Hydraulic Fracture Propagation Behavior in Tight Conglomerates and Field Applications

Abstract

1. Introduction

2. Failure Patterns and Fracture Characteristics of Tight Conglomerates

3. Experimental Investigation of Hydraulic Fracture Propagation and Network Formation Mechanisms in Tight Conglomerate Reservoirs

3.1. Preparation of Artificial Tight Conglomerate Samples

3.2. True Triaxial Hydraulic Fracturing Physical Simulation Experimental Protocol

3.2.1. Cluster-Controlled Dynamic Flow True Triaxial Fracturing Experimental System

3.2.2. Experimental Protocol for True Triaxial Hydraulic Fracturing Tests

3.3. Description and Evaluation of Hydraulic Fracture Morphology

- (1)

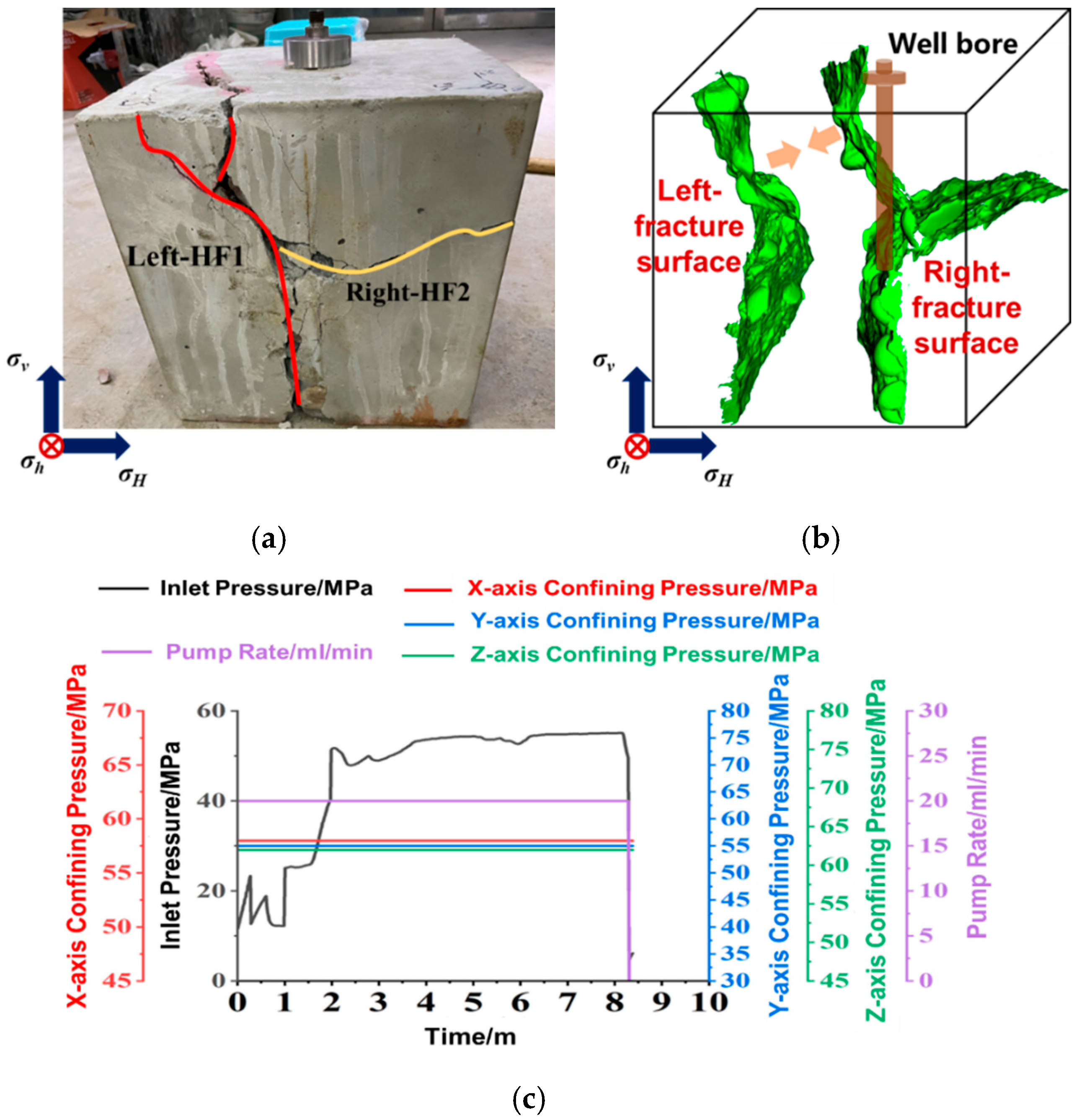

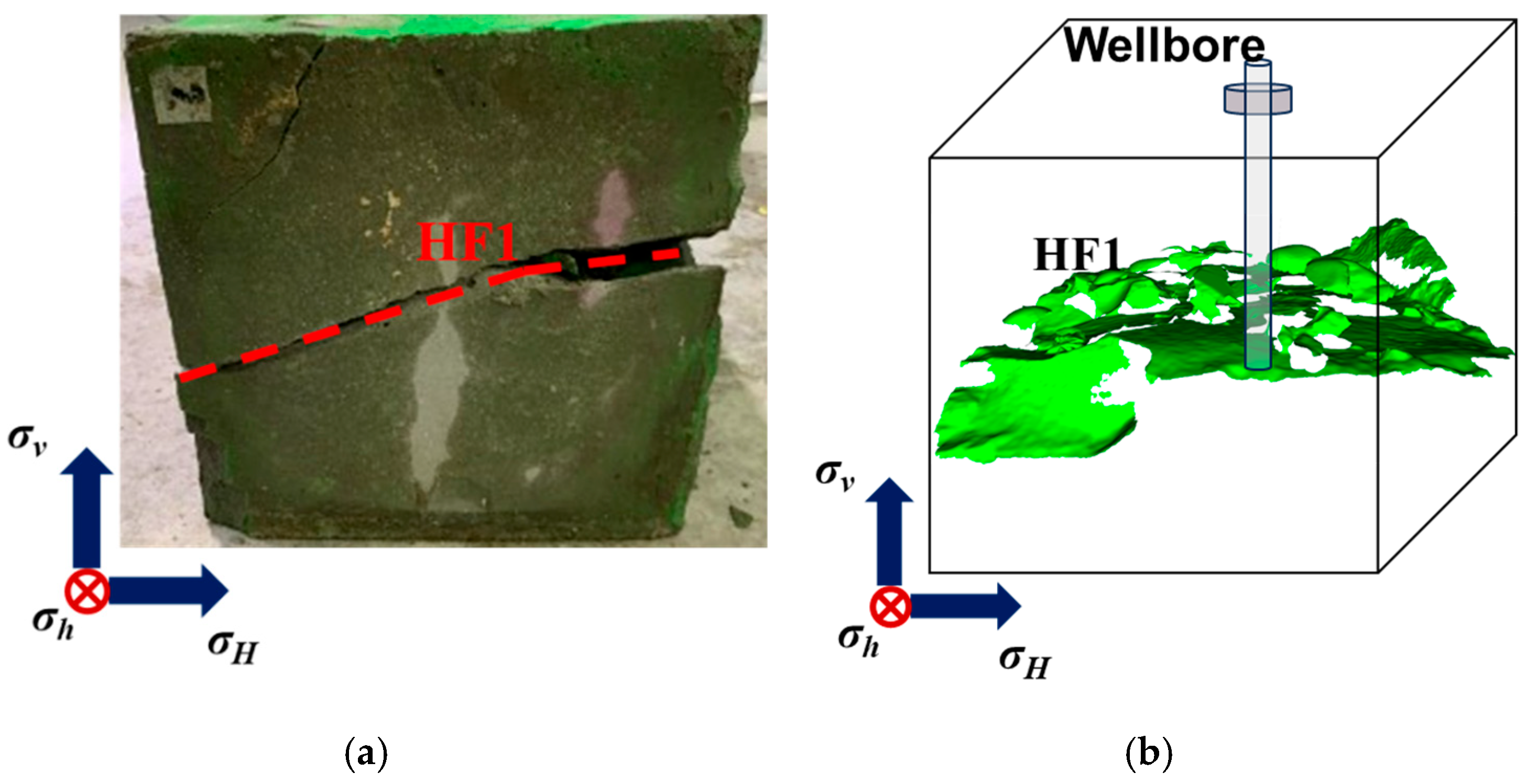

- Impact of Horizontal Stress Anisotropy on Fracture Geometry

- (2)

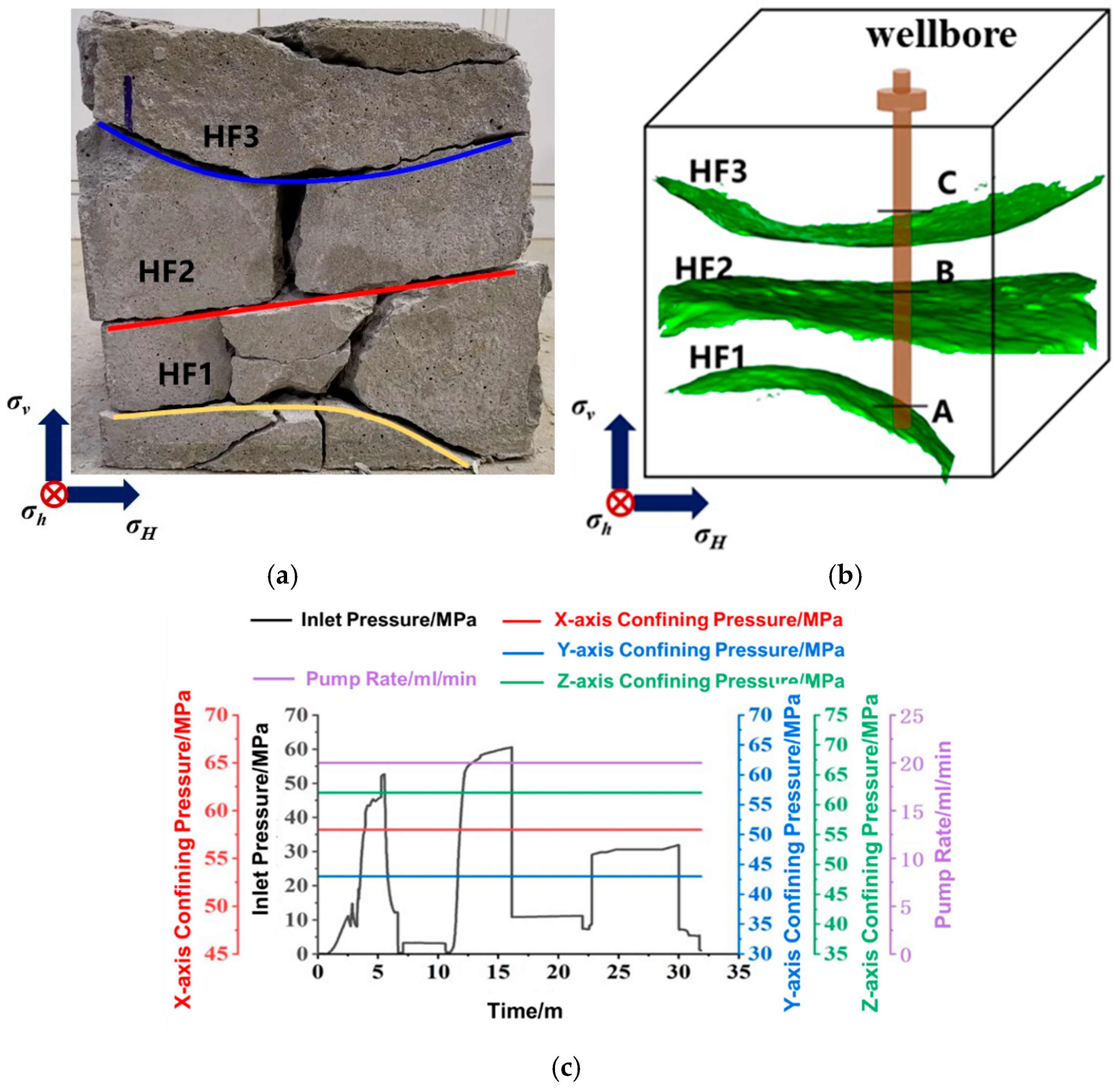

- Influence of Multi-Cluster Perforation on Fracture Morphology

- (3)

