Optimizing Bioactive Compound Recovery from Chestnut Shells Using Pressurized Liquid Extraction and the Box–Behnken Design

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Chestnut Material

2.3. Calculation of Nutritional Value of Chestnut Fruits

2.4. Design of the Experimental Procedure

2.5. Spectrophotometric Determinations

2.5.1. Total Polyphenolic Content (TPC)

2.5.2. Total Tannin Content (TTC)

2.5.3. Ferric-Reducing Antioxidant Power (FRAP) Evaluation of Antioxidant Activity

2.5.4. Evaluation of DPPH Radical Scavenging Activity

2.6. Colorimetric Analysis

2.7. UHPLC-TIMS-QTOF-MS Analysis

2.8. Statistical Analysis

3. Results and Discussion

3.1. Chestnut Fruit’s Nutritional Value

3.2. Optimization of PLE Parameters

3.3. Model Analysis

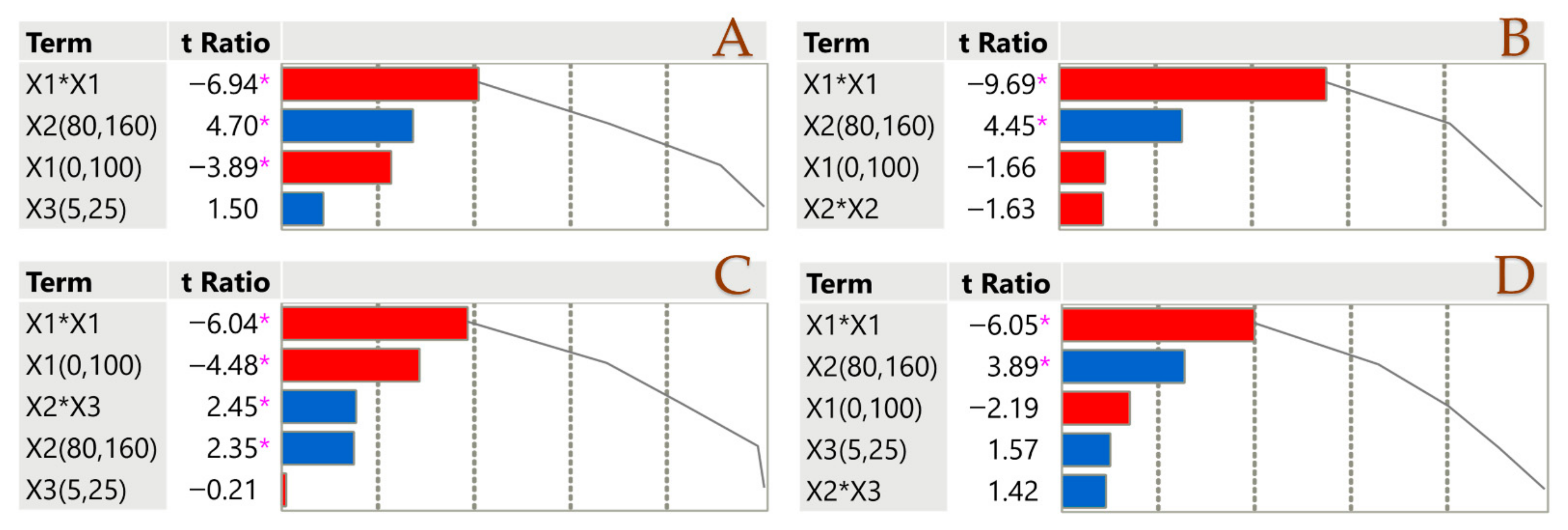

3.4. Impact of Extraction Parameters on Assays Through Pareto Plot Analysis

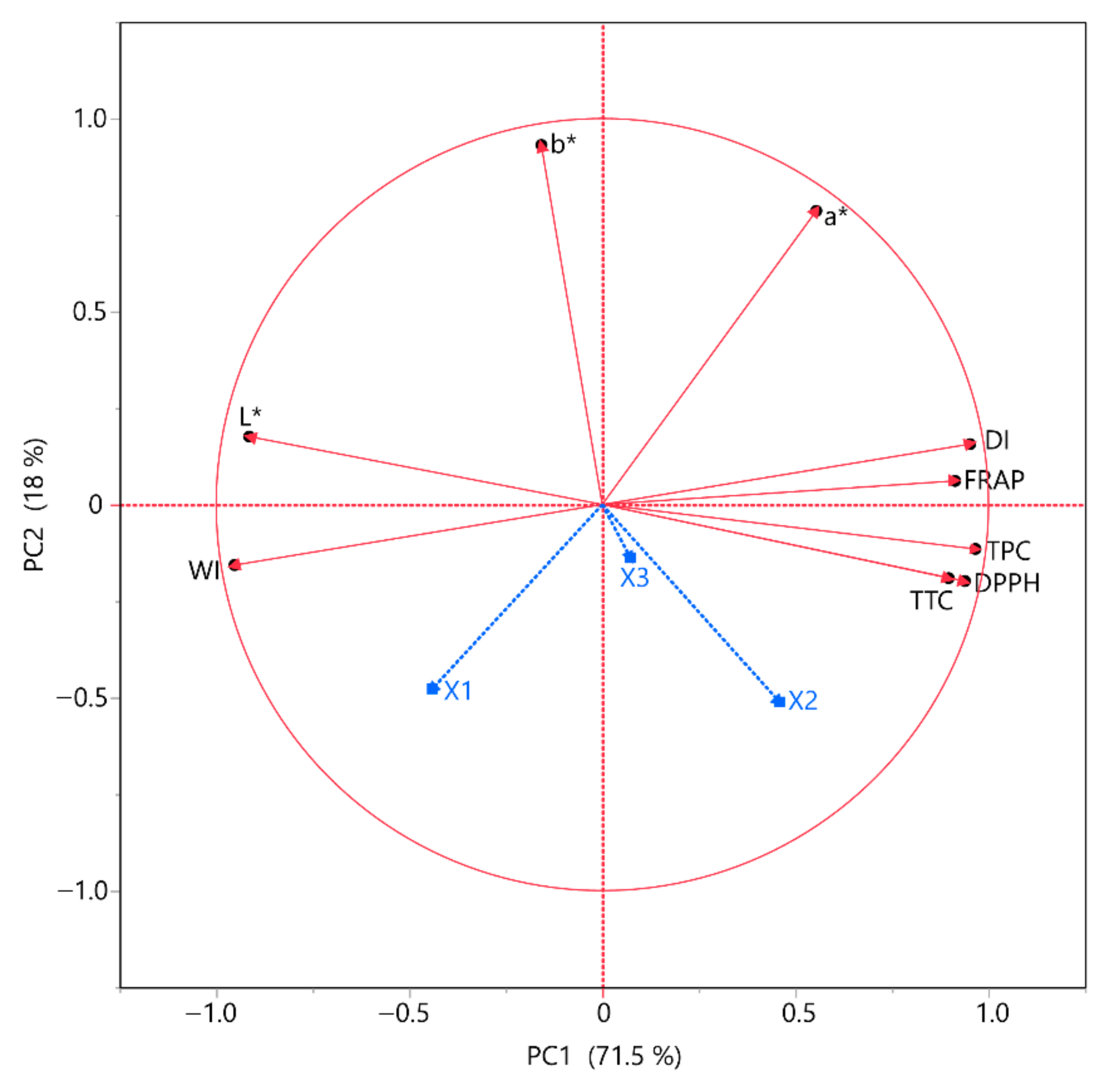

3.5. Principal Component Analysis (PCA) and Multivariate Component Analysis (MCA)

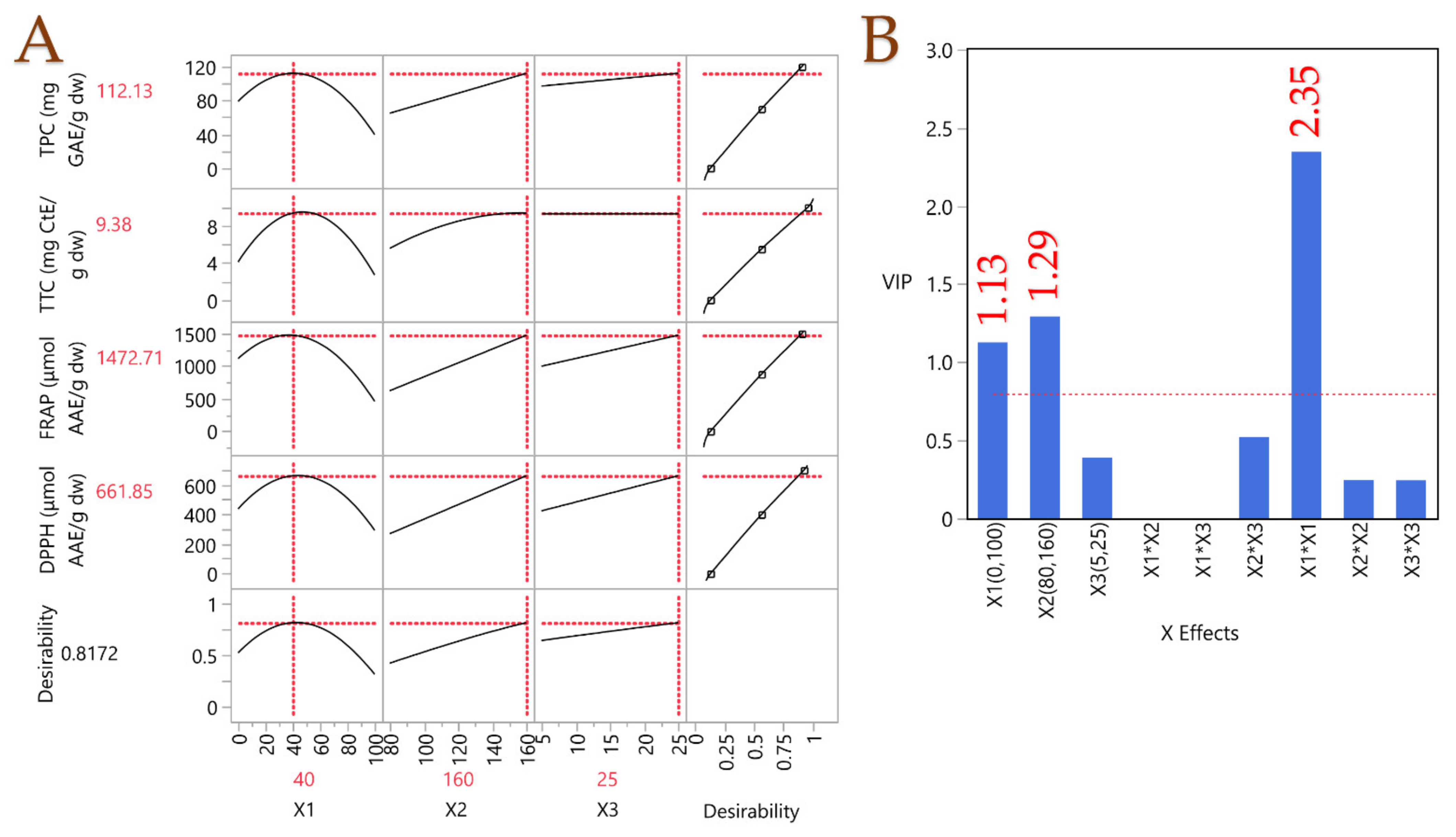

3.6. Partial Least Squares (PLS) Analysis

3.7. Compound Identification

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdelwahab, S.I.; Taha, M.M.E.; Aljahdali, I.; Oraibi, B.; Alzahrani, A.; Farasani, A.; Alfaifi, H.; Babiker, Y. Exploring the Potential of Chestnut (Castanea sativa Mill.): A Comprehensive Review and Conceptual Mapping. Bull. Natl. Res. Cent. 2024, 48, 82. [Google Scholar] [CrossRef]

