Research on Energy Saving, Low-Cost and High-Quality Cutting Parameter Optimization Based on Multi-Objective Egret Swarm Algorithm

Abstract

1. Introduction

2. Multi-Objective Optimization Model Based on Energy Saving, Low-Cost and High Quality

2.1. Variables

2.2. Objectives

2.3. Constraints

3. Case Study Based on the Multi-Objective Egret Swarm Optimization Algorithm

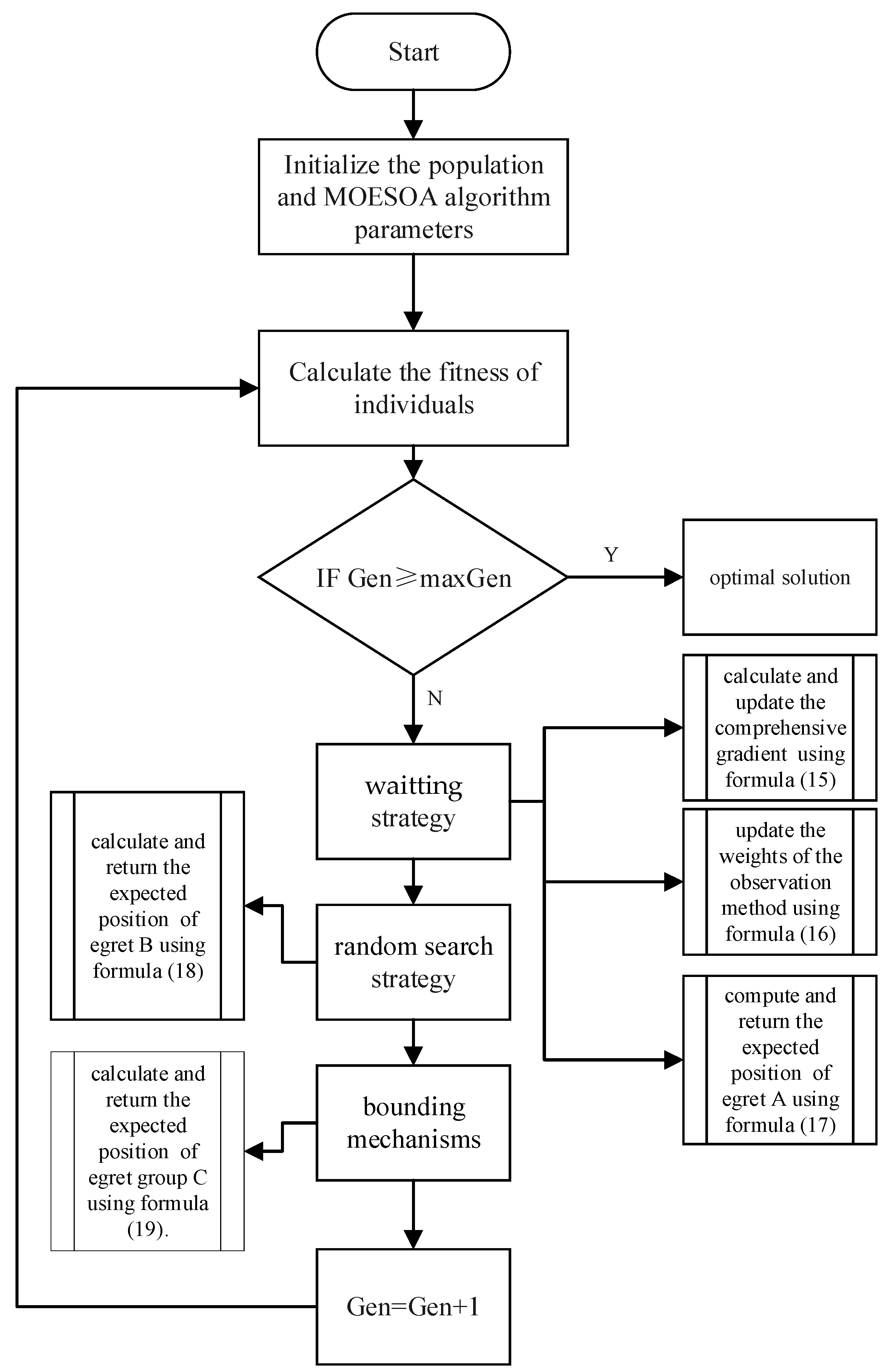

3.1. The Multi-Objective Egret Swarm Optimization Algorithm

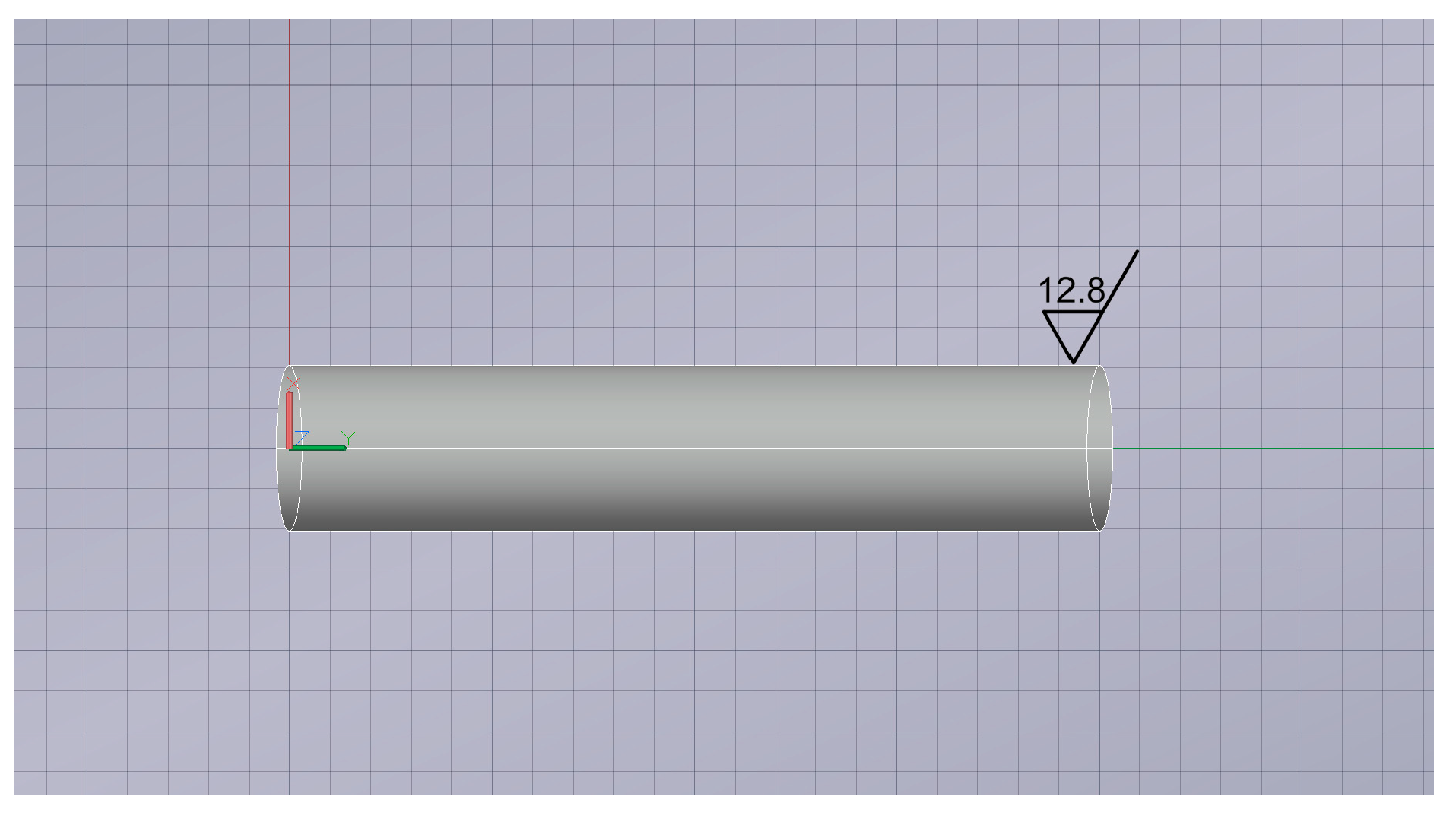