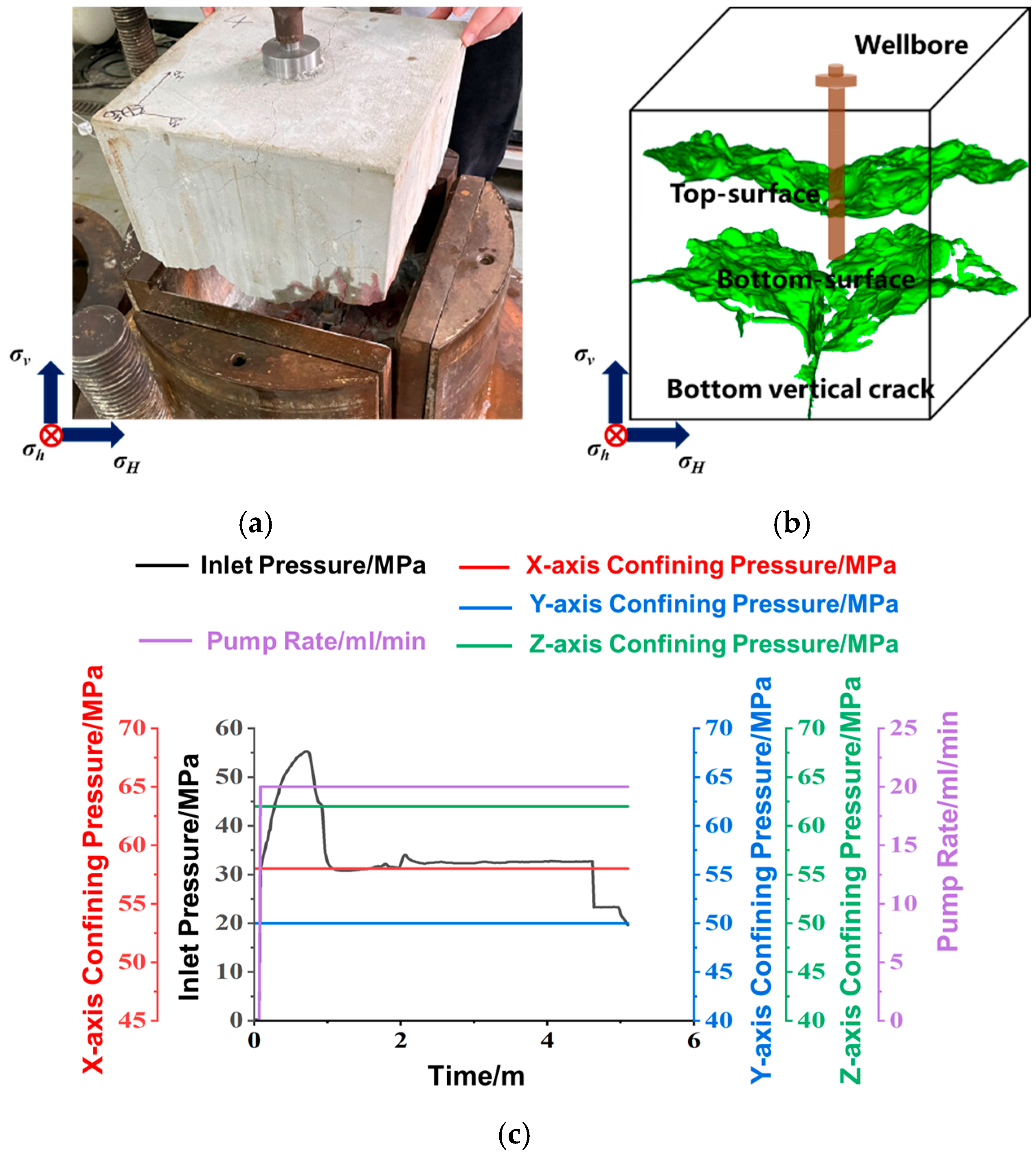

- Effect of Pumping Rate on Fracture Propagation

4. Variable-Rate Fracturing Optimization Design and Field Applications

4.1. Mechanism of Production Enhancement by Variable-Rate Hydraulic Fracturing

- (1)

- Enhanced fracture geometry:

- (2)

- Reduced gravel structural strength and breakdown pressure:

- (i)

- Oscillatory flow characteristics (pressure/rate modulation);

- (ii)

- Dynamic propagation pressure (peak-trough stress cycling).

