Abstract

Developing ultra-high-temperature geothermal resources is challenging, as traditional drilling fluids, including foam systems, lack thermal stability above 160 °C. To address this key technical bottleneck, this study delves into the screening principles for high-temperature-resistant foaming agents and foam stabilizers. Through high-temperature aging experiments (foaming performance evaluated up to 240 °C and rheological/filtration properties evaluated after aging at 200 °C), specific additives were selected that still exhibit good foaming and foam-stabilizing performance under high-temperature and high-salinity conditions. Building on this, the foam drilling fluid system formulation was optimized using an orthogonal experimental design. The optimized formulations were systematically evaluated for their density, volume, rheological properties (apparent viscosity and plastic viscosity), and filtration properties (API fluid loss and HTHP fluid loss) before and after high-temperature aging (at 200 °C). The research results indicate that specific formulation systems exhibit excellent high-temperature stability and particularly outstanding performance in filtration control, with the selected foaming agent FP-1 maintaining good performance up to 240 °C and optimized formulations demonstrating excellent HTHP fluid loss control at 200 °C. This provides an important theoretical basis and technical support for further research and field application of foam drilling fluid systems for deep high-temperature geothermal energy development.

1. Introduction

The increasing global demand for clean energy has spurred significant interest in developing deep geothermal resources, which present a promising sustainable alternative to traditional fossil fuels. However, the development of ultra-high-temperature geothermal resources faces extreme downhole environmental challenges. Traditional drilling fluid systems struggle to meet the requirements for wellbore stability, lost circulation prevention, and effective transport of cuttings under ultra-high-temperature conditions exceeding 200 °C or even 250 °C. These conventional systems often suffer from thermal degradation of their components, leading to severe issues such as increased fluid loss, compromised rheological properties, and loss of wellbore integrity.

Foam drilling fluid, due to its low density, high carrying capacity for cuttings, and potential for plugging lost circulation zones, shows application potential in high-temperature geothermal well drilling. Stable foam drilling fluid is composed of a liquid phase, a gas phase, a foaming agent, and a stabilizing agent. The gas phase primarily consists of air or nitrogen; the liquid phase is typically water-based. The foaming agent mainly includes surfactants, with commonly used types being dodecyl-based surfactants and alkyl glycerol ether sulfonate-based surfactants. The stabilizing agent primarily utilizes high molecular compounds or synthetic surfactants to maintain the stability of the foam after it is generated. The ability of foam to remain stable depends on the structural strength of the foam membrane; an increase in the strength of the foam membrane reduces the diffusion rate of gas between bubbles and slows down the gas diffusion between bubbles [1,2]. The viscosity of foam can be categorized into bulk viscosity and interfacial viscosity, both of which play significant roles in foam stability [3]. Micro-foam drilling fluid, characterized by independent rigid micro-bubbles with diameters ranging from 10 to 100 μm, offers enhanced pressure resistance (up to 27.3 MPa) and improved temperature resistance compared to conventional foam, making it a primary direction for development [4,5]. The properties of foam fluid drilling fluid, including the liquid phase and interfacial viscosity, adsorption of substances at the interface, interfacial membrane strength, and interfacial tension, are all influenced by temperature [6,7].

However, a critical limitation for foam drilling fluid in high-temperature applications is its inherent susceptibility to thermal degradation. Under high-temperature conditions, foaming agents and stabilizing agents are degraded by high temperatures, losing their foaming function. Foam drilling fluid performance is characterized by foaming capacity and stability. Therefore, the focus of research on high-temperature foam drilling fluids lies in the development of foaming agents and stabilizing agents.

