and automatic relevance determination squared-exponential (ARDSE) kernels were compared. The ARDSE kernel yields the highest R2 (>0.87) and lowest RMSE (<0.245 kg CO2-eq/kg MW), as demonstrated in Figure A2, likely because its individual length scales adaptively weight each input dimension [52,69]; so, it was selected for GPR in further analysis. Using similar hyperparameter selection criteria, the tree’s maximum depth (2–8) and minimum child weight (1–5) were tuned for XGBoost [70]. The results are shown in Figure A3. A maximum depth of 2 and a minimum child weight of 2 struck the best balance between bias and stability (circled in red), as indicated by cross-validated metrics (with an R2 of ~0.85 and an RMSE of ~0.26 kg CO2-eq/kg MW).

Figure 6.

Cross-validation performance (R2 and RMSE) of SVM surrogates across varying training-set sizes: (a) R2, (b) RMSE (the colored bars and error bars represent mean values and the standard deviations as the number of training samples varies. The dotted lines in (a,b) highlight the highest R2 and the lowest RMSE, respectively).

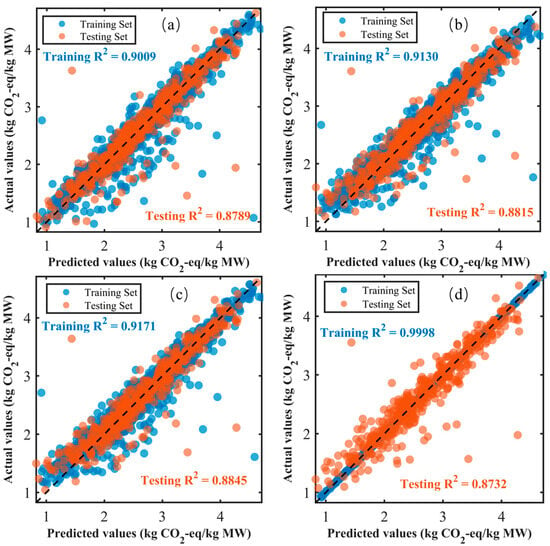

Based on the determined hyperparameters for each machine learning technique, each model’s accuracy on both the training and test sets was evaluated (see Figure 7). All four machine learning techniques achieved high training fidelity, with an R2 exceeding 0.9 and satisfactory generalization within the test set (with R2 close to 0.88). XGBoost, in particular, obtained an almost perfect training performance (R2 ≈ 1), highlighting its ability to capture complex feature interactions. Although its test R2 is obviously lower than that in the training set, showing evidence of modest overfitting, it remains comparable to other models’, with a test R2 of ~0.88. In comparison, SVM shows relatively lower training accuracy, reflecting limited ability to capture highly complex interactions, but benefited from strong regularization, which reduced variance. GPR stands out by combining competitive accuracy with principled predictive variance, which reduces risky extrapolation (relatively high test R2). To contextualize these results, each surrogate model was compared against a simple linear regression baseline using RMSE, MAE, and MRE as metrics. Table 1 presents the results. Machine learning models demonstrate a certain degree of improvement over the linear fit (with an RMSE < 0.27, MAE < 0.17 and MRE < 0.0711), confirming that nonlinear, data-driven approaches better capture the complex relationships between operating conditions and the resulting carbon emission within an MW-to-FT fuel process. It is worth noting that as this is a newly designed process, there is currently no actual data on the complete process available. Therefore, this paper introduces Gaussian errors into the simulation dataset to reflect the fluctuations in actual scenarios, which may introduce bias compared to actual operating conditions.

Figure 7.

Performances of different machine learning models: (a) SVM, (b) ANN, (c) GPR, (d) XGBoost.

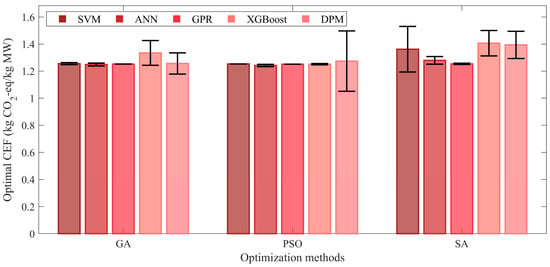

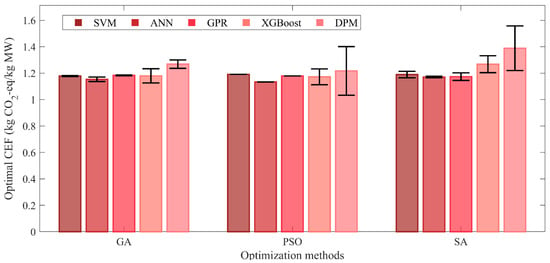

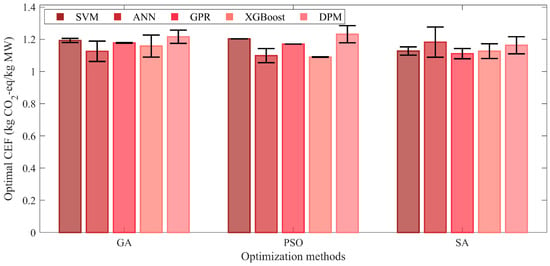

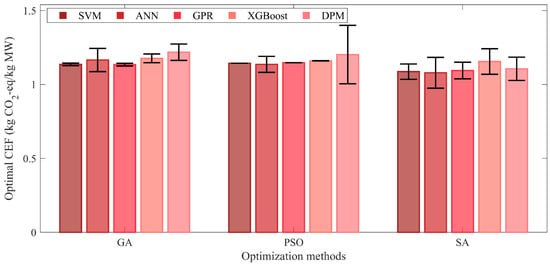

Using the obtained machine-learning-based surrogate models, operating parameters’ optimization was conducted under the four hydrogen-mix scenarios considered; then, the surrogate-derived optima were validated by inputting them into the high-fidelity DPM and performing the LCA calculation to determine the final CEF. To account for the stochastic nature of heuristic optimization (GA, PSO, SA), each algorithm was run three times per model. As shown in Figure 8, the bars indicate the optimal CEF’s mean of repeated optimization, while the error bars denote the standard deviation of repeated optimization. Regarding S-0.2, all methods, including machine-learning-based and DPM-based optimization, converge to a similar minimum CEF of ~1.3 kg CO2-eq/kg MW. Under a scenario of high LCEH, this underscores the improvement in CEF after optimization. The results of S-0.4, S-0.6 and S-0.8 are presented in Figure A4, Figure A5 and Figure A6. Similar to S-0.2, the results of machine-learning-driven searches are close to or even slightly better than the DPM baseline, confirming that the machine learning models reliably locate the best operating conditions compared to DPM. Regarding the variability in optimization for each scenario, a machine learning + PSO scheme is highlighted, with almost the same CEF for each repeated run. In contrast, PSO on the DPM showed larger scatter, likely because the maximum running time was reached before the true convergence. For GA and SA, generally, optimization based on DPM is still less stable than that based on machine learning. By comparing all optimization algorithms, the results reveal that PSO is the most compatible with the studied machine learning models, delivering both the lowest CEF and near-zero run-to-run variability, which has also been outlined in previous work [16]. Overall, these findings demonstrate that machine learning surrogates not only reproduce the solutions close to the DPM optimum but show better stability, highlighting their promise for reliable process optimization in waste-to-energy applications.