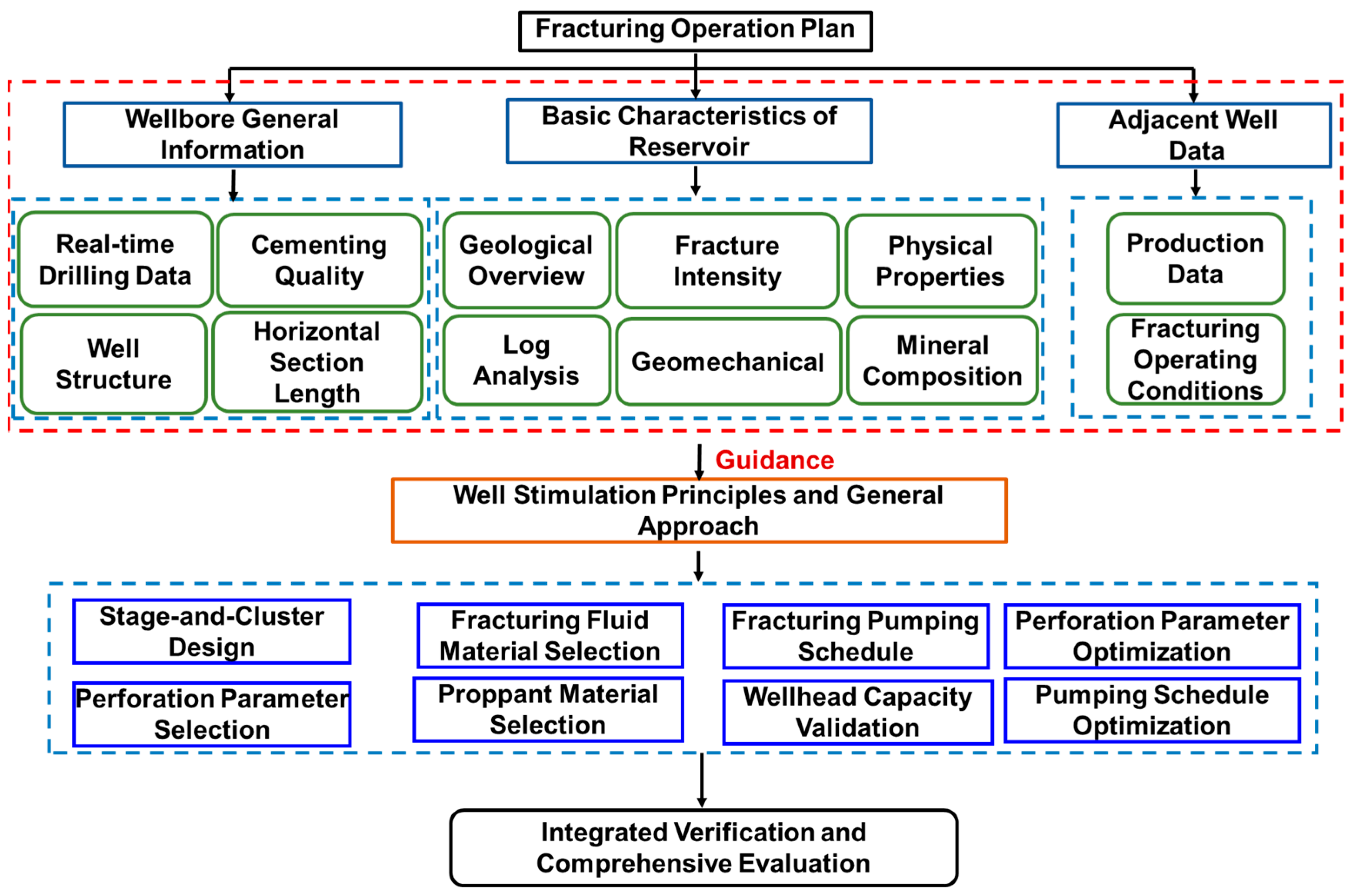

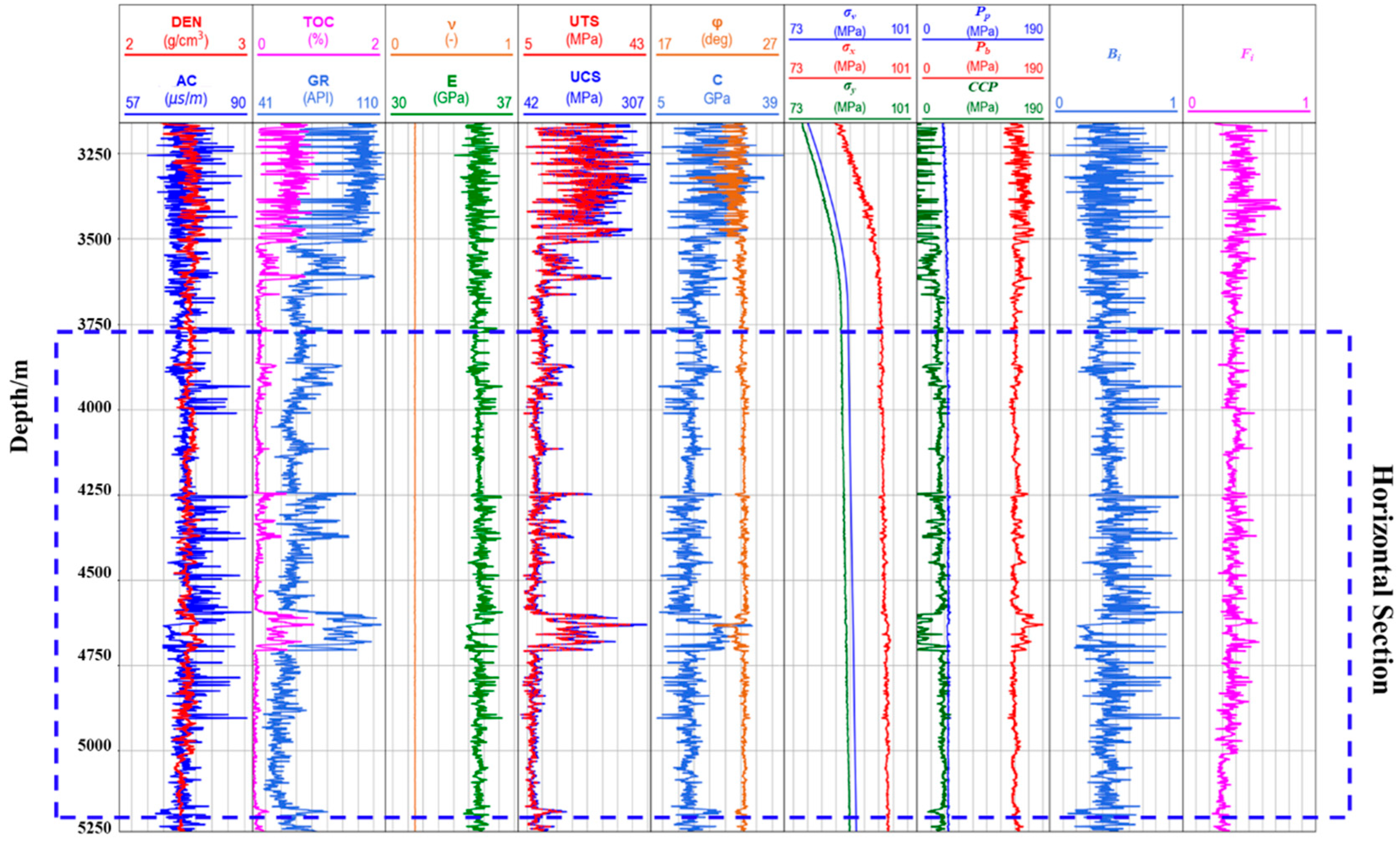

4.2. Design of Variable-Rate Hydraulic Fracturing Program

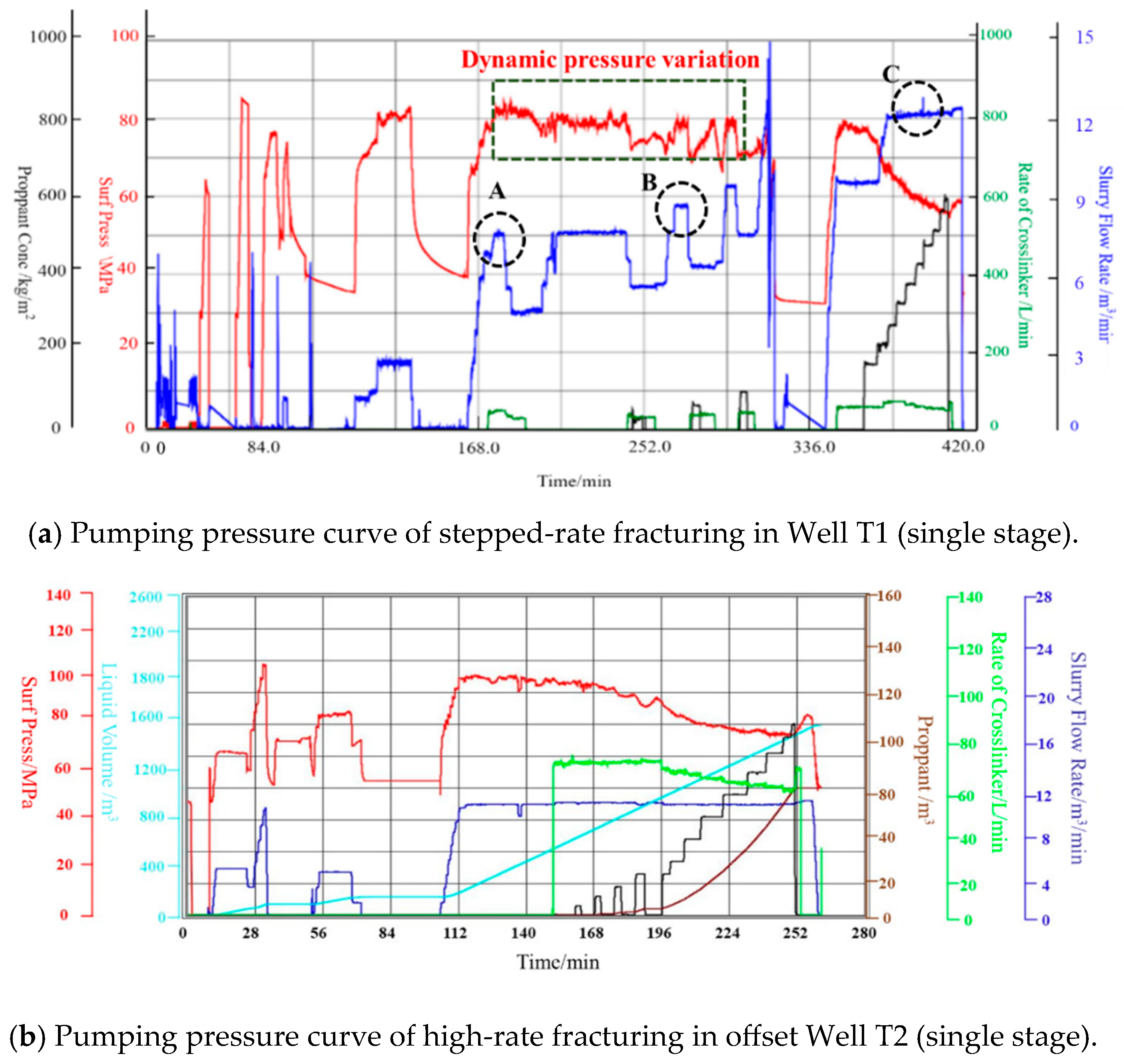

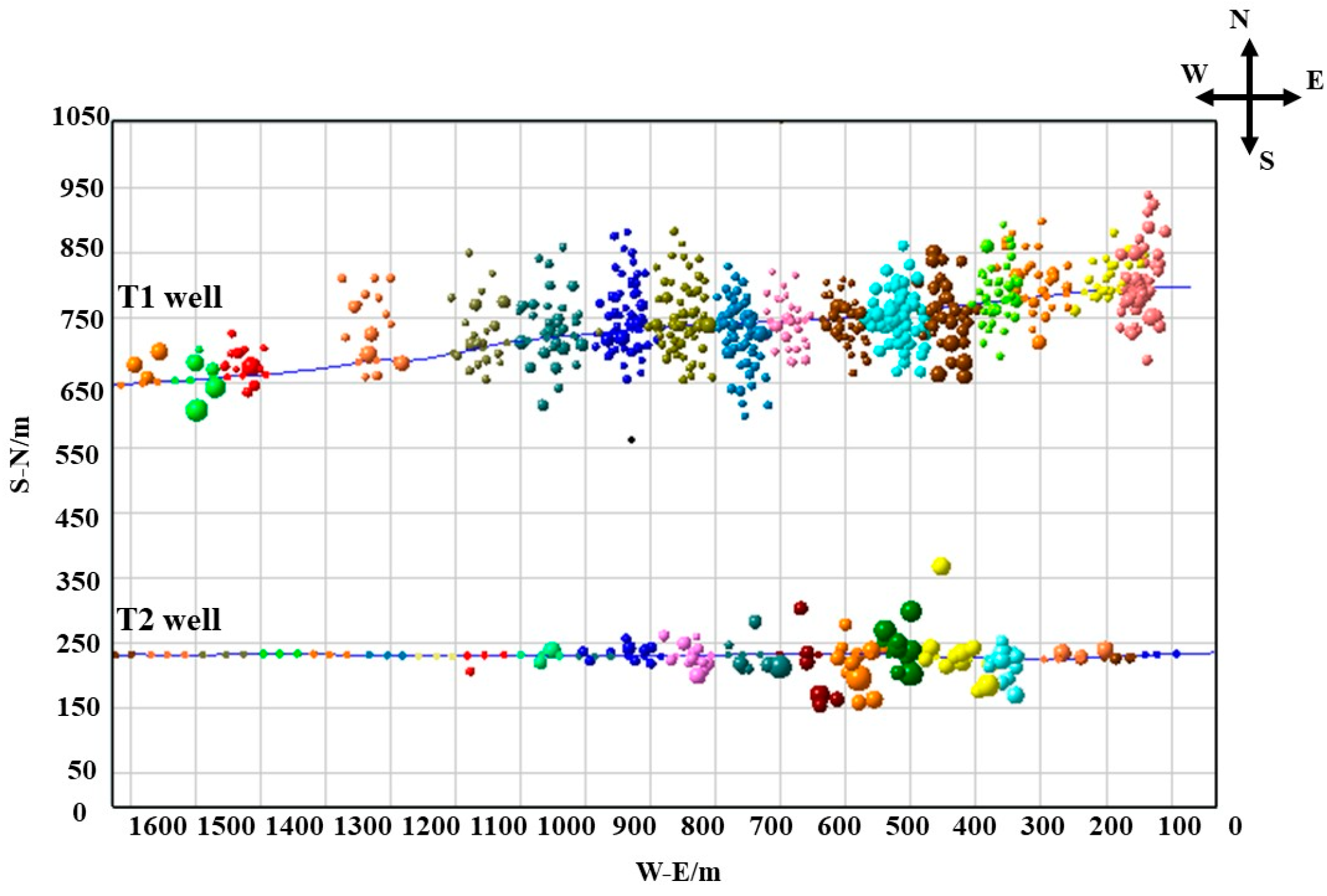

4.3. Pumping Pressure Curve Characteristics and Microseismic Event Description

5. Analysis and Conclusions

- (1)

- Triaxial compression tests revealed that tight conglomerate failure occurs through two distinct mechanisms—shear failure followed by plastic failure, with the plastic phase predominantly characterized by gravel particle fragmentation; meanwhile, weakly cemented argillaceous tight conglomerates develop both circumgranular (around gravel) and transgranular (through gravel) fracture paths.

- (2)

- True triaxial hydraulic fracturing experiments using synthetic cores demonstrated that weakly cemented conglomerates primarily form circumgranular fractures during stimulation, with horizontal stress anisotropy (Δσ = σH − σh) being the dominant factor controlling fracture propagation direction and geometry, while multi-cluster perforating showed minimal influence on fracture morphology.

