1. Introduction

Climate change is a global challenge facing humanity. With the development of industrialization, greenhouse gas emissions have surged, posing a threat to ecosystems. Moreover, as a major manufacturing country, China’s industrial production capacity continues to grow, yet its oil and gas resources are relatively scarce. Advocating for low-carbon production and developing a low-carbon economy holds significant security implications for achieving the dual-carbon goals [

1]. The high-energy-consuming industry is a key sector for carbon neutrality in industrial production [

2]. According to relevant statistics, taking the electrolytic aluminum industry as an example, China’s aluminum output in 2020 was 37.124 million tons, with a total electricity consumption of approximately 501.174 billion kWh, accounting for about 6.67% of the nation’s total electricity consumption. Meanwhile, the total CO

2 emissions reached about 426 million tons, representing roughly 5% of the country’s net CO

2 emissions. Formulating a low-carbon production plan suitable for aluminum enterprises is of great significance for enhancing their core competitiveness and sustainable development.

High-energy-consuming enterprises are characterized by their sensitivity to electricity prices and high production flexibility, creating conditions for coordinated dispatch between the source and load sides. Runze Chen and Hongyang Jin et al. conducted a detailed analysis of the operational and power consumption characteristics of high-energy-consuming loads in [

3,

4], establishing refined mathematical models for smelting and electrolytic loads, and thoroughly discussing various collaboration methods for their participation in economic dispatch. A robust unit commitment algorithm is proposed in [

5], considering the dual uncertainties of high-energy-consuming load power and renewable energy output, analyzing the impact of load power fluctuations on system revenue. To enhance the system’s ability to absorb renewable energy, such as hydropower and photovoltaics, Yu Qian et al. [

6] designed a collaborative framework where high-energy-consuming loads work with cascaded hydropower to mitigate fluctuations in wind and solar power output, significantly increasing the renewable integration capacity. Pi Xia and Zhao Yuyang et al. [

7] considered the impact of wind power forecasting errors on the revenue of high-energy-consuming enterprises and proposed a predictive revenue model based on predictive control theory. These studies primarily focus on grid-enterprise collaborative dispatch and uncertainty modeling of renewable energy but overlook the carbon emission constraints of high-energy-consuming enterprises, prioritizing economic benefits at the expense of environmental considerations.

Some experts and scholars have also conducted research on low-carbon production and dispatch in power systems. Tian Biyuan and Chang Xiqiang et al. [

8] achieved low-carbon economic dispatch in distribution networks through demand response and shared energy storage usage rights. Cui Yang and Deng Guibo et al. [

9] designed a low-carbon economic dispatch strategy for a concentrated solar power-wind hybrid system, considering carbon trading mechanisms and analyzing technical and policy aspects to reduce overall operational costs. Chen Jinpeng and Kang Lihong et al. [

10,

11] accounted for the actual carbon emissions of loads, refined carbon emission models, and introduced carbon trading mechanisms to further constrain emissions in integrated energy systems, balancing economic and low-carbon objectives through flexible scheduling of heating and cooling loads. However, these low-carbon dispatch studies primarily target renewable energy and integrated energy systems, excluding high-energy-consuming enterprises. In fact, as early as 2019, the China Nonferrous Metals Industry Association issued the “Technical Guidelines for Carbon Emission Trading in Electrolytic Aluminum Enterprises” [

12], detailing the carbon trading management system and technical specifications for such enterprises, with pilot programs implemented in multiple provinces. Some AI technologies have also been introduced into the field of power system scheduling to enhance decision-making efficiency and accuracy. Fan Shixiong et al. [

13] proposed a framework and key technologies for a human–machine hybrid augmented intelligence system for large-scale power grid dispatching and control. This study offers new ideas and methods for the dispatching and control of large-scale power grids. Z. Liu et al. [

14] presented a brain-inspired collaborative power dynamic dispatch method for digital twin smart generation systems. By drawing on the brain’s collaborative mechanisms, this method provides an innovative solution for power dynamic dispatch in digital twin environments. J. Chen et al. [

15] achieved stochastic dynamic power dispatch with human knowledge transfer using inverse reinforcement learning assisted by Graph-GAN. M. Li and J. Mohammadi [

16] conducted research on optimization learning for joint chance-constrained power dispatch problems, offering an effective approach to handling uncertainty factors in power dispatching. D. Ma et al. [

17] proposed an implicit dual gradient tracking algorithm under a randomly triggered transmission protocol for distributed economic dispatch with dynamic power demands. Y. Zhang et al. [

18] introduced a PI + R control scheme based on a multi-agent system for economic dispatch in isolated battery energy storage systems. This scheme leverages the advantages of multi-agent systems and combines them with the PI + R control strategy to achieve effective economic dispatch in isolated battery energy storage systems. Additionally, the abundant waste heat resources in electrolytic aluminum enterprises have rarely been addressed in previous dispatch and production studies. The aluminum production process involves stages such as petroleum coke calcination and anode baking, generating large amounts of high-temperature flue gas. Preliminary estimates suggest that adopting waste heat recovery technology can reduce energy consumption by 200–300 kWh per ton of aluminum, equivalent to saving 1.5–2 million tons of standard coal [

19]. Today, Organic Rankine Cycle (ORC) technology, based on different working fluids, has advanced significantly, enabling the recovery of low-grade waste heat from electrolytic cells [

20,

21]. Many domestic aluminum enterprises have already implemented waste heat recovery systems. For instance, since its launch in 2019, Yunnan Aluminum’s flue gas waste heat utilization system has cumulatively reduced greenhouse gas emissions by 7566 tons and achieved energy-saving benefits worth 6.9137 million yuan. This demonstrates that integrating aluminum production waste heat into power system dispatch and internal production processes, while consolidating waste heat resources of varying grades, can significantly improve resource utilization efficiency and enhance both economic and environmental benefits.

