Abstract

With the in-depth application of digital transformation in the oil industry, data-driven methods provide a new technical path for drilling engineering safety evaluation. In this paper, a data-driven drilling safety level evaluation system is proposed. By integrating the three-dimensional visualization technology of wellbore trajectory and the prediction model of friction torque, a dynamic and intelligent drilling risk evaluation framework is constructed. The Python platform is used to integrate geomechanical parameters, real-time drilling data, and historical working condition records, and the machine learning algorithm is used to train the friction torque prediction model to improve prediction accuracy. Based on the K-means clustering evaluation method, a three-tier drilling safety classification standard is established: Grade I (low risk) for friction (0–100 kN) and torque (0–10 kN·m), Grade II (medium risk) for friction (100–200 kN) and torque (10–20 kN·m), and Grade III (high risk) for friction (>200 kN) and torque (>20 kN·m). This enables intelligent quantitative evaluation of drilling difficulty. The system not only dynamically optimizes bottom-hole assembly (BHA) and drilling parameters but also continuously refines the evaluation model’s accuracy through a data backtracking mechanism. This provides a reliable theoretical foundation and technical support for risk early warning, parameter optimization, and intelligent decision-making in drilling engineering.

1. Introduction

At present, domestic drilling software products still exhibit significant shortcomings in terms of functional integration, application coverage, and intelligentization level, making it difficult to meet the precision and intelligent requirements for drilling safety evaluation in oilfield production [1]. Particularly in the assessment of drilling safety levels, traditional methods predominantly rely on empirical formulas and static models, lacking data-driven dynamic analysis capabilities, which results in insufficient accuracy and timeliness of evaluation outcomes [2]. With the advancement of digital-intelligent construction in oil and gas fields, data-driven drilling safety evaluation technologies have become a research hotspot in the industry. Scholars worldwide have achieved a series of important research results in this field [3].

The trajectory module of the domestic drilling software is still based on the simplified arc-line model, without considering the nonlinear contact between the drill string and the borehole wall and the formation anisotropy. The error of the target center distance in the horizontal section can reach 1.8 times that of the Landmark result [4,5]. The friction torque model has poor adaptability to long horizontal sections, and the friction and torque errors in well sections above 1500 m are as high as 18% and 22%, respectively. The main reason is that the dynamic effects of drill string buckling, whirling, and wellbore cleanliness are ignored [6]. At the same time, the lack of unified input standards for key parameters such as wellbore roughness and mud cake friction coefficient leads to a large dispersion of calculation results in the same block [7]. Although studies have confirmed that the introduction of an on-site big data self-correction module can reduce the error to less than 8%, However, no mature commercial software products currently exist in the industry market [8]. Low trajectory accuracy and poor friction torque reliability have become the “ neck “ links in the application of domestic software in deep and unconventional wells. It is urgent to upgrade high-order models, data inversion, and parameter standardization.

Data-driven methods have demonstrated remarkable advantages in international drilling safety evaluation. Research indicates that integrating machine learning algorithms with geomechanical models enables a dynamic assessment of wellbore stability risks [9]. For example, the Quantitative Risk Assessment (QRA) technique developed by Moos et al., which employs Monte Carlo simulation, can quantify the impact of uncertainties in key geomechanical parameters on safe drilling fluid density windows, significantly improving the reliability of wellbore stability predictions [10]. Similarly, Chinese researchers have developed a segmented friction torque calculation model for slim-hole extended-reach horizontal wells by analyzing influencing factors such as lateral length, trajectory profile, and bottom hole assembly (BHA), providing a theoretical basis for safe drilling operations [11].

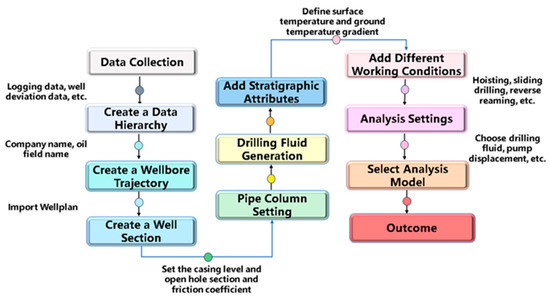

Landmark software, as an internationally recognized drilling engineering application, demonstrates comprehensive functionality but suffers from two notable operational limitations: firstly, its complex interface requires extensive parameter inputs (Figure 1) that demand specialized expertise, creating substantial barriers for novice users; secondly, the prohibitively expensive licensing structure. In response to these challenges, our research has developed a streamlined drilling engineering support tool featuring optimized human–machine interaction and simplified parameter input protocols. This innovation significantly reduces the learning curve and accessibility threshold, enabling efficient operation by non-specialist personnel while maintaining professional-grade functionality [12,13,14,15].

Figure 1.

Landmark operation process.

