Dynamic Simulation Model of Single Reheat Steam Turbine and Speed Control System Considering the Impact of Industrial Extraction Heat

Abstract

1. Introduction

- Integrating dynamic models of DC boilers and coal mills and accurately characterizing the coupling relationship between main steam pressure and flow rate improve simulation accuracy;

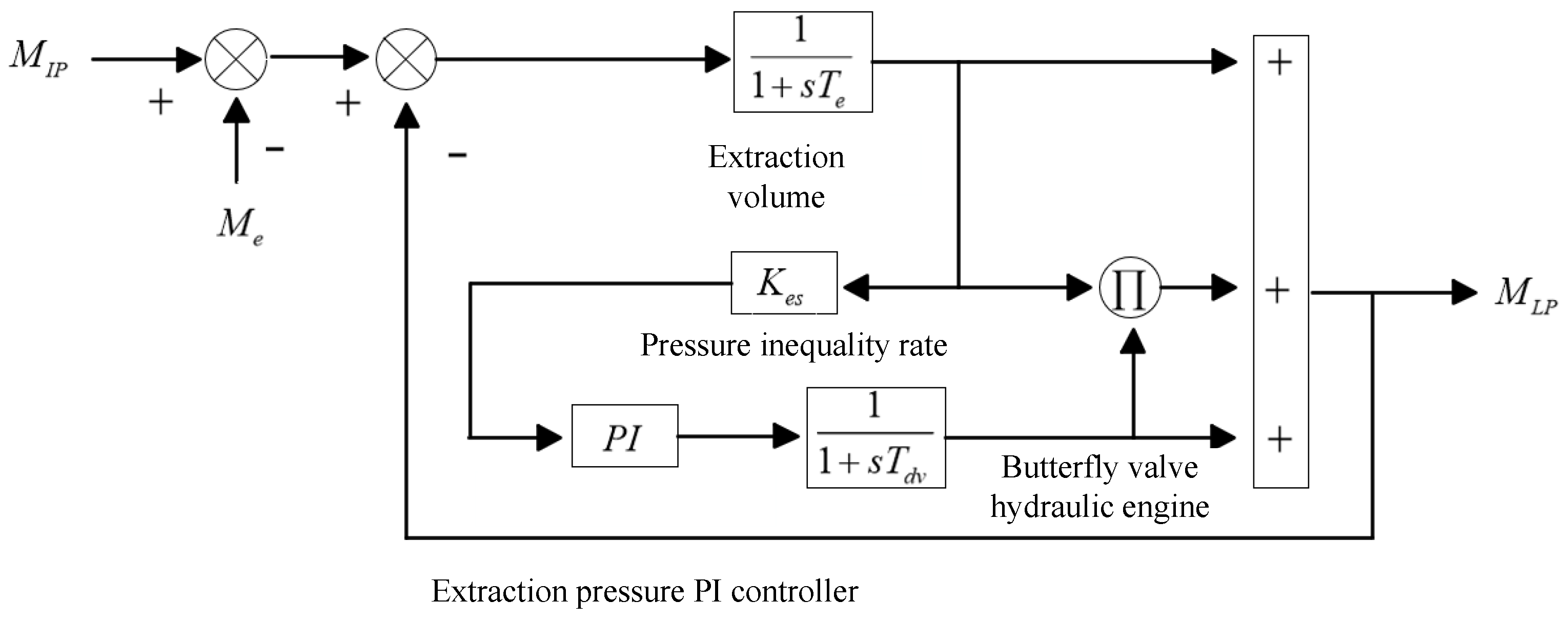

- Propose a medium- and low-pressure connected pipeline extraction and heat module based on butterfly valve control. Through closed-loop transfer function and pressure inequality compensation mechanism, coupled with the medium-pressure regulating valve actuator and two-stage bypass system model, the cascade energy conversion efficiency between main steam and reheated steam was optimized, achieving coordinated regulation of exhaust flow rate and unit power;

- Verify the dynamic characteristics of the model under frequency response, load regulation, and heat conditions by comparing parameter perturbation experiments with measured data.