To address the aforementioned issues and gaps in existing research, this paper designs a collaborative day-ahead low-carbon economic dispatch strategy for electrolytic aluminum enterprises and power grids. The scheduling method proposed in this paper differs significantly from traditional power grid scheduling strategies, primarily in the following aspects: Firstly, traditional scheduling methods typically make decisions with the power grid as the main entity, treating high-energy-consuming enterprises as passive recipients of scheduling. They overlook the substantial waste heat resources generated by these enterprises during production, resulting in energy waste and low resource utilization efficiency. Secondly, traditional methods solely pursue economic benefits on the grid side and fail to fully consider the carbon emission issues of high-energy-consuming industries, leading to poor environmental performance of the overall system. Thirdly, traditional optimization methods often adopt relatively conservative scheduling strategies, which are difficult to adapt to the uncertainty of renewable energy output, such as wind power, and fail to effectively coordinate the relationship between industrial production and clean energy consumption. The organizational framework of this paper is as follows: First,

Section 2 conducts an analysis of waste heat sources, pointing out the sources of waste heat in the three stages of petroleum coke calcination, green anode baking, and electrolytic aluminum production during the electrolytic aluminum manufacturing process, and establishes corresponding mathematical models. In

Section 3.1, an optimal production model for the electrolytic aluminum enterprise side is established, taking into account electrolyzer production constraints, captive power plant unit constraints, and a carbon emissions model. Finally, in

Section 3.2, a robust economic dispatch model for the power grid is presented, and its effectiveness and feasibility are verified through a case study in

Section 4. Lastly,

Section 5 summarizes the entire paper.

The main innovative points of this paper are summarized as follows:

(1) This paper constructs a model that considers waste heat utilization in high-energy-consuming enterprises, represented by the electrolytic aluminum industry, and formulates a low-carbon production scheme using a tiered carbon trading calculation formula, thereby changing the passive regulatory status of high-energy-consuming enterprises in research.

(2) By comprehensively considering factors such as local load levels, uncertainty in wind power output, and energy demands for aluminum production, this paper establishes a robust day-ahead economic dispatch model for the power grid side, balancing economic efficiency and low-carbon performance while reducing the conservatism of traditional optimization methods.

2. Modeling and Utilization Methods of Waste Heat in High Energy-Consuming Loads

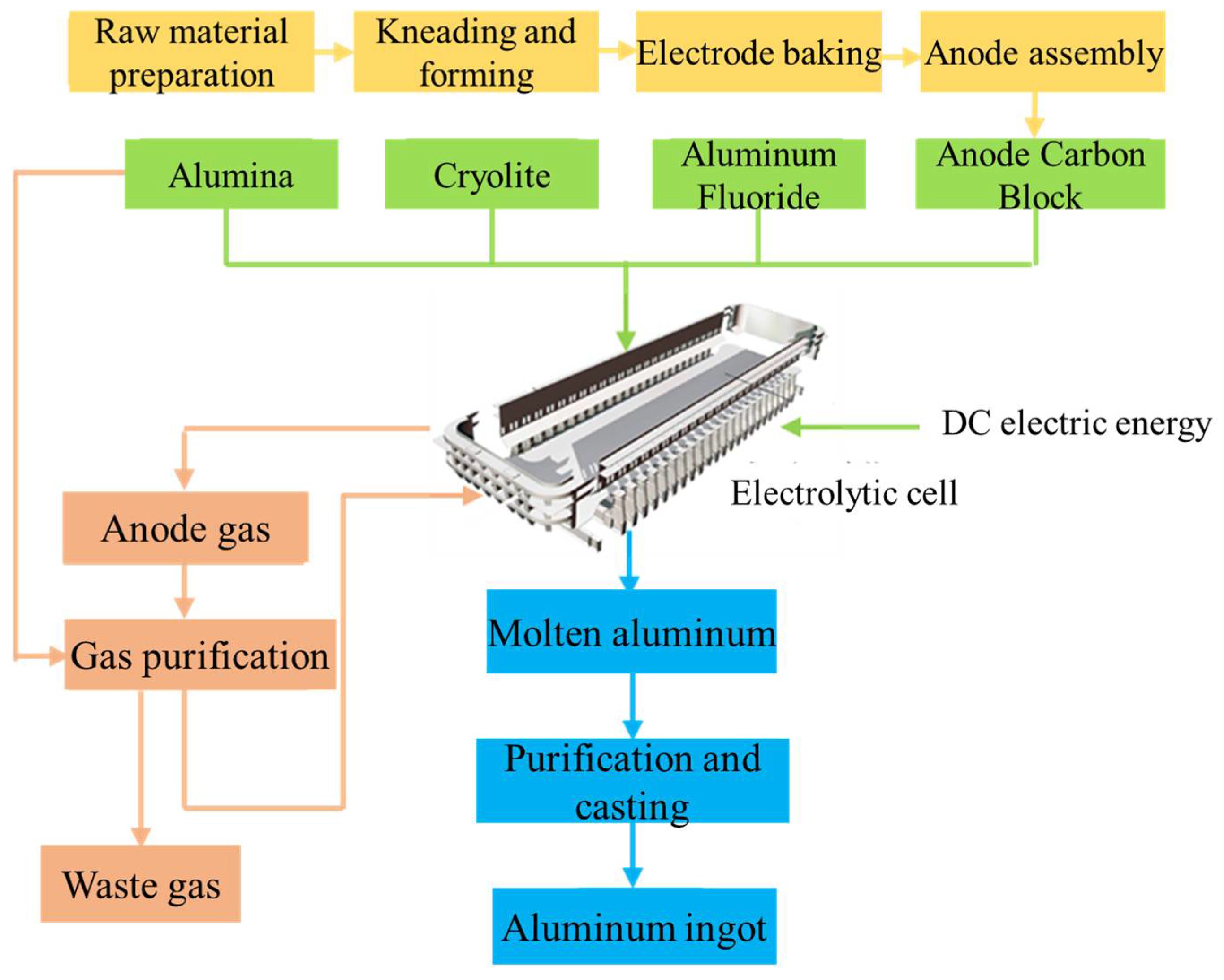

Due to technological advancements in recent years, aluminum production enterprises primarily use prebaked anode cells for electrolytic aluminum production.

