Abstract

This study investigates the relationship between the compressive strength of two-course masonry specimens and three-course masonry specimens extracted from previously constructed walls, to correlate the execution control specimens with the retest specimens. Compressive strength tests were performed on clay masonry units, laboratory-built two-course masonry specimens, and three-course masonry specimens extracted from constructed walls, following the prescriptions of NBR 15270 and NBR 16868-3. The results demonstrate that three-course masonry specimens exhibit lower compressive strength (characteristic and average, 44.83% and 40.29%, respectively) compared to two-course masonry specimens. Additionally, it was found that the dispersion of results is greater in three-course masonry specimens. Given that three-course specimens are typically used when it becomes necessary to verify the structural compliance of executed masonry—usually following unsatisfactory results from execution control using two-course specimens—more data are needed to compare such results. Factors such as increased height-to-thickness ratio, the presence of head joints, and the influence of execution conditions at the construction site seem to influence the difference between two and three-course specimens, as well as the dispersion of the results. Therefore, it is essential that technical standards provide supporting criteria to enable a reliable comparison between two-course specimens used for execution control and three-course specimens used as retest elements.

1. Theoretical Background

Structural masonry is one of the oldest and most widespread construction systems globally, employed in various regions and construction contexts. The interaction between units (bricks) and mortar, whose physical and mechanical properties vary significantly, directly influences the structural performance of masonry walls. Given this complexity, structural masonry design requires an in-depth analysis of the unit/mortar assembly behavior, considering the interactions between the materials [1].

1.1. Mechanical Properties of Masonry Structures

Compressive strength is the main mechanical property used to evaluate the quality of masonry and is the most relevant parameter in the structural design of these buildings. Like concrete, the 28-day compressive strength is widely adopted as a reference in normative codes worldwide, determined through standardized masonry specimen tests. To ensure a faithful representation of masonry’s structural behavior, these masonry specimens must be composed of multiple courses of units interspersed with mortar layers, using materials identical to those used in the construction of the structural element under study, such as units (bricks), mortar, and grout [2].

The performance of structural masonry elements depends on the characteristics of all their constituent materials (units, mortar, and grout) [3]. In design, the specification of units must consider not only their compressive strength but also their compatibility with the mortar, as the interaction between these elements is decisive for the structural performance of the assembly [4]. While masonry units play a primary role in absorbing compressive loads, mortar ensures load transmission between units, provides adhesion between the units, and accommodates deformations, ensuring the structural integrity of the masonry [5,6].

The mechanical performance of masonry specimens subjected to compression is directly influenced by failure mechanisms, which are intrinsically related to the mechanical properties of the constituent materials. However, several additional factors also impact their structural behavior, including the strength ratio between components, building and testing conditions, mortar bedding execution, curing procedures, load application rate, and geometric characteristics of the units [5,7,8].

Masonry specimen failure may be ductile or brittle, depending on the mechanical characteristics of the mortar relative to the units [3]. The widely accepted mechanism in the technical community [5] assumes that masonry specimens typically fail due to horizontal tensile stresses near the bed joints when the mortar’s compressive strength is lower than that of the unit, and due to unit crushing when the unit’s compressive strength is lower than that of the mortar.

In this context, masonry failure under compression can occur in three typical forms, depending on the relationship between the mortar’s compressive strength and the unit’s compressive strength [9].

- (a)

- When the mortar strength is significantly lower than that of the strength of the masonry unit, the overall masonry strength is conditioned by the mortar’s strength capacity, which tends to fail prematurely by crushing;

- (b)

- When the mortar exhibits moderate strength relative to the unit, masonry strength is governed by the interaction between the masonry unit’s compressive and tensile strengths, usually resulting in failure by lateral cracking due to transverse tension;

- (c)

- When the mortar strength exceeds that of the masonry unit, masonry strength is limited by the masonry unit’s compressive strength, making the unit the critical element for the structural collapse of the assembly.

Furthermore, the structural behavior of masonry units and mortar in the masonry wall differs significantly from that observed in compression strength tests of isolated specimens of these materials. This discrepancy occurs because the masonry mechanical behavior results from complex interactions between the materials, rather than intrinsic properties of each material alone, but rather the triaxial behavior resulting from the complex interaction between masonry elements.

Consequently, the failure mechanisms of a masonry specimen occur as a sequence of interdependent phenomena, directly conditioned by the relative strength between the mortar, units, and the bond interface between these materials [10,11,12].

1.2. Execution Control

Structural masonry is defined as a construction system in which masonry is the load-bearing structure of the building. In the context of evaluating the mechanical performance of this construction system, two-course and three-course masonry specimens are simplified test specimens widely used in execution control, ensuring that project execution complies with the design [5].

Masonry specimens have been widely used in academic research and execution control of masonry structures as they constitute simplified experimental models that are easy to construct and test, allowing for the assessment of the masonry’s mechanical behavior under controlled conditions. These test specimens offer operational and economic advantages over full-scale wall testing, in addition to representing the interaction between different masonry system components [13,14]. In this context, the standardization of two-course or three-course masonry specimens is crucial from a practical standpoint for execution control [5].

For specification in design, prior characterization of materials to be used is strongly recommended to avoid unexpected results. Furthermore, considering the importance and usefulness of a reference source for project specification, NBR 16868-1 [15] provides a table with suggested values for combinations of units and mortars, based on their mechanical properties. Table 1 below partially presents the data contained in the NBR 16868-1 [15].

Table 1.

Recommendation for design specifications with solid-web hollow clay units.

For the determination of the characteristic compressive strength of masonry, the Eurocode 6 standard [16] establishes equations based on the compressive strength of the unit, the mean compressive strength of the mortar, and the mortar bed joint thickness. The equation includes the factor K, a constant that depends on the type of unit and mortar used and is applied in situations where experimental results are not available.

fk = K × fb^(0.7) × fm^(0.3)

- fb: compressive strength of the masonry unit

- fm: compressive strength of the mortar

Furthermore, the European standard provides and allows for the execution of experimental tests through EN 1052 [17].

For execution control, the Brazilian standard NBR 16868-2 [18] regulates the characterization tests for masonry compressive strength, with the masonry components, such as masonry specimens, units, mortars, and grouts. This standard prescribes that the characteristic compressive strength obtained experimentally must be at least equivalent to the value defined in the design. Thus, destructive tests on masonry specimens, combined with rigorous execution control procedures, are essential to ensure structural safety and the proper performance of buildings [14].

There are several standards that prescribe procedures for specifying masonry materials in the design and execution control. For example, the American standard TMS 602 [19], the Australian standard AS 3700 [20], the European standard Eurocode 6 [16], and the Canadian standard CSA S304 [21]. These guidelines establish technical criteria for evaluating the mechanical strength of structural masonry, contributing to the standardization of testing procedures and the reliability of experimental results. However, there is no uniformity between the requirements of each standard. For example, while the Brazilian standard NBR 16868-1 [15] establishes that, for this purpose, two-course specimens must be made, the European standard Eurocode 6 [16] prescribes minimum dimensions for the test specimens, which are dependent on the dimensions of the masonry units. Figure 1 illustrates the characteristics of the test specimens in different standards.

Figure 1.

Masonry specimens according to different standards. Adapted by the authors from [22].

Some international standards, such as TMS 602 [19] and CSA S304 [21], present limitations as they do not include compressive strength values for masonry specimens constructed with high-strength units. Studies conducted by Fortes et al. [9] analyzed masonry specimens composed of concrete units with strengths ranging from 21.6 MPa to 74.7 MPa (net area), combined with mortar and grout of varying strength. The tests were carried out with grouted cavity specimens and non-grouted cavity specimens, allowing correlations to be established between the resistance of the units and the masonry specimens, with variations between 6 MPa and 70 MPa (net area) and between 3 MPa and 35 MPa (gross area). It is important to highlight that the study used high-strength concrete masonry units.

In cases where a retest is required, Annex B of NBR 16868-3 [18] prescribes the procedure for extracting three-course specimens from executed masonry walls. However, the standard does not provide correction factors or other guidelines for interpreting the results in a way that allows comparison between the obtained values and those specified in the design, which are determined through the testing of two-course masonry specimens.

1.3. Variables That Influence the Compressive Strength of Masonry Elements

The structural performance of masonry elements depends on factors such as execution quality, environmental conditions, material properties, and masonry unit geometry [23,24]. Examples include the individual strength of the mortar and masonry units, the relationship between these compressive strengths, the ratio between the masonry unit height and its smallest horizontal dimension, the orientation of the masonry units relative to the load application direction, and the mortar bed joint thickness. The interaction between these elements is crucial for the load-bearing capacity of the system, directly impacting the overall safety and performance of the structure [9,25,26].

For masonry units with the same material composition and identical geometry, an increase in the compressive strength of the unit generally tends to result in an increase in the compressive strength of the masonry. This phenomenon occurs because the higher compressive strength of the unit enhances its transverse tensile strength, directly contributing to the overall load-bearing capacity of the wall [27].

When dealing with uniaxial compressive forces, NBR 16868-1 [15] states that the masonry strength (fk) should be determined based on wall tests, as specified in part 3 of the standard. However, it can also be estimated when using masonry units with a height of 190 mm. In such cases, the characteristic compressive strength of masonry can be considered as 70% of the characteristic compressive strength of the masonry two-course specimen (fpk), or 85% of the small wall (fppk), an element that must have a minimum height equivalent to five times the masonry unit thickness.

