Abstract

Cacao (Theobroma cacao) is considered a functional food due to its composition, which is rich in bioactive compounds such as flavonoids, theobromine, dietary fiber, and essential minerals. Several studies have shown that flavonoids have antioxidant and anti-inflammatory properties, helping to reduce oxidative stress and protecting against cardiovascular diseases. In addition, their ability to stimulate nitric oxide production improves blood circulation and lowers blood pressure. These benefits, coupled with its ability to improve mood and cognitive function, position cocoa as a key ingredient in the development of functional foods aimed at improving quality of life and preventing chronic diseases. This research aims to create a product that incorporates cocoa and essential oils extracted from aromatic plants native to the department of Cauca. This represents a significant step toward the sustainable use of these ingredients in the region, promoting consumer welfare and health while strengthening sustainable practices, fostering innovation, and boosting economic and social development in the department. The research is developed in five phases: determination of the study area, characterization of the cocoa production chain in the department of Cauca, selection of essential oils, application of an experimental mixture design and physicochemical and microbiological analyses of the final product. From the experimental design of the mixture, it was determined that the most appropriate formulation of the bar is 60% dark chocolate (70% cocoa), 29% sweet chocolate, 10% pure strawberry and 1% fennel essential oil (Foeniculum vulgare), reaching an average sensory acceptability of 3.23 on a five-point hedonic scale. The qualitative properties (organoleptic, chemical and microbial) of the selected formulations are acceptable for human consumption and provide a high energy content of 506.25 kcal/100 g for chocolate bars filled with strawberry puree and fennel essential oil.

1. Introduction

Globally, cocoa is highly valued in various industries, including food and cosmetics, due to its versatility and nutritional properties. This underscores its great potential for the development of functional foods—products that not only provide essential nutrients but also offer additional health benefits. These foods are designed to improve key bodily functions, promote well-being, and reduce the risk of disease. Cocoa stands out as a rich source of bioactive compounds, especially polyphenols such as flavonoids (catechins, epicatechins, and procyanidins), which are known for their potent antioxidant and anti-inflammatory properties [1,2]. In addition, it contains alkaloids such as theobromine and small amounts of caffeine, which provide stimulant and cardioprotective effects [3]. It is also an important source of healthy lipids and essential minerals, such as magnesium and iron, which are crucial for maintaining various physiological functions. These characteristics make cocoa a key ingredient in the creation of functional foods that can contribute to the prevention of metabolic and cardiovascular diseases [4].

The department of Cauca, Colombia, comprises 42 municipalities with high agricultural potential [5], 28 of which are dedicated to cocoa cultivation. As of 2022, these crops occupied a total of 3255 hectares, with a registered production of 1747 tons [6]. This department has played a leading role in national cocoa production, establishing itself as a viable economic alternative for more than 4000 farming families, who contribute significantly to strengthening the rural economy of the region. However, despite its great productive potential and the diversity of favorable microclimates, Cauca has not been able to fully capitalize on these resources to promote sustainable economic and social development.

The limited use of cocoa in Cauca is reflected in the lack of innovation within processing industries, such as chocolate production. Although these organizations demonstrate a strong commitment to cocoa cultivation and chocolate manufacturing, they face significant challenges related to sustainability and product diversification [7]. The main obstacle lies in the lack of knowledge and limited research focused on the development of new products in this area, which has led to stagnation in the supply of conventional items. This situation restricts the ability of local entrepreneurs and companies to access new markets, limiting economic growth and hindering the sustainable development of the sector in the department of Cauca [8].

On the other hand, essential oils are natural compounds or plant-derived essences composed of complex mixtures of volatile secondary metabolites that are insoluble in water. Their unique characteristics depend on the varying amounts and proportions of these compounds. These substances are primarily found in the secretory tissues of plants and are generally in liquid form, with a certain degree of viscosity [9]. They have characteristic and intense aromas and are usually colorless or exhibit translucent yellow tones.

