Abstract

During large-scale pavement construction, the preparation of SBS-modified asphalt typically produces large amounts of harmful fumes. The emergence of deodorants can effectively alleviate the problem of smoke emissions during the asphalt manufacturing process. On the basis of ensuring the original road performance, exploring more suitable dosages and types of deodorant is urgently needed. Five commercial deodorants were evaluated using an asphalt smoke collection system, and UV-visible spectrophotometry (UV) was employed to screen the deodorants based on smoke concentration. Gas chromatography–mass spectrometry (GC-MS) was used to quantitatively analyze changes in harmful smoke components before and after adding two deodorants. Subsequently, the mechanisms of action of the two different types of deodorants were analyzed microscopically using fluorescence microscopy. Finally, the performance of bitumen and asphalt mixtures after adding deodorants was evaluated. The results showed that deodorant A (reactive type) and D (adsorption type) exhibited the best smoke suppression effects, with optimal addition rates of 0.6% and 0.5%, respectively. Deodorant A reduced benzene homologues by nearly 50% and esters by approximately 40%, while deodorant D reduced benzene homologues by approximately 70% and esters by approximately 60%, without producing new toxic gases. Both deodorants had a minimal impact on the basic properties of bitumen and the road performance of asphalt mixtures, with all indicators meeting technical specifications. This research provides a theoretical basis for the effective application of deodorants in the future, truly enabling a transition from laboratory research to large-scale engineering applications in the construction of environmentally friendly roads.

1. Introduction

Asphalt, a widely used petroleum-derived material, is extensively employed in the field of road pavement engineering. China consumes over 30 million tons of asphalt annually, with approximately 600 to 700 million tons of asphalt mixture being used each year [1]. During the high-temperature production, transportation, and construction of asphalt, a significant quantity of complex exhaust gases is released. These asphalt fumes contain a large amount of volatile organic pollutants (VOCs), with over 196 organic compounds identified, including VOCs, polycyclic aromatic hydrocarbons (PAHs), CO, H2S, NO2, and SO2 [2,3,4]. These substances pose serious threats to human health, such as respiratory system damage, skin irritation, and carcinogenicity. Additionally, VOCs are important precursors for the formation of fine particulate matter (PM2.5) and ozone (O3), both of which directly harm human health and exacerbate global warming [2,3,4,5].

Currently, the primary strategies for mitigating asphalt fume emissions include end-of-pipe purification and source suppression [6,7,8]. While purification technologies are widely applied in mixing plants, they are ineffective at construction sites due to the uncontrolled dispersion of gases. Source suppression, on the other hand, involves modifying asphalt properties through additives to directly reduce fume generation, offering a more practical solution. Existing research on asphalt deodorants can be broadly categorized into two types: adsorption-based (physical) and reaction-based (chemical) [9,10,11]. Adsorption deodorants mainly utilize physical adsorption (such as porous materials) or physical coating (such as polymer coatings), usually not altering the chemical composition of asphalt but achieving deodorization through physical interactions. Therefore, they have almost no impact on the basic properties of asphalt and the road performance of asphalt mixtures, and are suitable for scenarios that require short-term and efficient deodorization [2,3,4,5]. Reactive deodorants, on the other hand, undergo chemical reactions with the odor-causing components in asphalt, converting them into low-volatile or stable compounds [12]. This may affect the structure of asphaltene itself and, to some extent, the actual road performance. They are suitable for situations where long-term effective control of exhaust gas is required.

Previous studies have explored various deodorants for suppressing VOCs. Zhao et al. [13] used zeolite as the main adsorption material and combined it with layered double hydroxides (LDH) to synergically reduce VOC emissions during the asphalt production process, especially by reducing the emissions of alkanes and alkenes. Li et al. [14] modified base asphalt using organic montmorillonite nano-clay and assessed its inhibitory effect on asphalt VOC emissions using pyrolysis gas chromatography coupled with mass spectrometry (Py-GC/MS). Research has found that organic montmorillonite can effectively reduce the emission of VOCs, most of which are aliphatic hydrocarbons. Fadhilah et al. [15] attempted to reduce VOC emissions in rubber-modified asphalt using a wet scrubber. Zhou [16,17] and others found that biochar can continuously adsorb VOCs from asphalt fumes, reducing emissions of alkanes, polycyclic aromatic hydrocarbons (PAHs), and sulfur compounds. Other researchers have used alkylamine buffers [18,19] and organic montmorillonite (MMT) [20] to suppress asphalt VOC emissions. The former reduces the internal surface tension of asphalt, enabling it to coat aggregates at room temperature; the latter mitigates molecular decomposition by lowering the internal temperature of the asphalt material. However, both methods can adversely affect the pavement performance (such as high-temperature stability or water stability) of asphalt mixtures to some extent. Additionally, in the most commonly used SBS-modified asphalt, the selection of deodorants and their dosage remain urgent issues to address [21,22].

