Modeling of the Characteristics of Coal Burning in Boiler Plants of Thermal Power Plants

Abstract

1. Introduction

- Higher moisture in coal reduces the heat value of coal and increases coal consumption, which increases CO2 emissions.

- Higher ash content in coal can increase NO2 emissions, due to changes in flame temperature, and also causes deposits on equipment and reduces efficiency.

- The heat value of coal determines how much energy is obtained from combustion; lower heat value requires more fuel, which increases emissions.

- The sulfur content of coal affects SO2 emissions, which is proportional to the amount of sulfur burned.

- Filters, electrostatic precipitators and cyclones are more effective for coals with high ash content.

- Wet/dry Scrubber removes SO2 and high sulfur content in coal requires higher capacities.

- NO2 control (SCR/SNCR) depends on combustible components and flame temperature.

2. Qualitive Rating of Cooling Characteristics in Serbia

- Coal mixing (coal homogenization) to reduce the variability of coal characteristics;

- Automatic regulation of combustion and emissions.

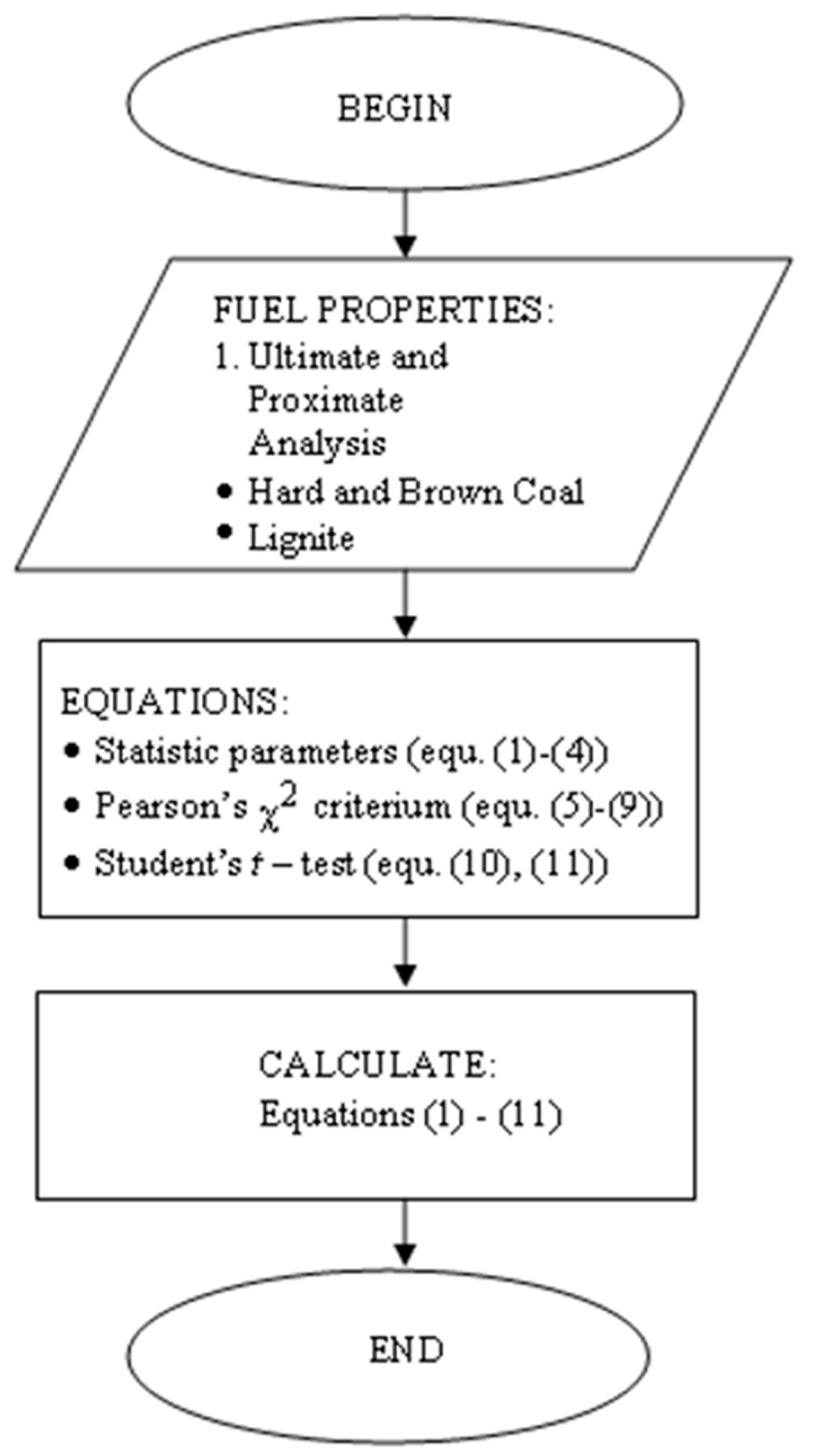

3. Results

4. Conclusions

- There are significant deviations in coal characteristics: moisture 70.20%, ash 62.21%, combustible materials 43.33% and lower heat capacity 44.10% deviation from the mean values, which is shown by the coefficient of variation Cv (Table 3).

- If the mean values of coal characteristics belong to the calculated intervals (Table 5), then for possible warriors, may be assumed coincidental, otherwise they are significant.

- Large fluctuations in coal characteristics around their mean values can negatively affect the operation of the boiler and electrostatic precipitator plants in Serbian thermal power plants. This also indicates the impossibility of applying dry flue-gas desulfurization (FGD) processes, due to the additional quantity of ash.

- The lack of uniformity in the quality of coal used in thermal power plant combustion plants in Serbia indicates the need for homogenization (mixing) of coals with different characteristics. Usage of homogenized coal would cause a wide range of positive effects, such as increased thermal power, reduced moisture and ash in coal, which results in better coal combustion, lower ash emissions, lower SOx and NOx emission values, and greater stability of electricity production.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| A | ash mass content in coal, % |