Based on the data-driven concept, this paper develops a set of intelligent drilling safety evaluation systems by using Python (version 3.12.1). By integrating multiple coupling trajectory prediction technologies and a multi-parameter coupling friction torque prediction algorithm, a three-level drilling safety intelligent evaluation system, including grade I (low risk), grade II (medium risk), and grade III (high risk), is constructed. The system realizes automatic analysis from drilling parameter input to safety level output, provides wellbore trajectory visualization, friction torque prediction, and optimization suggestions, and provides intelligent solutions for drilling engineering risk prevention and control and parameter optimization.

2. Multivariate Coupling Trajectory Prediction Model

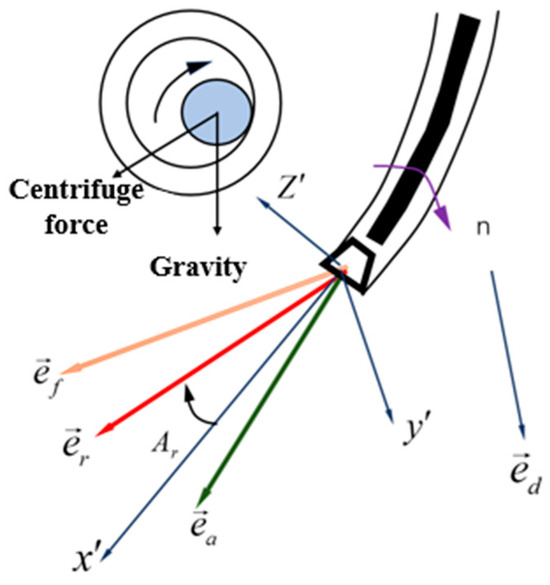

The formation of a wellbore trajectory is a dynamic process of complex interaction between drill bit and formation. Aiming at the technical bottlenecks such as insufficient trajectory control accuracy, trajectory deviation caused by formation heterogeneity, and complex mechanical properties of BHA ((Bottom Hole Assembly) refers to the combination of drill bits, drill collars, stabilizers and other components located at the bottom of the drill string, which significantly influences drilling direction and efficiency) in reservoir drilling, this paper proposes a trajectory prediction model based on an improved mechanical analysis method. By introducing the mechanical mechanism of the influence of rotational speed centrifugal force on the trajectory of high curvature section, the traditional equilibrium trend method is theoretically expanded, and a multi-coupling dynamic prediction system is established, as illustrated in Figure 2. The model integrates multidimensional influencing factors such as formation anisotropy, bit cutting characteristics, mechanical properties of steering tools, and drilling process parameters, and provides new theoretical support for precise trajectory control [16,17,18,19,20].

Figure 2.

BHA drilling trend analysis.

This trajectory prediction model is fundamentally established based on the mechanical equilibrium principle between centrifugal and gravitational forces. The inclination trend angle Ar, defined as the deviation between drilling trend direction (er) and actual trajectory (x), serves as the primary input. During build-up sections, the interplay of rotary centrifugal force (W4) and gravity causes systematic downward deviation, which is quantified by the modified expression:

(Note: The original model did not include the terminal correction term k14w4. This newly added term compensates for the additional influence of centrifugal force on well deviation tendency under ultra-high-speed operating conditions).

Here, k11, k12, k13 are the theoretical build-up rate, (°/30 m) (the build-up rate of the drilling tool under different working conditions is related to formation characteristics and drilling tool combination); w1, w2, w3 are the centrifugal effect coefficient, and the centrifugal force influences weight in different speed ranges (low, medium, and high) (dimensionless); k14 is the centrifugal correction factor, which is an additional correction factor of high-speed centrifugal force on well deviation trend (°/30 m); w4 is the centrifugal coefficient under special conditions and is the centrifugal correction coefficient at ultra-high speed or extreme speed (dimensionless).

The trajectory prediction model is in the dynamic synergy of slope, centrifugal effect, gravity compensation, and rotational speed. The theoretical build-up rate k1j is used to characterize the inherent build-up ability of the drilling tool, and the centrifugal effect coefficient wj is used to quantify the weighted influence of centrifugal force on the trajectory in different speed ranges, and then the gravity correction term k14w4 is used to dynamically offset the excessive build-up caused by centrifugal force. Among them, the weighted summation of the molecular part reflects the adaptability of the working condition, and the denominator normalization ensures the rationality of the angle. Finally, through the coupling calculation of the inverse cosine function and the gravity compensation, the accurate prediction of the well deviation trend is realized. This coupling mechanism dynamically correlates mechanical parameters (rotational speed, drilling tool characteristics) with physical effects (centrifugal force, gravity), providing a quantitative basis for optimizing drilling control.