Therefore, this study focuses on SBS-modified asphalt, which is widely used in road pavement construction, aiming to address the aforementioned research gaps. This paper prioritizes five commonly used deodorants available on the market. Using an asphalt fume generation and collection device, the inhibitory effects of the five different types of deodorants are evaluated, and the two most effective deodorants are selected. Subsequently, a comparative analysis is conducted on the two different types of deodorants at five different dosage levels ranging from 0.2 to 1.0, to determine the optimal dosage under their respective mechanisms of action. Subsequently, the components of the fumes were quantitatively determined using gas chromatography–mass spectrometry (GC-MS), and the microscopic mechanisms of action of the odor-eliminating agents were partially revealed using fluorescence microscopy. Finally, the basic physical properties of the bitumen and the pavement performance of the asphalt mixture after adding the two odor-eliminating agents were evaluated and analyzed. This study is dedicated to providing research ideas for reducing flue gas emissions during the preparation of SBS-modified asphalt and offering references for the subsequent selection of deodorants.

2. Materials and Methods

2.1. Raw Materials and Basic Performance

2.1.1. Asphalt

SBS-modified asphalt, which is the most widely used in actual road engineering, was selected as the research object. Basic performance tests and anti-aging performance tests were conducted on SBS-modified asphalt, and the technical parameters are shown in Table 1.

Table 1.

Basic performance index of SBS-modified asphalt.

2.1.2. Deodorants

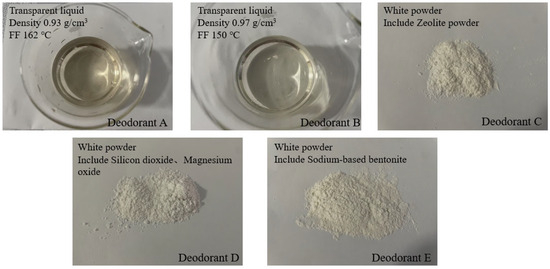

Five different types of deodorants were selected. The first two are reactive types that reduce VOC content by chemically reacting with toxic substances in the smoke, while the last three achieve the same effect through physical adsorption. All five deodorants are economical and environmentally friendly, and their forms are shown in Figure 1.

Figure 1.

Five types of deodorants.

2.1.3. Sample Preparation

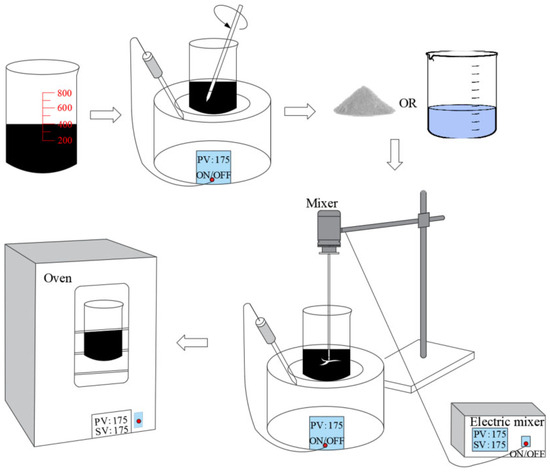

Five deodorants were separately added to SBS-modified asphalt, and the dosage of the deodorants was 0.1%. The specific preparation process is divided into the following three steps [23]. Step I: The SBS-modified asphalt was heated to a flowing state and stirred at low speed for 10~15 min at 175 °C. Step II: Slowly add the odor-eliminating agent, stir at a speed of 120~150 r/min for 5~10 min, then stir at a speed of 650~700 r/min for 20~30 min; then, place the stirred asphalt in a constant-temperature oven at 175 °C for 30 min. Step III: After the oven has completed its insulation process, the prepared odor-free asphalt is obtained. The preparation process for odorless asphalt is shown in Figure 2.

Figure 2.

Flow chart of odorless asphalt preparation.

2.2. Fume Collection Process of SBS-Modified Asphalt

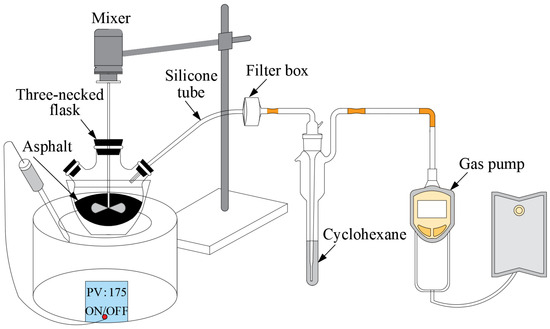

To investigate the suppression level and deodorization effect of odor neutralizers on asphalt fumes, this study designed an asphalt fume collection system based on relevant standards [23,24], targeting the state of substances produced during the asphalt heating process. The system consists of a heating and stirring device, a solid particle filtration device, an organic gas absorption device, and an inorganic gas collection device, as shown in Figure 3. The solid particle filtration device uses a PTFE filter membrane with a diameter of 47 mm and a pore size of 0.22 μm, which is the boundary point between solid and gas particle sizes. The organic gas absorption device employs a less toxic cyclohexane solution as the solvent, while the inorganic gas collection device uses gas sampling bags for collection.