In 2012, Xin Yinchang and colleagues developed a foaming agent, QR-1, by blending DM5512, betaine, and alkyl glycoside [8]. They also formulated a stabilizer, WD-1, by combining three additives: HPMC, SMP-2, and SP-8. Using QR-1, WD-1, and clay, they produced a micro-foam drilling fluid with excellent salt tolerance. This fluid maintained good performance in a base fluid with a salinity of 10 × 104 mg/L, with temperature resistance up to 130 °C and a foam half-life of 219 min. In 2014, Yang Peng et al. conducted research on oil-based, recyclable micro-foam drilling fluid technology to address challenges such as wellbore leakage, shale hydration expansion, and wellbore collapse during shale gas drilling [9]. The system demonstrated no fluid loss at a temperature of 150 °C and a pressure differential of 6 MPa, with strong pressure-bearing capacity and effective sealing of lost circulation zones. Xiao Chang et al. developed a micro-foam drilling fluid with excellent rheological properties, low filtration loss, and strong inhibition by optimizing the surfactant KZ to reduce water blockage damage, using a blend of ABS and SDS as the foaming agent and HV-CMC and PAC-141 as the stabilizer [10]. In 2016, Wang Xiaojun formulated a temperature- and salt-resistant, phase-free micro-foam drilling fluid with a density range of 0.85–0.95 g/cm3 by blending the synthesized foaming agent LF-2 and the stabilizer HMC-1 [11]. After thermal aging at 150 °C, the fluid exhibited minimal changes in rheological properties, with filtration loss consistently below 7.4 mL. After re-stirring, the foam stability exceeded 48 h, demonstrating high-temperature stability. In 2017, Guo Jinaì et al. developed a viscoelastic surfactant (VES-1) and used it to prepare a micro-foam drilling fluid [12]. After aging at 120 °C and treatment with 5% brine, the fluid showed no significant changes in density, viscosity, or yield stress. This system was successfully applied in the low-pressure, low-permeability, depleted sandstone reservoirs of the Wen 23 gas field (third-opening section) in 2018. Luo Huaidong et al. developed a temperature-resistant foaming agent, GWFOM-LS, capable of withstanding temperatures up to 150 °C and used XG and LV-PAC as stabilizers to formulate a micro-foam drilling fluid with a density of 0.73 g/cm3 and a pressure resistance of 21 MPa [13]. In 2018, Yao Jinxing et al. developed a polymer nano-assembled micro-foam drilling fluid system by adding 0.12–0.18% nano-SiO2 particles to AOS and guar gum micro-foam drilling fluid [14]. After aging at 160 °C and treatment with 4–8% KCl or 0.4–0.8% CaCl2 solutions, the fluid maintained excellent foaming capacity and foam morphology, significantly improving the high-temperature stability of micro-foams. Zhang Xiaodong et al. developed a weak gel micro-foam drilling fluid system with a controllable density range of 0.85–1.00 g/cm3 by blending a self-developed flow-regulating agent, BZ-LXJ, and foaming agent, MFN-1 [15]. In 2020, Li Zhiyong et al. designed an anionic gemini surfactant ULT-1 based on the negatively charged characteristics of coal seams, which exhibited superior foaming properties compared to commonly used anionic surfactants such as SDS, ABS, and SAS [16]. The half-life of ULT-1 was more than three times that of conventional foaming agents, meeting the requirements of drilling engineering. ULT-1, combined with betaine, biopolymers, guar gum, brown coal resin, ammonium salts, and potassium polyacrylate, formed a micro-foam drilling fluid system with excellent sealing efficiency, permeability recovery, and reservoir protection effects.

As observed from comprehensive field application results, the formulation of micro-foam drilling fluid systems is continuously optimized in response to varying geological conditions encountered during drilling. This optimization leads to a gradual improvement in the system’s temperature resistance, increasing from an initial 80 °C to 160 °C. The application depth of these systems extends up to 4005 m. Despite extensive research efforts, the temperature limit of existing foam drilling fluid systems in practical applications is primarily below 160 °C, as observed from comprehensive field application results. This temperature threshold is far below the requirements for developing ultra-high-temperature geothermal resources, which necessitates drilling fluids that are stable at temperatures exceeding 200 °C or even 250 °C. Furthermore, while laboratory research has developed numerous additives capable of withstanding temperatures exceeding 200 °C, such as high-temperature-resistant surfactants and polymer stabilizers, the adoption of these advancements in actual field applications remains limited. Changes in the reservoir environment and drilling fluid formulation have a profound impact on reservoir transformation, including wellbore stability, fluid invasion, and long-term productivity. Effective management of these interactions is crucial to minimize formation damage and ensure efficient hydrocarbon or geothermal energy recovery [17,18]. This underscores the necessity for drilling fluids that not only perform under extreme conditions but also mitigate adverse reservoir interactions.

Addressing this key technical bottleneck, this study aims to systematically investigate and develop a high-temperature-resistant foam drilling fluid system specifically tailored for ultra-high temperature geothermal well drilling. This paper systematically reviews the research progress of foam drilling fluid in high-temperature environments domestically and internationally. Our research delves into the screening principles for high-temperature-resistant foaming agents and foam stabilizers and optimizes the foam drilling fluid system formulation to ensure wellbore stability, prevent lost circulation, and facilitate effective transport of cuttings under extreme high-temperature and high-salinity conditions.

2. Materials and Methods

2.1. Experimental Materials

The foaming agents, foam stabilizers, and other drilling fluid treatment agents used in this study were all common laboratory products or specifically developed products. Specific details are provided in Table 1. Deionized water was used as the experimental water. For high-temperature and high-salt experiments, a 15% brine or 15% NaCl solution prepared with chemically pure NaCl was used. Please note that specific chemical structures for proprietary foaming agents (FP-1, FP-2, FAG-200) and foam stabilizers (GWPJ) are not disclosed due to confidentiality. However, the precise concentrations of all additives used in the optimized formulations are provided in a later section to ensure reproducibility of the experimental systems.

Table 1.

Main treatment agents and their functions.

2.2. Experimental Methods

2.2.1. Foaming Performance Evaluation

Foaming performance is evaluated using the Waring–Blender method. A solution of a certain concentration (as shown in Table 1, mass fraction) of the foaming agent (or a base fluid containing the foaming agent) is placed in a Waring–Blender high-speed mixer. The solution is stirred at a speed of 11,000 r/min for 1 min. Immediately after stirring, the initial foam volume (foaming volume, mL: the initial volume of foam generated immediately after stirring) and the foam half-life (the time required for the foam volume to decrease to half of its initial volume, measured in minutes or seconds) are measured. All foaming performance evaluations were conducted in triplicate, and the average values are reported to ensure the statistical reliability of the obtained data. Temperature resistance is evaluated by performing foaming tests on the solution after it has been thermally aged at specified temperatures (e.g., 30 °C, 180 °C, 210 °C, 240 °C) for 16 h. Salt resistance (the ability of the drilling fluid system or its components to maintain their performance in the presence of high concentrations of salts) is evaluated by performing foaming tests in solutions containing 15% brine or 15% NaCl. The general procedure follows API RP 13B [19].