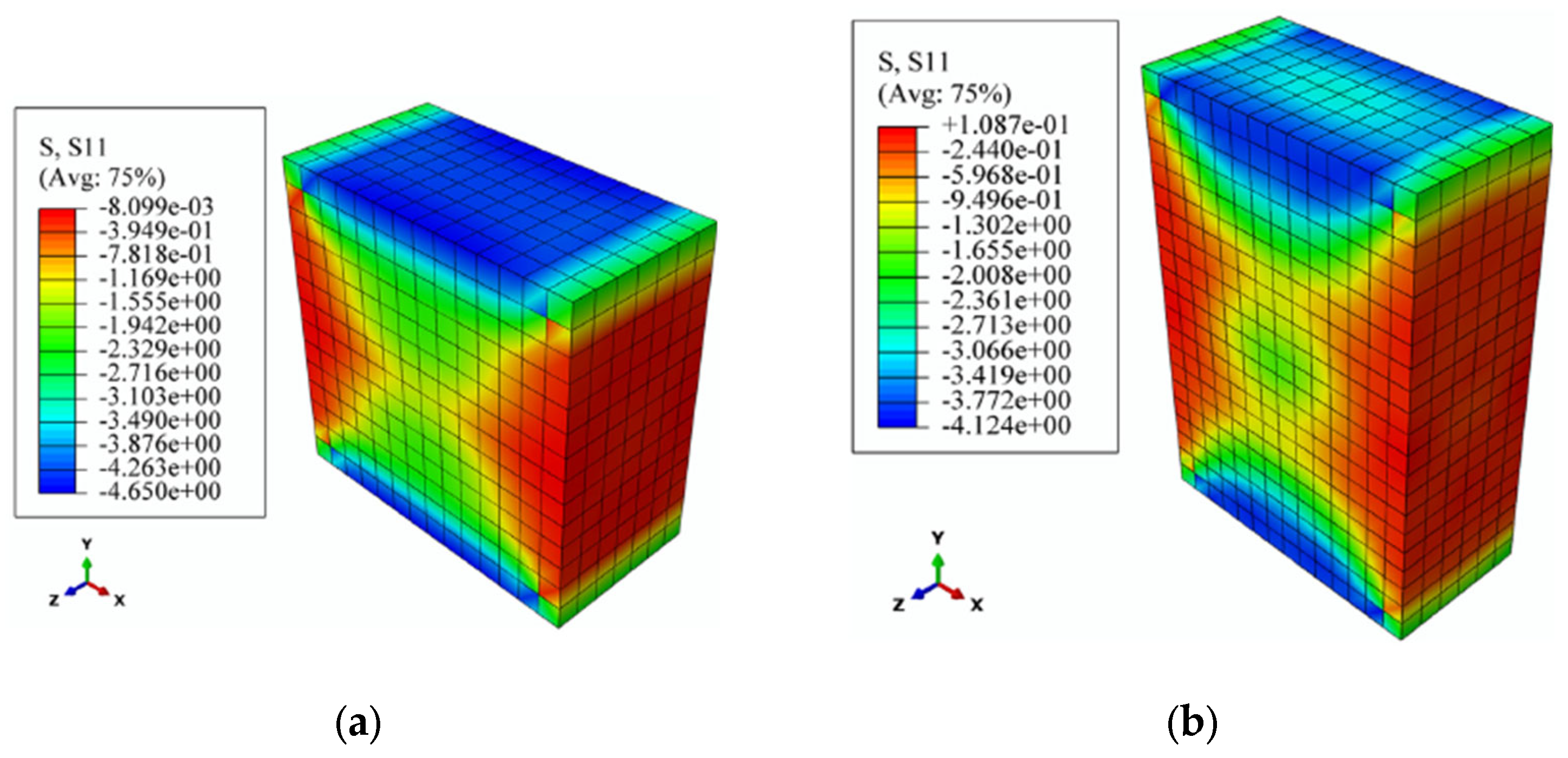

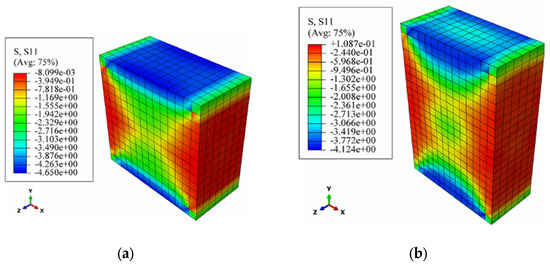

Regarding the dimensions of masonry specimens, it is observed that compressive strength decreases as the height/thickness ratio increases, a behavior previously reported in studies conducted by Hamid et al. [28] and Thomas and Ansar [29]. The reduction in compressive strength with increasing height is related to the decrease in the confinement effect provided by the loading plates, which facilitates the occurrence of the characteristic vertical cracking in masonry elements without lateral restraint [5], a behavior that can be visualized in numerical models such as that of Abasi et al. [13]. Furthermore, the authors’ numerical models demonstrate stress distribution in the two-course masonry specimen (Figure 2a) and three-course masonry specimen (Figure 2b) units, with solid masonry units.

Figure 2.

Stress distribution in two-course (a) and three-course (b) masonry specimens. Adapted by the authors from [13].

Masonry specimen tests with a reduced height/thickness ratio, typically lower than 2:1, exhibit a conical shear failure under compression, a behavior analogous to that observed in cylindrical concrete specimens. However, this failure mode differs from that observed in full-scale masonry walls, as described by Parsekian, Hamid, and Drysdale [5].

Under axial loading, masonry specimens tend to expand laterally due to the Poisson effect. However, this expansion is constrained at the top and bottom of the specimen due to friction between the steel plates of the testing machine and the surface of the specimen. As a result, the top and bottom regions of the masonry specimen remain under compression due to confinement pressure, while the middle region is subjected to tensile stresses. The depth of the compressed zone depends on the dimensions of the load application surface and is limited, as prescribed by Saint-Venant’s principle.

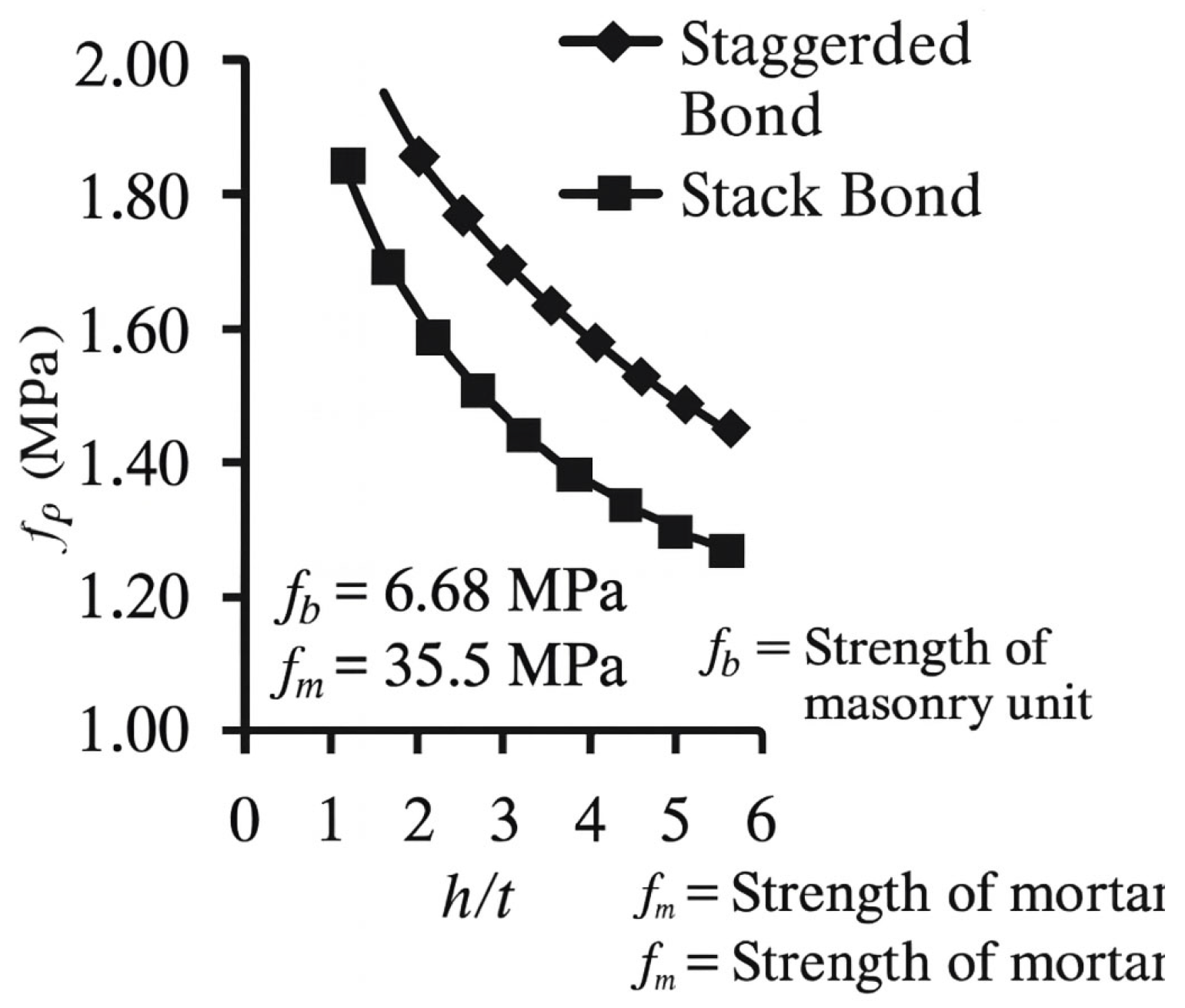

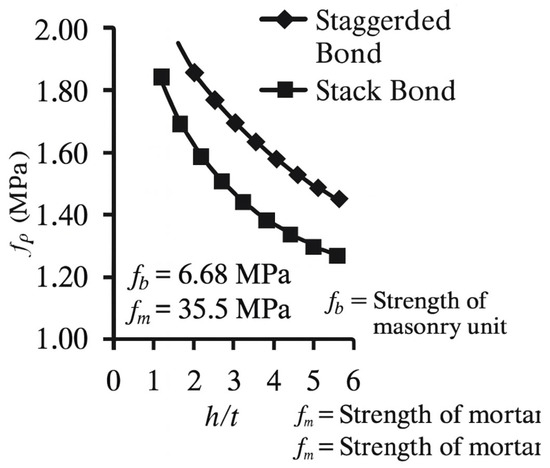

Masonry is characterized by its low tensile strength, as the interface between masonry units and mortar represents a structural weak point. As the height of the masonry specimen increases, the region subjected to lateral tensile stresses expands. This tensile zone is vulnerable to cracking, which contributes to the reduction in the overall strength of the masonry specimen as its height increases. Thus, the decrease in the mechanical strength of more slender specimens can be directly correlated with the increase in the h/t ratio [30]. Figure 3 presents data that corroborate this behavior.