Figure 1 illustrates the electrolytic aluminum production process, showing that prebaked anode electrolytic aluminum production requires significant amounts of prebaked anodes. Therefore, electrolytic aluminum plants typically perform processes such as calcination, baking, and assembly to produce sufficient prebaked anodes. Since some production stages generate waste heat with low calorific value, making it unsuitable for utilization, this paper focuses on analyzing, modeling, and utilizing the waste heat generated during the calcination of petroleum coke, green anode baking, and the electrolytic aluminum production process.

Equation (1) presents the calculation formula for the utilizable energy of flue gas waste heat. Here,

Pt represents the utilizable energy of flue gas waste heat,

cp denotes the average specific heat capacity of the flue gas,

m is the flue gas flow rate,

T0 and

T represent the thermodynamic temperatures of the flue gas and the environment, respectively, and

ηt signifies the efficiency during flue gas collection and transmission.

Petroleum coke calcination is the first step in producing anode carbon. During calcination, the generated flue gas has a high temperature, typically above 900 °C, making it a high-quality heat source with significant thermal value. In addition to power generation, this flue gas is often used to meet the plant’s thermal energy demands. Equations (2)–(8) describe the mathematical model for waste heat utilization in petroleum coke calcination. Here,

Py1,t represents the utilizable energy from high-temperature flue gas generated during calcination at time

t, the specific value of which can be calculated using Equation (1).

Pe1,t and

Ph1,t represent the electrical and thermal energy produced from flue gas utilization at time

t, respectively, while

ηe1 and

ηh1 represent the power generation efficiency and heat production efficiency, respectively.

ηloss represents the energy loss efficiency, and

PhL,t represents the thermal load power at time

t.

Cs,min and

Cs,max represent the lower and upper limits of the thermal storage capacity, respectively. In Equation (8),

Pc,max and

Pf,max represent the maximum charging and discharging power of the thermal storage system, respectively.

and

represents the thermal storage capacity at time

t and

t − 1, respectively.

represents the initial thermal storage capacity before production begins.

The final stage in anode production is the baking of green anodes. When air flows into the packing material layer with sufficient oxygen content, the baking furnace achieves complete combustion, generating flue gas typically at temperatures between 150 and 250 °C. Although this temperature is significantly lower than that of the calcination process, the large flue gas flow rate—often exceeding 100,000 Nm

3/h—still presents substantial potential for energy recovery. Due to the relatively low flue gas temperature, Organic Rankine Cycle (ORC) technology is widely adopted for waste heat power generation both domestically and internationally. For simplicity in calculations, the cooling water flow rate, heat exchange area, and working fluid efficiency of the ORC system are collectively converted into a single ORC power generation efficiency value,

ηORC. The waste heat utilization model for green anode baking can thus be expressed by Equations (9)–(11). Here,

Pe2,t and

Pe2,t−1 represent the electricity generated from the baking flue gas via ORC technology at time

t and

t − 1, while

Py2,t denotes the recovered energy from the flue gas, which can be calculated using Equation (1).

and

represent the upper and lower limits of the electricity generated from ORC technology.

and

represent the upper and lower limits of adjustment inertia given by ORC technology. Equations (10) and (11) define the upper and lower limits for power generation capacity and the ramp rate constraints, respectively.

