Abstract

Integrating ejectors into CO2 transcritical refrigeration systems to reduce energy consumption has been performed successfully throughout the industry in recent years. The objective of the present work is to investigate the effect of indoor and outdoor operating conditions on the energy efficiency of ejector expansion supermarket refrigeration plants. The analysis uses the measured energy consumptions and loads for two supermarket refrigeration plants operating in two cities in the Republic of Moldova (Chisinau and Balti). A model for the prediction of the plant’s annual energy consumption and the loads of the refrigeration and freezing compressors is developed using experimental results. Although there are theoretical and experimental analyses of the investigated systems in the specialized literature, no studies were found in the specialized literature regarding energy consumption increase due to pressure losses through the pipe route in transcritical CO2 refrigeration installations with an ejector for supermarkets. The results indicate that refrigeration compressors have a greater increase in energy consumption than freezing compressors with increases in the outdoor temperature. The study shows that the additional drop in evaporating pressure at the compressor rack due to incorrect sizing of the pipe route leads to higher energy consumption compared to what the same plant would consume if the pipe route were correctly sized and executed. For every one-degree increase in temperature loss due to additional pressure drop through the pipeline, the entire plant consumes around 1.5% more energy. Knowledge of these performance data of real systems provides designers and manufacturers with clues to understand the importance of the correct design of the pipe route to obtain maximum energy efficiency.

1. Introduction

Carbon dioxide is a popular Natref that replaces the Synrefs used in commercial HVAC&R systems worldwide [1], with a GWP equal to 1. By comparing the COP calculated by using field measurements and numerical simulation results for HFC and CO2 systems, it was concluded that the new CO2 systems have a higher overall COP than HFC systems for outdoor temperatures below 24 °C [2]. The many improvements made in recent years to refrigeration systems using CO2 refrigerant have led to increased energy efficiency, even in the transcritical regime. Of all the proposed solutions, some have provided the desired results, i.e., maximizing the COP, by methods such as optimizing the refrigerant pressure inside the GC [3], subcooling the CO2 refrigerant at the outlet of the GC [4], installing plate heat exchangers (HEXs) [5], the cascade refrigeration system (CS) [6], mechanical subcooling [7], integration of the organic Rankine cycle [8], and especially, the use of an EJ [9]. Compared with other transcritical CO2 refrigeration cycles, without ejectors, used in supermarkets, the ejector expansion cycle has the highest COP under all conditions due to expansion work recovery in the ejector. The performance of this cycle is even better under higher ambient conditions [10]. However, other solutions, that seemed promising in the beginning, such as the use of PC [11] and MEJ [12], have not proven to be effective in practice and have been replaced by ejectors, which can operate with biphasic CO2 (gas and liquid). In addition, the method of using flooded evaporators in areas with high temperatures [13] must be used with great care, relying on precise settings to eliminate the risk of damaging the compressors due to liquid refrigerant entering the crankcase. However, it is universally agreed that all new refrigeration plants must be equipped with an HR system [14]. Significant amounts of energy can be recovered from supermarket refrigeration systems and used to heat or air-condition the building, thereby increasing the energy efficiency of the entire system [15]. Apart from supermarkets, it is reasonable to assume that there are approximately 1.5 million cold stores in Europe, ranging from small warehouses with volumes of 10–20 m3 to large distribution warehouses of hundreds of thousands of cubic meters. Most cold stores (around 67%) are small, less than 400 m3 [16]. Cold stores require large amounts of energy. In cold storage facilities, it is estimated that 60–70% of the electricity consumed is used for refrigeration plants. Therefore, cold storage users are keen to reduce energy consumption. Thirty-eight detailed energy audits were conducted in cold stores. The audit sites were specifically selected to provide a range of cold stores in terms of temperature, volume, products stored, refrigerants, and location. When analysed, the cold stores were divided into small (those with a volume less than or equal to 100 m3) and large (those with a volume greater than 100 m3). The potential for large energy savings, between 8% and 72%, was identified by optimizing warehouse utilization, repairing refrigeration plants, and upgrading energy-efficient equipment. These improvements often have relatively short payback periods of less than one year [17]. Extensive data on the performance of chilled, frozen, and mixed (mixed means chilled and frozen warehouses operating with a single common refrigeration system) refrigerated food cold stores were collected to identify the major factors influencing energy consumption. First, it was found that the volume of the cold store had the most significant relationship with energy consumption and that none of the other factors collected had such a large impact on energy consumption. For cold warehouses, 93% of the variation in energy consumption was related to store volume. For frozen and mixed warehouses, 56% and 67% of the variation in energy consumption was related to warehouse volume, respectively. The results also demonstrated high variability in the performance of cold stores. The model showed that the store form factor (which had a major impact on store floor area), utilization, and, to a lesser extent, ambient temperature, all had an impact on energy consumption [18].

The international standard ISO 23953 [19] clearly describes how to test refrigerated display cabinets (RDCs) and measures their consumption under a “reference condition”. Unfortunately, the laboratory cannot reproduce the thermal stratification of the store, so the heat extraction rate (HER) must be corrected using a coefficient of reduction. Tests on both supermarkets in this study showed that class 3 was a representative size of the cooling pack, but a coefficient of reduction between 0.8 and 0.9 could be applied for open vertical cabinets. Although the electricity consumption of the refrigeration plant was not measured separately, an approximate 3% increase in electricity consumption was considered for each degree decrease in the evaporation temperature. A coefficient between 0.83 and 0.89 was obtained. The difference between the store and the ISO 23953 laboratory is explained by the significant thermal stratification in the store. This value could be used to design a cooling system to suit the application and thus reduce energy consumption [20]. If the relative humidity in the store can be maintained at a lower value, large amounts of energy can be saved on refrigeration, defrosting, and anti-condensation. To prove this, calculations were performed for a typical day of each month of the year in a standard store in Tampa, Florida, using available climate data. Using the hourly values of the relative humidity for 24 h, the distribution of the relative humidity in the store could be calculated for an entire year. The average annual relative humidity in the store was 51.1%. It was concluded that for a 5% reduction in the relative humidity in the store, the refrigeration load of the refrigerated display cases decreased by 9.25%, resulting in a total reduction in energy consumption of 4.84%. The results were compared with available experimental data and found to agree [21]. The energy consumption of a typical supermarket in the UK is about 1000 kWh/m2, of which 30–50% is used for refrigeration and the rest for lighting and heating. With this high energy consumption, supermarkets indirectly have a significant impact on greenhouse gas emissions [22]. One way to increase energy efficiency is to use the heat released from the condenser side of a supermarket refrigeration system. The amount of heat released by the high-pressure side is directly related to the control of the refrigeration load and pressure of the refrigerant in the condenser. Due to its negligible direct greenhouse gas emissions and excellent thermophysical and heat transfer properties, CO2 refrigerant has attracted significant attention for application in supermarket refrigeration systems [22].

The thermodynamic processes and states of a real refrigeration system significantly deviate from the theoretical cycle. The pressure drop is intrinsic to the real flow. The working fluid is not a pure substance due to the presence of oil and other contaminants, and the real compression process is not isentropic. The final temperature of the refrigerant after a real compression process is always higher than that after isentropic compression [23]. The heat transfer process is irreversible due to the finite temperature difference and is non-isobaric due to the pressure drop. These deviations imply irreversibility within a real refrigeration system, which indicates a reduction in efficiency and the need for additional compression power. In the design phase, the superheating of the refrigerant at the outlet of the evaporator and subcooling of the refrigerant at the outlet of the gas cooler were considered to ensure the efficient operation of the entire system [24].

Refrigeration systems using ejectors operate with higher compressor suction pressure than a standard system, which means lower energy consumption for compression and higher energy efficiency of the system [25,26]. However, the problem of increased energy consumption due to high pressure losses through the pipe route in large refrigeration plants has not been analysed to date. This study focused on determining the influence of indoor and outdoor operating conditions on the energy efficiency of refrigeration systems. A mathematical model was developed to simulate the operation of a refrigeration system. It was validated using measurements performed on two functional plants in two cities in the Republic of Moldova (Chișinău and Bălţi). The results indicate that refrigeration compressors have a greater variation in energy consumption than freezing compressors with outdoor temperature variation, and annual energy consumption can increase by 1.5% when the evaporating temperature decreases by 1 °C.

2. Materials and Methods

Description of the Studied Systems

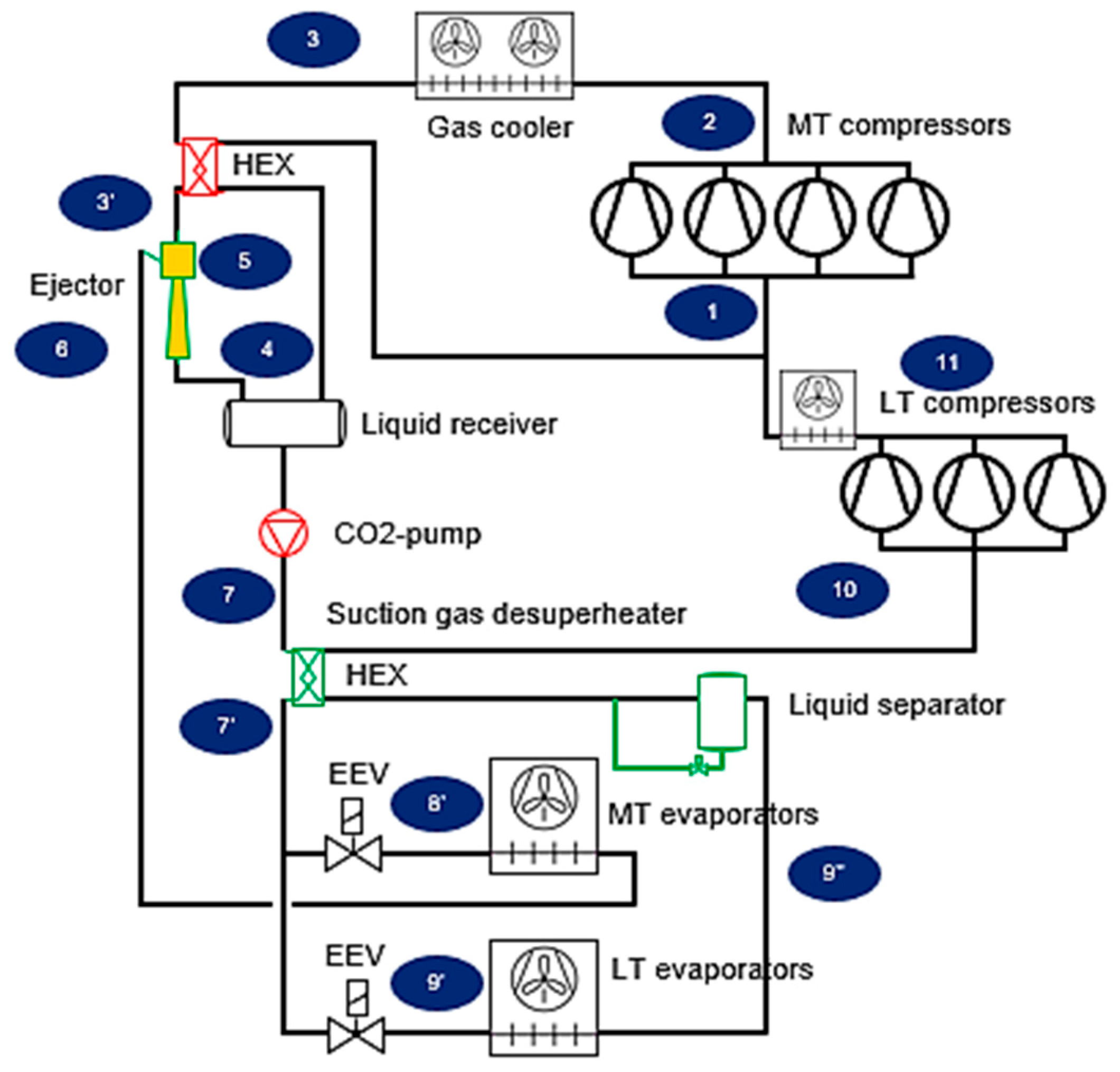

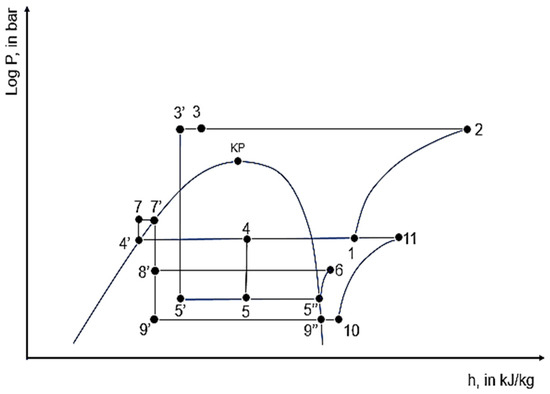

The first large-scale refrigeration plant, serving a supermarket with a total sales area of 5450 m2, is in the city of Bălți, in the northern part of the Republic of Moldova. The system is designed for a freezing refrigerating capacity of 44.8 kW at a consumer’s evaporating temperature of −29 °C and a refrigerating capacity of 362.1 kW at a consumer’s evaporating temperature of −3 °C. In addition, the system is equipped with heat recovery for domestic hot water, with a 2500-L storage boiler. The second large-scale refrigeration plant serves a supermarket with a sales area of 7500 m2 in the capital, Chișinău. The system is designed for a freezing refrigerating capacity of 52.5 kW at a consumer’s evaporating temperature of −29 °C and a refrigerating capacity of 368.6 kW at a consumer’s evaporating temperature of −3 °C. In addition, the system is integrated with heat recovery for domestic hot water with a 2500-L storage boiler. Both systems are designed for a maximum outdoor temperature of +39 °C and a maximum temperature inside the store of +25 °C, and relative humidity of 60%. The plants are of the “booster” type and are equipped with an ejector that can operate with two-phase refrigerant (liquid and gas) at an intermediate pressure in the liquid receiver. The scheme of the refrigeration plant with CO2 refrigerant is shown in Figure 1, and the corresponding refrigeration cycle is shown in Figure 2.

