Simulation of Dynamic Particle Trapping and Accumulation in HGMS Based on FEM-CFD-DEM Coupling Approach

Abstract

1. Introduction

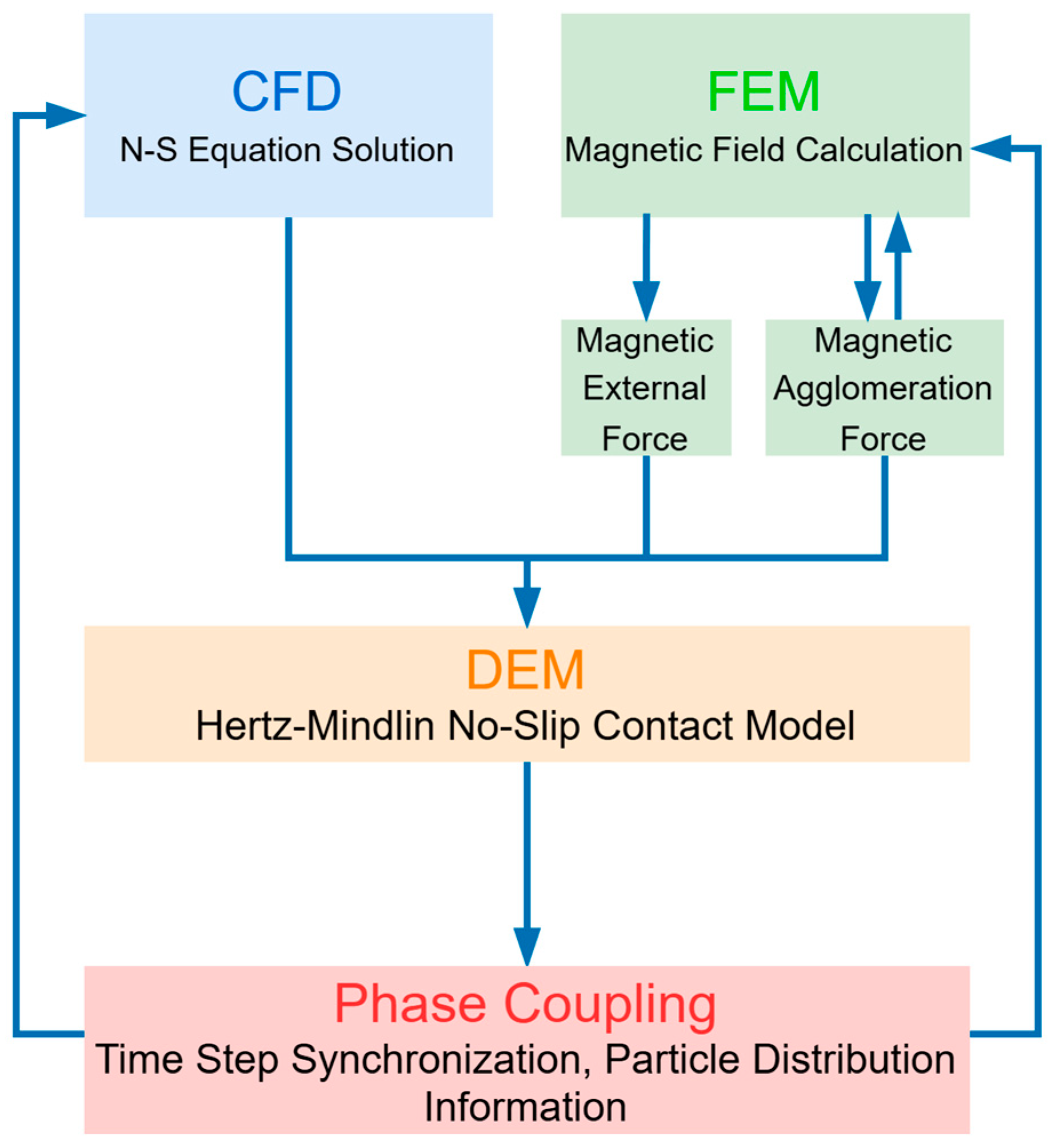

2. Dynamic Coupling Model Establishment

2.1. Multi-Field Coupling Calculation Model

2.1.1. Model of the Particle Phase

2.1.2. CFD Model of the Fluid

2.1.3. Magnetic Forces

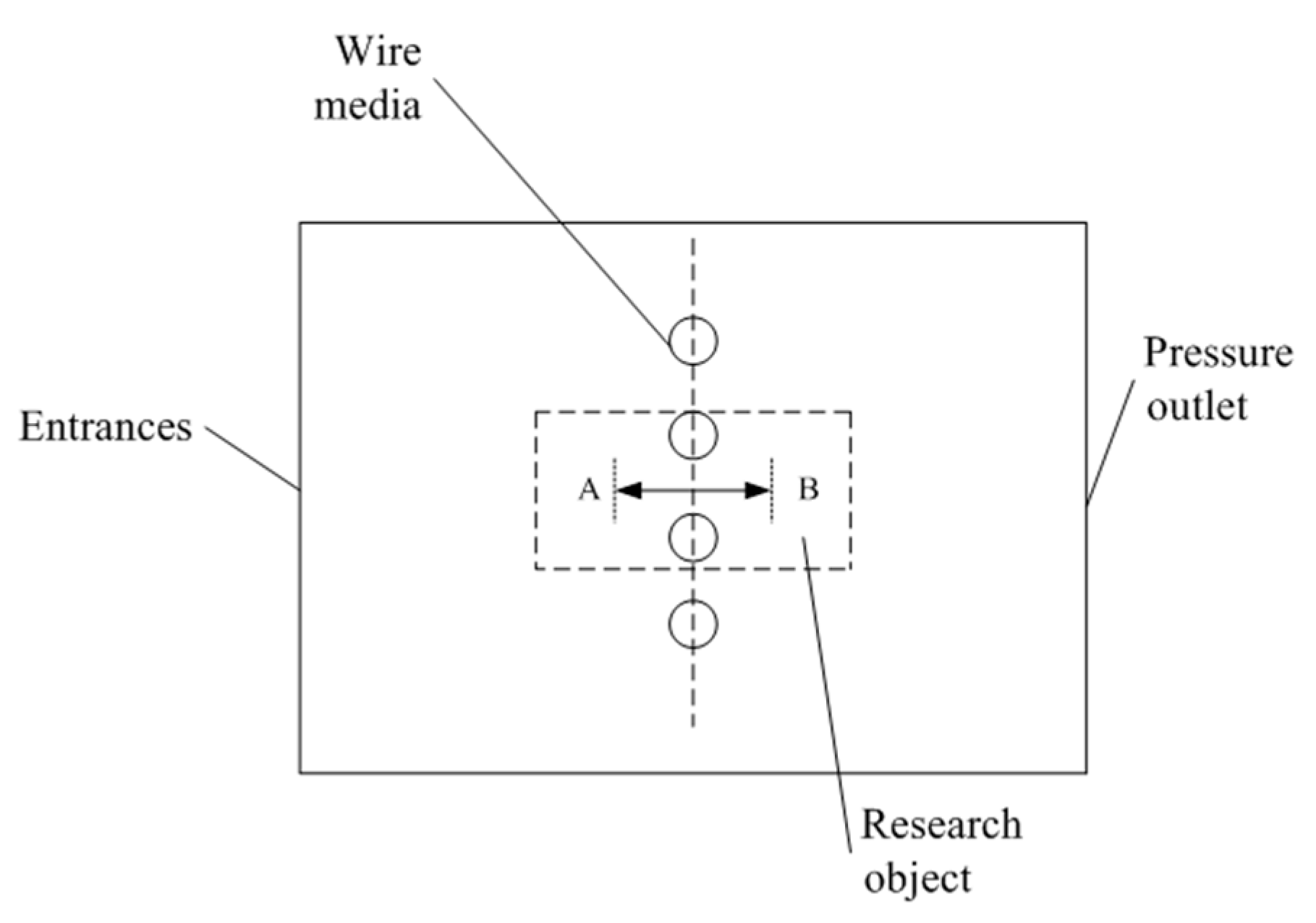

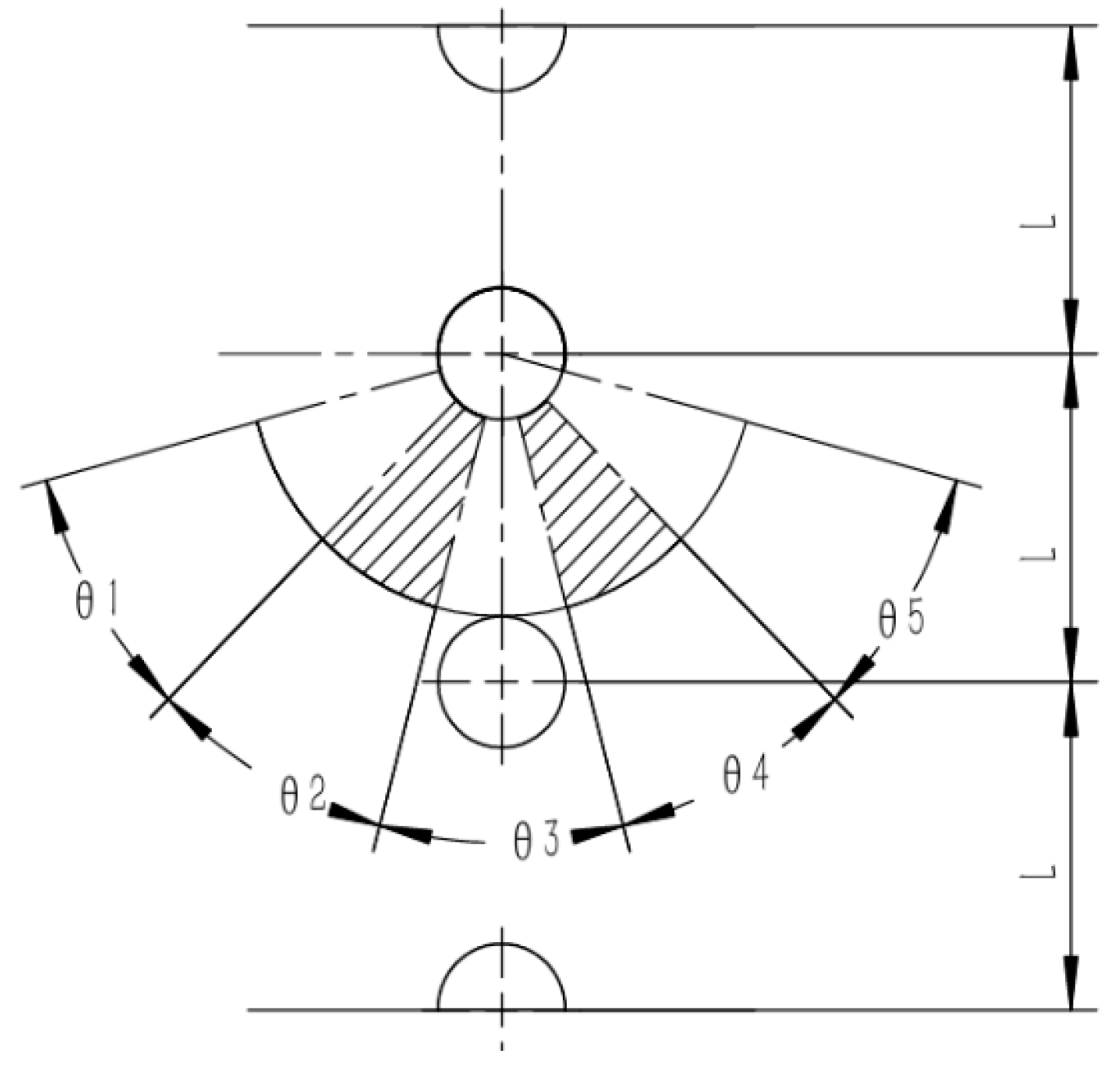

2.2. Physical Model of the Wire Medium

3. Results and Discussion