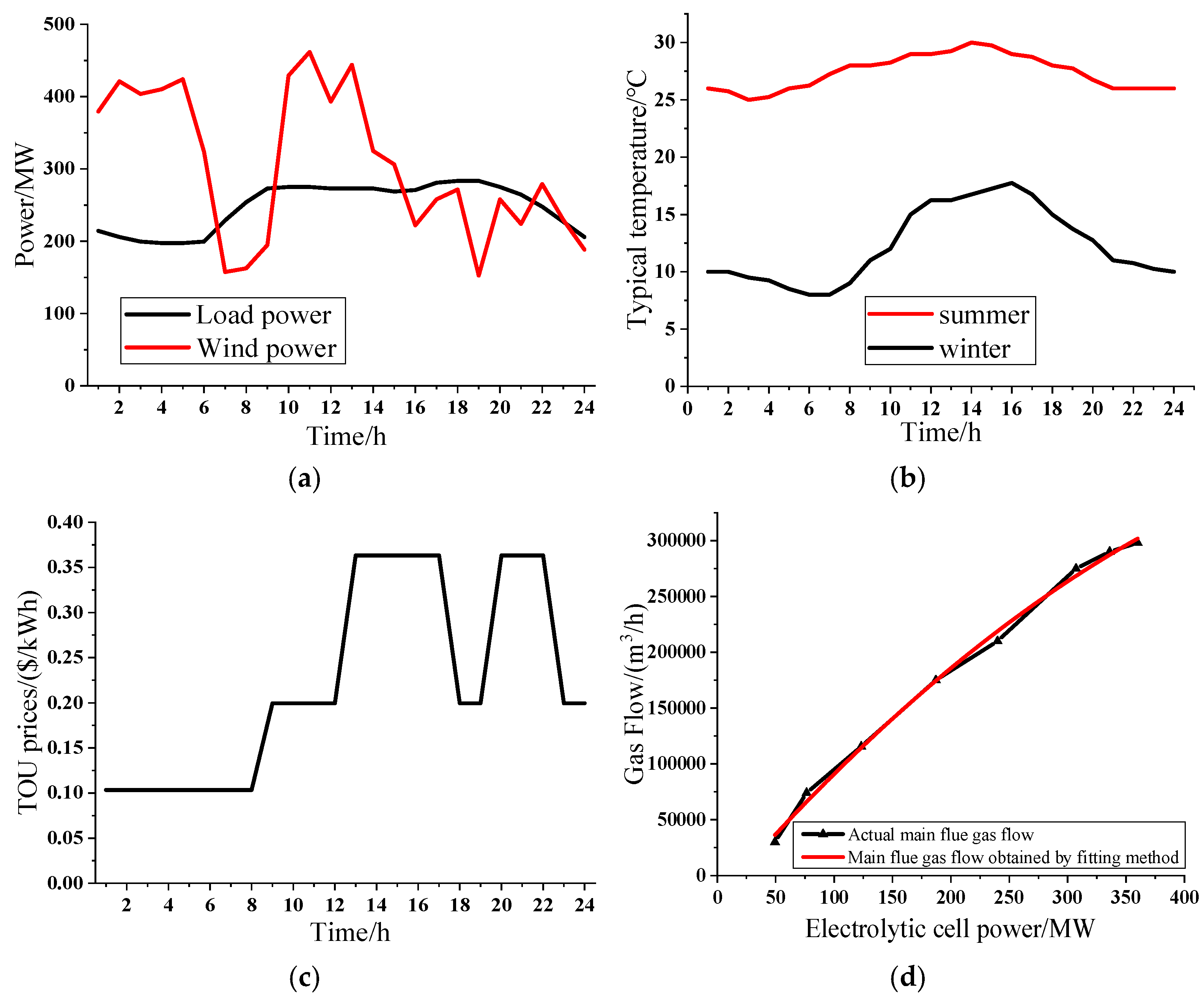

Finally, the aluminum electrolysis process also generates a significant amount of low-temperature flue gas, which is discharged through the main flue. The temperature of this flue gas typically ranges between 100 and 200 °C, making ORC technology suitable for its recovery. However, unlike the relatively stable flue gas flow rates in the lime coke calcination and green anode baking processes, the main flue gas flow fluctuates depending on the operating conditions of the electrolytic cells. In this study, the relationship between the main flue gas flow rate and the electrolytic cell power is derived using the least squares fitting method, with the detailed calculation formula provided in Equation (12). Here,

mal represents the main flue gas flow rate of the electrolytic cells,

Pal,t represents the electrolytic cell power, and

a,

b, and

c are the least squares fitting coefficients. The waste heat power generation

Pe3,t from this source can be calculated using Equation (1) in conjunction with Equations (9)–(11).