Figure 3.

Asphalt fume generation and enrichment devices.

The specific steps for collecting flue gas are divided into the following 5 steps.

- (1)

- Fill the bubble absorption tube with cyclohexane solvent to a volume of 10 mL;

- (2)

- Add a certain mass of asphalt to the three-neck flask and insert the stirrer;

- (3)

- Press the heating jacket heating button, control the stirrer speed to 300 r/min, maintain the temperature at 180 °C once the asphalt reaches this temperature, and start timing.

- (4)

- After 1 h, immediately connect the bubble absorption tube to the right port of the three-neck flask using a silicone tube, and activate the sampling pump to draw gas at a rate of 500 mL/min;

- (5)

- After sampling for 15 min, shut off the sampling pump, disconnect the bubble absorption tube from the three-neck flask, mix the cyclohexane solutions enriched with asphalt fumes from both bubble absorption tubes, pour into a brown reagent bottle, shake well, and store at 1 °C to minimize cyclohexane evaporation during storage.

2.3. Ultraviolet-Visible (UV) Spectrophotometry

In the process of preparing odorless asphalt, the selection of odorless agents is particularly important. First, the total amount of asphalt fumes is assessed using ultraviolet-visible (UV) spectrophotometry. By comparing the concentration of asphalt fumes, the best one or two deodorizing agents are selected from several deodorizing agents.

A good linear relationship is required between absorbance and asphalt smoke concentration in a certain range. The wavelength of 288 nm was selected as the absorbance evaluation index, and the concentration of asphalt fumes was calculated using the linear relationship between absorbance and asphalt fume concentration. In this paper, eight groups of cyclohexane solutions were prepared to absorb asphalt smoke through preliminary experiments.

The absorbance of the above eight groups of cyclohexane solutions was measured separately. With asphalt smoke concentration as the horizontal coordinate and absorbance as the vertical coordinate, a scatter plot was drawn and linear regression fitting was carried out. The linear regression equation is shown in Equation (1)

where x is the concentration of asphalt smoke and y is the absorbance. The linear coefficient R2 in the regression equation was 0.995, which showed a good linear relationship.

According to the same test conditions, the asphalt smoke produced by five kinds of smoke suppression asphalt was collected with cyclohexane, and then its absorbance was measured by ultraviolet spectrophotometer. The asphalt smoke concentration was calculated according to the linear regression formula fitted in this paper, and the results were shown in Figure 3. The smoke suppression effects were defined according to the following Equation (2):

where A is the asphalt smoke concentration produced by SBS asphalt, B is the concentration of asphalt smoke produced by smoke suppressant asphalt, and C is the effect of smoke suppressant.

After that, the optimal mixing ratio of the deodorant can be determined to better suppress the emission of traditional SBS asphalt fumes by designing deodorants with different mixing ratios. Finally, a gas chromatograph is used to further analyze the suppression effect of the deodorant on VOCs at the optimal mixing ratio.

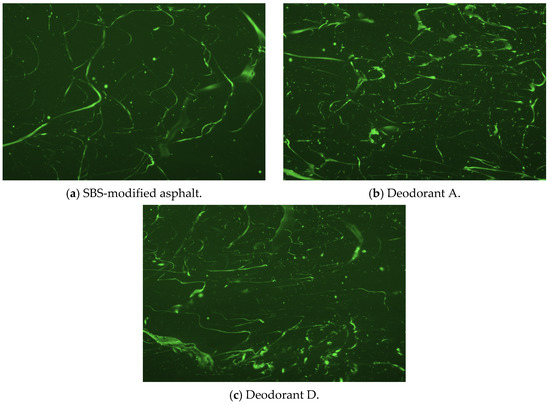

2.4. Fluorescence Microscopy Analysis

Fluorescence microscopy was used to further observe the microscopic structural changes in SBS-modified asphalt after the addition of two deodorants [12,25], as shown in Figure 4. SBS and other high-molecular-weight polymers exhibit yellow-green fluorescence under a fluorescence microscope, while asphalt appears black. Therefore, fluorescence can be used to analyze the distribution of the modifier in the asphalt.

Figure 4.

Fluorescence microscopy equipment.

2.5. Asphalt Physical Properties Test

According to the corresponding test standards [23], the influence of the deodorant on the basic properties of asphalt materials was evaluated through the penetration, softening point, ductility, residual penetration, and residual ductility after the rotary film oven test (RTFOT).

2.6. Asphalt Mixture Road Performance Test

According to the corresponding test standards [23], the effects of deodorants on the performance of asphalt mixtures were evaluated using high-temperature rutting tests, low-temperature crack resistance tests, and water stability tests.