Figure 3.

Influence of the height/thickness ratio of the masonry specimen on compressive strength. Adapted by the authors from [31].

Experimental studies [1,23,31,32] have shown that a reduction in compressive strength can be expected when comparing masonry specimens composed of three-course or four-course units to those with only two-course units. This reduction ranges from approximately 15% [1,23,32,33] to 16.8% [31]. However, numerical studies have reported lower values, around 4.5% [13]. This behavior is also accounted for by some technical standards. The IS 1905 standard [34] establishes that the height-to-thickness (h/t) ratio of masonry specimens should be between 2 and 5, with a minimum specimen height of 40 cm. Additionally, the American standard ASTM E447 [35] specifies that the minimum specimen height should be fifteen inches to ensure adequate structural representativeness.

A study conducted by Drysdale and Hamid [36] indicates that masonry specimens composed of three-course units provide a better characterization of the mechanical properties of masonry compared to those consisting of only two-course units. Francis et al. [37] suggest that masonry specimens with a height equivalent to five or six brick units can be considered structurally independent, minimizing the influence of end plates during load application in experimental tests.

Furthermore, it is important to highlight that masonry specimens composed of two-course units with only one mortar bed joint do not fully replicate the interaction between the unit and mortar as observed in real-scale walls [5]. Ganesan and Ramamurthy [7] recommend that experimental tests be conducted preferably on masonry specimens laid in running bond rather than stack bond, to better represent the structural behavior of masonry under real loading conditions. Thus, it is evident that different studies adopt distinct methodologies regarding the geometry and arrangement of masonry specimens, directly influencing the experimental characterization of the mechanical properties of the construction system.

The numerical analyses conducted by Hassanli, Elgawady, and Mills [2], using finite element modeling for masonry specimens of different dimensions, demonstrated that compressive strength is not solely a function of unit thickness but is also highly sensitive to the masonry specimen’s length. However, current masonry codes do not incorporate the influence of this parameter in determining the mechanical strength of masonry specimens. As the length-to-thickness (l/t) ratio increases, the compressive strength tends to be overestimated by current codes. Therefore, the l/t ratio should be recognized as a critical factor in the mechanical behavior of masonry, and its inclusion in the compressive strength correction coefficients adopted by regulatory standards is recommended to enhance the accuracy of structural prediction models. Furthermore, according to the authors, for masonry specimens with identical cross-sectional dimensions, the stress–strain relationship is significantly influenced by the height-to-thickness ratio (h/t), provided that this ratio remains below 3.0. In the analyzed study, a specimen configured as a half-unit, with a cross-sectional area of 190 × 190 mm, exhibited equivalent load capacities for specimens composed of three and five courses, indicating that increasing the height within this range did not result in a significant variation in mechanical strength.

In addition to the variables whose influence has been recognized through experimental tests, others have been identified through numerical modeling studies. For example, Álvarez-Pérez et al. [38] developed an analytical approach to estimate the compressive strength of hollow concrete masonry specimens using multifactorial statistical modeling and numerical micro modeling via ABAQUS, calibrated with experimental data. The tested specimens had dimensions of 39.3 cm × 59.9 cm × 14.4 cm, with 10 mm bed mortar joints. The study concluded that the primary factors influencing masonry compressive strength include the compressive and tensile strength of the masonry units, as well as the thickness of the bed mortar joint, emphasizing the need to incorporate these variables into standard codes’ structural prediction models.

Considering the strong influence of several variables on the mechanical behavior of structural masonry specimens, such as the number of courses and the height/thickness ratio of the masonry specimen, the objective of this article is to analyze the correlation between the compressive strength test results of different types of specimens used in the evaluation of structural masonry. This analysis aims to support the resolution of the gap in NBR 16868-3 [18] regarding the interpretation of retest results, which must be performed, according to this standard, on three-course specimens, unlike the tests performed for specification in design and execution control, which this same standard recommends be performed on two-course specimens. Through this study, the goal is to contribute to a better understanding of the technical implications of the current normative methodology, providing insights into future standard revisions and improvements in the acceptance criteria for the compressive strength of structural masonry.