Figure 1.

Schematic of the ejector expansion CO2 refrigeration system.

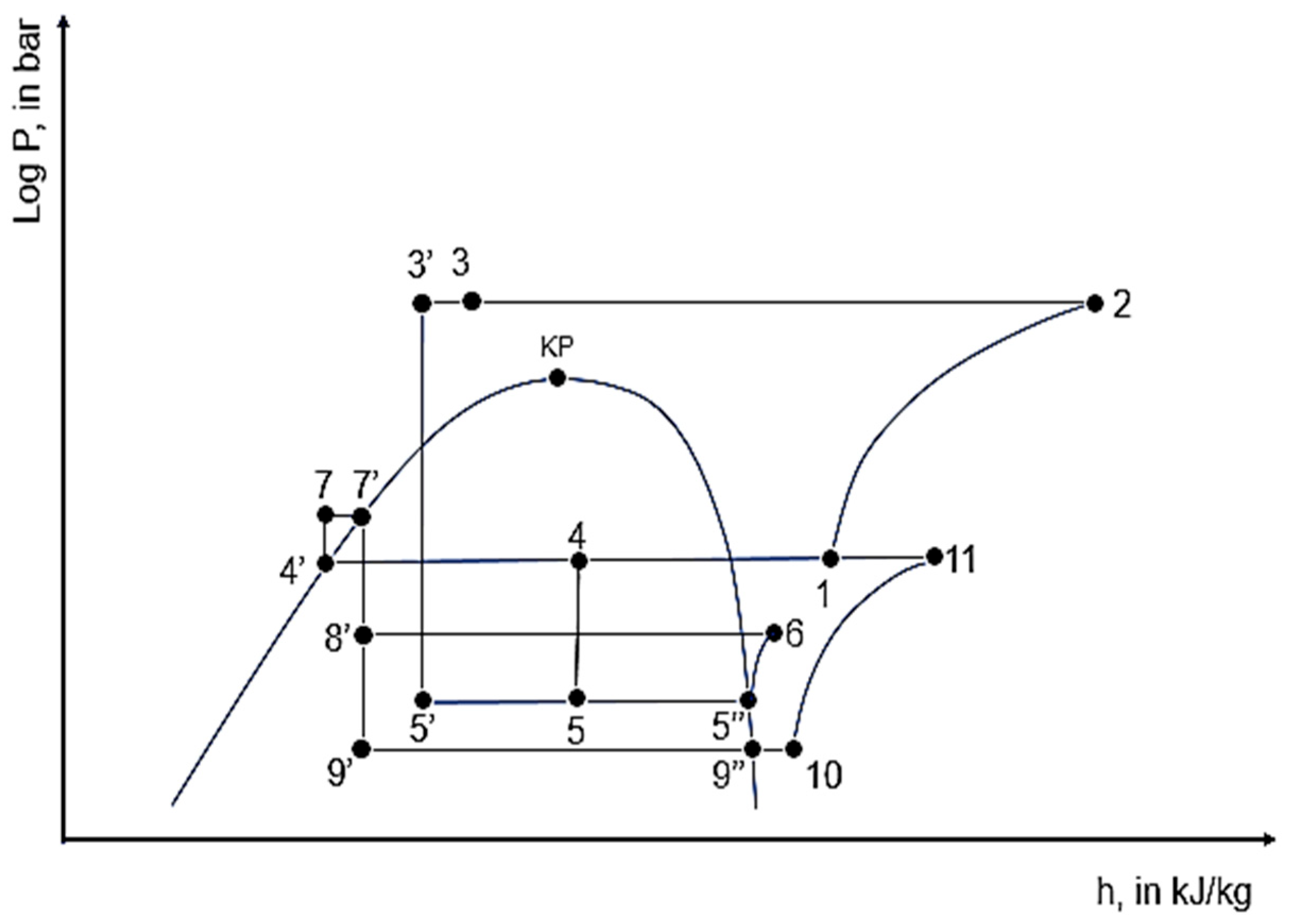

Figure 2.

Refrigeration cycle with two evaporation pressures.

The processes of the refrigeration cycle are as follows (Figure 2):

1-2: MT compressors compress the superheated CO2 gas from medium pressure to high pressure.

2-3: CO2 gas flows through the GC to transfer the heat to the surrounding air. Since the gas pressure is above the transcritical pressure of CO2, no condensation of the gas occurs.

3-3′-5-4: CO2 gas passes through a HEX of the gas line and then through the EJ (where it expands) to the liquid receiver. The ejector sucks in the gas from the medium-pressure consumers and increases its pressure to the higher-pressure receiver. The mixture of liquid and gas exiting the EJ flows to the liquid receiver.

4′-7-7′-8′: The liquid CO2 leaving the liquid receiver is pumped through the HEX to the expansion valves, where it expands until the MT evaporators. The CO2 pump only operates if the EJ lift pressure is too low.

8′-6: The refrigerant evaporates, extracting the heat from the ambient environment of the medium-temperature consumers (refrigerated display cases and cold rooms), which results in cooling of the products. The use of the EJ allows the MT evaporators to operate in flooded mode, that is, almost without overheating, as the compression of the CO2 liquid does not harm the ejector. Therefore, the evaporation temperature can be further optimized.

7′-9′-9″: The process is identical to 7′-8′-6, but for the freezing part (display cabinets and freezing cold rooms).

9″-10: To operate the LT evaporators in a flooded state, the suction line of the compressors is equipped with a liquid separator and a HEX.

10-11: The LT compressors compress the superheated CO2 gas from LP to MP.

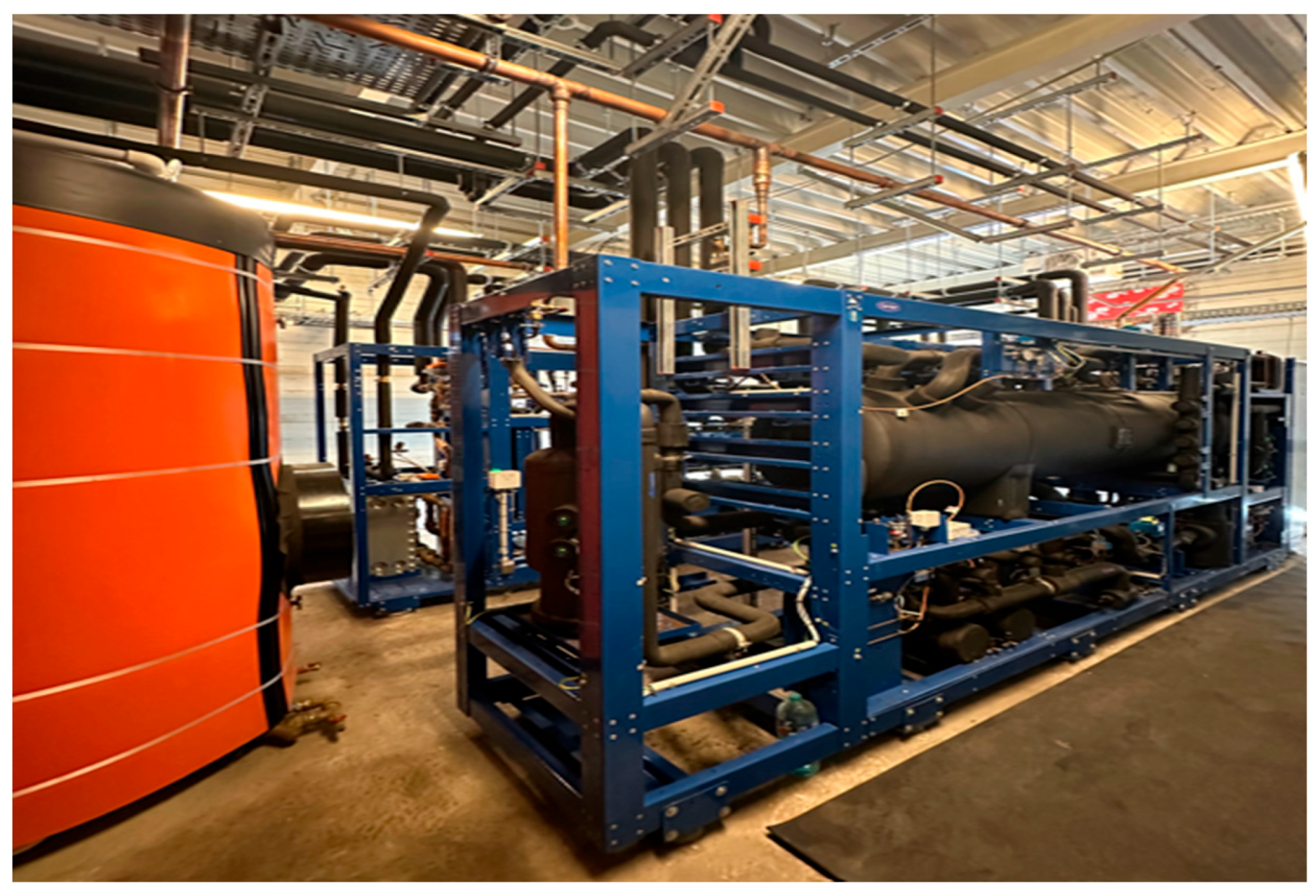

The plant in Bălți is composed, on the freezing side, of four Bitzer compressors of type 2FSL-4KB [24], with a total mass flow rate () of 688.8 kg/h, calculated at an evaporation temperature of −30.5 °C, a condensing temperature of 3.1 °C, and a superheat of 15 K through the suction circuit. The refrigeration circuit is composed of six compressors (4CTE-30KC) [27], with a total mass flow rate () of 11,418 kg/h (Figure 3). In both circuits, compressor no. 1 is equipped with a frequency inverter that allows the compressors to operate between 30 and 70 Hz. The plant in Chișinău is composed of three Bitzer compressors, two of which are 2CSL-6K [27] and one of which is 2FSL-4KB [27], with a total mass flow () of 794 kg/h, calculated under the same conditions as the plant in Bălți. The refrigeration circuit is composed of six compressors (4CTE-30KC) [27], having a total mass flow rate () of 11,842 kg/h. Also in this case, in both circuits, compressor no. 1 is equipped with a frequency inverter that allows the compressors to operate between 30 and 70 Hz. Both plants are equipped with an active oil management system (separator, receiver, electronic level regulators).

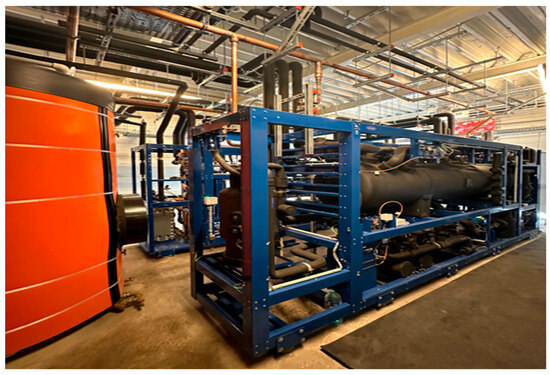

Figure 3.