2. Speed Control System Model and Single Reheat Steam Turbine

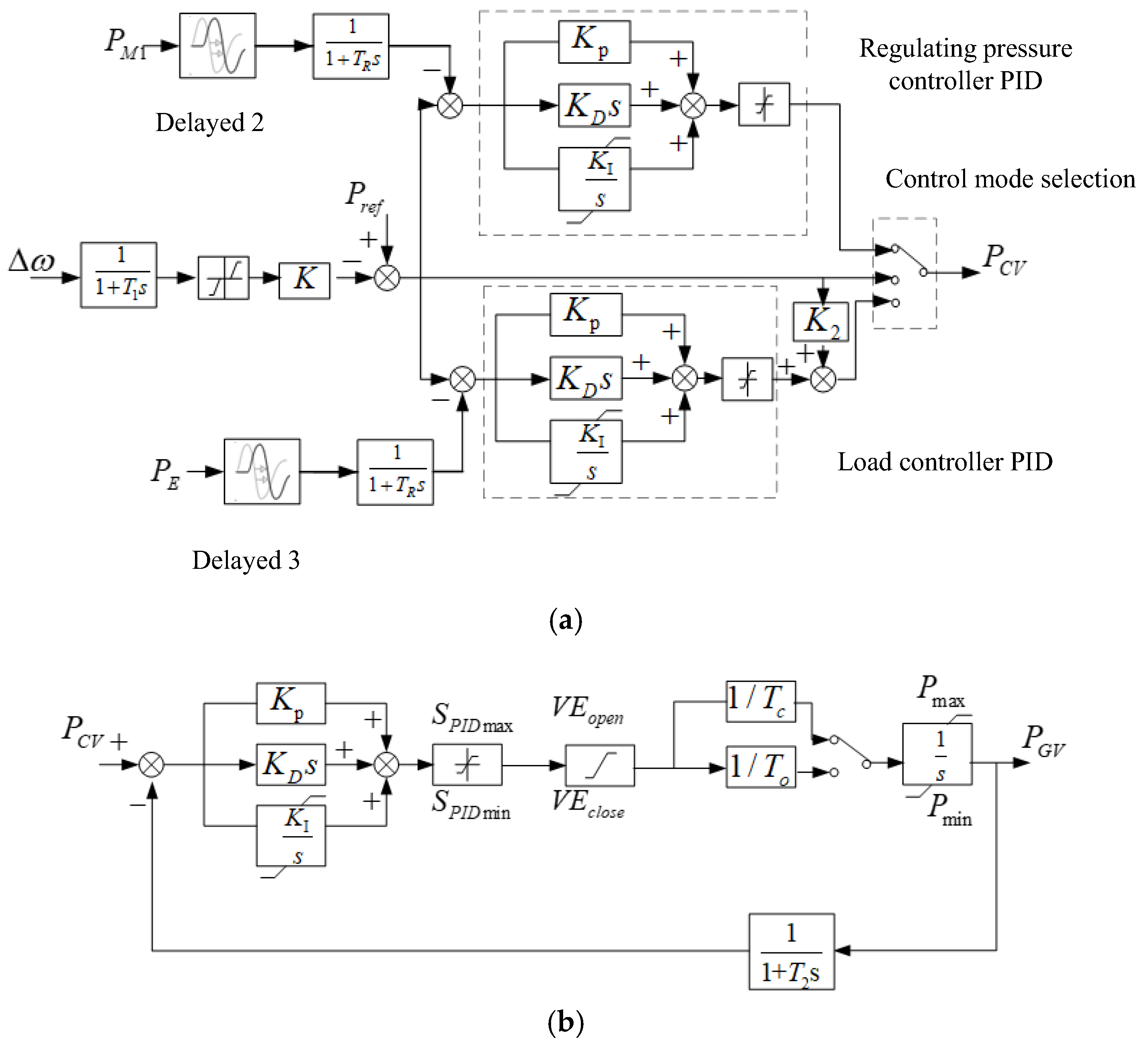

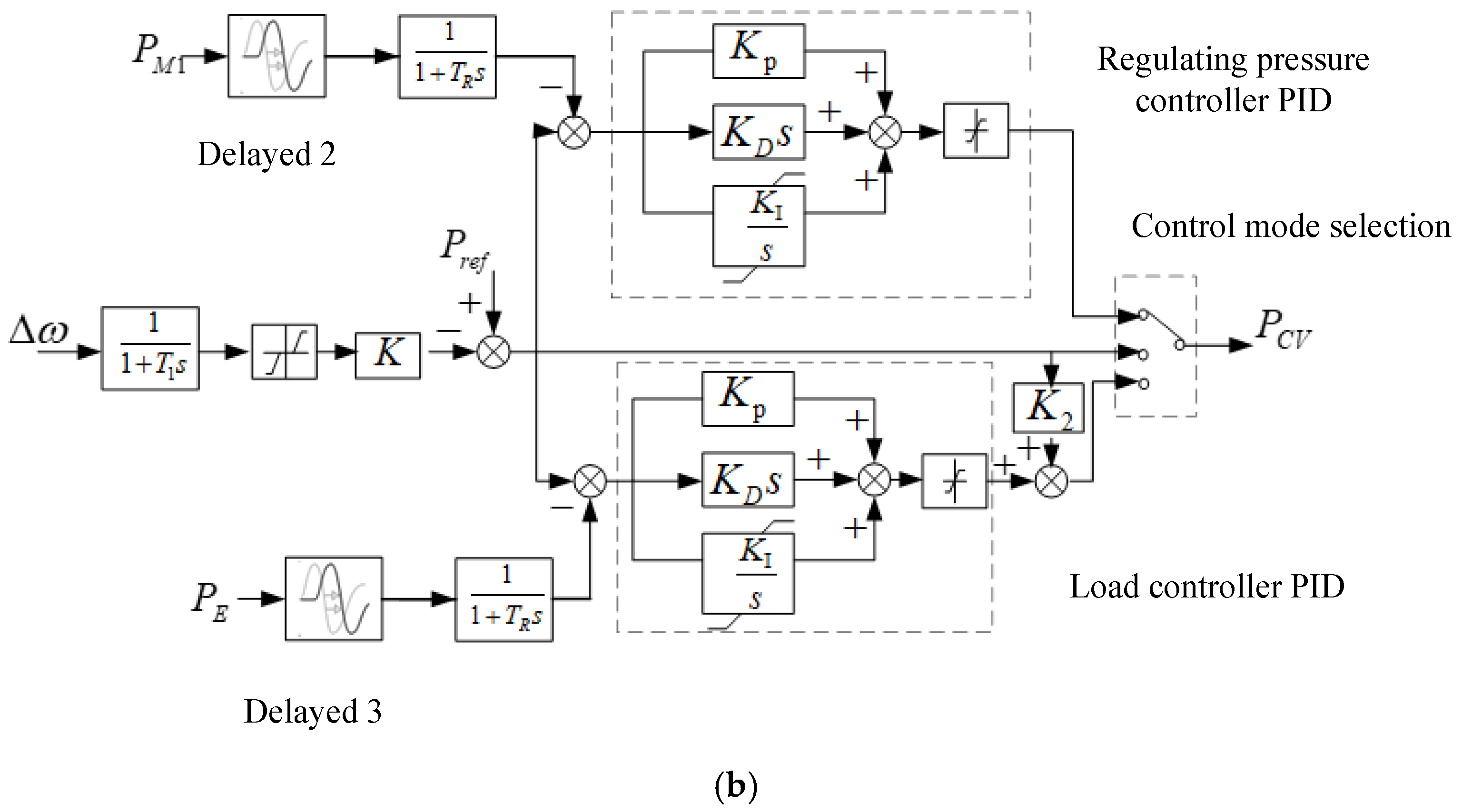

2.1. Speed Control System Model

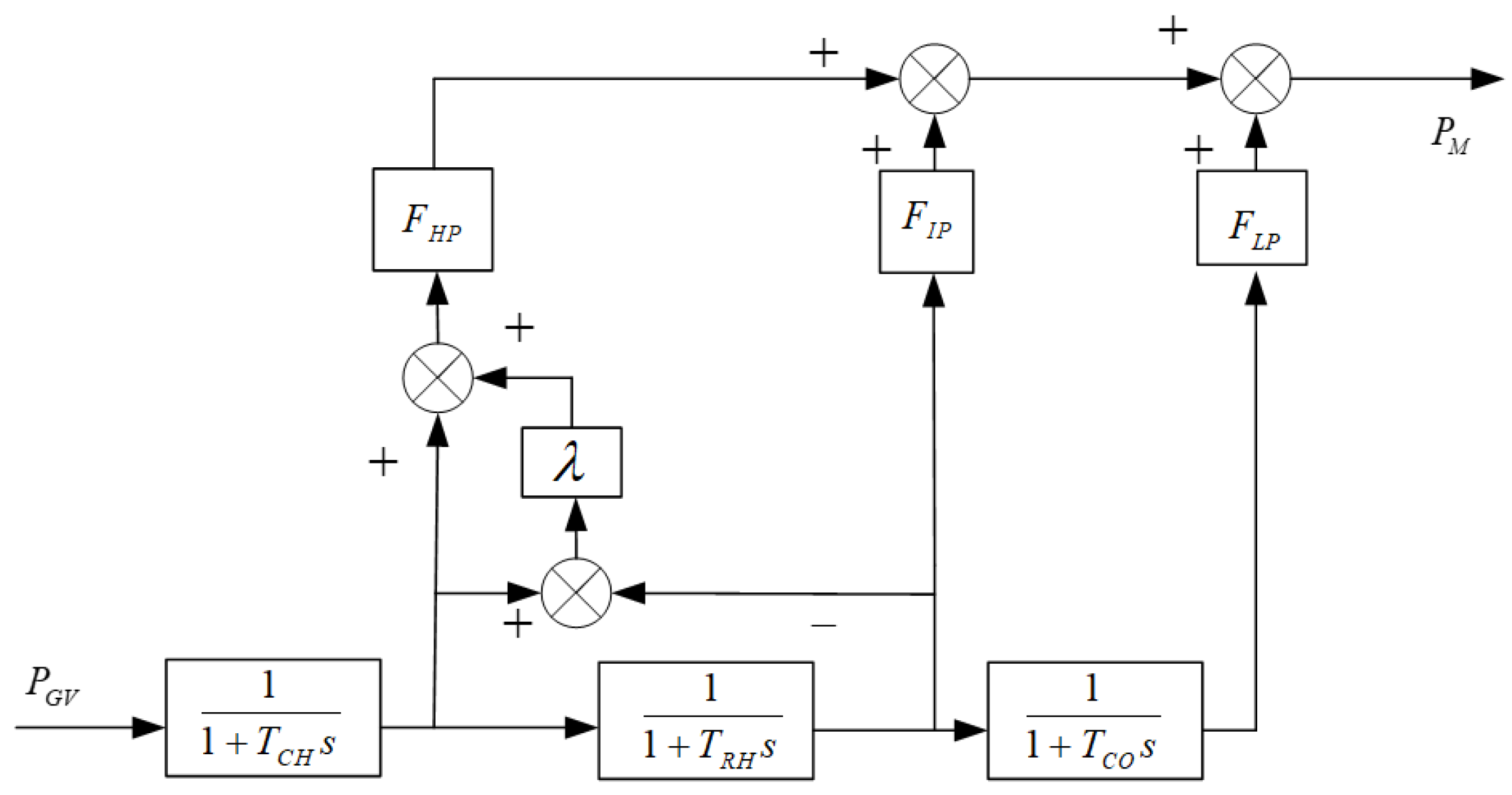

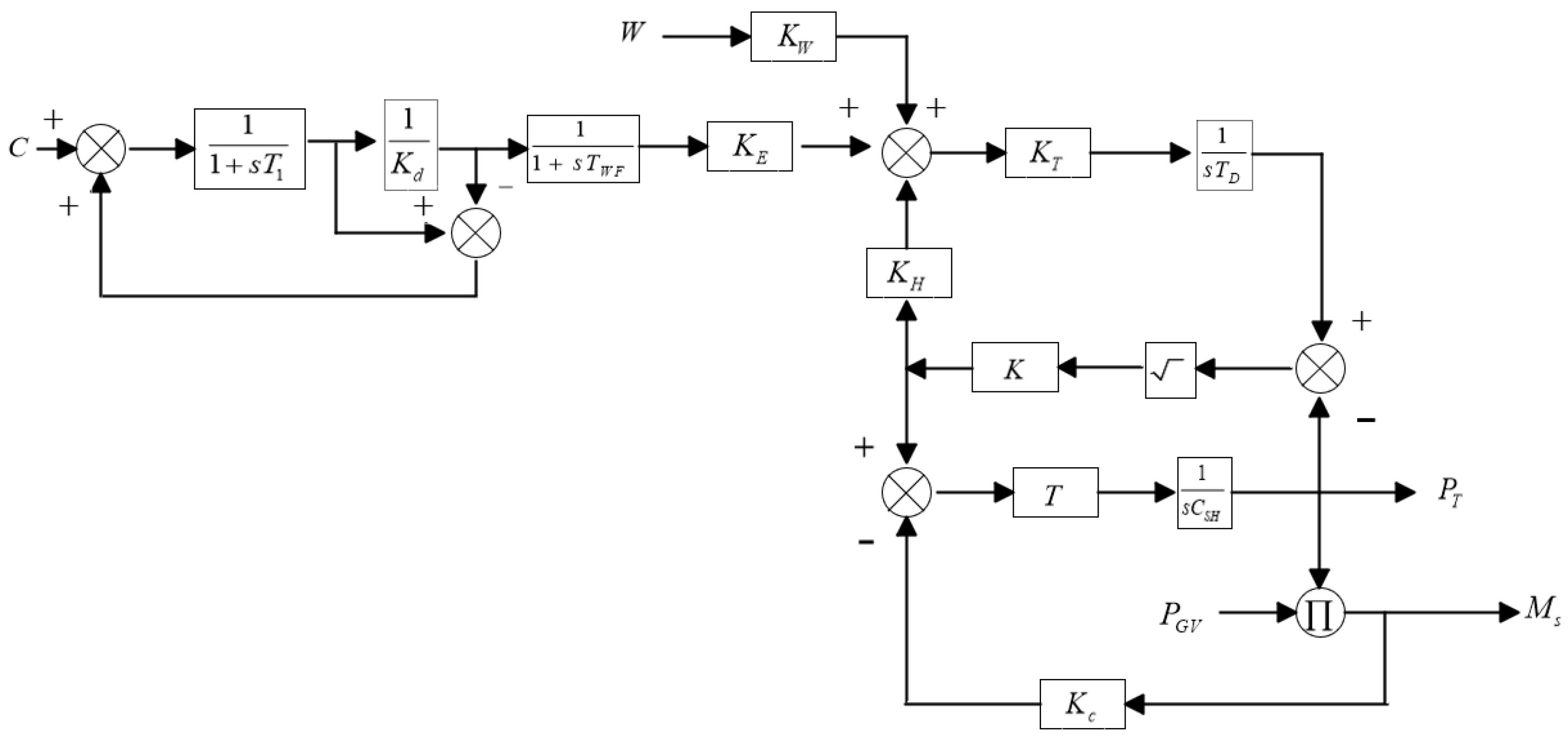

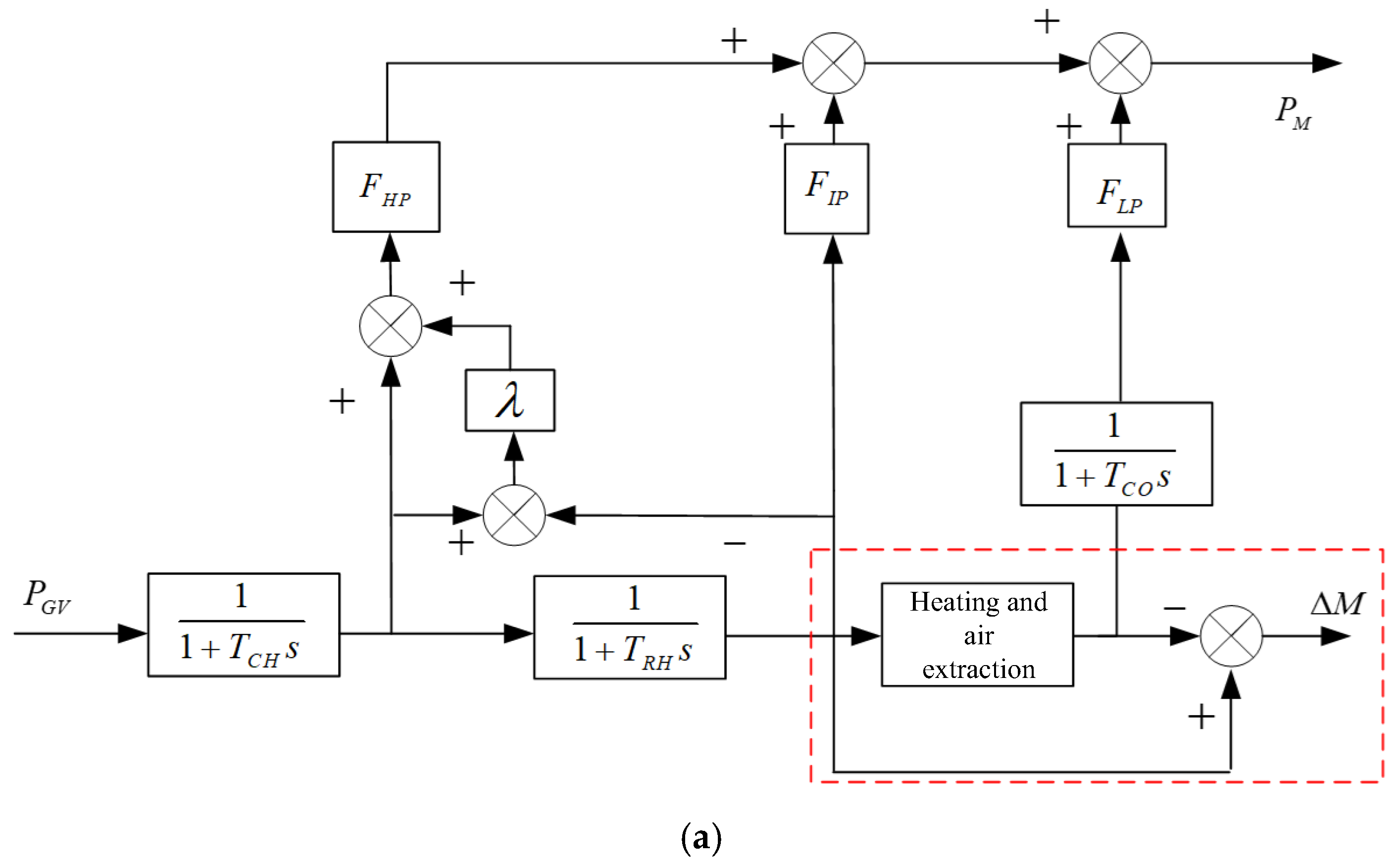

2.2. A Single Reheat Steam Turbine Model Considering the Influence of Boilers

3. Model of Steam Turbine and Speed Control System Considering Heat Effects