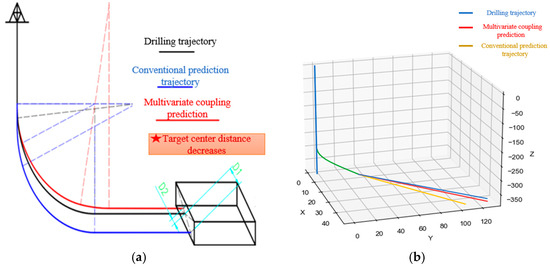

It can be seen from Formula (1) that the well deviation trend Ar is negatively correlated with the rotational speed centrifugal coefficient W4, so the smaller the rotational speed centrifugal coefficient W4, the greater the Ar. It shows that the model can more accurately reflect the actual trajectory of the drilling tool under the combined action of centrifugal force and gravity. Figure 3 comparatively demonstrates the accuracy improvement achieved by this new model, which effectively quantifies the rotational speed’s dynamic influence on centrifugal effects through its innovative coupling mechanism.

Figure 3.

Trajectory prediction comparison diagram: (a) real drilling hole trajectory prediction; (b) Simulated wellbore trajectory prediction.

3. Friction Torque Prediction Model

In the study of drilling string mechanics, the friction resistance calculation model can be classified into two dimensions: spatial dimension and material characteristics. From the perspective of spatial dimension, it can be divided into a two-dimensional plane model and a three-dimensional space model. Based on the assumption of the mechanical behavior of pipe string, it can be divided into two types: rigid rod and soft rod model [21,22,23,24].

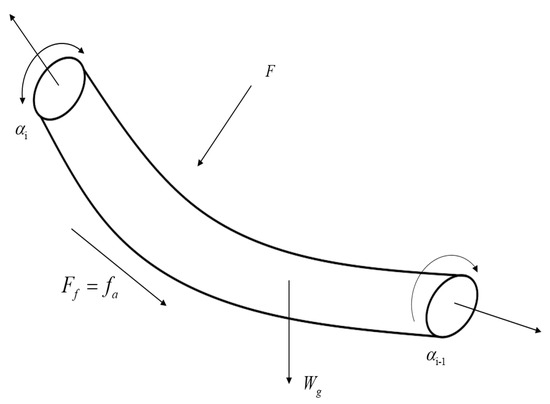

By fully considering the elastic deformation characteristics of the string, the soft rod model can more accurately simulate the actual stress state of the string in the wellbore. As shown in Figure 4, in the process of mechanical analysis of the pipe string, the discrete method is usually used to divide the pipe string into several micro-element segments for analysis. The model is based on the following basic assumptions: (1) The string and the borehole wall maintain continuous contact and produce normal positive pressure; (2) In the process of lifting or lowering the pipe string, the contact surface will produce friction force opposite to the direction of motion; (3) When the pipe string rotates axially, the contact surface will produce circumferential friction resistance moment. This modeling method can more truly reflect the mechanical behavior of the string in complex boreholes [10]. In view of the research conditions in this paper, the influence of the elastic deformation of the pipe string on the friction torque is particularly significant, so the soft rod model is used to improve the calculation accuracy.

where Ni is the lateral positive pressure on the i-segment micro-segment (N); is the lateral positive pressure on the azimuth plane (N); NG is the lateral positive pressure on the deviated plane (N); Fi is the upper axial force of the first segment of the i segment, the tension is positive, the pressure is negative (N); Ff is the axial friction force of the i-th micro-element segment (N); Ft is the circumferential friction force of the i-th segment (N); fa is the friction coefficient of the micro-element along the axial direction, dimensionless; f is the friction coefficient of the infinitesimal segment along the circumferential direction component, dimensionless; v is the axial velocity of the string in the wellbore, (m/s); Fv is the axial viscous resistance of the string (N); Mv is the circumferential viscous torque of the string (Nm); ω is the rotation speed of the pipe string (rad/s); D is the outer diameter of the pipe string (m); Mi is the torque of the upper part of the i-th segment (Nm); we is the floating weight per unit length of the i-th segment (N/m); γm is the density of drilling fluid (g/cm3 ); γs is the density of the column, generally (7.8 g/cm3); α is the average deviation angle of the micro-segment (rad); ∆α is the deviation angle difference between the upper and lower parts of the infinitesimal section, rad; ∆ is the azimuth difference between the upper and lower parts of the micro-element segment (rad).

Figure 4.

Mechanical state analysis of soft-string model.

This set of equations rigorously embodies the foundational assumptions of the soft-rod model, as outlined at the beginning of this section. Specifically, the following hold: (1) The pipe string maintains persistent contact with the wellbore wall, generating a normal pressure Ni (as defined by the resultant of Nϕ and NG). (2) During pipe lifting or lowering, the contact surface induces frictional forces (Ff) opposing the direction of motion, with Ff = faNi incorporating the velocity-dependent coefficient fa. (3) When the pipe rotates axially, circumferential frictional torque (Mi) arises, governed by the rotational friction term ft in Ft = ftNi. The geometric nonlinearities (incremental angles Δα, Δϕ) and dynamic effects (fa, ft) are explicitly derived from these assumptions, with all terms consistently linked to the physical constraints of the system.