| C | carbon mass content in coal, % |

| Cfix | mass content of fixed carbon in coal, % |

| Cv | variation coefficient, % |

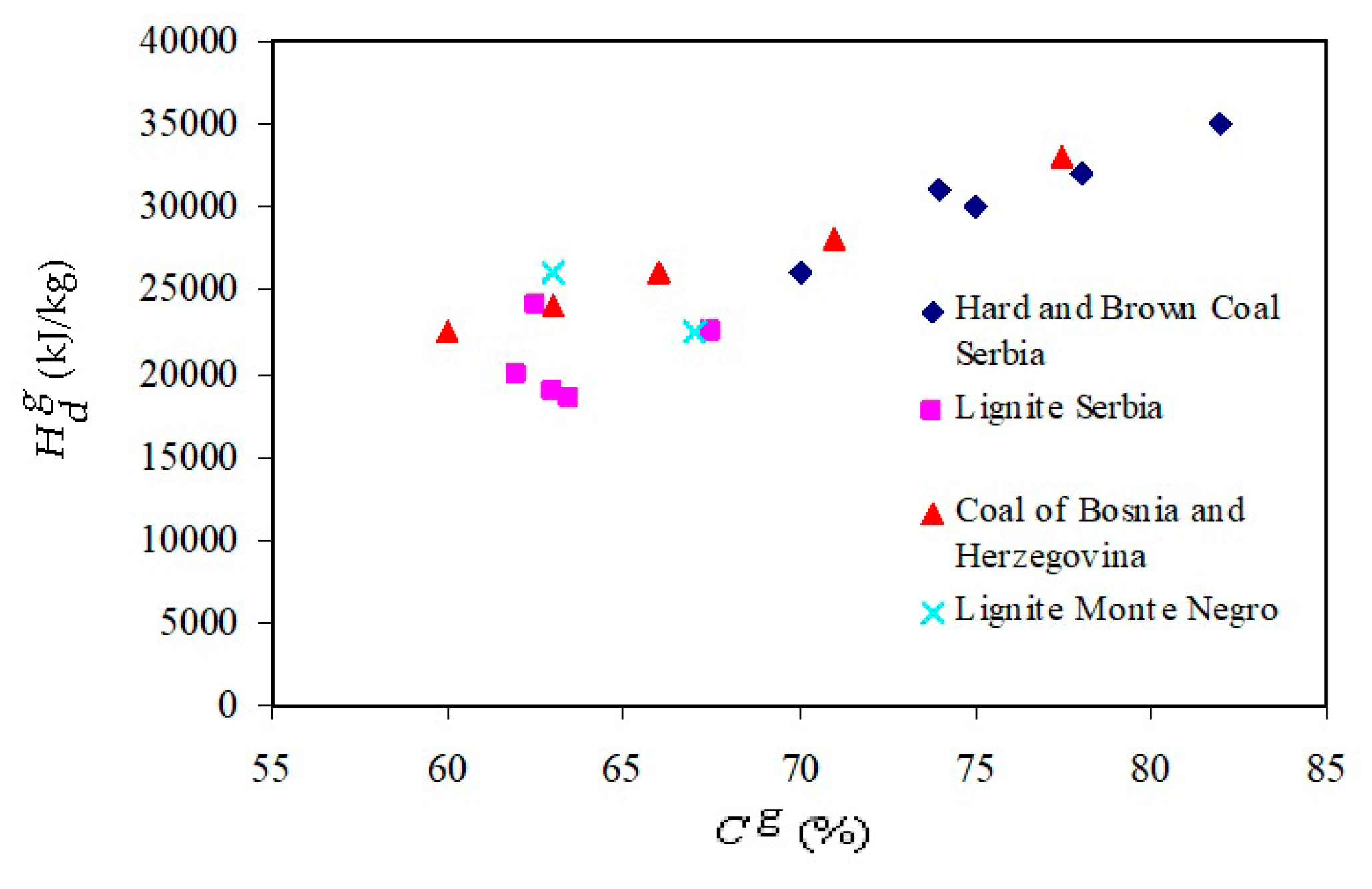

| Cg | carbon mass in coal reduced to combustible mass, % |

| mass content of fixed carbon in coal reduced to combustible mass, % | |

| fi | frequency |

| H | mass portion of hydrogen in coal, % |

| Hd | lower heating value of coal, kJ∙kg−1 |

| lower heating value of coal reduced to combustible mass, kJ∙kg−1 | |

| I | interval size |

| K | number of intervals |

| L | number of degrees of freedom |

| N | number of degrees of freedom |

| N | number of elements in a sample |

| M | auxiliary size |

| O | mass portion of oxygen in coal, % |

| mass portion of oxygen in coal reduced to combustible mass, % | |

| pi | probability of random variable taking value within interval |

| R | absolute range, % |

| S | mass portion of sulphur in coal, % |

| S | standard deviation, % |

| variable determined from the table for Student’s distribution at the selected level of significance (trust) α and the degree of freedom l = n − 1 | |

| ui | replacement (alternation) of variables |

| Vg | combustible matter, % |

| Vvol | mass portion of volatile components in coal, % |

| mass portion of volatile components in coal reduced to combustible mass, % | |

| arithmetic mean, % | |

| values of considered (features) characteristics of coal, % | |

| centers of intervals of coal characteristics, % | |

| Φ(ui) | Laplas function |

References

- U. S. Energy Information Administration (EIA). International Enrgy Outlook 2017 Washington, US Energy DC: Information Administration; Report Number: DOE/EIA-0484 (2017); U.S. Energy Information Administration (EIA): Washington, DC, USA, 2017.

- Singh, Y. Fly Ash Utilization in India, 2011. India, 2018. Available online: http://www.wealthywaste.com/fly-ash-utilization-in (accessed on 4 April 2024).

- Matić, D.; Čolić, Z. Coal is a strategic energy source. Kolubarski Sind. 2018, 168. [Google Scholar]

- Electric Power Industry of Serbia. Technical Yearbook; Electric Power Industry of Serbia: Belgrade, Serbia, 2023. [Google Scholar]

- EE Systems-Serbia. 2025. Available online: https://www.electricpower.info (accessed on 4 April 2024).

