Abstract

Extended-reach drilling (ERD) offers substantial economic and operational benefits by accessing extensive reservoir sections with fewer surface facilities, yet poses significant frictional challenges due to complex wellbore geometries and extreme operating conditions. This study introduces a multi-interface lubrication evaluation framework. It systematically assesses oil-based drilling fluids (OBDFs) across three downhole contact scenarios: metal–rock, metal–mud cake, and metal–metal interfaces under HTHP conditions. We developed a quantitative, normalized scoring system. Benchmarked against distilled water (score 0) and W1-110 mineral oil (score 100), it integrates frictional data from various tests into a unified metric for lubricant comparison. Three candidate lubricants—PF-LUBE EP, PF-LUBE OB, and CX-300—were evaluated at varying dosages, lithologies, and applied loads. Results show that at 2 wt%, PF-LUBE EP achieved the most consistent performance, reducing friction coefficients by 36.8% (metal–rock), 27.5% (metal–mud cake), and 32.5% (metal–metal), with a normalized average score of 155.39, outperforming PF-LUBE OB and CX-300 by 12.5% and 18.3%, respectively. Its superior performance is attributed to a bionic dual-layer film formed by organophosphorus anchoring and alkyl slip layers, enabling self-healing and stability under cyclic loading and HTHP environments. PF-LUBE OB and CX-300 also demonstrated friction reduction but with lower normalized scores (138.06 and 131.27), reflecting less stability across varied conditions. The proposed framework bridges the gap between laboratory testing and field-scale application by capturing multi-interface behaviors, enabling objective lubricant selection and dosage optimization for complex ERD operations. These findings not only validate PF-LUBE EP as a robust additive but also establish a scalable methodology for the development and optimization of next-generation OBDF formulations aimed at reducing torque, drag, and equipment wear in challenging drilling environments.

Keywords:

ERD; OBDFs; friction reduction; lubrication performance; multi-interface; extreme pressure 1. Introduction

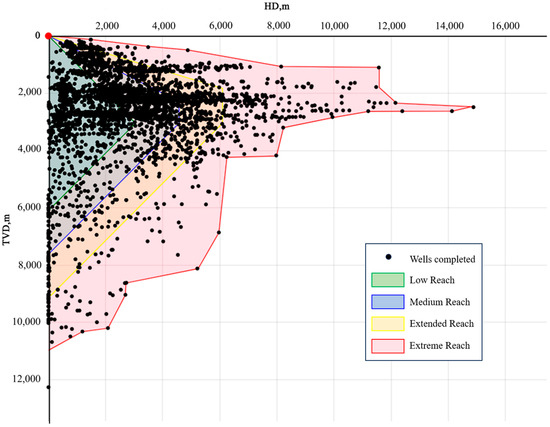

The ERD technology is currently widely used in oilfield development, particularly in offshore operations. Its primary advantage lies in the ability to cover a large area of reservoirs (especially thin layers or scattered oil reservoirs), while significantly reducing the number of drilling platforms and surface facilities required, cutting down development costs [1,2,3]. According to past experience, ERD can be classified into four types based on different horizontal–vertical ratio (HVR): low reach, medium reach, extended reach, and extreme reach, with an HVR exceeding 3.33 and horizontal displacements greater than 6096 m (20,000 ft) [4,5]. Figure 1 shows the drilling displacements worldwide [6]. It can be seen from the figure that with the demands of oilfield development and the advancement of technology, an increasing number of wells are located in the extremely extended reach area. Nowadays, the maximum well depth of extended-reach wells has exceeded 15,000 m, reaching 15,240 m (TVD of 2469 m and HD of 14,198 m) [7].

Figure 1.

Worldwide drilling displacements and classifications.

Despite these advancements, deeper ERD wells present a range of technical challenges, with friction being a primary concern [8]. Unlike vertical wells, ERD configurations involve much greater horizontal displacements. From a lateral perspective, the drill string bends under gravity and rests against the lower side of the wellbore wall [9,10]. This contact substantially increases the contact area and normal pressure, thereby resulting in a significant rise in frictional torque [11]. Jia et al. [12] investigated the frictional and torque behavior of drill strings in ERD wells by developing a modified three-dimensional soft-string model. Their model demonstrated strong predictive capabilities for well A but showed limitations when applied to large-scale or extreme-depth operations. Similarly, Ihua-Maduenyi et al. [13] conducted torque and drag simulations to evaluate drill string integrity under various frictional regimes, focusing on operations in the Niger Delta. Their findings emphasized the value of predictive modeling in mitigating downhole challenges. Nonetheless, they acknowledged the need for more robust models tailored to extreme wellbore conditions encountered in deep ERD scenarios.

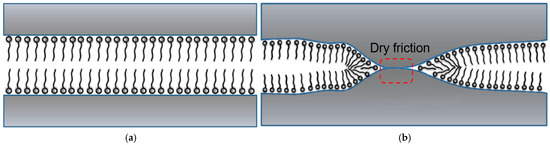

Oil-based fluids (OBDFs) are widely recognized for their superior lubricity, primarily attributed to the base oil component [14]. Compared with water-based drilling fluids, OBDFs exhibit significantly lower friction coefficients [15]. This advantage allows for the formation of a continuous and stable oil film between the drill string and the wellbore wall, which helps to minimize frictional resistance, reduce tool wear, and enhance drilling efficiency (Figure 2a). However, under extremely high-temperature and high-pressure (HTHP) conditions—typically above 150 °C and 30 MPa—the stability of the oil film deteriorates markedly [16]. The film becomes susceptible to rupture or desorption, leading to direct contact between the drill string and the wellbore or casing. This leads to a sharp increase in friction (Figure 2b), elevated consumption, and rising risks of downhole accidents such as pipe sticking, potentially interrupting operations and causing economic losses [17].

Figure 2.

Schematic diagrams of the lubrication mechanisms of oil-based drilling fluid under ideal conditions (a) and extreme pressure conditions (b).

In complex geological settings, particularly when drilling through low-permeability formations, filtration losses are minimal. As a result, the drilling fluid often fails to form an effective mud cake on the wellbore wall, leading to direct contact between the drill string and the exposed formation rock [18]. Conventional extreme-pressure lubrication tests typically assess steel–steel friction pairs, while mud cake adhesion tests examine steel–mud cake interfaces—neither of which fully replicates the range of actual downhole contact scenarios encountered in extended-reach drilling (ERD) operations [19,20]. Yu et al. [21] investigated the frictional behavior of rock surfaces under high-pressure conditions in tight gas reservoirs and highlighted the complexity of drill string–rock interactions. However, their work did not provide a comprehensive framework for steel–rock friction under ERD-specific conditions. Zhang et al. [22] examined wear-resistant materials used in drill joints for deep and ultra-deep wells, affirming the importance of lubrication in mitigating frictional wear. Yet, their research also fell short in addressing the nuanced friction dynamics specific to ERD environments, particularly where lubrication may be insufficient or absent due to formation properties.