3.2. Case Analysis

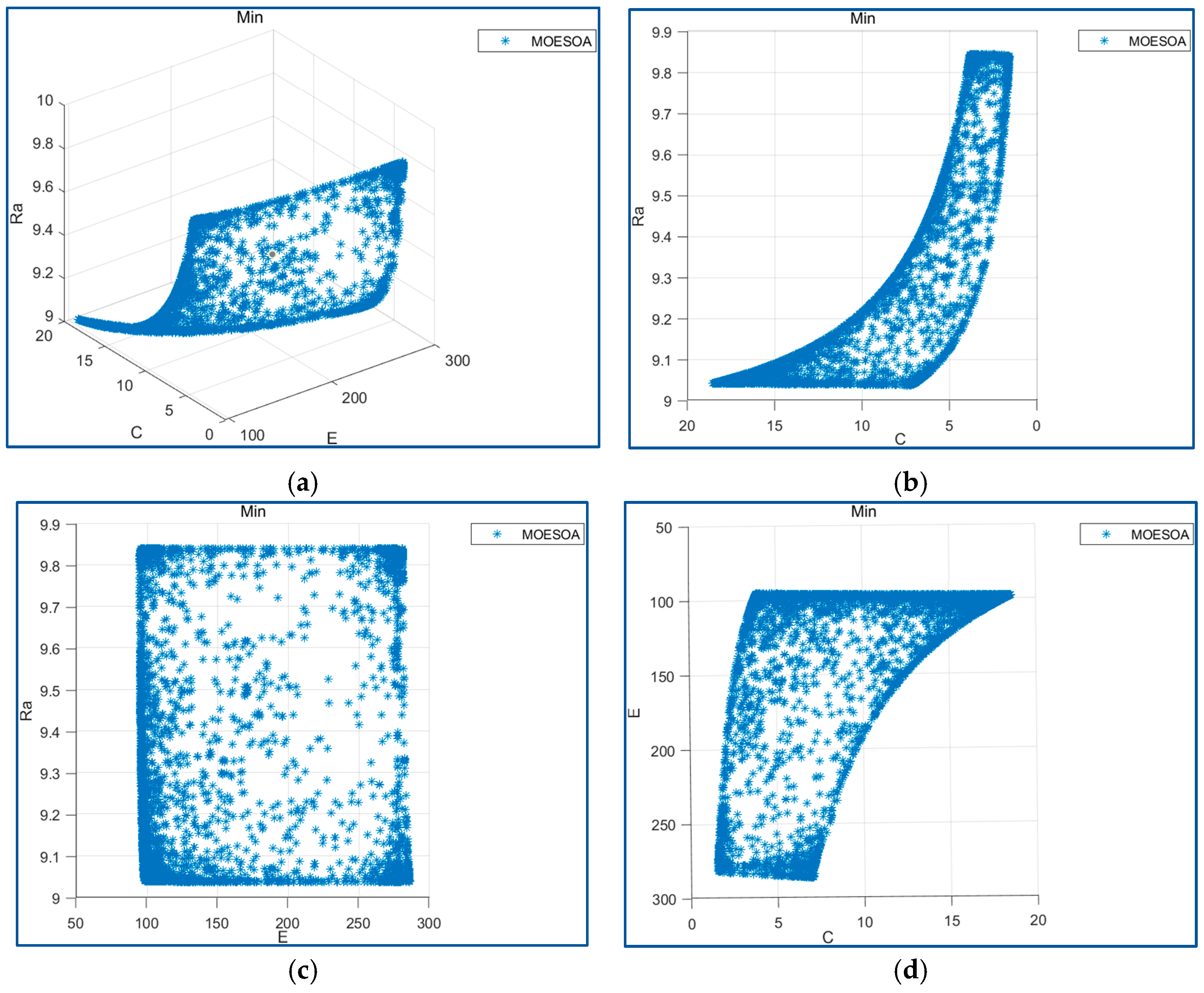

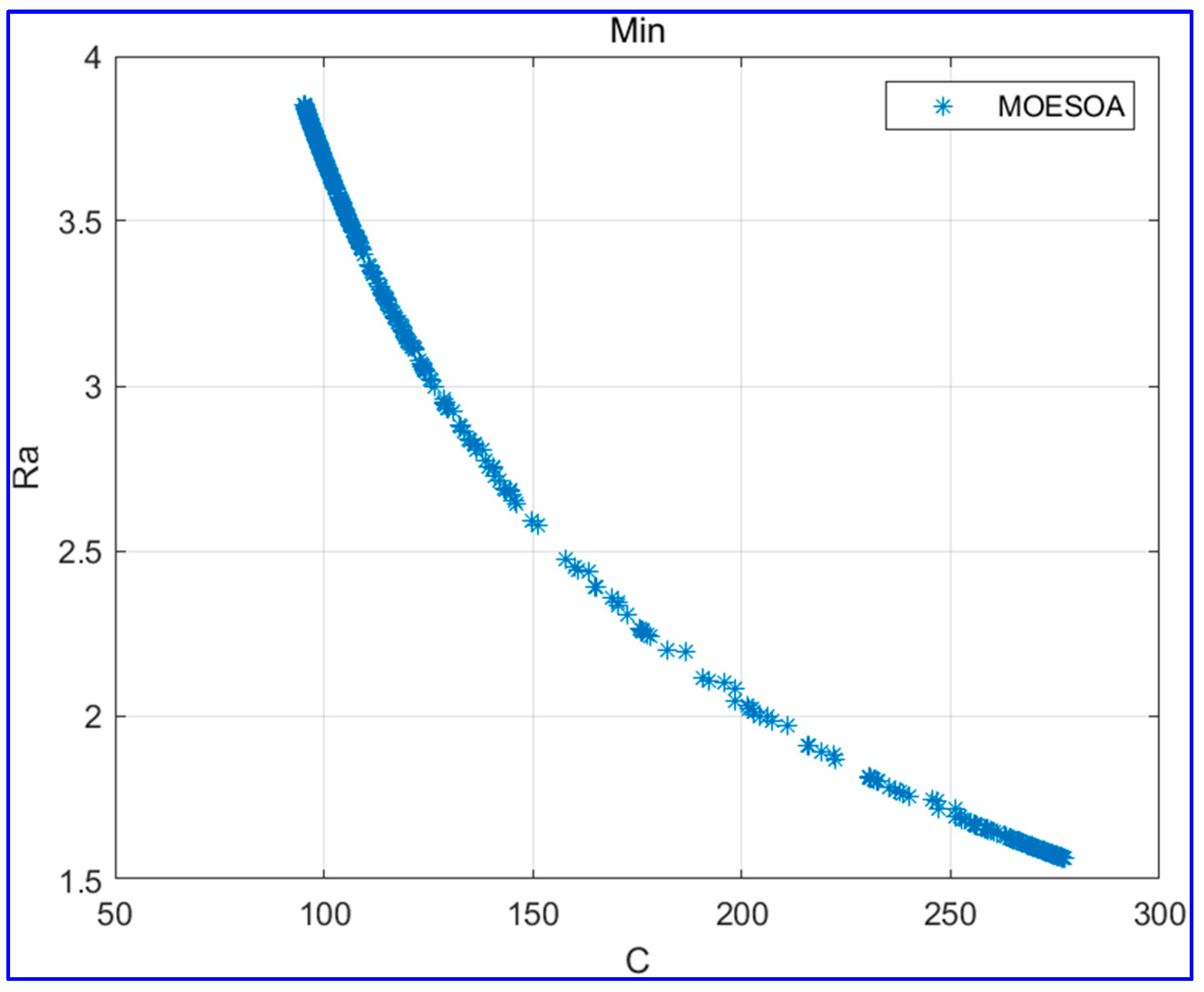

3.3. Analysis of Simulation Results Based on MOESOA

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zheng, J.; Jia, R.; Hu, X.; Qi, T.; Pan, Q.; Zhu, J.; Qiu, X.; Xia, Z.; Xv, B.; Deng, C. Regulating cutting fluid parameters for optimal energy and economic performance: Methods for efficient and Low-Energy electrical machining. Energy Convers. Manag. 2024, 314, 118707. [Google Scholar] [CrossRef]

