Evaluation and Optimization of Multi-Interface Lubrication Performance of Oil-Based Drilling Fluids for Extended-Reach Wells

Abstract

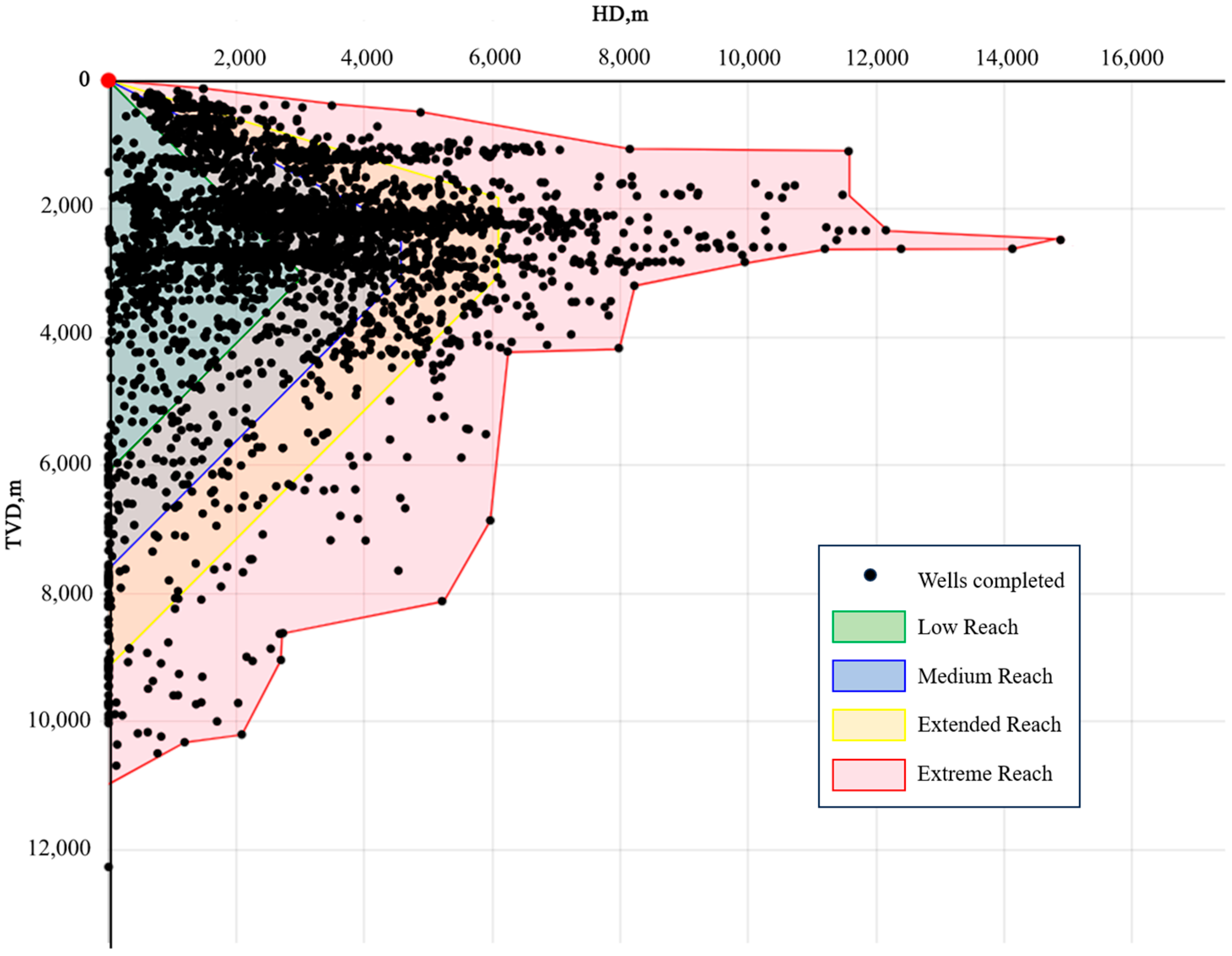

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experiment Apparatus

2.3. Methods

2.3.1. Drilling Fluid Properties

2.3.2. Friction Test at the Metal–Rock Interface

2.3.3. Friction Test at the Metal–Mud Cake Interface

2.3.4. Friction Test at the Metal–Metal Interface

3. Results

3.1. Base Properties

3.1.1. Rheological Properties

3.1.2. Plugging Properties

- Filtrate loss

- 2.