Currently, essential oils play a significant role in various industrial and healthcare fields due to their proven properties, including analgesic, soothing, anti-inflammatory, stimulant, regenerating, healing, toning, preservative, antimicrobial, antifungal, and antioxidant effects. Additionally, they improve the palatability of foods. In particular, the recent use of essential oils as additives in food processing has gained increasing importance, both for their bioactive properties and their ability to enhance the sensory attributes of food products [10,11].

Several studies have explored their application in different food formulations as follows: the incorporation of thyme, fennel and orange essential oils in extra virgin olive oil has been shown to improve its sensory profile and oxidative stability during storage, without compromising its nutritional quality [12]; the microencapsulation of thyme and oregano essential oils has been used in meat patties to improve their microbiological stability and prolong their shelf life, showing a significant reduction in the growth of pathogenic microorganisms [13]; the addition of clove and cinnamon essential oils in dulce de leche has shown antimicrobial and antioxidant effects, improving the stability of the product without negatively affecting its sensory characteristics [14]. These examples show the potential of essential oils as natural additives in the food industry, contributing to both the safety and sensory quality of products.

The combination of essential oils and cocoa in food products represents a promising strategy in the development of functional foods by integrating attractive sensory properties with proven physiological benefits, which can positively impact consumer health and respond to the growing demand for value-added products in the nutraceutical and food market.

The objective of this research is to develop a functional chocolate bar formulation using cocoa and essential oils from aromatic plants native to Cauca. To achieve this, an experimental mixture design will be employed to determine the optimal proportions of the ingredients. This study aims to contribute to the sustainable use of cocoa, promote innovation in the local chocolate industry, and generate a product with potential impact on the functional food market. The novelty of this research lies in the incorporation of underutilized native essential oils into a cocoa-based matrix, which not only enhances the sensory and functional properties of the product but also adds value to regional biodiversity. The findings are expected to provide a scientific foundation for future innovations in the development of bioactive-enriched confectionery products and to stimulate new market opportunities for agro-industrial producers in southern Colombia.

2. Materials and Methods

The methodological strategy for this study is defined as mixed, as it combines qualitative and quantitative research. Five phases are identified: (1) definition of the study area, (2) characterization of the cocoa production chain in the department of Cauca, (3) selection of essential oils with specific properties that influence the mental and physical health of the study population, (4) application of an experimental mixture design, and (5) physicochemical and microbiological analysis.

2.1. Study Area

The study was conducted in the department of Cauca, focusing on cacao-producing municipalities identified through institutional sources such as the Municipal Agricultural Assessment Report (EVA), the Departmental Agricultural Extension Plan (PDEA), and others. The primary study area was Timbío, where the cacao used in the research was sourced from.

2.2. Characterization of the Cocoa Production Chain

To characterize the cocoa production chain, a data collection process was conducted in several stages. First, a documentary review of previous studies, technical reports, and official statistics related to cocoa production and marketing in the study region was carried out. Institutional sources were also consulted, including the Municipal Agricultural Evaluation Report (EVA) issued by the Ministry of Agriculture.

Subsequently, direct interviews were designed and conducted with cocoa farmers in the department of Cauca, specifically with members of the AGROCACAO association in the municipality of Timbío, during field visits to the community. The purpose of these interviews was to identify the main problems and challenges faced by cocoa producers in the region. The data obtained from these interviews were qualitatively analyzed to identify recurrent patterns, shared opinions and priority needs expressed by producers. This information was key to contextualizing the study findings, enriching the discussion with local perspectives, and informing the final recommendations of the manuscript.

Finally, a quantitative data analysis was performed using statistical tools available in the InfoStat program, student version 2017.

2.3. Selection of Essential Oils

The selection of the specific essential oil for this research was conducted through a structured three-stage process:

- Identification of essential oils in the department of Cauca: To determine the availability of essential oils in the region, a field visit was conducted to the Misak indigenous community and institutional documents were reviewed. This process identified plant species with potential for essential oil extraction in Cauca, considering factors such as availability, local production, and applications in various fields of study.