2. Materials and Methods

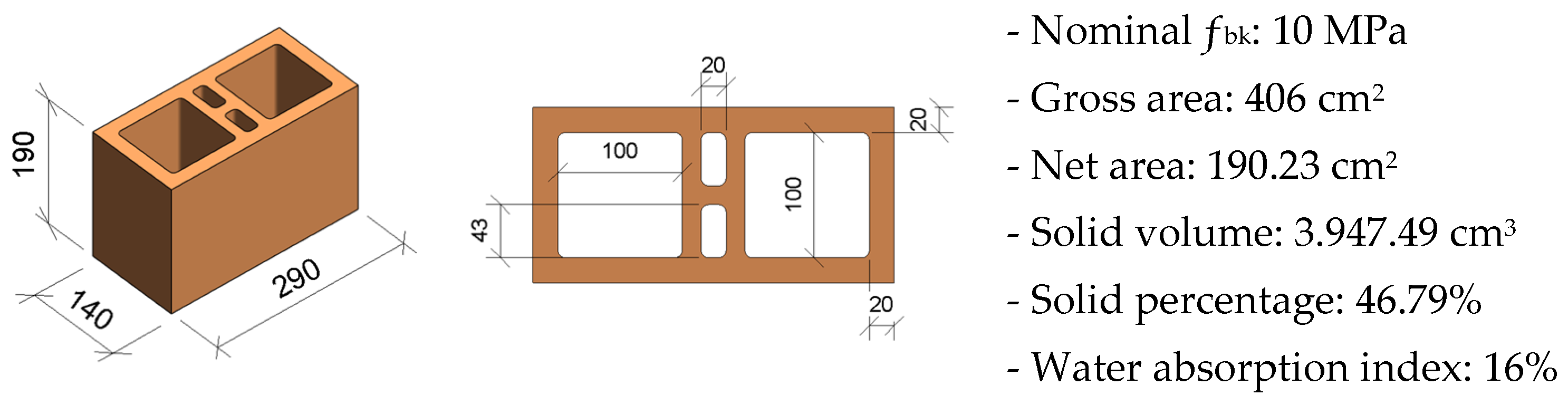

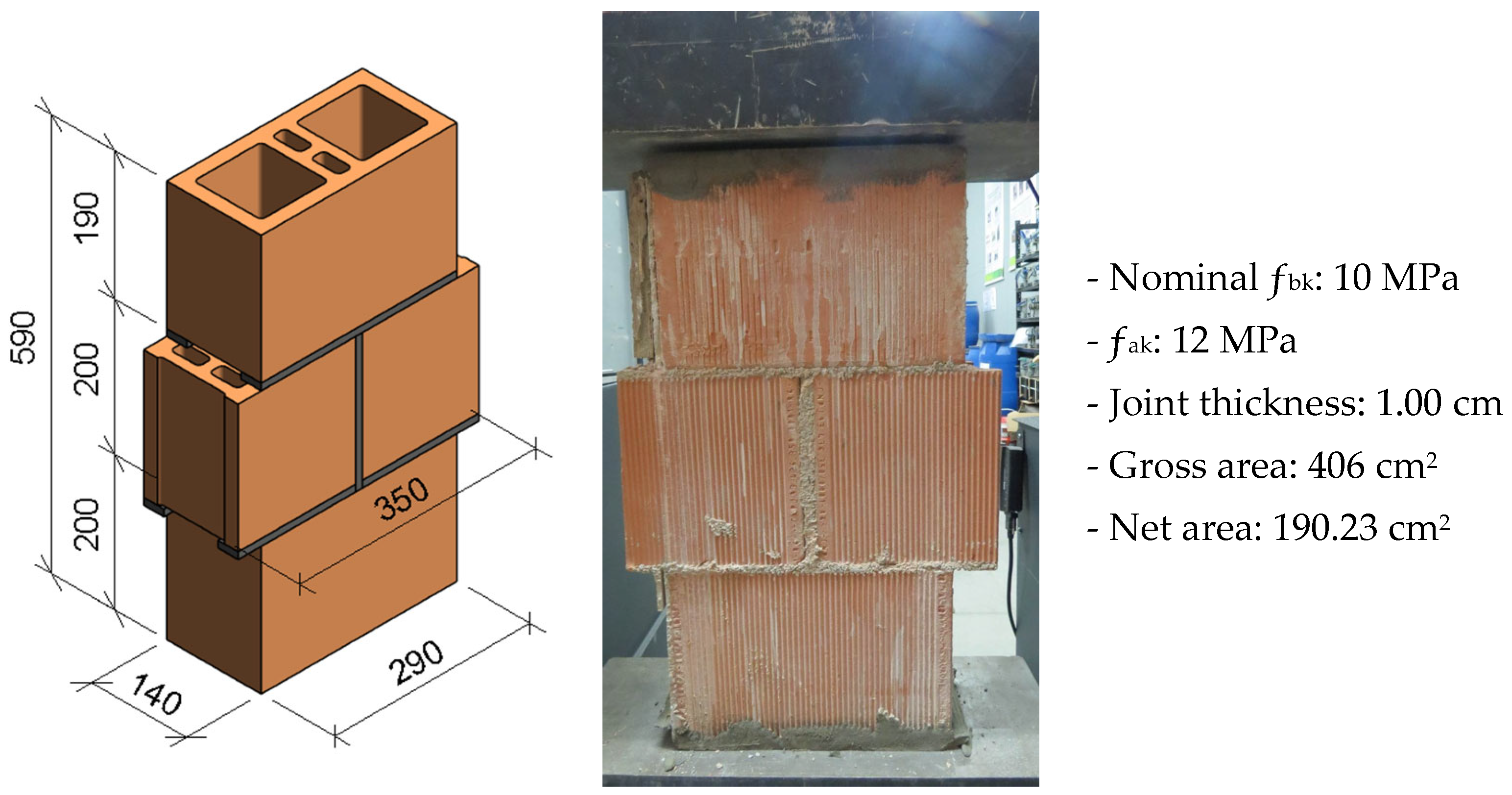

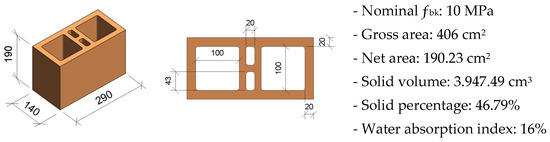

The materials used in this research consist of hollow clay masonry units with dimensions of 14 × 19 × 29 cm and a characteristic compressive strength (fbk) of 10 MPa. These masonry units are classified as EST100 according to NBR 15270-1 [39], the Brazilian standard that defines requirements and specifications for masonry clay units.

The study includes the evaluation of the mechanical strength of 46 masonry units (Figure 4) individually. These masonry units were tested following the procedures described in Annex C of NBR 15270-2 [40]. The unit faces were leveled using a compensation layer made of mortar with a compressive strength of at least 80% of the nominal compressive strength of the masonry unit in terms of net area, with a maximum thickness of 5 mm.

Figure 4.

Characteristics of masonry clay units.

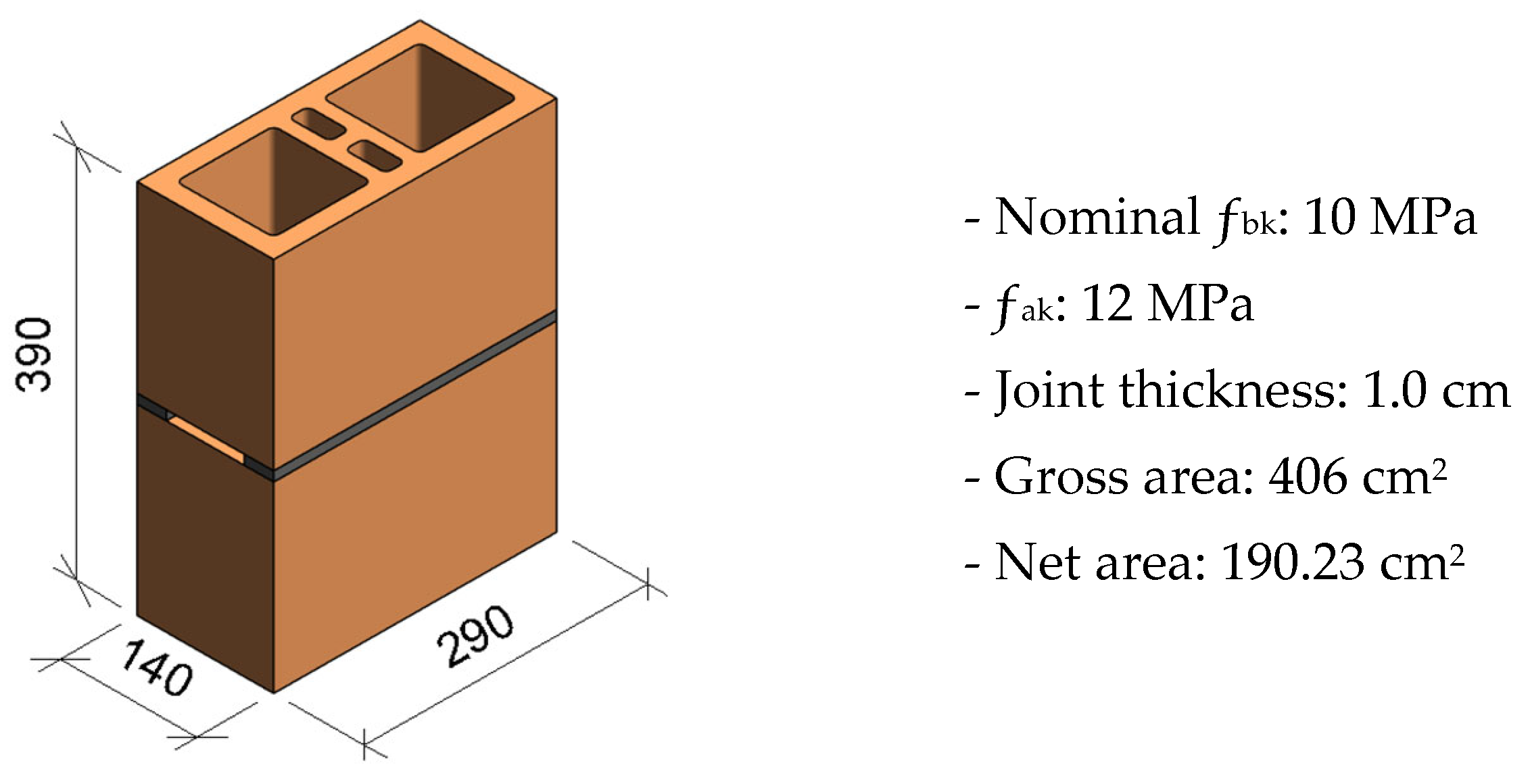

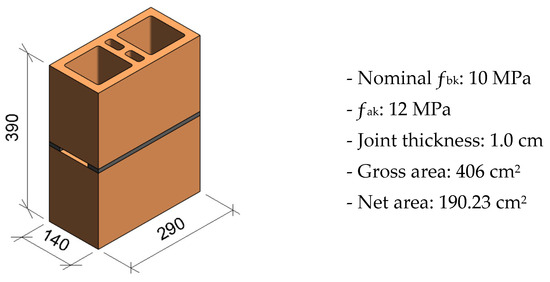

The two-course masonry (Figure 5) specimens were built and tested according to the procedures established in NBR 16868-3 [18], using a bed joint mortar with a characteristic compressive strength (fak) of 12 MPa, classified as type AAE10 according to NBR 13281 [38], the Brazilian standard for cementitious mortars used for masonry unit bedding. The thickness of bed joints is 10 mm. 6 masonry specimens were tested after a 28-day curing period.

Figure 5.

Two-course masonry specimen.

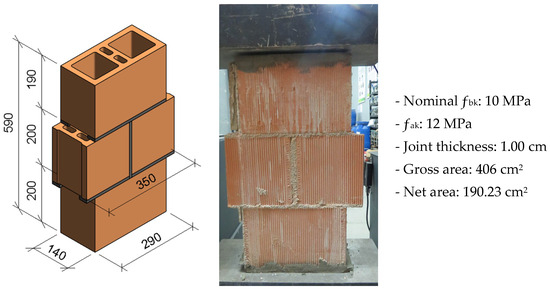

The three-course masonry specimens extracted from a masonry wall were built using the same masonry units and mortar as those used for the two-course laboratory-built specimens. The thickness of the bed and head joints is 10 mm. A total of six three-course masonry specimens were extracted from real-scale walls and tested following the procedures described in Annex B of NBR 16868-3 [18].