3. Results and Discussions

3.1. Composition of Asphalt Fumes Before and After Adding Deodorant

3.1.1. Analysis of UV Spectrophotometric Test

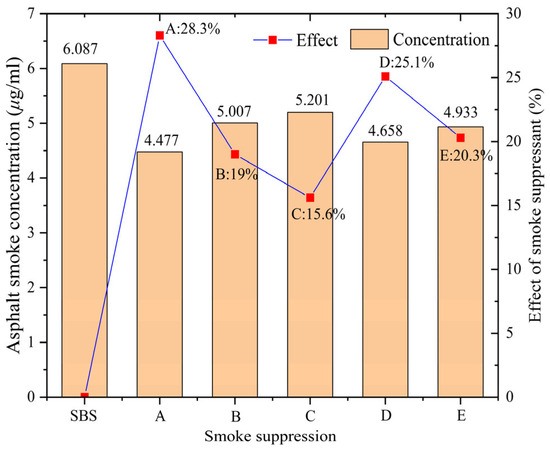

Comparing the concentration of asphalt smoke produced by SBS asphalt and five kinds of smoke suppressant asphalt, all five kinds of smoke suppressants had certain smoke suppression effects, as shown in Figure 5. In particular, the smoke suppression effect of smoke suppressants A, D, and E reached over 20%. Considering that the smoke suppression effect of smoke suppressant E was still inferior to that of smoke suppressant D at high dosages, smoke suppressants A and D showed the most excellent smoke suppression effect. Therefore, smoke suppressants A and D were selected to study the effect of smoke suppressant content on smoke suppression, asphalt properties, and asphalt mixture properties.

Figure 5.

Inhibitory effect of five smoke suppressants.

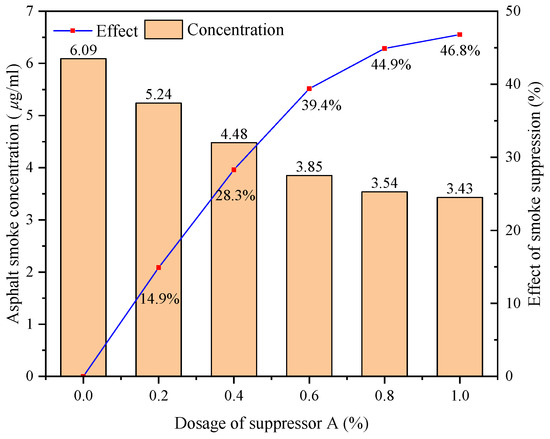

Accordingly, for smoke suppressants A and D, five groups of different dosage were set to determine the optimal dosage of smoke suppressant. For the smoke suppressant A, the dosage range was set between 0.2% and 1%. The absorbance was measured in the above manner, the asphalt smoke concentration and smoke suppression effect were calculated, and the results are shown in Figure 6.

Figure 6.

Smoke suppression effect of different dosages of suppressant A.

Smoke suppressant A was a reactive smoke suppressant. The concentration of asphalt smoke decreased gradually with the increase of smoke suppressant A content. When the content of smoke suppressant A reached 0.6%, the increase of the content had no obvious effect on the decrease of asphalt smoke concentration. The possible reason was that when the dosage was not more than 0.6%, the smoke suppressant and asphalt could have been fully stirred, which may have made some substances in the smoke suppressant react with the harmful pollutants in the asphalt smoke and produce low-toxic or even non-toxic substances, thus reducing the generation of asphalt smoke. However, when the dosage was greater than 0.6%, the substance that could have reacted chemically with the smoke suppressant had basically reacted, and the increase of the dosage could not bring about a decrease in the concentration of asphalt smoke but lead to an increase in cost.

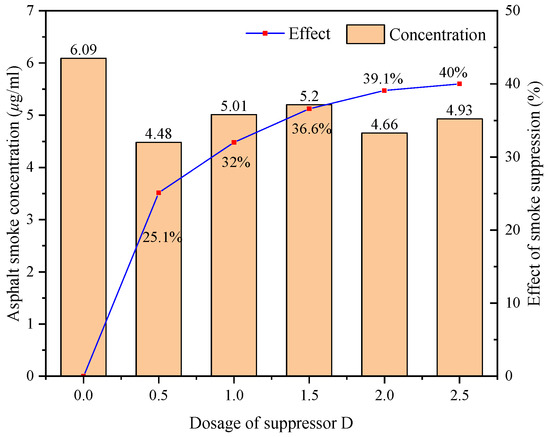

For the smoke suppressant D, the dosage range was set between 0.5% and 2.5%. The absorbance was measured in the above manner, the asphalt smoke concentration and smoke suppression effect were calculated, and the results are shown in Figure 7.

Figure 7.

Smoke suppression effect of different dosages of smoke suppressant D.

