Study on Solid and Pore Structures of Borehole Municipal Solid Waste Samples by X-Ray CT Scanning

Abstract

1. Introduction

2. Borehole Sampling

2.1. Site Description

2.2. Sampling

3. Testing Methods

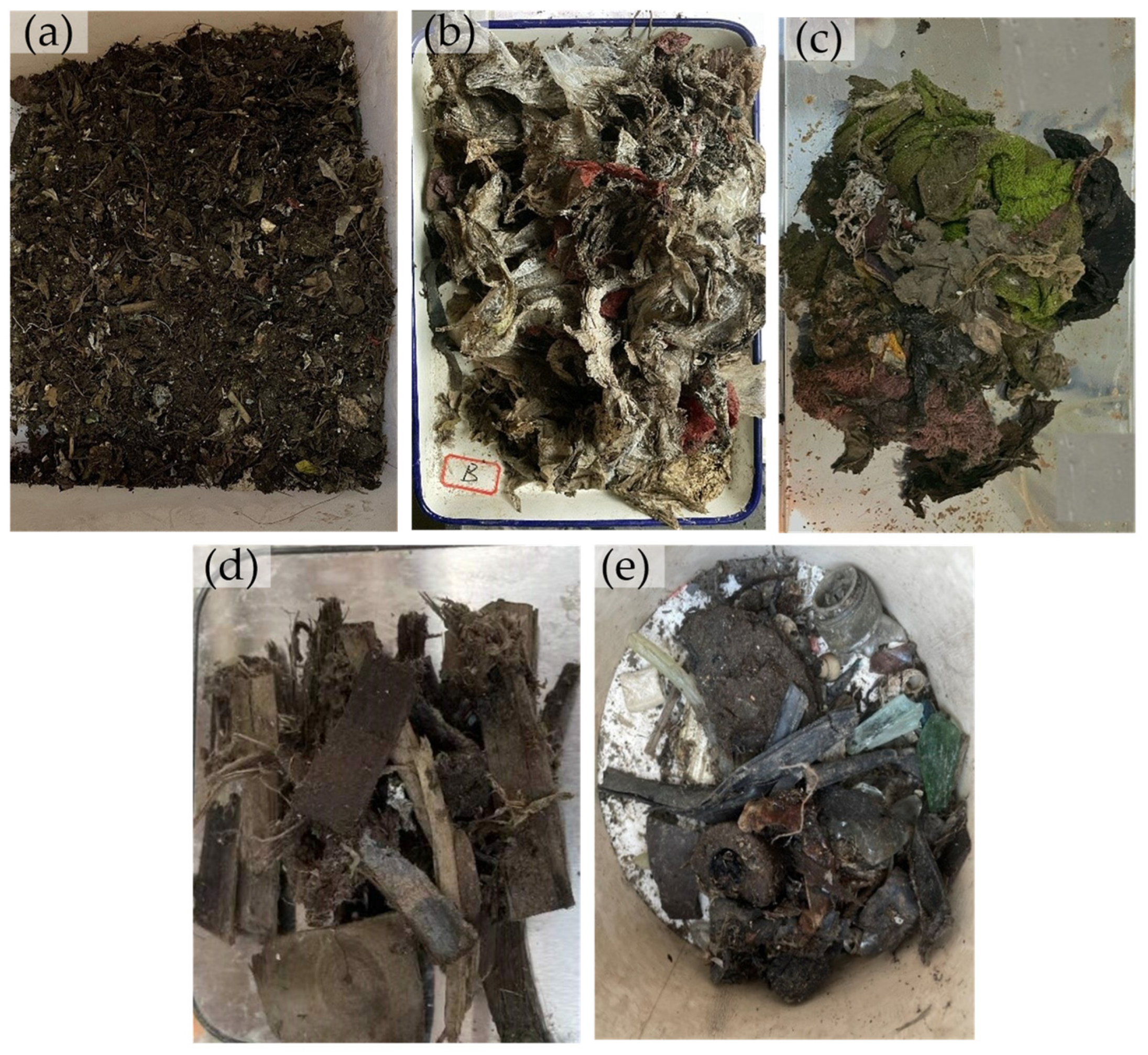

3.1. Waste Composition and Particle Shape

3.2. Basic Physical Properties and Degree of Degradation

3.3. CT Scanning