2.2.2. High-Temperature Aging Test

The prepared drilling fluid samples were placed in a high-temperature aging autoclave (a sealed, high-pressure, high-temperature vessel used to thermally age drilling fluid samples under controlled conditions to simulate downhole temperatures and pressures) and thermally aged at the specified temperatures for 16 h. The aging tests were conducted under normal air pressure within the sealed autoclave, simulating typical downhole conditions where oxygen or other reactive gases might be present. The 16 h aging duration is a widely accepted standard in the drilling fluid industry for accelerated high-temperature aging tests, providing a robust evaluation of long-term thermal stability. After aging, the samples are allowed to cool to room temperature. Following cooling, the samples are stirred for a specific period before conducting performance tests.

2.2.3. Rheological Performance Testing

Rheological performance is evaluated using a six-speed rotational viscometer to measure the shear stress of foam drilling fluid at different rotational speeds. Apparent viscosity (AV, mPa·s: a measure of the total resistance to flow, calculated at a specific shear rate) and plastic viscosity (PV, mPa·s: a measure of the internal resistance of the fluid to flow when under shear, primarily influenced by the concentration and size of solids) are calculated based on the measurements. The fluid flow type and suspension/solid-carrying capacity are assessed according to the test results. The measurements conform to API RP 13B standards.

2.2.4. High-Temperature High-Pressure (HTHP) Filtration Loss

Measure the filtrate volume (mL) for 30 min using an HTHP filtration apparatus under the specified temperature and pressure differential (at 200 °C and 3.5 MPa pressure differential). This measurement is conducted according to API RP 13B.

2.2.5. Density and Volume Measurement

Measure the density of the drilling fluid using a mud balance (g/cm3). Record the volume change of the drilling fluid before and after thermal aging. For foam systems, the density of the liquid portion or the overall apparent density is typically measured. The volume change reflects the loss of the gas phase or the evaporation/expansion of the liquid phase. Density measurements are performed using a mud balance as per API RP 13B.

3. Results and Discussion

3.1. Selection of High-Temperature-Resistant Foaming Agents

This study first systematically evaluated the foaming performance of multiple commercially available and self-developed high-temperature-resistant foaming agents under different temperatures (30 °C to 240 °C) and high-salinity conditions. Table 2 presents the foaming volume and half-life of five foaming agents (FP-1, FP-2, Defoamer, AC-200, FAG-200) after thermal aging at different temperatures for 16 h. At lower temperatures (180 °C), most foaming agents still maintained relatively good performance. However, when the temperature increased to 210 °C and 240 °C, the foaming volume and half-life of Defoamer, AC-200, and FP-2 significantly decreased, indicating poor thermal stability at temperatures above 200 °C, likely due to chemical degradation or aggregation failure of the surfactants. In contrast, FP-1 and FAG-200 maintained high foaming volumes and relatively stable half-lives at 210 °C and 240 °C, demonstrating better high-temperature resistance. Notably, after aging at 240 °C, FP-1 exhibited significantly superior foaming volume (500 mL) and half-life (5.9 min) compared to FP-2, Defoamer, and AC-200.

Table 2.

Performance evaluation test of the high-temperature-resistant foaming agent.

High-salinity conditions (15% brine/NaCl) also had a significant impact on the performance of the foaming agents. At 240 °C under high-salinity conditions, the performance of Defoamer and AC-200 was almost completely lost, while FP-2 experienced a substantial performance decline. FP-1 and FAG-200, however, demonstrated better salt resistance, with their foaming volumes even increasing slightly (possibly due to changes in surfactant aggregation states caused by salting-out effects, though this could also affect stability). Although the half-lives of these agents fluctuated, they remained at a maintainable level. FP-1 maintained the best overall performance (foaming volume and half-life) under high-temperature and high-salinity conditions at 240 °C.

Based on the evaluation results, FP-1 was selected as the high-temperature-resistant foaming agent for this study due to its excellent foaming volume and relatively stable half-life at 240 °C under high-salinity conditions. Its performance, as demonstrated in Table 2 against other high-temperature foaming agents, signifies a significant advantage over conventional products that typically fail at temperatures below 160 °C, thus laying a strong foundation for the development of drilling fluid systems capable of withstanding even higher temperatures. Its temperature resistance approaches 240 °C, laying a foundation for the development of drilling fluid systems capable of withstanding even higher temperatures.