- Çobanoğlu, H.; Cantürk, U.; Koç, İ.; Kulaç, Ş.; Sevik, H. Climate Change Effect on Potential Distribution of Anatolian Chestnut (Castanea sativa Mill.) in the Upcoming Century in Turkiye. Forestist 2023, 73, 247–256. [Google Scholar] [CrossRef]

- Santos, M.J.; Pinto, T.; Vilela, A. Sweet Chestnut (Castanea Sativa Mill.) Nutritional and Phenolic Composition Interactions with Chestnut Flavor Physiology. Foods 2022, 11, 4052. [Google Scholar] [CrossRef] [PubMed]

- Poljak, I.; Vahčić, N.; Vidaković, A.; Tumpa, K.; Žarković, I.; Idžojtić, M. Traditional Sweet Chestnut and Hybrid Varieties: Chemical Composition, Morphometric and Qualitative Nut Characteristics. Agronomy 2021, 11, 516. [Google Scholar] [CrossRef]

- Antoniewska-Krzeska, A.; Grygorieva, O.; Zhurba, M.; Goncharovska, I.; Brindza, J. Chemical Composition of Castanea Sativa Mill. Fruits. Agrobiodivers. Improv. Nutr. Health Life Qual. 2023, 7, 218–225. [Google Scholar] [CrossRef]

- Ciucure, C.T.; Geana, E.-I.; Sandru, C.; Tita, O.; Botu, M. Phytochemical and Nutritional Profile Composition in Fruits of Different Sweet Chestnut (Castanea sativa Mill.) Cultivars Grown in Romania. Separations 2022, 9, 66. [Google Scholar] [CrossRef]

- Mota, M.; Pinto, T.; Vilela, A.; Marques, T.; Borges, A.; Caço, J.; Ferreira-Cardoso, J.; Raimundo, F.; Gomes-Laranjo, J. Irrigation Positively Affects the Chestnut’s Quality: The Chemical Composition, Fruit Size and Sensory Attributes. Sci. Hortic. 2018, 238, 177–186. [Google Scholar] [CrossRef]

- El Khoury, D.; Balfour-Ducharme, S.; Joye, I.J. A Review on the Gluten-Free Diet: Technological and Nutritional Challenges. Nutrients 2018, 10, 1410. [Google Scholar] [CrossRef]

- Rodrigues, P.; Ferreira, T.; Nascimento-Gonçalves, E.; Seixas, F.; Gil da Costa, R.M.; Martins, T.; Neuparth, M.J.; Pires, M.J.; Lanzarin, G.; Félix, L.; et al. Dietary Supplementation with Chestnut (Castanea sativa) Reduces Abdominal Adiposity in FVB/n Mice: A Preliminary Study. Biomedicines 2020, 8, 75. [Google Scholar] [CrossRef]

- Choupina, A.B. Nutritional and Health Potential of European Chestnut. Rev. Ciênc. Agrár. 2019, 42, 801–807. [Google Scholar] [CrossRef]

- Cacciola, N.A.; Squillaci, G.; D’Apolito, M.; Petillo, O.; Veraldi, F.; La Cara, F.; Peluso, G.; Margarucci, S.; Morana, A. Castanea sativa Mill. Shells Aqueous Extract Exhibits Anticancer Properties Inducing Cytotoxic and Pro-Apoptotic Effects. Molecules 2019, 24, 3401. [Google Scholar] [CrossRef]

- Vella, F.M.; Laratta, B.; La Cara, F.; Morana, A. Recovery of Bioactive Molecules from Chestnut (Castanea sativa Mill.) by-Products through Extraction by Different Solvents. Nat. Prod. Res. 2018, 32, 1022–1032. [Google Scholar] [CrossRef]

- Morana, A.; Squillaci, G.; Paixão, S.M.; Alves, L.; Cara, F.L.; Moura, P. Development of an Energy Biorefinery Model for Chestnut (Castanea sativa Mill.) Shells. Energies 2017, 10, 1504. [Google Scholar] [CrossRef]

- Fraguela-Meissimilly, H.; Bastías-Monte, J.M.; Vergara, C.; Ortiz-Viedma, J.; Lemus-Mondaca, R.; Flores, M.; Toledo-Merma, P.; Alcázar-Alay, S.; Gallón-Bedoya, M. New Trends in Supercritical Fluid Technology and Pressurized Liquids for the Extraction and Recovery of Bioactive Compounds from Agro-Industrial and Marine Food Waste. Molecules 2023, 28, 4421. [Google Scholar] [CrossRef] [PubMed]

- Martinez, A.S.; Lanaridi, O.; Stagel, K.; Halbwirth, H.; Schnürch, M.; Bica-Schröder, K. Extraction Techniques for Bioactive Compounds of Cannabis. Nat. Prod. Rep. 2023, 40, 676–717. [Google Scholar] [CrossRef] [PubMed]

- Picot-Allain, C.; Mahomoodally, M.F.; Ak, G.; Zengin, G. Conventional versus Green Extraction Techniques—A Comparative Perspective. Curr. Opin. Food Sci. 2021, 40, 144–156. [Google Scholar] [CrossRef]

- Christoforidis, A.; Mantiniotou, M.; Athanasiadis, V.; Lalas, S.I. Caffeine and Polyphenolic Compound Recovery Optimization from Spent Coffee Grounds Utilizing Pressurized Liquid Extraction. Beverages 2025, 11, 74. [Google Scholar] [CrossRef]