- Sand bed test

3.2. Lubricating Properties

3.2.1. Friction Coefficient of Metal–Rock Interface

- Influence of Dosage

- 2.

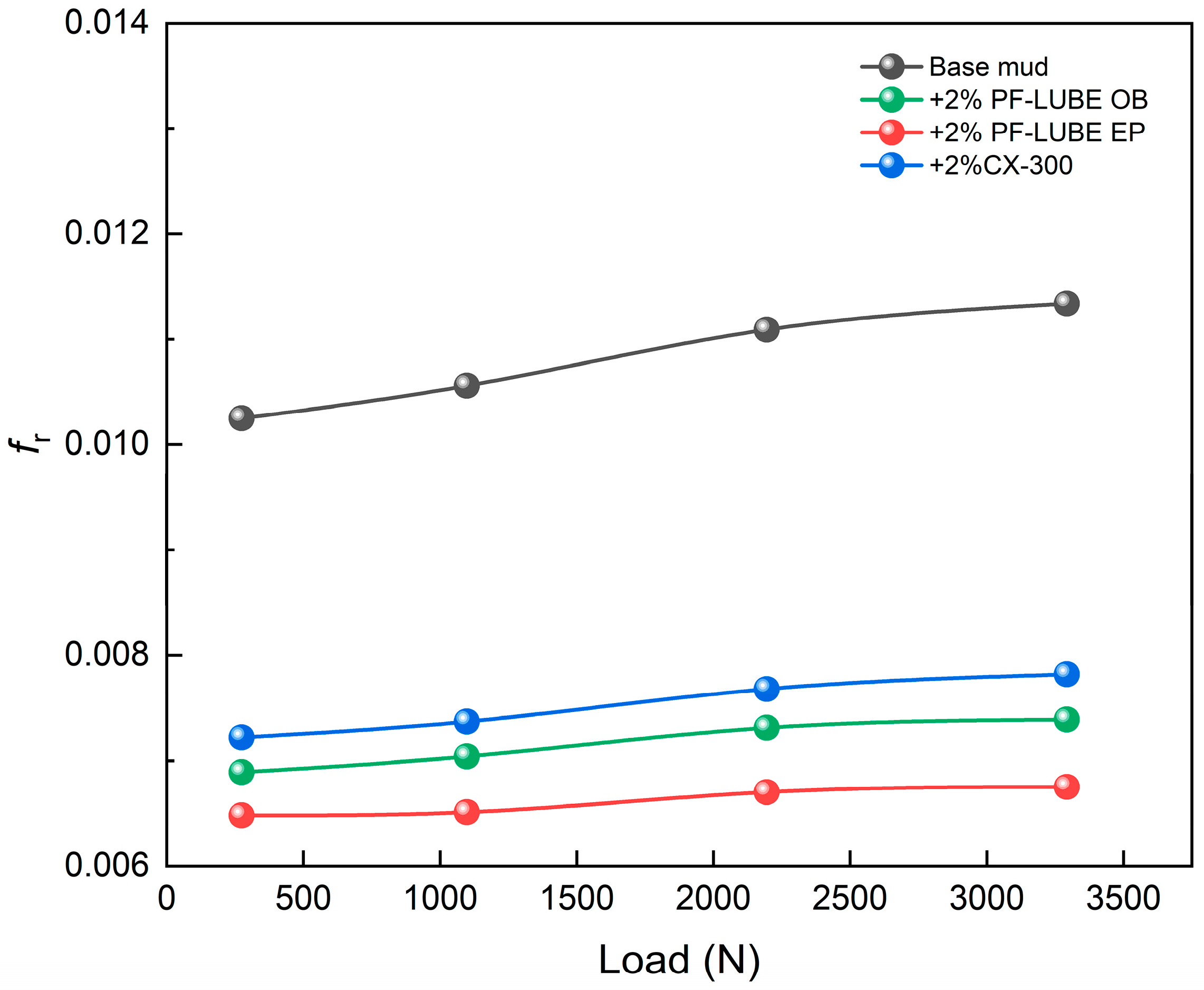

- Influence of load

- 3.