In recent years, extensive efforts have been devoted to developing advanced methods for evaluating the lubrication performance of drilling fluid systems. Lei et al. [23] developed an in-situ monitoring system using triboelectric signals to simultaneously detect lubrication states and wear behavior, but their work was confined to grease-lubricated systems under vacuum, which did not simulate HTHP or multi-interface drilling environments. Cao-Romero-Gallegos et al. [24] examined lubricant film thickness using ultrasonic reflection to study electrical current effects, yet their tests were constrained by low loads (80 N) and short durations, insufficient to represent downhole stress conditions. Huang et al. [25] synthesized a high-temperature and high-salinity-resistant ester-based lubricant, but their evaluation was limited to metal–metal interfaces without addressing multi-interface dynamics. Similarly, Yang et al. [26] enhanced the rheological and lubrication properties of drilling fluids by modifying barite with surfactants; however, their four-ball friction tests operated at a modest 147 N load, and anti-wear properties were assessed qualitatively via wear scar inspection rather than through a unified, quantitative metric. Collectively, these studies highlight key shortcomings in current lubrication research, including oversimplified experimental conditions, inadequate representation of diverse contact interfaces, and a lack of standardized, quantitative evaluation frameworks.

To address these limitations, this study establishes a multi-interface lubrication evaluation framework that systematically assesses lubricant performance across metal–rock, metal–mud cake, and metal–metal interfaces representative of ERD. A quantitative, normalized scoring system—benchmarked against distilled water (baseline) and W1-110 mineral oil (reference standard)—is developed to integrate and compare frictional performance across disparate tests. Three candidate lubricants (PF-LUBE OB, PF-LUBE EP, and CX-300) are evaluated, with emphasis on dosage optimization, lithology-specific behavior, and load-dependent performance. The proposed framework not only identifies PF-LUBE EP as the most robust additive, with a friction reduction of up to 36.8% at the metal–rock interface, but also provides a reproducible and scalable methodology for lubricant screening and optimization in challenging ERD environments, bridging the gap between laboratory evaluation and field application.

2. Materials and Methods

2.1. Materials

W1-110 mineral oil was used in accordance with the NB/SH/T 0913-2015 standard for Light White Oil [27]. Analytical-grade calcium chloride was employed. Additional materials for the preparation of OBDFs—including primary emulsifier PF-EMUL, auxiliary emulsifier PF-COAT, organoclay PF-HIVIS, alkalinity regulator PF-MOALK, plugging agent PF-MOLSF, filtrate reducer PF-MOHFR, gel-strength enhancer PF-HIRHEO-3, lubricants (PF-LUBE OB, PF-LUBE EP, CX-300), and weighting agents—were supplied by China Oilfield Services Limited (COSL) Shanghai Branch (Shanghai, China).

2.2. Experiment Apparatus

The HZKM-2 extreme pressure and anti-wear tester (Baoding Huazheng Electric, Baoding, Hebei, China) was used to evaluate lubrication under high-load conditions. The NZ-3A mud cake adhesion coefficient tester (Qingdao Haitongda, Qingdao, Shandong, China) and the 112-00-C-EP lubricity tester (OFI Testing Equipment, Houstion, TX, USA) were employed for interface-specific measurements. Additional apparatus used for testing OBDFs complied with the API RP 13B-2-2023 standard Field Testing of Nonaqueous-Based Drilling Fluids [28].

2.3. Methods

Before evaluating the improvement effect of the lubrication performance at each interface, it is necessary to assess its impact on the properties of the oil-based drilling fluid, so as to avoid adverse effects on the drilling fluid properties after its addition.

2.3.1. Drilling Fluid Properties

The oil-based drilling fluid was formulated as follows: 340 mL of W1-110 mineral oil, 60 mL of 25 wt% CaCl2 aqueous solution, 19.2 g of primary emulsifier (PF-EMUL), 4.8 g of auxiliary emulsifier (PF-COAT), 12 g of organoclay (PF-HIVIS), 12 g of alkalinity regulator (PF-MOALK), 12 g of plugging agent (PF-MOLSF), 12 g of filtrate reducer (PF-MOHFR), and 3.2 g of gel-strength enhancer (PF-HIRHEO-3). Weighting materials were then added to adjust the fluid density to 1.5 g/cm3.

The rheological and performance characteristics of the prepared oil-based drilling fluid were tested before and after hot-rolling at 150 °C, following procedures outlined in API RP 13B-2-2023 Field Testing of Nonaqueous-Based Drilling Fluids [28].

2.3.2. Friction Test at the Metal–Rock Interface

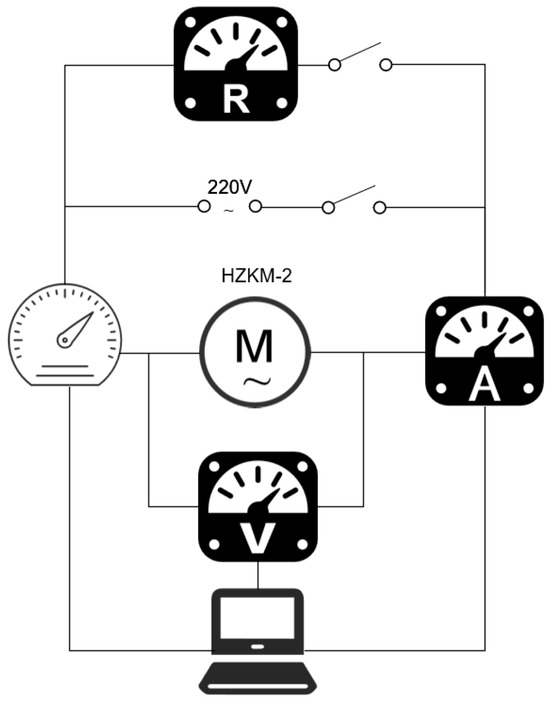

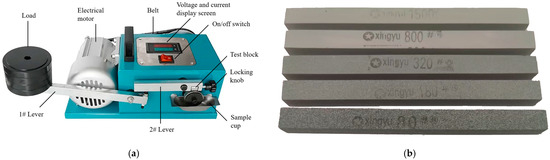

A schematic diagram of the metal–rock interface friction test apparatus is shown in Figure 3. The core testing unit is the HZKM-2 extreme pressure and anti-wear tester, which operates using an electric motor-driven rotating mechanism. On the left side of the setup, a tachometer is employed to monitor rotational speed, while a volt-ammeter measures real-time voltage and current outputs. Upon completion of the test, the circuit is switched, and a multimeter is used to measure the total resistance of the system. All time-dependent measurement data are collected and transferred to a computer for further analysis. In this test, the friction coefficient is calculated using the principle of energy conservation. The testing apparatus measures the total power changes in the rotating mechanism under applied loads. The energy loss due to friction is calculated, and the friction coefficient is derived accordingly. This method provides an accurate friction coefficient by evaluating the energy conversion during the friction process, highlighting the lubricant’s ability to reduce friction at the metal–rock interface.

Figure 3.

Instrument schematic diagram of metal–rock interface friction test.

The physical configuration of the HZKM-2 tester is illustrated in Figure 4a. Notably, the sliding component in contact with the sample is interchangeable. A steel slider is used initially to simulate steel–steel friction conditions. In this study, we replaced the steel slider with custom-fabricated artificial sandstone specimens (Figure 4b), prepared by cutting quartz-based sandstone blocks with varying particle sizes into 1 cm-long cuboids, to mimic formation rocks of different permeabilities.

Figure 4.

HZKM-2 extreme pressure and anti-wear tester (a) and artificial sandstones (b).