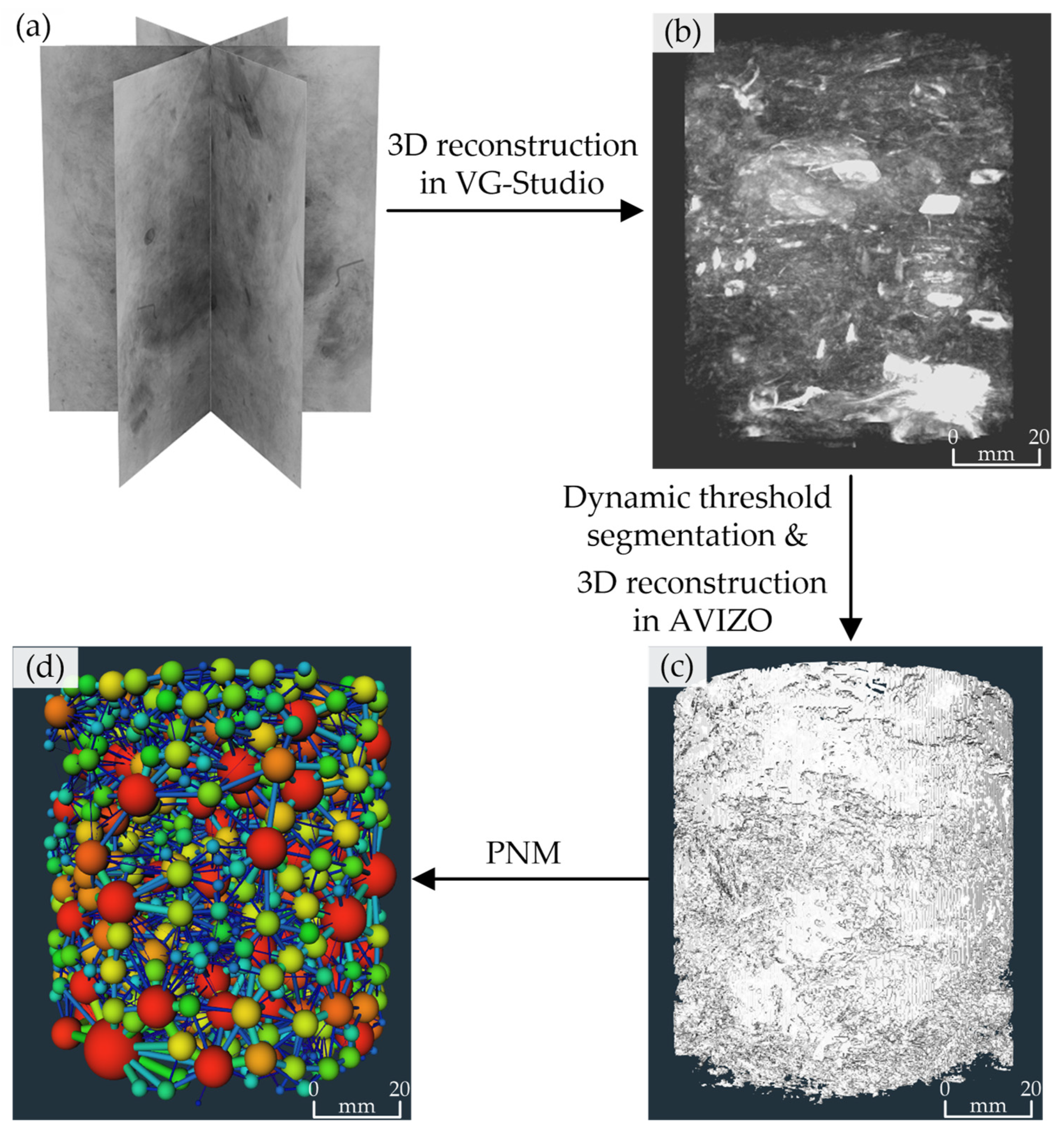

- (i)

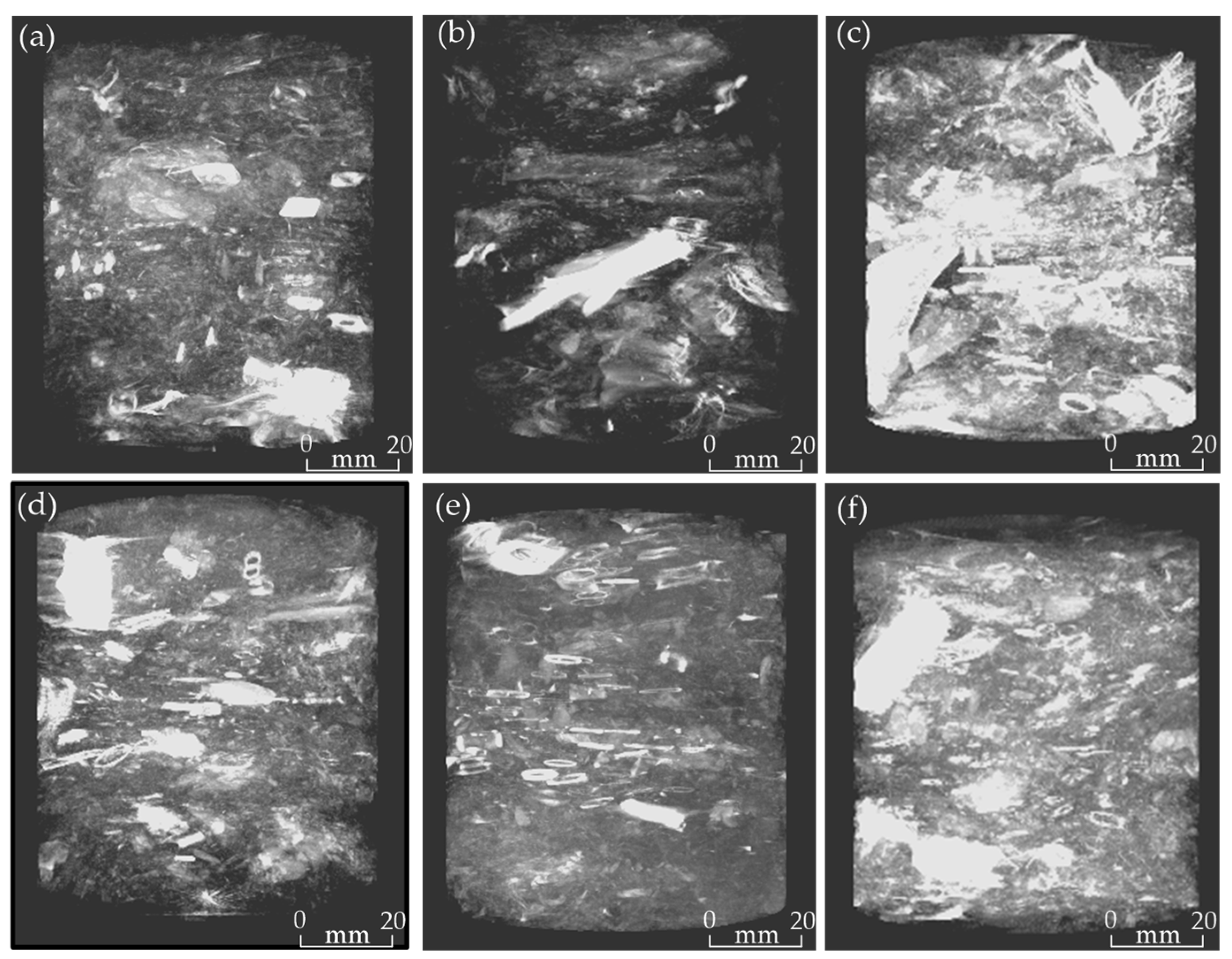

- The original data of the CT scan were imported into VG-Studio MAX. Then, according to Ke et al. [2], the visible pores and particles in the 3D reconstructed images were divided by dynamic threshold segmentation based on the background brightness and morphological denoising method.