Unlike smoke suppressant A, D was an adsorbent smoke suppressant. With the increase of smoke suppressant D dosage, asphalt smoke concentration decreased. When the dosage of smoke suppressant D was 0.5%, the asphalt smoke concentration appeared to decrease significantly, and as the smoke suppressant D dosage continued to increase, the reduction of asphalt smoke concentration grew smaller and smaller. Even when the dosage of smoke suppressant D was greater than 2%, the concentration of asphalt smoke did not change significantly. The possible reason was that when the content of smoke suppressant D was less than 0.5%, smoke suppressant D and asphalt were fully stirred, so smoke suppressant D could have fully played its role and absorbed a large number of harmful components in asphalt smoke. However, with the increase of the dosage, the smoke suppressant could not be effectively dispersed in the asphalt, the adsorption effect was affected to a certain extent, and the smoke suppressant D could only adsorb some of the harmful components in the asphalt smoke. Therefore, as the concentration of harmful components decreased, the adsorption capacity decreased significantly. Especially when the content was greater than 2%, the adsorption effect of asphalt flue gas was no longer obvious with the increase of the content.

3.1.2. GC-MS Test Result Analysis

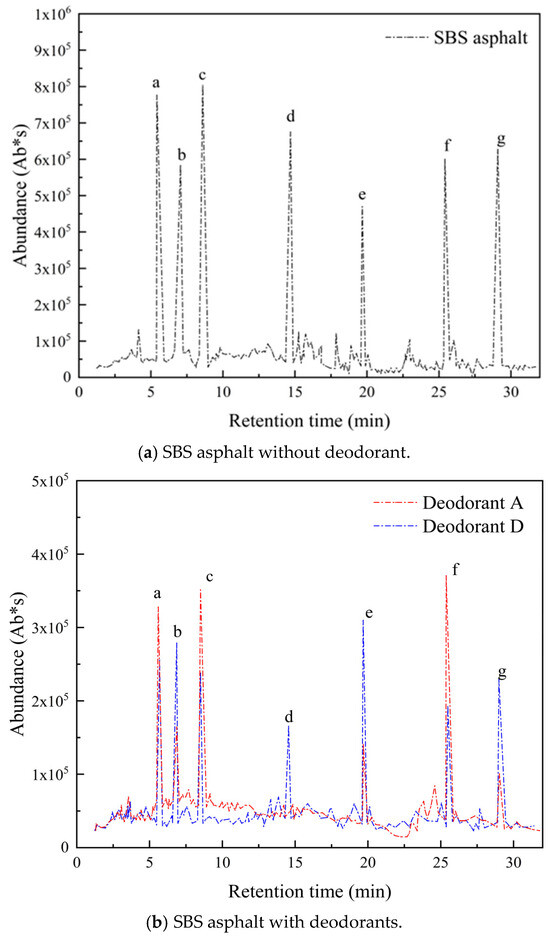

It can be learned from the above that the optimal blending ratios for the two better deodorants, A and D, are 0.6% and 0.5%, respectively. Therefore, two types of smoke-suppressing modified asphalt were prepared separately to further study the changes in the composition of asphalt smoke after smoke suppression modification. To further analyze the smoke suppression effects of liquid smoke-suppressing asphalt and powder smoke-suppressing asphalt, samples of cyclohexane solutions of asphalt smoke from the two types of smoke-suppressing modified asphalt and SBS asphalt were collected at 210 °C and analyzed using gas chromatography–mass spectrometry.

The GC-MS chromatograms of the SBS-modified asphalt without deodorant tested under different temperatures are shown in Figure 8. In order to more clearly show the changes in harmful substances in VOCs before and after the addition of the deodorant, a large number of alkanes are not labeled in the figure. Harmful substances are specially labeled and indicated by corresponding symbols. Compounds with a retention time difference of less than 0.005 min are labeled as the same substance. Flue gas primarily contains 30 types of organic compounds across 10 categories, including alkanes, alkenes, amines, benzene, phenols, naphthalene, thiophene, alcohols, mercaptans, and methyl esters. As the temperature increases, gases with a pungent odor are produced.

Figure 8.

GC-MS chromatogram of SBS-modified asphalt after addition of deodorant (In the figure, a–g are characteristic peak points).

Table 2 lists the composition of the harmful substances detected, including benzene compounds (a–c), naphthalene derivatives (d), nitrogen-containing compounds (e), esters (f), and phenols (g). These are the primary volatile components of SBS asphalt, with aromatic hydrocarbons (a–c) and esters (f) being the typical sources of odor. As shown in Figure 6, before the addition of deodorants A and D, the concentrations of 1,2,3-trimethylbenzene (RT = 5.54 min) and o-xylene (RT = 8.49 min) were higher than those of other benzene homologues. Compared to most less toxic alkanes, benzene and its homologues pose greater risks to environmental and human safety. With the addition of deodorants A and D, the areas of all peaks significantly decreased, and in some cases, peak d disappeared. The concentrations of 1,2,3-trimethylbenzene, p-xylene, o-xylene, 2-methylnaphthalene, and other highly toxic substances decreased. It can be observed that both liquid and powder smoke suppressants exhibit good smoke suppression effects. For deodorant D, the removal rate for benzene homologues reached nearly 50%, and the removal rate for ester compounds reached nearly 40%. For deodorant A, the removal rate for benzene homologues reached nearly 70%, the removal rate for ester compounds reached nearly 60%, and even peak d (2-Methylnaphthalene) was completely removed. This may be due to the presence of specific functional groups in deodorant A, which exhibit stronger affinity for aromatic hydrocarbons and esters, thereby providing superior deodorization performance for reducing harmful substances in SBS-modified asphalt. Furthermore, neither of these deodorants produces new toxic gases in the exhaust fumes of the original SBS-modified asphalt, making them more suitable for application in subsequent asphalt and asphalt mixture road applications.