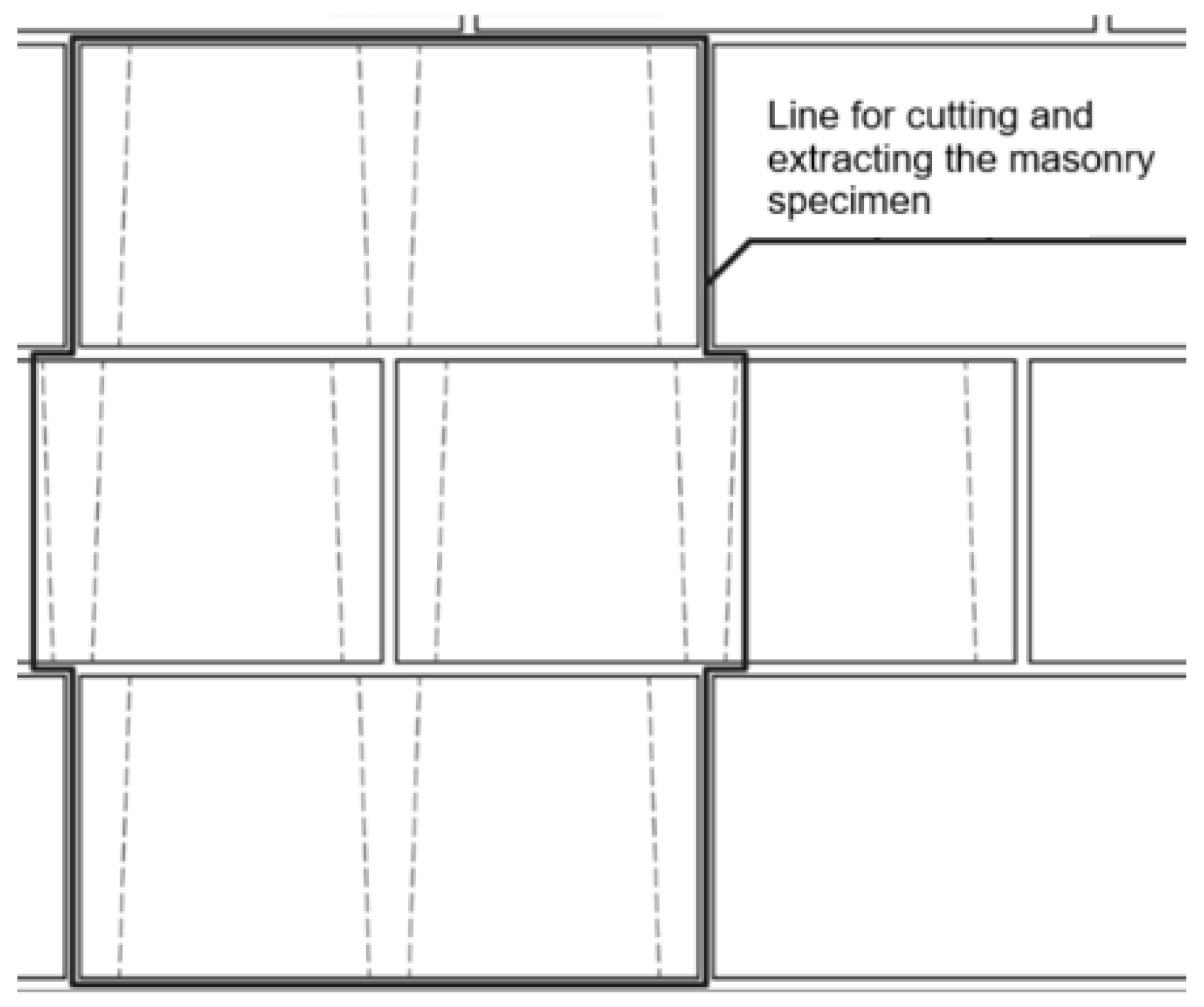

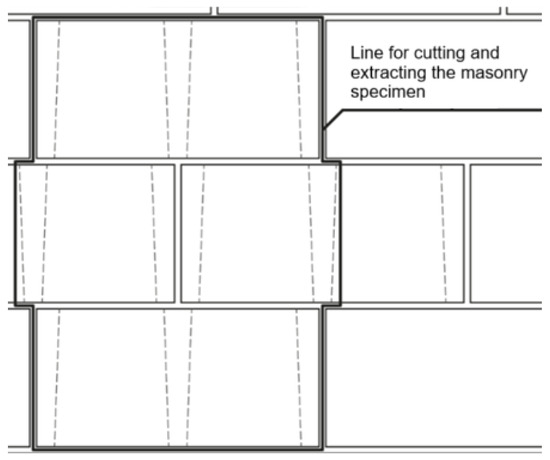

The procedure of NBR 16868-3 [18] for extracting prismatic masonry specimens consists of removing representative segments of the wall for subsequent laboratory testing. The specimens (prisms) must be extracted with three courses of height and one masonry unit (brick) of length (Figure 6). The extraction begins with horizontal cuts in the mortar joints located immediately above the upper brick and below the lower brick of the specimen. Then, lateral vertical cuts are made, which must be external to the central web of the bricks, so that it remains intact in the extracted masonry specimen. The assembly must be stabilized with plywood plates positioned under and over the cuts and tied with wire. The cuts must be made with an electric saw suitable for stone materials, preferably with a double disc. After extraction, the specimens must be identified as to their place of origin, packaged in a way that prevents damage during transportation and sent to the laboratory for testing according to the criteria established in Annex B of NBR 16868-3 [18].

Figure 6.

Cutting schematics for the removal of the masonry specimen from an already constructed wall. Adapted by the authors from NBR 16868-3 [18].

The extraction (Figure 7) and testing were conducted 28 days after the wall construction.

Figure 7.

Three-course masonry specimen, extracted from full-scale masonry.

The tests were conducted using a hydraulic press with a technical capacity of 2000 kN. For dimensional measurements of the specimens, a digital caliper with a measurement range of 0 to 450 mm was used.

3. Results

3.1. Masonry Units

The individual results of the masonry units are presented below in Table 2.

Table 2.

Compressive strength of the masonry units.

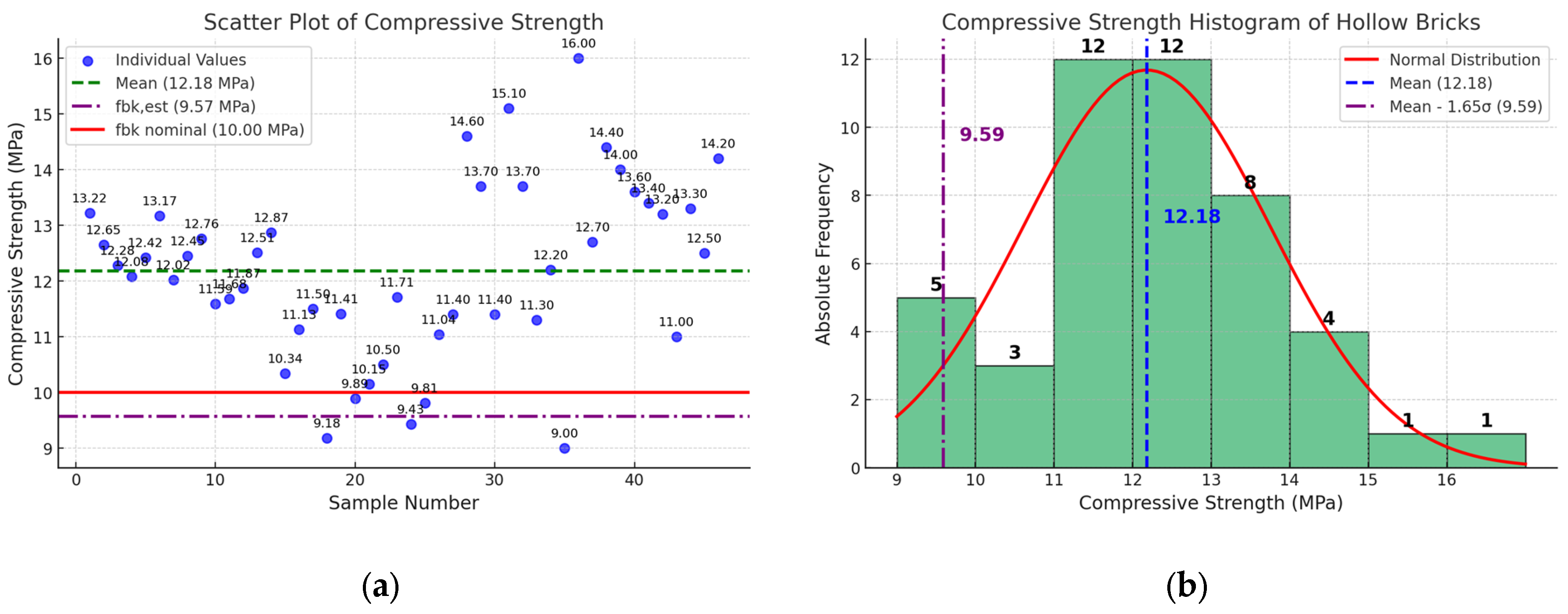

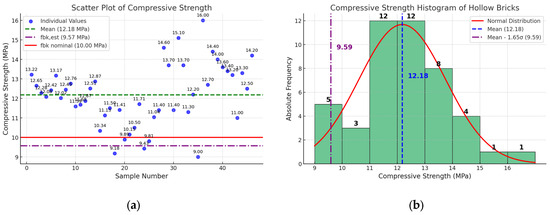

Figure 8 presents the dispersion of the individually measured values (a) and a histogram illustrating the absolute frequency of the samples, comparing them with the normal distribution.

Figure 8.

Scatter plot (a) and histogram (b) of compressive strength of the units. fbk: estimated characteristic compressive strength of masonry units, according to Brazilian standard NBR 15270-1 [39]; fbk nominal: specified compressive strength of the masonry units, according to Brazilian standard NBR 15270-1 [39].

The results indicate an average compressive strength (fbm) of 12.18 MPa, with a standard deviation of 1.57 MPa. The characteristic compressive strength (fbk), when calculated according to the prescriptions of NBR 15270-1 [39], is 9.57 MPa. The coefficient of variation is 12.52%. It is important to highlight that these values are lower than the nominal compressive strength of the EST100-class masonry unit, which corresponds to 10 MPa.

3.2. Two-Course Masonry Specimen

The results of the samples tested are presented below in Table 3.

Table 3.

Compressive strength of the two-course masonry specimens.