- (ii)

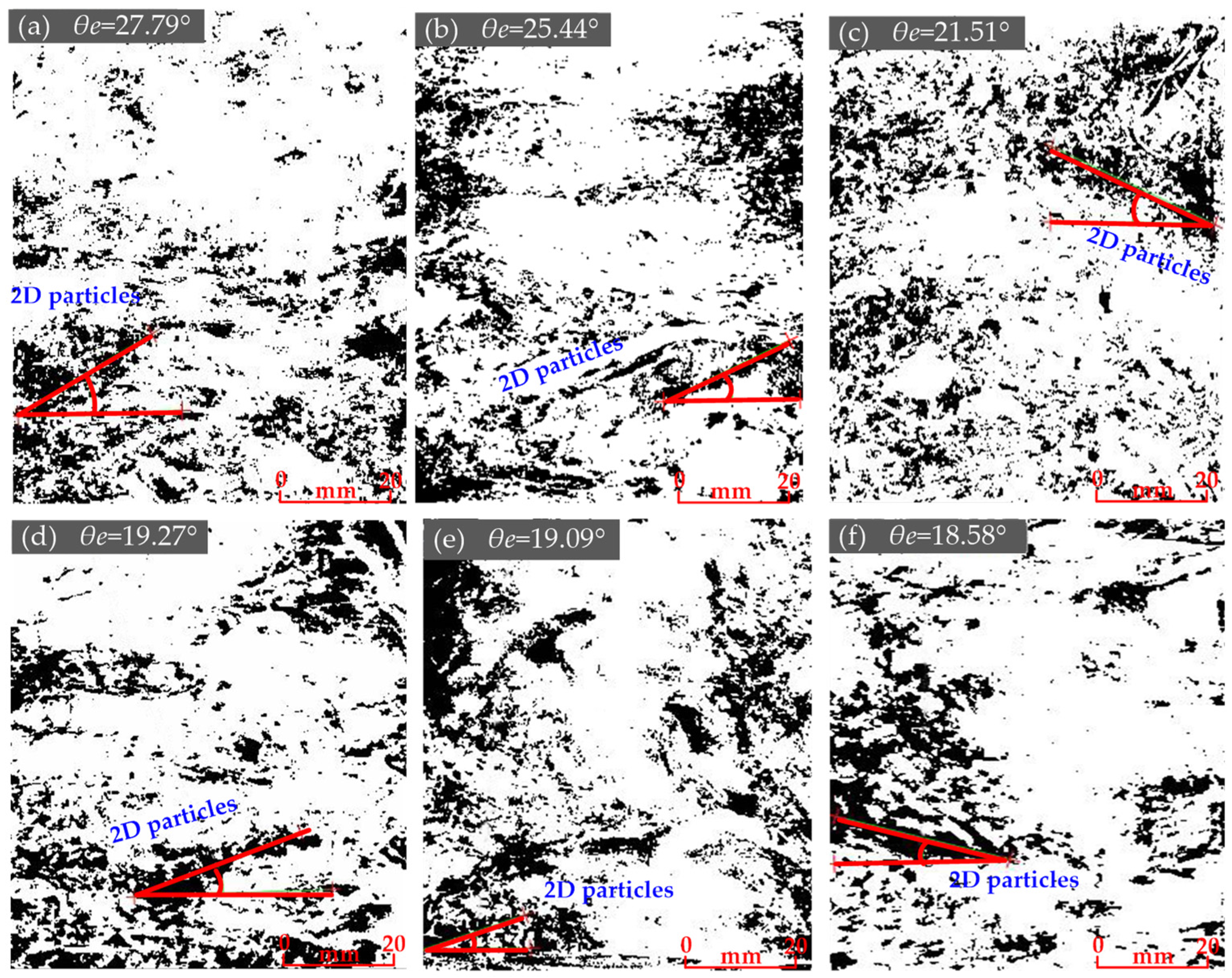

- Rotate the 3D reconstructed model in VG-Studio and slice it by every 1-degree angle. Then, the longest connected pore channel from the slices was obtained through the visual method. Its angles relative to the horizontal plane were determined as the characteristic angle of the connected pores in the sample.

- (iii)

