Enhancing Leanness Philosophies with Industry 5.0 Enables Reduction of Sustainable Supply Chain Risks: A Case Study of a New Energy Battery Manufacturer

Abstract

1. Introduction

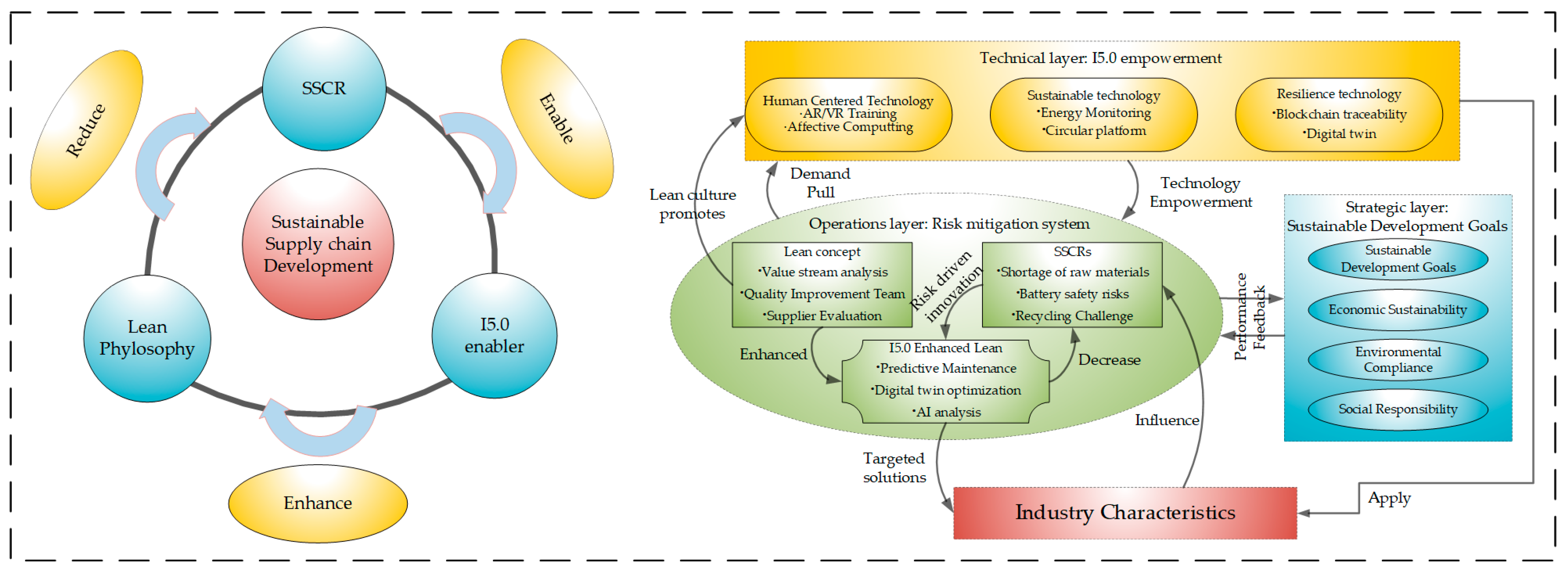

- I5.0 will be the next industrial revolution, and its improvement measures can enhance the role of leanness philosophies.

- Many different industries, including the industrial sector, have been positively influenced by leanness philosophies, which can effectively reduce the sustainability risks of enterprise supply chains.

- SSCRs will undergo changes in quantity and nature due to influences from society, economy, and the environment, which will also drive the progress of I5.0.

- What are the key sustainable risks, leanness philosophies, and I5.0 enablers in the supply chain of new energy battery enterprises?

- How can quality function deployment be integrated with multi-criteria decision-making to connect the relationships among the three sets of variables and provide decision support for SSCRs in new energy battery enterprises?

- How can new energy battery enterprises effectively reduce SSCRs by utilizing the proposed framework and leveraging I5.0 enablers to strengthen leanness philosophies?