This paper achieves deep integration between trajectory parameters and friction torque calculation through a soft-string model. The technical implementation occurs at two levels: (1) Theoretical modeling: Using discretized micro-segment analysis, wellbore curvature is converted into contact normal force input while inclination trend angle modifies centrifugal effect coefficients, establishing a quantitative trajectory-mechanics coupling relationship. (2) Software implementation: Through modular programming, we first execute wellbore trajectory prediction, then feed the predicted parameters (including curvature and inclination angle) into the friction torque calculation module—where curvature directly contributes to normal force computation and inclination angle dynamically adjusts centrifugal coefficients. The final friction torque output incorporates both geometric features and mechanical responses. This dual theoretical-algorithmic coupling enables dynamic reflection of trajectory control quality in predictions, providing multidimensional feature sets for safety evaluation systems.

4. Construction of Drilling Safety Grade Evaluation System

Based on the visualization of the wellbore trajectory, the prediction of friction torque in the whole well section is further studied with the calculation of friction torque as the core. By establishing an accurate mathematical model, the friction torque value of each well section is accurately calculated. Based on the system engineering methodology, this paper constructs a multi-level and modular data-driven drilling safety classification evaluation technology system to provide more scientific decision support for drilling engineering.

4.1. Data Acquisition and Feature Engineering

Based on the system engineering methodology, this study uses multi-source data fusion technology to systematically integrate the experimental data of friction and torque of drilling parameter combination and BHA, and constructs a high-reliability engineering data set. The research data are derived from the field-measured data of directional wells and horizontal wells, mainly including four key parameters: (1) drilling wellbore geometric parameters; (2) mechanical parameters of drilling tools; (3) drilling fluid performance parameters; (4) measurement parameters while drilling.

In the process of feature engineering, a series of strict data quality control measures are adopted in this study. Firstly, the interpolation algorithm is used to repair the missing data to ensure data integrity. Then the dimensional influence is eliminated by standardization; finally, the Pearson correlation analysis method is used to screen out the characteristic parameters with significant engineering significance, such as the torque coefficient and equivalent drilling speed. The optimized multidimensional feature space effectively improves the data signal-to-noise ratio and lays a solid foundation for subsequent analysis.

Based on the above high-quality data sets, this study applies the K-means++ clustering algorithm to realize the effective identification and classification of different drilling conditions. This method not only accurately captures the essential differences between working conditions but also provides reliable data support for subsequent statistical analysis and machine learning modeling.

4.2. Joint Density Distribution Characteristics of Friction and Torque

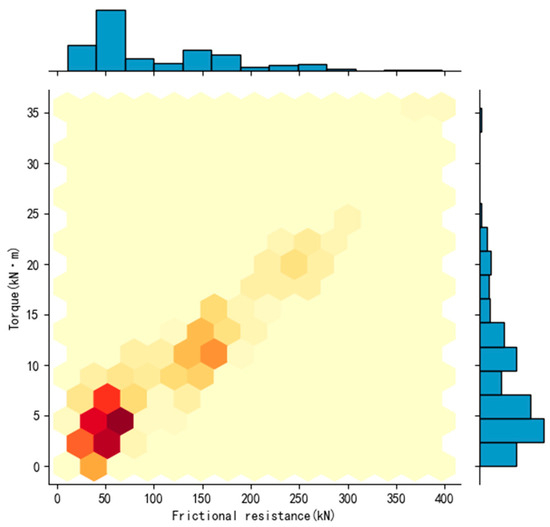

In the data analysis stage, the hexagonal binning method is used to analyze the binary joint density of friction and torque parameters. By dividing the data space into hexagonal units, this method effectively avoids the boundary effect of traditional rectangular bins and presents the distribution characteristics of data more intuitively. Further combined with kernel density estimation and probability density function calculation, the visualization of the two-dimensional joint distribution characteristics of friction and torque parameters is presented, and the nonlinear correlation and regional concentration trend between the two are quantitatively revealed.

The key mechanical properties of drilling conditions are revealed by analyzing the joint distribution density diagram of friction torque. The data distribution in Figure 5 intuitively verifies that there is a significant nonlinear positive correlation between friction and torque (Spearman, ρ = 0.78), indicating that there is a significant positive correlation between them. However, the distribution of data points showed a curve shape, and the nonlinear relationship between the two was further verified by polynomial regression (R2 = 0.85), which provided an important theoretical basis for the construction of a data-driven safety evaluation model.

Figure 5.