Compressor rack installed inside the machinery room.

The plant in Bălți is equipped with two gas coolers (Figure 4) of type GASCO.AL91 CO2 6MDE EC M1 SV, both with vertical air flow, six fans, a 121,800 m3/h air flow rate, and 1152 m2 coil surface, and with a total mass flow rate calculated on the refrigerant side of 11,418 kg/h. The plant in Chișinău is equipped with two gas coolers, type GASCO.AL91 CO2 10MDE EC M1 SV, both with vertical air flow, ten fans, 163,551 m3/h air flow rate, and 1280 m2 coil surface, with a total mass flow rate calculated on the refrigerant side of 11,842 kg/h.

Figure 4.

Gas coolers installed outside the machinery room.

Figure 5 shows horizontal remote cabinets for freezing products inside the sales area, and Figure 6 shows an evaporator inside the freezer room, equipped with kit for shut-up defrost (blue ones in front of the fans) and kit for rear air direction (insulated cover with same white colour as the evaporator and situated in the back side of the evaporator).

Figure 5.

Horizontal display cabinets for freezing products situated in the sales area.

Figure 6.

Evaporator inside the freezer room equipped with shut-up defrost and insulated cover.

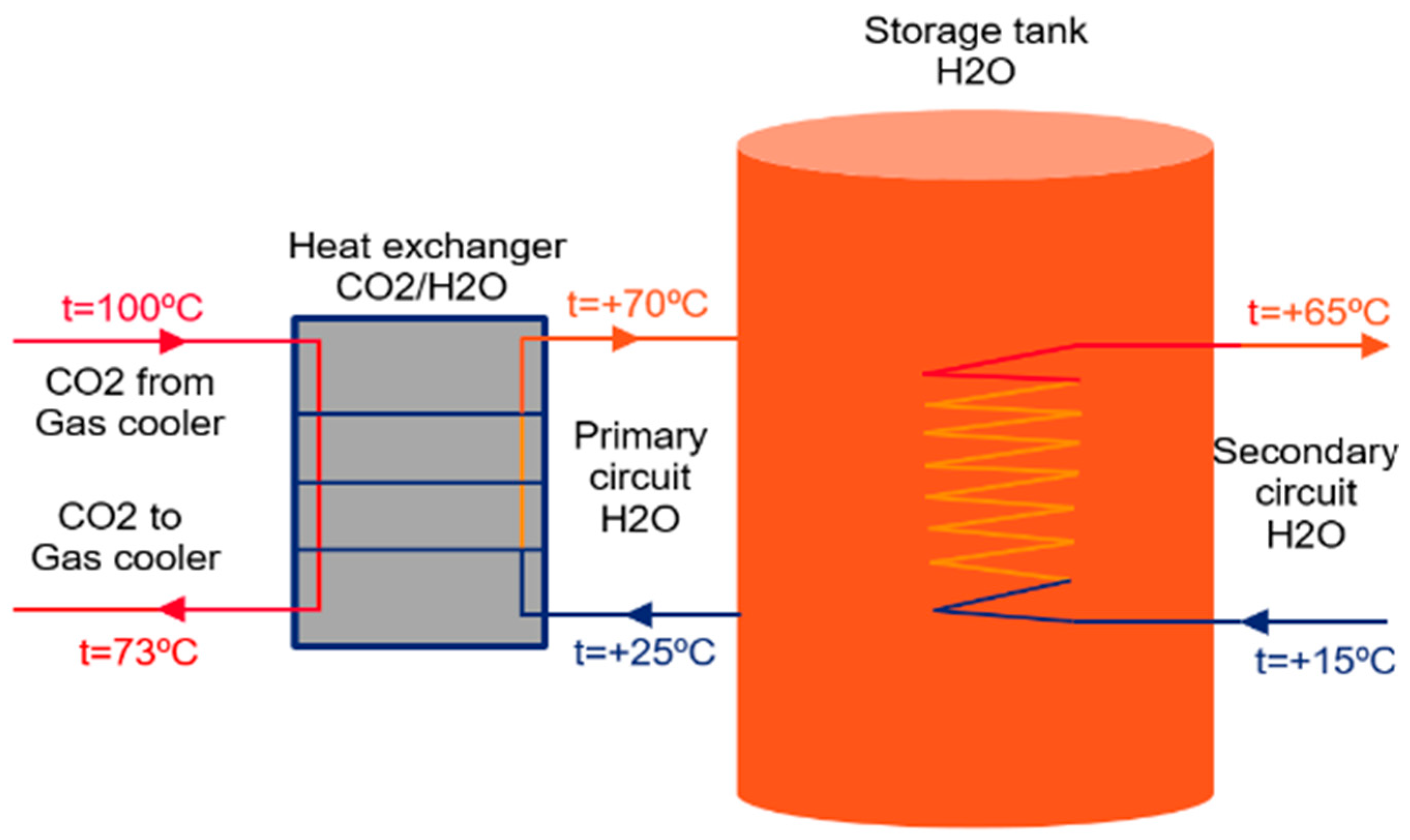

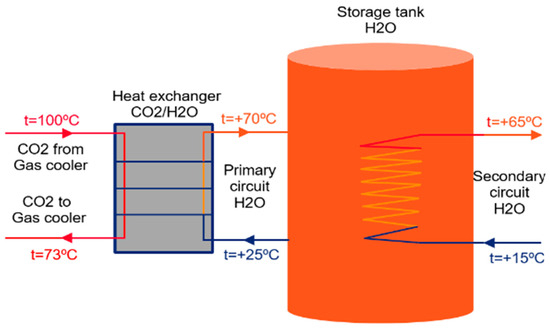

Waste heat utilization has become a priority research area in the international refrigeration field. Both refrigeration plants were designed to partially recover the condensing heat to produce domestic hot water. Therefore, a heat exchanger (HEX) CO2–H2O, with a capacity of 40 kW, was installed on the frame of the refrigeration plant, and a storage tank of 2500 L with an additional coil was installed. The primary circuit between the heat exchanger and the storage tank provides water at 70 °C flow and 25 °C return, and the secondary circuit between the storage tank and the consumers provides domestic hot water at 65 °C flow and 15 °C return. Figure 7 shows the storage tank in orange and the HEX in silver, and Figure 8 presents a schematic of the system.

Figure 7.

Heat recovery system for domestic hot water inside the machinery room.

Figure 8.

Schematic of heat recovery system for producing domestic hot water.

Both systems were designed for the following maximum pressure regime: LP = 30 bar; MP = 52 bar; ResP = 52 bar; OilP = 52 bar; and HP = 120 bar.

The temperature and pressure were measured by using industrial-type sensors, and the energy consumption by energy consumption recorders. The following measuring devices were used:

- Sensors for measuring consumer temperature (display cabinets and cold rooms are of the NTC type, which can operate in the temperature range of −50 °C to +50 °C).

- Sensors for measuring the temperature of compressor racks and gas coolers, PT1000 type, which can operate in the temperature range of −50 °C to +200 °C.

- Sensors for suction-pressure measurement: 4–20 mA; 1–26 bar.

- Sensors for medium-pressure measurement: 4–20 mA; 1–59 bar.

- Sensors for high-pressure measurement: 4–20 mA; 1–161 bar.

- Schneider energy consumption recorders of type iEM3255 with an accuracy of ±1 A.

The plant in Chișinău is equipped with four 135 kW ejectors, whereas the plant in Bălți is equipped with two 105 kW ejectors and two 135 kW ejectors.

3. Energy Model

The five primary subsystems that comprise the refrigeration system model are the compressors, gas cooler, ejector, expansion valves, and cold room and display cabinet evaporators [28].

3.1. Compressors

The mass flow rate ( on the suction side of the compressor is expressed as

where is the refrigerant density at the suction inlet of the compressor, and is the volumetric flow rate, which can also be expressed as the product of the volumetric efficiency (ηv) and compression ratio (Vcomp):

The volumetric efficiency can be expressed as

where pd and ps are the discharge and suction pressures, respectively; C1 and C2 are constants, and γ is the isentropic exponent of compression.

The electrical power of the compressor can be calculated as follows [29]:

where C3, C4, and C5 are constants.

The energy balance for the compressor is as follows:

where hd and hs are the CO2 enthalpies at discharge and suction, respectively, and ∅loss is the heat flow rate lost to the environment, which can be calculated as an empirical function of the ambient temperature and compressor discharge temperature [30].

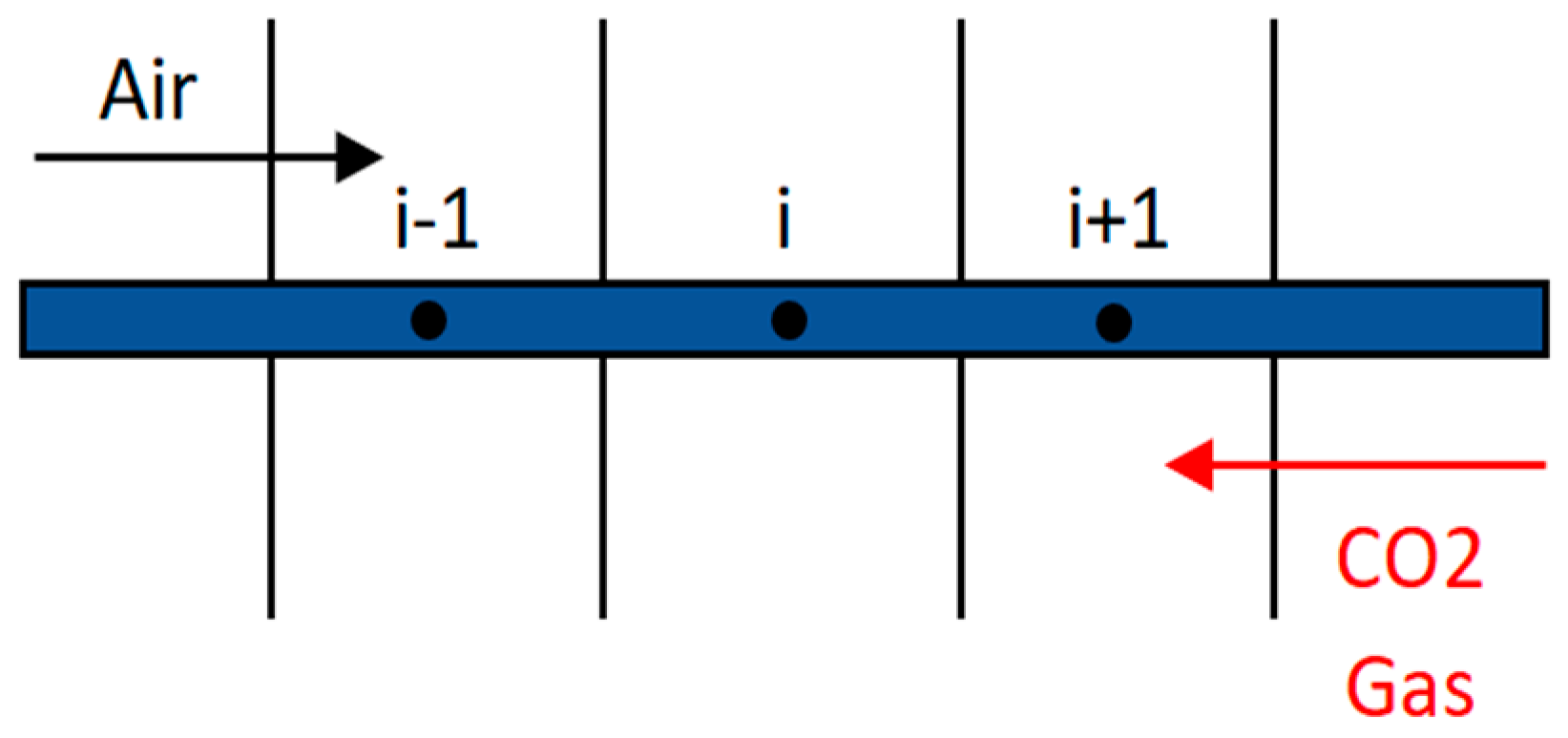

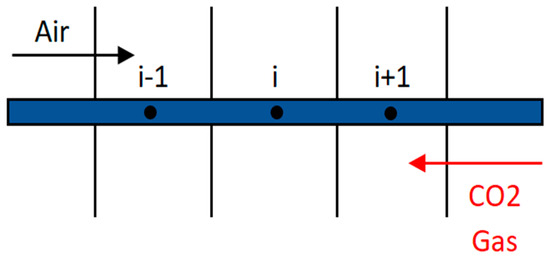

3.2. Gas Cooler

The operation of the air-cooled gas cooler can be described using the distributed modelling method [31]. For efficient modelling, the gas cooler was divided into discrete segments, as shown in Figure 9. The ε-NTU method establishes the governing equations in the i-th segment. Therefore, the heat flux in the i-th segment can be written as

Figure 9.