- Lazarević, V.; Lončar, S.; Mesarović, M. Equalizing the Quality of Coal for Thermal Power Plants. Thermotechnics 2007, 33, 13–19. [Google Scholar]

- Kazagić, A.; Smajević, I.; Duić, N. Selection of sustainable technologies for combustion of Bosnian coals. Therm. Sci. 2010, 14, 715–727. [Google Scholar] [CrossRef]

- Askarova, A.S.; Bolegenova, S.A.; Maximov, V.J.; Gabitova, Z.K.; Leithner, R.; Müller, H.; Heierle, Y. Numerical simulation of high-ash coal combustion with different moisture content at Aksu Thermal Power Plant. Int. J. Math. Phys. 2014, 5, 29–32. [Google Scholar] [CrossRef]

- Siddhartha, B.M. Effect of Ash in Coal on the Performance of Coal Fired Thermal Power Plants–Part I, High-Ash Coal. Prim. Energy Eff. 2006, 28, 25–41. [Google Scholar]

- Adi, P.; Feti, K.; Ghazidin, H.; Ruhiyat, A.S.; Adelia, N.; Prayoga, M.Z.E.; Romelan, R.; Utomo, S.M.; Cahyo, N.; Hartono, J.; et al. Ash deposition behavior during co-combustion of solid recovered fuel with different coals. Therm. Sci. Eng. Prog. 2024, 48, 102404. [Google Scholar] [CrossRef]

- Bogner, M. Thermotechnics 1; SMEITS: Beograd, Serbia, 2004. [Google Scholar]

- Jay, L.D.; Kenneth, N.M.; Matthew, A.C. Modern Mathematical Statistics with Applications; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Dennis, D.W.; Willian, M.; Richard, L.S. Mathematical Statistics with Applications; Cengange Learning: South Melbourne, Australia, 2018. [Google Scholar]

- Study of the Energy Sector in Bosnia and Herzegovina, Module 8—Coal Mines; Energy Institute Hrvoje Požar: Croatia, Zagreb, 2008.

- Energy Development Strategy of the Republic of Monte Negro Until 2025, Book C; Development of the Coal, Oil and Gas system of the Republic of Monte Negro, Energy Institute Hrvoje Požar: Ljubljana, Slovenia, 2006.

| Thermal Power Plants (TPP) | Operating from | Type of Coal | Installed Power (MW) |

|---|---|---|---|

| Kolubara (1) | 1956 | Lignite * | 270 |

| Kostolac A (2) | 1967 | Lignite | 310 |

| Kostolac B (2) | 1987 | Lignite | 698 |

| Kosovo A (3) | 1962 | Lignite | 617 |

| Kosovo B (3) | 1983 | Lignite | 618 |

| Morava (4) | 1969 | Lignite | 125 |

| Nikola Tesla A (5) | 1970 | Lignite | 1650 |

| Nikola Tesla B (5) | 1983 | Lignite | 1240 |

| AUNT Novi Sad (6) | 1981 | Lignite | 245 |

| Total | 5773 |

| Name of Coal | Proximate and Ultimate Analysis | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C % | H % | O % | N % | S % | W % | A % | Coke % | Cfix % | Volatile Vvol. % | Combustible Vg % | Low Heat Value of Coal Hd kJ∙kg−1 | |

| Hard and Brown coal ** | ||||||||||||

| Dobra sreća | 48.20 | 3.16 | 4.82 | 1.00 | 7.54 | 5.13 | 30.15 | 68.37 | 38.22 | 26.50 | 64.72 | 20,030 |

| Ibarski | 76.16 | 4.55 | 2.06 | 0.60 | 7.39 | 1.92 | 20.81 | 66.97 | 62.96 | 31.11 | 77.27 | 27,197 |

| Rtanj | 37.24 | 2.38 | 2.90 | 0.59 | 5.65 | 12.90 | 39.47 | 71.11 | 31.64 | 15.99 | 47.63 | 15,102 |

| Aleksinac | 55.97 | 3.57 | 10.53 | 0.34 | 3.46 | 15.30 | 10.83 | 49.65 | 39.40 | 35.05 | 74.45 | 21,659 |