The overall power of the instrument includes the kinetic energy change of the drive shaft, the internal frictional resistance of the instrument, the frictional resistance of the slider, and the current thermal effect. It can be expressed as follows:

where P is the total power, W; ΔPk is the kinetic energy change of the drive shaft, W; Pi is the internal frictional resistance of the instrument, W; Pf is the frictional resistance of the slider, W; PQ is the current thermal effect, W; I is the current, A; R is the resistance of instrument, Ω.

When the instrument rotates steadily, the kinetic energy of the drive shaft remains unchanged, and the power generated by the current is zero, that is

In the no-load condition, P0 reflects the internal frictional resistance of the instrument.

Since the heat generated by friction is proportional to the angular velocity, the interfacial friction coefficient can be expressed as follows [29]:

where D is the diameter of the ring, cm; fr is the friction coefficient of metal–rock interface; F is the contact load, N; ω is the angular velocity of the rotating shaft, rad/s.

So, we obtained the friction coefficient of the metal–rock interface according to Equations (1)–(4):

During the test, first turn on the switch and let the instrument rotate under no-load conditions for 15 min, then read the stable current I0 at this time. After turning off the switch, use a multimeter to measure the resistance R0 of the entire instrument. Put the simulated core in, and pour oil-based drilling fluid into the sample cup. After assembling the 1# and 2# levers, add a 1 kg load. Turn on the switch again, run it for 5 min, and read the stable current I1 and stable rotational speed ω at this time. After turning off the switch, use a multimeter to measure the resistance R1 of the entire instrument again.

2.3.3. Friction Test at the Metal–Mud Cake Interface

The friction behavior at the metal–mud cake interface was assessed using the NZ-3A mud cake adhesion coefficient tester (Figure 5). Prior to testing, mud cakes were prepared via an API fluid loss test on OBDFs subjected to hot rolling. The mud cake formed after a 30-minute test was collected for evaluation. This test evaluates the friction behavior between a metal block (simulating the drill string) and the mud cake formed along the wellbore wall. The friction force is a result of the balance between gravitational forces and the adhesive friction generated at the metal–mud cake interface. As the sliding plate tilts, the frictional resistance increases, which reflects the ability of the lubricant to reduce the interfacial adhesion and mechanical interlocking. This balance is crucial in preventing sticking and reducing drag during drilling operations, especially in environments where mud cake formation is critical.

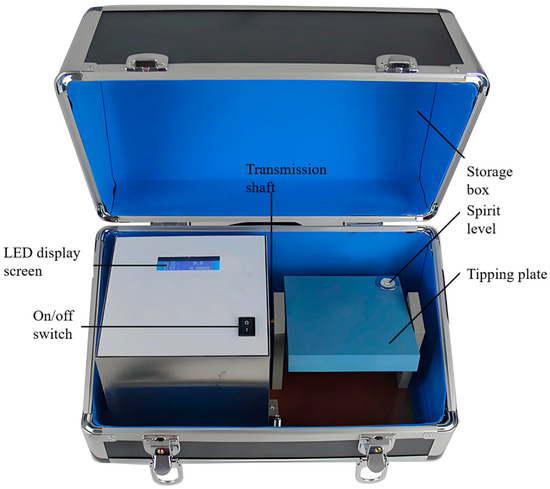

Figure 5.

NZ-3A mud cake adhesion coefficient tester.

To initiate the test, the sliding plate was rotated to a horizontal position, and the three leveling wheels located beneath the outer shell were adjusted to center the bubble in the spirit level. The zero-reset button was then pressed to calibrate the angle on the LCD display to zero. The prepared mud cake was gently placed onto the surface of the sliding plate, followed by the careful positioning of a metallic sliding block on top. The setup was allowed to rest undisturbed for one minute to stabilize the interface contact. Subsequently, the start/stop button was pressed to activate the micromotor, which gradually tilted the sliding plate via a transmission mechanism. When the sliding block began to move, the start/stop button was pressed again to halt the device. The critical tilt angle at which motion occurred was recorded from the LCD screen.

The friction coefficient between the metal and mud cake interface (fc) was calculated as the tangent of the measured angle θ, using the following equation:

where fc is the friction coefficient of metal–mud cake interface; θ is the angle at which the sliding block starts to slide.

2.3.4. Friction Test at the Metal–Metal Interface

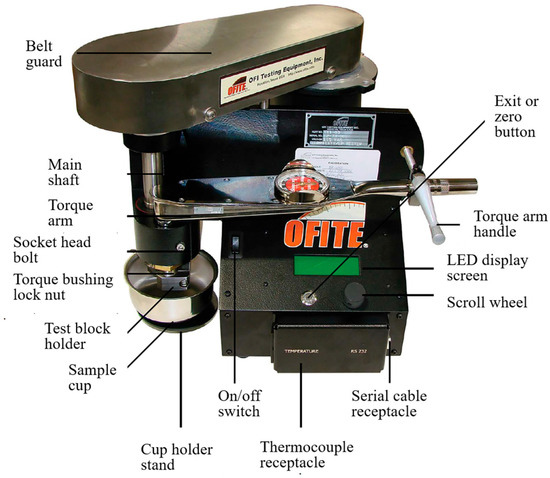

The frictional performance between metallic surfaces was evaluated using a standardized lubricity tester, as shown in Figure 6. To conduct the lubricity test, first clean the lubricity test ring and the test block with acetone, followed by thorough rinsing with deionized water, ensuring all machine parts in the sample area are spotless and avoiding bare-hand contact with metal surfaces. Install the test ring on the tapered main shaft, and preheat the machine for 15 min. Set the motor speed to 60 RPM, place the test block in the holder with the concave side outward, and zero the torque reading after 15 min of operation. This test evaluates the frictional performance between metallic surfaces by applying a constant torque. The friction force is primarily governed by the balance of applied torque and the frictional resistance between the metal surfaces. As the torque is applied, the lubricant’s effectiveness in reducing friction is measured by the torque required to maintain a constant rotational speed. This balance between the applied torque and the frictional resistance reflects the lubricant’s ability to reduce wear and friction under the high axial loads commonly encountered in drilling operations.

Figure 6.

112-00-C EP and lubricity tester.

After the instrument is preheated, fill the stainless-steel cup with 260–280 mL of the test fluid, submerge the ring, block, and holder, and zero the torque again. Position the torque arm, apply 150 inch-pounds of torque, start the timer, record the torque reading after 5 min, and release the torque. Use water as a reference with a friction coefficient of 34 ± 2 at 60 RPM and 150 inch-pounds; if outside this range, do not proceed. Calculate the friction coefficient of the metal–metal interface as follows:

where fm is the friction coefficient of the metal–metal interface; Nm is the torque reading for mud (oil-based drilling fluid); and Nw is the torque reading for distilled water.

3. Results

3.1. Base Properties

3.1.1. Rheological Properties

A six-speed rotational viscometer was employed to determine the rheological properties of OBDFs containing 2 wt% lubricant. The results are summarized in Table 1. Hot-rolling was carried out at 150 °C for 16 h to simulate the high-temperature conditions encountered during down-hole circulation. As shown in Table 1, the viscosity of the base fluid decreased after hot-rolling. This reduction is attributable to the thermally induced desorption of surfactants from the organoclay, which converts surface-bound, water-wetted bentonite into oil-wetted organoclay; the diminished lipophilicity weakens its viscosity-enhancing capability.

Table 1.

Influence of different lubricants on rheological properties of oil-based drilling fluids.