2. Literature Review

2.1. SSCRs

2.2. Leanness Philosophy and SSCR

2.3. I5.0 and Leanness

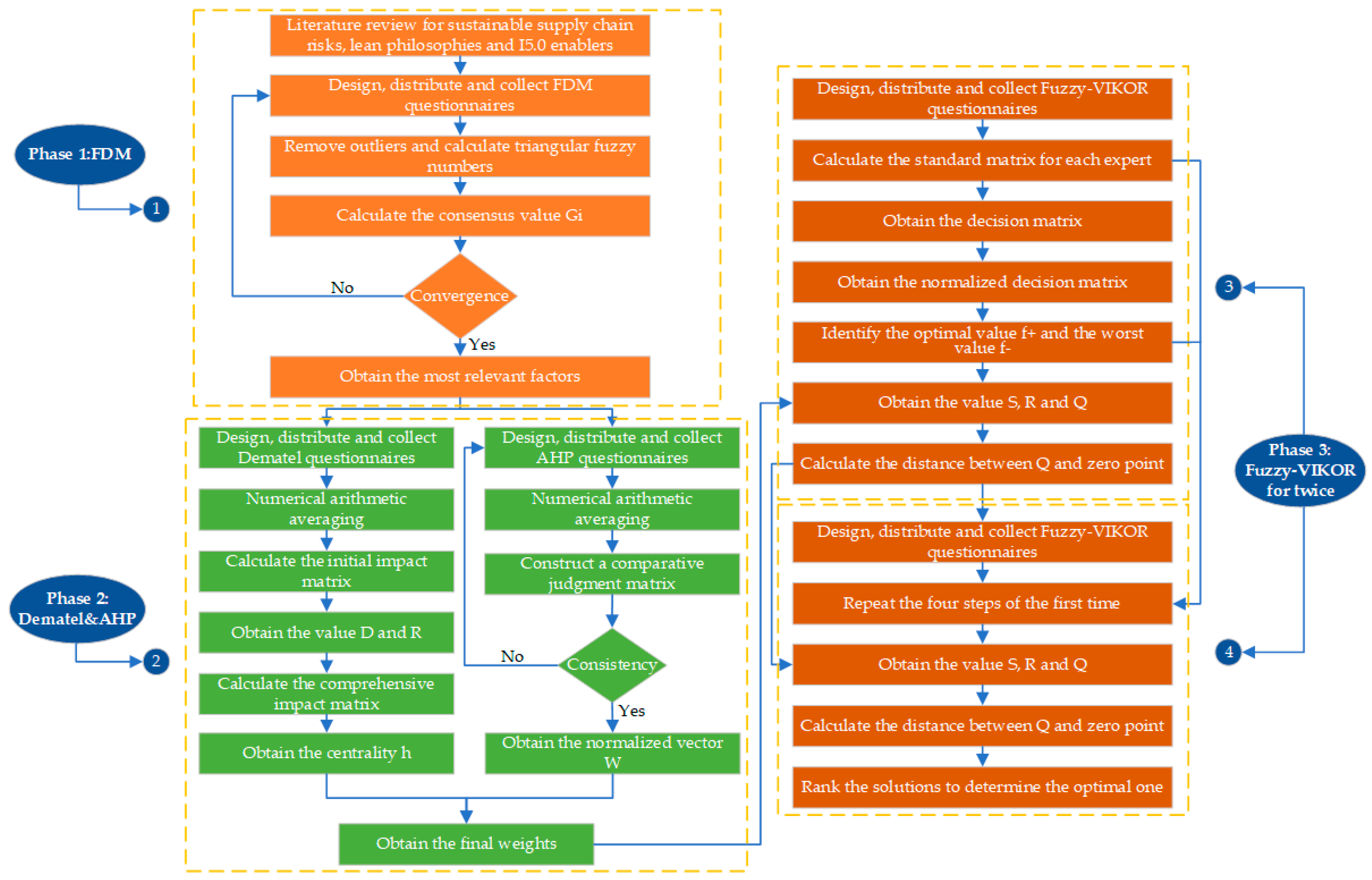

3. Method

3.1. Two HoQs

3.2. Analytical Framework

3.2.1. FDM

3.2.2. DEMATEL

3.2.3. AHP

3.2.4. Calculation of Comprehensive Weight

3.3. Fuzzy VIKOR

4. Case Study

4.1. Key Factors

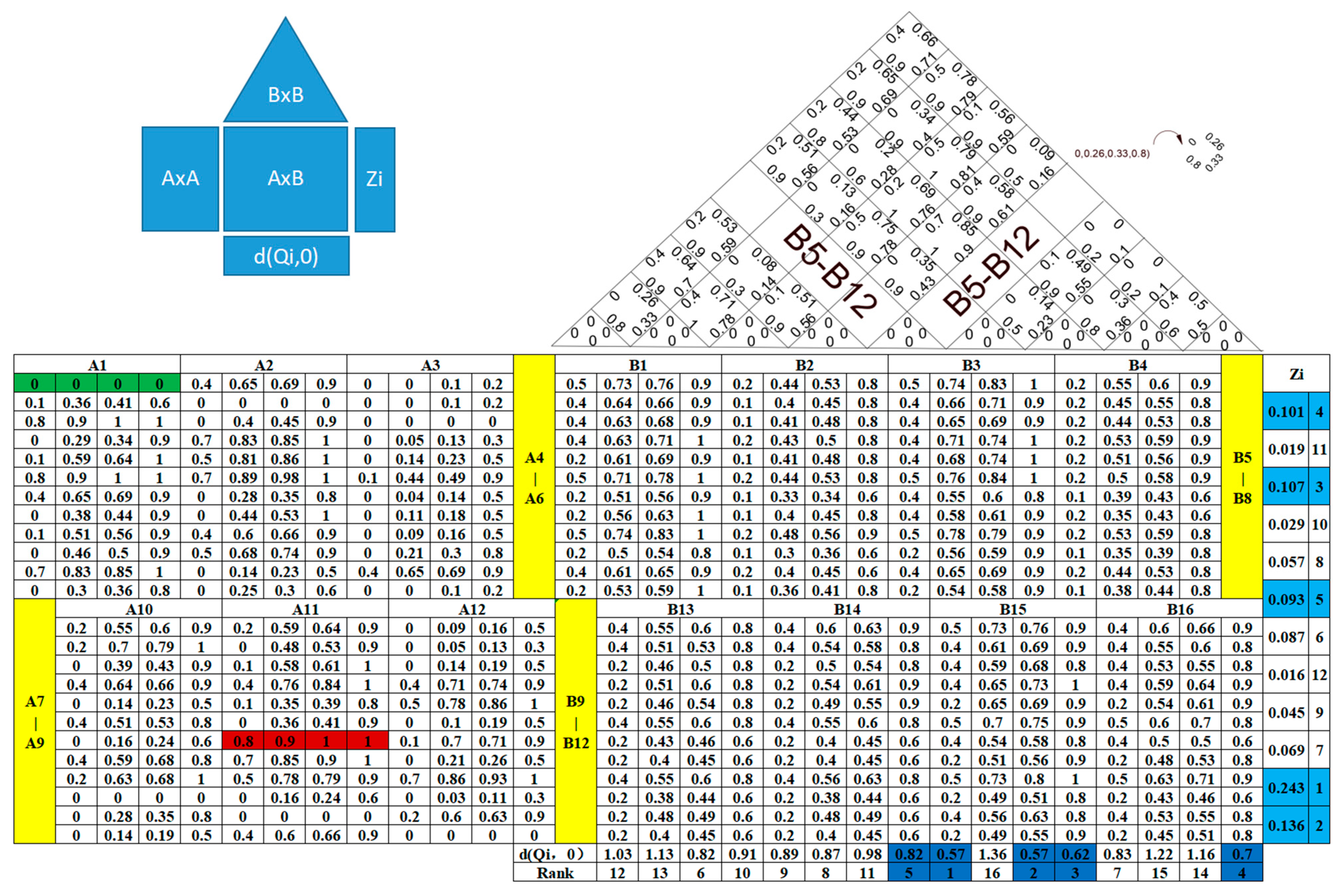

4.2. The First HoQ

4.2.1. Composite Weight of Risks

4.2.2. Order of Leanness Philosophies

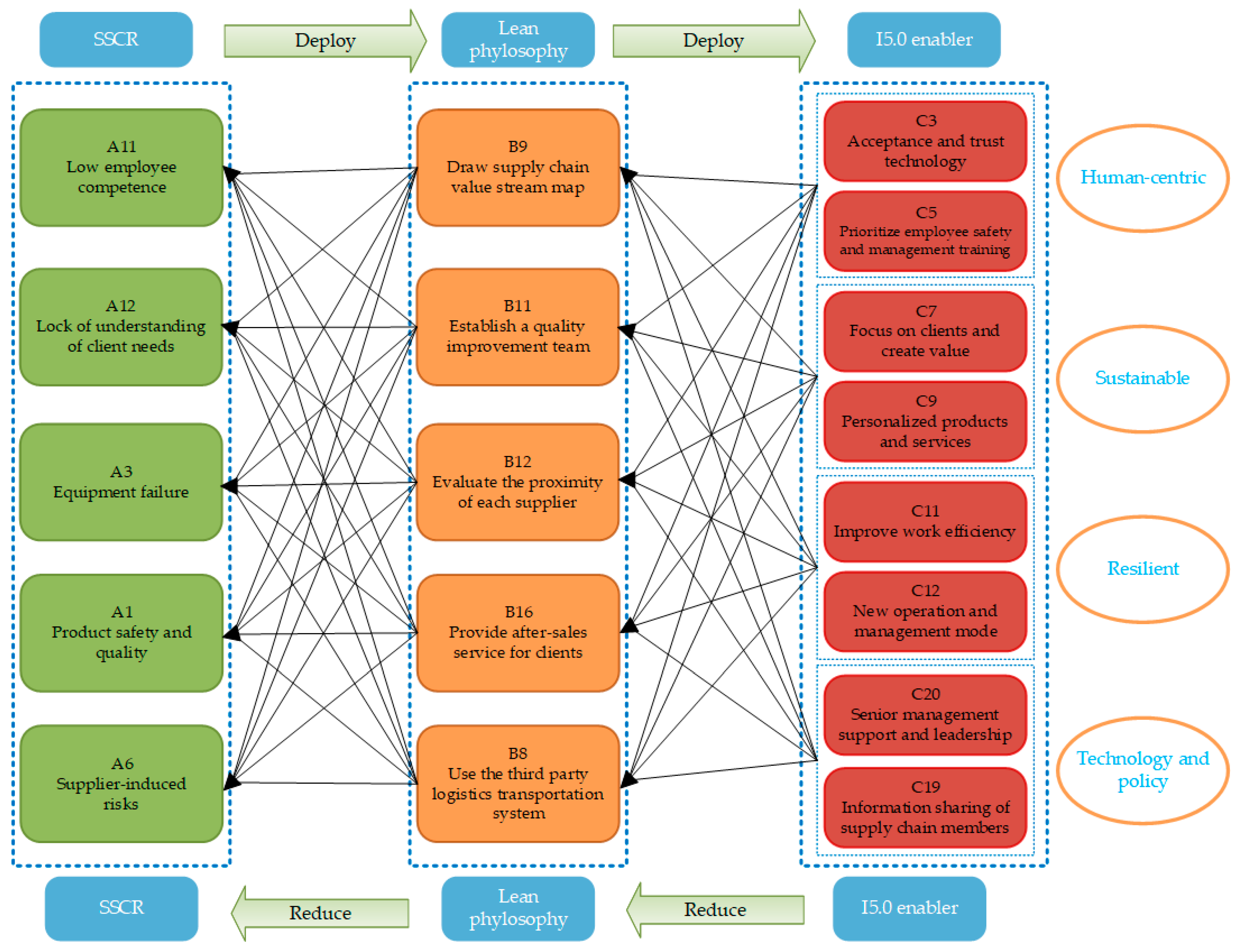

4.3. The Second HoQ

5. Discussion

5.1. The First HoQ

5.1.1. Key SSCRs

5.1.2. Key Leanness Philosophies

5.2. The Second HoQ

5.2.1. Dimension 1 (Human-Centric)

5.2.2. Dimension 2 (Sustainable)

5.2.3. Dimension 3 (Resilient)

5.2.4. Dimension 4 (Technological and Policy)

6. Conclusions

7. Limitations and Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, X.; Guo, Y.; Liu, Q.; Zhang, D. Dynamic Co-evolution analysis of low-carbon technology innovation compound system of new energy enterprise based on the perspective of sustainable development. J. Clean. Prod. 2022, 349, 131330. [Google Scholar] [CrossRef]

- Mangla, S.K.; Luthra, S.; Jakhar, S.; Gandhi, S.; Muduli, K.; Kumar, A. A step to clean energy—Sustainability in energy system management in an emerging economy context. J. Clean. Prod. 2020, 242, 118462. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, R.K.; Paul, J.; Sinha, O. Analyzing challenges for sustainable supply chain of electric vehicle batteries using a hybrid approach of Delphi and Best-Worst Method. Resour. Conserv. Recycl. 2021, 175, 105879. [Google Scholar] [CrossRef]