- Identification of essential oils suitable for human consumption: A bibliographic and documentary review was conducted using the specialized database Dimensions. The following scientific search model was designed and applied: (“essential oils” OR “aromatic oils” OR “volatile compounds”) AND (“flavor improvement” OR “sensory evaluation” OR “consumer perception” OR “health effect”* OR “nutritional impact”). This search model was constructed by combining Boolean operators to optimize and refine the results obtained. When executing the model, 104,606 results were found. Filters were then applied to limit the search to articles published in the last five years, displaying only titles and abstracts, which reduced the selection to 848 documents. Following this, the Bibliometrix tool [15] was used to analyze the cumulative publication trends in various journals over time.

- Obtaining essential oils: The essential oil used in this research was provided by the essential oil distillation laboratory of the Misak Indigenous Community (Guambia Ancestral Territory), located in the municipality of Silvia, Cauca. This laboratory has experience extracting essential oils from native plants using traditional methods and steam distillation techniques. It also has a brand called “Misak essential oils,” and Juan Carlos Misak is in charge of the extraction. The quality of the supplied oil was verified to ensure its purity and suitability for the study objectives. This methodological approach allowed for the selection of essential oils with local relevance, safety for human consumption, and reliable availability, which laid a solid foundation for the development of this research.

2.4. Experimental Mix Design

To define the optimal formulation of the functional chocolate bar, an experimental mixture design was used [16,17]. This type of design is applied when the main objective is to determine the appropriate proportions of multiple components that together sum to 100% of the formulation. In this case, the factors that make up the mixture are as follows:

X1 = % dark chocolate (70% cocoa)

X2 = % sweet chocolate

X3 = % fennel essential oil

X4 = % strawberry puree

The response variables considered in this study were as follows:

Y1 = weight performance

Y2 = Sensory acceptance

To guarantee the quality and viability of the product, the following restrictions on the mix factors were established:

60% ≤ X1 ≤ 80%

20% ≤ X2 ≤ 40%

1% ≤ X3 ≤ 4%

10% ≤ X4 ≤ 20%

These restrictions were proposed and adjusted in collaboration with chef Juan Camilo Ramos Velasco, a professor at CORPORACIÓN UNIVERSITARIA COMFACAUCA-UNICOMFACAUCA, to ensure flavor consistency and stability of the final product.

Once the variables and their restrictions were defined, the statistical model equations, Equations (1) and (2), were established for optimization, which was implemented in Minitab software Version 22.1 [18]. For this purpose, an extreme vertex design was applied, allowing the evaluation of ingredient combinations at the established limits and specific points within the design space. This model enables the assessment of each ingredient’s influence on yield and sensory acceptance, as well as the analysis of interactions between components to determine the optimal proportion that maximizes (or balances) the response variables according to the desired sensory quality and functionality criteria.

where

Y1 = β1X1 + β2X2 + β3X3 + β4X4 + β12X1X2 + β13X1X3 + β14X1X4 + β23X2X3 + β24X2X4 + β34X3X4 + £

Y2 = Y1X1 + Y2X2 + Y3X3 + Y4X4 + Y12X1X2 + Y13X1X3 + Y14X1X4 + Y23X2X3 + Y24X2X4 + Y34X3X4 + £

- ΒiYi are the regression coefficients that indicate the contribution of each component to the response variable.

- βijYij are the interaction coefficients between the ingredients.

- £ is the experimental error.

Formulation Preparation

Once this process was completed, the program generated thirteen formulations based on the executed data, as shown in Table 2 (Section 3). Based on the results obtained, 13 formulations of nutritional bars were prepared, each with 28 replicates, resulting in a total of 364 treatments. After the preparation was completed, the response variables in each treatment were analyzed to evaluate the influence of the components on the following variables:

- Performance: After the bars were prepared, they were left to rest for two days to achieve optimal consistency. They were then carefully sectioned and weighed on a precision balance to record their individual weights. Based on these measurements, the yield of each formulation was evaluated by comparing the amount of final product obtained with the expected quantity.