3.1. Experimental Set-Up

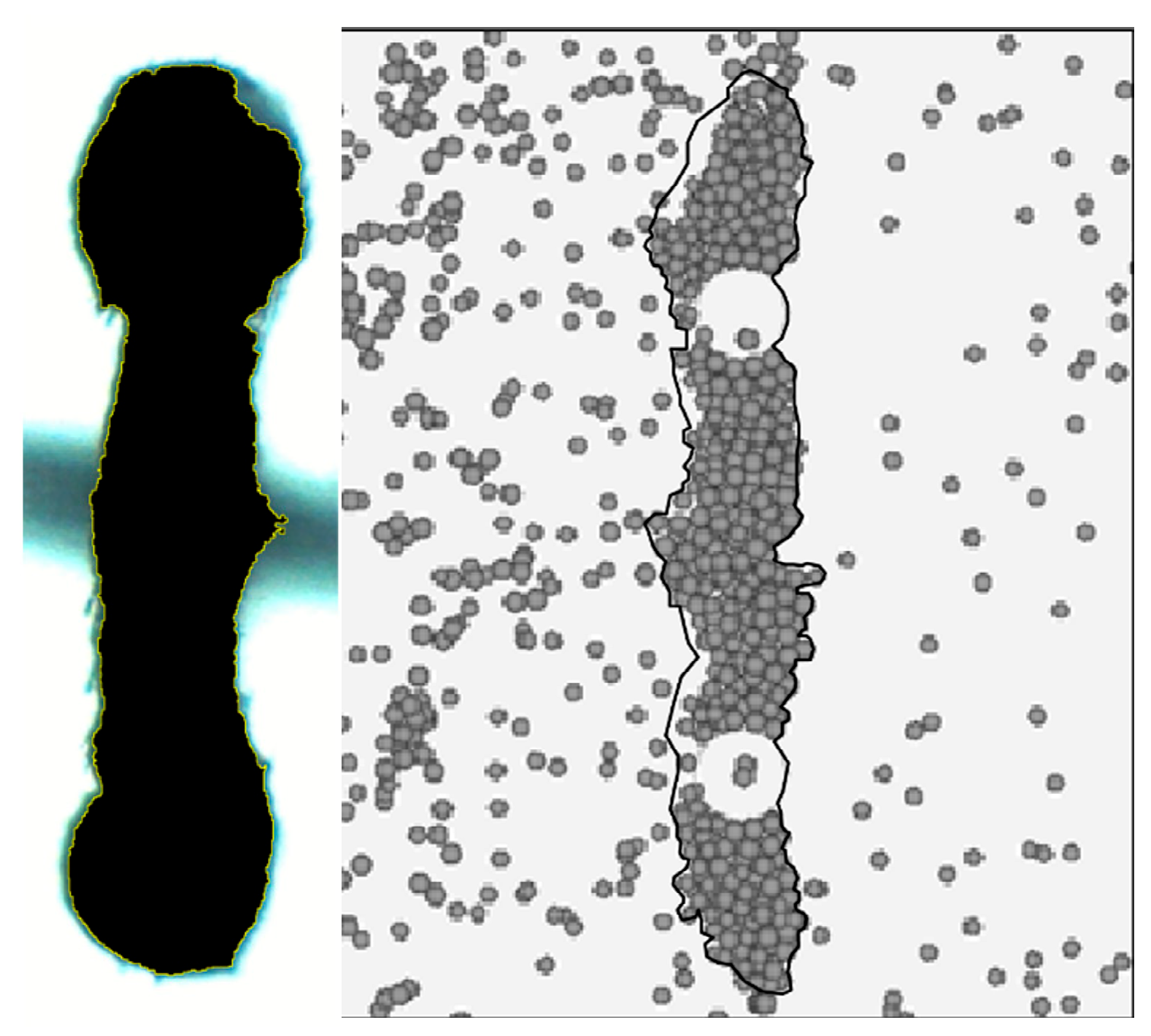

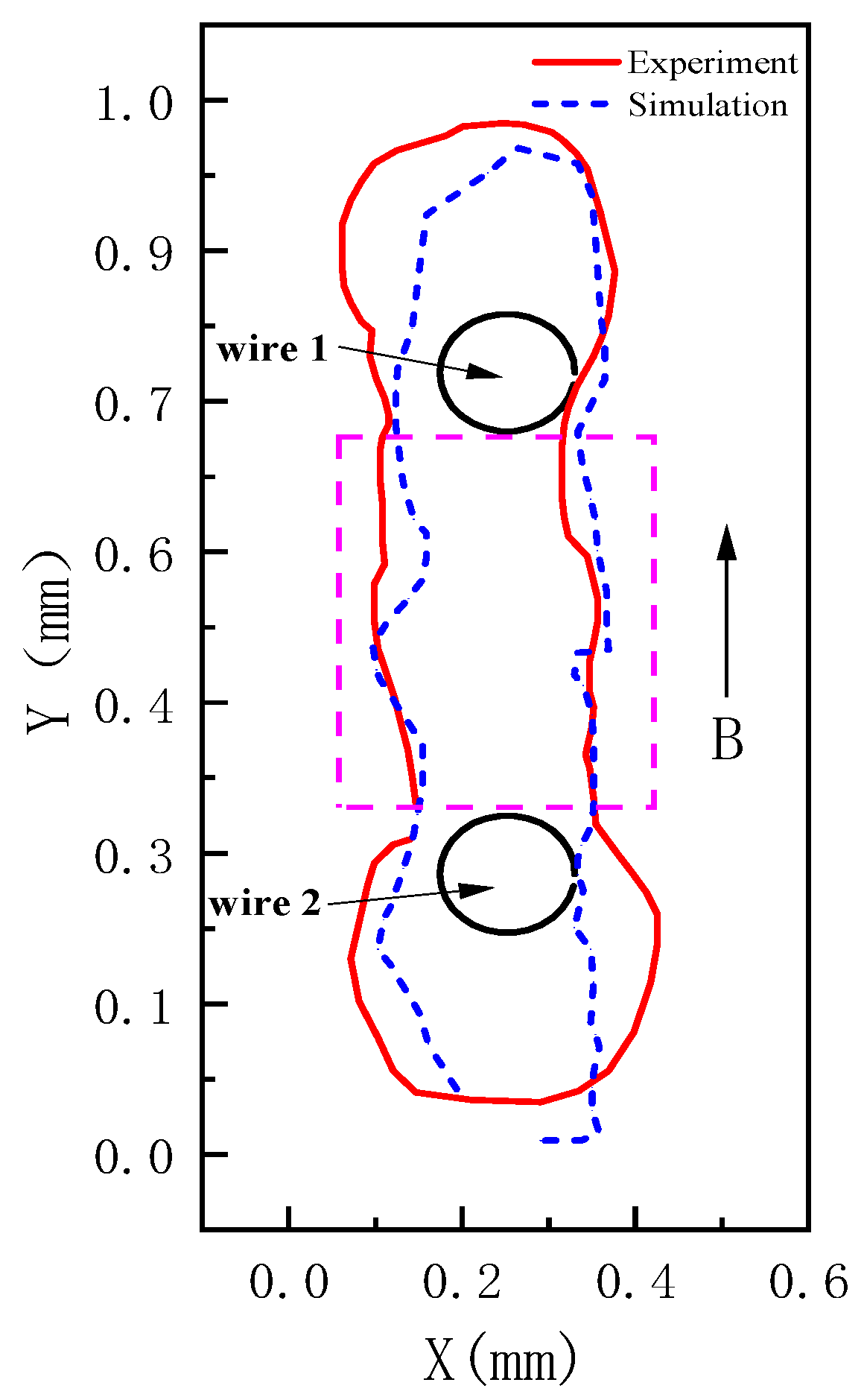

3.2. Experimental Results

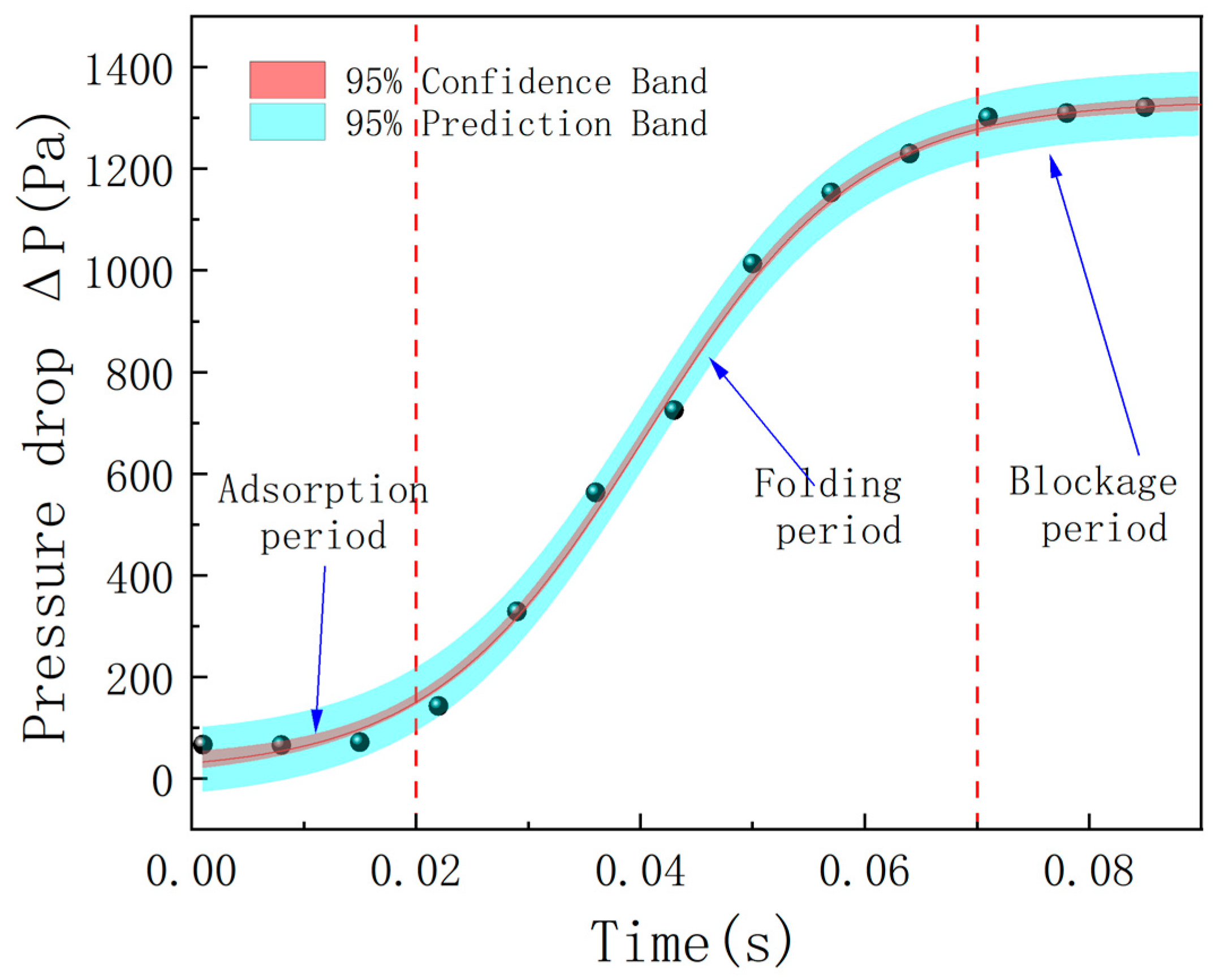

3.2.1. Division and Characteristics of the Separation Stage

- (1)

- Characteristics of the dominant force field: The external magnetic force serves as the core driving force, significantly suppressing the scouring effect of the fluid drag force on the deposited particles under low-flow-rate conditions;

- (2)

- Stability of the spatial structure: The initially deposited body has not yet formed a continuous structure, and the magnetic field distribution between the wire media and the flow channel remains in the original state, without a significant flow-channel contraction effect;

- (3)

- Characteristics of energy dissipation: The particle accumulation process is mainly in the form of discrete point contacts, without triggering large-scale eddy currents or turbulent kinetic energy loss. Due to the coupling effect of the multiple factors mentioned above, the resistance of the flow field in the deposition layer only increases linearly with the deposition mass, resulting in a gentle increase in the pressure drop between the monitoring points. In essence, this stage is the initial construction process of the directional arrangement of particles in a single layer driven by the magnetic field, laying a structural foundation for the agglomeration and aggregation in the subsequent stages.