- Çiçek, H.; Turan, H. The Effects of Process Improvement on Sustainable Supply Chain Management Performance. Int. J. Ind. Eng. Theory Appl. Pract. 2023, 30, 4. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Mohamed, R. A novel plithogenic TOPSIS- CRITIC model for sustainable supply chain risk management. J. Clean. Prod. 2020, 247, 119586. [Google Scholar] [CrossRef]

- Kalantari, F.; Hosseininezhad, S.J. A Multi-objective Cross Entropy-based algorithm for sustainable global food supply chain with risk considerations: A case study. Comput. Ind. Eng. 2022, 164, 107766. [Google Scholar] [CrossRef]

- Riley, J.M.; Klein, R.; Miller, J.; Sridharan, V. How internal integration, information sharing, and training affect supply chain risk management capabilities. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 953–980. [Google Scholar] [CrossRef]

- Das, K. Integrating lean systems in the design of a sustainable supply chain model. Int. J. Prod. Econ. 2018, 198, 177–190. [Google Scholar] [CrossRef]

- Ahmed, W.; Huma, S. Impact of lean and agile strategies on supply chain risk management. Total Qual. Manag. Bus. Excell. 2021, 32, 33–56. [Google Scholar] [CrossRef]

- Cagnetti, C.; Gallo, T.; Silvestri, C.; Ruggieri, A. Lean production and Industry 4.0: Strategy/management or technique/implementation? A systematic literature review. Procedia Comput. Sci. 2021, 180, 404–413. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Song, W.; Ming, X.; Liu, H.-C. Identifying critical risk factors of sustainable supply chain management: A rough strength-relation analysis method. J. Clean. Prod. 2017, 143, 100–115. [Google Scholar] [CrossRef]

- Rostamzadeh, R.; Ghorabaee, M.K.; Govindan, K.; Esmaeili, A.; Nobar, H.B.K. Evaluation of sustainable supply chain risk management using an integrated fuzzy TOPSIS- CRITIC approach. J. Clean. Prod. 2018, 175, 651–669. [Google Scholar] [CrossRef]

- Nazam, M.; Xu, J.; Tao, Z.; Ahmad, J.; Hashim, M. A fuzzy AHP-TOPSIS framework for the risk assessment of green supply chain implementation in the textile industry. Int. J. Supply Oper. Manag. 2015, 2, 548–568. [Google Scholar]

- Wieland, A.; Wallenburg, C.M. Dealing with supply chain risks: Linking risk management practices and strategies to performance. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 887–905. [Google Scholar] [CrossRef]

- Amin, F.U.; Dong, Q.-L.; Grzybowska, K.; Ahmed, Z.; Yan, B.-R. A Novel Fuzzy-Based VIKOR–CRITIC Soft Computing Method for Evaluation of Sustainable Supply Chain Risk Management. Sustainability 2022, 14, 2827. [Google Scholar] [CrossRef]

- Jackson, L.; Meinke, C.; Chandramohan, R. Challenges in the Battery Raw Materials Supply Chain: Achieving Decarbonisation from a Mineral Extraction Perspective. Min. Metall. Explor. 2024, 41, 2683–2692. [Google Scholar] [CrossRef]

- Miao, Y.; Liu, L.; Xu, K.; Li, J. High concentration from resources to market heightens risk for power lithium-ion battery supply chains globally. Environ. Sci. Pollut. Res. 2023, 30, 65558–65571. [Google Scholar] [CrossRef] [PubMed]

- Duffner, F.; Mauler, L.; Wentker, M.; Leker, J.; Winter, M. Large-scale automotive battery cell manufacturing: Analyzing strategic and operational effects on manufacturing costs. Int. J. Prod. Econ. 2021, 232, 107982. [Google Scholar] [CrossRef]

- Jamal, R.; Al Alam, M.A.; Sayeed, K.M.A.; Ahmed, S.A.; Haque, N.; Hossain, M.M.; Sujauddin, M. Patching sustainability loopholes within the lead-acid battery industry of Bangladesh: An environmental and occupational health risk perspective. Sustain. Prod. Consum. 2024, 48, 435–445. [Google Scholar] [CrossRef]

- Su, D.; Mei, Y.; Liu, T.; Amine, K. Global Regulations for Sustainable Battery Recycling: Challenges and Opportunities. Sustainability 2025, 17, 3045. [Google Scholar] [CrossRef]

- Shabana, R.; Sajid, Z.; Swamy, D.; Amin, M.T.; Khan, F. Why does the industry need battery safety management system (BSMS)? Process Saf. Environ. Prot. 2025, 197, 107029. [Google Scholar] [CrossRef]

- Hu, X.; Wang, C.; Lim, M.K.; Chen, W.Q.; Teng, L.; Wang, P.; Wang, H.; Zhang, C.; Yao, C.; Ghadimi, P. Critical systemic risk sources in global lithium-ion battery supply networks: Static and dynamic network perspectives. Renew. Sustain. Energy Rev. 2023, 173, 113083. [Google Scholar] [CrossRef]

- Chhimwal, M.; Agrawal, S.; Kumar, G. Sustainable supply chain risk mitigation: A mixed method approach. Int. J. Intell. Enterp. 2022, 9, 142. [Google Scholar] [CrossRef]

- Reinerth, D.; Busse, C.; Wagner, S.M. Using Country Sustainability Risk to Inform Sustainable Supply Chain Management: A Design Science Study. J. Bus. Logist. 2019, 40, 241–264. [Google Scholar] [CrossRef]

- Rahimi, M.; Ghezavati, V.; Asadi, F. A stochastic risk-averse sustainable supply chain network design problem with quantity discount considering multiple sources of uncertainty. Comput. Ind. Eng. 2019, 130, 430–449. [Google Scholar] [CrossRef]