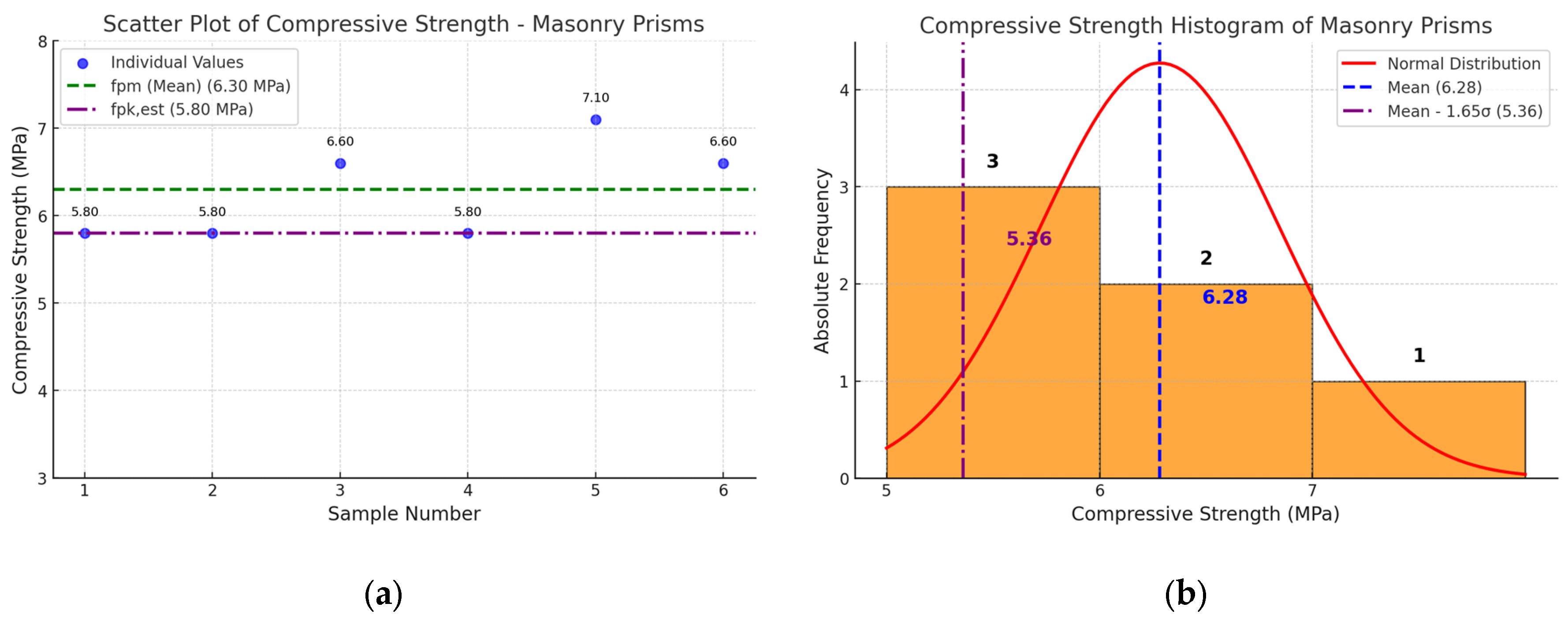

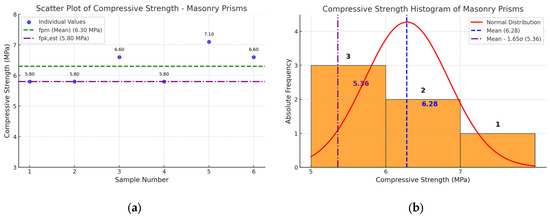

Below, Figure 9 presents the dispersion of the individually measured values (a) and a histogram illustrating the absolute frequency of the samples, comparing them with the normal distribution.

Figure 9.

Scatter plot (a) and histogram (b) of compressive strength of the two-course masonry specimens. fpm: average compressive strength of masonry units, according to Brazilian standad NBR 16868-1 [15]; fpk,est: estimated characteristic compressive strength of two-course masonry specimens, according to Brazilian standad NBR 16868-1 [15].

The obtained results indicate an average compressive strength (fpm) of 6.30 MPa, with a standard deviation of 0.56 MPa. The characteristic compressive strength (fpk) is 5.80 MPa, calculated using the method prescribed in NBR 16868-1 [15]. The coefficient of variation is 8.78%.

3.3. Three-Course Masonry Specimen, Extracted from Real-Scale Masonry Wall

The individual compressive strength results of the three-course masonry specimens extracted from a masonry wall are presented below in Table 4.

Table 4.

Compressive strength of the three-course masonry specimen, extracted from full-scale masonry.

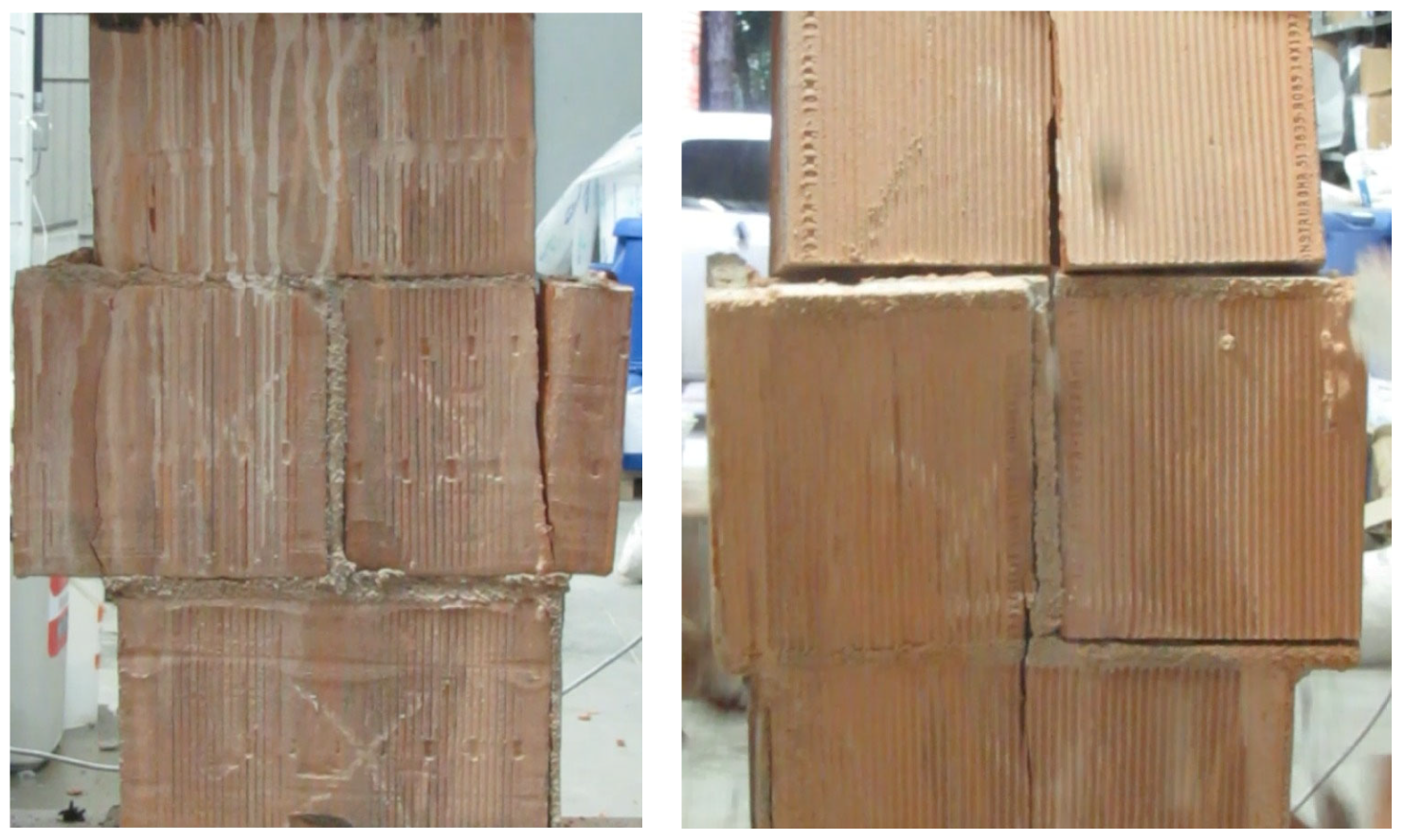

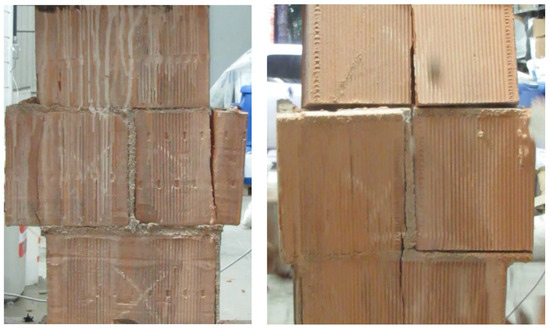

Below, Figure 10 illustrates the predominant failure mode observed in the samples.

Figure 10.

Three-course masonry specimen after test.