3. An Economic Dispatch Model for Power Grids Considering Waste Heat Utilization in Energy-Intensive Enterprises

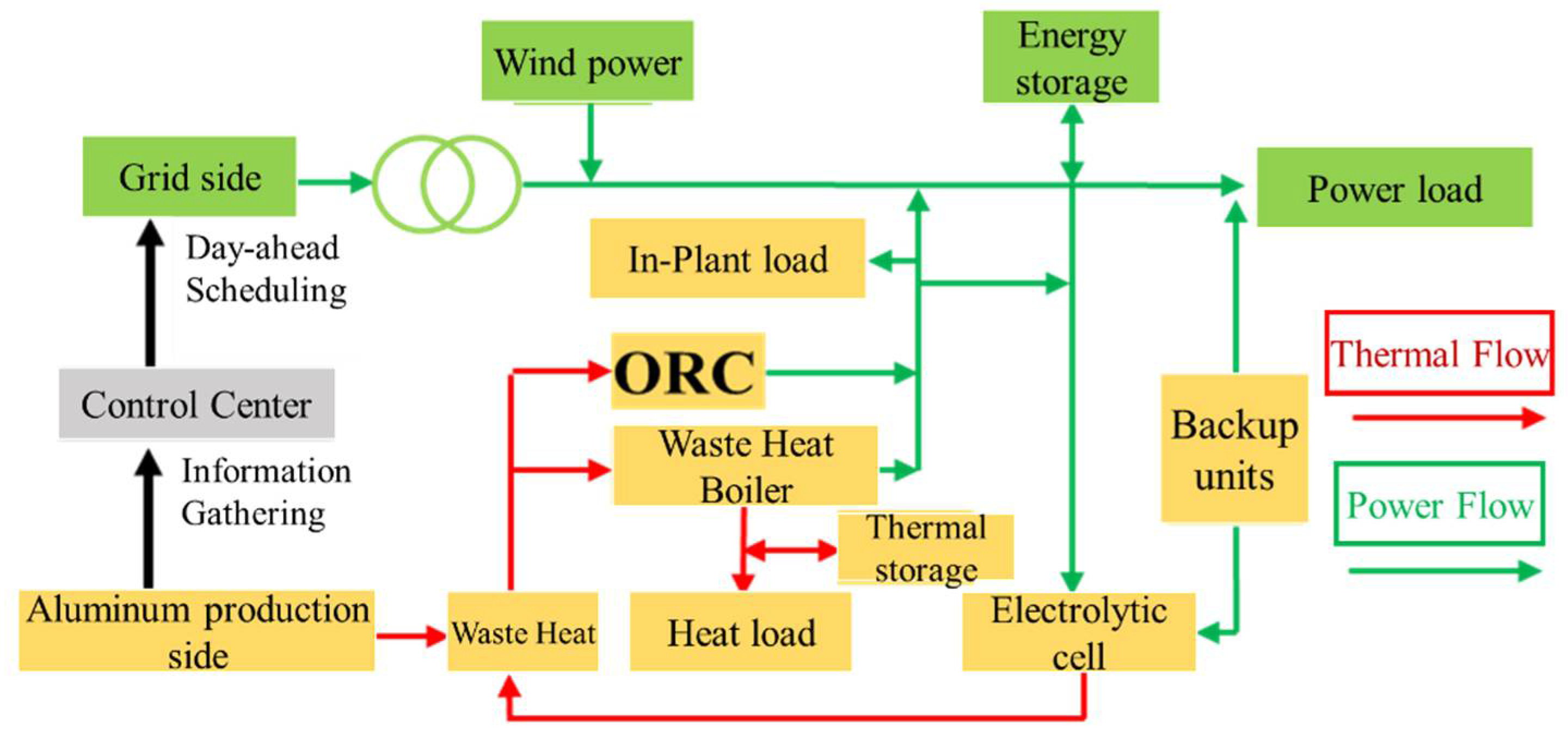

Figure 2 illustrates the schematic diagram of power grid economic dispatch considering waste heat utilization in energy-intensive enterprises. The aluminum production enterprise formulates its optimal production plan by comprehensively considering electrolytic cell energy consumption, standby unit output, and waste heat utilization, while simultaneously feeding back the required electricity purchase quantity to the control center. The control center then develops a robust day-ahead dispatch strategy by accounting for the aluminum enterprise’s power demand, renewable energy output, and load uncertainties. In terms of model characteristics, the aluminum electrolysis-grid-coordinated dispatch constitutes a two-stage optimization problem. The first-stage model, targeting the aluminum production enterprise, presents a mixed-integer nonlinear programming problem; the second-stage model, designed for the power grid, represents a robust mixed-integer linear programming problem considering uncertainties. The transmission variable between these two stages is precisely the electricity purchase quantity from the aluminum enterprise to the power grid.

3.1. Mathematical Model for Production on the Energy-Intensive Enterprise Side

The electrolytic cells accomplish production tasks through direct current. In actual production, these cells are formed by connecting multiple small-capacity electrolytic cells in series. Due to the highly time-consuming assembly process, power control of the electrolytic cells is typically achieved by adjusting the voltage across the terminals. The mathematical model for aluminum production via electrolysis can be expressed as follows:

(1) Electrolytic cell production constraints…

Equations (13) and (14) represent the upper and lower power limits and ramp rate constraints of the electrolytic cells respectively; considering that frequent power adjustments may affect the electrolysis state of raw materials and the quality of the final product, Equation (15) is used to limit the power adjustment frequency of the electrolytic cells, with the adjustment time interval Δt set to 1 h in this study; the primary objectives of the aluminum electrolysis enterprise are to complete production tasks and achieve profitability, where Equation (16) represents the production output constraint, with aal denoting the unit electricity production coefficient when the electrolytic cell operates at the minimum active power Pal,min, aal-ext representing the corresponding unit electricity production coefficient when the active power ranges between Pal,min and Pal,max, and Yorder indicating the daily production requirement of the aluminum manufacturing enterprise. and represent the upper and lower regulation inertia limit of the electrolytic cells.

(2) Constraints related to self-generation power plant units

Equation (17) represent the output constraints of self-generation power plant units considering reserve capacity; Equation (18) specify the ramp rate constraints of the units; Equation (19) define the value constraints for the operational status and start-up/shut-down states of self-generation power plant units; Equations (20) and (21) impose the minimum operating time and shut-down time constraints for the units, where Pru,t denotes the output of self-generation units at time t, xtG represents the unit status variable at time t, and utG and vtG indicate the unit start-up and shut-down variables at time t, respectively.

Equation (22) represents the power balance constraint within the aluminum electrolysis enterprise, where the left side of the equation consists of the total waste heat power generation, electricity purchased from the grid , and self-generated power output at time t, while the right side represents the power consumption of the electrolytic cells and other internal loads within the enterprise .

(4) Carbon emission modeling

The aluminum electrolysis industry is a key sector for carbon emissions. Calculating CO

2 emissions during aluminum production primarily depends on two factors: emissions converted from electricity consumption and emissions generated during raw material processing and product formation. The detailed calculation method is shown in Equation (23), where

Temi represents the total CO

2 emissions in aluminum production,

Ψ denotes the electricity emission factor,

Yt represents production output at time

t, and

γ represents the CO

2 emission coefficient for raw material processing and product formation. According to the “Technical Guidelines for Carbon Emission Trading in Aluminum Electrolysis Enterprises”, the values used in this study are

Ψ = 0.6858 tCO

2/MWh and

γ = 2.5 tCO

2/tAl.

The current determination of free carbon emission allowances for aluminum electrolysis primarily adopts the baseline method, which calculates based on historical production and benchmark values as shown in Equation (24), where

Tall represents the allocated free carbon emission allowance,

S represents the emission benchmark value (taken as 9.1132 tCO

2/tAl in this study), and

Yorder represents the daily production target (260 t in this case).

This paper adopts a tiered carbon trading cost calculation model that uses the allocated free carbon emission allowance as a baseline, dividing it into several intervals where higher emission ranges correspond to higher carbon trading prices. Equations (24) and (25) present the detailed calculation model, where λ represents the market unit carbon trading price and d represents the length of the carbon emission interval. When k is positive, it represents that the actual carbon emissions exceed the allocated free allowance, requiring the purchase of additional carbon credits from other producers; conversely, when k is negative, the actual emissions are below the allocated allowance, allowing the sale of surplus credits for profit.