Table 2.

Retention time of peaking compounds in the chromatogram.

3.2. Analysis of Fluorescence Microscopy Test

During fluorescence microscopy scanning, the magnification was uniformly set to 200×. The fluorescence microscopy images of each asphalt are shown in Figure 9. The fluorescence image of SBS-modified asphalt shows a continuous network-like structure, indicating that SBS forms a stable phase-separated structure in the asphalt, with a clear interface between the polymer phase (SBS) and the asphalt phase (matrix asphalt). After adding deodorant A, the fluorescence texture becomes fragmented, with broken filaments, forming more dispersed small particles, and the SBS network structure may be disrupted. This suggests that deodorant A interferes with the aggregated state of SBS through chemical interactions (such as polar group interactions), leading to more uniform dispersion of the polymer phase but reduced structural integrity, which may affect the macro-performance of the asphalt. After adding deodorant D, the asphalt fluorescence texture lies between that of SBS and SBS+A, retaining more continuous filaments, while also containing dispersed particles, indicating that deodorant D causes less damage to the microscopic structure of SBS asphalt. This suggests that it primarily targets volatile odor components (such as aromatic hydrocarbons and esters detected by GC-MS) by adsorbing odor molecules rather than significantly disrupting the SBS phase state.

Figure 9.

Fluorescence micrograph of asphalt.

3.3. Analysis of Asphalt Physical Properties Test

The changes in the physical properties of SBS-modified asphalt before and after the addition of deodorants A and D are shown in Table 1. As can be seen from Table 1, with the addition of deodorants A and D, the penetration and elongation of SBS-modified asphalt both decreased slightly, while the softening point increased slightly. Deodorant D has a more gradual effect on increasing the softening point of asphalt and has a minimal impact on changes in asphalt hardness, which aligns with the observations made under fluorescence microscopy regarding the preservation of better SBS network integrity.

For deodorants A and D, after heating the asphalt film, the residual penetration increased by 1.49% and 0.68%, respectively; the residual elongation increased by 8.9% and 3.0%, respectively; and the mass change decreased by 1.7% and 0.83%, respectively. For deodorant A, while inhibiting the volatilization of low-molecular-weight substances, it significantly improves the aging performance of SBS-modified asphalt. For deodorant D, it slightly improves the asphalt’s resistance to aging. Overall, deodorants A and D have minimal impact on the basic properties of SBS-modified asphalt, and both meet technical specification requirements.

3.4. Analysis of Road Performance of Asphalt Mixture

Using SMA-13 as the research subject, basalt was employed as the aggregate. And the optimal asphalt-to-aggregate ratio was set at 6.0%. Odor-neutralizing agents A and D were used at concentrations of 0.6% and 0.5%, respectively, to prepare odor-neutralized asphalt. Asphalt mixture specimens were then prepared according to standard methods, ensuring that the asphalt content of the odor-neutralized asphalt mixture was identical to that of SBS-modified asphalt. The water stability, high-temperature stability, and low-temperature crack resistance of the asphalt mixture after adding the two deodorants were investigated. The test results are shown in Table 3.

Table 3.

Pavement performance of asphalt mixture with deodorant.

According to the data in Table 3, after adding deodorants A and D, the rutting dynamic stability of the asphalt mixture increased by 7.87% and 9.59%, respectively; both slightly improved high-temperature rutting resistance, with D showing a more pronounced effect. The maximum bending strain decreased by 11.35% and increased by 6.88%, respectively. The decrease in maximum bending strain for SBS+A is attributed to the chemical reaction of deodorant A with SBS molecules, which disrupts the continuous SBS network (as evidenced by the fragmented appearance in the fluorescence image, Figure 9b). This structural damage reduces the asphalt’s flexibility at low temperatures. In contrast, SBS+D shows increased bending strain because deodorant D (adsorption type) preserves the SBS network integrity (Figure 9c) and may enhance intermolecular bonding through physical adsorption, improving low-temperature ductility. Both deodorants improved the water stability of the asphalt mixture, consistent with the aforementioned microstructural analysis and asphalt performance results. Overall, the addition of the two deodorants had little impact on the road performance of the asphalt mixture, and the road performance of both odorless asphalt mixtures met the specified requirements.