- Croxatto Vega, G.; Sohn, J.; Voogt, J.; Birkved, M.; Olsen, S.I.; Nilsson, A.E. Insights from Combining Techno-Economic and Life Cycle Assessment—A Case Study of Polyphenol Extraction from Red Wine Pomace. Resour. Conserv. Recycl. 2021, 167, 105318. [Google Scholar] [CrossRef]

- Hernández-Corroto, E.; Plaza, M.; Marina, M.L.; García, M.C. Sustainable Extraction of Proteins and Bioactive Substances from Pomegranate Peel (Punica granatum L.) Using Pressurized Liquids and Deep Eutectic Solvents. Innov. Food Sci. Emerg. Technol. 2020, 60, 102314. [Google Scholar] [CrossRef]

- Athanasiadis, V.; Mantiniotou, M.; Kalompatsios, D.; Makrygiannis, I.; Alibade, A.; Lalas, S.I. Evaluation of Antioxidant Properties of Residual Hemp Leaves Following Optimized Pressurized Liquid Extraction. AgriEngineering 2025, 7, 1. [Google Scholar] [CrossRef]

- Delima, D.; Trio, P. Method Validation for Protein Quantitation of Fish Muscle Tissues from Lake Taal, Batangas. KIMIKA 2019, 30, 5–16. [Google Scholar] [CrossRef]

- Bradford, M.M. A Rapid and Sensitive Method for the Quantitation of Microgram Quantities of Protein Utilizing the Principle of Protein-Dye Binding. Anal. Biochem. 1976, 72, 248–254. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Chen, Q. Improving Measurement of Reducing Sugar Content in Carbonated Beverages Using Fehling’s Reagent. J. Emerg. Investig. 2020, 2, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wan, W. Experimental Design Methods for Fermentative Hydrogen Production: A Review. Int. J. Hydrog. Energy 2009, 34, 235–244. [Google Scholar] [CrossRef]

- Pappas, V.M.; Athanasiadis, V.; Palaiogiannis, D.; Poulianiti, K.; Bozinou, E.; Lalas, S.I.; Makris, D.P. Pressurized Liquid Extraction of Polyphenols and Anthocyanins from Saffron Processing Waste with Aqueous Organic Acid Solutions: Comparison with Stirred-Tank and Ultrasound-Assisted Techniques. Sustainability 2021, 13, 12578. [Google Scholar] [CrossRef]

- Mantiniotou, M.; Athanasiadis, V.; Kalompatsios, D.; Lalas, S.I. Optimization of Carotenoids and Other Antioxidant Compounds Extraction from Carrot Peels Using Response Surface Methodology. Biomass 2025, 5, 3. [Google Scholar] [CrossRef]

- Sun, B.; Ricardo-da-Silva, J.M.; Spranger, I. Critical Factors of Vanillin Assay for Catechins and Proanthocyanidins. J. Agric. Food Chem. 1998, 46, 4267–4274. [Google Scholar] [CrossRef]

- Kalompatsios, D.; Athanasiadis, V.; Mantiniotou, M.; Lalas, S.I. Optimization of Ultrasonication Probe-Assisted Extraction Parameters for Bioactive Compounds from Opuntia Macrorhiza Using Taguchi Design and Assessment of Antioxidant Properties. Appl. Sci. 2024, 14, 10460. [Google Scholar] [CrossRef]

- Shehata, E.; Grigorakis, S.; Loupassaki, S.; Makris, D.P. Extraction Optimisation Using Water/Glycerol for the Efficient Recovery of Polyphenolic Antioxidants from Two Artemisia Species. Sep. Purif. Technol. 2015, 149, 462–469. [Google Scholar] [CrossRef]

- Pinto, D.; Delerue-Matos, C.; Rodrigues, F. Chestnut: Phytochemicals and Biological Activities. In Natural Products; Springer: Berlin/Heidelberg, Germany, 2025; pp. 1–38. ISBN 978-3-642-36202-6. [Google Scholar]

- Borges, O.; Gonçalves, B.; De Carvalho, J.L.S.; Correia, P.; Silva, A.P. Nutritional Quality of Chestnut (Castanea sativa Mill.) Cultivars from Portugal. Food Chem. 2008, 106, 976–984. [Google Scholar] [CrossRef]

- Barreira, J.C.M.; Casal, S.; Ferreira, I.C.F.R.; Oliveira, M.B.P.P.; Pereira, J.A. Nutritional, Fatty Acid and Triacylglycerol Profiles of Castanea sativa Mill. Cultivars: A Compositional and Chemometric Approach. J. Agric. Food Chem. 2009, 57, 2836–2842. [Google Scholar] [CrossRef]

- Thoo, Y.; Ng, S.Y.; Khoo, M.; Mustapha, W.; Ho, C. A Binary Solvent Extraction System for Phenolic Antioxidants and Its Application to the Estimation of Antioxidant Capacity in Andrographis paniculata Extracts. Int. Food Res. J. 2013, 20, 1103–1111. [Google Scholar]

- Athanasiadis, V.; Chatzimitakos, T.; Makrygiannis, I.; Kalompatsios, D.; Bozinou, E.; Lalas, S.I. Antioxidant-Rich Extracts from Lemon Verbena (Aloysia citrodora L.) Leaves through Response Surface Methodology. Oxygen 2024, 4, 1–19. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Meullemiestre, A.; Turk, M.; Perino, S.; Fabiano-Tixier, A.-S.; Abert-Vian, M. Review of Green Food Processing Techniques. Preservation, Transformation, and Extraction. Innov. Food Sci. Emerg. Technol. 2017, 41, 357–377. [Google Scholar] [CrossRef]