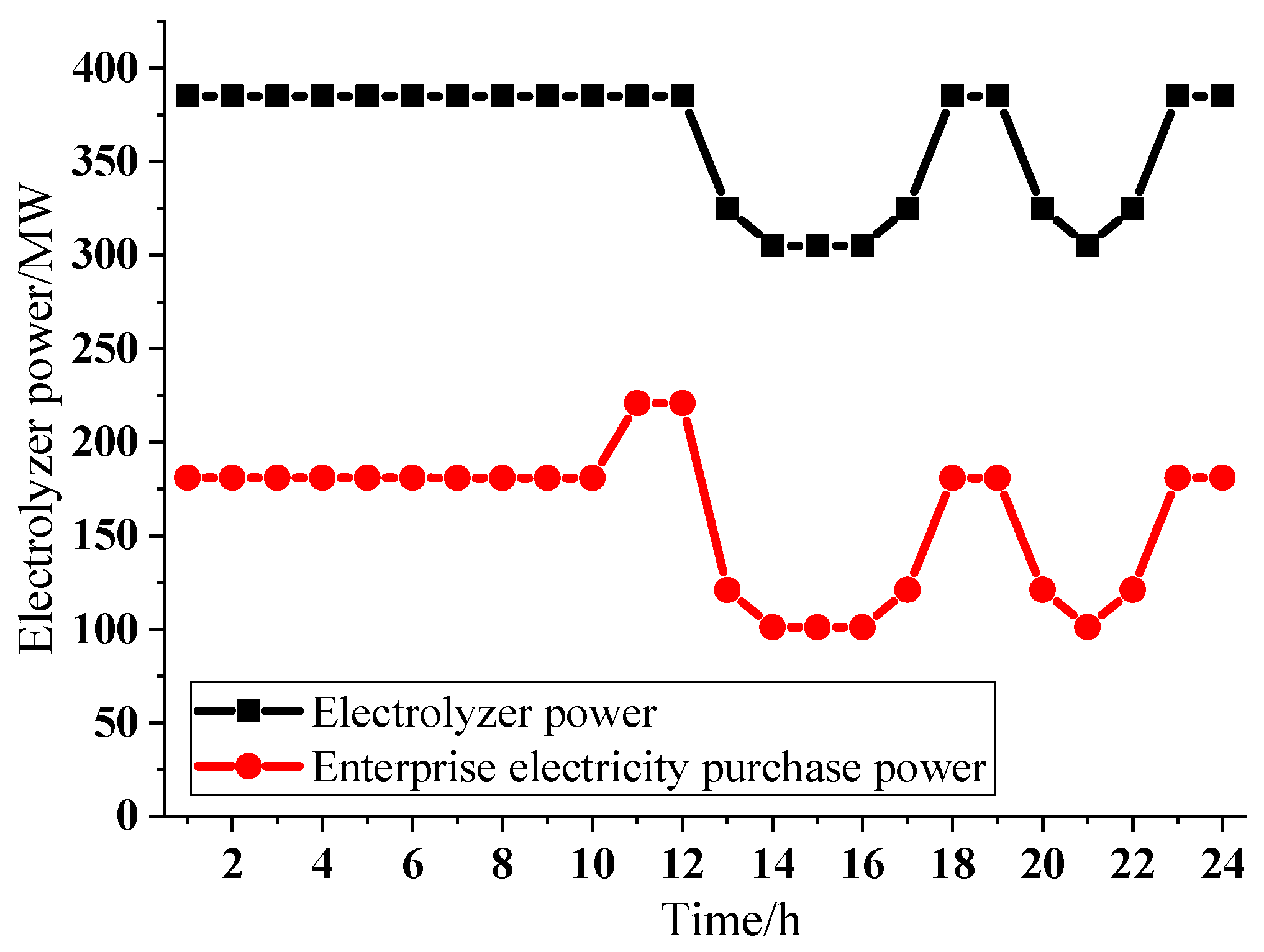

In summary, the optimal production model for the aluminum electrolysis enterprise can be formulated as Equations (27) and (28), with the objective function minimizing the difference between the sum of electricity purchase costs, self-generation power plant costs, and carbon trading costs, and the revenue from aluminum sales.

It can be observed that this optimization model contains integer variables such as unit status variables, along with a nonlinear constraint (12), making direct solution challenging. To simplify the computation, constraint (12) is piecewise linearized here, transforming the mixed-integer nonlinear programming problem into a mixed-integer linear programming problem, which can then be solved using established commercial solvers like CPLEX or Gurobi.

3.2. Mathematical Model for Power Grid Day-Ahead Dispatch

By solving Equations (27) and (28), the power grid dispatch control center obtains the aluminum electrolysis enterprise’s day-ahead electricity purchase demand, based on which it formulates the day-ahead dispatch plan. The detailed mathematical model is as follows:

(1) Constraints related to grid-connected generation units

The constraints for units within the power grid mainly include output limits, ramp rate constraints, unit status constraints, and minimum uptime/downtime constraints. The specific expressions are similar to Equations (17)–(21). To avoid repetitive descriptions and confusion, they are represented here in the general form shown in Equation (29).

(2) Power flow constraints

Equation (30) represents the transmission line power flow constraint. Since this study focuses on day-ahead scheduling without considering voltage and reactive power issues, this constraint is implemented by solving the DC power flow to ensure secure power flow operation.

(3) Power balance constraint

When considering the uncertainty of wind power forecast output and load in the system, the strict power balance constraint can be described by Equation (31). Here,

z represents the electricity purchase fluctuation coefficient. Since the waste heat recovery efficiency of aluminum electrolysis enterprises is affected by temperature,

z is introduced to ensure that the power system maintains a sufficient electricity supply for aluminum production even when fluctuations occur in the thermoelectric conversion power on the enterprise side.

PL,tfore and

Pw,tfore represent the forecasted load and wind power at time

t, respectively;

εL,tfore and

εW,tfore represent the forecast errors for load and wind power, respectively; △

Pw,tfore represents the curtailed wind power.

Pi,tG represents the output of the

i-th unit at time

t. To facilitate subsequent solution, wind power fuzzy coefficient

µw and load fuzzy coefficient

µL are introduced, allowing Equation (31) to be relaxed into the chance-constrained form shown in Equation (32).