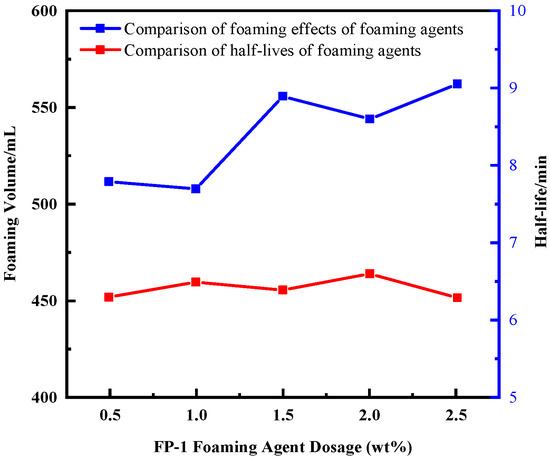

To further investigate the impact of different dosages of FP-1 foaming agent on foaming performance, this study tested the foaming volume and half-life under stirring conditions at 11,000 r/min for 1 min, within a dosage range of 0.5% to 2.5%. As shown in Figure 1, within the tested range, FP-1 exhibited some sensitivity to dosage changes in terms of foaming volume and half-life, but overall differences were relatively small. At a dosage of 1.5%, the foaming volume reached 556 mL, with a half-life of 6.4 min, demonstrating good overall performance. While higher dosages might yield marginally higher initial foaming volumes, 1.5% represents an optimal balance between achieving excellent foaming performance and practical considerations such as treatment agent costs and minimizing potential risks of formation damage. Considering treatment agent costs and potential risks of formation damage, a dosage of 1.5% was selected as an optimal range for subsequent system formulation optimization.

Figure 1.

Effect of different addition amounts of FP-1 foaming agent on foaming performance.

3.2. Selection of High-Temperature-Resistant Foam Stabilizers

Stabilizing agents play a critical role in high-temperature foam drilling fluid systems, primarily functioning to increase liquid-phase viscosity, enhance the strength and elasticity of the gas–liquid interfacial membrane, and reduce gas diffusion rates, thereby delaying foam breakdown. In this study, multiple potential high-temperature-resistant stabilizing agents were screened to evaluate their effects on the comprehensive performance of foam systems after high-temperature aging. Table 3 presents the performance changes of different stabilizing agents after aging at 200 °C for 16 h. Experimental results indicate:

Table 3.

Drilling fluid performance after adding unstable foaming agent.

- Rheological Performance: After high-temperature aging, PAC-H, GWPJ, and HEC-Hv maintained certain viscosities (AV, PV). However, POL and FLA exhibited significant decreases in viscosity (AV of 20 and 16.5 mPa·s, respectively), indicating severe thermal degradation of these polymers at 200 °C, resulting in the loss of their viscosity-increasing and stabilizing capabilities. GWPJ maintained a relatively stable and moderate rheological performance, with an AV of 46.5 mPa·s and a PV of 25 mPa·s after aging.

- Filtration Performance: After aging, both PAC-H and GWPJ achieved an API filtration loss of 10 mL, demonstrating excellent filtration control capabilities. In contrast, HEC-Hv (23 mL), POL (88 mL), and FLA (124 mL) exhibited significantly increased API filtration loss after aging, particularly POL and FLA, suggesting that their filtration control components failed or the mud cake structure was disrupted under high-temperature conditions. HTHP filtration loss data were unavailable for detailed comparison.

- Foam Stability: Although the half-life data were incomplete, combining rheological performance and filtration performance, stabilizing agents contributed to foam stability by maintaining system viscosity and filtration control capabilities. GWPJ demonstrated excellent performance in both rheology and filtration control, which helps maintain the dispersion of bubbles in the liquid and slows the thinning of the liquid film. It is inferred that GWPJ also exhibits relatively good foam stabilization effects.

In summary, considering rheological performance and API filtration loss after aging at 200 °C, GWPJ exhibited the best high-temperature resistance, maintaining good viscosity and excellent filtration control capabilities. It is the preferred stabilizing agent for constructing high-temperature foam drilling fluid systems. Although half-life data were incomplete, its superior rheological and filtration performance provides a strong foundation for high-temperature foam stabilization.

Table 4 shows the effect of different dosages of GWPJ on the foaming performance of 1% FP-1 after aging at 240 °C. It can be observed that the control group with 1% FP-1 had a foaming volume of 500 mL and a half-life of 5.9 min after aging at 240 °C. Adding a low concentration of GWPJ (0.25%) had little effect on the foaming volume and half-life, or even slightly improved them (volume 510 mL, half-life 6.5 min). When the GWPJ dosage was 0.5%, the foaming performance deteriorated sharply. The foaming volume significantly decreased to 160 mL, and the half-life was zero. This suggests that this concentration of GWPJ may have undergone unfavorable reactions with FP-1 or altered its aggregation state, thereby destroying the foaming ability. When the GWPJ dosage was increased to 2% and 2.5%, although the foaming volume of the mixture decreased (340 mL and 410 mL), the half-life was significantly extended (>65 min and 26.5 min), far exceeding the control group without GWPJ (5.9 min). Specifically for the 2.5wt% GWPJ content, while the initial foaming volume (345 mL) was lower compared to the control group without GWPJ (500 mL), the crucial foam half-life was dramatically improved to >65 min, indicating excellent long-term stability. This suggests a trade-off, where the high concentration of GWPJ, acting as a powerful foam stabilizer, enhances the strength and elasticity of the gas–liquid interfacial membrane and effectively reduces gas diffusion rates, thus delaying foam breakdown over prolonged high-temperature exposure. This protective mechanism is prioritized for high-temperature applications, even if it slightly affects initial foam generation efficiency. This result confirms the potential of GWPJ as a foam stabilizer, capable of enhancing the long-term stability of the foaming system at 240 °C within a certain dosage range (particularly at 2% and above). In subsequent formulation design, adding an appropriate amount of GWPJ can be considered to further enhance the temperature resistance of the system.

Table 4.

Effect of foaming agent with GWPJ high-temperature protective agent added.