- (3)

- The oscillatory pressure generated during variable-rate fracturing was identified as the key mechanism enhancing rock breakage efficiency, with staged rate variations proving particularly effective at reducing breakdown pressure in tight conglomerate reservoirs.

- (4)

- Comparative analysis confirmed that variable-rate fracturing significantly improves stimulated reservoir volume over conventional methods by 30–45%, achieved through enhanced activation of weakly cemented interfaces between gravel particles and superior fracture network coverage, as evidenced by 35% greater microseismic event density.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Du, H.; Xu, J.; Li, X.; Lu, J.; Zhang, J.; Peng, Y.; Chen, J.; Wang, L. Development and deepening of profitable development of tight glutenite oil reservoirs in Xinjiang oilfield: Application of geology-engineering integration in Mahu area and its enlightenment. China Pet. Explor. 2018, 23, 15–26. [Google Scholar] [CrossRef]

- Li, H.; Wang, X.; Li, Z. Evaluation of pore structure and classification method of glutenite reservoirs: A case study of the Triassic Baikouquan Formation in the Mabei Slope Zone. Pet. Geol. Eng. 2025, 39, 1–7. [Google Scholar]

- Gong, Q.; Ni, G.; Lu, S. Analysis on Features and Controlling Factors of Reservoir in Baikouquan Formation of Wuerhe Oilfield, Junggar Basin. China Pet. Explor. 2010, 15, 11–16+84. [Google Scholar]

- Guo, H.; Dan, X.; Li, Y.; Zou, Z.; Wang, L. Lower Limits of Reservoir Physical Properties and Controlling Factors of Baikouquan Formation on the Northern Slope of Mahu Sag. Xinjiang Pet. Geol. 2018, 39, 63–69. [Google Scholar]

- Kuang, L.; Tang, Y.; Lei, D.; Wu, T.; Qu, J. Exploration of Fan-Controlled Large-Area Lithologic Oil Reservoirs of Triassic Baikouquan Formation in Slope Zone of Mahu Depression in Junggar Basin. China Pet. Explor. 2014, 19, 14–23. [Google Scholar]

- Kuang, Y.; Sima, L.; Qu, J.; Wen, D.; Chen, M.; Wu, F. Influencing factors and quantitative evaluation for pore structure of tight glutenite reservoir:a case of the Triassic Baikouquan Formation in Ma 131 well field, Mahu Sag. Lithol. Reserv. 2017, 29, 91–100. [Google Scholar]