Figure 8.

Optimization results of different optimization schemes under S-0.2 (the colored bars and error bars represent mean values and the standard deviations across replicate optimization runs).

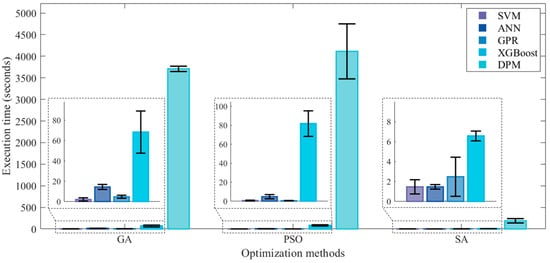

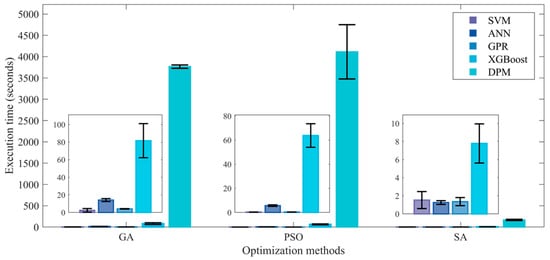

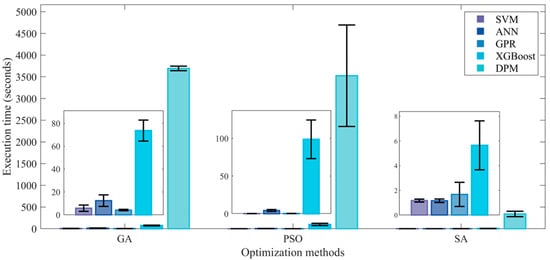

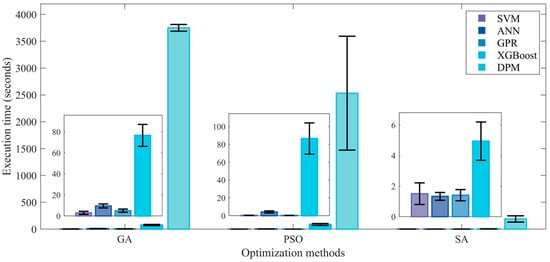

In order to explore the efficiency of different optimization schemes, the running time required for optimization was analyzed in detail. Figure 9 shows the comparison results under S-0.2. The comparison results in other scenarios are shown in Figure A7, Figure A8 and Figure A9. Obviously, optimizations based on DPM are markedly slower than those relying on machine learning surrogates. In particular, the GA + DPM and PSO + DPM optimizations reach the maximum allowed runtime (1 h), indicating that these algorithms terminated prematurely due to time constraints rather than convergence. This highlights the substantial computational burden associated with population-based heuristics when applied to first-principle-based simulations. Notably, obvious standard deviation is observed on the combination of PSO + DPM (see Figure 9 and Figure A7, Figure A8 and Figure A9), which can be attributed to the PSO algorithm’s high sensitivity to the initial solution, as previously reported [71]. When the randomly generated initial solution is optimal (for example, when the initial individual is close to a minimum), optimization converges rapidly. Otherwise, convergence may not be achieved within the maximum runtime. While the SA algorithm showed a relatively better runtime performance among DPM-based methods under different scenarios, this improvement is attributed to its single-point search mechanism, as introduced in Section 2, which requires fewer evaluations per iteration. Nevertheless, even SA-based optimization still requires hundreds of seconds for optimization on average, underscoring the inefficiency of relying solely on detailed simulation models for large-scale parametric optimization, especially for complex processes.

Figure 9.

Execution time required for different optimization schemes under S-0.2 (the colored bars and error bars represent the mean values and standard deviations across replicate optimization runs).

In comparison, machine-learning-based optimizations show outstanding efficiency, with seconds to tens of seconds for optimization. This improvement arises because machine learning models reduce the computational cost of each objective evaluation, enabling the optimizer to explore a broader feasible range within the same runtime. However, differences emerge among surrogate types that affect both runtime and the reliability of optimized solutions. Notably, the combination of GPR and PSO achieves exceptional performance, basically converging within a second. This efficiency can be attributed to the synergy between GPR’s compact predictive cost with uncertainty estimation and the population-based global search capability of PSO. The optimization efficiency is highlighted by comparison with previous studies. Earlier works have shown that while rigorous models can be used to find optimal operating parameters, optimization requires thousands of simulations [32,72], resulting in optimization times on the order of hours. To improve optimization efficiency, a simplified poly-generation system of a municipal solid waste model was employed but solving it using a mixed-integer nonlinear programming solver still required optimization times of nearly 300 s [73].

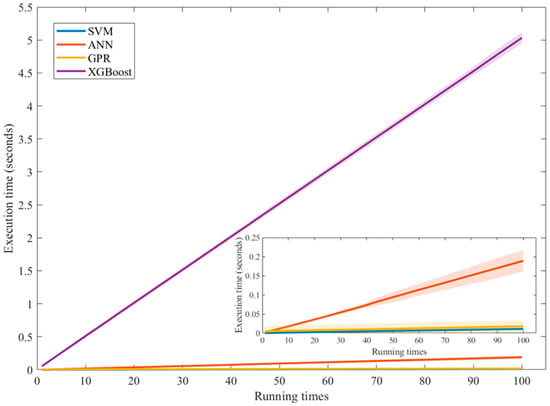

Although XGBoost consistently achieves competitive optimization outcomes, its runtime is comparatively higher than those of other machine learning techniques. This performance gap is explained primarily by differences in model architecture and per-call complexity. XGBoost predictions require traversing an ensemble of decision trees (one tree per boosting round); so, per-sample latency scales with the number of trees and tree depth. To further investigate this, the average prediction times of the four machine learning models were compared (as shown in Figure 10). XGBoost required approximately 0.05 s per prediction, markedly higher than the time required by SVM, ANN, and GPR, all of which completed inference in under 0.002 s. Because population-based optimizers evaluate numerous objective functions, even modest increases in per-call latency can lead to substantial increases in total optimization time. Supported by the reliability of the rigorous process model, our findings confirm that machine learning models can act as highly accurate surrogates, showing their strong potential for predicting process performance in real-world applications. Especially of note, when multiple optimization runs are required, such as uncertainty quantification, sensitivity analysis, or multi-scenario decision-making, the ability to replace time-consuming simulations with fast, high-fidelity models can drastically accelerate workflow efficiency. As such, incorporating high-performance machine learning surrogates into early-stage process design is not only practical but essential for advancing carbon-neutral waste management and enabling robust and efficient decision-making in industrial systems.