- Influence of formation

3.2.2. Friction Coefficient of Metal–Mud Cake Interface

3.2.3. Friction Coefficient of Metal–Metal Interface

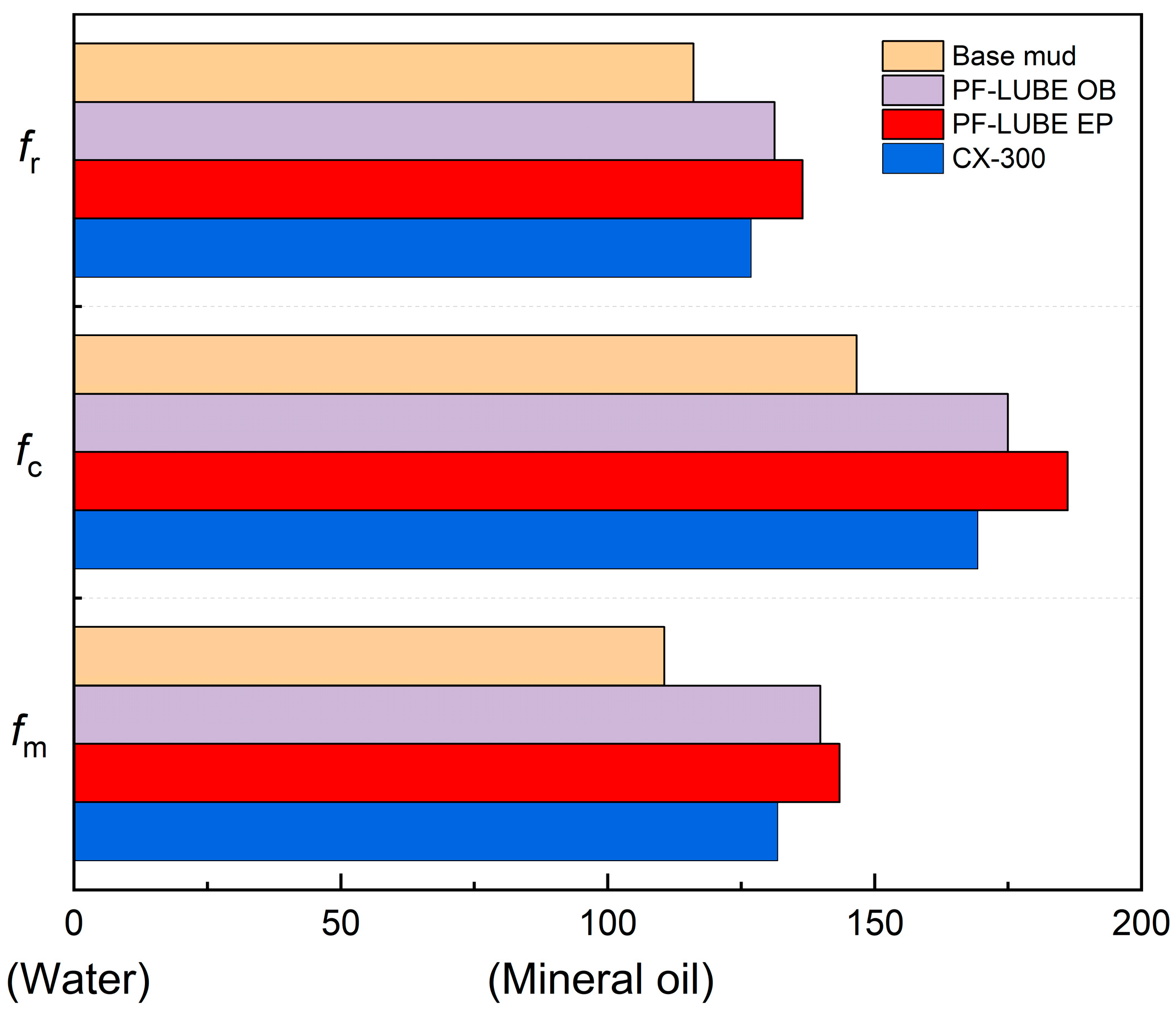

3.3. Quantitative Evaluation of Lubricants

4. Discussion

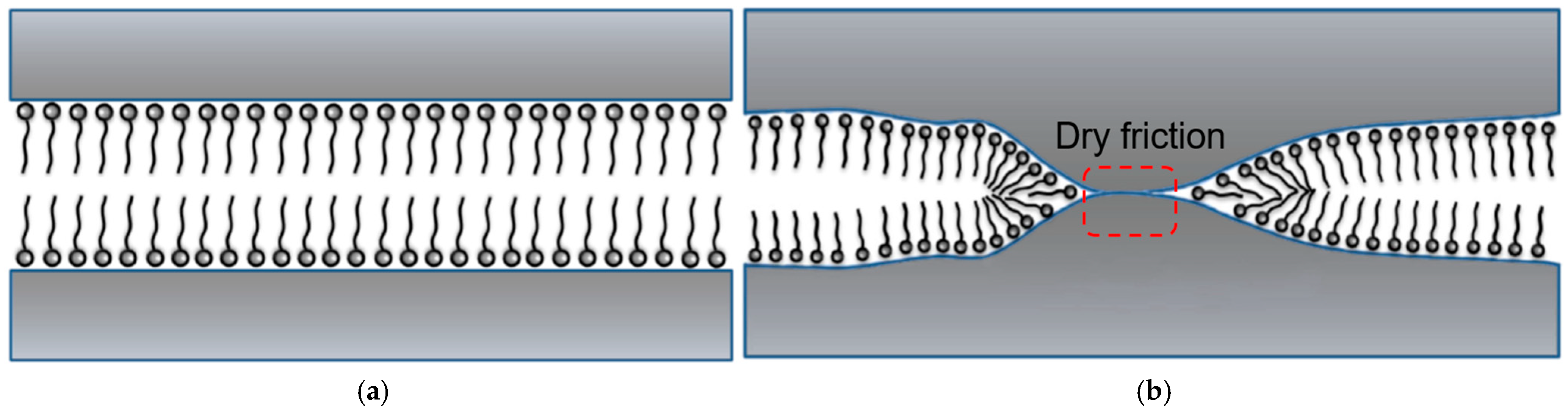

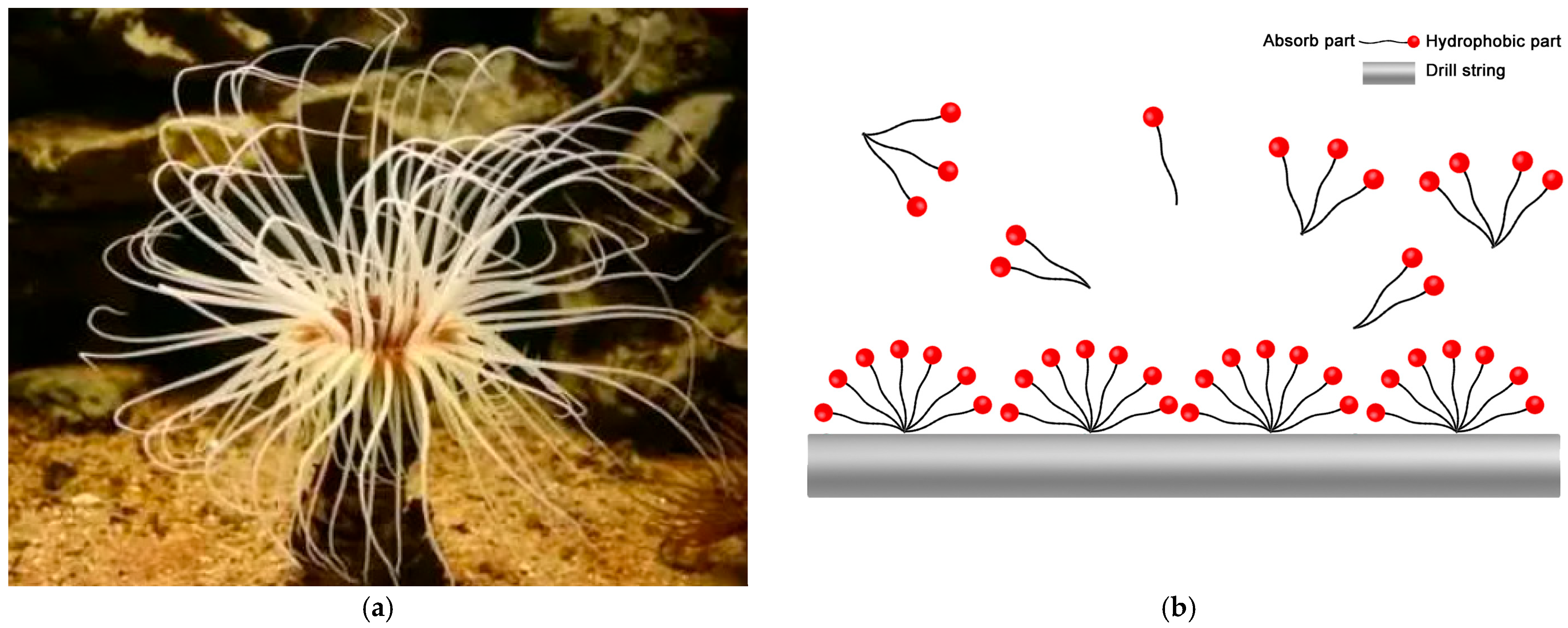

4.1. Lubrication Mechanism

4.2. Experimental Conditions and Limitations

4.3. Evaluation Framework and Methodological Expansion

4.4. Implications for ERD Operations

5. Conclusions

- PF-LUBE EP demonstrated the highest overall lubricating efficiency, reducing friction coefficients by 36.8% at the metal–rock interface (from 0.01025 to 0.00648), 27.5% at the metal–mud cake interface (from 0.23075 to 0.16726), and 32.5% at the metal–metal interface (from 0.11943 to 0.08058) at a dosage of 2 wt%. Its normalized multi-interface score reached 155.39 (baseline mineral oil = 100), confirming its robustness across varied lithologies and axial loads.

- The superior performance of PF-LUBE EP is attributed to its bionic dual-layer molecular structure, in which organophosphorus groups form a chemically adsorbed “anchoring layer” on metallic surfaces, while outward-oriented alkyl chains create a flexible “slip layer.” This architecture enables self-healing film formation, resistance to microcrack propagation, and sustained friction reduction even under cyclic loading and extreme pressure surges.

- Lubricant dosage optimization is critical for cost-effective performance. For PF-LUBE EP, 2 wt% represents the saturation point for adsorption and film integrity. Beyond this dosage, additional friction reduction was minimal (only 2.3% at 3 wt%), supporting a dosage strategy that balances additive cost with operational efficiency.