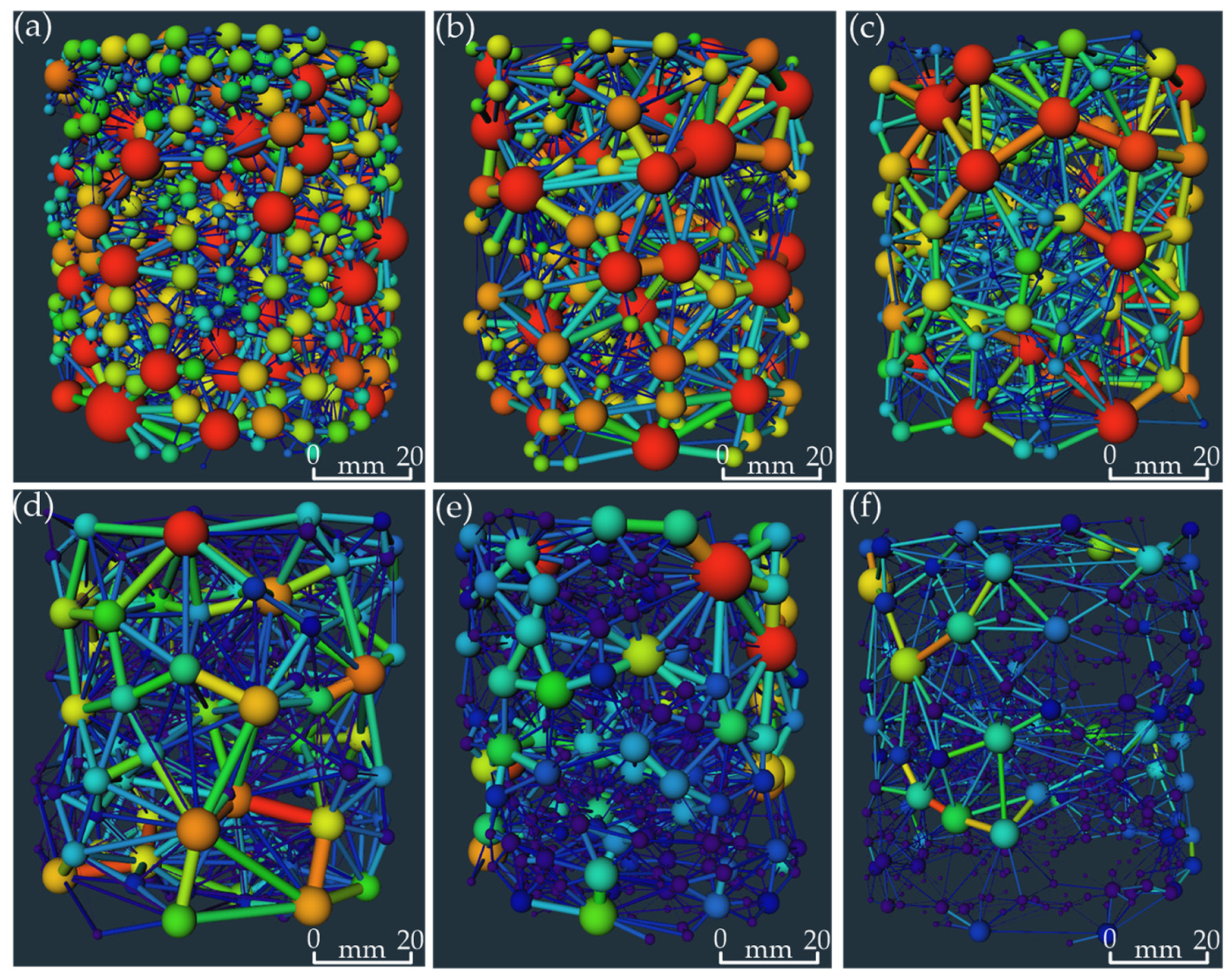

- Import the 3D reconstructed model from VG-Studio into AVIZO 2020. Through the dynamic adjustment of the gray-level threshold, the 3D reconstructed model of AVIZO was achieved.

- (iv)

- Separate the pores and solid particles in the 3D reconstructed model of AVIZO. Use the Generate Pore Network Model command to establish the equivalent pore network model (PNM) for connected pores. The pore structure parameters of the sample, including the diameter, volume, connectivity, and tortuosity of connected pores, were obtained through the PNM.