Figure 10.

Execution time of running machine learning models for prediction (the shaded areas denote the standard deviation across 10 repeated runs).

Table 2 presents the comparison of different machine learning techniques in modeling and optimization. GPR achieves a strong balance of accuracy (R2 of 0.917 for training and 0.885 for testing) and fast prediction latency, although exact GPR can face scalability issues when a very large dataset is involved. Notably, careful hyperparameter tuning is required for performance improvement, especially for ANN. XGBoost achieves near-perfect training accuracy (R2 of around 0.9998) but exhibits modest overfitting and substantially higher prediction latency due to its ensemble of decision trees. Overall, GPR shows the best trade-off between accuracy, robustness, and computational efficiency (for process optimization) in this case study.

Table 2.

Summary of machine learning models’ performances.

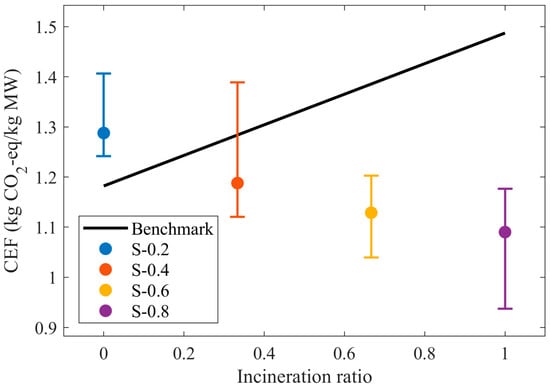

Figure 11 presents the optimization results under each hydrogen-mix scenario, with error bars indicating the range of optima across different optimization schemes. In addition, the black line traces the CEF for conventional mask disposal from pure landfilling (1.1821 kg CO2-eq/kg MW) to full incineration (1.4874 kg CO2-eq/kg MW) [16,74]. As the fraction of green H2 increases (the LECH decreases), the optimized CEF of the designed MW-to-FT process drops from about 1.3 to under 1.1 kg CO2-eq/kg MW. This trend highlights the critical role of low-carbon hydrogen sourcing in emission reduction in waste valorization. The variation in CEF across all optimizations (measured by error bars) demonstrates that optimal CEF is sensitive to operating conditions and thus effective optimization is essential for uncovering a process’s true potential. In our four scenarios, the DPM-based optimizations with GA and PSO consumed over four hours in total (shown in Figure 9 and Figure A7, Figure A8 and Figure A9), compared to under one minute when using machine learning surrogates. Given more optimizations are demanded in robust process design, this highlights the importance of efficiency in optimization. Regarding the results, as 40% green hydrogen is provided, the designed MW-to-FT fuel process becomes the most favorable conventional pathway (pure landfilling), offering carbon reduction and the avoidance of other landfill-related pollution risks [75]. Beyond environmental benefits, this waste-to-energy conversion follows the circular economy and provides new revenue from fuel production and selling [32]. Overall, these results confirm that a well-tuned machine-learning-assisted optimization framework can deliver superior, low-carbon solutions for MW treatment.

Figure 11.

Comparison of CEF between the proposed MW-to-FT process and conventional treatment routes. (Error bars indicate the maximum and minimum optimal CEFs determined by different optimization methods under each scenario and the black line indicates how CEF varies with the landfill-to-incineration split).

4. Conclusions, Limitations and Outlook

This study develops a comprehensive process for converting MW into FT fuel and quantifies the CEF using cradle-to-gate LCA. Integrating rigorous process simulation with LCA, a dataset covering diverse operating conditions, LCEH and CEF, is constructed for machine learning. Four distinct machine learning surrogate models (SVM, ANN, GPR, XGBoost) are constructed after tuning hyperparameters via cross-validation, each achieving high accuracy with test R2 of around 0.9. Coupling these models with heuristic algorithms (GA, PSO and SA), operation optimizations are performed under varying green-H2-blending scenarios (20–80%) and show identical or even lower CEF (~1.3 to ~1.1 kg CO2-eq/kg MW) compared to optimization based on DPM, but at a dramatically lower computational cost (<1–30 s versus hundreds to thousands of seconds). In particular, the combination of GPR and PSO demonstrates the best performance with satisfactory accuracy, efficiency and stability. Further analysis identifies the time for model execution as the main driver of optimization efficiency. Sensitivity analysis shows that as LECH decreases, the optimized CEF consistently falls below the landfill and incineration benchmarks, confirming the designed MW-to-FT fuel process’s environmental advantage. Our results demonstrate that machine learning surrogates can match mechanism-based model in accuracy while delivering gains within orders of magnitude in optimization speed and robustness, which is critical for accelerating process design and potential assessment under uncertainty.

Despite these promising results, several limitations remain. The success of ML surrogates relies on the availability of a rigorous and high-fidelity process model. For broader applicability, future studies should integrate experimental datasets to ensure that trained models are capable of capturing real-world process variability. In addition, variability in MW composition poses challenges for scale-up, necessitating adaptive retraining of ML models to maintain reliability under dynamic conditions. More efficient sampling strategies (e.g., Latin hypercube or stratified sampling) could further improve training data quality, while introducing controlled noise may help capture operational uncertainties in the real world. Addressing these aspects will be critical to advancing the proposed framework into practice, supporting reliable and scalable low-carbon MW-to-energy deployment.

Author Contributions

Conceptualization, J.Z. and J.R.; Methodology, J.Z., J.L. and J.R.; Software, C.H.; Validation, J.Z., J.L., J.R. and C.H.; Formal Analysis, J.Z. and J.R.; Investigation, J.Z.; Resources, J.R.; Data Curation, J.Z.; Writing—Original Draft, J.Z.; Writing—Review and Editing, J.L., J.R. and C.H.; Supervision, J.R.; Project Administration, J.R.; Funding Acquisition, J.R. All authors have read and agreed to the published version of the manuscript.