- Mantiniotou, M.; Bujor, B.-C.; Athanasiadis, V.; Chatzimitakos, T.; Kalompatsios, D.; Kotsou, K.; Bozinou, E.; Lalas, S.I. Response Surface Methodology-Aided Optimization of Bioactive Compound Extraction from Apple Peels Through Pulsed Electric Field Pretreatment and Ultrasonication. Eng 2024, 5, 2886–2901. [Google Scholar] [CrossRef]

- Nam, M.; Yu, J.M.; Park, Y.R.; Kim, Y.-S.; Kim, J.-H.; Kim, M.-S. Metabolic Profiling of Chestnut Shell (Castanea crenata) Cultivars Using UPLC-QTOF-MS and Their Antioxidant Capacity. Biomolecules 2022, 12, 1797. [Google Scholar] [CrossRef] [PubMed]

- Fuente-Maqueda, F.; Rodríguez, A.; Majada, J.; Fernández, B.; Feito, I. Methodology Optimization for the Analysis of Phenolic Compounds in Chestnut (Castanea sativa Mill.). Food Sci. Technol. Int. 2020, 26, 520–534. [Google Scholar] [CrossRef]

- Vázquez, G.; Freire, M.S.; Santos, J.; Antorrena, G.; González-Álvarez, J. Optimisation of Polyphenols Extraction from Chestnut Shell by Response Surface Methodology. Waste Biomass Valorization 2010, 1, 219–225. [Google Scholar] [CrossRef]

- Yang, F.; Wei, D.; Li, J.; Xie, C. Chestnut Shell Represents a Rich Source of Polyphenols: Preparation Methods, Antioxidant Activity and Composition Analysis of Extractable and Non-Extractable Polyphenols. Eur. Food Res. Technol. 2023, 249, 1273–1285. [Google Scholar] [CrossRef]

- Gago-Ferrero, P.; Schymanski, E.L.; Bletsou, A.A.; Aalizadeh, R.; Hollender, J.; Thomaidis, N.S. Extended Suspect and Non-Target Strategies to Characterize Emerging Polar Organic Contaminants in Raw Wastewater with LC-HRMS/MS. Environ. Sci. Technol. 2015, 49, 12333–12341. [Google Scholar] [CrossRef]

- Wolf, S.; Schmidt, S.; Müller-Hannemann, M.; Neumann, S. In Silico Fragmentation for Computer Assisted Identification of Metabolite Mass Spectra. BMC Bioinform. 2010, 11, 148. [Google Scholar] [CrossRef]

- Aalizadeh, R.; Thomaidis, N.S.; Bletsou, A.A.; Gago-Ferrero, P. Quantitative Structure–Retention Relationship Models To Support Nontarget High-Resolution Mass Spectrometric Screening of Emerging Contaminants in Environmental Samples. J. Chem. Inf. Model. 2016, 56, 1384–1398. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, C.; Zhang, L.; Xue, J.; Sun, Q.; Wang, H.; Cui, R.; Liu, R.; Song, L. Extraction of Pigments from Chestnut (Castanea mollissima) Shells Using Green Deep Eutectic Solvents: Optimization, HPLC-MS Identification, Stability, and Antioxidant Activities. Food Chem. 2025, 488, 144916. [Google Scholar] [CrossRef]

- Cravotto, C.; Grillo, G.; Binello, A.; Gallina, L.; Olivares-Vicente, M.; Herranz-López, M.; Micol, V.; Barrajón-Catalán, E.; Cravotto, G. Bioactive Antioxidant Compounds from Chestnut Peels through Semi-Industrial Subcritical Water Extraction. Antioxidants 2022, 11, 988. [Google Scholar] [CrossRef] [PubMed]

- Kocer, S.; Utku Copur, O.; Ece Tamer, C.; Suna, S.; Kayahan, S.; Uysal, E.; Cavus, S.; Akman, O. Optimization and Characterization of Chestnut Shell Pigment Extract Obtained Microwave Assisted Extraction by Response Surface Methodology. Food Chem. 2024, 443, 138424. [Google Scholar] [CrossRef] [PubMed]

- Diaz, A.B.; Blandino, A.; Caro, I. Value Added Products from Fermentation of Sugars Derived from Agro-Food Residues. Trends Food Sci. Technol. 2018, 71, 52–64. [Google Scholar] [CrossRef]

- Adetunji, A.I.; Oberholster, P.J.; Erasmus, M. From Garbage to Treasure: A Review on Biorefinery of Organic Solid Wastes into Valuable Biobased Products. Bioresour. Technol. Rep. 2023, 24, 101610. [Google Scholar] [CrossRef]

- Dong, J.; Zheng, H.; Zeng, Q.; Zhang, X.; Du, L.; Bais, S. Protective Effect of D-(−)-Quinic Acid as Food Supplement in Modulating AMP-Activated Protein Kinase Signalling Pathway Activation in HFD Induced Obesity. Hum. Exp. Toxicol. 2022, 41, 1–10. [Google Scholar] [CrossRef]

- Patel, V.B.; Preedy, V.R.; Rajendram, R. (Eds.) L-Arginine in Clinical Nutrition; Springer International Publishing: Cham, Switzerland, 2017; ISBN 978-3-319-26007-5. [Google Scholar]

- Arumugam, M.K.; Paal, M.C.; Donohue, T.M.; Ganesan, M.; Osna, N.A.; Kharbanda, K.K. Beneficial Effects of Betaine: A Comprehensive Review. Biology 2021, 10, 456. [Google Scholar] [CrossRef]

- Hadidi, M.; Liñán-Atero, R.; Tarahi, M.; Christodoulou, M.C.; Aghababaei, F. The Potential Health Benefits of Gallic Acid: Therapeutic and Food Applications. Antioxidants 2024, 13, 1001. [Google Scholar] [CrossRef]