4. Conclusions

This study systematically investigated the inhibitory effects of different deodorants on SBS-modified asphalt fume emissions, focusing on flue gas reduction efficiency, optimal dosage, mechanisms, and impacts on bitumen basic performance and asphalt mixture road performance. Key conclusions are as follows:

- (1)

- Deodorants can effectively reduce emissions of VOCs, CO, H2S, NO, and SO2, with the optimal dosage of deodorant A (reactive type) being 0.6% and that of deodorant D (adsorptive type) being 0.5%. At these dosages, the total flue gas emission reduction rate exceeds 50%, with VOCs (accounting for approximately 60% of total emissions) achieving a reduction rate of 40–70%. Notably, high-odor compounds such as benzene homologues and ethyl mercaptan can achieve removal rates as high as 70%, confirming targeted inhibition of harmful substances.

- (2)

- Deodorant A decomposes volatile components by chemically reacting with odor molecules (such as aromatic hydrocarbons and esters). Deodorant D captures harmful gases through physical adsorption, utilizing its specific surface area. Fluorescence microscopy observations show that deodorant D better preserves the SBS network structure, while deodorant A causes minor structural damage. This phenomenon aligns with the adsorption and reaction mechanisms of both agents. Both additives enhance intermolecular cohesion and inhibit the volatilization of small molecules.

- (3)

- Deodorants have minimal impact on the basic properties of asphalt: permeability and extensibility decrease slightly (<3%), while the softening point and aging resistance (residual permeability/extensibility) improve slightly. For asphalt mixtures, high-temperature rutting resistance (dynamic stability) improved by 7.87–9.59%, water stability (immersion residual stability) improved by 2.27–5.15%, and low-temperature crack resistance remained unchanged (deodorant A) or slightly improved (deodorant D). All performance indicators meet technical specifications, confirming their practical applicability.

- (4)

- The source and processing technology of SBS-modified asphalt can affect flue gas components and concentrations, even for the same type of asphalt. This highlights the necessity of adding appropriate amounts of deodorants during asphalt processing and mixing.

- (5)

- Deodorants achieve efficient flue gas emissions reduction while maintaining asphalt performance, making them suitable for environmentally friendly road construction. Future research should explore their applicability in other asphalt types (such as rubber-modified asphalt) and optimize formulations to accommodate a broader range of road asphalt sources.

Author Contributions

Conceptualization, Z.S.; Software, Z.S.; Formal analysis, N.Y.; Investigation, N.Y.; Resources, X.Z.; Data curation, N.Y.; Writing—original draft, Z.S.; Writing—review & editing, X.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research is especially grateful to Shandong Hi-Speed Infrastructure Construction Co., Ltd. for project funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Zhaoyan Sheng and Ning Yan were employed by the company Shandong Hi-Speed Infrastructure Construction Co., Ltd. The authors declare that this study received funding from Shandong Hi-Speed Infrastructure Construction Co., Ltd. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article or the decision to submit it for publication. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Pan, P.; Wu, S.; Xiao, Y.; Liu, G. A review on hydronic asphalt pavement for energy harvesting and snow melting. Renew. Sustain. Energy Rev. 2015, 48, 624–634. [Google Scholar] [CrossRef]

- Wang, M.; Li, P.; Nian, T.F.; Mao, Y. An overview of studies on the hazards, component analysis and suppression of fumes in asphalt and asphalt mixtures. Constr. Build. Mater. 2021, 289, 123185. [Google Scholar] [CrossRef]

- Yue, T.T.; Yue, X.; Chai, F.; Hu, J.; Lai, Y.; He, L.; Zhu, R. Characteristics of volatile organic compounds (VOCs) from the evaporative emissions of modern passenger cars. Atmos. Environ. 2017, 151, 62–69. [Google Scholar] [CrossRef]

- Kumar, A.P.; Singh, D.; Kumar, K.; Singh, B.B.; Jain, V.K. Distribution of VOCs in urban and rural atmospheres of subtropical India: Temporal variation, source attribution, ratios, OFP and risk assessment. Sci. Total Environ. 2018, 613–614, 492–501. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.S.; Chen, M.Z.; Yang, X.Y.; Zhang, J.W.; He, J.; Han, M.Y. Investigation on physical, rheological properties and VOCs emission of asphalt modified with hydrocarbon-based graphene. Constr. Build. Mater. 2025, 469, 140474. [Google Scholar] [CrossRef]

- Chauhan, S.K.; Sharma, S.; Shukla, A.; Gangopadhyay, S. Recent trends of the emission characteristics from the road construction industry. Environ. Sci. Pollut. Res. 2010, 17, 1493–1501. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Liu, S.; Zhang, J.; Li, Z.; Ning, A. Research status and development of asphalt flue gas treatment technology. Pet. Asph. 2021, 35, 1–5. [Google Scholar]

- Chong, D.; Wang, Y.H.; Zhao, K.; Wang, D.; Oeser, M. Asphalt fume exposures by pavement construction workers: Current status and project case. J. Constr. Eng. Manag. 2018, 144, 1–12. [Google Scholar] [CrossRef]