Funding

The work described in this study received support from a grant from the Research Committee of The Hong Kong Polytechnic University under the student account code RKQ1. The work described in this paper was mainly supported by funding support from the Research Institute for Advanced Manufacturing (RIAM) of The Hong Kong Polytechnic University (1-CDLY, Project ID: P0056082), and the work was supported by a grant from the Departmental General Research Fund (Grant No. 4-ZZXD, Project ID: P0056352). The authors would like to express their sincere thanks for the financial support from the Research Institute for Advanced Manufacturing (RIAM) of The Hong Kong Polytechnic University (project code: 1-CDK2, Project ID: P0050827). The work described in this paper was also supported by a grant from Research Grants Council of the Hong Kong Special Administrative Region, China-General Research Fund (Project ID: P0042030, Funding Body Ref. No: 15304222, Project No. B-Q97U), a grant from the Research Institute for Advanced Manufacturing (RIAM), The Hong Kong Polytechnic University (PolyU) (Project No. 1-CD4J, Project ID: P0041367), and a grant from the Environment and Conservation Fund (ECF) (Project ID: P0043333, Funding Body Ref. No: ECF 51/2022, Project No. K-ZB5Z).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

During the preparation of this manuscript, DeepSeek was used for the purposes of grammar checking.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

Proximate and ultimate analysis of MW [76].

Table A1.

Proximate and ultimate analysis of MW [76].

| Items | Compositions | Values |

|---|---|---|

| Proximate analysis (wt.%) a | Moisture | 5.00 |

| Ash | 0.20 | |

| Volatiles | 92.90 | |

| Fixed carbon | 1.90 | |

| Ultimate analysis (wt.%) b | C | 84.17 |

| H | 14.93 | |

| O | 0.7 | |

| Higher heating value (MJ/kg) c | - | 46.9 |

a: as-received basis; b: dry basis; c: raw basis.

Table A2.

Key operating parameters involved in process simulation [16,18,32,33,37].

Table A2.

Key operating parameters involved in process simulation [16,18,32,33,37].

| Processes | Operating Conditions | Values | Units |

|---|---|---|---|

| Plasma gasification | Temperature | 2000–3000 | °C |

| Equivalent ratio (ER) | 0.1–0.5 | - | |

| Steam-to-waste ratio (SWR) | 0.5–1 | - | |

| RWGS | Temperature | 600 | °C |

| Pressure | 24.5 | bar | |

| CO2 conversion rate | 36 | % | |

| FT synthesis | Temperature | 220 | °C |

| Pressure | 30 | Bar | |

| Splitting ratio of light gases (LGSR) | 0–1 | - | |

| PSA | H2 purity | 99.9 | % |

| H2 recovery rate | 85 | % | |

| Duty | 0.657 | kWh/kg | |

| Combined heat and power generation | Combustion temperature | 900 | °C |

| Inlet pressure of turbine | 70 | Bar | |

| Outlet pressure of turbine | 7 | kPa | |

| MEA-based carbon capture | Capture efficiency | 85 | % |

| Duty | 4 | MJ/kg |

Table A3.

Process simulation results of a base case.

Table A3.

Process simulation results of a base case.

| Items | MW | H2O | O2 | S1 | S2 | S3 | S4 | Water-1 | S5 | S6 | S7 | S8 | S9 | S10 | S11 | S12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature | 25.00 | 25.00 | 25.00 | 2500.00 | 25.00 | 18.80 | 2500.00 | 25.00 | 25.00 | 43.30 | 150.00 | 600.00 | 600.00 | 140.00 | 140.00 | 140.00 |

| Pressure | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 24.20 | 24.20 | 24.20 | 24.20 | 24.20 | 24.20 |

| Mass flowrate | 1000.00 | 750.00 | 1030.00 | 2780.00 | 2780.00 | 1780.00 | 1780.00 | 615.00 | 2160.00 | 4220.00 | 4220.00 | 4220.00 | 4220.00 | 4220.00 | 1210.00 | 3010.00 |

| XMW | 1.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| XH2 | 0.00 | 0.00 | 0.00 | 0.42 | 0.42 | 0.00 | 0.00 | 0.00 | 0.52 | 0.45 | 0.45 | 0.45 | 0.36 | 0.36 | 0.00 | 0.42 |

| XO2 | 0.00 | 0.00 | 1.00 | 0.00 | 0.00 | 0.44 | 0.44 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| XCH4 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| XCO | 0.00 | 0.00 | 0.00 | 0.34 | 0.34 | 0.00 | 0.00 | 0.00 | 0.42 | 0.29 | 0.29 | 0.29 | 0.38 | 0.38 | 0.00 | 0.44 |

| XCO2 | 0.00 | 0.00 | 0.00 | 0.03 | 0.03 | 0.00 | 0.00 | 0.00 | 0.03 | 0.24 | 0.24 | 0.24 | 0.15 | 0.15 | 1.00 | 0.03 |

| XH2O | 1.00 | 1.00 | 0.00 | 0.21 | 0.21 | 0.56 | 0.56 | 1.00 | 0.03 | 0.02 | 0.02 | 0.02 | 0.11 | 0.11 | 0.00 | 0.12 |

| Items | S13 | S14 | S15 | S16 | S17 | S18 | S19 | S20 | S21 | S22 | S23 | S24 | Wax | Naphtha | Jet fuel | |

| Temperature | 187.00 | 150.00 | 220.00 | 25.00 | 25.00 | 220.00 | 25.00 | 25.00 | 25.00 | 25.00 | 5.74 | 5.74 | 5.74 | 5.74 | 5.74 | |

| Pressure | 0.58 | 29.60 | 29.60 | 0.53 | 0.53 | 29.60 | 0.58 | 0.58 | 0.58 | 0.58 | 0.53 | 0.53 | 0.53 | 0.53 | 0.53 | |

| Mass flowrate | 4010.00 | 4010.00 | 4010.00 | 2370.00 | 1640.00 | 2370.00 | 1610.00 | 754.00 | 807.00 | 807.00 | 3200.00 | 2900.00 | 301.00 | 219.00 | 224.00 | |