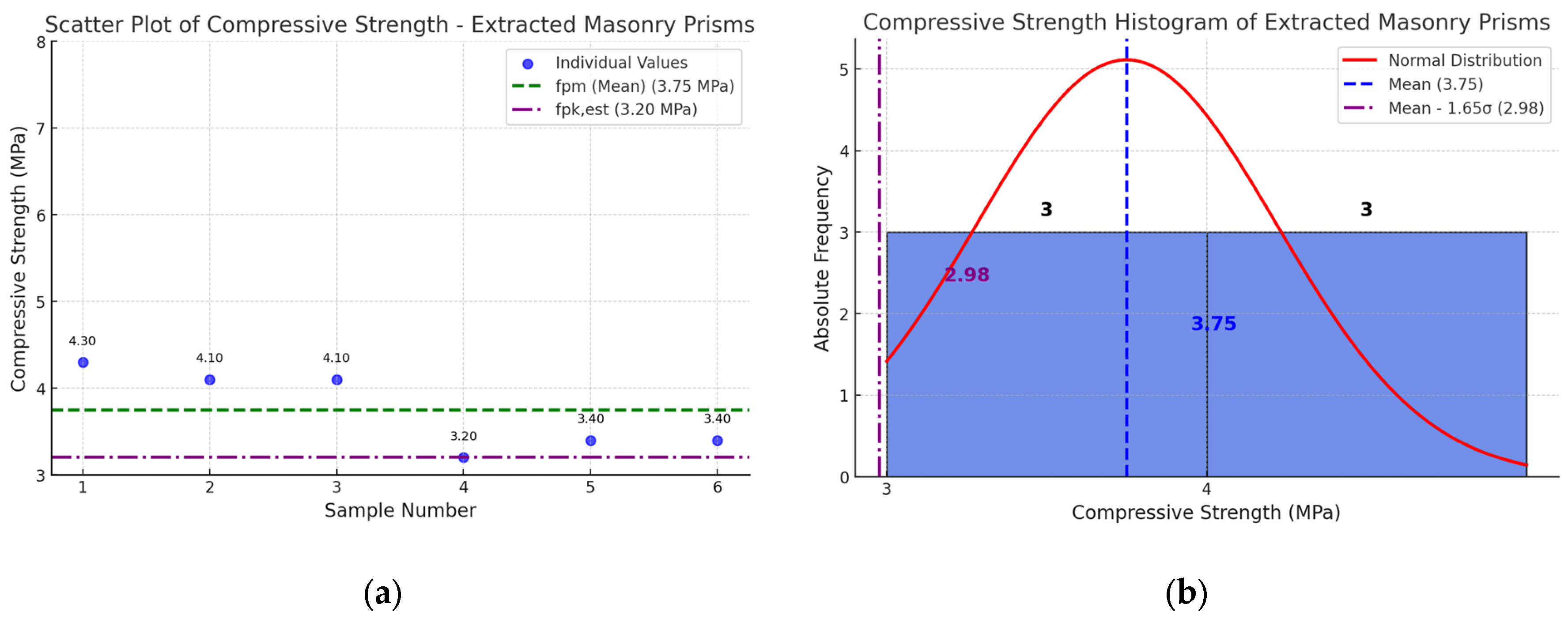

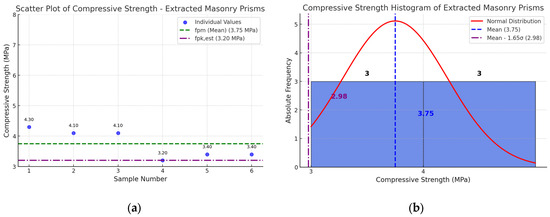

Next, Figure 11 presents the dispersion of the individually measured values (a) and a histogram illustrating the absolute frequency of the samples, comparing them with the normal distribution.

Figure 11.

Scatter plot (a) and histogram (b) of compressive strength of the three-course masonry specimens, extracted from full-scale masonry. fpm: average compressive strength of masonry units, according to Brazilian standard NBR 16868-1 [15]; fpk,est: estimated characteristic compressive strength of two-course masonry specimens, according to Brazilian standard NBR 16868-1 [15].

Based on the results presented, the average compressive strength (fpm) is 3.75 MPa, with a standard deviation of 0.47 MPa. The characteristic compressive strength (fpk) is 3.20 MPa, calculated using the method prescribed in NBR 16868-1 [15]. The coefficient of variation is 12.48%.

4. Discussion

The experimental results presented in this study indicate that the compressive strength of structural clay masonry specimens decreases as the height/thickness ratio increases, which is observed in both the average and characteristic compressive strength values. This behavior aligns with the theoretical foundation discussed in this article, highlighting the influence of lateral confinement and stress redistribution on the mechanical behavior of structural masonry [5,30].

Masonry specimens play a fundamental role as an intermediate element in evaluating masonry strength, whether for material specification in design, quality control during construction, or even as a retest method in the case of specimens extracted from masonry when there are uncertainties regarding the results of specimens used for execution control. However, the comparison between test specimens built in the laboratory and test specimens extracted from real walls should be conducted with caution, considering the variability of execution conditions.

Some authors [1,23,31,35] indicate that three-course specimens, such as the extracted specimens analyzed in this study, tend to exhibit compressive strength approximately 15% lower than two-course specimens. However, the findings of this study do not align with these values, as the three-course specimens (extracted from full-scale walls) exhibited fpm values 40.29% lower and fpk values 44.83% lower than two-course specimens. Beyond the height/thickness ratio, other factors should also be considered, such as existence of head joints in three-course test specimens, as well as execution imprecisions during the construction of the masonry wall from which the test specimens were extracted, which occur more easily on site than with test specimens executed in the laboratory, like the two-course specimens.

It is also important to consider the distinction between the average and characteristic compressive strength values for each type of masonry specimen, which are fundamental for assessing the reliability of experimental results and their normative application [41,42]. For the two-course specimens (built in the laboratory), the characteristic strength showed a reduction of 7.94% compared to the average strength (6.30 MPa to 5.80 MPa). On the other hand, for the three-course specimens extracted from real-scale masonry, this difference was significantly higher, reaching 14.67% (3.75 MPa to 3.20 MPa). This greater discrepancy reinforces the higher variability and dispersion of results for in situ extracted specimens, a phenomenon that can be attributed to the influence of in situ construction factors, such as heterogeneity in unit placement, variations in bed mortar joint thickness, and other material and execution related variables that are not present in laboratory specimens.

5. Conclusions

Based on the analysis of the observed results, the following conclusions can be drawn:

- (a)

- The analysis of the experimental results confirms that the compressive strength of structural masonry is significantly influenced by the height of the masonry specimen. Specimens with greater slenderness exhibit lower compressive strength due to increased susceptibility to lateral cracking. These findings align with previous studies [2,31] and suggest that normative adjustment coefficients may be useful when interpreting test results from specimens with geometries different from the standard two-course specimens, such as those extracted from real-scale masonry walls.

- (b)

- The greater variability and dispersion of results for the extracted masonry specimens can be attributed to the influence of in situ construction factors, such as heterogeneity in execution of the walls, variations in bed mortar joint thickness, and other material and execution-related variables that are not present in the execution control two-course specimens. The two-course specimens also do not have head joints. Additionally, the extraction and transportation of the specimens may also contribute to the increased dispersion of results.

- (c)

- In the normative context, NBR 16868 [15] establishes relationships between the compressive strength of masonry units, masonry two-course specimens, and walls, with two-course specimens serving as an intermediate element for predicting the in-field strength of masonry. Considering the results of this study, the exclusive use of characteristic compressive strength values to compare two-course laboratory specimens and three-course extracted specimens (for retest, for example) can be questioned, as the observed dispersion of results suggests that adopting average values may provide a more realistic representation of the structural behavior of masonry.

- (d)

- Considering that three-course masonry specimens are extracted from already constructed walls in situations where there is uncertainty regarding the compressive strength conformity (typically due to unsatisfactory results obtained from execution control tests performed on two-course specimens), it is essential that technical standards provide clear guidelines to allow comparison between these two types of specimens.Since this comparison is necessary for a realistic assessment of the actual strength of the executed masonry, it is crucial to account for the geometric differences between the specimens (notably the height/thickness ratio), as these differences directly affect the test results. The lack of normative criteria for this comparison may hinder the proper interpretation of the retest results, potentially compromising the verification of structural compliance. Therefore, it is recommended that future revisions of technical standards include correlation methods or correction factors that enable a coherent analysis between the different specimen types used at various stages of masonry strength verification.

- (e)

- Regarding the height/thickness ratio, this study used two-course specimens, in accordance with the requirements of the Brazilian structural masonry standard, NBR 16868-2 [15]. It is important to highlight that this standard does not consider the width of the masonry unit when defining the minimum dimensions of the masonry specimen, unlike Eurocode 6 [16]. For example, according to Eurocode 6 [16], the masonry specimens with 14 cm wide and 19 cm high units used in this study should have at least three-course. In view of this, it is recommended that new studies be carried out with wider masonry units (such as 19 cm bricks) to further analyze the differences between test specimens with two-course and three-course, considering that the height/thickness ratio varies even when the number of courses is kept constant.

- (f)

- The difference between the average and characteristic compressive strength of the three-course specimens suggests that the variation coefficients adopted in normative standards should account for these aspects, considering the greater dispersion of results obtained in situ [42]. This adjustment could enable more realistic predictions of the final compressive strength of structural masonry in the field, reducing error margins.