| Rakova Bara | 46.00 | 3.02 | 14.46 | 0.83 | 1.54 | 16.76 | 17.93 | 51.84 | 34.45 | 31.40 | 65.85 | 16,739 |

| Lignite | ||||||||||||

| Kolubara | 20.43 | 1.69 | 9.12 | 0.60 | 0.51 | 54.70 | 13.06 | 25.68 | 12.62 | 19.62 | 32.24 | 6096 |

| Kostolac | 35.50 | 2.45 | 18.00 | 0.70 | 0.31 | 35.36 | 7.68 | 31.69 | 24.01 | 32.95 | 56.96 | 11,388 |

| Zaječar | 36.56 | 3.48 | 15.00 | 0.80 | 2.97 | 33.80 | 7.79 | 34.00 | 27.61 | 32.20 | 59.80 | 13,741 |

| Kosovo | 23.28 | 1.79 | 10.70 | 1.05 | 0.60 | 48.80 | 14.26 | 28.48 | 14.21 | 22.72 | 36.93 | 7223 |

| Ćirikovac | 31.91 | 2.20 | 11.10 | 0.91 | 1.06 | 44.80 | 8.02 | - | - | - | - | 10,777 |

| Coal Characteristics | Statistical Parameters | |||

|---|---|---|---|---|

| R | ||||

| W (%) | 52.78 | 26.95 | 18.92 | 70.20 |

| A (%) | 31.79 | 17.00 | 10.58 | 62.21 |

| Vg (%) | 45.03 | 51.58 | 23.38 | 43.33 |

| Hd (kJ∙kg−1) | 19,101 | 14,995.20 | 6613.73 | 44.10 |

| (%) | Center of Interval (%) | Frequencies | (%) | Normed Intervals | ||||

|---|---|---|---|---|---|---|---|---|

| 8.52 | 3 | −18.43 | 0.2676 | 2.6760 | 0.1050 | 0.0392 | ||

| 21.72 | 2 | −5.23 | 0.2045 | 2.0450 | 0.0020 | 0.0010 | ||

| 34.92 | 2 | 7.97 | 0.3073 | 3.0730 | 1.1513 | 0.3746 | ||

| 48.12 | 3 | 21.17 | 0.2206 | 2.2060 | 0.6304 | 0.2858 | ||

| Total | - | 10 | - | - | 1 | 10 | - |

| Coal Characteristics | ||||||

|---|---|---|---|---|---|---|

| W (%) | 26.95 | 18.92 | 2.26 | 12.70 | 41.20 | |

| A (%) | 17.00 | 10.58 | 2.26 | 9.03 | 24.97 | |

| Vg (%) | 51.58 | 23.38 | 2.26 | 33.97 | 69.19 | |

| Hd (kJ∙kg−1) | 14,995.20 | 6613.73 | 2.26 | 10,012.86 | 19,977.54 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ceranic, M.; Davidovic, N.; Jaric, M.; Djuric, S.; Kuzmic, G.; Milotic, M. Modeling of the Characteristics of Coal Burning in Boiler Plants of Thermal Power Plants. Processes 2025, 13, 2618. https://doi.org/10.3390/pr13082618

Ceranic M, Davidovic N, Jaric M, Djuric S, Kuzmic G, Milotic M. Modeling of the Characteristics of Coal Burning in Boiler Plants of Thermal Power Plants. Processes. 2025; 13(8):2618. https://doi.org/10.3390/pr13082618

Chicago/Turabian StyleCeranic, Mirjana, Nikola Davidovic, Marko Jaric, Slavko Djuric, Goran Kuzmic, and Milan Milotic. 2025. "Modeling of the Characteristics of Coal Burning in Boiler Plants of Thermal Power Plants" Processes 13, no. 8: 2618. https://doi.org/10.3390/pr13082618

APA StyleCeranic, M., Davidovic, N., Jaric, M., Djuric, S., Kuzmic, G., & Milotic, M. (2025). Modeling of the Characteristics of Coal Burning in Boiler Plants of Thermal Power Plants. Processes, 13(8), 2618. https://doi.org/10.3390/pr13082618