Here, the credibility function represents the measure of event reliability, with r denoting the predetermined confidence level (set at 0.95 in this study). Compared to deterministic programming, Equation (32) employs credibility-based chance constraints to handle uncertainty factors, ensuring that the constraint satisfaction probability meets power grid dispatchers’ operational requirements. Following the equivalent transformation conditions and methods for fuzzy chance-constrained programming proposed in references [

22,

23], we convert this into the deterministic equivalent form of power balance constraints as shown in Equation (33), where

Pw1,t,

Pw2,t,

PL3,t, and

PL4,t represent the membership function parameters for wind power and load. Detailed derivation steps and parameter specifications can be found in reference [

17], which are omitted here due to space limitations.

(4) Wind farm power constraints

In summary, the lower-level optimization model for the power grid can be formulated as shown in Equations (35)–(38).

In the objective function, FGu, Fpen, and Fman represent the generation cost of units, the penalty cost for wind curtailment, and the operation and maintenance (O&M) cost of wind power, respectively. Here, ξ represents the wind curtailment penalty coefficient, and w represents the O&M cost coefficient of wind power. At this point, the model becomes a mixed-integer linear programming (MILP) problem, which can be solved directly to obtain the day-ahead dispatch scheme for the grid side, under the uncertainties of wind power and load demand.