The addition of lubricants had little influence on the fluid’s rheology, indicating that cuttings-transport performance remains adequate for normal drilling operations. A slight post-rolling viscosity decline was observed for the CX-300-treated system, probably because ester-based lubricants undergo hydrolysis at elevated temperatures, producing fatty acids that react with the alkalinity regulator, thereby lowering system alkalinity and hindering organoclay dispersion.

3.1.2. Plugging Properties

- Filtrate loss

The filtrate loss is a critical parameter in evaluating the performance of drilling fluids. When filtrate from the drilling fluid invades the formation, it can gradually transmit hydrostatic pressure from the wellbore to the surrounding strata. This pressure transmission elevates near-wellbore stress and may contribute to wellbore instability. The effects of different lubricants on the filtration behavior of OBDFs are summarized in Table 2. Results indicate that the addition of lubricants had minimal impact on both standard API and HTHP filtrate loss.

Table 2.

Influence of different lubricants on filtrate loss of oil-based drilling fluids.

- 2.

- Sand bed test

The sand bed test offers direct insight into the depth of filtrate invasion, using quartz sand to simulate reservoir rock. The invasion depths of OBDFs formulated with different lubricants are presented in Table 3. Among the tested systems, the fluid containing CX-300 exhibited a notably deeper invasion depth compared to the others. This effect is likely due to the adsorption of the lubricant onto the quartz surface, which alters the surface wettability and capillary pressure, thereby facilitating filtrate penetration into the formation. Such behavior may pose potential operational risks during drilling.

Table 3.

Influence of different lubricants on invasion depth of oil-based drilling fluids.

3.2. Lubricating Properties

Before conducting the lubrication performance tests, a base mud was prepared following the standard formulation. Different types and dosages of lubricants were then added to the base mud. The mixtures were subjected to hot rolling at 150 °C for 16 h and subsequently cooled to room temperature. To simulate shear conditions typical of drilling operations, each sample was further sheared at 10,000 rpm using high-speed mixing for 20 min. Lubrication tests were then performed on the conditioned fluids.

3.2.1. Friction Coefficient of Metal–Rock Interface

- Influence of Dosage

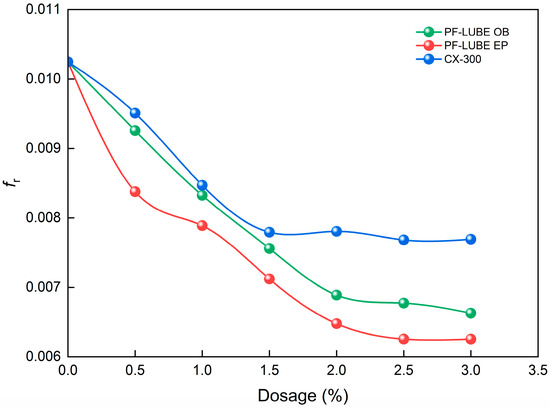

The amount of lubricant added is a key factor influencing the friction coefficient. Through friction performance tests at the metal–rock interface, we found that at the initial stage of lubricant addition, the friction coefficient decreased significantly. This effect is attributed to the lubricant’s ability to fill microscopic surface irregularities between the metal and rock, thereby smoothing the contact interface and reducing friction. Figure 7 shows the friction coefficient of the metal–rock interface under various lubricants and dosage levels.

Figure 7.

Changes in the metal–rock friction coefficient under different addition dosages.

For PF-LUBE EP, increasing the concentration from 0% to 2 wt% reduced the metal–rock friction coefficient from 0.010246 to 0.006478, reflecting a reduction ratio of 36.8%. This decline suggests that 2 wt% represents the saturation point for surface adsorption and lubricating film formation. A further increase to 3 wt% yielded only a slight improvement, lowering the coefficient to 0.006255 (an additional 2.3% reduction).

For CX-300, the minimum friction coefficient was observed at 1.5 wt%, indicating that surface adsorption reaches saturation at this dosage. Additional increases in lubricant concentration did not significantly enhance performance, suggesting diminishing returns beyond the saturation threshold.

From a cost-effectiveness perspective, it is essential to optimize lubricant dosage based on specific operational conditions to minimize additive costs without compromising performance. Based on these findings, a 2 wt% lubricant concentration was selected as the benchmark for all subsequent experimental evaluations.

- 2.

- Influence of load

The influence of applied load on the friction coefficient is also non-negligible. Under extreme pressure conditions, rupture of the lubricating oil film is the primary cause of the rapid increase in friction. In the test setup, the unit load applied to the contact surface was amplified 28-fold through the combined action of the primary (lever #1) and secondary (lever #2) force arms.

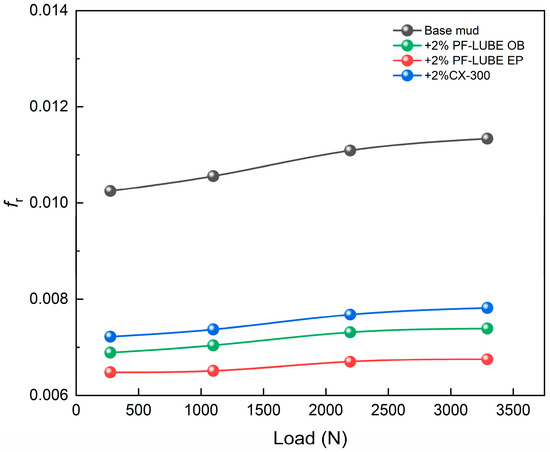

During the experiment, the system was first operated under a constant load for 5 min to ensure stable performance. The load was then incrementally increased, and testing continued for an additional 5 min. Friction coefficients under different loading conditions were calculated and are presented in Figure 8.

Figure 8.

Changes in the metal–rock friction coefficient under different loads.

At the standard load of 1 kg—equivalent to 28 kg or approximately 274.4 N at the contact surface—the friction coefficient of the base fluid was measured at 0.10246. With the addition of 2 wt% PF-LUBE OB, the coefficient was significantly reduced to 0.00689. However, when the applied load was increased to 12 kg, the coefficient rose to 0.1134, reflecting a 10.6% increase relative to the initial condition. This increase is attributed to the partial breakdown of the lubricating film under higher stress.

As shown in Figure 8, when the lubricant concentration is held constant, the friction coefficient generally increases with rising applied load. This trend is attributed to the increased number of asperity contact points between the metal and rock surfaces under higher load, which leads to elevated contact pressure and enhanced adhesive friction.

Although the addition of lubricant moderates the rate of increase in the friction coefficient, the distribution and stability of the lubricant film become critical determinants of frictional behavior under high-load conditions. Thus, maintaining the structural integrity and effectiveness of the lubricating film is essential for achieving optimal lubrication performance in extreme loading environments.

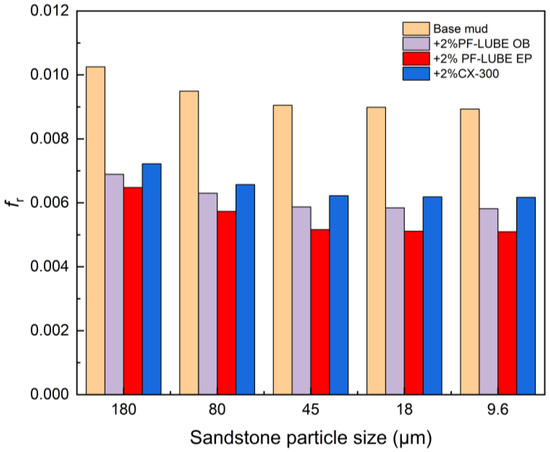

- 3.

