Modification of Bitumen with Mechanochemically Devulcanized Crumb Rubber

Abstract

1. Introduction

2. Materials and Methods

- Heating the road bitumen in an oven to 140 °C.

- Gradual addition of devulcanized crumb rubber to the bitumen, followed by mixing at 6000 rpm at 190 °C.

3. Results

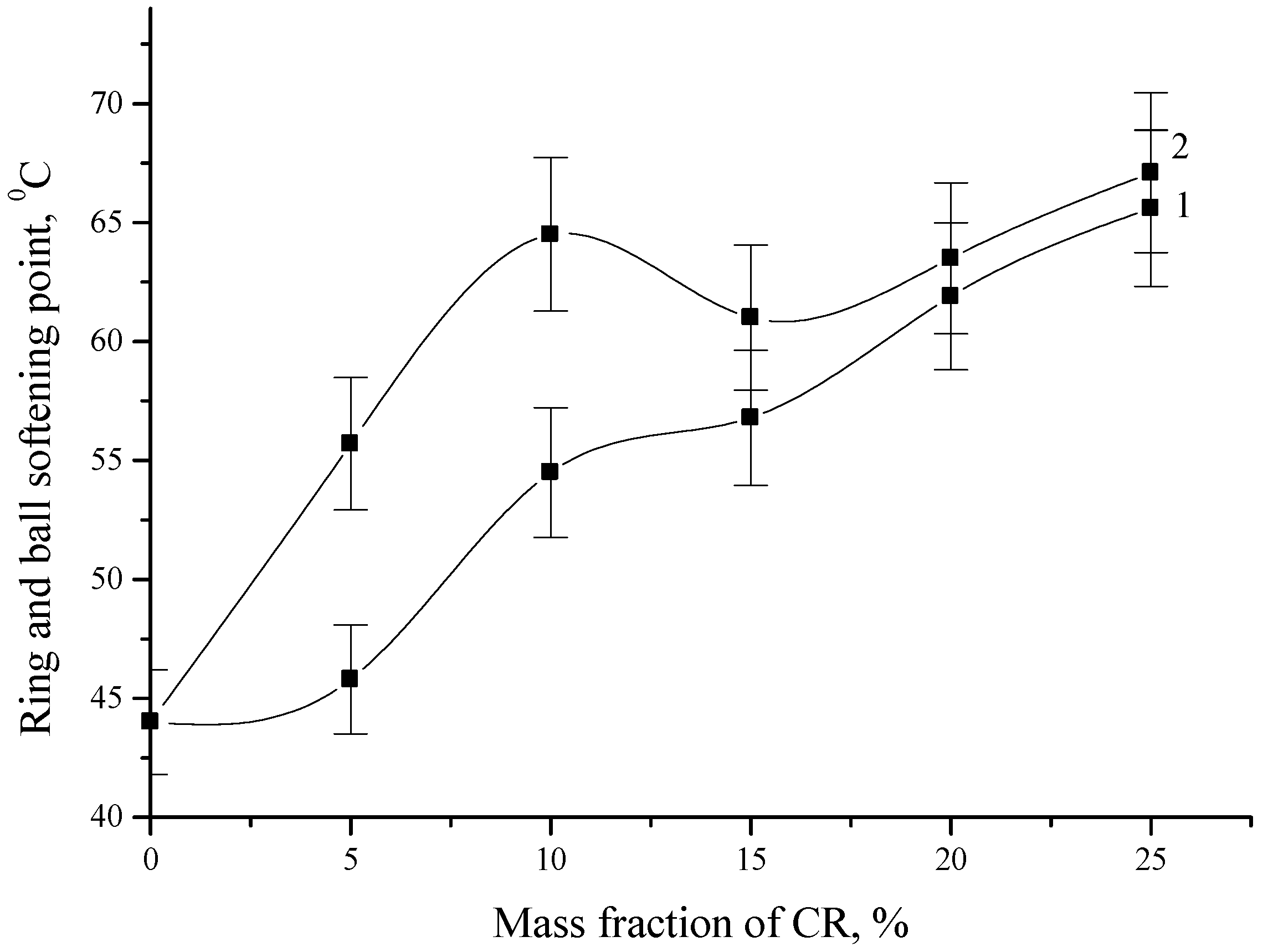

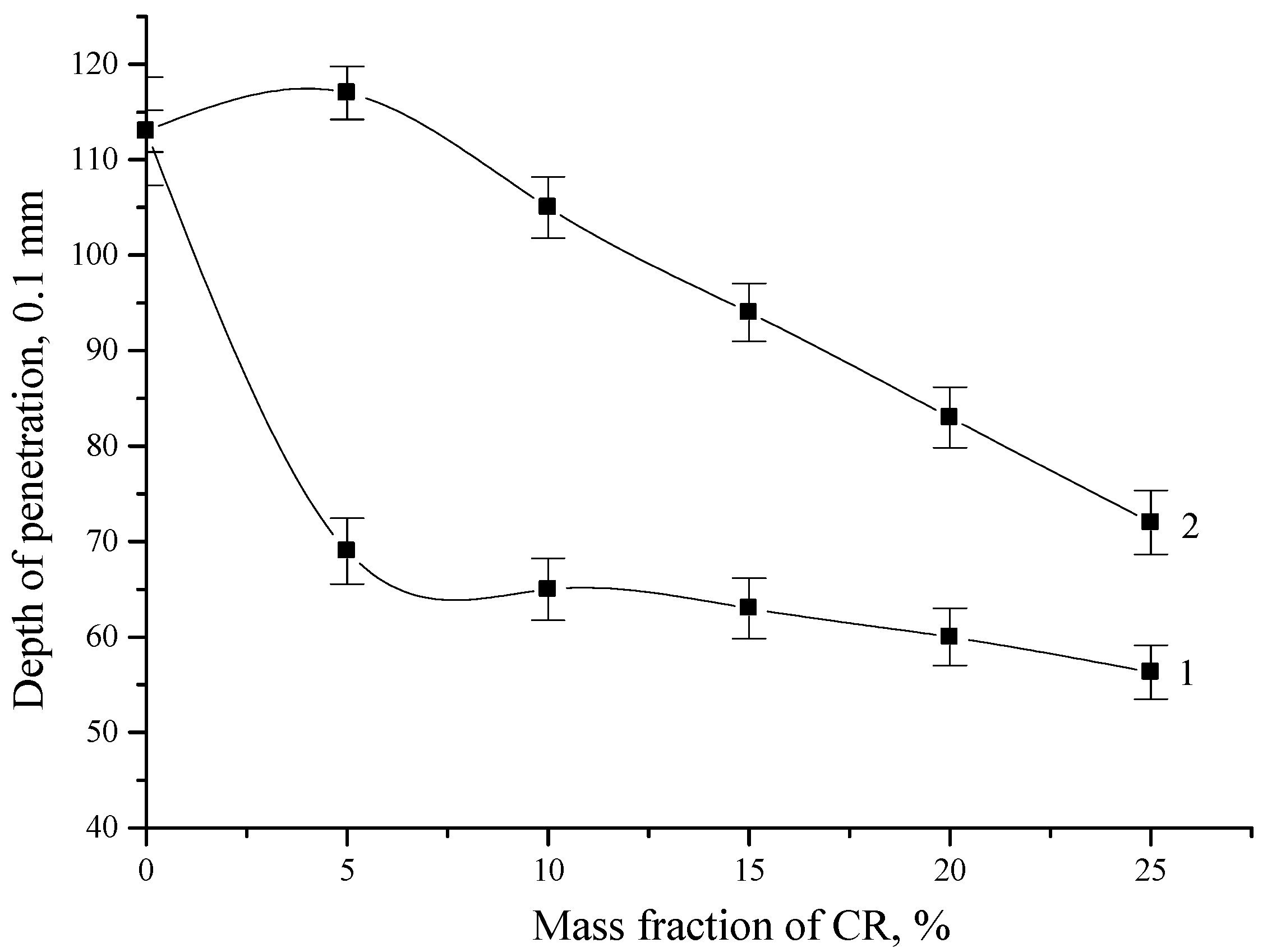

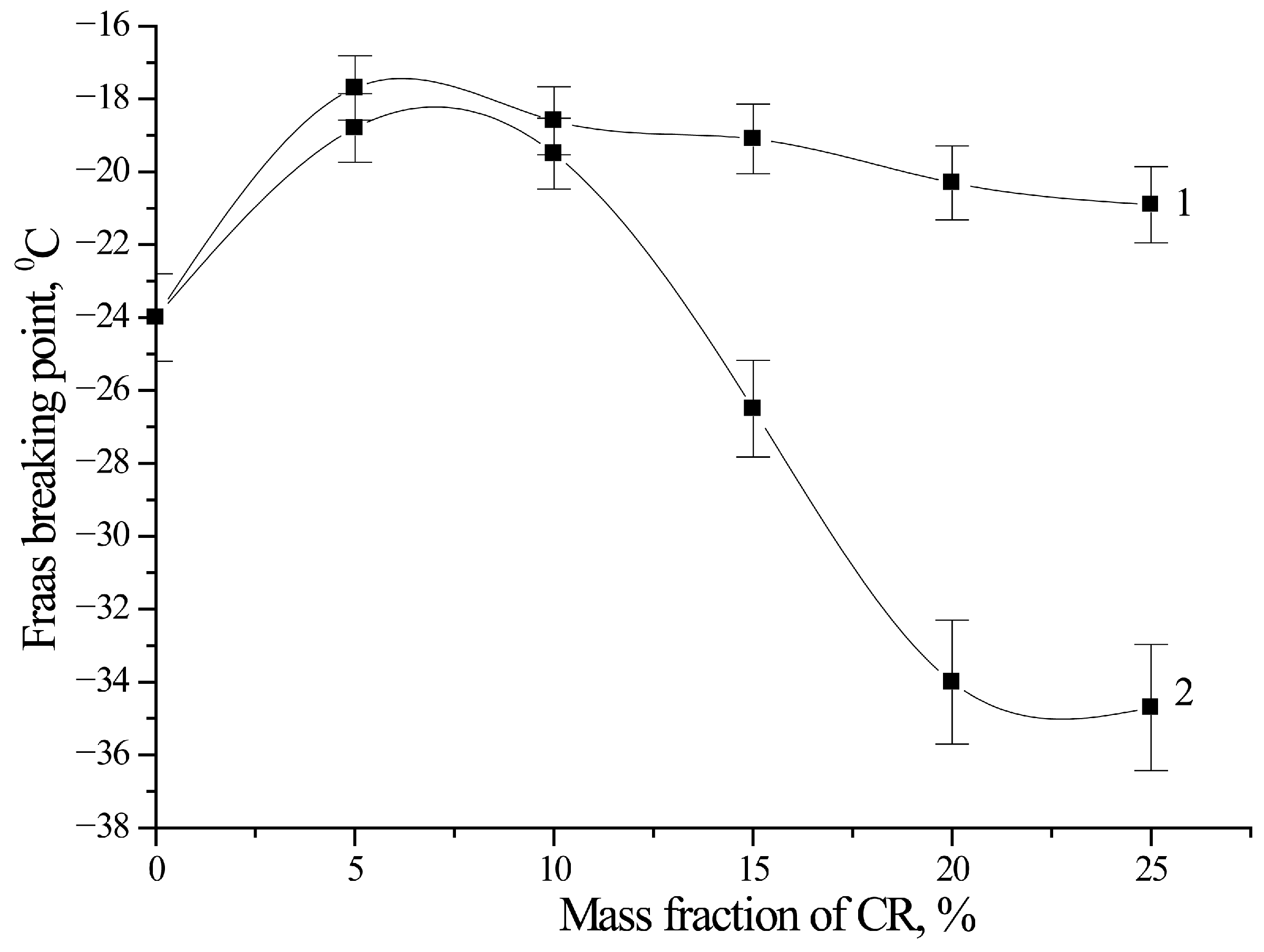

- Binders with 15–25 wt% conventional crumb rubber (CCR) meet the RBB 50/70 specifications: softening point (ring and ball) ≥ 56 °C, penetration at 25 °C of 50–70, extensibility ≥ 10 cm, and brittleness temperature ≤ −15 °C.

- Binders with 5–25 wt% devulcanized crumb rubber (DCR) meet the Kazakhstani RBB 70/100 standard: softening point ≥ 52 °C, penetration at 25 °C of 71–100, extensibility ≥ 12 cm, and brittleness temperature ≤ −18 °C.