Gas cooler divided into discrete segments.

For the first segment, the heat transfer flux on the refrigerant side of the gas cooler of the i-th segment is given by the following equation:

where is the CO2 mass flow rate through the gas cooler; and and are the CO2 enthalpies at the inlet and outlet of the i-th segment. In the same way, the air-side heat flow rate is expressed as

where is the heat flow rate on the air side at the i-th segment; is the mass flow rate of air passing through the gas cooler; is the specific heat of air; and are the inlet and outlet temperatures of air at the i-th segment.

According to the ε-NTU method, the heat flow rate between the CO2 refrigerant and air can be calculated as follows:

where is the maximum possible energy transferred from the CO2 to the air in segment i, and can be expressed as

with

and (effectiveness of the heat exchanger) as described in [32].

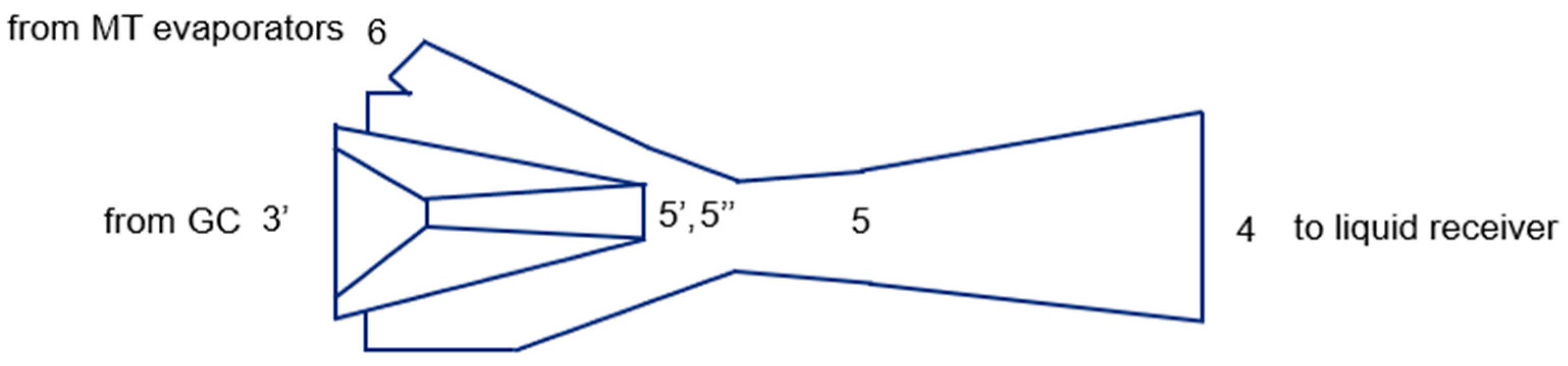

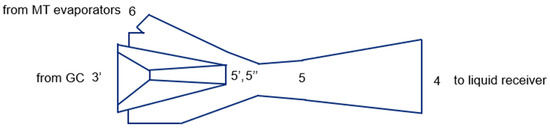

3.3. Ejector

The performance of the ejector (Figure 10) can be correctly evaluated if its operation is divided into three distinct parts: critical mode, subcritical mode, and backflow mode. The ejector function completely disappears in backflow mode. At the critical point, the primary and secondary mass flow rates are given by the following equations [33]:

Figure 10.

Schematic diagram of the ejector.

The energy conservation equation in the mixing chamber is given as

The pressure at the outlet of the diffuser can be calculated as

In subcritical mode the entrainment ratio is between the critical entrainment ratio and zero, and so . In the analysed plant, CO2 expands into the (liquid) receiver after exiting the EJ.

At the breakdown, the energy conservation equation in the mixing chamber is expressed as

The pressure at the outlet of the diffuser can be calculated as

The EJ performance in the critical and subcritical modes can be predicted as follows:

- −

- If the liquid receiver pressure Pr is not higher than the critical pressure Prc, and the ejector is working at critical mode, then

- −

- If Pr is between the critical pressure Prc and the breakdown pressure Prb, the entrainment ratio u can be obtained by the following equation:

3.4. Electronic Expansion Valves

The performance of the electronic expansion valves is modelled based on a semi-thermodynamic model, which optimizes the estimation of the mass flow rate of CO2 refrigerant with the compressor type to obtain convergence of the system simulation. It is reasonably assumed that the process in the electronic expansion valves is an isentropic process, and the mass flow rate is a function of the pressure drop:

where Cve is the flow coefficient and can be either a constant or a function of the opening position as

where Pos is the valve opening expressed in percent and is the input variable in this simulation, which can be obtained by the controller; and k1, k2, and k3 are constants. These above models are calculated by using the successive approximation method (SAM). The successive approximation method is a simulation approach that combines the equation-oriented method (EOM) and the sequential component method (SCM). At the whole-system level, the SCM is used to link the component-level computation with the connection equation and the constraint equation to solve the whole system. At the component level, the EOM is applied to solve all model equations at the same time [34].

3.5. Evaporators in Cold Rooms and Display Cabinets

In general, there are three types of modelling strategies for simulating heat exchangers, which are also valid for evaporators: lumped modelling, which assumes a constant specific heat; zonal modelling [35]; and distributed modelling, in which the evaporator’s coil is subdivided into several elementary control volumes and analysed in detail [36]. Due to its excellent results, distributed modelling is widespread in the design of heat exchangers in general, and evaporators in particular. Zonal modelling divides the evaporator into two zones: the superheated zone and the two-phase zone. The heat transfer between the CO2 refrigerant and the air is balanced by the calculated cooling capacities, both for the CO2 and the air side. For the CO2 refrigerant, the heat transfer rates of the two-phase zone and of the superheated zone are given by the following equations:

where is the mass flow rate of the CO2 refrigerant; hro and hri are the enthalpies at the outlet and inlet of the evaporator; hrsat is the enthalpy of the CO2 in the refrigerant saturated vapour state (quality = 1); A is the surface area of the evaporator; ftp and fsh are the ratios between the surface area of the two-phase zone and the superheated zone to the entire evaporator surface area; and are the logarithmic mean temperature differences at the two-phase and the superheated zones; and Utp and Ush are the overall heat transfer coefficients at the two-phase zone and the superheated zone.

Taking into consideration the air-side heat transfer, the energy balance is

where is the air mass flow rate; and are the enthalpies of the air at the evaporator’s inlet and outlet; is the condensate enthalpy; and is the condensate mass flow rate, and can be calculated as

where and are the absolute humidity ratios of the air at the evaporator’s inlet and outlet, which are calculated based on air pressure and the air dry- and wet-bulb temperatures. The enthalpy potential method with an apparatus dew-point temperature is used for the latent capacity calculation [37].

4. Estimation of Annual Energy Consumption

The operation of the plant shown in Figure 1 was simulated based on the mathematical model, using the thermodynamic relationships for each process described above. The simulation was carried out by using the Microsoft Excel program as an interface with the REFPROP library, version 9.1, developed by NIST in 2013 [38]. The input data used were the energy characteristics of each item of equipment and the atmospheric temperature variation in each city from the meteorological data available online on the State Hydrometeorological Service of the Republic of Moldova web site. To simplify the calculations, certain parameters were adopted (Table 1).

Table 1.

Fixed values of measured parameters.

The statistical temperature records were considered, and thus an average annual temperature of +10.3 °C was considered for Balti city and +10.8 °C for Chisinau city. It was also considered that an adiabatic spray-aeration system was in operation when the outdoor temperature reached +31 °C. The adiabatic spray-aeration system is installed in summer only, being installed in late spring and dismantled in early fall for safe storage.

Table 2 shows the estimated number of hours of operation of the plants for variation in the outside temperature from −20 °C to +40 °C; in total 8760 h.

Table 2.

Estimated number of hours of operation.

Table 3 shows the pressure drop considered for each circuit in the design phase of the two systems.

Table 3.

Evaporation temperature (t0) and temperature decrease (Δt) due to pressure drop through pipes (Δp).