| XH2 | 0.60 | 0.60 | 0.40 | 0.57 | 0.00 | 0.37 | 0.49 | 0.00 | 0.49 | 0.49 | 0.15 | 0.15 | 0.00 | 0.00 | 0.00 | |

| XO2 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XCH4 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XCO | 0.29 | 0.29 | 0.19 | 0.28 | 0.00 | 0.18 | 0.25 | 0.00 | 0.25 | 0.25 | 0.08 | 0.08 | 0.00 | 0.00 | 0.00 | |

| XCO2 | 0.03 | 0.03 | 0.04 | 0.06 | 0.00 | 0.09 | 0.12 | 0.00 | 0.12 | 0.12 | 0.04 | 0.04 | 0.00 | 0.00 | 0.00 | |

| XH2O | 0.08 | 0.08 | 0.32 | 0.05 | 0.97 | 0.27 | 0.05 | 0.95 | 0.05 | 0.05 | 0.68 | 0.68 | 0.00 | 0.00 | 0.00 | |

| XC1 | 0.00 | 0.00 | 0.01 | 0.01 | 0.00 | 0.01 | 0.02 | 0.00 | 0.02 | 0.02 | 0.01 | 0.01 | 0.00 | 0.00 | 0.00 | |

| XC2 | 0.00 | 0.00 | 0.01 | 0.01 | 0.00 | 0.01 | 0.02 | 0.00 | 0.02 | 0.02 | 0.01 | 0.01 | 0.00 | 0.00 | 0.00 | |

| XC3 | 0.00 | 0.00 | 0.00 | 0.01 | 0.00 | 0.01 | 0.02 | 0.00 | 0.02 | 0.02 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC4 | 0.00 | 0.00 | 0.00 | 0.01 | 0.00 | 0.01 | 0.01 | 0.00 | 0.01 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC5 | 0.00 | 0.00 | 0.00 | 0.01 | 0.00 | 0.01 | 0.01 | 0.00 | 0.01 | 0.01 | 0.00 | 0.00 | 0.00 | 0.24 | 0.00 | |

| XC6 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 | 0.01 | 0.00 | 0.01 | 0.01 | 0.00 | 0.00 | 0.00 | 0.22 | 0.00 | |

| XC7 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 | 0.01 | 0.00 | 0.01 | 0.01 | 0.00 | 0.00 | 0.00 | 0.20 | 0.00 | |

| XC8 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.18 | 0.00 | |

| XC9 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.16 | 0.00 | |

| XC10 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.24 | |

| XC11 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.22 | |

| XC12 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.20 | |

| XC13 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.18 | |

| XC14 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.16 | |

| XC15 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC16 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC17 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC18 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC19 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.14 | 0.00 | 0.00 | |

| XC20 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.13 | 0.00 | 0.00 | |

| XC21 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.11 | 0.00 | 0.00 | |

| XC22 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.10 | 0.00 | 0.00 | |

| XC23 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.09 | 0.00 | 0.00 | |

| XC24 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.08 | 0.00 | 0.00 | |

| XC25 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.07 | 0.00 | 0.00 | |

| XC26 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.07 | 0.00 | 0.00 | |

| XC27 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.06 | 0.00 | 0.00 | |

| XC28 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.05 | 0.00 | 0.00 | |

| XC29 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.05 | 0.00 | 0.00 | |

| XC30 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.04 | 0.00 | 0.00 | |

| Items | Diesel | S26 | S27 | Air | S28 | S29 | S30 | S31 | S32 | S33 | S34 | S35 | S36 | Emitted gases | Water-2 | |

| Temperature | 5.74 | 5.74 | 25.00 | 25.00 | 25.00 | 900.00 | 40.00 | 859.00 | 104.00 | 30.00 | 30.60 | 40.00 | 40.00 | 25.00 | 25.00 | |

| Pressure | 0.53 | 0.53 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 69.10 | 0.07 | 0.04 | 69.10 | 1.00 | 1.00 | 1.00 | 1.00 | |

| Mass flowrate | 154.00 | 2300.00 | 627.00 | 2540.00 | 35.70 | 3170.00 | 3170.00 | 859.00 | 859.00 | 859.00 | 859.00 | 2350.00 | 815.00 | 2130.00 | 223.00 | |

| XMW | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XH2 | 0.00 | 0.16 | 0.14 | 0.00 | 1.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XO2 | 0.00 | 0.00 | 0.00 | 0.21 | 0.00 | 0.01 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 | 0.00 | 0.01 | 0.00 | |

| XCH4 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC2H4 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC2H6 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XCO | 0.00 | 0.08 | 0.47 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XCO2 | 0.00 | 0.04 | 0.22 | 0.00 | 0.00 | 0.21 | 0.21 | 0.00 | 0.00 | 0.00 | 0.00 | 0.04 | 1.00 | 0.04 | 0.00 | |

| XH2O | 0.00 | 0.70 | 0.05 | 0.01 | 0.00 | 0.14 | 0.14 | 1.00 | 1.00 | 1.00 | 1.00 | 0.17 | 0.00 | 0.03 | 1.00 | |

| XN2 | 0.00 | 0.00 | 0.00 | 0.78 | 0.00 | 0.65 | 0.65 | 0.00 | 0.00 | 0.00 | 0.00 | 0.79 | 0.00 | 0.92 | 0.00 | |

| XC1 | 0.00 | 0.01 | 0.03 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC2 | 0.00 | 0.01 | 0.03 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC3 | 0.00 | 0.01 | 0.03 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC4 | 0.00 | 0.00 | 0.03 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC15 | 0.29 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC16 | 0.26 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC17 | 0.24 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| XC18 | 0.21 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

X: mole fraction.

Figure A1.

Cross validation results of ANN: (a) R2, (b) RMSE. (The colored bars and error bars represent mean values and the standard deviations as the number of training samples varies. The error bars do not imply the model can actually achieve the extreme values indicated. The dotted circles highlight the optimal results).

Figure A2.

Cross-validation performance of GPR surrogates across varying training-set sizes: (a) R2 (b) RMSE. (The colored bars and error bars represent mean values and the standard deviations as the number of training samples varies. The dotted lines in (a,b) highlight the highest R2 and the lowest RMSE, respectively).

Figure A3.

Cross-validation performance of XGBoost surrogates across varying training-set sizes: (a) R2; (b) RMSE. (The colored points and error bars represent mean values and the standard deviations as the number of training samples varies. Other hyperparameters, such as learning rate, column subsample rate, and gamma value, follow the previous literature [70]. The dotted circles highlight the optimal results).

Figure A4.

Optimization results of different optimization schemes under S-0.4. (The colored bars and error bars represent mean values and the standard deviations across replicate optimization runs).

Figure A5.