- Nasseriyan, P.; Jafari, S.; Khajehpour, H.; Edalati, S. Toward a green steel production powered by a hybrid renewable energy system: Techno-economic and environmental assessment. Energy Convers. Manag. 2025, 332, 119716. [Google Scholar] [CrossRef]

- Li, T.; Kong, L.L.; Zhang, H.-C.; Iqbal, A. Recent research and development of typical cutting machine tool’s energy consumption model. J. Mech. Eng. 2014, 50, 102–111. [Google Scholar] [CrossRef]

- Wang, W.; Sun, J.; Yan, S.; Yuan, Y.; Xiao, T.; Chen, B.; Du, T.; Na, H. Multi-objective optimization analysis of on-demand design in multi-source heating system for low carbon development. Energy 2025, 324, 135917. [Google Scholar] [CrossRef]

- Sun, S.; Gao, Z.; Qiao, Y.; Wang, J. Research on thermal characteristic modeling and cooling system parameter optimization of high-speed motorized spindle. Manuf. Technol. Mach. Tool 2023, 10, 90–97. [Google Scholar] [CrossRef]

- Li, G.; Bai, X.; Wang, L.; Li, C.; Li, Y. Key technologies and development trends of multi-axis tool grinding software. China Mech. Eng. 2022, 33, 943–951. [Google Scholar]

- Lv, Q.; Wang, L.; Li, Z.; Song, W.; Bu, F.; Wang, L. Robust optimization for integrated production and energy scheduling in low-carbon factories with captive power plants under decision-dependent uncertainty. Appl. Energy 2025, 379, 124827. [Google Scholar] [CrossRef]

- Xing, J.L. Application of digital twin in mechanical processing technology and optimization of cutting parameters. Intern. Combust. Engine Parts 2024, 10, 107–109. [Google Scholar] [CrossRef]

- Yang, W.Y.; Li, B.T.; Chen, J.X. Consideration of tool material selection in the fuzzy optimization of CNC machining process parameters. Mach. China 2023, 28, 34–37. [Google Scholar]

- Liu, Z. Optimization analysis of process parameters for NC turning and milling. Mod. Manuf. Technol. Equip. 2022, 58, 142–144. [Google Scholar]

- Zhou, C.; Jiang, Z.H.; Zhang, Y.; Shao, Z.W.; Wang, D.Y. Influence of cutting parameters on cutting force of 34CrNi3Mo high strength steel processed by plunge milling. Tool Eng. 2022, 56, 111–114. [Google Scholar]

- Zhao, S.Z. Simulation Analysis of Steel Micro-Cutting Process and Optimization of Cutting Parameters from Macro and Micro Angles. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2022. Available online: https://kns.cnki.net/kcms2/article/abstract?v=Qc2UN8NgW0vHOK4GSuJhnno_9X1Y6iyL1EfEGY2pnTILNZKphehcdcOXd8l7qp9hAMDbLb6xKTtkQsAU0AkEqMRNBZrzZ00LF5Rd-RQBC7XhaTuR7iVhKW8BdV_0mDZvDse2mKe5KYxqzWZIN2j-NUZsvCY_r28NgLwxfXqUL50=&uniplatform=NZKPT (accessed on 1 March 2025).

- Wang, L.P.; Kong, X.Y.; Yu, G. Motor servo control parameter tuning for parallel and hybrid machine tools based on a genetic algorithm. J. Tsinghua Univ. Sci. Technol. 2021, 61, 1106–1114. [Google Scholar]

- Sel, A.; Gurkan, M.E.; Hamzaday, A. Energy-aware production lot-sizing and parallel machine scheduling with the product-specific machining tools and power requirements. Comput. Ind. Eng. 2024, 196, 110503. [Google Scholar] [CrossRef]

- Chen, M.C. Optimization machining economics models of turning operations using the scatter search approach. Int. J. Prod. Res. 2004, 42, 2611–2625. [Google Scholar] [CrossRef]