- He, L.; Wu, Z.; Xiang, W.; Goh, M.; Xu, Z.; Song, W.; Ming, X.; Wu, X. A novel Kano-QFD-DEMATEL approach to optimise the risk resilience solution for sustainable supply chain. Int. J. Prod. Res. 2021, 59, 1714–1735. [Google Scholar] [CrossRef]

- Tavakoli Haji Abadi, Y.; Avakh Darestani, S. Evaluation of sustainable supply chain risk: Evidence from the Iranian food industry. J. Sci. Technol. Policy Manag. 2023, 14, 127–156. [Google Scholar] [CrossRef]

- Zhang, F.; Song, W. Sustainability risk assessment of blockchain adoption in sustainable supply chain: An integrated method. Comput. Ind. Eng. 2022, 171, 108378. [Google Scholar] [CrossRef]

- Jakhar, S.K.; Rathore, H.; Mangla, S.K. Is lean synergistic with sustainable supply chain? An empirical investigation from emerging economy. Resour. Conserv. Recycl. 2018, 139, 262–269. [Google Scholar] [CrossRef]

- Zhu, Q.; Shah, P.; Sarkis, J. Addition by subtraction: Integrating product deletion with lean and sustainable supply chain management. Int. J. Prod. Econ. 2018, 205, 201–214. [Google Scholar] [CrossRef]

- Huo, B.; Gu, M.; Wang, Z. Green or lean? A supply chain approach to sustainable performance. J. Clean. Prod. 2019, 216, 152–166. [Google Scholar] [CrossRef]

- Essaber, F.E.; Benmoussa, R.; De Guio, R.; Dubois, S. A Hybrid Supply Chain Risk Management Approach for Lean Green Performance Based on AHP, RCA and TRIZ: A Case Study. Sustainability 2021, 13, 8492. [Google Scholar] [CrossRef]

- Senthil, J.; Muthukannan, M. Development of lean construction supply chain risk management based on enhanced neural network. Mater. Today Proc. 2022, 56, 1752–1757. [Google Scholar] [CrossRef]

- Zhan, Y.; Tan, K.H.; Ji, G.; Chung, L.; Chiu, A.S.F. Green and lean sustainable development path in China: Guanxi, practices and performance. Resour. Conserv. Recycl. 2018, 128, 240–249. [Google Scholar] [CrossRef]

- Moyano-Fuentes, J.; Maqueira-Marín, J.M.; Martínez-Jurado, P.J.; Sacristán-Díaz, M. Extending lean management along the supply chain: Impact on efficiency. J. Manuf. Technol. Manag. 2021, 32, 63–84. [Google Scholar] [CrossRef]

- Nath, V.; Agrawal, R. Agility and lean practices as antecedents of supply chain social sustainability. Int. J. Oper. Prod. Manag. 2020, 40, 1589–1611. [Google Scholar] [CrossRef]

- Maddikunta, P.K.R.; Pham, Q.-V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Akundi, A.; Euresti, D.; Luna, S.; Ankobiah, W.; Lopes, A.; Edinbarough, I. State of Industry 5.0—Analysis and Identification of Current Research Trends. Appl. Syst. Innov. 2022, 5, 27. [Google Scholar] [CrossRef]

- Grabowska, S.; Saniuk, S.; Gajdzik, B. Industry 5.0: Improving humanization and sustainability of Industry 4.0. Scientometrics 2022, 127, 3117–3144. [Google Scholar] [CrossRef] [PubMed]

- Gladysz, B.; Tran, T.; Romero, D.; Van Erp, T.; Abonyi, J.; Ruppert, T. Current development on the Operator 4.0 and transition towards the Operator 5.0: A systematic literature review in light of Industry 5.0. J. Manuf. Syst. 2023, 70, 160–185. [Google Scholar] [CrossRef]

- Rahardjo, B.; Wang, F.K.; Lo, S.C.; Chu, T.-H. A Sustainable Innovation Framework Based on Lean Six Sigma and Industry 5.0. Arab. J. Sci. Eng. 2024, 49, 7625–7642. [Google Scholar] [CrossRef]

- Fani, V.; Bucci, I.; Rossi, M.; Bandinelli, R. Lean and industry 4.0 principles toward industry 5.0: A conceptual framework and empirical insights from fashion industry. J. Manuf. Technol. Manag. 2024, 35, 122–141. [Google Scholar] [CrossRef]

- Pekkaya, M.; Pulat İmamoğlu, Ö.; Koca, H. Evaluation of healthcare service quality via Servqual scale: An application on a hospital. Int. J. Healthc. Manag. 2019, 12, 340–347. [Google Scholar] [CrossRef]

- Hessing, T. Quality Function Deployment (QFD) and House of Quality (HOQ). Available online: https://sixsigmastudyguide.com/house-of-quality-HOQ/ (accessed on 22 July 2019).

- Zhang, M.-C.; Zhu, B.-W.; Huang, C.-M.; Tzeng, G.-H. Systematic Evaluation Model for Developing Sustainable World-Class Universities: An East Asian Perspective. Mathematics 2021, 9, 837. [Google Scholar] [CrossRef]

- Antônio Rufino Júnior, C.; Sanseverino, E.R.; Gallo, P.; Koch, D.; Schweiger, H.-G.; Zanin, H. Blockchain review for battery supply chain monitoring and battery trading. Renew. Sustain. Energy Rev. 2022, 157, 112078. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A. Method of improve the level of product quality. Prod. Eng. Arch. 2021, 27, 1–7. [Google Scholar] [CrossRef]

- Omair, M.; Noor, S.; Tayyab, M.; Maqsood, S.; Ahmed, W.; Sarkar, B.; Habib, M.S. The Selection of the Sustainable Suppliers by the Development of a Decision Support Framework Based on Analytical Hierarchical Process and Fuzzy Inference System. Int. J. Fuzzy Syst. 2021, 23, 1986–2003. [Google Scholar] [CrossRef]