- Li, G.; Qin, J.; Xian, C.; Fan, X.; Zhang, J.; Ding, Y. Theoretical understandings, key technologies and practices of tight conglomerate oilfield efficient development: A case study of the Mahu oilfield, Junggar Basin, NW China. Pet. Explor. Dev. 2020, 47, 1185–1197. [Google Scholar] [CrossRef]

- Li, J.; Wu, B.; Zhao, H.; Cheng, N.; Huang, J. Adaptability of horizontal well volume fracturing to tight conglomerate reservoirs in Mahu oilfield. China Pet. Explor. 2019, 24, 250–259. [Google Scholar]

- Liu, T.; Shi, S.; Zheng, Z.; Ji, Y.; Wang, L. Application of geology-engineering integration for developing tight oil in glutenite reservoir by horizontal wells in Mahu sag. China Pet. Explor. 2018, 23, 90–103. [Google Scholar]

- Qin, J.; Xian, C.; Zhang, J.; Liang, T.; Wang, W.; Li, S.; Zhang, J.; Zhang, Y.; Zhou, J. Characteristics of hydraulic fracture network in the tight conglomerate reservoir based on a hydraulic fracturing test site. Pet. Explor. Dev. 2025, 52, 217–228. [Google Scholar] [CrossRef]

- Khormali, A.; Ahmadi, S.; Aleksandrov, A.N. Analysis of reservoir rock permeability changes due to solid precipitation during waterflooding using artificial neural network. J. Pet. Explor. Prod. Technol. 2025, 15, 17. [Google Scholar] [CrossRef]

- Debotyam, M.; Jordan, C. A systematic interpretation of subsurface of proppant concentration from drilling mud returns: Case study from hydraulic fracturing test site (HFTS-2) in Delaware basin. In Proceedings of the Unconventional Resources Technology Conference, Houston, TX, USA, 26–28 July 2021. URTEC 2021-5189-MS. [Google Scholar]

- Maity, D.; Ciezobka, J. An Interpretation of Proppant Transport Within the Stimulated Rock Volume at the Hydraulic-Fracturing Test Site in the Permian Basin. SPE Reserv. Eval. Eng. 2019, 22, 477–491. [Google Scholar] [CrossRef]

- Tang, H.; Liang, H.; Zhang, L.; Qin, J.; Li, Y.; Zhang, J. Hydraulic fracture extension patterns of conglomerate reservoirs and relevant influencing factors. Acta Pet. Sin. 2022, 43, 871–884. [Google Scholar]

- Cai, W.; Feng, Y.; Yan, W.; Jiang, Q.; Meng, X.; Liu, K. Fracability Evaluation of Conglomerate Reservoirs in Baikouquan Formation in Ma-131 Well Block. Xinjiang Pet. Geol. 2022, 43, 194–199. [Google Scholar]

- Fan, M.; Jin, Y.; Fu, W.; Chen, M. Experimental study on fracture propagation behavior based on acoustic emission characteristics. Chin. J. Rock Mech. Eng. 2018, 37 (Suppl. S2), 3834–3841. [Google Scholar]

- Wang, L.; Yang, C.; Guo, Y.; Heng, S.; Wei, Y.; Hou, Z.; Li, D. Investigation on fracture initiation modes of horizontal wells based on laboratory hydraulic fracturing test. Chin. J. Rock Mech. Eng. 2015, 34 (Suppl. S2), 3624–3632. [Google Scholar]

- Xu, Y.; Lei, Q.; Chen, M.; Wu, Q.; Yang, N.; Wang, D.; Li, D.; Jiang, H. Progress and development of volume stimulation techniques. Pet. Explor. Dev. 2018, 45, 874–887. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, G.; Wang, R. Rock mechanics problems in horizontal well fracturing. Chin. J. Rock Mech. Eng. 2004, 23, 2463–2466. [Google Scholar]

- Zhang, J.; Zhang, C.; Zhang, Z.; Zhang, C.; Nie, X. Brittleness of tight gas reservoirs based on stress-strain curves. Lithol. Reserv. 2017, 29, 126–131. [Google Scholar]

- Whebell, R.J.; Moroney, T.J.; Turner, I.W.; Pethiyagoda, R.; McCue, S.W. Implicit reconstructions of thin leaf surfaces from large, noisy point clouds. Appl. Math. Model. 2021, 98, 416–434. [Google Scholar] [CrossRef]

- Maurel-Pantel, A.; Vosin, M.; Bui, Q.; Cocheteau, N.; Lebon, F.; Hochard, C. A cohesive zone model for fracture initiation and propagation of fused silica direct bonding interface. Eng. Fract. Mech. 2019, 219, 106649. [Google Scholar] [CrossRef]

- Bayat, M.; Ahmadi, H.R.; Kia, M.; Cao, M. Probabilistic seismic demand of isolated straight concrete girder highway bridges using fragility functions. Adv. Concr. Constr. 2019, 7, 183–189. [Google Scholar]

- Hou, B.; Chen, M.; Cheng, W.; Tan, P. Fracturing mechanism of shale gas reservoir with variable pump rates. Chin. J. Geotech. Eng. 2014, 36, 2149–2152. [Google Scholar]