- He, H.-F. Recognition of Gallotannins and the Physiological Activities: From Chemical View. Front. Nutr. 2022, 9, 888892. [Google Scholar] [CrossRef]

- Maity, S.; Kinra, M.; Nampoothiri, M.; Arora, D.; Pai, K.S.R.; Mudgal, J. Caffeic Acid, a Dietary Polyphenol, as a Promising Candidate for Combination Therapy. Chem. Pap. 2022, 76, 1271–1283. [Google Scholar] [CrossRef]

- Dasiman, R.; Nor, N.M.; Eshak, Z.; Mutalip, S.S.M.; Suwandi, N.R.; Bidin, H. A Review of Procyanidin: Updates on Current Bioactivities and Potential Health Benefits. Biointerface Res. Appl. Chem. 2021, 12, 5918–5940. [Google Scholar] [CrossRef]

- Isemura, M. Catechin in Human Health and Disease. Molecules 2019, 24, 528. [Google Scholar] [CrossRef]

- Nakhate, K.T.; Badwaik, H.; Choudhary, R.; Sakure, K.; Agrawal, Y.O.; Sharma, C.; Ojha, S.; Goyal, S.N. Therapeutic Potential and Pharmaceutical Development of a Multitargeted Flavonoid Phloretin. Nutrients 2022, 14, 3638. [Google Scholar] [CrossRef] [PubMed]

- Punia Bangar, S.; Kajla, P.; Chaudhary, V.; Sharma, N.; Ozogul, F. Luteolin: A Flavone with Myriads of Bioactivities and Food Applications. Food Biosci. 2023, 52, 102366. [Google Scholar] [CrossRef]

- Mushtaq, Z.; Sadeer, N.B.; Hussain, M.; Mahwish; Alsagaby, S.A.; Imran, M.; Mumtaz, T.; Umar, M.; Tauseef, A.; Al Abdulmonem, W.; et al. Therapeutical Properties of Apigenin: A Review on the Experimental Evidence and Basic Mechanisms. Int. J. Food Prop. 2023, 26, 1914–1939. [Google Scholar] [CrossRef]

- Bai, C.; Sun, Y.; Pan, X.; Yang, J.; Li, X.; Wu, A.; Qin, D.; Cao, S.; Zou, W.; Wu, J. Antitumor Effects of Trimethylellagic Acid Isolated from Sanguisorba officinalis L. on Colorectal Cancer via Angiogenesis Inhibition and Apoptosis Induction. Front. Pharmacol. 2020, 10, 1646. [Google Scholar] [CrossRef]

- Vigbedor, B.Y.; Akoto, C.O.; Neglo, D. Isolation and Characterization of 3,3′-Di-O-Methyl Ellagic Acid from the Root Bark of Afzelia africana and Its Antimicrobial and Antioxidant Activities. Sci. Afr. 2022, 17, e01332. [Google Scholar] [CrossRef]

| Independent Variables | Coded Units | Coded Levels | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| Ethanol concentration (C, % v/v) | X1 | 0 | 50 | 100 |

| Extraction temperature (T, °C) | X2 | 80 | 120 | 160 |

| Extraction duration (t, min) | X3 | 5 | 15 | 25 |

| Nutritive Ingredients | Quantity per 100 g (Literature [30]) | Quantity per 100 g (Current Study) |

|---|---|---|

| Calories (kcal) | 196 | 256 ± 13 |

| Proteins (g) | 2.0 | 2.0 ± 0.1 |

| Fats (g) | 1.4 | 2.5 ± 0.1 |

| Carbohydrates (g) | 44.0 | 56.4 ± 3.0 |

| Of which sugars (g) | 10.6 | 12.5 ± 0.6 |

| Design Point | Independent Variables | Actual PLE Responses * | |||||

|---|---|---|---|---|---|---|---|

| C (%) (X1) | T (°C) (X2) | t (min) (X3) | TPC | TTC | FRAP | DPPH | |

| 1 | 100 (1) | 120 (0) | 25 (1) | 8.07 | 1.44 | 34.65 | 43.27 |

| 2 | 50 (0) | 120 (0) | 15 (0) | 81.37 | 9.16 | 990.31 | 406.95 |

| 3 | 50 (0) | 120 (0) | 15 (0) | 79.88 | 9.18 | 960.73 | 408.91 |

| 4 | 100 (1) | 120 (0) | 5 (−1) | 6.04 | 1.08 | 30.34 | 36.54 |

| 5 | 50 (0) | 80 (−1) | 5 (−1) | 33.81 | 3.62 | 894.80 | 167.59 |

| 6 | 100 (1) | 80 (−1) | 15 (0) | 3.40 | 0.56 | 42.98 | 11.40 |

| 7 | 0 (−1) | 80 (−1) | 15 (0) | 33.51 | 1.50 | 731.11 | 141.44 |

| 8 | 0 (−1) | 160 (1) | 15 (0) | 59.45 | 2.97 | 596.59 | 222.41 |

| 9 | 0 (−1) | 120 (0) | 5 (−1) | 46.58 | 2.76 | 890.66 | 178.68 |

| 10 | 50 (0) | 160 (1) | 5 (−1) | 96.49 | 9.84 | 1128.49 | 472.98 |

| 11 | 50 (0) | 160 (1) | 25 (1) | 135.58 | 10.89 | 1721.04 | 793.18 |

| 12 | 50 (0) | 120 (0) | 15 (0) | 78.01 | 8.61 | 987.24 | 406.55 |

| 13 | 0 (−1) | 120 (0) | 25 (1) | 51.05 | 3.59 | 592.55 | 215.70 |

| 14 | 100 (1) | 160 (1) | 15 (0) | 16.58 | 2.05 | 76.42 | 86.10 |

| 15 | 50 (0) | 80 (−1) | 25 (1) | 48.65 | 4.81 | 473.54 | 220.64 |

| Design Point | Independent Variables | Responses | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C (%) (X1) | T (°C) (X2) | t (min) (X3) | L* | a* | b* | Whiteness Index (WI) 1 | Darkness Index (DI) 2 | HEX Code | Color 3 | |