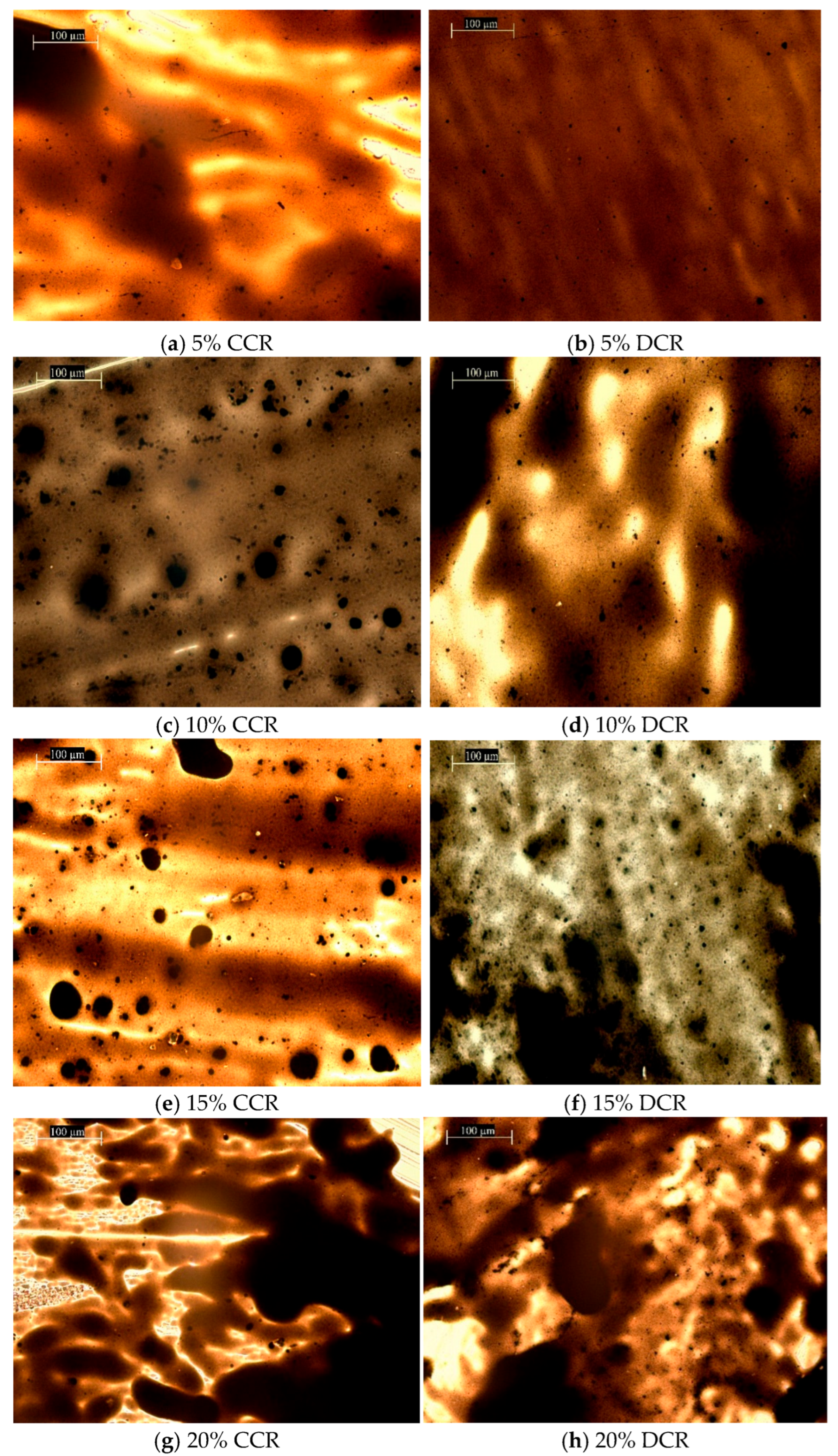

- At 5% rubber content (Figure 7a,b), particle fusion with bitumen occur. DCR modified bitumen composition demonstrates much better dispersion of rubber particles within bitumen matrix.

- At 10% (Figure 7c,d), fibrous structure form. The addition of 10% devulcanized crumb rubber resulted in significantly improved dispersion within the bitumen matrix (Figure 7d) compared to the same concentration of conventional crumb rubber (Figure 7c). Moreover, the incorporation of devulcanized rubber at this concentration led to the formation of fibrous structure, which is associated with enhanced mechanical strength and elasticity (Figure 7d).

- At 15% dosage (Figure 7e), the morphology of the CCR modified binder shows poorer dispersion with the formation of large agglomerates [71]. At 15% dosage (Figure 7f), dispersion of DCR particles in the bitumen matrix occurs and the formation of network structures [72] begins, which are observed in Figure 7h. This observation explains why the previously measured performance of DCR modified bitumen is superior to that of CCR modified bitumen. Moreover, the formation of a network structure seems to start at lower dosages in DCR modified systems, indicating a more efficient interaction and compatibility with the bitumen matrix. This supports previous findings that mechanochemical treatment enhances surface roughness and reactivity [29].

- Increasing the concentration of devulcanized rubber crumb to 20% resulted in further improvement of dispersion in the bitumen matrix (Figure 7h) and development of a network structure.

4. Conclusions

- Devulcanized rubber crumb readily interacts with bitumen, partially dissolving into its components and promoting closer physical compatibility. This leads to the formation of a more homogeneous modified system. Consequently, the microstructure of the modified binder differs fundamentally from that of unmodified bitumen, as elastic network structures are formed throughout the binder matrix.