Friction torque joint distribution density.

Through the systematic analysis of the joint distribution of friction and torque, it is found that the data distribution shows a significant multi-peak characteristic, which indicates that there are obvious clustering differences in the combination of friction and torque under different drilling conditions. Further research reveals that the identification method of abnormal working conditions based on kernel density estimation can effectively capture the high-risk working conditions of an abnormal increase in friction torque. These key findings provide data support and a theoretical basis for establishing a scientific and reasonable three-level safety classification standard.

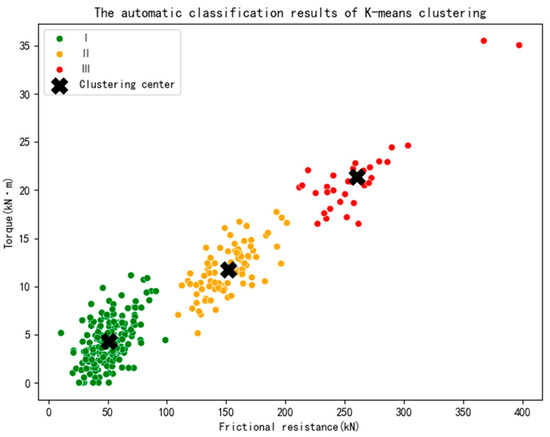

4.3. Risk Classification Based on Improved K-Means++

Based on the results of friction torque joint density analysis, this paper innovatively uses the improved K-means++ clustering algorithm to classify the working conditions intelligently [25,26,27]. The application of the K-means++ clustering algorithm in this study is supported by solid theoretical foundations and practical validation. This algorithm has demonstrated outstanding performance across multiple critical aspects of petroleum engineering: Lv Qiang [28,29] successfully achieved refined three-tier productivity classification for over 150 production wells, providing a basis for shut-in strategy optimization; Ali A [30] established a lithofacies identification system with 89% accuracy, significantly enhancing geosteering capabilities; Zhang [31] effectively delineated hydraulic flow units in carbonate reservoirs; URTeC [32] further confirmed its ability to increase estimated ultimate recovery (EUR) per well by over 15%. Compared to DBSCAN or Gaussian Mixture Models, K-means++ not only offers superior engineering interpretability but also exhibits better performance in terms of feature space dimensionality sensitivity. These advantages align perfectly with the feature engineering results of this study, fully demonstrating the suitability and advanced nature of this algorithm for our research.

Firstly, the initial clustering center selection strategy is optimized based on the density distribution characteristics, so that the division of I–III risk intervals is more in line with engineering practice. Secondly, the feature weighting mechanism is introduced to make the clustering process more focused on the key influencing factors. Finally, by dynamically adjusting the iteration termination condition, the computational efficiency is significantly improved while ensuring the accuracy. These improvements make the classification results highly consistent with the actual working conditions on site.The classification schematic is shown in Figure 6.

Figure 6.

K-means clustering classification results.

Using the systematic clustering analysis method, the optimal clustering number K = 3 was scientifically determined by the double verification of the Silhouette Coefficient and the Elbow Method. In terms of distance measurement, Euclidean distance is selected as the similarity evaluation standard, and the feature weight optimization mechanism is introduced. Finally, the experimental data are objectively divided into three risk levels with significant statistical differences: Grade I low-risk area (friction 0–100 kN/torque 0–10 kN·m), Grade II medium-risk area (friction 100–200 kN/torque 10–20 kN·m), Grade III high-risk area (friction > 200 kN/torque > 20 kN·m). The clustering results not only naturally form a classification threshold with engineering significance but also have various centroids that more accurately characterize the typical mechanical characteristics of different risk levels. This method, based on unsupervised learning, effectively avoids the subjective deviation of artificially set thresholds and provides a reliable data-driven mathematical basis for establishing a scientific and reasonable drilling safety classification standard.

4.4. The Construction and Application of Evaluation System

4.4.1. Establishment of Assessment Standards

This study developed a data-driven friction torque prediction model through multi-source drilling data integration and machine learning analysis, systematically incorporating multidimensional variables including well trajectory parameters, bottom hole assembly characteristics, and formation conditions. Using an improved K-means++ clustering algorithm for intelligent analysis of experimental data, we found that setting the cluster number to 3 yielded optimal silhouette coefficients, demonstrating that drilling risk parameters naturally form a three-tier distribution in feature space. Building upon these data-driven findings and practical engineering requirements, we established a three-level drilling safety evaluation standard.

The three-tier risk classification system was designed based on two key considerations: (1) enabling rapid on-site decision-making through an efficient data feedback mechanism—when drilling parameters approach risk thresholds, engineers can proactively mitigate risks by adjusting operational parameters to ensure safe and efficient drilling; (2) compliance with industry standards as evidenced by similar classification systems in existing literature. The three distinct risk levels are defined as follows: Level I (Low risk: allowing unrestricted parameter optimization), Level II (Medium risk: requiring parameter adjustments), and Level III (High risk: necessitating immediate intervention). This classification provides field operations with clear, actionable risk management benchmarks. with detailed classification criteria shown in Table 1.