3.3. Optimization of High-Temperature-Resistant Foam Drilling Fluid Formulation

Based on the selection of the high-temperature-resistant foaming agent FP-1 and the foam stabilizer GWPJ, this study designed multiple formulations (Table 5) to investigate the effects of different additive combinations and dosages on the performance of foam drilling fluid after high-temperature aging. The formulations listed in Table 5 were systematically designed using an orthogonal experimental approach. This method efficiently explores the multi-dimensional parameter space by varying multiple factors (e.g., concentrations of different additives) simultaneously with a reduced number of experiments, allowing for robust optimization of the drilling fluid system. The goal was to identify the formulation with the best overall performance, specifically prioritizing minimized HTHP filtration loss while maintaining desirable rheological properties and overall foam system stability (density and volume).

Table 5.

Composition of formulations designed using orthogonal experimental design.

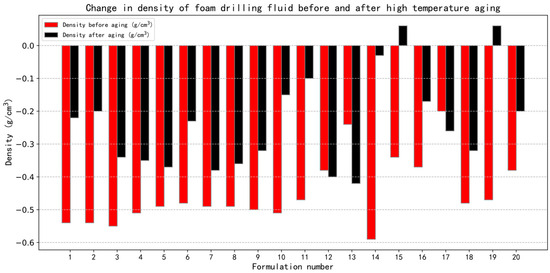

3.3.1. Density Change Analysis

Figure 2 illustrates the density changes of all tested formulations before and after 16 h of aging at 200 °C. A clear trend observed is that the density of nearly all formulations increased to varying degrees after aging. Formulations 3, 6, 9, and 13 exhibited particularly significant increases in density, often rising by over 0.1 g/cm3 (e.g., Formulation 3 increased from ~1.03 to ~1.15 g/cm3), indicating substantial liquid phase loss or degradation. The primary reason for this increase is the evaporation of part of the liquid phase (water), the increased solubility of the gas phase (air/nitrogen), or its escape from the system during high-temperature and high-pressure aging. This leads to a relative enrichment of heavier solid or non-volatile liquid components in the system, resulting in an overall increase in macroscopic density. A smaller increase in density indicates less water loss or gas phase loss at high temperatures, suggesting better stability. Quantitatively, a density increase of less than 0.05 g/cm3 is considered indicative of excellent stability, while increases greater than 0.1 g/cm3 suggest significant instability. As shown in Figure 2, Formulations 10, 11, 14, 15, and 19 exhibited relatively smaller increases in density, indicating that these systems maintained better component stability at 200 °C.

Figure 2.

Density changes in foam drilling fluid before and after aging.

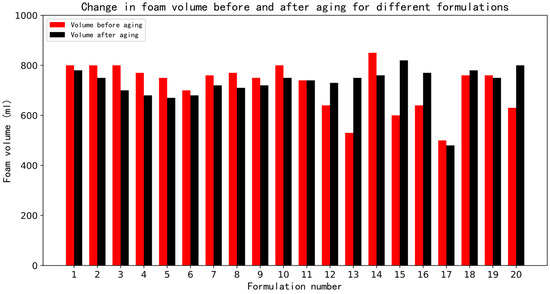

3.3.2. Volume Change Trend Analysis

Figure 3 illustrates the volume changes of the foam drilling fluid systems before and after 16 h of aging at 200 °C. Volume change is a direct indicator of foam stability. A decrease in volume is typically caused by foam breakdown, gas phase escape, and liquid phase evaporation due to high temperatures. Interestingly, the volumes of some formulations slightly increased (e.g., Formulations 12 and 13). This phenomenon may be attributed to high-temperature-induced hydration expansion of certain water-sensitive polymers or cross-linkers within the system, leading to an increase in the overall volume of the liquid phase. Alternatively, minor decomposition of certain components at elevated temperatures might generate gaseous byproducts, contributing to a slight increase in total volume if trapped within the system. However, this trend is not prominent overall. A smaller volume change indicates better stability of the foam structure and liquid phase volume under high-temperature conditions. Specifically, volume changes within ±10 mL indicate good stability, whereas larger changes point to significant foam breakdown or liquid phase loss/expansion. As shown in Figure 3, Formulations 7, 8, 9, 11, 16, and 18 exhibited smaller volume changes, demonstrating relatively better volume stability. This suggests that these formulations are more effective in maintaining the macroscopic structure of the foam system at 200 °C.

Figure 3.

Changes in volume of foam drilling fluid before and after high-temperature aging.

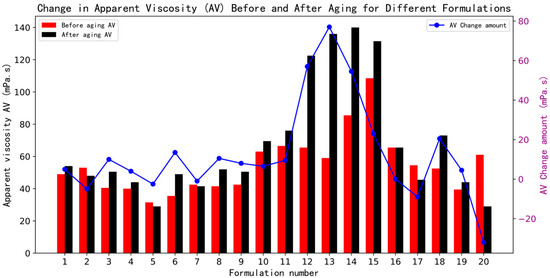

3.3.3. Analysis of Apparent Viscosity (AV) Trend

Figure 4 illustrates the changes in the apparent viscosity (AV) of the foam drilling fluid systems before and after 16 h of aging at 200 °C. AV reflects the total viscosity of the fluid under a specific shear rate and is closely related to the fluid’s rock-carrying capacity. A clear trend is observed where the AV of most formulations increased after aging, particularly for Formulations 12–15, where the increase was significant, often more than doubling from initial values (e.g., Formulation 12 increasing from ~50 mPa·s to ~105 mPa·s). This increase in viscosity may be attributed to high-temperature-induced partial cross-linking of polymers, changes in molecular chain conformation leading to enhanced entanglement, or alterations in the dispersion state of solid particles. However, excessive or uncontrolled viscosity increases can negatively impact pumping and solid–liquid separation.