5. Conclusions

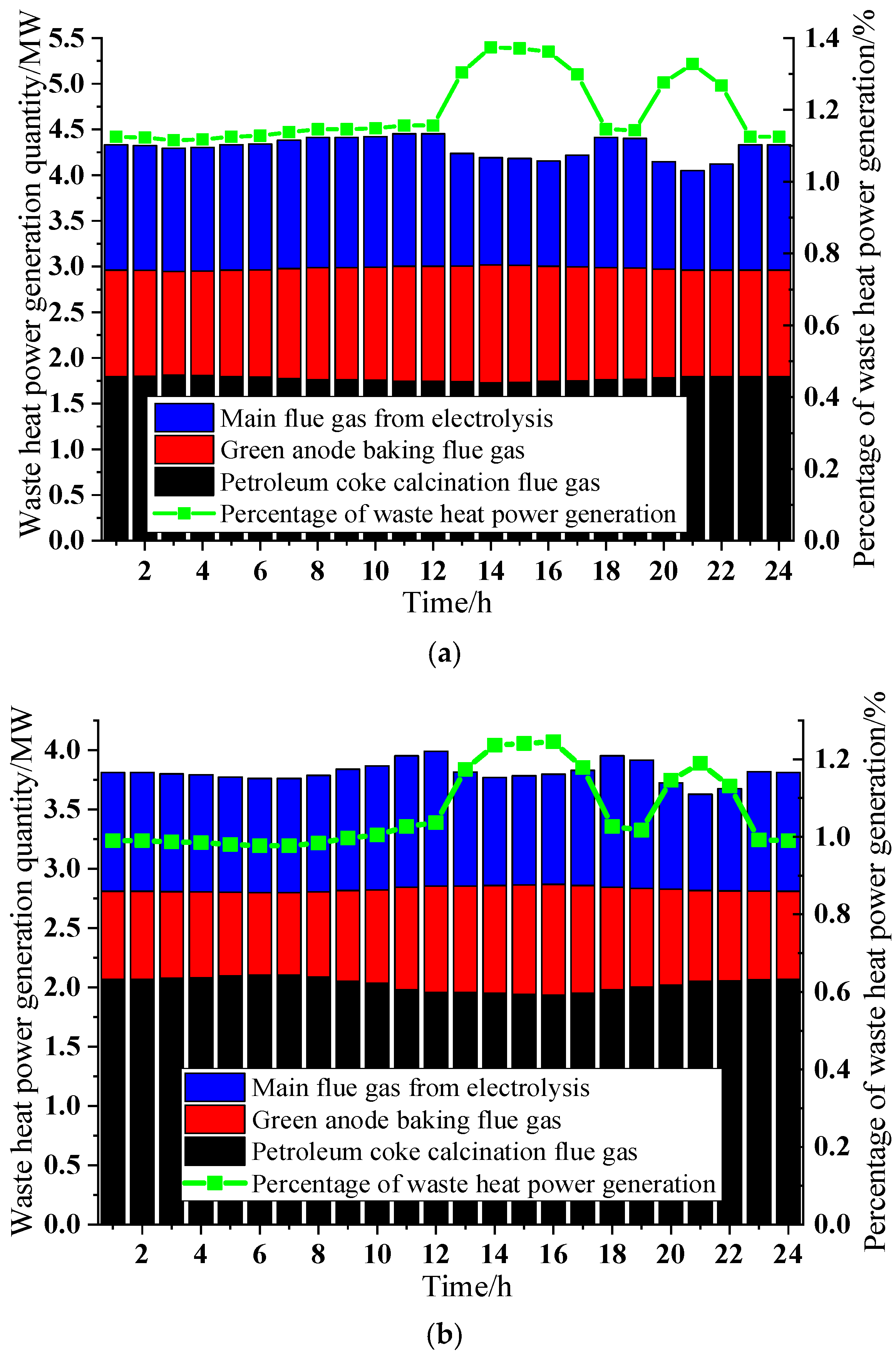

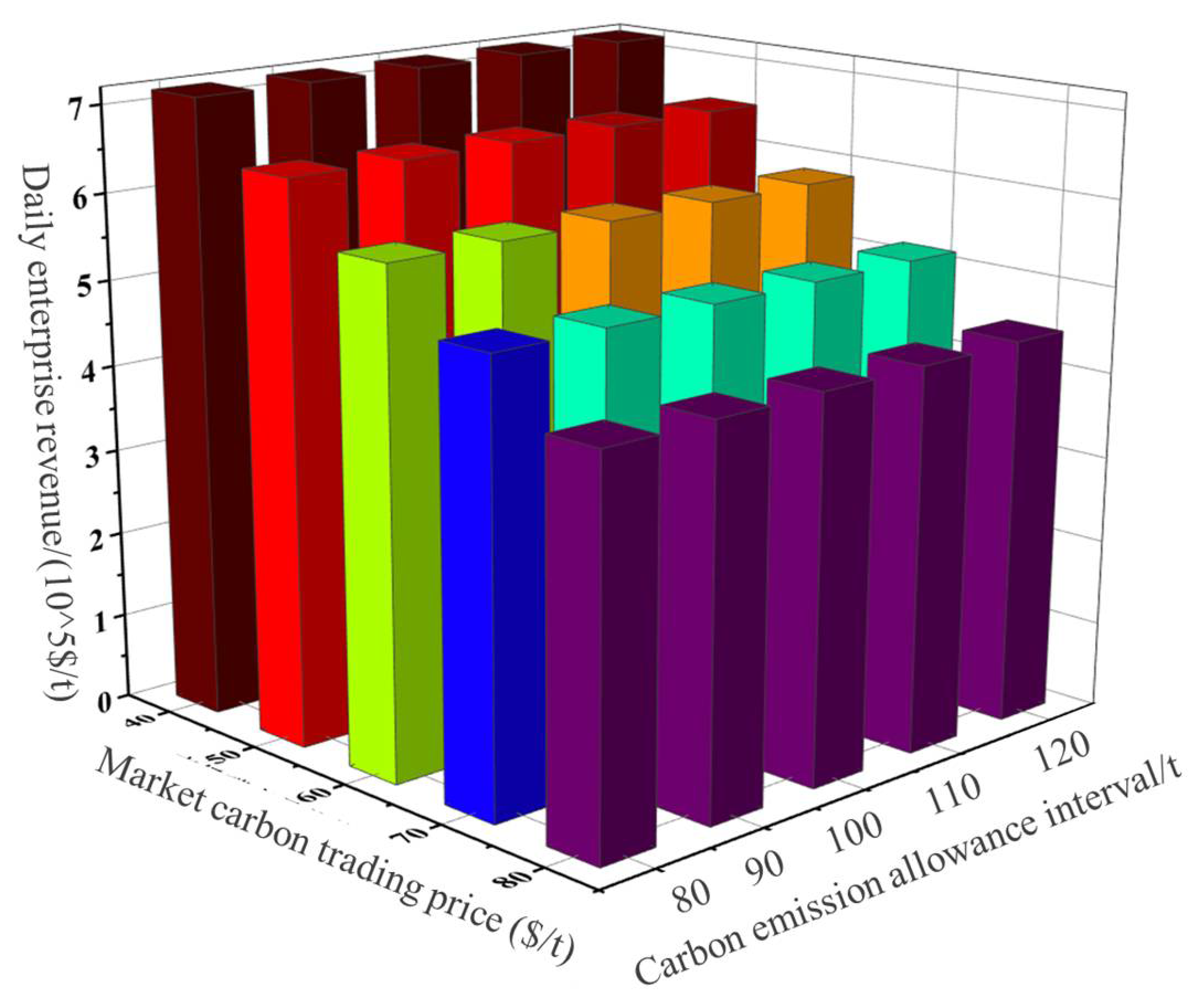

To evaluate both the economic and environmental benefits of internal production processes in aluminum manufacturing enterprises while simultaneously considering the economic interests of both aluminum producers and the power grid, this study designs a coordinated low-carbon economic dispatch strategy for aluminum electrolysis and the power grid that incorporates waste heat utilization. On the aluminum production side, the optimal production plan is formulated by accounting for flue gas waste heat and carbon emission models. On the power grid side, a robust day-ahead economic dispatch strategy is developed, fully considering the uncertainties in electricity demand from aluminum producers, renewable energy generation, and load fluctuations. The case study results lead to the following conclusions: (1) For aluminum producers, electricity prices are the primary factor influencing production output. Aluminum electrolysis enterprises typically reduce production during peak electricity price periods and increase output during low-price periods to meet minimum production constraints. When the power grid requires a response, the production power of electrolytic aluminum enterprises can be reduced by up to 45% or increased by up to 61%. (2) The substantial flue gas generated during petroleum coke calcination, green anode baking, and electrolysis in aluminum production holds significant utilization value. Case analysis shows that, in addition to meeting on-site thermal load demands, waste heat power generation from these three processes can account for up to 1.4% of the total energy consumption in aluminum production. Although this proportion appears modest, considering that aluminum electrolysis consumes hundreds of megawatts per hour, the resulting economic and environmental benefits remain substantial. Through waste heat utilization, enterprises can reduce carbon emissions by 11.4% and increase economic returns by 6.8%. (3) When carbon emission constraints are considered in aluminum production, both carbon market trading prices and carbon emission allowance ranges affect final profits. Carbon trading prices have a greater impact—higher prices lead to lower enterprise profits, while wider emission allowance ranges positively influence profits, albeit to a lesser degree. When the carbon trading price increases by 10%, the enterprise’s profit decreases by approximately 5.4%. (4) The power grid’s robust day-ahead dispatch strategy ensures stable and secure system operation amid renewable energy and load power fluctuations by increasing economic investment in reserve capacity. Through coordinated scheduling, the average renewable energy consumption rate has increased by 7.5%, while the system operating costs have decreased by 9.4%, achieving a win-win outcome.

Potential future research directions include the following: (1) Exploring the application of reinforcement learning in power grid economic dispatching. This involves constructing intelligent agents to interact with the power grid environment, optimizing dispatching decisions through continuous trial-and-error and learning to cope with the complex and ever-changing operational conditions of the power grid, as well as production variations in high-energy-consuming enterprises. (2) Taking data privacy protection into account. By employing techniques such as differential privacy and federated learning, the privacy information of enterprises and users can be safeguarded while ensuring data availability, thereby facilitating data sharing and collaboration.