4. Testing Results

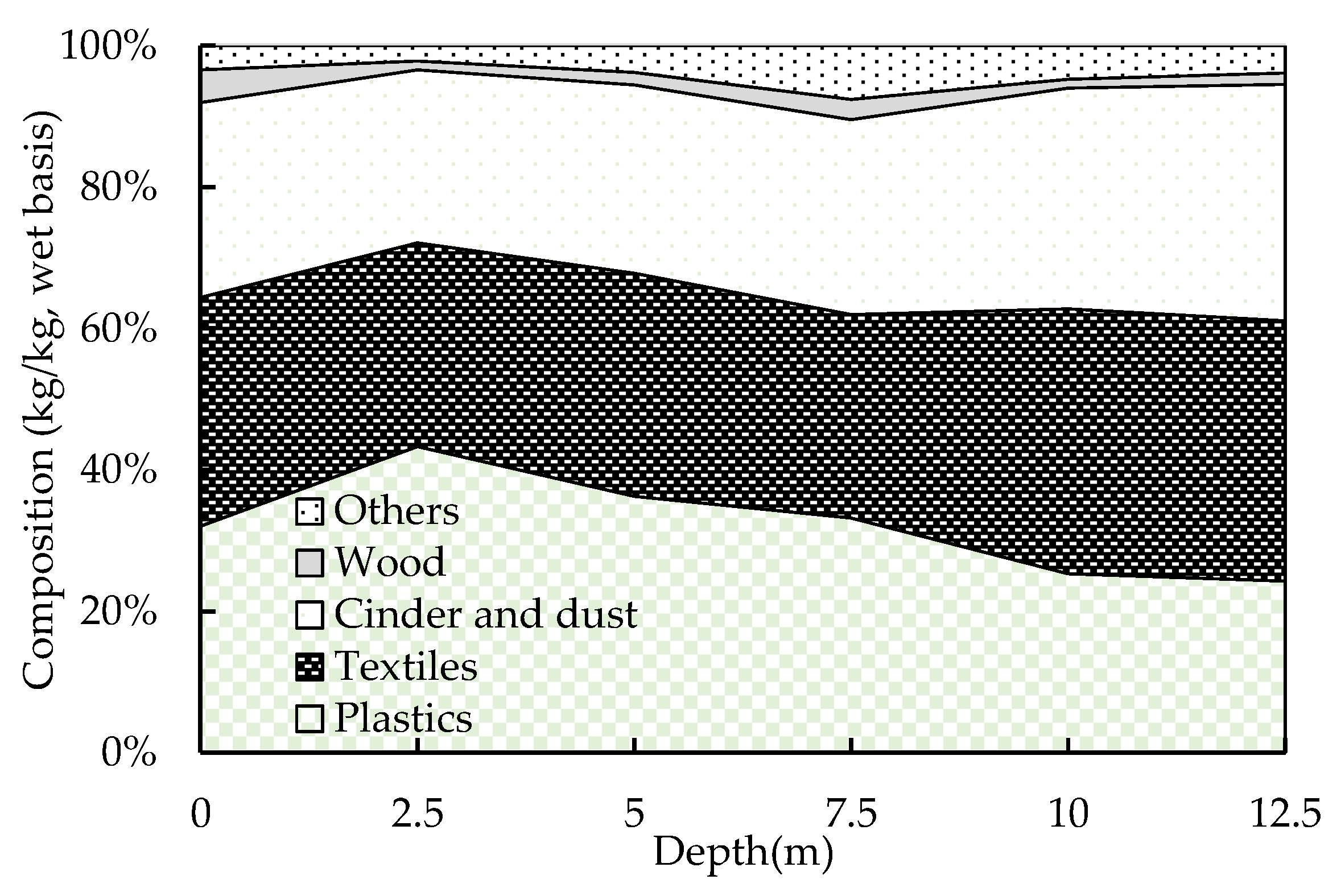

4.1. Waste Composition, Degree of Degradation, and Basic Physical Properties

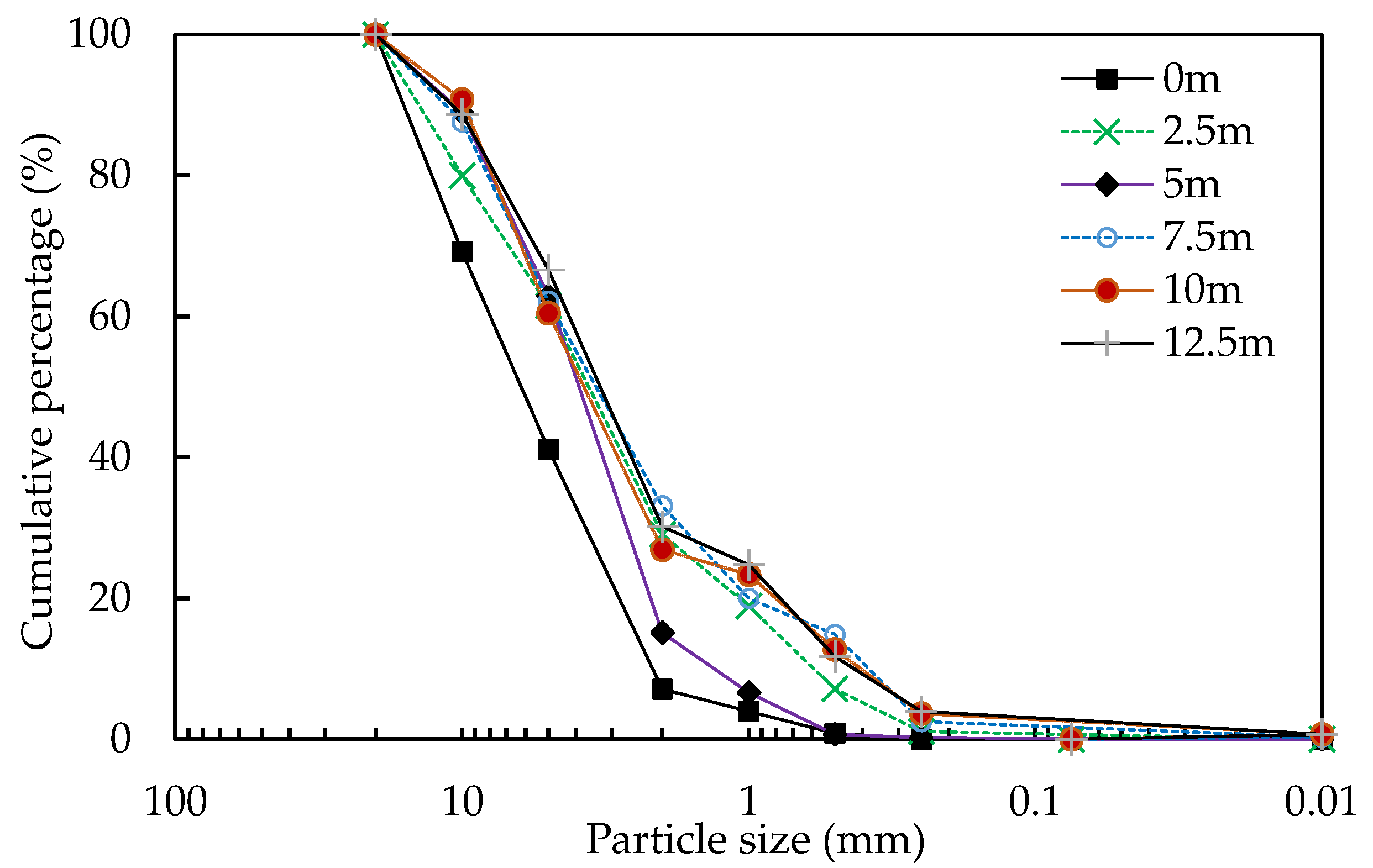

4.2. Particle Shape

4.3. Size of Connected Pores

4.4. Connectivity, Tortuosity, and Angle of Connected Pores

5. Discussions

6. Conclusions

- (i)

- The ratio of cellulose content to lignin content (i.e., C/L) decreased from 0.85 to 0.47 with increasing depth, which showed that the deeper sample had a greater degree of degradation.

- (ii)

- For solid particles in the samples, 2D particles constituted the greatest fraction (60.22~72.16%), which showed a decrease with increasing depth. The content of 0D particles increased with increasing depth, which was in the range of 25.74~30.15%. The contents of 1D and 3D particles showed no clear variations with depth.

- (iii)

- For pores in the samples, the void ratio decreased from 1.68 to 1.10 with increasing depth, indicating the deeper sample had a greater degree of compression. With the increase in depth, there were more small-pore channels with an average pore diameter coefficient (λ) decreasing from 0.209 to 0.190. Furthermore, the pore angle (θe) decreased from 29.6° to 17.8°, tortuosity (τ) increased from 1.129 to 1.184, and connectivity (ce) decreased from 12.0 to 4.1.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Muaaz-Us-Salam, S.; Cleall, P.J.; Harbottle, M.J. The case for examining fluid flow in municipal solid waste at the pore-scale—A review. Waste Manag. Res. 2019, 37, 315–332. [Google Scholar] [CrossRef]

- Ke, H.; Liu, Y.; Meng, M.; Hu, J.; Zhao, S.Y.; Qin, R.; Wu, X.W. Experimental study on the pore and solid structures of municipal solid waste under compression based on computed tomography (CT) scans. Environ. Sci. Pollut. Res. 2022, 29, 37359–37374. [Google Scholar] [CrossRef] [PubMed]

- Nanda, S.; Berruti, F. Municipal solid waste management and landfilling technologies: A review. Environ. Chem. Lett. 2021, 19, 1433–1456. [Google Scholar] [CrossRef]

- Chen, Y.M. Soil Degradation-Consolidation Theory and Its Applications; Springer: Singapore, 2024. [Google Scholar]

- Rosqvist, H.; Destouni, G. Solute transport through preferential pathways in municipal solid waste. J. Contam. Hydrol. 2000, 46, 39–60. [Google Scholar] [CrossRef]