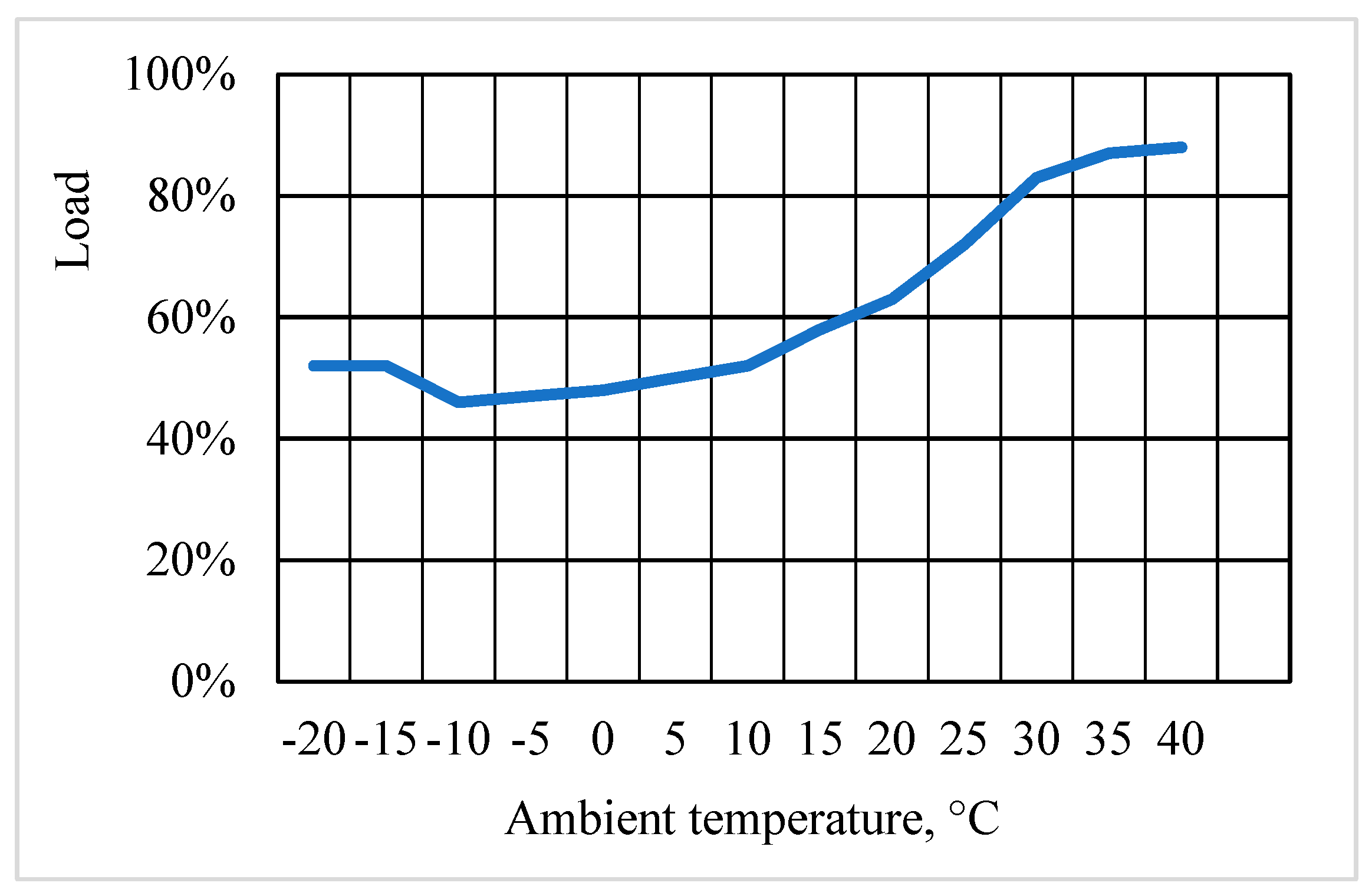

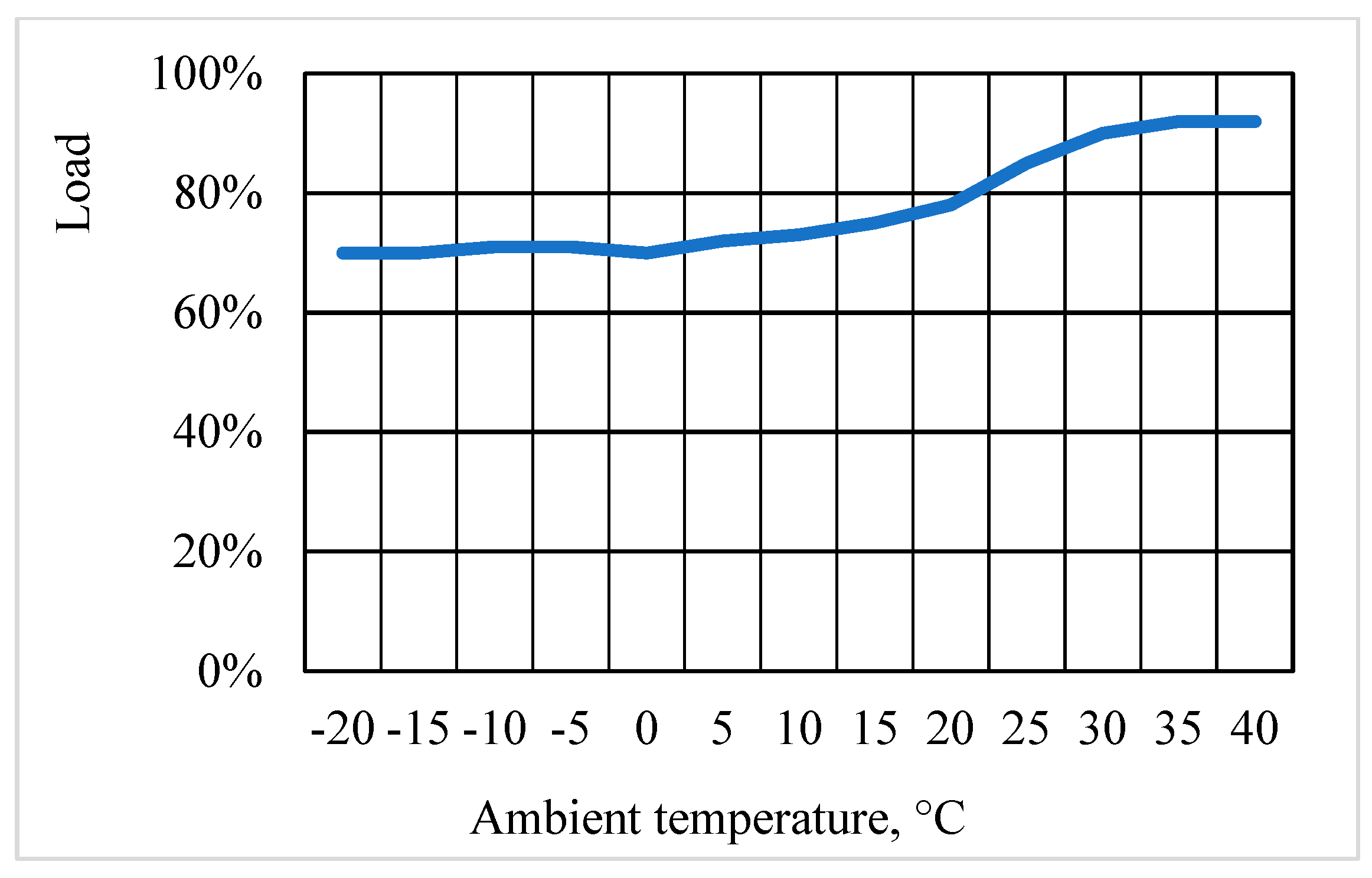

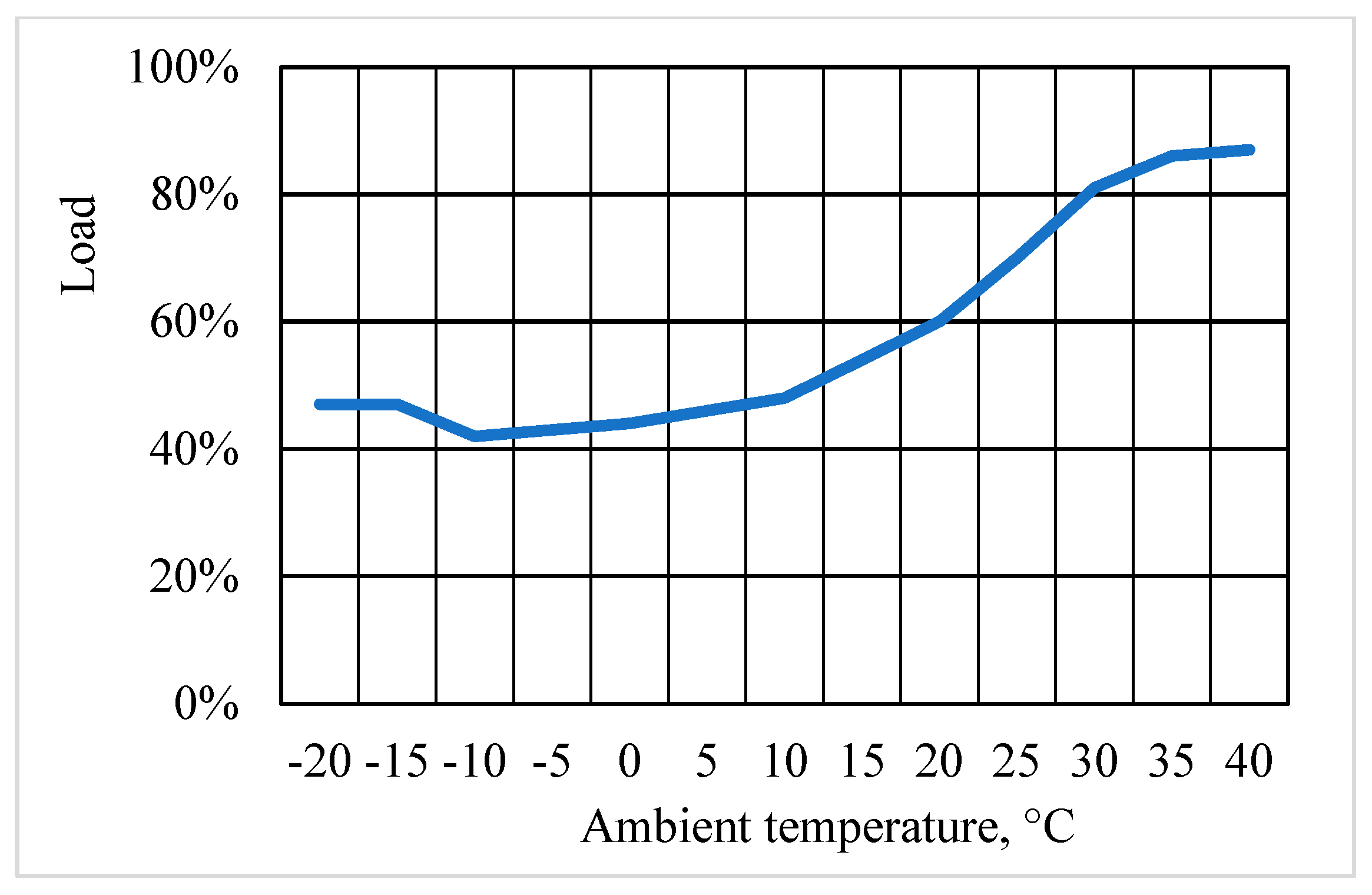

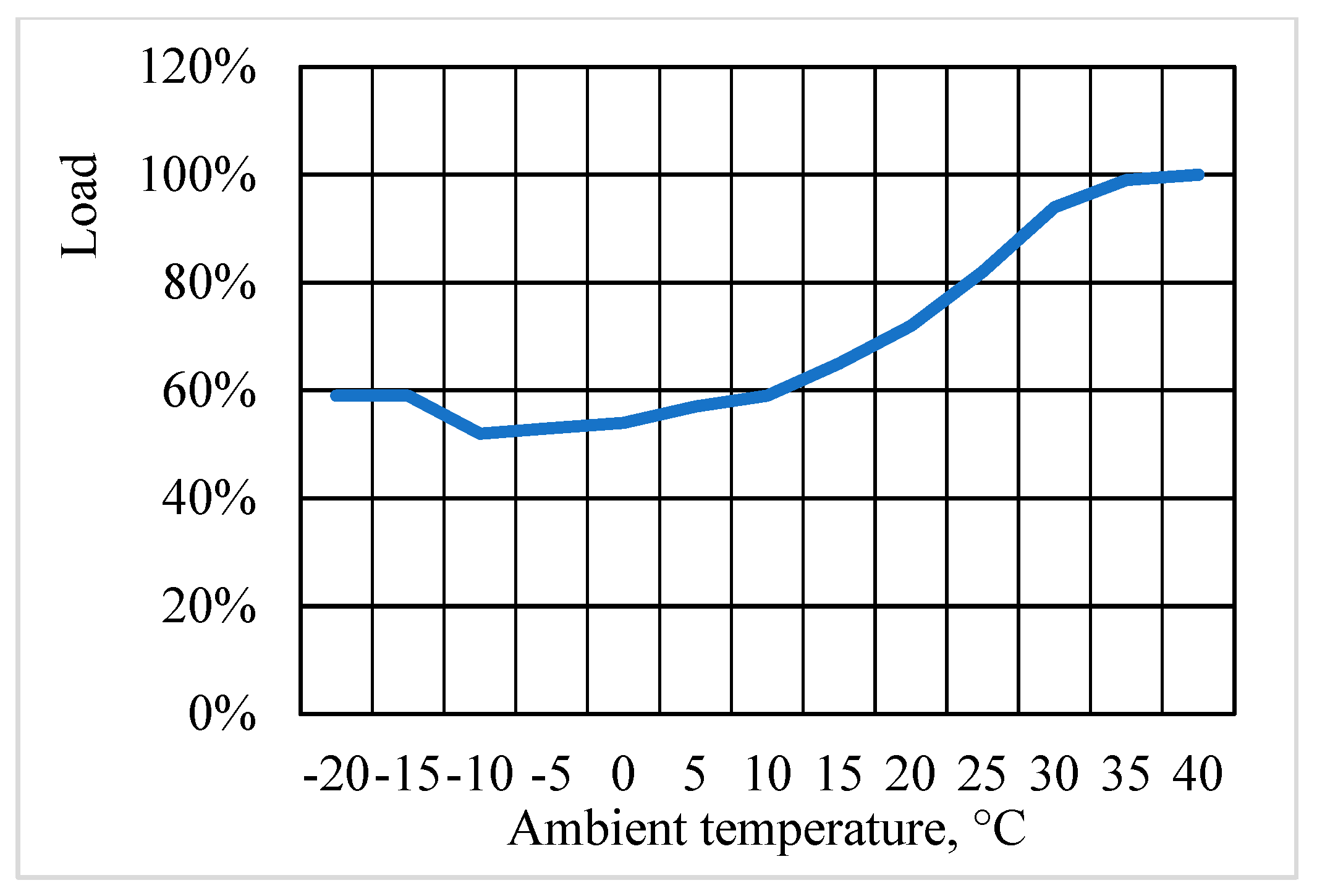

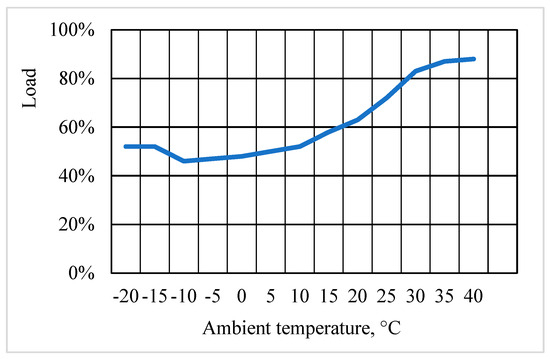

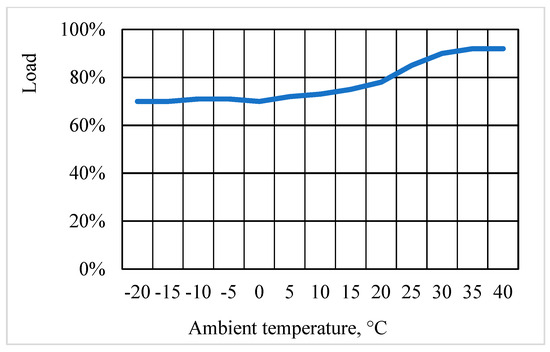

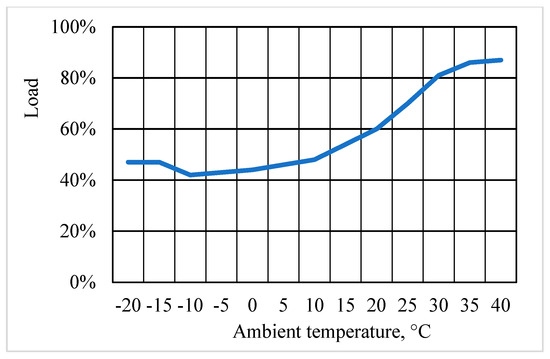

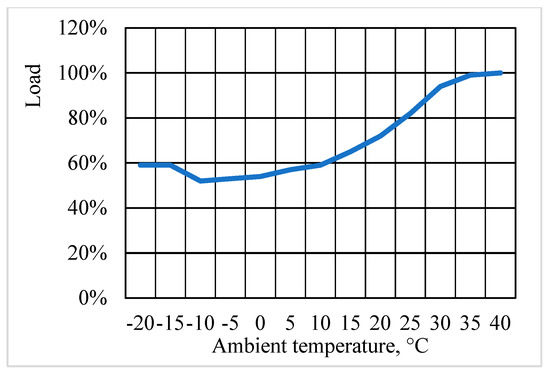

To estimate the refrigeration load of the consumers, the variation in the temperature inside the supermarket was considered, both in the sales room and in the storage space. The required load during the day and during the night was also considered. With these assumptions, the load was estimated for the largest system components: freezing and refrigeration compressors, gas coolers, and desuperheater. Figure 11 shows the estimated load of the refrigeration plant on the gas coolers, Figure 12 shows the load of the compressors on the freezing circuit, Figure 13 shows the estimated load of the compressors on the refrigeration circuit, and Figure 14 shows the estimated load of the refrigeration plant on the desuperheater. The loads for the gas coolers, refrigeration compressors, and desuperheater have the same profile, they decrease slightly with increasing external temperature, reach a minimum around −10 °C, and then increase sharply. The increase is because the lowest temperature, according to the available data, is recorded during the day, when there are customers in the store, and the temperature increases during the night when there are no customers, with this leading to a higher load during the day even though the outside temperature is lower in this case. The load for the freezing compressors has a smoother increase with increasing external temperature. Table 4 shows the calculated annual energy consumption. The simulation was performed with the following assumptions:

Figure 11.

CO2 gas coolers’ load vs. outdoor temperature.

Figure 12.

Freezing compressors’ load vs. outdoor temperature.

Figure 13.

Refrigeration compressors’ load vs. outdoor temperature.

Figure 14.

Desuperheater’s load vs. outdoor temperature.

Table 4.

Calculated annual energy consumption for both supermarkets.

- −

- All thermodynamic transformations occur in steady-state;

- −

- Pressure drops in heat exchangers are neglected;

- −

- Expansion processes in the expansion valves are assumed to be isenthalpic;

- −

- Efficiency of liquid–vapour separation in liquid receiver is 100%;

- −

- The outside temperature varies from −20 °C to +40 °C.

The lowest temperature for the low-temperature circuit is −29 °C, and for the medium-temperature circuit is −3 °C (in refrigerated display cases and cold rooms), which is maintained all the time.

5. Results and Discussion

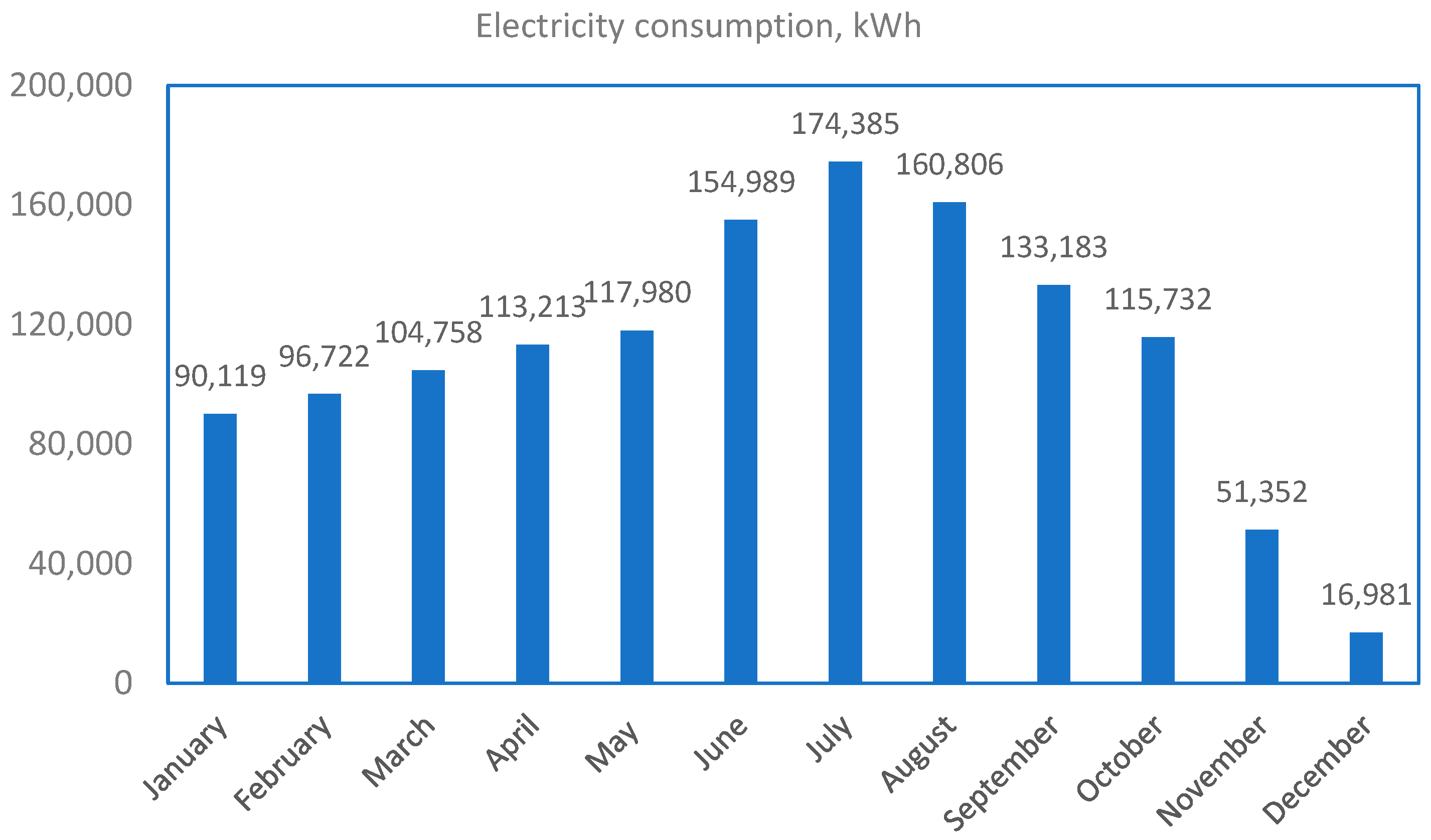

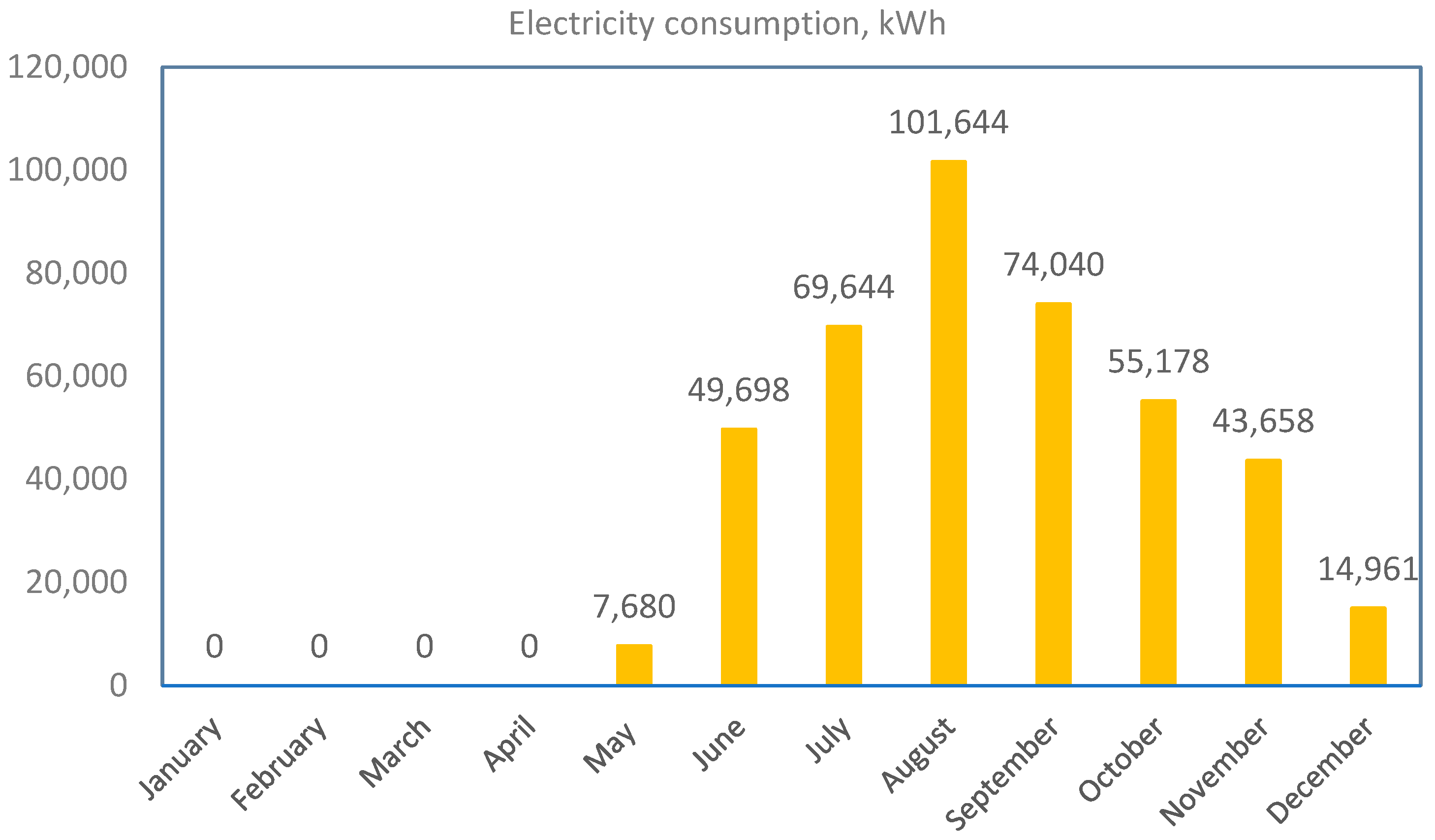

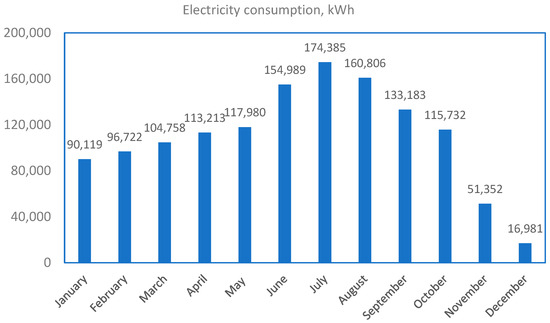

The remote monitoring systems for the refrigeration systems of both supermarkets allowed extraction of the energy consumption data for the year 2024 (Figure 15 and Figure 16).

Figure 15.

Energy consumption data for Chișinău supermarket.

Figure 16.

Energy consumption data for Bălți supermarket.

The supermarket in Bălți was fully operational on the new plant at the end of July 2024, while the plant in Chișinău was fully operational for the whole year 2024. Therefore, the actual annual energy consumption in the Bălți supermarket is partially estimated considering the actual data recorded in the period August–December 2024. The data for both supermarkets are specified in Table 5.

Table 5.

Measured annual energy consumption for both supermarkets.