Optimization results of different optimization schemes under S-0.6. (The colored bars and error bars represent mean values and the standard deviations across replicate optimization runs).

Figure A6.

Optimization results of different optimization schemes under S-0.8. (The colored bars and error bars represent mean values and the standard deviations across replicate optimization runs).

Figure A7.

Execution time required for different optimization schemes under S-0.4. (The colored bars and error bars represent the mean values and standard deviations across replicate optimization runs).

Figure A8.

Execution time required for different optimization schemes under S-0.6. (The colored bars and error bars represent the mean values and standard deviations across replicate optimization runs).

Figure A9.

Execution time required for different optimization schemes under S-0.8. (The colored bars and error bars represent the mean values and standard deviations across replicate optimization runs).

References

- Mohee, R. Medical Wastes Characterisation in Healthcare Institutions in Mauritius. Waste Manag. 2005, 25, 575–581. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Song, Q.; Wu, N.; Li, J.; Zhong, Y.; Zeng, W. Repercussions of COVID-19 Pandemic on Solid Waste Generation and Management Strategies. Front. Environ. Sci. Eng. 2021, 15, 115. [Google Scholar] [CrossRef]

- You, S.; Sonne, C.; Ok, Y.S. COVID-19’s Unsustainable Waste Management. Science 2020, 368, 1438. [Google Scholar] [CrossRef]

- Ghasemi, M.K.; Yusuff, R.B.M. Advantages and Disadvantages of Healthcare Waste Treatment and Disposal Alternatives: Malaysian Scenario. Pol. J. Environ. Stud. 2016, 25, 17–25. [Google Scholar] [CrossRef]

- Mazzei, H.G.; Specchia, S. Latest Insights on Technologies for the Treatment of Solid Medical Waste: A review. J. Environ. Chem. Eng. 2023, 11, 109309. [Google Scholar] [CrossRef]

- Reyes-López, J.A.; Ramírez-Hernández, J.; Lázaro-Mancilla, O.; Carreón-Diazconti, C.; Garrido, M.M.L. Assessment of Groundwater Contamination by Landfill Leachate: A Case in México. Waste Manag. 2008, 28, S33–S39. [Google Scholar] [CrossRef]

- Mukherjee, S.; Mukhopadhyay, S.; Hashim, M.A.; Gupta, B. Sen Contemporary Environmental Issues of Landfill Leachate: Assessment and Remedies. Crit. Rev. Environ. Sci. Technol. 2015, 45, 472–590. [Google Scholar] [CrossRef]

- Khan, M.S.; Mubeen, I.; Caimeng, Y.; Zhu, G.; Khalid, A.; Yan, M. Waste to Energy Incineration Technology: Recent Development under Climate Change Scenarios. Waste Manag. Res. 2022, 40, 1708–1729. [Google Scholar] [CrossRef]

- Imran, M.; Jijian, Z.; Sharif, A.; Magazzino, C. Evolving Waste Management: The Impact of Environmental Technology, Taxes, and Carbon Emissions on Incineration in EU Countries. J. Environ. Manag. 2024, 364, 121440. [Google Scholar] [CrossRef] [PubMed]

- Li, C.H.; Lee, T.T.; Lau, S.S.Y. Enhancement of Municipal Solid Waste Management in Hong Kong through Innovative Solutions: A Review. Sustainability 2023, 15, 3310. [Google Scholar] [CrossRef]

- Zhu, J.; Fei, X.; Yin, K. Assessment of Waste-to-Energy Conversion Technologies for Biomass Waste under Different Shared Socioeconomic Pathways. Energy Environ. Sustain. 2025, 1, 100021. [Google Scholar] [CrossRef]

- Chaiyat, N. Energy, Exergy, Economic, and Environmental Analysis of an Organic Rankine Cycle Integrating with Infectious Medical Waste Incinerator. Therm. Sci. Eng. Prog. 2021, 22, 100810. [Google Scholar] [CrossRef]

- Su, L.; Wu, S.; Fu, G.; Zhu, W.; Zhang, X.; Liang, B. Creep Characterisation and Microstructural Analysis of Municipal Solid Waste Incineration Fly Ash Geopolymer Backfill. Sci. Rep. 2024, 14, 29828. [Google Scholar] [CrossRef]

- Zhao, X.; You, F. Waste Respirator Processing System for Public Health Protection and Climate Change Mitigation under COVID-19 Pandemic: Novel Process Design and Energy, Environmental, and Techno-Economic Perspectives. Appl. Energy 2021, 283, 116129. [Google Scholar] [CrossRef] [PubMed]

- Kuo, P.C.; Illathukandy, B.; Wu, W.; Chang, J.S. Plasma Gasification Performances of Various Raw and Torrefied Biomass Materials Using Different Gasifying Agents. Bioresour. Technol. 2020, 314, 123740. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, C.; Ren, J.; He, C. Targeting Carbon-Neutral Waste Reduction: Novel Process Design, Modelling and Optimization for Converting Medical Waste into Hydrogen. Energy 2024, 310, 133272. [Google Scholar] [CrossRef]

- Li, J.; Wang, H.; Chen, H.; Wu, H.; Xu, G.; Dong, Y.; Zhao, Q.; Liu, T. Comparative Thermodynamic and Techno-Economic Analysis of Various Medical Waste-to-Hydrogen/Methanol Pathways Based on Plasma Gasification. Appl. Therm. Eng. 2023, 221, 119762. [Google Scholar] [CrossRef]

- Zhou, J.; Ren, J.; Zhu, L.; He, C. Turning Waste into Energy through a Solar-Powered Multi-Generation System with Novel Machine Learning-Based Life Cycle Optimization. Chem. Eng. Sci. 2025, 307, 121348. [Google Scholar] [CrossRef]

- Mehdi, M.; Ammar Taqvi, S.A.; Shaikh, A.A.; Khan, S.; Naqvi, S.R.; Shahbaz, M.; Juchelková, D. Aspen plus Simulation Model of Municipal Solid Waste Gasification of Metropolitan City for Syngas Production. Fuel 2023, 344, 128128. [Google Scholar] [CrossRef]

- Ali, A.M.; Shahbaz, M.; Inayat, M.; Shahzad, K.; Al-Zahrani, A.A.; Mahpudz, A.B. Conversion of Municipals Waste into Syngas and Methanol via Steam Gasification Using CaO as Sorbent: An Aspen Plus Modelling. Fuel 2023, 349, 128640. [Google Scholar] [CrossRef]