- Kurata, H.; Nam, S.-H. After-sales service competition in a supply chain: Optimization of customer satisfaction level or profit or both? Int. J. Prod. Econ. 2010, 127, 136–146. [Google Scholar] [CrossRef]

- Sremac, S.; Stević, Ž.; Pamučar, D.; Arsić, M.; Matić, B. Evaluation of a Third-Party Logistics (3PL) Provider Using a Rough SWARA–WASPAS Model Based on a New Rough Dombi Agregator. Symmetry 2018, 10, 305. [Google Scholar] [CrossRef]

- Keshta, I.; Aoudni, Y.; Sandhu, M.; Singh, A.; Xalikovich, P.A.; Rizwan, A.; Soni, M.; Lalar, S. Blockchain aware proxy re-encryption algorithm-based data sharing scheme. Phys. Commun. 2023, 58, 102048. [Google Scholar] [CrossRef]

- Zuo, Y. Exploring the Synergy: AI Enhancing Blockchain, Blockchain Empowering AI, and their Convergence across IoT Applications and Beyond. IEEE Internet Things J. 2024, 12, 6171–6195. [Google Scholar] [CrossRef]

- Abdelhamid, M.; Sliman, L.; Ben Djemaa, R.; Perboli, G. A Review on Blockchain Technology, Current Challenges, and AI-Driven Solutions. ACM Comput. Surv. 2024, 57, 1–39. [Google Scholar] [CrossRef]

- Bencsik, A.; Hargitai, D.M.; Kulachinskaya, A. Trust in and Risk of Technology in Organizational Digitalization. Risks 2022, 10, 90. [Google Scholar] [CrossRef]

- Han, Y.; Feng, Z.; Zhang, J.; Jin, R.; Aboagye-Nimo, E. Employees’ Safety Perceptions of Site Hazard and Accident Scenes. J. Constr. Eng. Manag. 2019, 145, 04018117. [Google Scholar] [CrossRef]

- Kula, B.; Roxas, A.L.; Cetin, K.; Berghorn, G.; Anctil, A. Implementation of VR Technology for Energy Audit Training and Workforce Development. J. Manag. Eng. 2025, 41, 04025002. [Google Scholar] [CrossRef]

- Ensslen, A.; Gnann, T.; Jochem, P.; Plötz, P.; Dütschke, E.; Fichtner, W. Can product service systems support electric vehicle adoption? Transp. Res. Part A Policy Pract. 2020, 137, 343–359. [Google Scholar] [CrossRef]

- Zhang, T.; Agarwal, L. The Value of It-Enabled Retailer Learning: Personalized Product Recommendations and Customer Store Loyalty in Electronic Markets. MIS Q. 2011, 35, 859. [Google Scholar] [CrossRef]

- Mohsen, B.M. Ai-driven optimization of urban logistics in smart cities: Integrating autonomous vehicles and iot for efficient delivery systems. Sustainability 2024, 16, 11265. [Google Scholar] [CrossRef]

- Govindan, K.; Asgari, F.; Fard, F.S.N.; Mina, H. Application of IoT technology for enhancing the consumer willingness to return E-waste for achieving circular economy: A Lagrangian relaxation approach. J. Clean. Prod. 2024, 459, 142421. [Google Scholar] [CrossRef]

- Jiang, Q.; Ke, G. Information sharing and bullwhip effect in smart destination network system. Ad Hoc Netw. 2019, 87, 17–25. [Google Scholar] [CrossRef]

- Villena-Manzanares, F.; García-Segura, T.; Pellicer, E. Organizational Factors That Drive to BIM Effectiveness: Technological Learning, Collaborative Culture, and Senior Management Support. Appl. Sci. 2020, 11, 199. [Google Scholar] [CrossRef]

- Liu, H.L.; Song, J.L.; Wang, G.B. User satisfaction of building information modeling (BIM) and its inflfluencing factors in AEC industry. J. China Civ. Eng. 2019, 52, 118–128. [Google Scholar]

- Wang, Y.; Han, J.H.; Beynon-Davies, P. Understanding blockchain technology for future supply chains: A systematic literature review and research agenda. Supply Chain. Manag. Int. J. 2019, 24, 62–84. [Google Scholar] [CrossRef]

- Baah, C.; Opoku Agyeman, D.; Acquah, I.S.K.; Agyabeng-Mensah, Y.; Afum, E.; Issau, K.; Ofori, D.; Faibil, D. Effect of information sharing in supply chains: Understanding the roles of supply chain visibility, agility, collaboration on supply chain performance. Benchmarking Int. J. 2022, 29, 434–455. [Google Scholar] [CrossRef]