- Devulcanized rubber derived from waste materials enhances the binder performance, notably improving penetration values, brittleness temperature, and the ring-and-ball softening point compared to the conventional crumb rubber.

- The mechanochemical method offers more selective cleavage of sulfur (sulfide) bonds compared to thermal or microwave alternatives, causing minimal damage to the main polymer chain. This selectivity, achieved through the synergy of mechanical grinding and mild chemical action, helps preserve the rubber’s elasticity and structural integrity. Using environmentally friendly reagents such as glycine, the process is safe, scalable, and energy-efficient, with no need for complex by-product disposal.

- Devulcanized rubber, as a result of the cleavage of sulfur (sulfide) crosslinks, is more effectively dispersed within the bitumen matrix, forming a homogeneous, mesh-like structure. This microstructure facilitates uniform stress distribution and enhances the compatibility between the rubber and bitumen phases, thereby improving the elasticity and thermal stability of the binder. Consequently, the modified bitumen exhibits increased resistance to high-temperature deformation while maintaining flexibility at low temperatures—attributes that significantly enhance the mechanical performance of asphalt concrete pavements.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, T.; Xiao, F.; Zhu, X.; Huang, B.; Wang, J.; Amirkhanian, S. Energy consumption and environmental impact of rubberized asphalt pavement. J. Clean. Prod. 2018, 180, 139–158. [Google Scholar] [CrossRef]

- Presti, D.L. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Brasileiro, L.; Moreno-Navarro, F.; Tauste-Martínez, R.; Matos, J.; Rubio-Gámez, M.D.C. Reclaimed polymers as asphalt binder modifiers for more sustainable roads: A review. Sustainability 2019, 11, 646. [Google Scholar] [CrossRef]

- Li, J.; Xing, X.; Hou, X.; Wang, T.; Wang, J.; Xiao, F. Determination of SARA fractions in asphalts by mid-infrared spectroscopy and multivariate calibration. Measurement 2022, 198, 111361. [Google Scholar] [CrossRef]