Figure 4.

Changes in apparent viscosity (AV) of foam drilling fluid before and after high-temperature aging.

For Formulations 5 and 20, the AV decreased after aging, dropping significantly from its initial values (e.g., Formulation 5 decreased from ~60 mPa·s to ~20 mPa·s), which is typically caused by the thermal degradation of polymers (e.g., stabilizers or viscosity enhancers) under high-temperature conditions, resulting in molecular chain breakage. This indicates insufficient temperature resistance of key polymers in these formulations, significantly affecting the rheological stability of the system. Generally, maintaining AV values between 30 and 60 mPa·s after aging is desirable for effective cuttings transport and pumping, with significant increases or decreases indicating performance degradation. Formulations 7 and 17 exhibited relatively low AV values after aging, with smooth and stable changes, maintaining AV values between 40 and 50 mPa·s (e.g., Formulation 7 from 47.5 to 46.5 mPa·s), indicating that these formulations have good viscosity control performance.

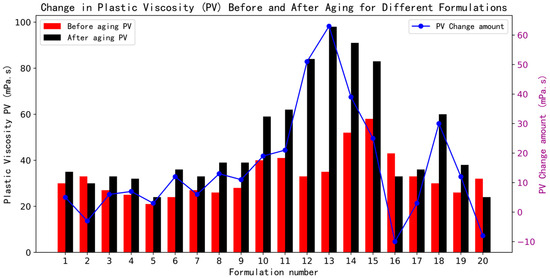

3.3.4. Analysis of Plastic Viscosity (PV) Trend

Figure 5 presents the changes in plastic viscosity (PV) of the foam drilling fluid systems before and after 16 h of aging at 200 °C. PV primarily reflects the internal friction force of the fluid under higher shear rates and is related to the efficiency of rock removal at the well bottom. Similar to AV, the PV of most formulations showed an increasing trend after aging, although the magnitude of the increase was generally smaller than that of AV. For instance, Formulations 12, 13, 14, and 15 saw PV increase from around 20–30 mPa·s to 40–60 mPa·s, suggesting increased solid–liquid interactions or particle aggregation. The increase in PV may be attributed to enhanced aggregation or interaction of dispersed phases under high-temperature conditions. For Formulation 20, PV significantly decreased, dropping from approximately 30 mPa·s to around 10 mPa·s, and Formulation 5 also showed a slight decrease, which further confirms polymer degradation or insufficient system stability in these formulations at 200 °C. Optimally, PV values should remain below 35 mPa·s after aging for good flow efficiency and reduced pressure losses, and stable changes are preferred. Formulations 1, 2, 7, 8, and 17 exhibited relatively low PV values after aging, with smooth and stable changes, generally remaining below 30 mPa·s after aging (e.g., Formulation 7 from 24.5 to 25 mPa·s), indicating better control of dispersed phase behavior and high-shear rheological performance under high-temperature conditions.

Figure 5.

Changes in plastic viscosity (PV) of foam drilling fluid before and after high-temperature aging.

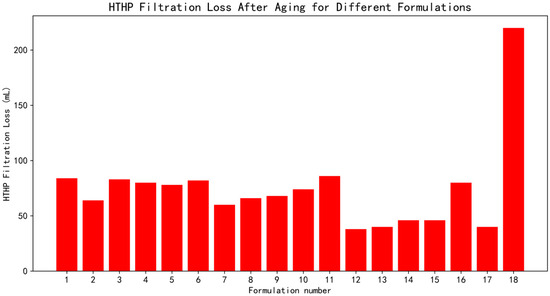

3.3.5. High-Temperature, High-Pressure Filtrate Loss Analysis

Figure 6 illustrates the high-temperature, high-pressure (HTHP) filtration loss of the foam drilling fluid systems after 16 h of aging at 200 °C. HTHP filtration loss is a critical indicator for evaluating the water loss capability of drilling fluids under real in-well high-temperature and high-pressure conditions, closely related to formation damage and wellbore stability. For HTHP fluid loss, values below 20 mL are considered excellent, 20–50 mL are good, and above 50 mL are poor. A distinct and crucial trend observed in Figure 6 is the remarkably lower HTHP filtration loss values exhibited by Formulations 12, 13, 15, 16, and 19 compared to other formulations. For example, these superior formulations generally maintain HTHP fluid loss below 20 mL, while others like Formulations 1, 2, 5, 6, and particularly 10 and 11, show significantly higher values, often exceeding 100 mL (e.g., Formulation 10 reached over 200 mL). This trend indicates superior filtration control under extreme conditions. Low HTHP filtration loss is typically attributed to thermally stable polymers, small and uniformly dispersed solid particles, and the formation of a dense, low-permeability mud cake. Notably, Formulation 16, which incorporates 1% FP-1 and 0.3% GWPJ (the selected high-temperature-resistant foaming agent and foam stabilizer, respectively), exhibited excellent HTHP filtration control, highlighting the synergistic effect of these components in maintaining system integrity under extreme conditions. Formulations 12, 13, 15, and 16 demonstrate excellent performance in both API and HTHP filtration loss, indicating a significant advantage in filtration control across the full temperature range (ambient and 200 °C HTHP conditions). This highlights their robust performance and reliability in practical drilling operations under diverse thermal and pressure conditions.