| 1 | 100 (1) | 120 (0) | 25 (1) | 73.1 | 1.5 | 15.6 | 68.9 | 31.1 | BFB297 | |

| 2 | 50 (0) | 120 (0) | 15 (0) | 39.1 | 14.5 | 5.9 | 37.1 | 62.9 | 755353 | |

| 3 | 50 (0) | 120 (0) | 15 (0) | 42.2 | 16.1 | 6.7 | 39.7 | 60.3 | 805A59 | |

| 4 | 100 (1) | 120 (0) | 5 (−1) | 67.2 | 0.4 | 7.5 | 66.4 | 33.6 | A9A396 | |

| 5 | 50 (0) | 80 (−1) | 5 (−1) | 61.5 | 17.1 | 36.0 | 44.6 | 55.4 | BE8855 | |

| 6 | 100 (1) | 80 (−1) | 15 (0) | 69.0 | −0.5 | 2.0 | 68.9 | 31.1 | ABA8A5 | |

| 7 | 0 (−1) | 80 (−1) | 15 (0) | 51.8 | 15.8 | 20.8 | 45.1 | 54.9 | 9D7159 | |

| 8 | 0 (−1) | 160 (1) | 15 (0) | 46.6 | 12.9 | 8.0 | 44.4 | 55.6 | 876662 | |

| 9 | 0 (−1) | 120 (0) | 5 (−1) | 54.9 | 16.6 | 24.4 | 46.1 | 53.9 | A8785A | |

| 10 | 50 (0) | 160 (1) | 5 (−1) | 35.4 | 12.9 | 4.0 | 34.0 | 66.0 | 694C4D | |

| 11 | 50 (0) | 160 (1) | 25 (1) | 32.0 | 3.2 | 0.1 | 32.0 | 68.0 | 504A4B | |

| 12 | 50 (0) | 120 (0) | 15 (0) | 40.8 | 16.1 | 5.9 | 38.4 | 61.6 | 7C5657 | |

| 13 | 0 (−1) | 120 (0) | 25 (1) | 48.5 | 18.4 | 16.4 | 42.9 | 57.1 | 976758 | |

| 14 | 100 (1) | 160 (1) | 15 (0) | 38.9 | 13.7 | 10.9 | 36.5 | 63.5 | 75534B | |

| 15 | 50 (0) | 80 (−1) | 25 (1) | 53.4 | 21.3 | 24.7 | 43.1 | 56.9 | AB7156 | |

| Factor | TPC | TTC | FRAP | DPPH |

|---|---|---|---|---|

| Stepwise regression coefficients | ||||

| Intercept | 73.11 * | 8.6 * | 1022 * | 411 * |

| X1—Ethanol concentration | −19.6 * | −0.71 | −328 * | −72.6 |

| X2—Temperature | 23.59 * | 1.908 * | 172.5 * | 129.2 * |

| X3—Extraction time | 7.554 | - | −15.3 | 52.13 |

| X1X2 | - | - | - | - |

| X1X3 | - | - | - | - |

| X2X3 | - | - | 253.5 * | 66.79 |

| −51 * | −6.1 * | −648 * | −294 * | |

| - | −1.02 | - | - | |

| - | - | - | - | |

| ANOVA | ||||

| F-value (model) | 21.91 | 29.32 | 13.62 | 12.2 |

| F-value (lack of fit) | 88.76 | 10.24 | 208.6 | 7110 |

| p-value (model) | <0.0001 * | <0.0001 * | 0.0006 * | 0.0009 * |

| p-value (lack of fit) | 0.0112 * | 0.0075 * | 0.0048 * | 0.0001 * |

| R2 | 0.898 | 0.921 | 0.883 | 0.871 |

| Adjusted R2 | 0.857 | 0.89 | 0.818 | 0.8 |

| RMSE | 14.21 | 1.212 | 207.3 | 93.92 |

| CV | 68.5 | 76.1 | 67.56 | 77.13 |

| DF (total) | 14 | 14 | 14 | 14 |

| Parameters | Independent Variables | Desirability | Stepwise Regression | ||

|---|---|---|---|---|---|

| C (%) (X1) | T (°C) (X2) | t (min) (X3) | |||

| TPC (mg GAE/g dw) | 40 | 160 | 25 | 0.7876 | 112.13 ± 19.69 |

| TTC (mg CtE/g dw) | 47 | 160 | - | 0.8496 | 9.51 ± 1.52 |

| FRAP (μmol AAE/g dw) | 37 | 160 | 25 | 0.8285 | 1474.52 ± 373.22 |

| DPPH (μmol AAE/g dw) | 44 | 160 | 25 | 0.8156 | 663.56 ± 170.06 |

| Variables | TPC | TTC | FRAP | DPPH | L* | a* | b* | WI | DI |

|---|---|---|---|---|---|---|---|---|---|

| TPC | - | 0.9267 | 0.9073 | 0.9728 | −0.8442 | 0.4365 | −0.2241 | −0.8551 | 0.8551 |

| TTC | - | 0.8488 | 0.9339 | −0.7423 | 0.3368 | −0.2547 | −0.7457 | 0.7457 | |

| FRAP | - | 0.9097 | −0.7196 | 0.4758 | −0.0068 | −0.8144 | 0.8144 | ||

| DPPH | - | −0.8073 | 0.3117 | −0.2549 | −0.8102 | 0.8102 | |||

| L* | - | −0.4246 | 0.3973 | 0.9329 | −0.9329 | ||||

| a* | - | 0.5219 | −0.6589 | 0.6589 | |||||

| b* | - | 0.0492 | −0.0492 | ||||||

| WI | - | −1.0000 | |||||||

| DI | - |

| Parameters | Independent Variables | PLS Regression | PLE Experimental Values | STE Experimental Values | ||