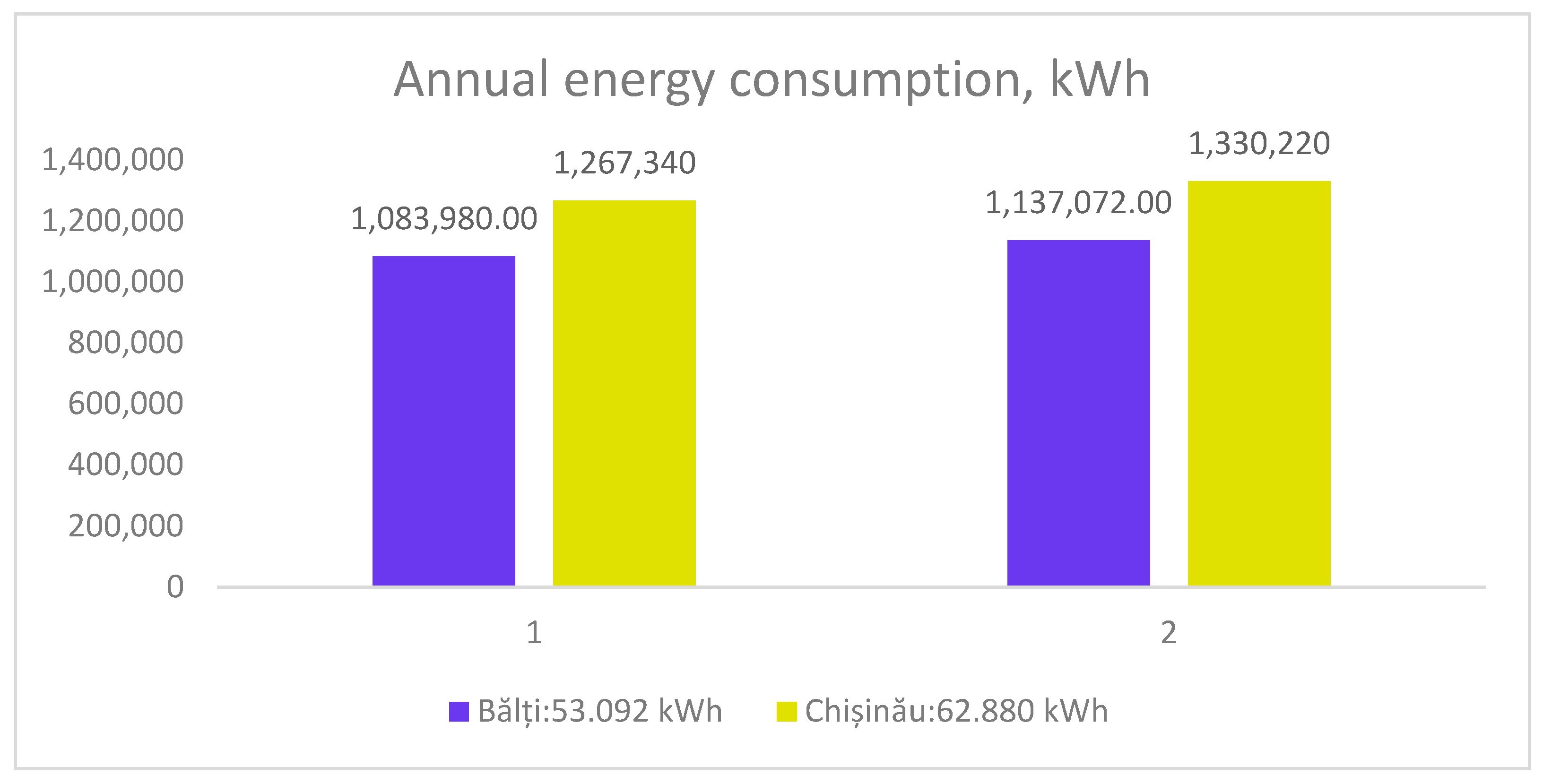

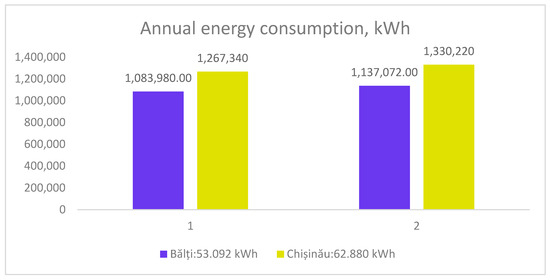

Figure 17 presents a comparison of the estimated (1) and real annual energy consumption (2) for the two supermarkets.

Figure 17.

Estimated (1) and measured (2) annual energy consumption.

There is a difference of about 5% between the measured and estimated annual energy consumption. This difference can be attributed to the difference between the real temperature values registered in 2024 and the historical data available for the two cities.

The COP of the plant in Bălți, corresponding to an average outdoor temperature of 10.3 °C, is 3.28, which is very close to the COP (3.25) of a similar plant, but with a lower capacity (cooling capacity of 90 kW and refrigerating capacity of 22 kW) and with low-temperature evaporation of −30 °C and medium-temperature evaporation of −4 °C, analysed in [39], for the same outdoor temperature.

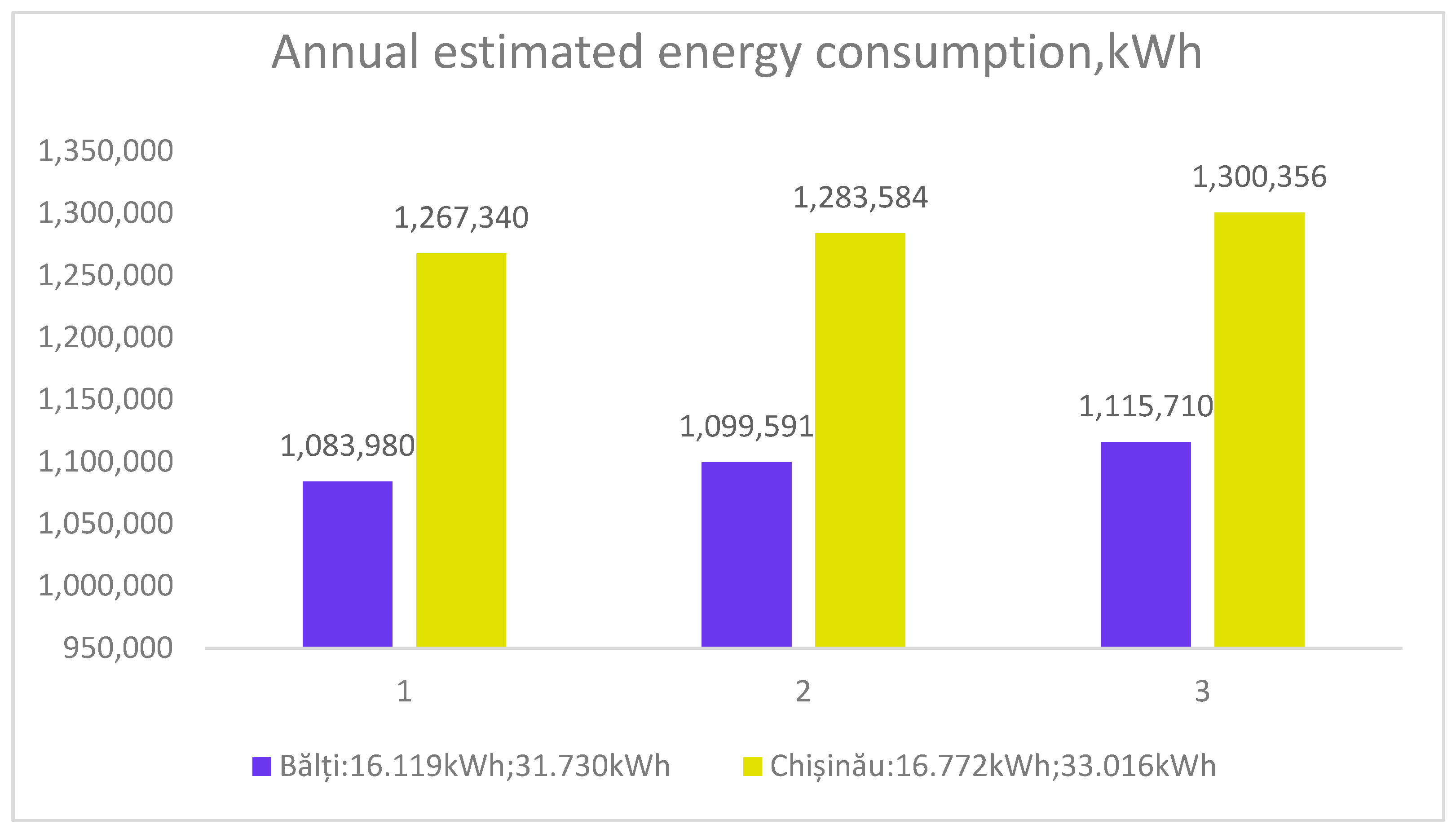

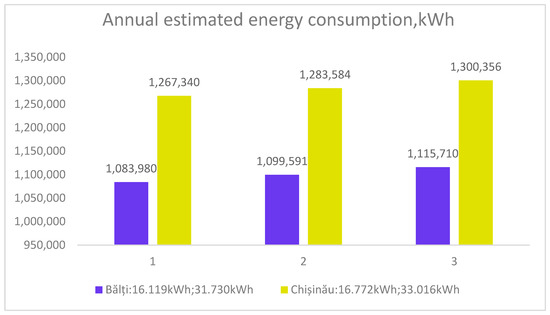

When the evaporation temperature at the compressor rack decreases by one degree (due to wrong sizing of the pipe route on the suction circuit or due to improper adjustment), the calculated energy consumption increases, as shown in Table 6.

Table 6.

Increase in annual energy consumption for lowering the evaporation temperature by one degree.

The annual energy consumption calculated in case of an evaporation temperature increase at the compressor rack of 2 degrees is given in Table 7.

Table 7.

Increase in annual energy consumption for incresing the evaporation temperature by two degrees.

In Figure 18 the calculated annual energy consumption (1), annual energy consumption calculated for lowering the evaporation temperature by one degree (2), and annual energy consumption calculated for lowering the evaporation temperature by two degrees (3) are compared. Increases in annual energy consumption of 1.28% and 1.44%, respectively, are observed when the evaporation temperature decreases by 1 degree, and by 2.93% and 2.61%, respectively, when the evaporation temperature decreases by 2 degrees.

Figure 18.

Estimated annual energy consumption of basic system (1) and system with evaporation temperature lowered by one (2) and two (3) degrees.

6. Conclusions

A theoretical and experimental investigation on the energy consumption of a high-capacity CO2 refrigeration plant under changing operating conditions was performed. The developed energy model integrates the data recorded during the operation of two commercial plants. By simulating the required cooling capacities of the cabinets and cold rooms during a whole year, considering the variation in the outside temperature as well as the variation in the indoor temperature of the supermarket, it was possible to determine the annual energy consumption of the entire plant. The comparison between the calculated and measured values showed a difference of approximately 5%, which can be attributed to the difference between the real values of the external temperature and those provided by the hydrometeorological service. The model can be used to estimate the energy consumption of any type of CO2 refrigeration system for which solutions to increase energy efficiency are proposed. The study was focused on finding the magnitude of energy consumption increase with increases in the evaporation temperature. The evaluation of energy consumption in a high-capacity refrigeration plant, which operates with a large number of consumers, is very difficult to perform because it requires the estimation of a large number of variables, such as the annual variation in the outdoor temperature in the respective areas, the number of operating hours, the variation in the indoor temperature of the hypermarket, and the variation in the refrigerating capacity of the consumers with the temperature variation and their usage. For a correct estimate, as close to reality as possible, all these variables need to be correlated with each other. The calculation of energy consumption in the case of reducing the evaporation temperature, due to pressure losses through the pipeline route (or due to improper adjustment), showed that for each degree lost, energy consumption increases by approximately 1.5%. An incorrectly sized pipe network can cause the evaporation temperature to drop due to pressure losses through the pipes. The piping network of a large plant must always be sized and executed for a temperature increase corresponding to a pressure loss of 1.5 K to a maximum of 2 K.

A 1.5% increase in electricity consumption means an increase in the electricity cost of the plant by EUR 1600/year considering the average electricity price for non-household consumers in 2024 in the Republic of Moldova of EUR 0.120/kWh, or by EUR 3000/year considering the average price in the EU of EUR 0.120/kWh.