Figure 6.

The high-temperature, high-pressure filtration loss variation curve of foam drilling fluid after high-temperature aging.

It is important to analyze the notably high fluid loss for Formulation 20 (the last group in Figure 6), which approaches 100 mL. This indicates a significant failure in its filtration control mechanism under extreme conditions. From a microscopic molecular and chemical bond perspective, this high fluid loss is primarily attributed to the thermal degradation of one or more polymeric components (such as HPS, GDDP, GWPJ, or GHTS) present in this specific formulation combination and concentration at 200 °C. High temperatures can cause chain scission of these polymers, breaking larger molecules into smaller fragments. These smaller fragments lose their ability to effectively increase the continuous phase viscosity and, critically, their capacity to adsorb onto solid particles or bridge across pore throats in the formation. The chemical bonds (e.g., hydrogen bonds, van der Waals forces) that hold the polymer–particle network together within the filter cake are weakened or broken, leading to a more porous and permeable mud cake. Furthermore, the relatively lower concentrations of key stabilizers (e.g., 0.5% GWPJ and 0.5% GHTS) in Formulation 20 compared to the better-performing systems might be insufficient to protect other components or maintain overall system integrity at such elevated temperatures.

3.3.6. Comprehensive Analysis of the Performance Indices of Various Formulations After Aging at 200 °C

While specific numerical thresholds for “better” or “worse” are context-dependent and subject to specific drilling requirements, the evaluation herein is based on comparative performance relative to other tested formulations and general industry expectations for high-temperature drilling fluids. As established, lower filtration loss values (HTHP FL < 20 mL, excellent) are considered superior. Smaller changes in density (increase < 0.05 g/cm3 excellent) and volume (change within ±10 mL good) after aging indicate better stability. For rheological properties (AV 30–60 mPa·s desirable, PV < 35 mPa·s desirable), values within a moderate and stable range are preferred for effective cuttings transport and pumping, with significant increases or decreases indicating performance degradation. Although a detailed statistical analysis (e.g., ANOVA) of the significance of differences between systems was beyond the scope of this empirical evaluation, the observed performance disparities were quantitatively significant and sufficiently distinct to identify promising formulations, without the need for complex statistical tables that would unduly expand the manuscript.

- Density and Volume Stability: Formulations 10, 11, 14, 15, and 19 demonstrated relatively better performance in terms of density, while Formulations 7, 8, 9, 11, 16, and 18 showed better performance in volume stability. These formulations may have effectively maintained the gas–liquid component balance and foam structure of the system.

- Rheological Performance: The viscosity of most formulations increased after aging, while Formulations 5 and 20 exhibited a decrease in viscosity. Formulations 7 and 17 displayed relatively stable viscosity control. Rheological properties need to be moderate to ensure efficient rock-carrying and pumping performance.

- Filtration Control: Filtration control is a critical factor for high-temperature stability. Formulations 12, 13, 14, 15, and 16 demonstrated significant advantages in HTHP (high-temperature, high-pressure) filtration loss. These formulations effectively controlled filtrate invasion under high-temperature and high-pressure conditions, which is essential for protecting the formation and maintaining wellbore stability.

- Potential of the Formulations: Considering that filtration control is one of the primary performance requirements for drilling fluids in high-temperature complex formations, these formulations exhibit excellent potential. Based on their outstanding performance in filtration control and a comprehensive evaluation of density, volume, and rheological properties, Formulations 12, 13, 14, 15, and 16 are identified as the most promising high-temperature, reusable foam drilling fluid system formulations. They warrant further in-depth research and optimization. Notably, Formulation 12 stands out particularly for its exceptional performance in HTHP filtration control.

4. Conclusions

This study successfully developed and optimized a high-temperature-resistant foam drilling fluid system to address challenges in ultra-high temperature geothermal well drilling. The core findings are as follows.

- (1)

- The high-temperature-resistant foaming agent FP-1 was identified as highly effective, maintaining excellent foaming performance and stability under extreme conditions up to 240 °C and 15% brine/NaCl salinity.

- (2)

- The foam stabilizer GWPJ significantly enhanced the system’s thermal stability. It effectively maintained rheological properties and filtration control after 200 °C aging and notably extended the foam half-life of the FP-1 system at 240 °C when added in appropriate concentrations.

- (3)

- Through orthogonal experimental design, an optimized foam drilling fluid system (specifically Formulation 12) was achieved. This formulation demonstrated exceptional high-temperature stability and superior HTHP filtration control at 200 °C, offering a robust technical solution for complex high-temperature and high-pressure formations. The observed excellent performance under laboratory-simulated high-temperature and high-pressure conditions suggests a high potential for robust performance and reliability in deep geothermal well applications, laying a strong foundation for future field testing and commercialization.