- Caicedo-Concha, D.M.; Sandoval-Cobo, J.J.; Whiting, K. An experimental study on the impact of two dimensional materials in waste disposal sites: What are the implications for engineered landfills? Sustain. Environ. Res. 2016, 26, 255–261. [Google Scholar] [CrossRef][Green Version]

- Zhang, W.; Yuan, S. Characterizing preferential flow in landfilled municipal solid waste. Waste Manag. 2019, 84, 20–28. [Google Scholar] [CrossRef]

- Athanasopoulos, G.; Grizi, A.; Zekkos, D.; Founta, P.; Zisimatou, E. Municipal solid waste as a reinforced soil: Investigation using synthetic waste. In GeoCongress 2008: Geotechnics of Waste Management and Remediation; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2008. [Google Scholar] [CrossRef]

- Zekkos, D.; Grizi, A.; Athanasopoulos, G. Experimental investigation of the effect of fibrous reinforcement on shear resistance of soil-waste mixtures. Geotech. Test. J. 2013, 36, 867–881. [Google Scholar] [CrossRef]

- Ramaiah, B.J.; Ramana, G.V. Study of stress-strain and volume change behavior of emplaced municipal solid waste using large-scale triaxial testing. Waste Manag. 2017, 63, 366–379. [Google Scholar] [CrossRef]

- Jing, X.; Wu, S.; Qin, J.; Li, X.; Liu, X.; Zhang, Y.; Mao, J.; Nie, W. Multiscale mechanical characterizations of ultrafine tailings mixed with incineration slag. Front. Earth Sci. 2023, 11, 1123529. [Google Scholar] [CrossRef]

- Powrie, W.; Xu, X.B.; Richards, D.; Zhan, L.T.; Chen, Y.M. Mechanisms of settlement in municipal solid waste landfills. J. Zhejiang Univ.—Sci. A 2019, 20, 927–947. [Google Scholar] [CrossRef]

- Pi, X.; Fei, X.; Wang, Y.; Sun, X.; Guo, Y. Global void ratio of municipal solid waste for compression indices estimation. Waste Manag. 2023, 160, 69–79. [Google Scholar] [CrossRef] [PubMed]

- Reddy, K.R.; Kumar, G.; Giri, R.K. Modeling coupled processes in municipal solid waste landfills: An overview with key engineering challenges. Int. J. Geosynth. Ground Eng. 2017, 3, 6. [Google Scholar] [CrossRef]

- Feng, S.; Zheng, Q.; Chen, H.X. Unsaturated flow parameters of municipal solid waste. Waste Manag. 2017, 63, 107–121. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhang, L.; Wu, S.; Shao, Y.; Wu, X.; Li, Z. Changes in municipal solid waste pore structure during degradation: Analysis of synthetic waste using X-ray computed microtomography. Sci. Total Environ. 2020, 708, 135089. [Google Scholar] [CrossRef]

- Hanson, J.L.; Cox, J.T.; Yesiller, N. Evolution of municipal solid waste structure over time: Compaction and settlement effects. Environ. Geotech. 2023, 10, 455–463. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, X.; Wu, S.; Li, Z. CT measurement analysis for simulation experiment of pore structure of domestic waste landfill pile. Environ. Eng. 2018, 36, 165–170. [Google Scholar]

- Qin, R.; Ke, H.; Hu, J.; Lan, J.W. Analysis of particle composition and structure of MSW based on permeability. China Environ. Sci. 2019, 39, 203–209. [Google Scholar]

- Meng, M.; Qin, R.; Luo, P.; Ke, H. Structure and hydraulic characteristics of municipal solid waste based on CT scanning. J. Cent. South Univ. Sci. Technol. 2020, 51, 126–133. [Google Scholar]

- Ke, H.; Liu, Y.; Hu, J.; Qin, R.; Xu, X.B.; Chen, Y.M. Experimental study on anisotropy of hydraulic conductivity for municipal solid waste. Waste Manag. 2022, 137, 39–49. [Google Scholar] [CrossRef]

- Juarez, M.B.; Mondelli, G.; Giacheti, H.L. An overview of in situ testing and geophysical methods to investigate municipal solid waste landfills. Environ. Sci. Pollut. Res. 2023, 30, 24779–24789. [Google Scholar] [CrossRef]

- Orlando, L.; Marchesi, E. Georadar as a tool to identify and characterise solid waste dump deposites. J. Appl. Geophys. 2001, 48, 163–174. [Google Scholar] [CrossRef]

- Vargemezis, G.; Tsourlos, P.; Giannopoulos, A.; Trilyrakis, P. 3D electrical resistivity tomography technique for the investigation of a construction and demolition waste landfill site. Stud. Geophys. Et Geod. 2015, 59, 461–476. [Google Scholar] [CrossRef]

- Zhao, R.; Anderson, N.; Sun, J. Geophysical investigation of a solid waste disposal site using integrated electrical resistivity tomography and multichannel analyses of surface waves methods. J. Geosci. Environ. Prot. 2020, 8, 55–69. [Google Scholar] [CrossRef]

- Clément, R.; Legchenko, A.; Quetu, M.; Descloitres, M.; Oxarango, L.; Guyard, H.; Girard, J. Experimental study of domestic waste material using magnetic resonance measurements. Exp. Study Domest. Waste Mater. Using Magn. Reson. Meas. Near Surf. Geophys. 2011, 9, 179–185. [Google Scholar] [CrossRef]

- Abreu, A.E.S.; Gandolfo, O.C.B.; Vilar, O.M. Characterizing a Brazilian sanitary landfill using geophysical seismic techniques. Waste Manag. 2016, 53, 116–127. [Google Scholar] [CrossRef]

- Wille, E.; Martens, K.; Behets, T.; Umans, L.; Walraevens, K. Exploring the Anthropocene: Mapping and Surveying of Landfills in Flanders. In Proceedings Sardinia 2013; Italy, 2013. Available online: https://ovam.vlaanderen.be/c/document_library/get_file?uuid=f452c518-8ab5-5956-bf89-4c1d72aac18e&groupId=177281 (accessed on 1 January 2025).