- Influence of formation

In the laboratory, artificial sandstones with varying particle sizes were used to simulate the effects of different geological formations on the friction coefficient. The particle sizes ranged from 180 μm to 9.6 μm, representing a spectrum from coarse sandstone to siltstone formations. The corresponding friction coefficients are presented in Figure 9. Experimental results demonstrate that rock type significantly influences lubricant performance. When simulating drilling through formations with particle sizes decreasing from 180 μm (coarse sandstone) to 9.6 μm (siltstone), the friction coefficient associated with PF-LUBE EP decreased from 0.006478 to 0.005092—a 21.4% reduction. This decline is attributed to the smoother contact interfaces and lower permeability of fine-grained formations, which facilitate the formation of a stable, continuous oil film and thus reduce friction more effectively.

Figure 9.

Changes in the metal–rock friction coefficient under different formations.

In contrast, high-permeability sandstones or crushed rocks present rougher and more irregular contact surfaces. These conditions hinder the uniform distribution of the lubricant and compromise the integrity of the lubricating film, resulting in elevated friction coefficients.

However, under actual drilling conditions, the friction interface varies depending on the formation permeability. In high-permeability formations, filtrate from the drilling fluid readily invades the formation, leading to the formation of a mud cake along the wellbore wall. As a result, the friction coefficient between the drill string and the mud cake becomes the primary parameter of interest.

As low-permeability formations typically do not allow sufficient filtrate invasion to form an effective mud cake. Under such conditions, dry contact occurs between the drill string and the bare formation rock, often under high axial loads. This scenario poses a greater frictional challenge and is therefore the key concern when drilling through tight formations.

It is important to note, however, that the reduced friction coefficients observed in laboratory simulations of low-permeability formations do not necessarily indicate improved operational lubricity in the field. In real drilling conditions, such formations often do not allow the development of a continuous mud cake due to limited filtrate invasion. As a result, the drill string may come into direct contact with bare formation rock under high axial stress, leading to increased abrasive wear and frictional resistance. Therefore, the frictional advantages seen in fine-grained artificial rock specimens should be interpreted within the limitations of static laboratory conditions.

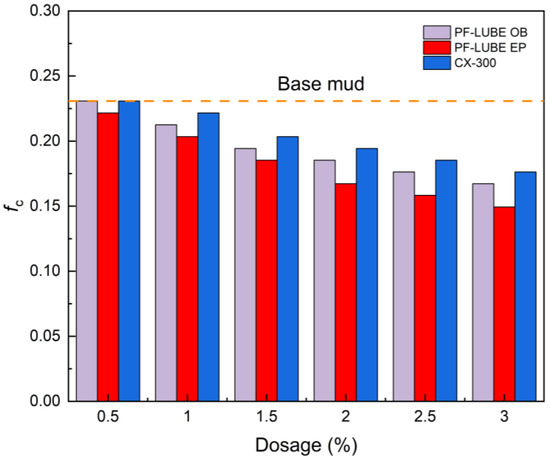

3.2.2. Friction Coefficient of Metal–Mud Cake Interface

When the drill string contacts the mud cake, interfacial lubrication directly influences torque and drag during drilling operations. Inadequate lubrication at this interface can lead to increased friction, resulting in drill string sticking or jamming. To evaluate this behavior, a friction test was conducted between a metal block (simulating the drill string) and an API-standard mud cake (simulating the filter cake formed along the wellbore wall), thereby replicating the metal–mud cake interface encountered in real drilling scenarios.

This test enables the assessment of mud cake lubricity and anti-sticking performance, offering guidance for drilling fluid formulation adjustments to mitigate the risk of stuck pipe incidents. The experimental results for various lubricants are presented in Figure 10. Quantitatively, the base mud exhibited a friction coefficient of 0.23075. With the addition of 2 wt% PF-LUBE EP, the coefficient was reduced to 0.16726, representing a 27.5% decrease. Under the same dosage, PF-LUBE OB and CX-300 achieved coefficients of 0.18524 and 0.19428, corresponding to reductions of 19.3% and 15.8%, respectively, compared to the base mud.

Figure 10.

Comparison of metal–mud cake interfacial friction coefficients of different lubricants.

The superior lubricating performance of PF-LUBE EP may be attributed to its ability to chemically interact with both the metallic surface and the mud cake, forming a semi-permanent boundary film. This film potentially prevents direct metal-to-cake contact and reduces adhesive friction. Furthermore, the enhanced hydrophobicity of the PF-LUBE EP–treated mud cake likely reduces mechanical interlocking between the drill string and filter particles, thereby contributing to lower drag forces.

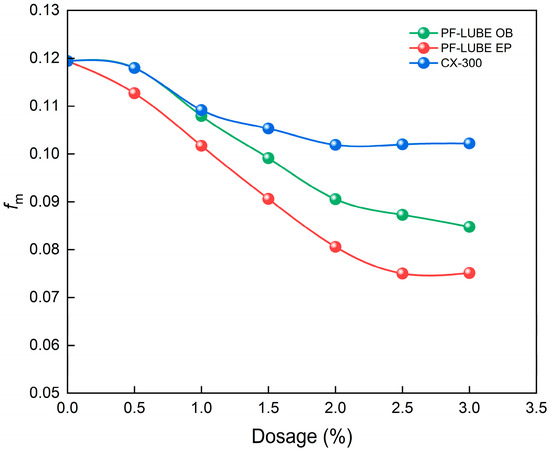

3.2.3. Friction Coefficient of Metal–Metal Interface

Due to the substantial axial load applied during drilling, the drill string is subject to deformation and bending, which causes it to come into contact with the upper casing. This phenomenon is particularly pronounced in extended-reach drilling (ERD) operations. Such contact can result in wear on either the drill string or the casing, posing a significant risk of downhole failure or equipment damage. The friction coefficients at the metal–metal interface, as measured under different lubricant conditions, are presented in Figure 11.

Figure 11.

Changes in the friction coefficient under different lubricants.

As illustrated in Figure 11, all three lubricants contributed to a reduction in the metal–metal friction coefficient, with PF-LUBE EP exhibiting the most pronounced effect. The base mud displayed a friction coefficient of 0.11943, whereas the addition of 2 wt% PF-LUBE EP reduced this value to 0.08058—a 32.5% decrease.

PF-LUBE OB and CX-300 also demonstrated notable improvements, reducing the friction coefficient by 24.2% and 17.2%, respectively, compared to the base mud.