Author Contributions

Y.Z.: Visualization, Writing—original draft. D.L.: Methodology, Supervision, Investigation. F.Z.: Investigation, Writing—review and editing. Y.S.: Writing—original draft, Supervision, Writing—review and editing. C.M.: Writing—review and editing. W.J.: Data curation. W.S.: Conceptualization, Data curation. All authors have read and agreed to the published version of the manuscript.

Funding

The authors gratefully expressed their thanks for the financial supported by the Foundation of the National Natural Science Foundation of China (No. 41802196), Dynamic Assessment and Deployment Strategy Research on Oil and Gas Prospecting Initiatives (No. DD20242067), CNPC Innovation Found (No. 2024DQ02-0149).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Weijun Ji was employed by the company Beijing Sanhe Runjing Technology Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Smith, D.H. Foams: Fundamentals and Applications in the Petroleum Industry Edited by Laurier L. Schramm (Petroleum Research Institute); American Chemical Society: Washington, DC, USA, 1994; ISBN 0-8412-2719-5. [Google Scholar]

- Gu, M.; Mohanty, K.K. Rheology of polymer-free foam fracturing fluids. J. Pet. Sci. Eng. 2015, 134, 87–96. [Google Scholar] [CrossRef]

- Foam Engineering: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2012.

- Jiang, G.; Dong, T.; Cui, K.; He, Y.; Quan, X.; Yang, L.; Fu, Y. Research status and development directions of intelligent drilling fluid technologies. Pet. Explor. Dev. 2022, 49, 660–670. [Google Scholar] [CrossRef]

- Li, S.; Li, Z.; Li, B. Experimental study and application on profile control using high-temperature foam. J. Pet. Sci. Eng. 2011, 78, 567–574. [Google Scholar] [CrossRef]

- Li, J.; Pan, R.; Guo, B.; Shan, J. Thermal stability of brine foams for shale gas drilling. J. Nat. Gas Sci. Eng. 2014, 17, 131–135. [Google Scholar] [CrossRef]

- Wen, Y.; Lai, N.; Li, W.; Zhang, Y.; Du, Z.; Han, L.; Song, Z. Factors influencing the stability of natural gas foam prepared by alkyl polyglycosides and its decay rules. J. Pet. Sci. Eng. 2021, 196, 108039. [Google Scholar] [CrossRef]

- Xin, Y.; Wang, X.; Xie, R.; Huang, W. Preparation Methods on High Temperature Salt-tolerant and Oil-resisting Water Base Micro-Bubble Drilling Fluid System. Drill. Fluid Complet. Fluid 2012, 29, 15–18. [Google Scholar]

- Yang, P.; Li, J.; Sun, Y.; Guan, J.; Kuang, X.; Zheng, L. Development and Application of an Oil-Based Circulating Micro-Foam Drilling Fluid. Nat. Gas Ind. 2014, 34, 78–84. [Google Scholar] [CrossRef]

- Xiao, C.; Yu, L. Optimization of drilling fluid formulation in the Tanan Block of the Haita Basin. Drill. Fluid Complet. Fluid 2014, 31, 85–88. [Google Scholar] [CrossRef]

- Wang, X. The Development and Application of Solid-Free Micro-Foam Drilling Fluid with Temperature Resistance and Salt Tolerance. Pet. Drill. Tech. 2016, 44, 58–64. [Google Scholar] [CrossRef]

- Guo, J.; Xie, J.; Sun, J.; Liu, G.; Lu, G.; Yang, G.; Tan, A. A viscoelastic surfactants: Its development and application in micro foam drilling fluids. Drill. Fluid Complet. Fluid 2017, 34, 1–7. [Google Scholar] [CrossRef]

- Luo, H.; Shi, L.; Zuo, J.; Shi, K.; Song, J. Recyclable micro foam drilling fluid: Its study and application in burial hill structure in Chad. Drill. Fluid Complet. Fluid 2017, 34, 8–13. [Google Scholar] [CrossRef]

- Yao, J.; Wan, L.; Gao, P.; Liu, Z.; Chen, Y. Polymer nano-assembled micro-foam drilling fluid system and its performance evaluation. Oil Drill. Prod. Technol. 2018, 40, 577–581. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, J.; Zu, C.; Tian, Y.; Li, S.; Huang, J.; Liu, Q. Study and application of a weak gel micro foam drilling fluid in horizontal wells through loose sand in Venezuela. Drill. Fluid Complet. Fluid 2018, 35, 77–81. [Google Scholar] [CrossRef]

- Li, Z.; Li, Q.; Sun, H.; Yang, G.; Ma, T.; Zhang, F. Research on micro-foam drilling fluid suitable for coalbed methane drilling. J. China Coal Soc. 2020, 45, 703–711. [Google Scholar] [CrossRef]

- Dun, J.; Xu, C.; Kang, Y.; Jing, H.; Yang, B.; You, L.; Long, Y. Formation damage mechanism and control strategy of the compound function of drilling fluid and fracturing fluid in shale reservoirs. Pet. Explor. Dev. 2024, 51, 430–439. [Google Scholar] [CrossRef]

- Yuan, B.; Wood, D.A. A holistic review of geosystem damage during unconventional oil, gas and geothermal energy recovery. Fuel 2018, 227, 99–110. [Google Scholar] [CrossRef]

- API RP 13B; Recommended Practice for Field Testing Oil-Based Drilling Fluids. American Petroleum Institute: Washington, DC, USA, 2014.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).