|---|---|---|---|---|---|---|

| C (%) (X1) | T (°C) (X2) | t (min) (X3) | ||||

| TPC (mg GAE/g dw) | 40 | 160 | 25 | 112.13 | 113.68 ± 7.84 a | 18.93 ± 0.59 b |

| TTC (mg CtE/g dw) | 9.38 | 9.62 ± 0.24 a | 1.85 ± 0.11 b | |||

| FRAP (μmol AAE/g dw) | 1472.71 | 1320.28 ± 34.33 a | 239.15 ± 13.15 b | |||

| DPPH (μmol AAE/g dw) | 661.85 | 708.65 ± 24.8 a | 135.02 ± 6.15 b | |||

| No | Compound | Formula | Rt (min) | [M − H]− (m/z) | [M + H]+ (m/z) | Δ (ppm) | MS/MS Fragments | PLE Extract | STE Extract | Compound Type |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Malic acid | C4H6O5 | 1.10 | 133.0141 | +7.14 | 110.9757, 96.9604 | + | + | Alpha-hydroxy acid | |

| 2 | Quinic acid | C7H12O6 | 1.20 | 191.0559 | +4.71 | 169.0141, 133.0148 | + | + | Hydroxycarboxylic acid | |

| 3 | Citric acid | C6H8O7 | 1.21 | 191.0194 | +4.04 | 133.0141, 96.9610 | + | + | Alpha-hydroxy acid | |

| 4 | Arginine | C6H14N4O2 | 1.28 | 175.1185 | −2.58 | 118.0867 83.0602 | + | Amino Acid | ||

| 5 | Gallic acid | C7H6O5 | 1.30 | 169.0129 | −1.18 | 125.0244, 69.0346 | + | + | Trihydroxybenzoic acid | |

| 6 | Betaine (Trimethylglycine) | C5H11NO2 | 1.31 | 118.0868 | +4.61 | 104.1074, 83.0602 | + | + | Methylated amino acid derivative | |

| 7 | Caffeic acid | C9H8O4 | 1.40 | 179.0335 | −2.15 | 135.0452, 134.0373 | + | + | Hydroxycinnamic acid | |

| 8 | Galloylglucose | C13H16O10 | 2.90 | 333.0820 | +1.20 | 201.0739, 83.0607 | + | O-acyl carbohydrate | ||

| 9 | C-C B-type dimer (C: epicatechin or catechin) | C30H26O12 | 3.41 | 579.1506 | +1.55 | 316.2124, 239.1485, 197.1281, 83.0603 | + | + | Procyanidin dimer | |

| 10 | Catechin | C15H14O6 | 3.85 | 219.0864 | +0.54 | 169.0492, 130.1881, 83.0603 | + | + | Flavanol aglycone | |

| 11 | Phloretin | C15H14O5 | 8.00 | 273.0768 | +4.03 | 167.0343, 123.0450 | + | Dihydrochalcone | ||

| 12 | Luteolin | C15H10O6 | 8.10 | 285.0407 | +4.91 | 175.0401, 151.0037, 133.0295 | + | + | Flavone aglycone | |

| 13 | Trimethylellagic acid | C17H12O8 | 8.52 | 345.0602 | −0.58 | 158.1544, 102.1286, 83.0614 | + | + | Ellagic acid methylated derivative | |

| 14 | Apigenin | C15H10O5 | 8.80 | 269.0461 | +6.31 | 151.0031, 117.0343 | + | + | Flavone aglycone | |

| 15 | Dimethylellagic acid | C16H10O8 | 9.63 | 329.0305 | +4.26 | 255.2334, 217.0026, 141.0163 | + | + | Ellagic acid methylated derivative |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pazara, M.; Provelengiadi, G.; Mantiniotou, M.; Athanasiadis, V.; Samanidis, I.; Makrygiannis, I.; Tzavellas, I.F.; Martakos, I.C.; Thomaidis, N.S.; Lalas, S.I. Optimizing Bioactive Compound Recovery from Chestnut Shells Using Pressurized Liquid Extraction and the Box–Behnken Design. Processes 2025, 13, 2283. https://doi.org/10.3390/pr13072283

Pazara M, Provelengiadi G, Mantiniotou M, Athanasiadis V, Samanidis I, Makrygiannis I, Tzavellas IF, Martakos IC, Thomaidis NS, Lalas SI. Optimizing Bioactive Compound Recovery from Chestnut Shells Using Pressurized Liquid Extraction and the Box–Behnken Design. Processes. 2025; 13(7):2283. https://doi.org/10.3390/pr13072283

Chicago/Turabian StylePazara, Magdalini, Georgia Provelengiadi, Martha Mantiniotou, Vassilis Athanasiadis, Iordanis Samanidis, Ioannis Makrygiannis, Ilias F. Tzavellas, Ioannis C. Martakos, Nikolaos S. Thomaidis, and Stavros I. Lalas. 2025. "Optimizing Bioactive Compound Recovery from Chestnut Shells Using Pressurized Liquid Extraction and the Box–Behnken Design" Processes 13, no. 7: 2283. https://doi.org/10.3390/pr13072283

APA StylePazara, M., Provelengiadi, G., Mantiniotou, M., Athanasiadis, V., Samanidis, I., Makrygiannis, I., Tzavellas, I. F., Martakos, I. C., Thomaidis, N. S., & Lalas, S. I. (2025). Optimizing Bioactive Compound Recovery from Chestnut Shells Using Pressurized Liquid Extraction and the Box–Behnken Design. Processes, 13(7), 2283. https://doi.org/10.3390/pr13072283