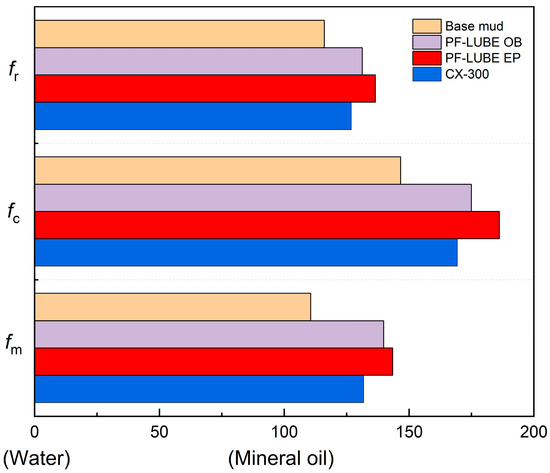

3.3. Quantitative Evaluation of Lubricants

Due to the differences in test apparatus, interfacial mechanics, and evaluation methodologies across the metal–rock, metal–mud cake, and metal–metal interfaces, direct comparison of absolute friction coefficients lacks inherent consistency. To enable a unified and objective assessment of lubricant performance, a normalized scoring system was established. In this framework, distilled water was designated as the baseline (score = 0), and W1-110 mineral oil served as the optimal reference (score = 100). The friction coefficients obtained under each interfacial condition were normalized via linear transformation and subsequently integrated using a weighted average to yield a comprehensive performance score (Figure 12).

Figure 12.

Quantitative comparison of multi-interfacial friction coefficients of different lubricants.

Among the tested candidates, PF-LUBE EP achieved the highest overall score of 466.17 (155.39 on average), indicating superior and well-balanced performance across all three interfaces. At the metal–rock interface, PF-LUBE EP reduced the friction coefficient to 0.00648, compared to 0.02294 for water and 0.01146 for W1-110 mineral oil, yielding a normalized score of 143.45—outperforming PF-LUBE OB and CX-300 by 2.6% and 8.7%, respectively. At the metal–mud cake interface, the coefficient decreased to 0.16726, corresponding to a score of 186.19, again surpassing PF-LUBE OB (174.99) and CX-300 (169.35). For the metal–metal interface, PF-LUBE EP achieved a coefficient of 0.08058 and a normalized score of 136.54, marking a 17.6% improvement relative to base mud.

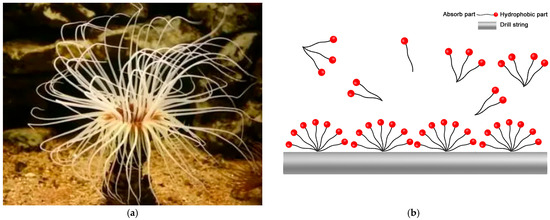

A key finding of this analysis is the consistency and robustness of PF-LUBE EP under varying conditions, including dosage levels, applied loads, and simulated formation lithologies. This superior performance is attributed to its molecular architecture: the organophosphorus groups form strong coordination bonds with Fe atoms on the metal surface, generating a stable “anchoring layer,” while the outward-oriented alkyl chains establish a mobile “slip layer.” This dual-layer structure, inspired by the bionic architecture of sea anemones, enables the formation of a self-repairing lubricating film that resists microcrack propagation and pressure-induced breakdown.

The proposed multi-interface scoring framework offers a systematic and quantitative approach for screening and optimizing lubricants in ERD applications. It facilitates rational formulation design under complex wellbore geometries and heterogeneous lithologies, ultimately improving drilling safety, efficiency, and cost-effectiveness.

4. Discussion

4.1. Lubrication Mechanism

PF LUBE EP’s outstanding performance stems from its unique molecular architecture and biomimetic lubrication mechanism. The organophosphorus groups form strong coordination bonds with Fe atoms on metal surfaces, creating a chemically adsorbed anchoring layer. Meanwhile, the flexible alkyl chains extend outward into the oil medium, forming a dynamic slip layer that handles shear deformation at the lubricant–fluid interface. Inspired by sea anemones’ dual-layer structure, this setup enables a self-healing lubricating film. It withstands microcrack disturbances and high-pressure conditions in ERD operations (Figure 13).

Figure 13.

Bionic sea anemone lubrication mechanism of PF-LUBE EP. Bionic sea anemone lubrication mechanism of PF-LUBE EP: (a) sea anemone adsorption, and (b) bionic mechanism.

This anchoring mechanism ensures exceptional shear stability and self-repair capability, preventing direct metal-to-metal contact and reducing wear—even under extreme downhole environments. Unlike conventional lubricants that suffer from film rupture or molecular desorption under HTHP conditions, PF-LUBE EP maintains interfacial integrity. Its robust self-healing behavior ensures continued effectiveness under extreme ERD conditions, such as high axial loads and abrasive contact.

Under metal–rock contact conditions, PF-LUBE EP exhibits a remarkable ability to preserve film structure even as loading increases. This feature is especially critical in tight formations, where low permeability hinders mud cake formation, resulting in direct metal–rock contact under high axial stress. In these scenarios, PF-LUBE EP outperforms other lubricants such as CX-300 and PF-LUBE OB in terms of both absolute friction reduction and normalized coefficient values. At the metal–mud cake interface, PF-LUBE EP reduces adhesive interactions by altering surface energy and enhancing hydrophobicity. This promotes the formation of a semi-permanent boundary film that resists mechanical interlocking, thereby improving the anti-sticking properties of the drilling fluid.

Collectively, these lubrication mechanisms translate into meaningful operational improvements in ERD drilling, including reduced risks of pipe sticking, torque spikes, and tool failure. However, it is important to recognize that these benefits rely on the strong coordination between organophosphorus groups and iron atoms on metal surfaces. Excessive organophosphorus may remain free in the drilling fluid, raising potential environmental concerns. Future studies should investigate the consumption of active phosphorus groups via simulated interactions with drill cuttings and interfacial adsorption, to evaluate the environmental impact of residual phosphorus compounds.

4.2. Experimental Conditions and Limitations

The HZKM-2 extreme pressure tribometer employed in this study provides a maximum loading capacity of 3292.8 N (approximately 50 MPa), allowing for simulation of realistic downhole stress conditions. Compared with conventional tribological test setups, this instrument enables a closer approximation of ERD operational stress environments, making it particularly suitable for evaluating lubricant performance under high axial loads.

Nonetheless, several limitations in the experimental design should be acknowledged. Although hot rolling was used to simulate thermal aging of the lubricants, real-time high-temperature tribological evaluation was constrained by instrument capability. The friction tests were conducted at ambient temperature, with interface temperatures rising above 100 °C only due to frictional heating. As such, the tests did not fully replicate the sustained thermo-mechanical coupling typical of actual ERD conditions.

Test results also revealed that friction coefficients are significantly influenced by geological parameters such as lithology and formation permeability. Experiments using artificial sandstones of varying grain sizes simulated different formation types and highlighted how smaller grain sizes (e.g., 9.6 μm, simulating siltstone) promote lubricant dispersion and film formation. However, caution is warranted when extrapolating these laboratory findings to field applications. In reality, tight formations often exhibit minimal filtrate loss, preventing effective mud cake development. This results in more frequent direct contact between the drill string and the formation under axial stress, a situation that is more abrasive and friction-intensive than suggested by static lab tests. Therefore, the observed improvements in lubrication under tight formation conditions may underestimate the actual frictional challenges encountered during ERD operations.

Future improvements to the experimental platform should incorporate real-time thermal control, cyclic loading, variable shear rates, and multiphase flow testing to better simulate field environments. Additionally, the inclusion of real reservoir core samples would enhance the relevance of the findings for practical drilling operations.

4.3. Evaluation Framework and Methodological Expansion

This study introduces a standardized, quantitative scoring framework for multi-interface lubricant evaluation. Friction coefficients measured across metal–rock, metal–mud cake, and metal–metal interfaces were normalized and integrated into a weighted average score. PF-LUBE EP achieved a high cumulative score of 155.39, confirming its superior cross-interface performance.