- Isobe, Y.; Ishimori, H. Continuous electrical resistivity tomography monitoring in waste landfill sites with different properties and visualization of water channels. Appl. Sci. 2025, 15, 6920. [Google Scholar] [CrossRef]

- Ministry of Construction of the PRC (MCPRC). Technical Code for Municipal Solid Waste Sanitary Landfill (CJJ 17–2004); China Architecture & Building Press: Beijing, China, 2004. [Google Scholar]

- Zhou, H.; Meng, A.; Long, Y.; Li, Q.; Zhang, Y. An overview of characteristics of municipal solid waste fuel in China: Physical, chemical composition and heating value. Renew. Sustain. Energy Rev. 2014, 36, 107–122. [Google Scholar] [CrossRef]

- Edjabou, M.E.; Jensen, M.B.; Götze, R.; Pivnenko, K.; Petersen, C.; Scheutz, C.; Astrup, T.F. Municipal solid waste composition: Sampling methodology, statistical analyses, and case study evaluation. Waste Manag. 2015, 36, 12–23. [Google Scholar] [CrossRef]

- Kolsch, F. Material Values for Some Mechanical Properties of Domestic Waste. In Proceedings Sardinia 1995; Italy, 1995. Available online: http://www.dr-koelsch.de/assets/Downloads/sardinia95.pdf (accessed on 1 January 2025).

- Velkushanova, K.; Caicedo, D.; Richards, D.J.; Powrie, W. A detailed characterisation of an MBT waste. In Proceedings Sardinia 2009; Italy, 2009. Available online: https://www.researchgate.net/publication/281774367_A_detailed_characterisation_of_an_MBT_waste (accessed on 1 January 2025).

- Caicedo-Concha, D.M. A Study of the Structure in Solid Wastes and Some Implications for Fluid Flow in Landfills. Ph.D. Thesis, University of Southampton, Southampton, UK, 2013. [Google Scholar]

- Qin, R. Study on Structure and Preferential Flow Characteristics of Waste Under Different Degradation Ages. Master’s Thesis, Zhejiang University, Hangzhou, China, 2019. [Google Scholar]

- Chen, Y.M.; Liu, X.C.; Xu, W.J.; Li, Y.C.; Lan, J.W.; Zhan, L.T.; Li, H.; Li, C.M. Analysis of stabilization characteristics and exploitability of landfilled municipal solid waste: Case of a typical landfill in China. Sci. Sin. Technol. 2019, 49, 199–211. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of the PRC (MHURDPRC). Technical Specification for Soil Test of Landfilled Municipal Solid Waste (CJJ/T 204–2013); China Architecture & Building Press: Beijing, China, 2013. [Google Scholar]

- Van Soest, P.J.; Wine, R.H. Determination of lignin and cellulose in acid-detergent fiber with permanganate. J. Assoc. Off. Anal. Chem. 1968, 51, 780–785. [Google Scholar] [CrossRef]

- Barlaz, M.A. Forest products decomposition in municipal solid waste. Waste Manag. 2006, 26, 321–333. [Google Scholar] [CrossRef]

- Callow, B.; Falcon-Suarez, I.; Marin-Moreno, H.; Bull, J.M.; Ahmed, S. Optimal X-ray micro-CT image based methods for porosity and permeability quantification in heterogeneous sandstones. Geophys. J. Int. 2020, 223, 1210–1229. [Google Scholar] [CrossRef]

- Fan, N.; Wang, J.; Deng, C.; Fan, Y.; Wang, T.; Guo, X. Quantitative characterization of coal microstructure and visualization seepage of macropores using CT-based 3D reconstruction. J. Nat. Gas Sci. Eng. 2020, 81, 103384. [Google Scholar] [CrossRef]

- Xing, M.; Wu, J.S.; Zhang, C.Y.; Li, G.C.; Gao, S. Extraction and research on the pore structure of coal and rock based on CT scanning technology. J. North China Inst. Sci. Technol. 2021, 18, 32–38. [Google Scholar]

- Shanti, N.O.; Chan, V.W.L.; Stock, S.R.; Carlo, F.D.; Thornton, K.; Faber, K.T. X-ray micro-computed tomography and tortuosity calculations of percolating pore networks. Acta Mater. 2014, 71, 126–135. [Google Scholar] [CrossRef]

- Zhu, Y.; Yue, W.; Zhang, X.; Wang, Z.; Lu, M. Advances on the calculation methods of tortuosity in porous media. Prog. Geophys. 2023, 38, 1293–1304. [Google Scholar]

- Wu, H.; Chen, T.; Wang, H.; Lu, W. Field air permeability and hydraulic conductivity of landfilled municipal solid waste in China. J. Environ. Manag. 2012, 98, 15–22. [Google Scholar] [CrossRef]

- Yang, R.; Xu, Z.; Chai, J.; Qin, Y.; Li, Y. Permeability test and slope stability analysis of municipal solid waste in Jiangcungou Landfill, Shaanxi, China. J. Air Waste Manag. Assoc. 2016, 66, 655–662. [Google Scholar] [CrossRef]

- Feng, S.; Gao, K.; Chen, Y.; Li, Y.; Zhang, L.M.; Chen, H.X. Geotechnical properties of municipal solid waste at Laogang Landfill, China. Waste Manag. 2017, 63, 354–365. [Google Scholar] [CrossRef]

- Xu, X.B.; Zhan, T.L.T.; Chen, Y.M.; Beaven, R.P. Intrinsic and relative permeabilities of shredded municipal solid wastes from the Qizishan landfill, China. Can. Geotech. J. 2014, 51, 1243–1252. [Google Scholar] [CrossRef]

- Cao, W.; Hu, N.; Yan, G.; Hofmann, H.; Scheuermann, A. Permeability–porosity model considering oxidative precipitation of Fe (II) in granular porous media. J. Hydrol. 2024, 636, 131346. [Google Scholar] [CrossRef]