- Wang, T.; Xiao, F.; Amirkhanian, S.; Huang, W.; Zheng, M. A review on low temperature performances of rubberized asphalt materials. Constr. Build. Mater. 2017, 145, 483–505. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, M.; Li, Y.; Zou, Y.; Chen, A.; Wang, F.; Liu, L.; Gu, D.; Zhou, S. Swelled Mechanism of Crumb Rubber and Technical Properties of Crumb Rubber Modified Bitumen. Materials 2022, 15, 7987. [Google Scholar] [CrossRef]

- Zanetti, M.C.; Fiore, S.; Ruffino, B.; Santagata, E.; Dalmazzo, D.; Lanotte, M. Characterization of crumb rubber from end-of-life tyres for paving applications. Waste Manag. 2015, 45, 161–170. [Google Scholar] [CrossRef]

- Nejad, F.M.; Aghajani, P.; Modarres, A.; Firoozifar, H. Investigating the properties of crumb rubber modified bitumen using classic and SHRP testing methods. Constr. Build. Mater. 2012, 26, 481–489. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, Z.; Yu, T.; Liu, S.; Jiang, H. Experimental evaluation of crumb rubber and polyethylene integrated modified asphalt mixture upon related properties. Road Mater. Pavement Des. 2019, 20, 1413–1428. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Borzędowska-Labuda, K.; Wojtkiewicz, A.; Janik, H. Development of methods improving storage stability of bitumen modified with ground tire rubber: A review. Fuel Process. Technol. 2017, 159, 272–279. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Martínez-Boza, F.; Gallegos, C. Thermo-rheological behaviour and storage stability of ground tire rubber-modified bitumens. Fuel 2004, 83, 2041–2049. [Google Scholar] [CrossRef]

- Kerni, C.; Tangri, A. Utilization of crumb rubber as a partial replacement of bitumen in flexible pavement. In E3S Web of Conferences; EDP Sciences: Castanet-Tolosan, France, 2024; Volume 596, p. 01030. [Google Scholar] [CrossRef]

- Musa, S.S.; Al-Mukaram, N.; Dakhil, I.H. Asphalt binder modified with recycled tyre rubber. Open Eng. 2024, 14, 20220495. [Google Scholar] [CrossRef]

- Malomoa, D.; Akintayoa, C.; Abimbadea, S.; Abidemia, S.T.; Egharevbab, O.; Olasupoa, A.D.; Adewuyia, S.O.; Odubunmi, J.O. Production and properties of composites from scrap-tyre-rubber modified bitumen. Niger. J. Appl. Sci. 2023, 41, 8–15. [Google Scholar]

- Nagurskyy, A.; Khlibyshyn, Y.; Grynyshyn, O.; Kochubei, V. Rubber Crumb Modified Bitumen Produced from Crude Oils Residuals of Ukrainian Deposits. Chem. Chem. Technol. 2020, 14, 420–425. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; Wang, D.; Leng, Z.; Lu, G.; Erkens, S. and Skarpas, A. Investigating the High- and Low-Temperature Performance of Warm Crumb Rubber–Modified Bituminous Binders Using Rheological Tests. J. Transp. Eng. Part B Pavements 2021, 147, 04021067. [Google Scholar] [CrossRef]

- Rodríguez-Alloza, A.M.; Gallego, J. Mechanical performance of asphalt rubber mixtures with warm mix asphalt additives. Mater. Struct. 2017, 50, 147. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Sun, H.; Yao, Y.; Xing, B. Viscous properties, storage stability and their relationships with microstructure of tire scrap rubber modified asphalt. Constr. Build. Mater. 2015, 74, 124–131. [Google Scholar] [CrossRef]

- Hassan, M.M.; Aly, R.O.; Abdel Aal, S.E.; El-Masry, A.M.; Fathy, E.S. Mechanochemical devulcanization and gamma irradiation of devulcanized waste rubber/high density polyethylene thermoplastic elastomer. J. Ind. Eng. Chem. 2013, 19, 1722–1729. [Google Scholar] [CrossRef]

- Sagitova, G.F.; Ainabekov, N.B.; Daurenbek, N.M.; Assylbekova, D.D.; Sadyrbayeva, A.S.; Bitemirova, A.E.; Takibayeva, G.A. Modified Bitumen Materials from Kazakhstani Oilfield. Adv. Polym. Technol. 2024, 2024, 8078021. [Google Scholar] [CrossRef]

- Subhy, A.; Presti, D.L.; Airey, G. An investigation on using pre-treated tyre rubber as a replacement of synthetic polymers for bitumen modification. Road Mater. Pavement Des. 2015, 16, 245–264. [Google Scholar] [CrossRef]

- Xie, J.; Yang, Y.; Lv, S.; Zhang, Y.; Zhu, X.; Zheng, C. Investigation on Rheological Properties and Storage Stability of Modified Asphalt Based on the Grafting Activation of Crumb Rubber. Polymers 2019, 11, 1563. [Google Scholar] [CrossRef] [PubMed]

- Gawdzik, B.; Matynia, T.; Błażejowski, K. The Use of De-Vulcanized Recycled Rubber in the Modification of Road Bitumen. Materials 2020, 13, 4864. [Google Scholar] [CrossRef]