Author Contributions

Conceptualization, methodology, formal analysis; investigation; data curation.; writing—original draft preparation, I.D.; validation, supervision, writing—review and editing, I.V.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Acknowledgments

The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

The following abbreviations are used in this manuscript:

| Abbreviations | |

| ah | Air absolute humidity in kg/kg |

| C1, C2, C3, C4, C5 | Constants |

| cp | Specific heat at constant pressure in kJ/kg·K |

| cv | Specific heat at constant volume in kJ/kg·K |

| CO2 | Carbon dioxide |

| COP | Coefficient of performance |

| CS | Cascade system |

| EEV | Electronic expansion valve |

| EJ | Ejector |

| EOM | Equation-oriented method |

| GC | Gas cooler |

| GWP | Global warming potential |

| HER | Heat extraction rate |

| HEX | Heat exchanger |

| HFC | Hydrofluorocarbon |

| HP | High pressure |

| HR | Heat recovery |

| HVAC&R | Heating, ventilation, air conditioning, and refrigeration |

| LP | Low pressure |

| LS | Liquid separator |

| LT | Low temperature |

| Mass flow rate in kg·s−1 | |

| MEJ | Multi-ejector |

| MP | Medium pressure |

| MT | Medium temperature |

| Natref | Natural refrigerant |

| ODS | Ozone depleting substance |

| OilP | Oil pressure |

| p | Pressure in Pa |

| PC | Parallel compression |

| R | Gas constant in J·kg−1·K−1 |

| RDC | Refrigerated display cabinet |

| RH | Air relative humidity in % |

| S | Surface in m2 |

| SAM | Successive approximation method |

| SCM | Sequential component method |

| Synrefs | Synthetic refrigerant |

| T | Temperature in K |

| TEWI | Total Equivalent Warming Impact |

| u | Entrainment ratio |

| V | Volume in m3 |

| V | Velocity in m·s−1 |

| W | Electrical power in kW |

| ε | GC efficiency |

| Φ | Heat flow rate in kW |

| Γ | Isentropic exponent |

| λ | Coefficient of friction |

| η | Isentropic efficiency |

| γ | Adiabatic exponent |

| ρ | Density in kg/m3 |

| Subscripts | |

| ai | Air inlet |

| ao | Air outlet |

| comp | Compression |

| d | Discharge |

| p | Primary |

| r | Refrigerant |

| ri | Refrigerant inlet |

| ro | Refrigerant outlet |

| s | Suction; secondary |

| sat | Saturated |

| sh | Superheated |

| tp | Two-phase |

| V | Volumetric |

| ve | Expansion valve |

| w | Condensate |

| m | Logarithmic mean |

| mf | Missing flow |

| max | Maximum |

| min | Minimum |

| rc | To receiver, critical |

| s | Secondary flow |

| y | Position of the hypothetical throat |

| u | Critical entrainment ratio |

References

- Dilshad, S.; Kalair, A.R.; Khan, N. Review of carbon dioxide (CO2) based heating and cooling technologies: Past, present, and future outlook. Int. J. Energy Res. 2020, 44, 1408–1463. [Google Scholar] [CrossRef]

- Sawalha, S.; Piscopiello, S.; Karampour, M.; Manickam, L.; Rogstam, J. Field measurements of supermarket refrigeration systems. Part II: Analysis of HFC refrigeration systems and comparison to CO2 trans-critical. Appl. Therm. Eng. 2017, 111, 170–182. [Google Scholar] [CrossRef]

- Liao, S.M.; Zhao, T.S.; Jakobsen, A. Correlation of optimal heat rejection pressures in transcritical carbon dioxide cycles. Appl. Therm. Eng. 2000, 20, 831–841. [Google Scholar] [CrossRef]

- Vidan-Falomir, F.; Larrondo-Sancho, R.; Sanchez, D.; Cabello, R. Evaluation of different subcooling arrangements in a CO2 refrigeration plant using extractions from the flash-gas tank. Int. J. Refrig. 2025, 175, 334–344. [Google Scholar] [CrossRef]

- Ge, Y.T.; Tassou, S.A. Thermodynamic analysis of transcritical CO2 booster refrigeration systems in supermarket. Energy Convers. Manag. 2011, 52, 1868–1875. [Google Scholar] [CrossRef]

- Dubey, A.M.; Kumar, S.; Agrawal, G.D. Thermodynamic analysis of a transcritical CO2/propylene (R744–R1270) cascade system for cooling and heating applications. Energy Convers. Manag. 2014, 86, 774–783. [Google Scholar] [CrossRef]

- Llopis, R.; Cabello, R.; Sánchez, D.; Torrella, E. Energy improvements of CO2 transcritical refrigeration cycles using dedicated mechanical subcooling. Int. J. Refrig. 2015, 55, 129–141. [Google Scholar] [CrossRef]

- Śmierciew, K.; Butrymowicz, D.; Gagan, J.; Jakończuk, P.; Pawłowski, M. Design and Manufacture of a Micro-Ejector and the Testing Stand for Investigation of Micro-Ejector Refrigeration Systems. Micromachines 2024, 15, 429. [Google Scholar] [CrossRef]

- Pardiñas, Á.Á.; Hafner, A.; Banasiak, K. Novel integrated CO2 vapour compression racks for supermarkets. Thermodynamic analysis of possible system configurations and influence of operational conditions. Appl. Therm. Eng. 2018, 131, 1008–1025. [Google Scholar] [CrossRef]

- Sengupta, A.; Gullo, P.; Dasgupta, M.S.; Khorshidi, V. Performance Analysis of an R744 Supermarket Refrigeration System Integrated with an Organic Rankine Cycle. Energies 2023, 16, 7478. [Google Scholar] [CrossRef]

- Sarkar, J.; Agrawal, N. Performance optimization of transcritical CO2 cycle with parallel compression economization. Int. J. Therm. Sci. 2010, 49, 838–843. [Google Scholar] [CrossRef]

- Gullo, P.; Hafner, A.; Cortella, G. Multi-ejector R744 booster refrigerating plant and air conditioning system integration—A theoretical evaluation of energy benefits for supermarket applications. Int. J. Refrig. 2017, 75, 164–176. [Google Scholar] [CrossRef]

- Karampour, M.; Sawalha, S. State-of-the-art integrated CO2 refrigeration system for supermarkets: A comparative analysis. Int. J. Refrig. 2018, 86, 239–257. [Google Scholar] [CrossRef]

- Polzot, A.; D’Agaro, P.; Cortella, G. Energy analysis of a transcritical CO2 supermarket refrigeration system with heat recovery. Energy Procedia 2017, 111, 648–657. [Google Scholar] [CrossRef]

- Steuer, D.; Termens, J.; Arias, J.; Sawalha, S. Thermal energy export from supermarket refrigeration systems: Drivers and barriers. Energy Rep. 2024, 12, 5875–5885. [Google Scholar] [CrossRef]

- Evans, J.; Hammond, E.; Gigiel, A.; Reinholdt, L.; Fikiin, K.; Zilio, C. Improving the energy performance of cold stores. In Proceedings of the 2nd IIR Conference on Sustainability and the Cold Chain, Paris, France, 2–4 April 2013; International Institute of Refrigeration: Paris, France. Available online: https://iifiir.org/en/fridoc/improving-the-energy-performance-of-cold-stores-29339 (accessed on 13 December 2024).

- Evans, J.A.; Hammond, E.C.; Gigiel, A.J.; Fostera, A.M..; Reinholdt, L.; Fikiin, K.; Zilio, C. Assessment of methods to reduce the energy consumption of food cold stores. Appl. Therm. Eng. 2014, 62, 697–705. [Google Scholar] [CrossRef]

- Evans, J.A.; Foster, A.M.; Huet, J.M.; Reinholdt, L.; Fikiin, K.; Zilio, C.; Houska, M.; Landfeld, A.; Bond, C.; Scheurs, M.; et al. Specific energy consumption values for various refrigerated food cold stores. Energy Build. 2014, 74, 141–151. [Google Scholar] [CrossRef]

- ISO 23953-1:2024; Refrigerated display cabinets—Part 1: Vocabulary. International Organization for Standardization (ISO): Geneva, Switzerland, 2024.

- Mousset, S.; Libsig, M. Energy Consumptions of Display Cabinets in Supermarket. 2011. Available online: https://iifiir.org/en/fridoc/energy-consumptions-of-display-cabinets-in-a-supermarket-28145 (accessed on 13 December 2024).

- Bahman, A.; Rosario, L.; Rahman, M.M. Analysis of energy savings in a supermarket refrigeration/HVAC system. Appl. Energy 2012, 98, 11–21. [Google Scholar] [CrossRef]

- Ge, Y.T.; Tassou, S.A. Control optimizations for heat recovery from CO2 refrigeration systems in supermarket. Energy Convers. Manag. 2014, 78, 245–252. [Google Scholar] [CrossRef]

- Constantino, M.C.; Kanizawa, F.T. Evaluation of pressure drop effect on COP of single-stage vapor compression refrigeration cycles. Therm. Sci. Eng. Prog. 2022, 28, 101048. [Google Scholar] [CrossRef]

- Oldřich, J. Isentropic efficiency of centrifugal compressor working with real gas. Acta Polytech. CTU Proc. 2018, 20, 65–72. [Google Scholar] [CrossRef]

- Li, D.; Groll, E.A. Transcritical CO2 refrigeration cycle with ejector-expansion device. Int. J. Refrig. 2005, 28, 766–773. [Google Scholar] [CrossRef]

- Lei, Y.; Li, S.; Lu, J.; Xu, Y.; Yong, Y.; Xing, D. Numerical Analysis of Steam Ejector Performance with Non-Equilibrium Condensation for Refrigeration Applications. Buildings 2023, 13, 1672. [Google Scholar] [CrossRef]

- Bankole, A.T.; Bello-Salau, H.; Haruna, Z. Nonlinear Identification of the Suction Manifold of a Supermarket Refrigeration System Using Wavelet Networks. Eng. Proc. 2024, 67, 37. [Google Scholar] [CrossRef]

- Bitzer Websoftware. Available online: https://www.bitzer.de/websoftware/calculate/HHK/?tab=results (accessed on 22 February 2025).

- Sun, J.; Kuruganti, T.; Munk, J.; Dong, J.; Cui, B. Low global warming potential (GWP) refrigerant supermarket refrigeration system modeling and its application. Int. J. Refrig. 2021, 126, 195–209. [Google Scholar] [CrossRef]

- Kim, M.H.; Bullard, C.W. Thermal performance analysis of small hermetic refrigeration and air-conditioning compressor. JEME Int. J. Ser. B. 2002, 45, 857–864. [Google Scholar] [CrossRef]

- Sun, J.; Li, W. Operation optimization of an Organic Rankine cycle (ORC) heat recovery power plant. Appl. Therm. Eng. 2011, 31, 2032–2041. [Google Scholar] [CrossRef]

- Sawalha, S.; Karampour, M.; Rogstam, J. Field measurements of supermarket refrigeration systems. Part I: Analysis of CO2 transcritical refrigeration systems. Appl. Therm. Eng. 2015, 87, 633–647. [Google Scholar] [CrossRef]

- Li, F.; Tian, Q.; Wu, C.; Wang, X.; Lee, J.M. Ejector performance prediction at critical and subcritical operational modes. Appl. Therm. Eng. 2017, 115, 444–454. [Google Scholar] [CrossRef]

- Sun, J.; Reddy, A.T. A new approach to develop building energy system simulation programs suitable for both design and optimal operation. ASHRAE Trans. 2006, 112, 729–738. [Google Scholar]

- Xue, X.; Feng, X.; Wang, J.; Liu, F. Modeling and Simulation of an Air-cooling Condenser under Transient Conditions. Procedia Eng. 2012, 31, 817–822. [Google Scholar] [CrossRef]

- Bendaoud, A.; Ouzzane, M.; Aidoun, Z.; Galanis, N. A new modeling approach for the study of finned coils with CO2. Int. J. Therm. Sci. 2010, 49, 1702–1711. [Google Scholar] [CrossRef]

- Kuehn, T.; Ramsey, J.W.; Threlkeld, J.L. Thermal Environmental Engineering, 3rd ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 1998; pp. 314–445. [Google Scholar]

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O. Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 9.1; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2013; Standard Reference Data Program. Available online: https://www.nist.gov/publications/nist-standard-reference-database-23-reference-fluid-thermodynamic-and-transport (accessed on 15 December 2024).

- Söylemez, E. Energy and Conventional Exergy Analysis of an Integrated Transcritical CO2 (R-744) Refrigeration System. Energies 2024, 17, 479. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).