- The multi-interface quantitative scoring framework, benchmarked against distilled water (0) and W1-110 mineral oil (100), provides a standardized and reproducible method for lubricant evaluation. By integrating results across metal–rock, metal–mud cake, and metal–metal tests, this approach bridges laboratory characterization with field-scale decision-making, enabling more reliable additive selection and formulation for complex ERD operations.

- The findings establish a technical foundation for improving OBDF formulations to mitigate frictional risks—including torque spikes, stuck pipe, and tool or casing wear—in offshore and onshore ERD wells. Future research should focus on incorporating dynamic testing protocols (circulation, cyclic shear, and evolving mud cake behavior) and developing a multi-objective optimization framework that balances friction reduction, additive cost, and environmental compliance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ERD | Extended-reach drilling |

| HVR | Horizontal–vertical ratio |

| TVD | True vertical depth |

| HD | Horizontal displacement |

| OBDF | Oil-based drilling fluid |

| COSL | China Oilfield Services Limited |

| EP | Extreme pressure |

| API | American Petroleum Institute |

| RP | Recommended practice |

| RPM | Round per minute |

| AV | Apparent viscosity |

| PV | Plastic viscosity |

| YP | Yield point |

| FL | Filtrate loss |

| ES | Electrical stability |

| BHR | Before hot rolling |

| AHR | After hot rolling |

References

- Zhang, L.; Xie, T.; Hou, X.; Li, W.; Jin, J. Study on Safe Drilling Cycle of Soft Mudstone of Minghuazhen Formation in an Oilfield in Bohai Sea. Unconv. Oil Gas 2024, 11, 134–139. [Google Scholar] [CrossRef]

- Szymczak, P.D. Extended-Reach Drilling Hits Mainstream to Squeeze Difficult Reservoirs. J. Pet. Technol. 2021, 73, 35–40. [Google Scholar] [CrossRef]

- Wu, R.; Liu, Y.; Yu, H.; Lan, X.; Ai, X.; Guo, X.; Gao, P.; Deng, F. “Three-Low” Drilling Fluid Technology for Ultra-Shallow Horizontal Well with Extended Reach. Unconv. Oil Gas 2024, 11, 119–127. [Google Scholar] [CrossRef]

- Zhao, L.; Yi, T. Analysis of Coalbed Methane Horizontal Well Types and Drilling Technology Optimization. Coal Sci. Technol. 2020, 48, 45–53. [Google Scholar] [CrossRef]

- Li, Y.; Tian, J.; Guo, S.; Cai, B.; Ge, J. Research on Wellbore Cleaning Technology for Extended-Reach Wells in the East China Sea. J. Nat. Sci. 2023, 12, 187–195. [Google Scholar] [CrossRef]

- Dog Nose Plot—K&M Technology Group. Available online: https://kmtechnology.com/dog-nose-plot/ (accessed on 8 June 2025).

- Adnoc Drilling Claims Longest Well Record. Available online: https://www.energyvoice.com/oilandgas/middle-east/exploration-production-middle-east/453178/adnoc-drilling-record-zakum/ (accessed on 10 June 2025).

- Huang, W.; Gao, D. Analysis of Drilling Difficulty of Extended-Reach Wells Based on Drilling Limit Theory. Pet. Sci. 2022, 19, 211–222. [Google Scholar] [CrossRef]

- Mohammed, A.; Musab, A.; Bassam, A.; Kamran, A. An Innovative Approach Towards Real-Time Torque and Drag Model and Its Analysis-A Case Study. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 24–27 April 2017. [Google Scholar] [CrossRef]

- Rostagno, I. Friction Reduction Optimization for Extended Reach and Horizontal Wells. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, May 2019. [Google Scholar] [CrossRef]

- Livescu, S.; Craig, S. A Critical Review of the Coiled Tubing Friction-Reducing Technologies in Extended-Reach Wells. J. Pet. Sci. Eng. 2017, 155, 252–260. [Google Scholar] [CrossRef]