- Gontarz, S.; Patyk, R.; Bohdal, L.; Jackiewicz, D. Multiparameter optimization of mechanical cutting process of grain-oriented silicon steel. Acta Phys. Pol. A 2020, 137, 930–932. [Google Scholar] [CrossRef]

- Zhao, H.; Cao, Y.; Huang, L.; Zeng, M.; Meng, Z.; Lei, Y. Multi-objective optimization of cutting parameters of ZL205A aluminium alloy based on genetic algorithm. Ordnance Mater. Sci. Eng. 2023, 46, 58–65. [Google Scholar]

- Sarwade, J.M.; Bankar, S.; Janrao, S.; Sakure, K.; Patil, R.; Bokefode, S.; Kulal, N. A novel approach for iris recognition system using genetic algorithm. J. Artif. Intell. Technol. 2024, 4, 9–17. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, L.; Zhang, C.; Li, J.; He, K. Optimization of cutting parameters of CNC lathe using black hole-continuous ant colony algorithm. Mech. Sci. Technol. Aerosp. Eng. 2023, 42, 1705–1711. [Google Scholar]

- Yang, A.; Fang, T.; Serrano, E.A.; Liu, B.; Liu, F.; Chen, Z. Charging Pile Fault Prediction Model Based on GRU Network and WOA. J. Artif. Intell. Technol. 2025, 5, 57–65. [Google Scholar] [CrossRef]

- Xu, J.Y.; Zhong, G.Y.; Yang, S.F. Improved NSGA-II algorithm and its application in optimization of machining parameters. Comput. Eng. Appl. 2017, 53, 227–234. [Google Scholar]

- Chen, Z.; Francis, A.; Li, S.; Liao, B.; Xiao, D.; Ha, T.T.; Li, J.; Ding, L.; Cao, X. Egret swarm optimization algorithm: An evolutionary computation approach for model free optimization. Biomimetics 2022, 7, 144. [Google Scholar] [CrossRef] [PubMed]

- Kordonowy, D.N. A Power Assessment of Machining Tools; Massachusetts Institute of Technology: Cambridge, MA, USA, 2003. [Google Scholar]

- Yin, R.X.; Ke, J. Optimization of milling cutting parameters under carbon efficiency target. Mach. Des. Manuf. 2022, 1888, 012008. [Google Scholar] [CrossRef]

- Xu, X.; Li, F.; Kong, W.; Yu, W.; Zhou, J.; Zhou, L. Energy consumptions modeling and simulation of machine tools based on vericut. Chin. Mech. Eng. Soc. J. 2018, 29, 2533–2538. [Google Scholar]

- Zhang, H.; Li, S.; Yan, W.; Jiang, Z.; Zhu, S.; Ma, F. A data and model hybrid driven method for machining energy consumption prediction of boxy parts. Chin. Mech. Eng. Soc. J. 2023, 59, 97–108. [Google Scholar] [CrossRef]

- Han, J.; Xiong, F.S.; Yao, S.; Xu, R. Study on the energy consumption evaluation of nc machining tool paths exergy loss method. Mach. Des. Manuf. 2024, 118–124. [Google Scholar]

- Liu, F.; Liu, S. Multi-period energy model of electro-mechanical main driving system during the service process of machine tools. Chin. Mech. Eng. Soc. J. 2012, 48, 9. [Google Scholar] [CrossRef]

- Li, C.B.; Cao, H.J.; Liu, F. Key Technologies and Applications of Green Manufacturing in Machine Tools; China Mechine Press: Beijing, China, 2022. [Google Scholar]

- Wu, D.; Sotnikov, D.; Haajari, M.; Salmi, T. Minimizing conductor consumption in high-field hts solenoid design using adaptive ANN-based optimization algorithm. IEEE Trans. Appl. Supercond. 2025, 35, 4603505. [Google Scholar] [CrossRef]

- Hamdipour, A.; Basiri, A.; Zaare, M.; Mirjalili, S. Artificial rabbit’s optimization algorithm with automatically DBSCAN clustering algorithm to similarity agent update for features selection problems. J. Supercomput. 2024, 81, 150. [Google Scholar] [CrossRef]