- Singh, K.; Kadambala, R.; Jain, P.; Xu, Q.Y.; Townsend, T.G. Anisotropy estimation of compacted municipal solid waste using pressurised vertical well liquids injection. Waste Manag. Res. 2014, 32, 482–491. [Google Scholar] [CrossRef] [PubMed]

| Depth (m) | Degree of Degradation C/L | Specific Gravity Gs | Water Content w (%) | Void Ratio e |

|---|---|---|---|---|

| 0 | 0.85 | 1.14 | 26.5 | 1.68 |

| 2.5 | 0.60 | 1.01 | 33.9 | 1.53 |

| 5.0 | 0.54 | 1.18 | 29.9 | 1.40 |

| 7.5 | 0.50 | 1.22 | 43.3 | 1.20 |

| 10.0 | 0.48 | 1.23 | 45.5 | 1.12 |

| 12.5 | 0.47 | 1.25 | 48.7 | 1.10 |

| Depth (m) | Pore Size Distribution Parameters λ and η | Average Coordination Number ce | Tortuosity τ | Pore Angle θe (°) |

|---|---|---|---|---|

| 0 | 0.209 and 2.358 | 12.0 | 1.129 | 29.6 |

| 2.5 | 0.207 and 2.402 | 11.3 | 1.147 | 25.4 |

| 5 | 0.205 and 2.313 | 11.3 | 1.134 | 22.6 |

| 7.5 | 0.196 and 2.009 | 10.6 | 1.182 | 21.6 |

| 10 | 0.191 and 1.968 | 6.1 | 1.177 | 19.2 |

| 12.5 | 0.190 and 1.981 | 4.1 | 1.184 | 17.8 |

| Waste Type | Test Method | Particle Structure | Pore Structure | References |

|---|---|---|---|---|

| Compressed and aged MSW (γd = 4.8 kN/m3 and e = 0.46) | Visual method after cutting the sample vertically into sections | Horizontal orientation of 2D particles (i.e., plastics, textiles, and paper). | Layered structure leads to increased tortuosity for vertical flow. | Caicedo-Concha et al. [6] |

| Synthetic MSW with degradation (Initial γ = 8 kN/m3) | CT scans of the sample on day 2 and day 260 | - | Fewer pores and connectivity. Day 2: n = 0.40, ce = 5.68. Day 260: n = 0.11, ce = 3.61. | Zhang et al. [18] |

| Degraded synthetic MSW under compression (Surcharge load of 50 kPa~200 kPa) | Visual method after cutting the sample | Horizontal orientation of 2D particles due to the surcharge load. | Fewer large pores, flatter pore structure, and greater tortuosity with increasing surcharge load. The value of θe decreases from 22°~23° to 8°~10° under compression. | Qin et al. [19] |

| Synthetic, fresh, Chinese MSW under compression (Initial Gs = 1.3 and w = 33%, surcharge load of 50 kPa~200 kPa) | CT scanning | Horizontal orientation of 2D particles (e.g., plastics and paper) under compression. | Large pores occur around 2D particles. Pore channels become flat with the horizontal orientation of 2D particles. The value of θe decreases from 30° to 20° under compression. | Meng et al. [20] |

| Synthetic MSW sample with enhanced degradation | CT scans of the sample on day 2 and day 260 | - | Less connected paths and more isolated paths with degradation. Connected path becomes more curved. Its tortuosity increases and the connectivity decreases. Day 2: n = 0.40, ce = 4.35. Day 260: n = 0.10, ce = 3.45. | Liu et al. [16] |

| Synthetic MSW sample with the elimination of microorganisms | CT scans of the sample on day 2 and day 260 | - | Slight change in pore structure. Day 2: n = 0.42, ce = 4.35. Day 260: n = 0.38, ce = 4.21. | Liu et al. [16] |

| Degraded synthetic MSW under compression (C/L = 2.19, surcharge load of 50 kPa~400 kPa) | CT scanning | The structural solids tend to be horizontal under compression, but the influence of vertical stress is limited. The structural solid angle is mainly concentrated at 30°~32°. | The porosity of large pores (>1 mm) decreases significantly, while that of the medium (0.1 mm~1 mm) and small (<0.1 mm) pores remains almost unchanged. The value of λ decreases from 2.09 to 1.30. | Ke et al. [2] |

| Borehole MSW samples (Depths of 5 m, 7 m, and 9 m) | Depth of 5 m: λ = 2.722. Depth of 7 m: λ = 1.818. Depth of 9 m: λ = 1.548. | |||

| Degraded synthetic MSW under compression (Degradation time of 0~18 months, Gs of 1.30~1.75, C/L of 3.93~0.61, surcharge load of 50 kPa~400 kPa) | Visual method and CT scanning | The content of 2D particles decreases from 78.7% to 47.2%, and that of 0D particles increases from 12.3% to 38.8%. The contents of 1D and 3D particles show little change. | Pores are mostly arranged along 2D particles. | Ke et al. [21] |

| Borehole MSW samples (Depths of 0 m~15m, Gs of 1.14~1.25, e of 1.68~1.10, C/L of 0.85~0.47). | Visual method and CT scanning | Horizontal orientation of 2D particles. More fine particles with increasing depth. | The value of ce decreases from 12.0 to 4.1 with increasing depth. The value of θe decreases from 29.6 to 17.8 accordingly. The decreases of λ and τ are not significant. | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Zhang, Z.; Hu, J.; Ke, H.; Lang, L.; Chen, C. Study on Solid and Pore Structures of Borehole Municipal Solid Waste Samples by X-Ray CT Scanning. Processes 2025, 13, 2176. https://doi.org/10.3390/pr13072176

Xu X, Zhang Z, Hu J, Ke H, Lang L, Chen C. Study on Solid and Pore Structures of Borehole Municipal Solid Waste Samples by X-Ray CT Scanning. Processes. 2025; 13(7):2176. https://doi.org/10.3390/pr13072176

Chicago/Turabian StyleXu, Xiaobing, Zhiyu Zhang, Jie Hu, Han Ke, Lei Lang, and Changjie Chen. 2025. "Study on Solid and Pore Structures of Borehole Municipal Solid Waste Samples by X-Ray CT Scanning" Processes 13, no. 7: 2176. https://doi.org/10.3390/pr13072176

APA StyleXu, X., Zhang, Z., Hu, J., Ke, H., Lang, L., & Chen, C. (2025). Study on Solid and Pore Structures of Borehole Municipal Solid Waste Samples by X-Ray CT Scanning. Processes, 13(7), 2176. https://doi.org/10.3390/pr13072176