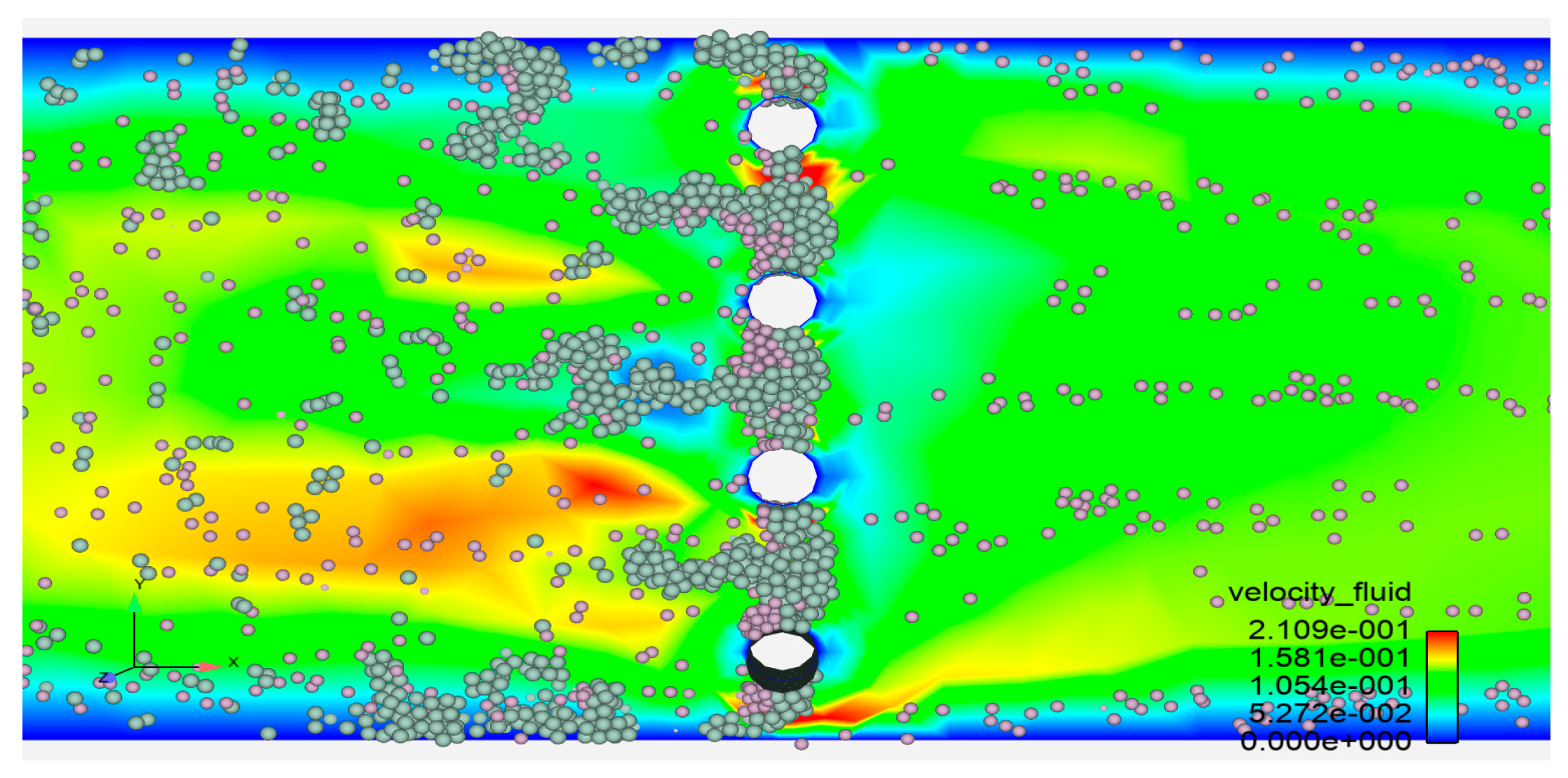

3.2.2. Changes in the Number of Magnetic Particles in Different Regions

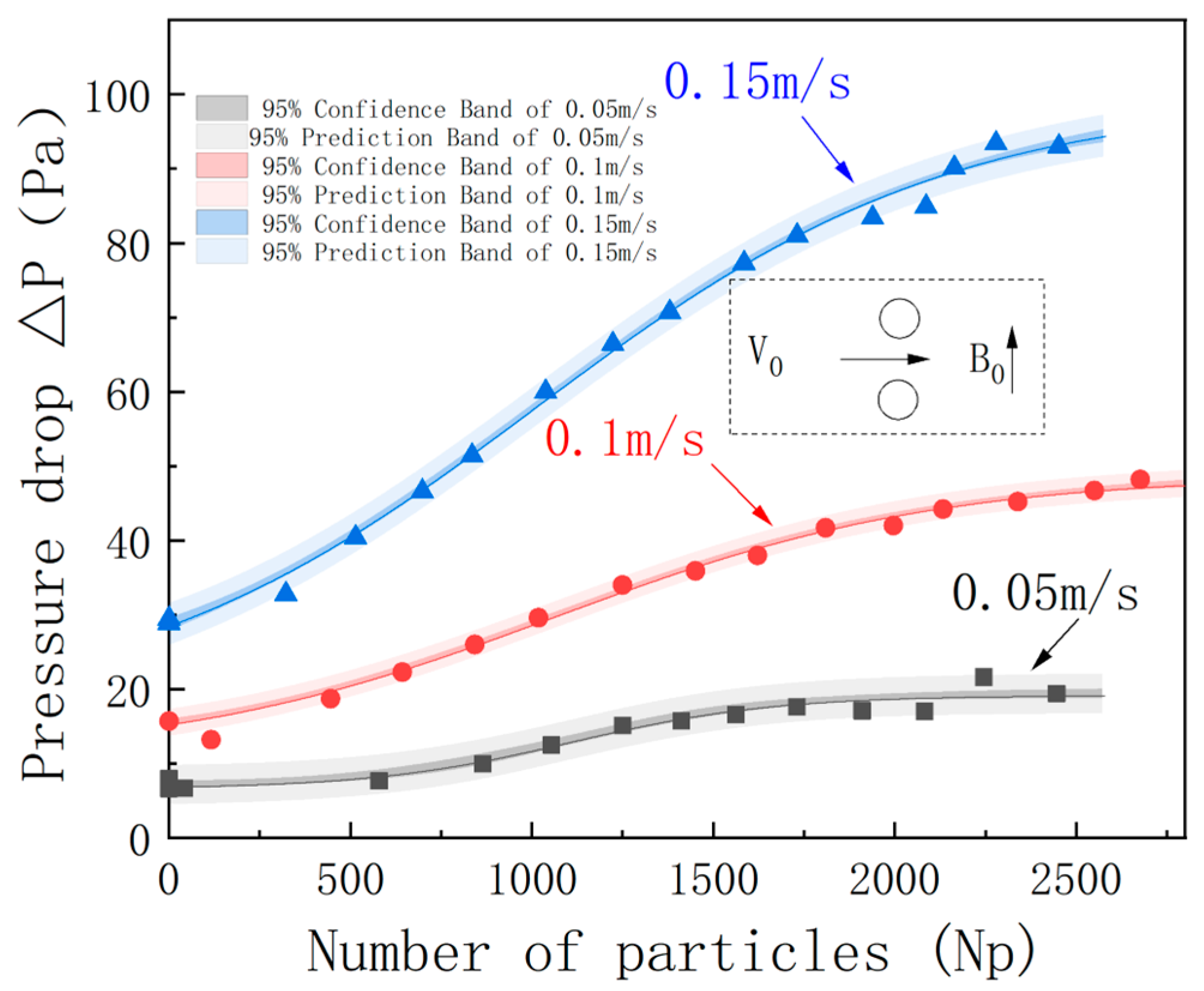

3.2.3. Influences of Separation Parameters on the Separation Process

- (1)

- Feeding Velocity

- (2)

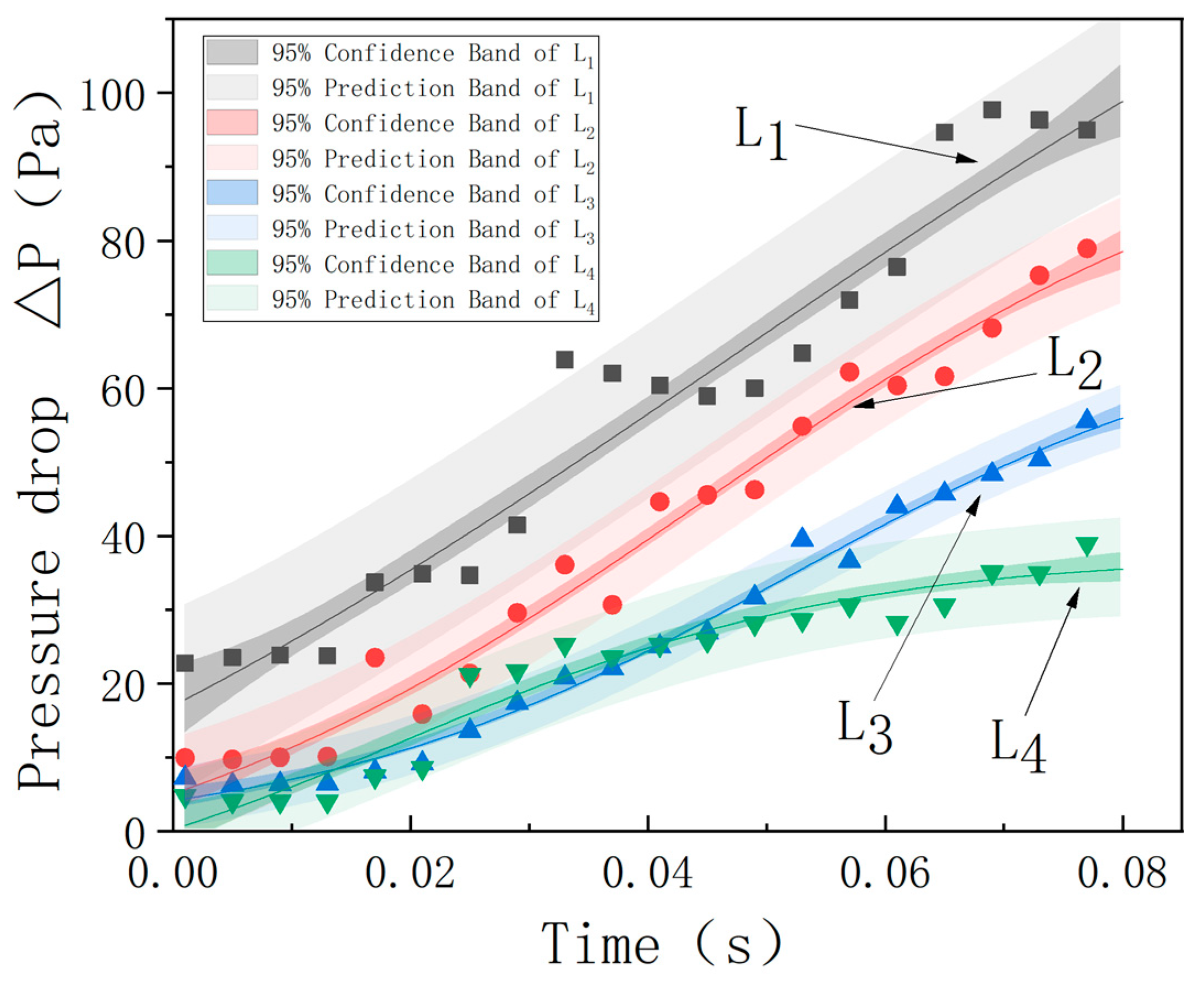

- Filling Ratio

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, S.; Sahoo, H.; Rath, S.S.; Sahu, A.K.; Das, B. Recovery of iron minerals from Indian iron ore slimes using colloidal magnetic coating. Powder Technol. 2015, 269, 38–45. [Google Scholar] [CrossRef]

- Peng, N.; Pan, Q.; Liu, H.; Yang, Z.; Wang, G. Recovery of iron and manganese from iron-bearing manganese residues by multi-step roasting and magnetic separation. Miner. Eng. 2018, 126, 177–183. [Google Scholar] [CrossRef]