However, the current equal-weight scheme assumes that all interface types are equally critical, which may not reflect real ERD operations. For instance, in tight formations with minimal mud cake development, metal–rock friction dominates; in unconsolidated sands, metal–mud cake interactions are more relevant. A more flexible, scenario-specific weighting system is needed to account for varying formation characteristics and operational priorities.

Future research should explore multi-objective optimization frameworks such as analytic hierarchy process (AHP) or multi-criteria decision making (MCDM). These methods would allow for interface-specific weighting based on formation properties, drilling parameters, and operational goals. Integration of fuzzy logic or machine learning algorithms could further enhance the system’s ability to capture complex, nonlinear relationships and predict lubricant performance under a wide range of operating conditions. Notably, because lubricant addition in drilling operations is typically discontinuous, understanding how lubricity degrades over time due to cuttings contamination and interfacial consumption is critical. Intelligent modeling based on big data could inform when re-dosing is necessary and support smarter decision-making in lubricant selection, formulation, and operational planning.

4.4. Implications for ERD Operations

PF-LUBE EP demonstrated exceptional practical performance across the three primary downhole contact interfaces encountered in ERD drilling. At the metal–rock interface, it achieved a 36.8% reduction in friction coefficient (from 0.010246 to 0.006478), directly addressing the challenge of mud cake deficiency in tight formations where high axial loads frequently result in metal–rock contact. This friction reduction is crucial for mitigating pipe sticking and ensuring smooth drill string movement in low-permeability formations.

At the metal–mud cake interface, the friction coefficient was reduced by 27.5% (from 0.23075 to 0.16726), effectively lowering the risk of differential sticking and enhancing hole cleaning. Improved mud cake hydrophobicity reduced mechanical interlocking between the drill string and filter cake particles, resulting in decreased resistance and enhanced drilling performance. These improvements are especially critical in ERD operations, where differential sticking and poor hole cleaning are common challenges.

At the metal–metal interface, the friction coefficient decreased by 32.5% (from 0.11943 to 0.08058), enhancing tool life and reducing casing wear—both of which are vital in complex ERD wellbores where drill string–casing contact is frequent due to hole geometry and gravitational effects. PF-LUBE EP’s consistent performance across a range of formation types—from coarse sandstone (180 μm) to fine siltstone (9.6 μm)—underscores its versatility and adaptability to the diverse geological conditions encountered in ERD drilling.

Importantly, these lubrication improvements were achieved without compromising other critical drilling fluid properties, including rheology, filtrate loss, and invasion depth. For example, sand-bed invasion depth with PF-LUBE EP was only 2.2 cm, compared with 3.0 cm for CX-300, indicating reduced fluid penetration into formations. This lowers the rate of pressure transmission from the wellbore to the formation, thereby improving wellbore stability—a particularly beneficial effect in the high-risk, pressure-sensitive environments of ERD applications.

In this study, the optimal dosage was determined under a single base oil system (W1-110 mineral oil). However, it is important to recognize that different base oils exhibit varying polarities, viscosities, and thermal stability, all of which can affect lubricant dispersion, adsorption behavior, and film-forming capacity. These factors, in turn, influence the effective concentration required to achieve optimal lubricating performance. Future work should include comparative tests under different base oil systems to refine dosage recommendations and ensure broad applicability across diverse operational environments.

5. Conclusions

Through a systematic evaluation of three oil-based drilling fluid lubricants—PF-LUBE EP, PF-LUBE OB, and CX-300—under representative ERD conditions, this study delivers the following key conclusions:

- PF-LUBE EP demonstrated the highest overall lubricating efficiency, reducing friction coefficients by 36.8% at the metal–rock interface (from 0.01025 to 0.00648), 27.5% at the metal–mud cake interface (from 0.23075 to 0.16726), and 32.5% at the metal–metal interface (from 0.11943 to 0.08058) at a dosage of 2 wt%. Its normalized multi-interface score reached 155.39 (baseline mineral oil = 100), confirming its robustness across varied lithologies and axial loads.

- The superior performance of PF-LUBE EP is attributed to its bionic dual-layer molecular structure, in which organophosphorus groups form a chemically adsorbed “anchoring layer” on metallic surfaces, while outward-oriented alkyl chains create a flexible “slip layer.” This architecture enables self-healing film formation, resistance to microcrack propagation, and sustained friction reduction even under cyclic loading and extreme pressure surges.

- Lubricant dosage optimization is critical for cost-effective performance. For PF-LUBE EP, 2 wt% represents the saturation point for adsorption and film integrity. Beyond this dosage, additional friction reduction was minimal (only 2.3% at 3 wt%), supporting a dosage strategy that balances additive cost with operational efficiency.

- The multi-interface quantitative scoring framework, benchmarked against distilled water (0) and W1-110 mineral oil (100), provides a standardized and reproducible method for lubricant evaluation. By integrating results across metal–rock, metal–mud cake, and metal–metal tests, this approach bridges laboratory characterization with field-scale decision-making, enabling more reliable additive selection and formulation for complex ERD operations.

- The findings establish a technical foundation for improving OBDF formulations to mitigate frictional risks—including torque spikes, stuck pipe, and tool or casing wear—in offshore and onshore ERD wells. Future research should focus on incorporating dynamic testing protocols (circulation, cyclic shear, and evolving mud cake behavior) and developing a multi-objective optimization framework that balances friction reduction, additive cost, and environmental compliance.

Collectively, these outcomes not only validate PF-LUBE EP as a robust additive for challenging ERD environments but also demonstrate the value of the proposed multi-interface framework as a practical tool for next-generation drilling fluid design and optimization.

Author Contributions

Conceptualization, W.L. and L.W.; methodology, F.S.; validation, X.T. and J.W.; formal analysis, X.T.; investigation, J.W.; resources, B.C.; data curation, X.T.; writing—original draft preparation, X.T.; writing—review and editing, J.W.; visualization, X.T.; supervision, F.S.; project administration, W.L.; funding acquisition, M.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Research on Drilling Fluid Technology Optimization for Ten-thousand-meter Extended-reach Wells in the East China Sea, grant number CCL2024SHPS006ET.

Data Availability Statement

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

Acknowledgments

The authors thank the anonymous reviewers for their valuable comments and suggestions.