- Jia, J.; Yan, Z.; Dou, Y.; Huang, G.; Ma, Q. The New Method and Application of Friction Torque for Extended Reach Well. Adv. Pet. Explor. Dev. 2014, 8, 37–42. [Google Scholar] [CrossRef]

- Ihua-Maduenyi, I.E.; Oguta, E. Mechanistic Evaluation of Drill string Integrity in Extended Reach Wells Using Stiff String Torque and Drag Simulations under Variable Frictional Regimes. Int. J. Acad. Appl. Res. 2025, 9, 83–98. [Google Scholar]

- Oghenejoboh, K.M.; Ohimor, E.O. Application of Re-Refined Used Lubricating Oil as Base Oil for the Formulation of Oil-Based Drilling Mud-A Comparative Study. J. Pet. Sci. Eng. 2013, 4, 78–84. [Google Scholar]

- Geng, Y.; Zhang, Z.; Yan, Z.; Yuan, Y.; Zhou, X.; Yue, W. A Novel Graphene/Triolein Complex-Based Lubricant for Improving High-Temperature Water Based Drilling Fluid. RSC Adv. 2023, 49, 34772–34781. [Google Scholar] [CrossRef]

- Khan, M.A.; Al-Salim, H.S.; Leila, N. Development of High Temperature High Pressure (HTHP) Water Based Drilling Mud Using Synthetic Polymers, and Nanoparticles. Adv. Res. Fluid Mech. Therm. Sci. 2018, 45, 99–108. [Google Scholar]

- D’Amicis, S.; Pagani, M.; Matteucci, M.; Piroddi, L. Stuck Pipe Prediction from Rare Events in Oil Drilling Operations. Upstream Oil Gas 2023, 29, 125–140. [Google Scholar] [CrossRef]

- Dong, W.; Pu, X.; Ma, B. An Investigation on the Function of Mud Cakes on the Inhibition of Low Molecular Inhibitor for Water-Based Drilling Fluids. Energies 2019, 12, 3726. [Google Scholar] [CrossRef]

- Magzoub, M.I.; Ibrahim, M.H.; Nasser, M.S.; El-Naas, M.H.; Amani, M. Utilization of Steel-Making Dust in Drilling Fluids Formulations. Processes 2020, 8, 538. [Google Scholar] [CrossRef]

- Ezeakacha, C.P.; Salehi, S. Experimental Study of Drilling Fluid’s Filtration and Mud Cake Evolution in Sandstone Formations. J. Energy Resour. Technol. 2017, 139, 022912. [Google Scholar] [CrossRef]

- Yu, H.; Chen, Y.; Shu, Q.; Fang, F. Experimental Study of Friction Coefficient of Rocks in High Pressure and Tight Gas Reservoirs in Sichuan. Proc. Inst. Mech. Eng. 2018, 232, 678–687. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, Z.Q.; Wang, D.G. Friction and Wear Behavior of Wear-Resistant Belts in Drill Joints for Deep and Ultra-Deep Wells. Strength Mater. 2015, 47, 771–781. [Google Scholar] [CrossRef]

- Lei, Y.; Feng, Y.; Wu, Z.; Gao, Q.; Zhang, Z.; Wang, W.; Wang, L.; Wang, Y.; Wang, D. Monitoring of Lubrication and Wear In-Situ by Triboelectrification under Grease Lubrication. Friction 2025, 13, 9440938. [Google Scholar] [CrossRef]

- Cao-Romero-Gallegos, J.A.; Taghizadeh, S.; Aguilar-Rosas, O.A.; Dwyer-Joyce, R.S.; Farfan-Cabrera, L.I. The Effect of Electrical Current on Lubricant Film Thickness in Boundary and Mixed Lubrication Contacts Measured with Ultrasound. Friction 2024, 12, 1882–1896. [Google Scholar] [CrossRef]