- Miura, O.; Tachibana, S. Mercury Removal from Solution by High Gradient Magnetic Separation with Functional Group Modified Magnetic Activated Carbon. IEEE Trans. Appl. Supercond. 2014, 24, 3700904. [Google Scholar] [CrossRef]

- Oka, T.; Takayanagi, Y.; Machida, S.; Ichiju, K.; Fukui, S.; Ogawa, J.; Sato, T.; Ooizumi, M.; Tsujimura, M.; Yokoyama, K. Magnetic Separation for Recovering Ni Compounds from Plating Waste with Use of HTS Bulk Magnets. IEEE Trans. Appl. Supercond. 2016, 26, 3700204. [Google Scholar] [CrossRef]

- Kim, J.E.; Ha, D.W.; Kim, Y.H. Separation of Steel Slag from Landfill Waste for the Purpose of Decontamination Using a Superconducting Magnetic Separation System. IEEE Trans. Appl. Supercond. 2015, 25, 3700404. [Google Scholar] [CrossRef]

- Yamashita, M.; Akai, T.; Murakami, M.; Oki, T. Recovery of LaPO4:Ce,Tb from waste phosphors using high-gradient magnetic separation. Waste Manag. 2018, 79, 164–168. [Google Scholar] [CrossRef]

- Yang, C.; Li, S.; Yang, R.; Bai, J.; Guo, Z. Recovery of silicon powder from kerf loss slurry waste using superconducting high gradient magnetic separation technology. J. Mater. Cycles Waste Manag. 2018, 20, 937–945. [Google Scholar] [CrossRef]

- Ahmed, N.; Li, X.; Xue, Z.; Ren, X.; Huang, H.; Chen, L. Enhancing PHGMS performance for recovery of ultra-fine ilmenite from tailings. Physicochem. Probl. Miner. Process. 2024, 60, 189617. [Google Scholar] [CrossRef]

- Chen, H.; Ebner, A.D.; Kaminski, M.D.; Rosengart, A.J.; Ritter, J.A. Analysis of magnetic drug carrier particle capture by a magnetizable intravascular stent—2: Parametric study with multi-wire two-dimensional model. J. Magn. Magn. Mater. 2005, 293, 616–632. [Google Scholar] [CrossRef]

- Marshall, J.S. Discrete-element modeling of particulate aerosol flows. J. Comput. Phys. 2009, 228, 1541–1561. [Google Scholar] [CrossRef]

- Avilés, M.O.; Ebner, A.D.; Chen, H.; Rosengart, A.J.; Kaminski, M.D.; Ritter, J.A. Theoretical analysis of a transdermal ferromagnetic implant for retention of magnetic drug carrier particles. J. Magn. Magn. Mater. 2005, 293, 605–615. [Google Scholar] [CrossRef]

- Misael OAvilés Ebner, A.D.; Ritter, J.A. Ferromagnetic seeding for the magnetic targeting of drugs and radiation in capillary beds. J. Magn. Magn. Mater. 2007, 310, 131–144. [Google Scholar] [CrossRef]

- Larimi, M.M.; Ramiar, A.; Ranjbar, A.A. Numerical simulation of magnetic nanoparticles targeting in a bifurcation vessel. J. Magn. Magn. Mater. 2014, 362, 58–71. [Google Scholar] [CrossRef]

- Haverkort, J.W.; Kenjereš, S.; Kleijn, C.R. Computational Simulations of Magnetic Particle Capture in Arterial Flows. Ann. Biomed. Eng. 2009, 37, 2436–2448. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhou, Y.; Tan, J.; Xu, J.; Yang, J.; Liu, Y. Computational modeling of magnetic nanoparticle targeting to stent surface under high gradient field. Comput. Mech. 2014, 53, 403–412. [Google Scholar] [CrossRef]

- Cregg, P.J.; Murphy, K.; Mardinoglu, A. Inclusion of interactions in mathematical modelling of implant assisted magnetic drug targeting. Appl. Math. Model. 2012, 36, 1–34. [Google Scholar] [CrossRef]

- Hournkumnuard, K.; Natenapit, M. Magnetic drug targeting by ferromagnetic microwires implanted within blood vessels. Med. Phys. 2013, 40, 062302. [Google Scholar] [CrossRef]

- Sharma, S.; Singh, U.; Katiyar, V.K. Modeling and in vitro study on capture efficiency of magnetic nanoparticles transported in an implant-assisted cylindrical tube under magnetic field. Microfluid. Nanofluidics 2015, 19, 1061–1070. [Google Scholar] [CrossRef]

- McFarlane, J.; Weber, C.; Wiechert, A.; Yiacoumi, S.; Tsouris, C. High-gradient magnetic separation of colloidal uranium oxide particles from soil components in aqueous suspensions. Colloids Surf. C Environ. Asp. 2024, 2, 100023. [Google Scholar] [CrossRef]

- Okada, H.; Mitsuhashi, K.; Ohara, T.; Whitby, E.R.; Wada, H. Computational Fluid Dynamics Simulation of High Gradient Magnetic Separation. Sep. Sci. Technol. 2005, 40, 1567–1584. [Google Scholar] [CrossRef]

- Watson, J.H.P. Magnetic filtration. J. Appl. Phys. 1973, 44, 4209–4213. [Google Scholar] [CrossRef]

- Uchiyama, S.; Takayasu, M.; Kurinobu, S. Performance of parallel-stream-type magnetic filter for high gradient magnetic separation. Trans. Inst. Electr. Eng. Jpn. 1977, 97, 75–82. [Google Scholar] [CrossRef]

- Uchiyama, S.; Kondo, S.; Takayasu, M.; Eguchi, I. Performance of parallel stream type magnetic filter for HGMS. IEEE Trans. Magn. 1976, 12, 895–897. [Google Scholar] [CrossRef]

- Uchiyama, S.; Kurinobu, S.; Kumazawa, M.; Takayasu, M. Magnetic particle buildup processes in parallel stream type HGMS filter. IEEE Trans. Magn. 1977, 13, 1490–1492. [Google Scholar] [CrossRef]

- Lawson, W.F.; Simons, W.H.; Treat, R.P. The dynamics of a particle attracted by a magnetized wire. J. Appl. Phy. 1977, 48, 3213–3224. [Google Scholar] [CrossRef]