3.1. Heat and Exhaust Module Model

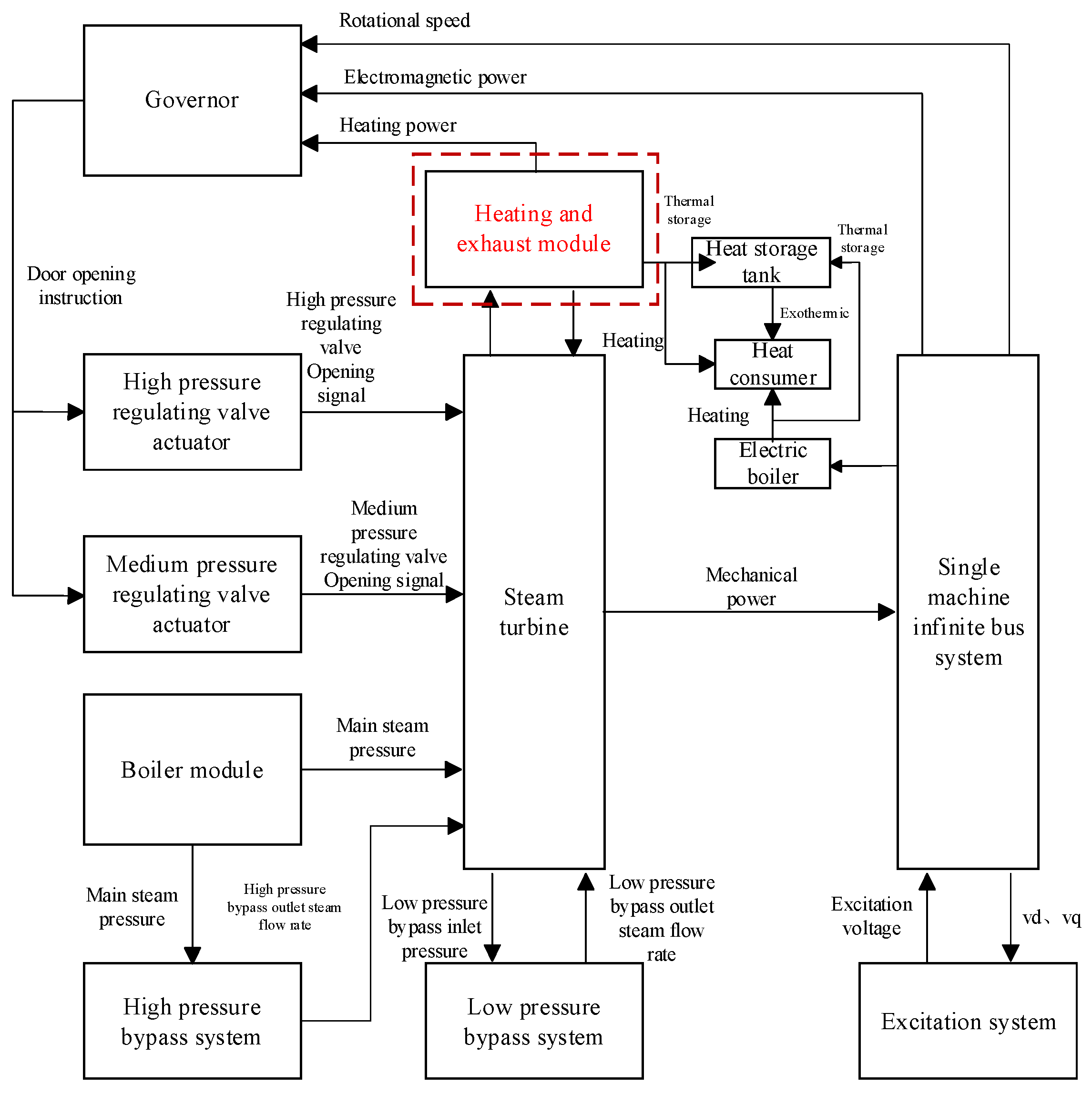

3.2. Consider the Model of the Steam Turbine and Speed Control System for the Heat and Extraction Module

4. Simulation Verification of Steam Turbine and Speed Control System Affected by Heat Module

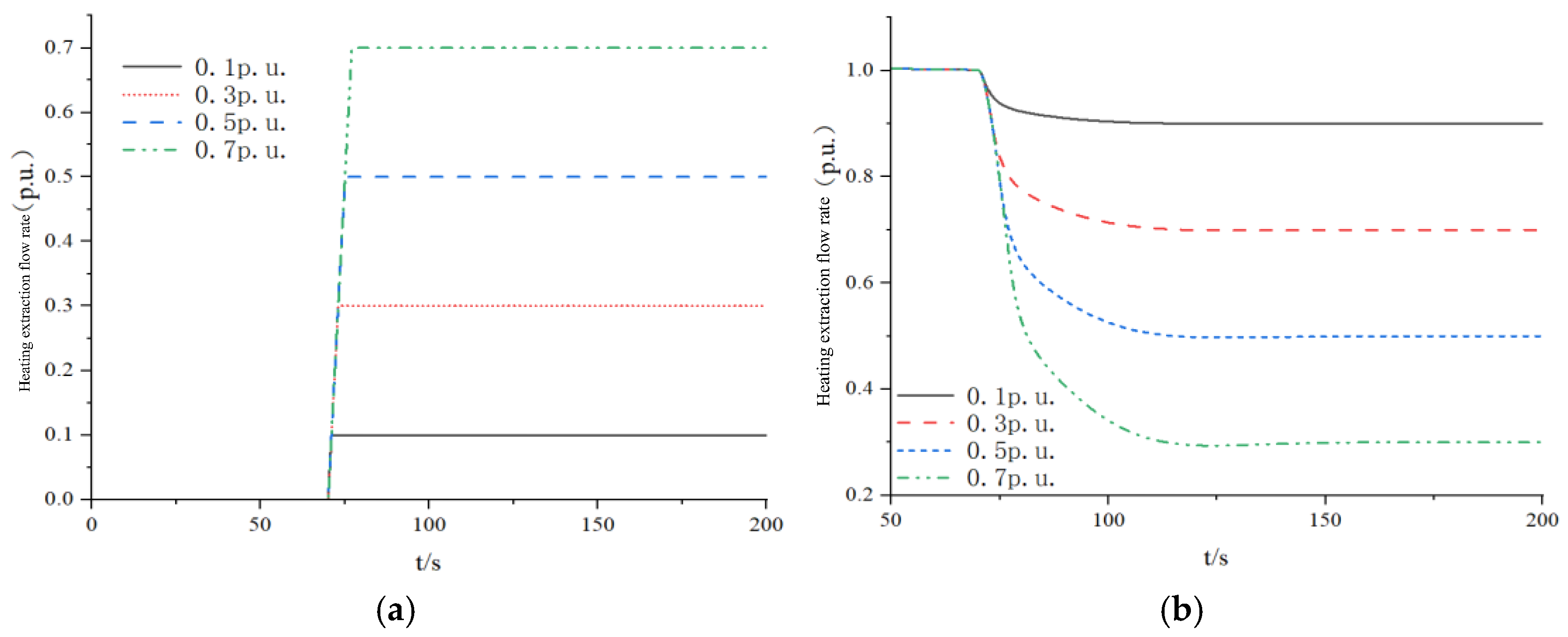

4.1. Analysis of Exhaust Flow Regulation for Heat Module

4.2. Dynamic Follow Performance Analysis of Heat Modules