Author Contributions

Conceptualization, B.T. and F.S.; methodology, B.T.; formal analysis, B.T.; investigation, F.S. and B.T.; resources, F.S.; data curation, F.S.; writing—original draft preparation, F.S.; writing—review and editing, F.S. and B.T.; visualization, B.T.; supervision, B.T.; project administration, B.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Dhanasekar, M.; Thamboo, J.A.; Nazir, S. On the in-plane shear response of the high bond strength concrete masonry walls. Mater. Struct. 2017, 50, 214. [Google Scholar] [CrossRef]

- Hassanli, R.; ElGawady, M.A.; Mills, J.E. Effect of dimensions on the compressive strength of concrete masonry prisms. Adv. Civ. Eng. Mater. 2015, 4, 175–201. [Google Scholar] [CrossRef]

- Paulino, R.S.; Toralles, B.M. Influence of the relationships between compressive strengths of mixed and industrialized mortars and concrete blocks on the behavior of masonry prisms. Rev. IBRACON Estrut. E Mater. 2024, 17, e17503. [Google Scholar] [CrossRef]

- Steil, J.F.; Prudêncio, L.R. Avaliação experimental do comportamento de alvenaria estrutural de blocos de concreto com diferentes tipos de argamassas. Rev. Eng. Civ. 2002, 37, 25–38. [Google Scholar]

- Parsekian, G.A.; Soares, S.M. Alvenaria Estrutural: Produção e Projeto; Ed. Blucher: São Paulo, Brazil, 2012. [Google Scholar]

- Holanda, O.G.D., Jr.; Ramalho, M.A.; Corrêa, M.R.S. Experimental and numerical analysis of masonry load-bearing walls subjected to differential settlements. In Proceedings of the 9th North American Masonry Conference, Clemson, SC, USA, 1–4 June 2003; Clemson University/The Masonry Society: Clemson, SC, USA, 2003. [Google Scholar]

- Ganesan, T.P.; Ramamurthy, K. Behavior of concrete hollow-block masonry prisms under axial compression. J. Struct. Eng. 1992, 118, 1751–1769. [Google Scholar] [CrossRef]

- Mohamad, G.; Fonseca, F.S.; Vermeltfoort, A.T.; Martens, D.R.; Lourenço, P.B. Strength, behavior, and failure mode of hollow concrete masonry constructed with mortars of different strengths. Constr. Build. Mater. 2017, 134, 489–496. [Google Scholar] [CrossRef]

- Fortes, E.S.; Parsekian, G.A.; Camacho, J.S.; Fonseca, F.S. Compressive strength of masonry constructed with high strength concrete blocks. Rev. IBRACON Estrut. E Mater. 2017, 10, 1273–1319. [Google Scholar] [CrossRef]

- Drougkas, A.; Verstrynge, E.; Hayen, R.; Van Balen, K. The confinement of mortar in masonry under compression: Experimental data and micro-mechanical analysis. Int. J. Solids Struct. 2019, 162, 105–120. [Google Scholar] [CrossRef]

- Llorens, J.; Llorens, M.; Chamorro, M.A.; Gómez, J.; Barris, C. Experimental study on the vertical interface of thin-tile masonry. Constr. Build. Mater. 2020, 261, 119976. [Google Scholar] [CrossRef]

- Mohamad, G.; Fonseca, F.S.; Vermeltfoort, A.T.; Lubeck, A. Stiffness plasticity degradation of masonry mortar under compression: Preliminar results. Rev. IBRACON Estrut. E Mater. 2018, 11, 279–295. [Google Scholar] [CrossRef]

- Abasi, A.; Hassanli, R.; Vincent, T.; Manalo, A. Influence of prism geometry on the compressive strength of concrete masonry. Constr. Build. Mater. 2020, 264, 120182. [Google Scholar] [CrossRef]

- Nalon, G.H.; Ribeiro, J.C.L.; Pedroti, L.G.; da Silva, R.M.; de Araújo, E.N.D.; Santos, R.F.; de Lima, G.E.S. Review of recent progress on the compressive behavior of masonry prisms. Constr. Build. Mater. 2022, 320, 126181. [Google Scholar] [CrossRef]

- NBR 16868-1:2020; Alvenaria Estrutural—Parte 1: Projeto. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2020.

- EN 1996-1-1:2022; Eurocode 6: Design of Masonry Structures—Part 1-1: General Rules for Reinforced and Unreinforced Masonry Structures. European Committee for Standardization (EN): Brussels, Belgium, 2022.

- EN 1052; Masonry—Structural Design of Reinforced and Unreinforced Masonry Structures. CEN: Brussels, Belgium, 2007.

- NBR 16868-3:2020; Alvenaria Estrutural—Parte 3: Métodos de Ensaio. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2020.

- TMS 402/602; Building Code Requirements for Masonry Structures. The Masonry Society: Longmont, CO, USA, 2021.

- AS 3700; Masonry Structures. Australian Standard: Sydney, Australia, 2011.

- CSA S304; Design of Masonry Structures. Canadian Standards Association: Mississauga, ON, Canada, 2014.

- Leite, M.D.L.P.; Liberati, E.A.P.; Parsekian, G.A. Estimate models of compression strength of prisms from structural masonry components. Rev. IBRACON Estrut. E Mater. 2024, 17, e17601. [Google Scholar] [CrossRef]

- Chahine, G.N. Behaviour Characteristics of Face Shell Mortared Block Masonry Under Axial Compression. Master of Engineering Degree, McMaster University, Hamilton, ON, Canada, 1989. Available online: http://hdl.handle.net/11375/7219 (accessed on 6 July 2025).

- Tutikian, B.; Zuchetto, L.; Souza, R.; Oliveira, M.F. Uso de agregado leve de EVA em contrapiso argamassado para isolamento ao ruído de impacto em edificações residenciais. Ambiente Construído 2017, 17, 295–306. [Google Scholar] [CrossRef]

- Garzón-Roca, J.; Marco, C.O.; Adam, J.M. Compressive strength of masonry made of clay bricks and cement mortar: Estimation based on neural networks and fuzzy logic. Eng. Struct. 2013, 48, 21–27. [Google Scholar] [CrossRef]

- Ravula, S.; Subramaniam, K.V. Influence of masonry unit properties on compressive strength of masonry walls. Constr. Build. Mater. 2017, 157, 819–827. [Google Scholar] [CrossRef]

- Prudêncio, L.R., Jr.; Oliveira, A.L.; Bedin, C.A. Alvenaria Estrutural de Blocos de Concreto; Associação Brasileira de Cimento Portland, Editora Gráfica Pallotti: Florianópolis, Brazil, 2002. [Google Scholar]

- Hamid, A.A.; Abboud, B.E.; Harris, H.G. Direct Modeling of Concrete Block Masonry Under Axial Compression. In Masonry: Research, Application, and Problems; ASTM STP, 871, Grogan, J.C., Conway, J.T., Eds.; American Society for Testing and Materials: Philadelphia, PA, USA, 1985; pp. 151–166. [Google Scholar]

- Thomas, J.; Ansar, E.M. Parametric study of the strength of brickwork prisms. In Proceedings of the First CUSAT National Conference on Recent Advances in Civil Engineering, Kochi, Índia, March 2004; pp. 431–437. [Google Scholar]

- NBR 13281-1:2023; Argamassas Inorgânicas—Requisitos e Métodos de Ensaios—Parte 1: Argamassas para Revestimento de Paredes e Tetos. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2023.

- Thaickavil, N.N.; Thomas, J. Behaviour and strength assessment of masonry prisms. Case Stud. Constr. Mater. 2018, 8, 23–38. [Google Scholar] [CrossRef]

- Page, A.; Brooks, D. Load bearing masonry—A review. In Proceedings of the 7th IBMC; 1985. [Google Scholar]

- IS: 1905; Indian Standard Code of Practice for Structural Use of Unreinforced Masonry. Bureau of Indian Standards: New Delhi, India, 1987.

- Christ, R.; Pacheco, F.; Ehrenbring, H.; Quinino, U.; Mancio, M.; Muñoz, Y.; Tutikian, B. Study of mechanical behavior of ultra-high performance concrete (UHPC) reinforced with hybrid fibers and with reduced cement consumption. Rev. Ing. Construcción 2019, 34, 159–168. [Google Scholar] [CrossRef]

- E447-97; Test Methods for Compressive Strength of Laboratory Constructed Masonry Prisms. American Society for Testing and Materials: Philadelphia, PA, USA, 1997.

- Drysdale, R.G.; Hamid, A.A. Behavior of concrete block masonry under axial compression. ACI J. Proc. 1979, 76, 707–722. [Google Scholar] [CrossRef]

- Francis, A.J.; Horman, C.B.; Jerrems, L.E. The effect of joint thickness and other factors on compressive strength of brickwork. In Proceedings of the 2nd International Brick Masonry Conference, Stoke-on-Trent, UK, 12–15 April 1971; pp. 31–37. [Google Scholar]

- Alvarez-Perez, J.; Chavez-Gomez, J.H.; Teran-Torres, B.T.; Mesa-Lavista, M.; Balandrano-Vazquez, R. Multifactorial behavior of the elastic modulus and compressive strength in masonry prisms of hollow concrete blocks. Constr. Build. Mater. 2020, 241, 118002. [Google Scholar] [CrossRef]

- NBR 15270-1:2023; Componentes Cerâmicos—Blocos Cerâmicos para Alvenaria Estrutural e de Vedação—Parte 1: Requisitos. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2023.

- NBR 15270-2:2023; Componentes Cerâmicos—Blocos Cerâmicos para Alvenaria Estrutural e de Vedação—Parte 2: Métodos de Ensaio. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2023.

- Souza, J.; Kern, A.; Tutikian, B. Análise quantiqualitativa da norma de desempenho (NBR nº 15.575/2013) e principais desafios da implantação do nível superior em edificação residencial de multipavimentos. Gestão Tecnol. Projetos 2018, 13, 127–144. [Google Scholar] [CrossRef]

- Tutikian, B.; Pacheco, M. Inspeção, Diagnóstico e Prognóstico na Construção Civil; ALCONPAT: Mérida, Mexico, 2013. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).