- Yang, B.; Jiang, T.; Ding, Y.; Wang, Y.; Wang, S. Low damage fracturing technology for explo-ration wells in low porosity and permeability reservoirs. Pet. Explor. Dev. 2005, 32, 119–122. [Google Scholar]

| Set | Test Number | Formation | Type | Gravel Hardness | Matrix Hardness | Experimental Confining Pressure |

|---|---|---|---|---|---|---|

| GPa | GPa | MPa | ||||

| 1 | 1-1 | T1b3 | Clay matrix binding | 3.21 | 0.18 | 0 |

| 1-2 | T1b3 | Clay matrix binding | 20 | |||

| 1-3 | T1b3 | Clay matrix binding | 40 | |||

| 2 | 2-1 | T1b1 | Calcareous cementation | 3.14 | 1.56 | 0 |

| 2-2 | T1b1 | Calcareous cementation | 20 | |||

| 2-3 | T1b1 | Calcareous cementation | 40 | |||

| 2-4 | T1b1 | Calcareous cementation | 60 | |||

| 2-5 | T1b1 | Calcareous cementation | 80 |

| Well ID | Layer | Lithology | Content/% | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Clay Minerals | Quartz | K-Feldspar | Plagioclase | Calcite | Ankerite | Ferroan Calcite | |||

| MH01 | T1b3 | Conglomeratic sandstone | 5.65 | 37.48 | 14.22 | 38.77 | (-) | 3.88 | (-) |

| T1b2 | Conglomeratic sandstone | 9.23 | 52.49 | 8.75 | 26.25 | (-) | 3.28 | (-) | |

| MH 02 | T1b2 | Conglomeratic sandstone | 2.29 | 58.85 | 11.1 | 27.76 | (-) | (-) | (-) |

| MH 03 | T1b3 | Conglomeratic sandstone | 5.15 | 53.03 | 11.22 | 27.54 | (-) | 3.06 | (-) |

| T1b2 | Conglomeratic sandstone | 6.35 | 54.9 | 9.69 | 26.91 | (-) | 2.15 | (-) | |

| MH 04 | T1b3 | Conglomeratic sandstone | 8.92 | 25.58 | 15.35 | 17.4 | (-) | (-) | 32.75 |

| T1b3 | Conglomeratic sandstone | 6.05 | 55.26 | 9.95 | 26.53 | (-) | (-) | 2.21 | |

| T1b3 | Conglomeratic sandstone | 6.62 | 46.69 | 21.55 | 25.14 | (-) | (-) | (-) | |

| T1b3 | Conglomeratic sandstone | 6.16 | 52.78 | 10.56 | 26.98 | (-) | 3.52 | (-) | |

| T1b3 | Conglomeratic sandstone | 9.84 | 38.8 | 23.97 | 27.39 | (-) | (-) | (-) | |

| T1b3 | Conglomeratic sandstone | 6.78 | 33.78 | 5.83 | 25.64 | (-) | (-) | 27.97 | |

| T1b3 | Conglomeratic sandstone | 5.65 | 44.26 | 9.32 | 26.79 | (-) | (-) | 13.98 | |

| MH 05 | T1b2 | Conglomeratic sandstone | 9.35 | 52.6 | 10.07 | 25.74 | (-) | 2.24 | (-) |

| MH 06 | T1b3 | Conglomeratic sandstone | 3.55 | 44.92 | 14.53 | 30.39 | 6.61 | (-) | (-) |

| MH 07 | T1b1 | Conglomeratic sandstone | 6.21 | 32.62 | (-) | 57.09 | (-) | 4.08 | (-) |

| T1b2 | Conglomeratic sandstone | 8.74 | 52.65 | 10.53 | 28.08 | (-) | 3.65 | (-) | |

| T1b1 | Conglomeratic sandstone | 9.97 | 42.58 | 10.95 | 32.85 | (-) | (-) | (-) | |

| Mean | (-) | (-) | 6.85 | 45.84 | 12.35 | 29.25 | 6.61 | 3.23 | 19.23 |

| Number | Elastic Modulus/GPa | Poisson’s Ratio/ν | Compressive Strength/MPa |

|---|---|---|---|

| Sample | 20.01 | 0.26 | 67.52 |

| Artificial sample 1 | 25.62 | 0.24 | 72.52 |

| Artificial sample 2 | 23.38 | 0.24 | 73.33 |

| Artificial sample 3 | 19.53 | 0.25 | 65.89 |

| Artificial sample 4 | 24.51 | 0.26 | 63.32 |

| Artificial sample 5 | 23.36 | 0.24 | 75.83 |

| Artificial sample 6 | 21.06 | 0.26 | 61.23 |

| Number | Labeling | Gravel Size | Packing Style | σH/MPa | σh/MPa | σV/MPa | Injection Rate/mL/min | Cluster Spacing/cm |

|---|---|---|---|---|---|---|---|---|

| 1 | G1 | Mixed size | Bulk disorder | 58 | 54 | 62 | 20 | 0 |

| G2 | Mixed size | Bulk disorder | 58 | 50 | 62 | 20 | 0 | |

| G3 | Mixed size | Bulk disorder | 58 | 43 | 62 | 20 | 0 | |

| 2 | G4 | Mixed size | Bulk disorder | 58 | 43 | 62 | 20 | 6 (Two clusters) |

| G5 | Mixed size | Bulk disorder | 58 | 43 | 62 | 20 | 4 (Three clusters) | |

| 3 | G6 | Mixed size | Bulk disorder | 58 | 43 | 62 | 15 | 0 |

| G7 | Mixed size | Bulk disorder | 58 | 43 | 62 | 10/15/20 | 0 | |

| G8 | Mixed size | Bulk disorder | 58 | 43 | 62 | 35 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Xiao, W.; Wei, S.; Fang, Z.; Cao, X. Hydraulic Fracture Propagation Behavior in Tight Conglomerates and Field Applications. Processes 2025, 13, 2494. https://doi.org/10.3390/pr13082494

Wang Z, Xiao W, Wei S, Fang Z, Cao X. Hydraulic Fracture Propagation Behavior in Tight Conglomerates and Field Applications. Processes. 2025; 13(8):2494. https://doi.org/10.3390/pr13082494

Chicago/Turabian StyleWang, Zhenyu, Wei Xiao, Shiming Wei, Zheng Fang, and Xianping Cao. 2025. "Hydraulic Fracture Propagation Behavior in Tight Conglomerates and Field Applications" Processes 13, no. 8: 2494. https://doi.org/10.3390/pr13082494

APA StyleWang, Z., Xiao, W., Wei, S., Fang, Z., & Cao, X. (2025). Hydraulic Fracture Propagation Behavior in Tight Conglomerates and Field Applications. Processes, 13(8), 2494. https://doi.org/10.3390/pr13082494