- Shaikh, A.; Memon, N.A.; Kumar, A.; Shaikh, G.Y. Performance characterization of crumb rubber modified bitumen using pyrolyzed waste tyre treated bitumen. Mehran Univ. Res. J. Eng. Technol. 2023, 42, 59–66. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, H.; Zhang, C.; Wang, S. Laboratory testing and field application of devulcanized rubber/ SBS composite modified asphalt. Case Stud. Constr. Mater. 2023, 19, e02285. [Google Scholar] [CrossRef]

- Zhou, Y.; Lu, Q.; Cheng, Z.; Wang, J.; Zhong, J.; Lu, Q.; Xie, S.; Huang, B. Synergy of devulcanized rubber and rock asphalt for asphalt modification. Case Stud. Constr. Mater. 2024, 21, e03432. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, Y.; Guo, R.; Yan, Y.; Huan, H.; Wan, B. Study on the Low-Temperature Pre-Desulfurization of Crumb Rubber-Modified Asphalt. Polymers 2023, 15, 2273. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Y.; Chen, J.; Liu, W.; Wang, W. Effect of Desulfurization Process Variables on the Properties of Crumb Rubber Modified Asphalt. Polymers 2022, 14, 1365. [Google Scholar] [CrossRef]

- Xiao-qing, Z.; Can-hui, L.; Mei, L. Rheological Property of Bitumen Modified by the Mixture of the Mechanochemically Devulcanized Tire Rubber Powder and SBS. J. Mater. Civ. Eng. 2009, 21, 699–705. [Google Scholar] [CrossRef]

- Xie, S.; Cheng, Z.; Zhou, Y.; Cao, Y.; Wang, T.; Zhang, Z.; Dai, Y.; Zhang, W. Performance of Asphalt Mixtures Modified with Desulfurized Rubber and Rock Asphalt Composites. Buildings 2024, 14, 3026. [Google Scholar] [CrossRef]

- Saputra, R.; Walvekar, R.; Khalid, M.; Mubarak, N.M.; Sillanpa, A.M. Current progress in waste tire rubber devulcanization. Chemosphere 2021, 265, 129033. [Google Scholar] [CrossRef]

- Ramarad, S.; Khalid, M.; Ratnam, C.; Chuah, A.L.; Rashmi, W. Waste tire rubber in polymer blends: A review on the evolution, properties and future. Prog. Mater. Sci. 2015, 72, 100–140. [Google Scholar] [CrossRef]

- Sabzekar, M.; Chenar, M.P.; Mortazavi, S.M.; Kariminejad, M.; Asadi, S.; Zohuri, G. Influence of process variables on chemical devulcanization of sulfur-cured natural rubber. Polym. Degrad. Stab. 2015, 118, 88–95. [Google Scholar] [CrossRef]

- Seghar, S.; Asaro, L.; Rolland-Monnet, M.; Hocine, N.A. Thermo-mechanical devulcanization and recycling of rubber industry waste. Resour. Conserv. Recycl. 2019, 144, 180–186. [Google Scholar] [CrossRef]

- Edwards, D.W.; Danon, B.; van der Gryp, P.; Gorgens, J.F. Quantifying and comparing the selectivity for crosslink scission in mechanical and mechanochemical devulcanization processes. J. Appl. Polym. Sci. 2016, 133, 43932. [Google Scholar] [CrossRef]

- Adhikari, B.; De, D.; Maiti, S. Reclamation and recycling of waste rubber. Prog. Chem. Org. Nat. Prod. Polym. Sci. 2000, 25, 909–948. [Google Scholar] [CrossRef]

- Maridass, B.; Gupta, B.R. Effect of extruder parameters on mechanical properties of revulcanized ground rubber tire powder. Polimery 2007, 52, 456–460. [Google Scholar] [CrossRef]

- Formela, K.; Korol, J.; Saeb, M.R. Interfacially modified LDPE/GTR composites with non-polar elastomers: From microstructure to macro-behavior. Polymer Testing 2015, 42, 89–98. [Google Scholar] [CrossRef]

- Barbosa, R.; Nunes, A.T.; Ambrosio, J.D. Devulcanization of natural rubber in composites with distinct crosslink densities by twin-screw extruder. Mater. Res. 2017, 20, 77–83. [Google Scholar] [CrossRef][Green Version]

- Simon, D.Á.; Pirityi, D.; Tamás-Bényei, P.; Bárány, T. Microwave devulcanization of ground tire rubber and applicability in SBR compounds. J. Appl. Polym. Sci. 2020, 137, 48351. [Google Scholar] [CrossRef]

- Jones, D.A.; Lelyveld, T.; Mavrofidis, S.; Kingman, S.; Miles, N. Microwave heating applications in environmental engineering—A review. Resour. Conserv. Recycl. 2002, 34, 75–90. [Google Scholar] [CrossRef]

- Colom, X.; Faliq, A.; Formela, K.; Canavate, J. FTIR spectroscopic and thermogravimetric characterization of ground tyre rubber devulcanized by microwave treatment. Polym. Test. 2016, 52, 200–208. [Google Scholar] [CrossRef]