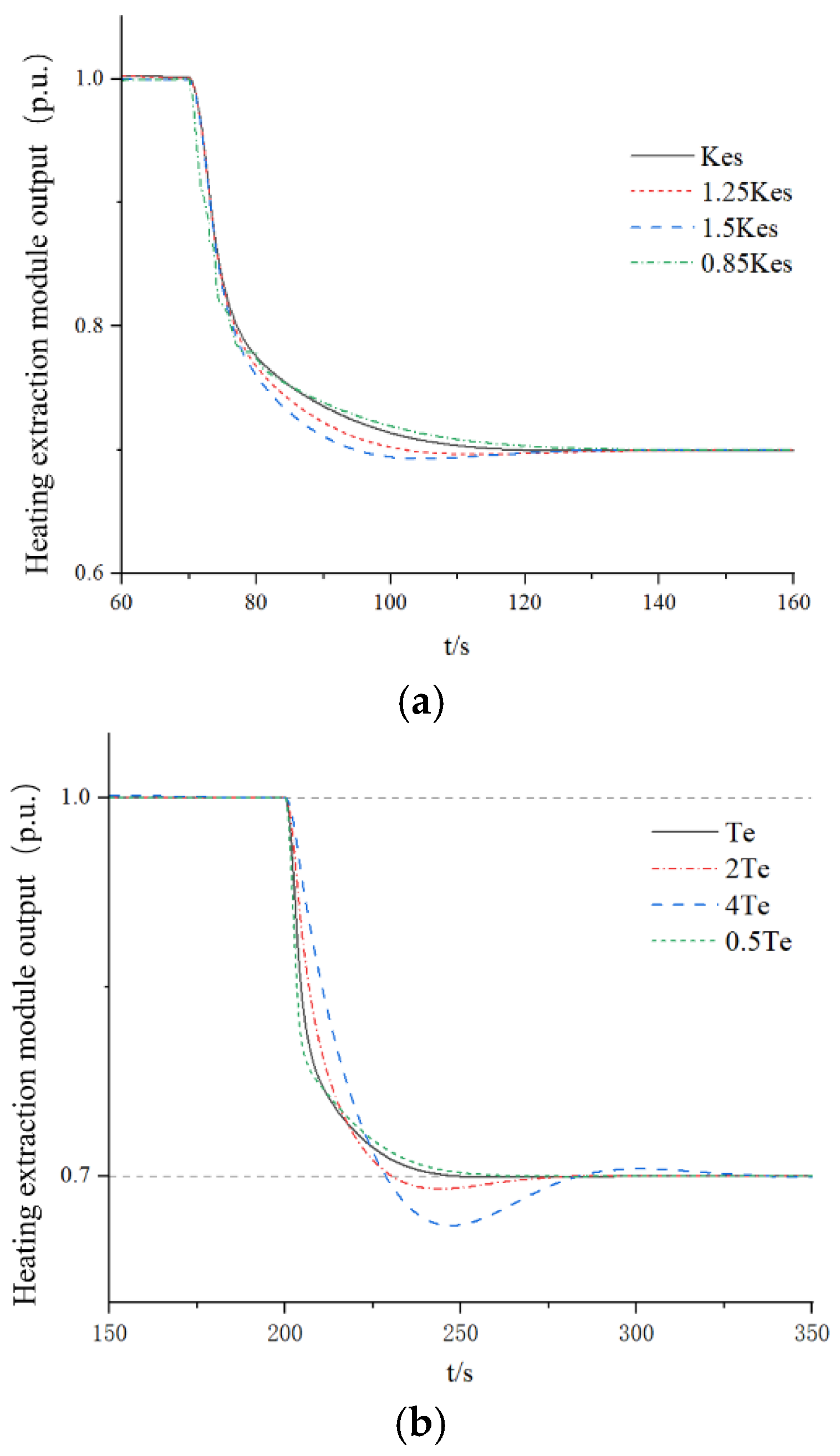

4.3. Analysis of Control Parameters of Heat Module Model

- The inequality in pumping pressure rate has a negligible effect on system overshoot. The larger is, the worse the dynamic response performance is. The parameters of the butterfly valve oil motor have a great influence on the overshoot of the system, and the larger the value, the greater the overshoot, and the