Conflicts of Interest

Authors Wei Liu, Lei Wang and Ming Zheng were employed by China National Offshore Oil Corporation Limited Shanghai Branch. Author Bo Chen was employed by China Oilfield Services Limited Shanghai Branch. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| ERD | Extended-reach drilling |

| HVR | Horizontal–vertical ratio |

| TVD | True vertical depth |

| HD | Horizontal displacement |

| OBDF | Oil-based drilling fluid |

| COSL | China Oilfield Services Limited |

| EP | Extreme pressure |

| API | American Petroleum Institute |

| RP | Recommended practice |

| RPM | Round per minute |

| AV | Apparent viscosity |

| PV | Plastic viscosity |

| YP | Yield point |

| FL | Filtrate loss |

| ES | Electrical stability |

| BHR | Before hot rolling |

| AHR | After hot rolling |

References

- Zhang, L.; Xie, T.; Hou, X.; Li, W.; Jin, J. Study on Safe Drilling Cycle of Soft Mudstone of Minghuazhen Formation in an Oilfield in Bohai Sea. Unconv. Oil Gas 2024, 11, 134–139. [Google Scholar] [CrossRef]

- Szymczak, P.D. Extended-Reach Drilling Hits Mainstream to Squeeze Difficult Reservoirs. J. Pet. Technol. 2021, 73, 35–40. [Google Scholar] [CrossRef]

- Wu, R.; Liu, Y.; Yu, H.; Lan, X.; Ai, X.; Guo, X.; Gao, P.; Deng, F. “Three-Low” Drilling Fluid Technology for Ultra-Shallow Horizontal Well with Extended Reach. Unconv. Oil Gas 2024, 11, 119–127. [Google Scholar] [CrossRef]

- Zhao, L.; Yi, T. Analysis of Coalbed Methane Horizontal Well Types and Drilling Technology Optimization. Coal Sci. Technol. 2020, 48, 45–53. [Google Scholar] [CrossRef]

- Li, Y.; Tian, J.; Guo, S.; Cai, B.; Ge, J. Research on Wellbore Cleaning Technology for Extended-Reach Wells in the East China Sea. J. Nat. Sci. 2023, 12, 187–195. [Google Scholar] [CrossRef]

- Dog Nose Plot—K&M Technology Group. Available online: https://kmtechnology.com/dog-nose-plot/ (accessed on 8 June 2025).

- Adnoc Drilling Claims Longest Well Record. Available online: https://www.energyvoice.com/oilandgas/middle-east/exploration-production-middle-east/453178/adnoc-drilling-record-zakum/ (accessed on 10 June 2025).

- Huang, W.; Gao, D. Analysis of Drilling Difficulty of Extended-Reach Wells Based on Drilling Limit Theory. Pet. Sci. 2022, 19, 211–222. [Google Scholar] [CrossRef]

- Mohammed, A.; Musab, A.; Bassam, A.; Kamran, A. An Innovative Approach Towards Real-Time Torque and Drag Model and Its Analysis-A Case Study. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 24–27 April 2017. [Google Scholar] [CrossRef]

- Rostagno, I. Friction Reduction Optimization for Extended Reach and Horizontal Wells. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, May 2019. [Google Scholar] [CrossRef]

- Livescu, S.; Craig, S. A Critical Review of the Coiled Tubing Friction-Reducing Technologies in Extended-Reach Wells. J. Pet. Sci. Eng. 2017, 155, 252–260. [Google Scholar] [CrossRef]

- Jia, J.; Yan, Z.; Dou, Y.; Huang, G.; Ma, Q. The New Method and Application of Friction Torque for Extended Reach Well. Adv. Pet. Explor. Dev. 2014, 8, 37–42. [Google Scholar] [CrossRef]

- Ihua-Maduenyi, I.E.; Oguta, E. Mechanistic Evaluation of Drill string Integrity in Extended Reach Wells Using Stiff String Torque and Drag Simulations under Variable Frictional Regimes. Int. J. Acad. Appl. Res. 2025, 9, 83–98. [Google Scholar]

- Oghenejoboh, K.M.; Ohimor, E.O. Application of Re-Refined Used Lubricating Oil as Base Oil for the Formulation of Oil-Based Drilling Mud-A Comparative Study. J. Pet. Sci. Eng. 2013, 4, 78–84. [Google Scholar]

- Geng, Y.; Zhang, Z.; Yan, Z.; Yuan, Y.; Zhou, X.; Yue, W. A Novel Graphene/Triolein Complex-Based Lubricant for Improving High-Temperature Water Based Drilling Fluid. RSC Adv. 2023, 49, 34772–34781. [Google Scholar] [CrossRef]

- Khan, M.A.; Al-Salim, H.S.; Leila, N. Development of High Temperature High Pressure (HTHP) Water Based Drilling Mud Using Synthetic Polymers, and Nanoparticles. Adv. Res. Fluid Mech. Therm. Sci. 2018, 45, 99–108. [Google Scholar]

- D’Amicis, S.; Pagani, M.; Matteucci, M.; Piroddi, L. Stuck Pipe Prediction from Rare Events in Oil Drilling Operations. Upstream Oil Gas 2023, 29, 125–140. [Google Scholar] [CrossRef]

- Dong, W.; Pu, X.; Ma, B. An Investigation on the Function of Mud Cakes on the Inhibition of Low Molecular Inhibitor for Water-Based Drilling Fluids. Energies 2019, 12, 3726. [Google Scholar] [CrossRef]

- Magzoub, M.I.; Ibrahim, M.H.; Nasser, M.S.; El-Naas, M.H.; Amani, M. Utilization of Steel-Making Dust in Drilling Fluids Formulations. Processes 2020, 8, 538. [Google Scholar] [CrossRef]

- Ezeakacha, C.P.; Salehi, S. Experimental Study of Drilling Fluid’s Filtration and Mud Cake Evolution in Sandstone Formations. J. Energy Resour. Technol. 2017, 139, 022912. [Google Scholar] [CrossRef]

- Yu, H.; Chen, Y.; Shu, Q.; Fang, F. Experimental Study of Friction Coefficient of Rocks in High Pressure and Tight Gas Reservoirs in Sichuan. Proc. Inst. Mech. Eng. 2018, 232, 678–687. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, Z.Q.; Wang, D.G. Friction and Wear Behavior of Wear-Resistant Belts in Drill Joints for Deep and Ultra-Deep Wells. Strength Mater. 2015, 47, 771–781. [Google Scholar] [CrossRef]

- Lei, Y.; Feng, Y.; Wu, Z.; Gao, Q.; Zhang, Z.; Wang, W.; Wang, L.; Wang, Y.; Wang, D. Monitoring of Lubrication and Wear In-Situ by Triboelectrification under Grease Lubrication. Friction 2025, 13, 9440938. [Google Scholar] [CrossRef]

- Cao-Romero-Gallegos, J.A.; Taghizadeh, S.; Aguilar-Rosas, O.A.; Dwyer-Joyce, R.S.; Farfan-Cabrera, L.I. The Effect of Electrical Current on Lubricant Film Thickness in Boundary and Mixed Lubrication Contacts Measured with Ultrasound. Friction 2024, 12, 1882–1896. [Google Scholar] [CrossRef]

- Huang, S.; Dong, T.; Jiang, G.; Yang, J.; Yang, X.; Wang, Q. Synthesis and Performance Evaluation of High-Temperature-Resistant Extreme-Pressure Lubricants for a Water-Based Drilling Fluid Gel System. Gels 2024, 10, 505. [Google Scholar] [CrossRef]

- Yang, L.L.; Liu, Z.Y.; Wang, S.B.; Zhu, Q.Q.; He, M.; Zhang, J. Chemical Modification of Barite for Improving Sag Stability of Weighted Water-Based Drilling Fluids. Pet. Sci. 2024, 21, 551–566. [Google Scholar] [CrossRef]

- NB/SH/T 0913-2015; Light White Oil. China Petrochemical Press: Beijing, China, 2015.

- API RP 13B-2-2023; Field Testing of Nonaqueous-Based Drilling Fluids. American Petroleum Institute: Washington, DC, USA, 2023.

- Zhang, C.; Guo, D.; Tian, J.; Niu, Q. Research on the Influencing Factors of Thermal Characteristics of High-Speed Grease Lubricated Angular Contact Ball Bearing. Adv. Mech. Eng. 2021, 13, 16878140211027398. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).