- Garcia, P.S.; de Sousa, F.D.B.; de Lima, J.A.; Cruz, S.A.; Scuracchio, C.H. Devulcanization of ground tire rubber: Physical and chemical changes after different microwave exposure times. Express Polym. Lett. 2015, 9, 1015–1026. [Google Scholar] [CrossRef]

- de Sousa, F.D.; Scuracchio, C.H.; Hu, G.-H.; Hoppe, S. Devulcanization of waste tire rubber by microwaves. Polym. Degrad. Stab. 2017, 138, 169–181. [Google Scholar] [CrossRef]

- Yang, X.L.; Shen, A.Q.; Li, B.; Wu, H.S.; Lyu, Z.H.; Wang, H.; Lyu, Z.F. Effect of microwave-activated crumb rubber on reaction mechanism, rheological properties, thermal stability, and released volatiles of asphalt binder. J. Clean. Prod. 2020, 248, 119230. [Google Scholar] [CrossRef]

- Guo, L.; Lv, D.J.; Ren, D.H.; Qu, L.N.; Wang, W.C.; Hao, K.F.; Guo, X.R.; Chen, T.C.; Sun, J.Y.; Wang, C.S.; et al. Effectiveness of original additives in waste rubbers for revulcanization after reclamation with a low-temperature mechanochemical devulcanization method. J. Clean. Prod. 2021, 297, 126620. [Google Scholar] [CrossRef]

- Vahdatbin, M.; Hajikarimi, P.; Fini, E.H. Devulcanization of Waste Tire Rubber via Microwave and Biological Methods: A Review. Polymers 2025, 17, 285. [Google Scholar] [CrossRef]

- Valdes, C.; Hernandez, C.; Morales-Vera, R.; Andler, R. Desulfurization of vulcanized rubber particles using biological and couple microwave-chemical methods. Front. Environ. Sci.-Switz. 2021, 9, 633165. [Google Scholar] [CrossRef]

- Asaroa, L.; Grattona, M.; Segharb, S.; Hocinea, N. Recycling of rubber wastes by devulcanization. Resour. Conserv. Recycl. 2018, 133, 250–262. [Google Scholar] [CrossRef]

- Qian, C.; Fan, W.; Liang, M.; He, Y.; Ren, S.; Lv, X.; Nan, G.; Luo, H. Rheological properties, storage stability and morphologyof CR/SBS composite modified asphalt by high-cured method. Constr. Build. Mater. 2018, 193, 312–322. [Google Scholar] [CrossRef]

- Dong, R.; Li, J.; Wang, S. Laboratory evaluation of pre-devulcanized crumb rubber–modified asphalt as a binder in hot-mix asphalt. J. Mater. Civ. Eng. 2011, 23, 1138–1144. [Google Scholar] [CrossRef]

- Xu, O.; Rangaraju, P.R.; Wang, S.; Xiao, F. Comparison of rheological properties and hot storage characteristics of asphalt binders modified with devulcanized ground tire rubber and other modifiers. Constr. Build. Mater. 2017, 154, 841–848. [Google Scholar] [CrossRef]

- Ghasemirad, A.; Asgharzadeh, S.M.; Tabatabaee, N. A comparative evaluation of crumb rubber and devulcanized rubber modified binders. Pet. Sci. Technol. 2017, 35, 1091–1096. [Google Scholar] [CrossRef]

- EN 1426:2024; Bitumen and Bituminous Binders—Determination of Needle Penetration. CEN-CENELEC Management Centre: Brussels, Belgium, 2024.

- LVS EN 1427:2015; Bitumen and Bituminous Binders—Determination of the Softening Point—Ring and Ball Method. CENCENELEC Management Centre: Brussels, Belgium, 2015.

- EN 13589:2018; Bitumen and Bituminous Binders—Determination of the Tensile Properties of Modified Bitumen by the Force Ductility Method. CEN-CENELEC Management Centre: Brussels, Belgium, 2018.

- EN 12596:2023; Bitumen and Bituminous Binders—Determination of Dynamic Viscosity by Vacuum Capillary. CEN-CENELEC Management Centre: Brussels, Belgium, 2023.

- EN ISO 2592:2017; Petroleum and Related Products Determination of Flash and Fire points Cleveland Open Cup Method. International Organization for Standardization: Geneva, Switzerland, 2017.

- EN 12593:2015; Bitumen and Bituminous Binders—Determination of the Fraass Breaking Point. CEN-CENELEC Management Centre: Brussels, Belgium, 2015.

- EN 12592:2015; Bitumen and Bituminous Binders—Determination of Solubility. SIST EN: Nitra, Slovakia, 2015.

- Asadauskas, S.; Jukna, A. Devulcanizing Agent for Production of Reclaim Rubber Powder (WO2014062043A1). 2012. Available online: https://patents.google.com/patent/WO2014062043A1/en?oq=WO2014062043A1 (accessed on 31 July 2025).

- Zhang, B.; Deng, W.; Huang, H.; Ding, L. Application of Glycine in Rubber Vulcanization, Reinforcement and Anti-Aging (CN102850580A). 2012. Available online: https://patents.google.com/patent/CN102850580A/en:Method (accessed on 31 July 2025).