longer the initial stability time of the system. The influence of the time constant of the heat extraction volume on the system is between and .The larger the dynamic response overshoot of the system is, the more difficult the system is to stabilize.

- The mapping inheritance strategy of the execution mechanism parameters of the speed control system can achieve global optimal control performance. At the level of system performance analysis, a two-layer evaluation framework needs to be established: single-parameter sensitivity analysis and comprehensive dynamic quality evaluation under multiphysics field coupling.

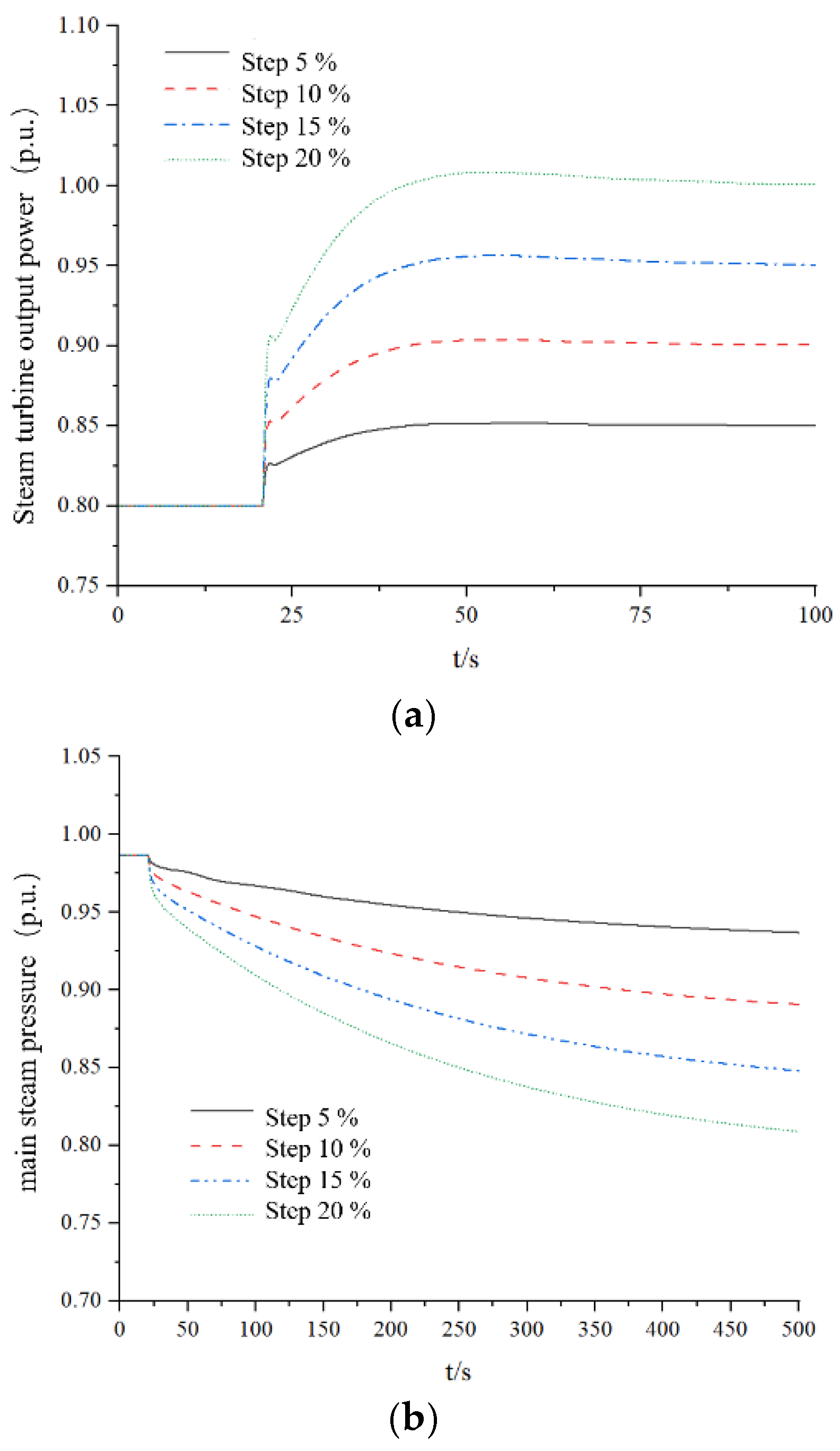

4.4. Analysis of the Output Mechanical Power of the Steam Turbine Considering the Heat Extraction Module

4.5. System Primary Frequency Modulation Simulation Analysis

4.6. System Load Regulation Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Yan, S.; Zeng, D.L.; Liu, J.Z.; Liang, Q.J. A Simplified Non-linear Model of a Once-through Boiler-turbine Unit and Its Application. Chin. J. Electr. Eng. 2012, 32, 126–134. [Google Scholar] [CrossRef]

- Su, Z. Modeling of Boiler Steam Turbine Based on Adaptive Neuro-Fuzzy Inference System. Master’s Thesis, North China Electric Power University, Beijing, China, 2020. [Google Scholar] [CrossRef]