- Li, L.W.; Wang, P.; Zhou, T.; Cao, L.P.; Ding, X.; Zhang, B.T.; Wei, L.D. Performance evaluation and multiscale investigation of deodorant on mechanism of rubber modified asphalt. J. Clean. Prod. 2023, 425, 138954. [Google Scholar] [CrossRef]

- Guo, Y.N.; Zhao, Y.; Sun, L.H.; Xu, X.C.; Zhang, H.C. Characterization of Fume Suppression Effect and Performance of SBS-Modified Asphalt with Deodorant. Processes 2024, 12, 2603. [Google Scholar] [CrossRef]

- Zhu, C.Z.; Li, D.Q.; Zhang, H.L.; Guo, X.G.; Xu, F.; Xiao, F.P.; Amir Khanian, S.; Zhang, D.M. Effect of microwave and deodorant treatments on long-term aging characteristics of crumb rubber modified asphalt. Case Stud. Constr. Mater. 2024, 21, e03620. [Google Scholar]

- Cao, L.P.; Yang, C.; Li, A.; Wang, P.; Zhang, Y.; Dong, Z.J. Flue gas composition of waste rubber modified asphalt (WRMA) and effect of deodorants on hazardous constituents and WRMA. J. Hazard. Mater. 2021, 403, 123814. [Google Scholar] [CrossRef]

- Zhao, H.W.; Chen, A.Q.; Wu, S.P.; Xu, H.Q.; Wang, H.; Wang, H.; Lyu, Y.L.; Yang, L. Synergistic Reduction in Asphalt VOC Emissions by Hydrochloric Acid-Modified Zeolite and LDHs. Materials 2024, 17, 5664. [Google Scholar] [CrossRef]

- Li, L.; Wu, S.; Liu, G.; Cao, T.; Amirkhanian, S. Effect of organo-montmorillonite nanoclay on VOCs inhibition of bitumen. Constr. Build. Mater. 2017, 146, 429–435. [Google Scholar] [CrossRef]

- Idris, N.F.; Le-Minh, N.; Hayes, J.E.; Stuetz, R.M. Performance of wet scrubbers to remove VOCs from rubber emissions. J. Environ. Manag. 2022, 305, 114426. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Moghaddam, T.B.; Chen, M.; Wu, S.; Adhikari, S. Biochar removes volatile organic compounds generated from asphalt. Sci. Total Environ. 2020, 745, 141096. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Shi, L.; Moghaddam, T.B.; Chen, M.; Wu, S.; Yuan, X. Adsorption mechanism of polycyclic aromatic hydrocarbons using wood waste-derived biochar. J. Hazard. Mater. 2022, 425, 128003. [Google Scholar] [CrossRef]

- Qin, Q.; Farrar, M.J.; Pauli, A.T.; Adams, J.J. Morphology, thermal analysis and rheology of Sasobit modified warm mix asphalt binders. Fuel 2014, 115, 416–425. [Google Scholar] [CrossRef]

- Yu, H.Y.; Leng, Z.; Dong, Z.J.; Tan, Z.F.; Guo, F.; Yan, J.H. Workability and mechanical property characterization of asphalt rubber mixtures modified with various warm mix asphalt additives. Constr. Build. Mater. 2018, 175, 392–401. [Google Scholar] [CrossRef]

- Jin, J.; Liu, M.H.; Liu, S.; Chen, B.Z.; Liu, X.Y. Study on CeO2 Pillared Montmorillonite Modified Asphalt and Its Catalytic Performance Based on the Emission Reduction of Ecological Pavement. Mater. Rev. 2023, 36, 26–32. [Google Scholar]

- Li, P.T.; Guan, B.W.; Huang, Z.H.; Liu, M.; Ma, Z.X.; Zhou, C.; Ma, X.Y.; Nian, J.N. Effect of layered double hydroxides on the VOCs emission and the properties of SBS modified asphalt. Constr. Build. Mater. 2024, 439, 137398. [Google Scholar] [CrossRef]

- Zhao, Z.G.; Wang, Z.P.; Wu, S.P.; Xie, J.; Yang, C.; Li, N.; Cui, P.D. Road performance, VOCs emission and economic benefit evaluation of asphalt mixture by incorporating steel slag and SBS/CR composite modified asphalt. Case Stud. Constr. Mater. 2023, 18, 01929. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communications Press: Beijing, China, 2011.

- US Environmental Protection Agency (EPA). Determination of Total Gaseous Organic Concentration Using a Flame Ionization Analyzer: Method 25A[S]; U.S. Environmental Protection Agency: Washington, DC, USA, 2012. [Google Scholar]

- Xu, X.; Guo, H.Y.; Wang, X.F.; Zhang, M.X.; Wang, Z.J.; Yang, B. Physical properties and anti-aging characteristics of asphalt modified with nano-zinc oxide powder. Constr. Build. Mater. 2019, 224, 732–742. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).