Table 1.

Evaluation standard of drilling safety grade.

The data-driven drilling safety level evaluation system constructed in this paper analyzes the correlation characteristics between the friction torque prediction value and the wellbore trajectory parameters in real time through the machine learning algorithm, and intelligently optimizes the BHA and drilling parameters. The system realizes closed-loop management from mechanical calculation to risk early warning, which can dynamically identify and prevent risk conditions such as sticking and abnormal bit wear, significantly improve drilling efficiency, and provide intelligent decision support for safe and efficient drilling.

4.4.2. Actual Application Analysis

Taking wells A1, A2, and A3 as specific examples, the drilling safety level is evaluated. with detailed drilling operation parameters presented in Table 2.

Table 2.

Parameter input data table.

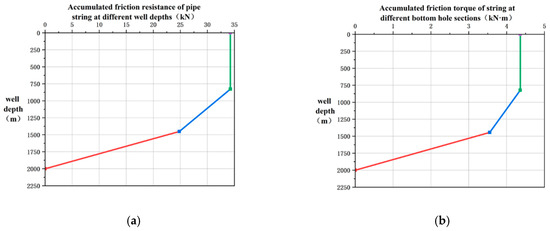

The calculation results of Well A1:

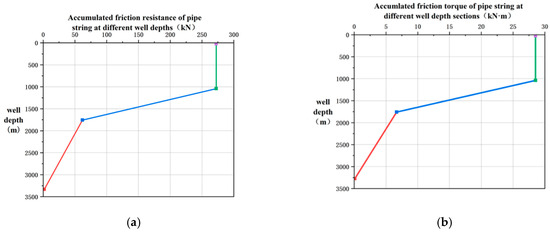

According to Figure 7, the friction is 34.25 kN, the torque is 4.36 kN·m, and the drilling safety evaluation grade is grade I (low risk). It can be inferred that the scheme is reasonable and meets the requirements of safe drilling under this working condition.

Figure 7.

Variation of pipe string friction resistance and torque with well depth. (a) Accumulated friction resistance of pipe string at different well depths. (b) Accumulated friction torque of string at different well depths.

The calculation results of Well A2:

It can be seen from Figure 8 that the friction is 175.12 kN, the torque is 11.36 kN · m, and the safety level of drilling evaluation is grade II (medium risk). This feature indicates that the downhole friction torque has been increasing, and the goal of reducing friction and drag can be achieved by optimizing drilling parameters and optimizing BHA.

Figure 8.

Variation of pipe string friction resistance and torque with well depth. (a) Accumulated friction resistance of pipe string at different well depths. (b) Accumulated friction torque of string at different well depths.

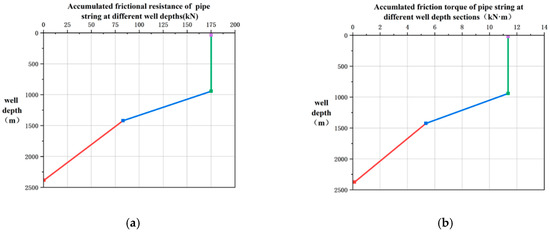

The calculation results of Well A3:

It can be seen from Figure 9 that the friction is 272.34 kN and the torque is 28.53 kN·m, so the drilling safety level is evaluated as grade III. The calculation results show that the current drilling scheme has reached the warning threshold, and the following optimization measures should be taken to reduce the friction torque: (1) re-optimize the wellbore trajectory and reduce the full-angle change rate; (2) adjust drilling fluid performance parameters, improve lubrication characteristics and adjust drilling parameters such as drilling pressure; (3) optimize the configuration of BHA to reduce the contact force between string and borehole wall.

Figure 9.

Variation of pipe string friction resistance and torque with well depth. (a) Accumulated friction resistance of pipe string at different well depths. (b) Accumulated friction torque of string at different well depths.

In this paper, through the engineering verification of three wells A1, A2, and A3, it is confirmed that the data-driven drilling safety evaluation system has significant engineering value. It also reflects the unique advantages of data-driven methods in drilling risk prevention and control: through the complete closed-loop of quantitative evaluation → precise early warning → intelligent optimization, the transformation from “post-processing” to “pre-prevention” is realized. In the future, the dynamic response capability of the system can be further improved by accessing real-time data while drilling.