- Gerber, R. Theory of particle capture in axial filters for high gradient magnetic separation. J. Phys. D Appl. Phys. 2001, 11, 2119. [Google Scholar] [CrossRef]

- Schewe, H.; Takayasu, M.; Friedlaender, F. Observation of particle trajectories in an HGMS single-wire system. IEEE Trans. Magn. 1980, 16, 149–154. [Google Scholar] [CrossRef]

- Abbasov, T.; Gebakan, V.; Karada, T. Particle capture modeling for an axial magnetic filter with a bounded non-Newtonian flow field. Powder Technol. 2015, 291, 223–228. [Google Scholar] [CrossRef]

- Kksal, M.; Abbasov, T.; Herdem, S. Mathematical Modeling of the Magnetic Filtration Processes. Int. J. Appl. Electromagn. Mech. 2003, 18, 227–234. [Google Scholar] [CrossRef]

- Li, Z.; Watson, J.H.P. A study of vortex magnetic separation (VMS) with a high-speed video system. Miner. Eng. 1994, 7, 759–768. [Google Scholar] [CrossRef]

- Zn, L.I.; Watson, J.H.P. Vortex magnetic separation (VMS). IEEE Trans. Magn. 1994, 30, 4662–4664. [Google Scholar] [CrossRef]

- Svoboda, J. Vortex magnetic separation: An illusion or reality. Miner. Eng. 1995, 8, 571–573. [Google Scholar] [CrossRef]

- Hournkumnuard, K.; Chantrapornchai, C. Parallel simulation of concentration dynamics of nano-particles in High Gradient Magnetic Separation. Simul. Model. Pract. Theory 2011, 19, 847–871. [Google Scholar] [CrossRef]

- Mishra, S.M.D.K. A preliminary investigation into magnetic separation process using CFD. Miner. Eng. 2011, 24, 1651–1657. [Google Scholar] [CrossRef]

- Khashan, S.A.; Furlani, E. CFD-based, Lagrangian-Eulerian coupling approach for magnetophoretic particle capture. In Proceedings of the Micro & Nano Flows Conference, Thessaloniki, Greece, 22–24 August 2011. [Google Scholar]

- Chen, F.; Smith, K.A.; Hatton, T.A. Alan Hatton.A dynamic buildup growth model for magnetic particle accumulation on single wires in high-gradient magnetic separation. Aiche J. 2012, 58, 2865–2874. [Google Scholar] [CrossRef]

- Bilgili, H.; Kele, C.; Abbasov, T. Modeling of the Particle Build-Up Evolution on a Single-Wire Magnetic Capture from Axial Stream Flow. Magnetochemistry 2022, 8, 15. [Google Scholar] [CrossRef]

- Lindner, J.; Menzel, K.; Nirschl, H. Simulation of magnetic suspensions for HGMS using CFD, FEM and DEM modeling. Comput. Chem. Eng. 2013, 54, 111–121. [Google Scholar] [CrossRef]

- Cowen, C.; Friedlaender, F. Single wire model of high gradient magnetic separation processes III. IEEE Trans. Magn. 1977, 12, 466–470. [Google Scholar] [CrossRef]

- Bai, H.; Qian, X.; Fan, J.; Shi, Y.; Duo, Y.; Guo, C.; Wang, X. Theoretical Model of Single Fiber Efficiency and the Effect of Microstructure on Fibrous Filtration Performance: A Review. Ind. Eng. Chem. Res. 2020, 60, 3–36. [Google Scholar] [CrossRef]

- Tao, R.; Yang, M.; Li, S. Effect of adhesion on clogging of microparticles in fiber filtration by DEM-CFD simulation. Powder Technol. 2020, 360, 289–300. [Google Scholar] [CrossRef]

- Wang, X.; Shen, Z.; Hu, Y.; Liang, G. Dynamic Coupling Model of the Magnetic Separation Process Based on FEM, CFD, and DEM. Processes 2025, 13, 1303. [Google Scholar] [CrossRef]

- Satoh, A.; Coverdale, G.N.; Chantrell, R.W. Stokesian Dynamics Simulations of Ferromagnetic Colloidal Dispersions Subjected to a Sinusoidal Shear Flow. J. Colloid Interface 2000, 231, 238–246. [Google Scholar] [CrossRef]

| Material Property | Value | Unit |

|---|---|---|

| Particle density | 3720 | Kg/m3 |

| Particle Poisson ratio | 0.3 | - |

| Particle shear modulus | 6.1 × 1010 | Pa |

| Static friction coefficient between particles | 0.4 | - |

| Friction coefficient between particle and wall | 0.2 | - |

| Time step | 5.0 × 10−9 | s |

| Calculation time | 5.0 × 10−3 | s |

| Number | Spacing/mm | Filling Ratio/% |

|---|---|---|

| L1 | 0.6 | 1 |

| L2 | 0.5 | 2 |

| L3 | 0.4 | 3 |

| L4 | 0.3 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Hu, Y.; Hao, Y.; Shen, Z.; Liang, G.; Zhang, M. Simulation of Dynamic Particle Trapping and Accumulation in HGMS Based on FEM-CFD-DEM Coupling Approach. Processes 2025, 13, 2391. https://doi.org/10.3390/pr13082391

Wang X, Hu Y, Hao Y, Shen Z, Liang G, Zhang M. Simulation of Dynamic Particle Trapping and Accumulation in HGMS Based on FEM-CFD-DEM Coupling Approach. Processes. 2025; 13(8):2391. https://doi.org/10.3390/pr13082391

Chicago/Turabian StyleWang, Xiaoming, Yonghui Hu, Yefei Hao, Zhengchang Shen, Guodong Liang, and Ming Zhang. 2025. "Simulation of Dynamic Particle Trapping and Accumulation in HGMS Based on FEM-CFD-DEM Coupling Approach" Processes 13, no. 8: 2391. https://doi.org/10.3390/pr13082391

APA StyleWang, X., Hu, Y., Hao, Y., Shen, Z., Liang, G., & Zhang, M. (2025). Simulation of Dynamic Particle Trapping and Accumulation in HGMS Based on FEM-CFD-DEM Coupling Approach. Processes, 13(8), 2391. https://doi.org/10.3390/pr13082391