| Evaluation Scale | Define | Value |

|---|---|---|

| VH | Very high | 5 |

| H | High | 4 |

| O | Normal | 3 |

| L | Low | 2 |

| VL | Very low | 1 |

| Linguistic Variables | Precise Numbers | Fuzzy Numbers |

|---|---|---|

| Very low | 1 | (0.0, 0.0, 0.1, 0.2) |

| Low | 2 | (0.1, 0.2, 0.2, 0.3) |

| Comparatively low | 3 | (0.2, 0.3, 0.4, 0.5) |

| Normal | 4 | (0.4, 0.5, 0.5, 0.6) |

| Comparatively high | 5 | (0.5, 0.6, 0.7, 0.8) |

| Very high | 6 | (0.7, 0.8, 0.8, 0.9) |

| Extremely high | 7 | (0.8, 0.9, 1.0, 1.0) |

| SSCR (A) | LP (B) | I5.0 Enabler (C) |

|---|---|---|

| Correlation matrix of A&B | Correlation matrix of B&C | |

| ①

② ③ | ①

② ③ | |

| Decision matrix of A&B: ① × ② × ③ | Decision matrix of B&C: ① × ② × ③ | |

| Factors | Gi | Rank |

|---|---|---|

| Product safety and quality | 8.19 | 1 |

| Single supplier | 8.18 | 2 |

| Equipment failure | 7.49 | 3 |

| Limited supply capacity | 7.42 | 4 |

| Different business standards | 7.38 | 5 |

| Supplier-related risks | 6.91 | 6 |

| Improper employee salary allocation | 6.8 | 7 |

| Task failed | 6.79 | 8 |

| Excessive reliance on small clients | 6.76 | 9 |

| Limited warehouse capacity | 6.72 | 10 |

| Low employee competence | 6.72 | 11 |

| Lack of understanding of client needs | 6.68 | 12 |

| Factors | Gi | Rank |

|---|---|---|

| On-time delivery | 7.3 | 1 |

| Establish a training department | 7.18 | 2 |

| Integrate the overall strategy | 6.93 | 3 |

| Collaborate with suppliers to reduce costs | 6.74 | 4 |

| Develop decision support systems | 6.73 | 5 |

| Continuously assess client feedback | 6.67 | 6 |

| Value engineering | 6.45 | 7 |

| Use the third-party logistics | 6.39 | 8 |

| Draw a supply chain value stream map | 6.34 | 9 |

| Establish an internal quality system | 6.29 | 10 |

| Establish a quality improvement team | 6.23 | 11 |

| Evaluate the proximity of each supplier | 6.23 | 12 |

| Implement pilot tool systems | 6.16 | 13 |

| Conduct cost negotiations with suppliers | 6.06 | 14 |

| Quality function deployment | 6.03 | 15 |

| Provide after-sales service for clients | 5.97 | 16 |

| Dimension | Factors | Gi | Rank |

|---|---|---|---|

| Human-Centric | Organizational fairness, job satisfaction, trust, and innovation | 7.32 | 1 |

| Emphasizing employees’ emotional intelligence | 7.30 | 2 | |

| Acceptance and trust in technology | 7.12 | 3 | |

| Enhancing worker capabilities | 6.62 | 4 | |

| Prioritizing employee safety and management training | 6.52 | 5 | |

| Sustainable | Focusing on personalized customer needs | 7.07 | 1 |

| Client-centric approach and value creation | 6.88 | 2 | |

| Resource efficiency a top priority | 6.31 | 3 | |

| Personalized products and services | 6.22 | 4 | |

| Energy conservation and emissions reduction | 6.01 | 5 | |

| Resilient | Improving work efficiency | 6.60 | 1 |

| New operational management models | 6.55 | 2 | |

| Flexible and adaptable business processes | 6.42 | 3 | |

| Establishing a robust supply chain recovery and risk investment mechanism | 6.34 | 4 | |

| Enhancing production flexibility | 6.33 | 5 | |

| Technology and Policy | Enhancing information technology standards and implementing I4.0 regulations | 7.50 | 1 |

| National economic security | 7.38 | 2 | |

| Collaborative learning | 7.29 | 3 | |

| Sharing information among supply chain members | 7.26 | 4 | |

| Support and leadership from senior management | 7.25 | 5 |

| Second-Level Indicators | Third-Level Indicators | ||

|---|---|---|---|

| A1 | Enterprise supply | product safety and quality | B1 |

| limited supply capacity | B2 | ||

| task failure | B3 | ||

| A2 | Supplier’s material supply | single supplier | C1 |

| supplier-induced risks | C2 | ||

| A3 | Client needs | different business standards | D1 |

| excessive reliance on small clients | D2 | ||

| lack of understanding of client needs | D3 | ||

| A4 | Business production capacity | equipment failure | E1 |

| improper employee salary allocation | E2 | ||

| limited warehouse capacity | E3 | ||

| low employee competence | E4 | ||

| Num | Factor | Attribute | Rank | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A1 | product safety and quality | 2.43 | 3.07 | 5.507 | −0.64 | effect | 0.09 | 0.101 | 4 |

| A2 | single supplier | 2.64 | 2.62 | 5.266 | 0.02 | causal | 0.02 | 0.019 | 11 |

| A3 | equipment failure | 2.54 | 1.95 | 4.488 | 0.60 | causal | 0.12 | 0.107 | 3 |

| A4 | limited supply capacity | 2.91 | 3.27 | 6.180 | −0.37 | effect | 0.02 | 0.029 | 10 |

| A5 | different business standards | 2.43 | 2.16 | 4.590 | 0.28 | causal | 0.06 | 0.057 | 8 |

| A6 | supplier-induced risks | 2.84 | 1.98 | 4.823 | 0.86 | causal | 0.09 | 0.093 | 5 |

| A7 | improper employee salary allocation | 2.23 | 1.96 | 4.190 | 0.26 | causal | 0.10 | 0.087 | 6 |

| A8 | task failure | 2.75 | 3.43 | 6.181 | −0.69 | effect | 0.01 | 0.016 | 12 |

| A9 | excessive reliance on small clients | 2.41 | 2.25 | 4.658 | 0.17 | causal | 0.05 | 0.045 | 9 |

| A10 | limited warehouse capacity | 1.78 | 2.35 | 4.133 | −0.57 | effect | 0.08 | 0.069 | 7 |

| A11 | low employee competence | 2.78 | 2.64 | 5.414 | 0.14 | causal | 0.22 | 0.243 | 1 |

| A12 | lack of understanding of client needs | 2.27 | 2.32 | 4.587 | −0.06 | effect | 0.14 | 0.136 | 2 |

| Values | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B1 | B2 | B3 | B4 | |||||||||||||