- Ibrahim, H.; Marini, S.; Desidery, L.; Lanotte, M. Recycled plastics and rubber for green roads: The case study of devulcanized tire rubber and waste plastics compounds to enhance bitumen performance. Resour. Conserv. Recycl. Adv. 2023, 18, 200157. [Google Scholar] [CrossRef]

- Dong, R.; Zhao, M. Research on the pyrolysis process of crumb tire rubber in waste cooking oil. Renew. Energy 2018, 125, 557–567. [Google Scholar] [CrossRef]

- Paul, S.; Rahaman, M.; Ghosh, S.; Katheria, A.; Das, N. Rubber compounds from pilot-scale supercritical carbon dioxide assisted devulcanized rubber: Curing characteristics, mechanical and thermal properties. SPE Polym. 2025, 6. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, H.X.; Zhang, H.G.; Kuang, D.L.; Wu, J.Y.; Zhang, X.L. A study on physical and rheological properties of rubberized bitumen modified by different methods. Materials 2019, 12, 3538. [Google Scholar] [CrossRef]

- Ghosh, R.; Mani, C.; Krafczyk, R.; Schnell, R.; Talma, A.; Blume, A.; Dierkes, W.K. Exploring the Impact of Reinforcing Filler Systems on Devulcanizate Composites. Polymers 2024, 16, 1448. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, C.; Li, L.; You, Z.; Diab, A. Characterization of low temperature crack resistance of crumb rubber modified asphalt mixtures using semi-circular bending tests. J. Test. Eval. 2016, 44, 847–855. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Rheological characterization of styrene–butadiene–styrene copolymer modified bitumens. Constr. Build. Mater. 1997, 11, 23–32. [Google Scholar] [CrossRef]

- Zhang, J.W.; Chen, M.Z.; Wu, S.P.; Zhou, X.X.; Zhao, G.Y.; Zhao, Y.C.; Cheng, M. Evaluation of vocs inhibited effects and rheological properties of asphalt with high-content waste rubber powder. Constr. Build. Mater. 2021, 300, 124320. [Google Scholar] [CrossRef]

- Liu, S.J.; Zhou, S.B.; Peng, A.H.; Xuan, W.A.; Li, W. Analysis of the performance and mechanism of desulfurized rubber and low-density polyethylene compound-modified asphalt. J. Appl. Polym. Sci. 2019, 136, 48194. [Google Scholar] [CrossRef]

| Bitumen Properties | Normative Indicators of the Road Bitumen | Actual Value | Test Method |

|---|---|---|---|

| Penetration at 25 °C, not lower | 101–130 | 113 | Kazakhstani standards 1226/ EN 1426:2024 [55] |

| Softening point °C, not below | 43 | 44 | Kazakhstani standards 1227/ EN 1427:2015 [56] |

| Ductility at 25 °C, not less than, cm | 90 | >150 | Kazakhstani standards 1374/ EN 13589:2018 [57] |

| Dynamic viscosity at 135 °C, mm2/s, not less | 180 | 352 | Kazakhstani standards 1210/ EN 12596:2023 [58] |

| Flash point °C, not below | 230 | 282 | Kazakhstani standards 1804/ EN ISO 2592:2017 [59] |

| Fraass breaking point, °C, not higher | −22 | −24 | Kazakhstani standards 1229/ EN 12593:2015 [60] |

| Solubility %, not less | 99.0 | 99.9 | Kazakhstani standards 1228/EN 12592:2015 [61] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akkenzheyeva, A.; Bussurmanova, A.; Yensegenova, U.; Haritonovs, V.; Meri, R.M.; Imanbayev, Y.; Ayapbergenov, Y.; Sydykov, S.; Murzabekov, A. Modification of Bitumen with Mechanochemically Devulcanized Crumb Rubber. Processes 2025, 13, 2489. https://doi.org/10.3390/pr13082489

Akkenzheyeva A, Bussurmanova A, Yensegenova U, Haritonovs V, Meri RM, Imanbayev Y, Ayapbergenov Y, Sydykov S, Murzabekov A. Modification of Bitumen with Mechanochemically Devulcanized Crumb Rubber. Processes. 2025; 13(8):2489. https://doi.org/10.3390/pr13082489

Chicago/Turabian StyleAkkenzheyeva, Anar, Akkenzhe Bussurmanova, Uzilkhan Yensegenova, Viktors Haritonovs, Remo Merijs Meri, Yerzhan Imanbayev, Yerbolat Ayapbergenov, Serik Sydykov, and Aibar Murzabekov. 2025. "Modification of Bitumen with Mechanochemically Devulcanized Crumb Rubber" Processes 13, no. 8: 2489. https://doi.org/10.3390/pr13082489

APA StyleAkkenzheyeva, A., Bussurmanova, A., Yensegenova, U., Haritonovs, V., Meri, R. M., Imanbayev, Y., Ayapbergenov, Y., Sydykov, S., & Murzabekov, A. (2025). Modification of Bitumen with Mechanochemically Devulcanized Crumb Rubber. Processes, 13(8), 2489. https://doi.org/10.3390/pr13082489