5. Conclusions

- This study developed a data-driven drilling safety classification system through a statistical analysis of field data and an improved K-means++ algorithm, establishing a three-tier risk assessment framework: Grade I (low risk) for friction (0–100 kN) and torque (0–10 kN·m), Grade II (medium risk) for friction (100–200 kN) and torque (10–20 kN·m), and Grade III (high risk) for friction (>200 kN) and torque (>20 kN·m). This classification standard significantly improves evaluation accuracy and timeliness, providing a scientific basis for drilling parameter optimization and BHA (Bottom Hole Assembly) selection.

- Collaborative optimization of wellbore trajectory and BHA: Aiming at the high-friction section, a differential optimization strategy is proposed. By optimizing the deviation angle and azimuth angle, combined with the adjustment of drilling fluid performance and the optimization of BHA, the targeted friction reduction and drag reduction are realized.

- This paper provides complete supporting data for drilling engineering from risk warning to optimization decision. Field application shows that the accident rate is reduced, which verifies the practical value of the data-driven method in drilling safety evaluation. In the future, the dynamic intelligent upgrading of the evaluation system will be further promoted by integrating real-time data while using drilling and deep learning algorithms.

- The well trajectory design is significantly constrained by multiple geological factors that have not been fully considered in this study, including geological structures, anisotropic stress fields, and rock mechanical constitutive relationships. These geological factors directly influence the mechanical response characteristics of drilling tools and computational accuracy. Furthermore, the timeliness of acquiring geological parameters while drilling and the uncertainties in lithology identification further increase operational risks. These limitations require special attention in subsequent research and field applications.

Author Contributions

Methodology, Software, and Writing—original draft, S.M.; Writing—review and editing, C.W.; Supervision, Y.Z. and L.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of Heilongjiang Province (Grant No. LH2022E027) and the Open Research Fund of State Key Laboratory of Intelligent Construction and Healthy Operation & Maintenance of Deep Underground Engineering (Grant No. SDGZ2526).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the first author.

Conflicts of Interest

Author Lidong Hou was employed by the company Heli (Tianjin) Energy Technology Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zou, C.N.; Yang, Z.; Zhang, G.S.; Zhu, R. Theories, technologies and practices of unconventional petroleum geology. Earth Sci. 2023, 48, 2376–2397. [Google Scholar] [CrossRef]

- Gao, D.L.; Huang, W.J. Research progress on downhole tubular mechanics and control methods. Adv. Mech. 2021, 51, 620–647. [Google Scholar]

- Li, G.S.; Song, X.Z.; Tian, S.C. Research status and development trends of intelligent drilling technology. Pet. Drill. Technol. 2020, 48, 505–512. [Google Scholar]

- Chen, P.; Li, X.; Wang, J.; Zhao, Y. Error analysis and control countermeasures of well trajectory in deep horizontal wells. Pet. Drill. Technol. 2023, 51, 88–94. [Google Scholar]

- Zhang, H.L.; Liu, G.; Chen, W.D.; Yang, Q. Impact assessment of well trajectory error on subsequent operation risks. Nat. Gas Ind. 2022, 42, 96–103. [Google Scholar]

- Li, J.; Wang, T.; Zhang, K.; Zhou, M. Adaptability study of friction-torque prediction model for long lateral horizontal wells. Oil Drill. Prod. Technol. 2021, 43, 412–418. [Google Scholar]

- Wang, L.; Sun, F.; Hu, J.; Zheng, X. Standardization study on key parameters for friction-torque calculation. Drill. Eng. 2022, 49, 75–81. [Google Scholar]

- Liu, W.; Yang, D.; Xu, R.; Zhao, K. Self-correcting method of friction coefficient based on field big data. Acta Pet. Sin. 2024, 45, 1–9. [Google Scholar]

- Yang, B.; Xu, C.Y.; Zhang, H.; Guo, Y.; Yang, J.; Li, Y.; Zhao, J. Research progress and breakthrough strategies of wellbore instability mechanisms in deep fractured formations. Acta Pet. Sin. 2024, 45, 875–888. [Google Scholar]

- Moos, D.; Peska, P.; Finkbeiner, T. Quantitative risk assessment improves wellbore stability predictions. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 10–21 February 2023; pp. 1–12. [Google Scholar]

- Zhao, J.Z.; Shen, Y.; Wang, X.L.; Liu, H.Q. Development bottlenecks and countermeasures of domestic intelligent drilling systems. Pet. Drill. Technol. 2023, 51, 1–9. [Google Scholar]

- Li, G.S.; Tian, S.C.; Chen, W.D.; Zhang, K. Segmented friction-torque model for slim-hole extended-reach horizontal wells. Oil Drill. Prod. Technol. 2020, 42, 547–553. [Google Scholar]

- Wang, L.; Zhang, J.J.; Yang, Q.; Zhou, M. Research on functional limitations of domestic drilling risk assessment systems. Nat. Gas Ind. 2021, 41, 89–96. [Google Scholar]