| 0.75 | 0.44 | 0.68 | 0.25 | 4.59 | 0.65 | 0.59 | 0.05 | 0.59 | 0.49 | 0.61 | 0.27 | 0.1 | 0.49 | 0.44 | 0.92 | |

| B5 | B6 | B7 | B8 | |||||||||||||

| 0.24 | 0.42 | 0.58 | 0.45 | 3.16 | 0.71 | 0.51 | 0.14 | 3.35 | 0.68 | 0.52 | 0.14 | 0.44 | 0.5 | 0.56 | 0.27 | |

| B9 | B10 | B11 | B12 | |||||||||||||

| 2.94 | 0.61 | 0.4 | 0.14 | 6.51 | 0.92 | 0.34 | 0.06 | 1.58 | 0.64 | 0.46 | 0.14 | 2.94 | 0.64 | 0.44 | 0.09 | |

| B13 | B14 | B15 | B16 | |||||||||||||

| 1.54 | 0.82 | 0.36 | 0.07 | 0.5 | 0.64 | 0.47 | 0.96 | 7.69 | 0.47 | 0.57 | 0.03 | 3.37 | 0.57 | 0.52 | 0.13 | |

| B1 | B2 | B3 | B4 | |||||||||||||

| 0.2 | 0.11 | 0.18 | 0.08 | 2.19 | 0.17 | 0.15 | 0.01 | 0.2 | 0.12 | 0.15 | 0.08 | 0.05 | 0.13 | 0.11 | 0.26 | |

| B5 | B6 | B7 | B8 | |||||||||||||

| 0.09 | 0.12 | 0.17 | 0.13 | 1.09 | 0.18 | 0.12 | 0.03 | 1.09 | 0.19 | 0.15 | 0.03 | 0.14 | 0.13 | 0.17 | 0.08 | |

| B9 | B10 | B11 | B12 | |||||||||||||

| 1.09 | 0.15 | 0.08 | 0.03 | 2.43 | 0.25 | 0.09 | 0.01 | 0.49 | 0.14 | 0.12 | 0.03 | 1.09 | 0.15 | 0.09 | 0.02 | |

| B13 | B14 | B15 | B16 | |||||||||||||

| 0.6 | 0.22 | 0.07 | 0.02 | 0.16 | 0.16 | 0.15 | 0.36 | 2.43 | 0.1 | 0.13 | 0.01 | 1.09 | 0.14 | 0.11 | 0.03 | |

| Values of Qi | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B1 | B2 | B3 | B4 | ||||||||||||

| 0.08 | 0.05 | 1 | 0.22 | 0.74 | 0.47 | 0.71 | 0.02 | 0.07 | 0.15 | 0.77 | 0.23 | 0 | 0.18 | 0.32 | 0.84 |

| B5 | B6 | B7 | B8 | ||||||||||||

| 0.02 | 0.08 | 0.79 | 0.4 | 0.42 | 0.58 | 0.49 | 0.1 | 0.43 | 0.57 | 0.66 | 0.1 | 0.04 | 0.2 | 0.76 | 0.24 |

| B9 | B10 | B11 | B12 | ||||||||||||

| 0.41 | 0.37 | 0.13 | 0.1 | 0.92 | 1 | 0.08 | 0.03 | 0.19 | 0.36 | 0.38 | 0.1 | 0.41 | 0.4 | 0.22 | 0.05 |

| B13 | B14 | B15 | B16 | ||||||||||||

| 0.21 | 0.8 | 0.03 | 0.04 | 0.05 | 0.43 | 0.55 | 1 | 1 | 0.05 | 0.59 | 0 | 0.44 | 0.3 | 0.44 | 0.09 |

| B1 | B2 | B3 | B4 | B5 | B6 | B7 | B8 | |||||||||

| 1.029 | 1.129 | 0.823 | 0.914 | 0.891 | 0.871 | 0.975 | 0.822 | |||||||||

| B9 | B10 | B11 | B12 | B13 | B14 | B15 | B16 | |||||||||

| 0.572 | 1.363 | 0.567 | 0.617 | 0.831 | 1.220 | 1.162 | 0.698 | |||||||||

| Rank | B1 | B2 | B3 | B4 | B5 | B6 | B7 | B8 | B9 | B10 | B11 | B12 | B13 | B14 | B15 | B16 |

| 12 | 13 | 6 | 10 | 9 | 8 | 11 | 5 | 2 | 16 | 1 | 3 | 7 | 15 | 14 | 4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, D.-X.; Huang, S.-W.; Hsu, C.-H.; Wu, Q.-H. Enhancing Leanness Philosophies with Industry 5.0 Enables Reduction of Sustainable Supply Chain Risks: A Case Study of a New Energy Battery Manufacturer. Processes 2025, 13, 2339. https://doi.org/10.3390/pr13082339

Zhu D-X, Huang S-W, Hsu C-H, Wu Q-H. Enhancing Leanness Philosophies with Industry 5.0 Enables Reduction of Sustainable Supply Chain Risks: A Case Study of a New Energy Battery Manufacturer. Processes. 2025; 13(8):2339. https://doi.org/10.3390/pr13082339

Chicago/Turabian StyleZhu, De-Xuan, Shao-Wei Huang, Chih-Hung Hsu, and Qi-Hui Wu. 2025. "Enhancing Leanness Philosophies with Industry 5.0 Enables Reduction of Sustainable Supply Chain Risks: A Case Study of a New Energy Battery Manufacturer" Processes 13, no. 8: 2339. https://doi.org/10.3390/pr13082339

APA StyleZhu, D.-X., Huang, S.-W., Hsu, C.-H., & Wu, Q.-H. (2025). Enhancing Leanness Philosophies with Industry 5.0 Enables Reduction of Sustainable Supply Chain Risks: A Case Study of a New Energy Battery Manufacturer. Processes, 13(8), 2339. https://doi.org/10.3390/pr13082339