- Zhu, X.; Li, Y.; Wang, X. Machine Learning Prediction of Biochar Yield and Carbon Contents in Biochar Based on Biomass Characteristics and Pyrolysis Conditions. Bioresour. Technol. 2019, 288, 121527. [Google Scholar] [CrossRef]

- Tang, Q.; Chen, Y.; Yang, H.; Liu, M.; Xiao, H.; Wang, S.; Chen, H.; Raza Naqvi, S. Machine Learning Prediction of Pyrolytic Gas Yield and Compositions with Feature Reduction Methods: Effects of Pyrolysis Conditions and Biomass Characteristics. Bioresour. Technol. 2021, 339, 125581. [Google Scholar] [CrossRef] [PubMed]

- Timilsina, M.S.; Chaudhary, Y.; Shah, A.K.; Lohani, S.P.; Bhandari, R.; Uprety, B. Syngas Composition Analysis for Waste to Methanol Production: Techno-Economic Assessment Using Machine Learning and Aspen Plus. Renew. Energy 2024, 228, 120574. [Google Scholar] [CrossRef]

- Wang, Z.; Li, J.; Rangaiah, G.P.; Wu, Z. Machine Learning Aided Multi-Objective Optimization and Multi-Criteria Decision Making: Framework and Two Applications in Chemical Engineering. Comput. Chem. Eng. 2022, 165, 107945. [Google Scholar] [CrossRef]

- Fath, V.; Kockmann, N.; Otto, J.; Röder, T. Self-Optimising Processes and Real-Time-Optimisation of Organic Syntheses in a Microreactor System Using Nelder–Mead and Design of Experiments. React. Chem. Eng. 2020, 5, 1281–1299. [Google Scholar] [CrossRef]

- Diehl, M.; Bock, H.G.; Schlöder, J.P.; Findeisen, R.; Nagy, Z.; Allgöwer, F. Real-Time Optimization and Nonlinear Model Predictive Control of Processes Governed by Differential-Algebraic Equations. J. Process Control 2002, 12, 577–585. [Google Scholar] [CrossRef]

- Meng, Q.; Xu, J.; Luo, F.; Jin, X.; Xu, L.; Yao, W.; Jin, S. Collaborative and Effective Scheduling of Integrated Energy Systems with Consideration of Carbon Restrictions. IET Gener. Transm. Distrib. 2023, 17, 4134–4145. [Google Scholar] [CrossRef]

- Singh, D.K.; Tirkey, J.V. Valorisation of Hazardous Medical Waste Using Steam Injected Plasma Gasifier: A Parametric Study on the Modelling and Multi-Objective Optimisation by Integrating Aspen plus with RSM. Environ. Technol. 2022, 43, 4291–4305. [Google Scholar] [CrossRef]

- Kaushal, R.; Rohit; Dhaka, A.K. A Comprehensive Review of the Application of Plasma Gasification Technology in Circumventing the Medical Waste in a Post-COVID-19 Scenario. Biomass Convers. Biorefinery 2024, 14, 1427–1442. [Google Scholar] [CrossRef]

- Rosha, P.; Ibrahim, H. Hydrogen Production via Solid Waste Gasification with Subsequent Amine-Based Carbon Dioxide Removal Using Aspen Plus. Int. J. Hydrogen Energy 2023, 48, 24607–24618. [Google Scholar] [CrossRef]

- Rosha, P.; Kumar, S.; Vikram, S.; Ibrahim, H.; Al-Muhtaseb, A.H. H2-Enriched Gaseous Fuel Production via Co-Gasification of an Algae-Plastic Waste Mixture Using Aspen PLUS. Int. J. Hydrogen Energy 2022, 47, 26294–26302. [Google Scholar] [CrossRef]

- Zhou, J.; Ayub, Y.; Shi, T.; Ren, J.; He, C. Sustainable Co-Valorization of Medical Waste and Biomass Waste: Innovative Process Design, Optimization and Assessment. Energy 2024, 288, 129803. [Google Scholar] [CrossRef]

- Kim, D.H.; Park, J.L.; Park, E.J.; Kim, Y.D.; Uhm, S. Dopant Effect of Barium Zirconate-Based Perovskite-Type Catalysts for the Intermediate-Temperature Reverse Water Gas Shift Reaction. ACS Catal. 2014, 4, 3117–3122. [Google Scholar] [CrossRef]

- Fazeli, H.; Panahi, M.; Rafiee, A. Investigating the Potential of Carbon Dioxide Utilization in a Gas-to-Liquids Process with Iron-Based Fischer-Tropsch Catalyst. J. Nat. Gas Sci. Eng. 2018, 52, 549–558. [Google Scholar] [CrossRef]

- Zang, G.; Sun, P.; Delgado, H.E.; Cappello, V.; Ng, C.; Elgowainy, A. The Modeling of the Synfuel Production Process: Process Models of Fischer-Tropsch Production with Electricity and Hydrogen Provided by Various Scales of Nuclear Plants (Program Document). Available online: https://www.osti.gov/biblio/1868524 (accessed on 31 July 2023).

- Li, K.; Leigh, W.; Feron, P.; Yu, H.; Tade, M. Systematic study of aqueous monoethanolamine (MEA)-based CO2 capture process: Techno-economic assessment of the MEA process and its improvements. Appl. Energy 2016, 165, 648–659. [Google Scholar] [CrossRef]

- Zhou, J.; Ren, J.; He, C. Turning Sewage Sludge and Medical Waste into Energy: Sustainable Process Synthesis via Surrogate-Based Superstructure Optimization. Green Chem. 2025, 27, 1777–1788. [Google Scholar] [CrossRef]

- Sun, Z.; Zeng, L.; Russell, C.K.; Assabumrungrat, S.; Chen, S.; Duan, L.; Xiang, W.; Gong, J. Solar-Wind-Bio Ecosystem for Biomass Cascade Utilization with Multigeneration of Formic Acid, Hydrogen, and Graphene. ACS Sustain. Chem. Eng. 2019, 7, 2558–2568. [Google Scholar] [CrossRef]

- Paulillo, A.; Sebastiani, A.; Lettieri, P.; Materazzi, M. Decarbonising Waste-to-Energy: A Life Cycle Assessment Study. Resour. Conserv. Recycl. 2024, 209, 107812. [Google Scholar] [CrossRef]

- Solomon, S.; Qin, D.; Manning, M.; Marquis, M.; Averyt, K.; Tignor, M.M.B.; Miller, H.L., Jr.; Chen, Z. Climate Change 2007: The Physical Science Basis. In Contribution of Working Group II to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, MA, USA, 2007; Volume 446, pp. 727–728. [Google Scholar]