- Buchibabu, P.; Somlal, J. Sustainable energy management in microgrids: A multi-objective approach for stochastic load and intermittent renewable energy resources. Electr. Eng. 2025, 107, 285–299. [Google Scholar] [CrossRef]

- Kulkarni, P.P.; Ghawghawe, N.D. Hybrid DA-PSO approach for optimal location and parameter settings for TCSC controller in power system. IET Gener. Transm. Distrib. 2020, 14, 1222–1232. [Google Scholar] [CrossRef]

- Wei, P.; Shang, M.; Zhou, J.; Shi, X. Efficient adaptive learning rate for convolutional neural network based on quadratic interpolation egret swarm optimization algorithm. Heliyon 2024, 10, e37814. [Google Scholar] [CrossRef] [PubMed]

- Simon, J.; Kapileswar, N.; Padmavathi, B.; Devi, K.D.; Kumar, P.P. Optimization of node deployment in underwater internet of things using novel adaptive long short-term memory-based egret swarm optimization algorithm. Int. J. Commun. Syst. 2024, 37, 22. [Google Scholar] [CrossRef]

- Ansho, P.M.; Nisha, M.G. Egret swarm optimized distributed power flow controller for power quality enhancement in grid connected hybrid system. J. Electr. Eng. Technol. 2024, 19, 2047–2057. [Google Scholar]

- Yuan, B.R.; Nie, Z.R.; Di, X.H.; Zuo, T.Y. Life cycle inventories of fossil fuels in China (II): Final life cycle inventories. Modern Chem. Ind. 2006, 26, 59–61. [Google Scholar]

- Kalpakjian, S.; Schmid, S.R. Manufacturing Engineering and Technology: Machining; Tsinghua University Press: Beijing, China, 2006. [Google Scholar]

- Deb, K.; Datta, R. Hybrid evolutionary multi-objective optimization and analysis of machining operations. Eng. Optim. 2012, 44, 685–706. [Google Scholar] [CrossRef]

| Rear Angle | Main Cutting Edge Angle | Secondary Cutting Edge Angle | Cutting Edge Inclination Angle | Chamfer Radius |

|---|---|---|---|---|

| 10° | 75° | 45° | 5° | 1 mm |

| 1.023 | 0.92 | 1 | 1 | 2795 | 1 | 0.75 | −0.15 | 2.13 | 1 | 900 |

| Experimental Schemes | Cutting Depth (mm) | Feed Rate (mm/r) | Cutting Speed (m/min) | Energy Consumption (kJ) | Manufacturing Cost (dollar) | Surface Roughness (μm) |

|---|---|---|---|---|---|---|

| 1 | 2.5 | 0.75 | 45 | 95.33 | 3.85 | 9.84 |

| 2 | 2.5 | 0.75 | 120 | 277.26 | 1.56 | 9.84 |

| 3 | 4 | 0.5 | 90 | 203.54 | 2.94 | 9.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Xiao, Y.; Zhu, X. Research on Energy Saving, Low-Cost and High-Quality Cutting Parameter Optimization Based on Multi-Objective Egret Swarm Algorithm. Processes 2025, 13, 2390. https://doi.org/10.3390/pr13082390

Zheng Y, Xiao Y, Zhu X. Research on Energy Saving, Low-Cost and High-Quality Cutting Parameter Optimization Based on Multi-Objective Egret Swarm Algorithm. Processes. 2025; 13(8):2390. https://doi.org/10.3390/pr13082390

Chicago/Turabian StyleZheng, Yanfang, Yongmao Xiao, and Xiaoyong Zhu. 2025. "Research on Energy Saving, Low-Cost and High-Quality Cutting Parameter Optimization Based on Multi-Objective Egret Swarm Algorithm" Processes 13, no. 8: 2390. https://doi.org/10.3390/pr13082390

APA StyleZheng, Y., Xiao, Y., & Zhu, X. (2025). Research on Energy Saving, Low-Cost and High-Quality Cutting Parameter Optimization Based on Multi-Objective Egret Swarm Algorithm. Processes, 13(8), 2390. https://doi.org/10.3390/pr13082390