- Ren, Y.F. Research on Intelligent Design and Optimization Methods for Wellbore Trajectory. Ph.D. Dissertation, Yangtze University, Jingzhou, China, 2024. [Google Scholar] [CrossRef]

- Zhang, J. Analysis of Friction and Torque in Directional Sections of Deep Shale Gas Wells in Sichuan-Chongqing Area and Study on Drag Reduction Technology. Ph.D. Thesis, Chongqing University of Science and Technology, Chongqing, China, 2023. [Google Scholar]

- Peng, W.G. Research and Implementation of Lightweight 3D Visualization Platform for Drilling Data. Comput. Knowl. Technol. 2022, 18, 99–100+106. [Google Scholar] [CrossRef]

- Wang, P.-D.; Wang, T.-S. Dynamics Modeling and Control of Multibody Systems Based on Dual Quaternions. Chin. J. Theor. Appl. Mech. 2024, 56, 2091–2102. [Google Scholar]

- Bai, J.; Zhong, Y.; Wang, L.; Li, X.; Chen, H. Intelligent prediction method of build-up rate based on mechanism-data fusion. China Pet. Mach. 2025, 53, 1–9. [Google Scholar]

- Dai, X. Research on Intelligent Steering Method for 3D Well Trajectory Based on Deep Learning Pattern. Master’s Thesis, China University of Petroleum, Beijing, China, 2024. [Google Scholar]

- Zou, T. Research on Intelligent Well Trajectory Control Model and Prediction Software Development. Ph.D. Thesis, Northeast Petroleum University, Daqing, China, 2024. [Google Scholar] [CrossRef]

- Zhang, S.; Che, Y.; Sun, D. Optimization of Kick-Off Point Position for Large-Offset Platform Dual-2D Horizontal Wells Based on Friction Analysis. Equip. Manuf. Technol. 2022, 55, 39–42+48. [Google Scholar]

- Zhang, Y.; Yang, Y.; Zhang, W.; Liu, J.; Zhou, M. Intelligent prediction method of drilling sticking risk based on mechanism-data fusion. Xinjiang Oil Gas 2025, 21, 35–44. [Google Scholar]

- Yu, G.; Zhang, B.; Zhang, J.; Shen, X.; Sun, W. Research and application progress of mechanical models for downhole drill string friction and torque. Inn. Mong. Petrochem. Ind. 2024, 50, 11–15. [Google Scholar]

- Liu, W.; Feng, J.; Wang, Y.; Zhu, X.; Li, Z. Dynamic Friction Torque Analysis of Drill String in Deep Shale Gas Horizontal Wells. Pet. Mach. 2023, 51, 18–25. [Google Scholar] [CrossRef]

- Zhu, S.; Song, X.; Li, G.; Zhu, Z.; Yao, X. Intelligent Real-Time Analysis of Drill String Friction Torque and Prediction of Sticking Tendency. Oil Drill. Prod. Technol. 2021, 43, 428–435. [Google Scholar] [CrossRef]

- Li, A. Research on Evaluation System and Methods for Horizontal Well Drilling Difficulty Based on Regional Statistical Data. Ph.D. Thesis, Xi’an Shiyou University, Xi’an, China, 2023. [Google Scholar]

- Zhang, F.; Xu, H.; Zhu, X.; Li, W.; Li, X. Calculation of Distribution Function and Probability for Two-Dimensional Continuous Random Variables. Comput. Knowl. Technol. 2019, 15, 195–198. [Google Scholar] [CrossRef]

- Lu, Q.; Yu, J. K-Means Optimal Clustering Algorithm Based on Hybrid Genetic Algorithm. J. East China Univ. Sci. Technol. (Nat. Sci. Ed.) 2005, 31, 219–222. [Google Scholar] [CrossRef]

- Silva, T.P.; Oliveira, L.F. Selection of Candidate Oil Wells for Extended Shut-In Using K-Means Clustering. SSRN Electron. J. 2023. [Google Scholar] [CrossRef]

- Ali, A.; Sheng-Chang, C. Characterization of Well Logs Using K-Means Cluster Analysis. J. Pet. Explor. Prod. Technol. 2020, 10, 1234–1245. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, S.; Chen, Z. Integrating Horizontal Borehole Imagery and Cluster Analysis with Microseismic Data for Niobrara Reservoir Characterization, Wattenberg Field. In Proceedings of the Unconventional Resources Technology Conference, San Antonio, TX, USA, 1–3 August 2016. [Google Scholar]

- Rezaee, M.R.; Kadkhodaie-Ilkhchi, A.; Barabadi, A. Consistent Porosity–Permeability Modeling, Reservoir Rock Typing and Hydraulic Flow Unitization in a Giant Carbonate Reservoir. J. Pet. Sci. Eng. 2015, 131, 82–93. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).