- Zhou, J.; Ren, J.; He, C. Improved Medical Waste Plasma Gasification Modelling Based on Implicit Knowledge-Guided Interpretable Machine Learning. Waste Manag. 2024, 188, 48–59. [Google Scholar] [CrossRef] [PubMed]

- Minghui, M.; Chuanfeng, Z. Application of Support Vector Machines to a Small-Sample Prediction. Adv. Pet. Explor. Dev. 2015, 10, 72–75. [Google Scholar] [CrossRef]

- Herceg, S.; Ujević Andrijić, Ž.; Bolf, N. Development of Soft Sensors for Isomerization Process Based on Support Vector Machine Regression and Dynamic Polynomial Models. Chem. Eng. Res. Des. 2019, 149, 95–103. [Google Scholar] [CrossRef]

- Alade, I.O.; Zhang, Y.; Xu, X. Modeling and Prediction of Lattice Parameters of Binary Spinel Compounds (AM2X4) Using Support Vector Regression with Bayesian Optimization. New J. Chem. 2021, 45, 15255–15266. [Google Scholar] [CrossRef]

- Schölkopf, B. SVMs—A Practical Consequence of Learning Theory. IEEE Intell. Syst. Their Appl. 1998, 13, 18–21. [Google Scholar] [CrossRef]

- Pisner, D.A.; Schnyer, D.M. Support Vector Machine. Machine Learning: Methods and Applications to Brain Disorders; Academic Press: Cambridge, MA, USA, 2020; pp. 101–121. [Google Scholar] [CrossRef]

- Understanding Support Vector Machine Regression—MATLAB & Simulink. Available online: https://ch.mathworks.com/help/stats/understanding-support-vector-machine-regression.html (accessed on 7 July 2025).

- Jain, A.K.; Mao, J.; Mohiuddin, K.M. Artificial Neural Networks: A Tutorial. Computer 1996, 29, 31–44. [Google Scholar] [CrossRef]

- Zhou, J.; Chu, Y.T.; Ren, J.; Shen, W.; He, C. Integrating Machine Learning and Mathematical Programming for Efficient Optimization of Operating Conditions in Organic Rankine Cycle (ORC) Based Combined Systems. Energy 2023, 281, 128218. [Google Scholar] [CrossRef]

- Schulz, E.; Speekenbrink, M.; Krause, A. A Tutorial on Gaussian Process Regression: Modelling, Exploring, and Exploiting Functions. J. Math. Psychol. 2018, 85, 1–16. [Google Scholar] [CrossRef]

- Jäkel, F.; Schölkopf, B.; Wichmann, F.A. A Tutorial on Kernel Methods for Categorization. J. Math. Psychol. 2007, 51, 343–358. [Google Scholar] [CrossRef]

- Rasmussen, C.E.; Williams, C.K.I. Gaussian Processes for Machine Learning; Mit Press: Cambridge, MA, USA, 2005. [Google Scholar] [CrossRef]

- Neal, R.M. Bayesian Learning for Neural Networks; Springer: Berlin/Heidelberg, Germany, 1996; p. 118. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, X.; Pan, R.; Wang, Y.; Chen, Z. A Novel Gaussian Process Regression Model for State-of-Health Estimation of Lithium-Ion Battery Using Charging Curve. J. Power Sources 2018, 384, 387–395. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar] [CrossRef]

- Elavarasan, D.; Vincent, D.R. Reinforced XGBoost Machine Learning Model for Sustainable Intelligent Agrarian Applications. J. Intell. Fuzzy Syst. 2020, 39, 7605–7620. [Google Scholar] [CrossRef]

- Pekel, E. Estimation of Soil Moisture Using Decision Tree Regression. Theor. Appl. Clim. 2020, 139, 1111–1119. [Google Scholar] [CrossRef]

- Zhang, W.; Wu, C.; Tang, L.; Gu, X.; Wang, L. Efficient Time-Variant Reliability Analysis of Bazimen Landslide in the Three Gorges Reservoir Area Using XGBoost and LightGBM Algorithms. Gondwana Res. 2023, 123, 41–53. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, W.; Sun, G. Predicting Environmental Pollution with Gradient Boosting: Application of GBDT Regression Models in Time Series Models. Lect. Notes Electr. Eng. 2025, 1328, 138–148. [Google Scholar] [CrossRef]

- Ma, M.; Zhao, G.; He, B.; Li, Q.; Dong, H.; Wang, S.; Wang, Z. XGBoost-Based Method for Flash Flood Risk Assessment. J Hydrol. 2021, 598, 126382. [Google Scholar] [CrossRef]

- Ullah, Z.; Khan, M.; Naqvi, S.R.; Farooq, W.; Yang, H.; Wang, S.; Vo, D.-V.N. A Comparative Study of Machine Learning Methods for Bio-Oil Yield Prediction—A Genetic Algorithm-Based Features Selection. Bioresour Technol. 2021, 335, 125292. [Google Scholar] [CrossRef]

- Suleman, F.; Dincer, I.; Agelin-Chaab, M. Comparative Impact Assessment Study of Various Hydrogen Production Methods in Terms of Emissions. Int. J. Hydrogen Energy 2016, 41, 8364–8375. [Google Scholar] [CrossRef]

- Heuristic Optimization. Portfolio Management with Heuristic Optimization; Springer: Boston, MA, USA, 2005; pp. 38–76. [Google Scholar] [CrossRef]

- Lambora, A.; Gupta, K.; Chopra, K. Genetic Algorithm—A Literature Review. In Proceedings of the International Conference on Machine Learning, Big Data, Cloud and Parallel Computing: Trends, Prespectives and Prospects, COMITCon 2019, Faridabad, India, 14–16 February 2019; pp. 380–384. [Google Scholar] [CrossRef]

- Zhong, J.; Hu, X.; Zhang, J.; Gu, M. Comparison of Performance between Different Selection Strategies on Simple Genetic Algorithms. In Proceedings of the International Conference on Computational Intelligence for Modelling, Control and Automation, Vienna, Austria, 28–30 November 2005; IEEE: New York, NY, USA; Volume 2, pp. 1115–1120. [Google Scholar] [CrossRef]

- Zambrano-Bigiarini, M.; Clerc, M.; Rojas, R. Standard Particle Swarm Optimisation 2011 at CEC-2013: A Baseline for Future PSO Improvements. In Proceedings of the 2013 IEEE Congress on Evolutionary Computation, CEC, Cancun, Mexico, 20–23 June 2013; pp. 2337–2344. [Google Scholar] [CrossRef]