- Huang, S.; Dong, T.; Jiang, G.; Yang, J.; Yang, X.; Wang, Q. Synthesis and Performance Evaluation of High-Temperature-Resistant Extreme-Pressure Lubricants for a Water-Based Drilling Fluid Gel System. Gels 2024, 10, 505. [Google Scholar] [CrossRef]

- Yang, L.L.; Liu, Z.Y.; Wang, S.B.; Zhu, Q.Q.; He, M.; Zhang, J. Chemical Modification of Barite for Improving Sag Stability of Weighted Water-Based Drilling Fluids. Pet. Sci. 2024, 21, 551–566. [Google Scholar] [CrossRef]

- NB/SH/T 0913-2015; Light White Oil. China Petrochemical Press: Beijing, China, 2015.

- API RP 13B-2-2023; Field Testing of Nonaqueous-Based Drilling Fluids. American Petroleum Institute: Washington, DC, USA, 2023.

- Zhang, C.; Guo, D.; Tian, J.; Niu, Q. Research on the Influencing Factors of Thermal Characteristics of High-Speed Grease Lubricated Angular Contact Ball Bearing. Adv. Mech. Eng. 2021, 13, 16878140211027398. [Google Scholar] [CrossRef]

| Sample | Test Time | AV (mPa·s) | PV (mPa·s) | YP (Pa) | 6/3 Reading |

|---|---|---|---|---|---|

| Base mud | BHR 1 | 36 | 24 | 12 | 11/9 |

| AHR | 32 | 23 | 11 | 10/8 | |

| Base mud + 2%PF-LUBE OB | BHR | 36 | 24 | 12 | 11/9 |

| AHR | 32 | 23 | 11 | 10/8 | |

| Base mud + 2%PF-LUBE EP | BHR | 36 | 24 | 12 | 11/9 |

| AHR | 32 | 23 | 11 | 10/8 | |

| Base mud + 2%CX-300 | BHR | 36 | 24 | 12 | 11/9 |

| AHR | 32 | 22 | 10 | 9/7 |

| Sample | FLAPI 2 | FLHTHP 3 |

|---|---|---|

| Base mud | 1.0 | 3.6 |

| Base mud + 2%PF-LUBE OB | 0.8 | 3.2 |

| Base mud + 2%PF-LUBE EP | 0.8 | 3.2 |

| Base mud+ 2%CX-300 | 0.8 | 3.4 |

| Sample | Invasion Depth (cm) 4 |

|---|---|

| Base mud | 2.4 |

| Base mud + 2%PF-LUBE OB | 2.2 |

| Base mud + 2%PF-LUBE EP | 2.2 |

| Base mud + 2%CX-300 | 3.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Wang, L.; Zheng, M.; Chen, B.; Wang, J.; Shu, F.; Tan, X. Evaluation and Optimization of Multi-Interface Lubrication Performance of Oil-Based Drilling Fluids for Extended-Reach Wells. Processes 2025, 13, 2620. https://doi.org/10.3390/pr13082620

Liu W, Wang L, Zheng M, Chen B, Wang J, Shu F, Tan X. Evaluation and Optimization of Multi-Interface Lubrication Performance of Oil-Based Drilling Fluids for Extended-Reach Wells. Processes. 2025; 13(8):2620. https://doi.org/10.3390/pr13082620

Chicago/Turabian StyleLiu, Wei, Lei Wang, Ming Zheng, Bo Chen, Jian Wang, Fuchang Shu, and Xiaoqi Tan. 2025. "Evaluation and Optimization of Multi-Interface Lubrication Performance of Oil-Based Drilling Fluids for Extended-Reach Wells" Processes 13, no. 8: 2620. https://doi.org/10.3390/pr13082620

APA StyleLiu, W., Wang, L., Zheng, M., Chen, B., Wang, J., Shu, F., & Tan, X. (2025). Evaluation and Optimization of Multi-Interface Lubrication Performance of Oil-Based Drilling Fluids for Extended-Reach Wells. Processes, 13(8), 2620. https://doi.org/10.3390/pr13082620