- Yan, P. Research on Multiple Model Nonlinear Decoupling Control Method for 660 MW Large Thermal Power Units. Master’s Thesis, Shenyang Agricultural University, Shenyang, China, 2023. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, L.; Wang, Y. Research on modeling of cogeneration units based on digital twin technology. Therm. Power Gener. 2023, 52, 106–114. [Google Scholar] [CrossRef]

- Wu, J. Units Research on Modeling and Predictive Control of Multiple Cogeneration Units. Master’s Thesis, North China Electric Power University, Beijing, China, 2023. [Google Scholar] [CrossRef]

- Zhang, G. Research on Flexible Operation Characteristics and Control of Combined Heat and Power Units. Ph.D. Thesis, North China Electric Power University, Beijing, China, 2022. [Google Scholar] [CrossRef]

- Liu, Z. Study of Operation Characteristics of Gas-Steam in Combination Cycle with chp Unit Coupled in Combination with Compression Heat Pump. Master’s Thesis, Southeast University, Nanjing, China, 2022. [Google Scholar] [CrossRef]

- Hou, G.; Ye, L.; Huang, T.; Huang, C. Intelligent modeling of combined heat and power unit under full operating conditions via improved cross former and precise sparrow search algorithm. Energy 2024, 308, 132879. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, H.; Hong, F.; Yang, J.; Chen, Z.; Cui, H.; Feng, J. Modeling and optimization of combined heat and power with power-to-gas and carbon capture system in integrated energy system. Energy 2021, 236, 121392. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, Q.; Wen, J.; Lin, Z.; Fang, F.; Chen, Q. Optimal operation of integrated electricity and heat system: A review of modeling and solution methods. Renew. Sustain. Energy Rev. 2021, 135, 110098. [Google Scholar] [CrossRef]

- Koch, K.; Alt, B.; Gaderer, M. Dynamic Modeling of a Decarbonized District Heating System with CHP Plants in Electricity-Based Mode of Operation. Energies 2020, 13, 4134. [Google Scholar] [CrossRef]

- Li, L.; Liu, X. Control Strategy Optimization for Thermal Power Unit Adapted to Deep Peak Shaving for Large-Scale New Energy Source Integration. China Electr. Power 2020, 53, 155–161. [Google Scholar] [CrossRef]

- Wu, H.; Wang, F.; Yuan, M.; Wang, X.; Lin, C.; Xu, J. Application Study of Micro -output Technology for Low- pressure Cylinder of 300 MW Heating Unit. Valve 2024, 1397–1400. [Google Scholar] [CrossRef]

- Zhou, X. Modeling and Control of Supercritical Heat and Power Cogeneration Unit. Master’s Thesis, North China Electric Power University, Beijing, China, 2022. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, X.; Xin, G.; Liu, K.; Cui, F.; Zhao, Z. Experimental study on deep peak regulation operation of coal-fired thermal power unit. Clean Coal Technol. 2022, 28, 144–150. [Google Scholar] [CrossRef]

- Wang, L. Flexibility and Performance Analysis of Integrated Electric Boiler Heating Unit Operation. Energy Res. Util. 2024, 34–39. [Google Scholar] [CrossRef]

- Liu, D.; Ma, H.; Wang, B.; Gao, W.; Wang, J.; Yan, B. Operation Optimization of Regional lntegrated Energy system with CCHP and Energy Storage System. Power Syst. Autom. 2018, 42, 113–120+141. [Google Scholar] [CrossRef]

- DL/T 1235-2019; Guide for Measurement and Modeling of Synchronous Generator Prime Mover and Regulating System Parameters. National Energy Administration (NEA): Beijing, China, 2019.

| Parameter | Numerical Value | Parameter | Numerical Value |

|---|---|---|---|

| Steam volume time constant | 0.22 | Output upper limit of amplification stage | 10.0 |

| High-pressure cylinder power proportional coefficient | 0.3005 | Output lower limit of amplification stage | −10.0 |

| Proportional coefficient of intermediate pressure cylinder power | 0.2801 | Overspeed opening coefficient | 0.1619 |

| Low-pressure cylinder power proportional coefficient | 0.4194 | Oil engine opening time constant | −0.2394 |

| Reheater time constant | 10.0 | Oil engine opening time constant | 6.744 |

| Cross-tube time constant | 2.30 | Closing time constant of hydraulic actuator | 4.521 |

| Kp, Ki, Kd of the governor model | 0.1, 0.06667, 0 | Time constant of stroke feedback loop for hydraulic engine | 0.02 |

| Natural overshoot coefficient of high-pressure cylinder power | 0.6006 | \ | \ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, L.; Hu, H.; Xi, J. Dynamic Simulation Model of Single Reheat Steam Turbine and Speed Control System Considering the Impact of Industrial Extraction Heat. Processes 2025, 13, 2445. https://doi.org/10.3390/pr13082445

Wen L, Hu H, Xi J. Dynamic Simulation Model of Single Reheat Steam Turbine and Speed Control System Considering the Impact of Industrial Extraction Heat. Processes. 2025; 13(8):2445. https://doi.org/10.3390/pr13082445

Chicago/Turabian StyleWen, Libin, Hong Hu, and Jinji Xi. 2025. "Dynamic Simulation Model of Single Reheat Steam Turbine and Speed Control System Considering the Impact of Industrial Extraction Heat" Processes 13, no. 8: 2445. https://doi.org/10.3390/pr13082445

APA StyleWen, L., Hu, H., & Xi, J. (2025). Dynamic Simulation Model of Single Reheat Steam Turbine and Speed Control System Considering the Impact of Industrial Extraction Heat. Processes, 13(8), 2445. https://doi.org/10.3390/pr13082445