- Sensory acceptance: A sensory analysis was conducted using a five-point mixed facial hedonic scale: (1) I hated it, (2) I did not like it, (3) Indifferent, (4) I liked it, and (5) I loved it. The objective of this test was to measure the overall acceptance of each formulation. To achieve this, a panel of 28 participants from the university’s gastronomy management program, which has expert personnel in the subject, was used to evaluate the 13 formulations, and each participant received a sample of each one. To collect the data, a form was used to identify the samples and allow each evaluator to individually record their sensory perception. This procedure combined the objective assessment of performance with the subjective perception of potential consumers, thus providing comprehensive information on the viability and quality of the developed nutritional bars [19].

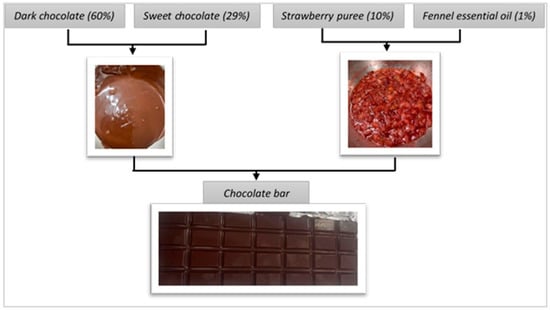

2.5. Physicochemical and Microbiological Analysis

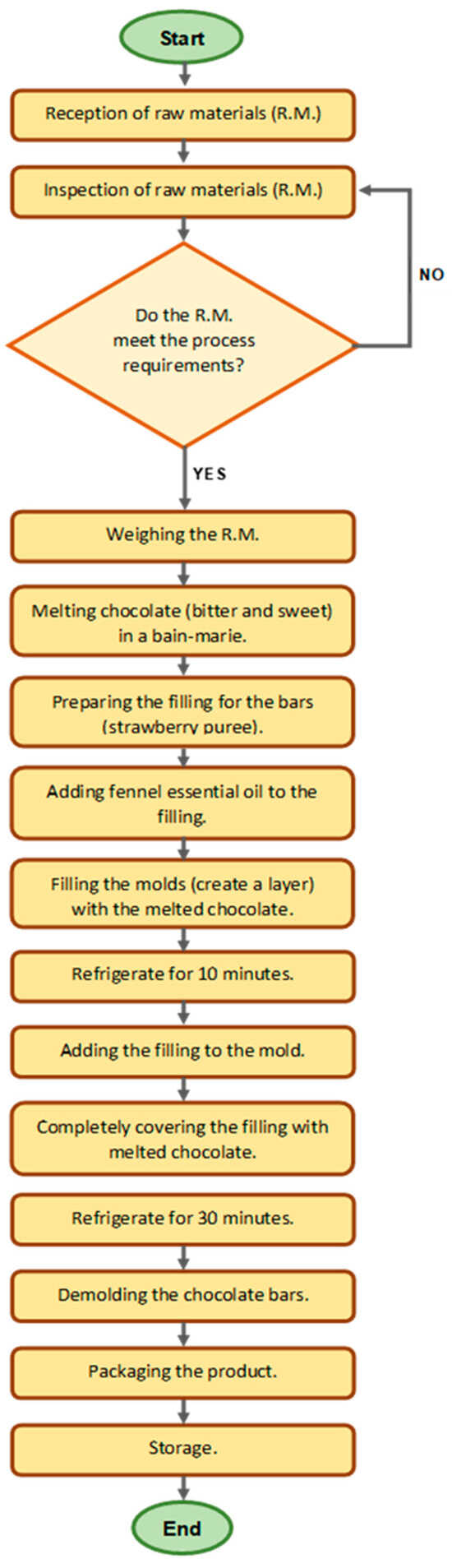

The samples were prepared in the food laboratory of the CORPORACIÓN UNIVERSITARIA COMFACAUCA-UNICOMFACAUCA, according to the flow chart for the production of chocolate bars with essential oils, as shown in Figure 1. Amounts of 200 g of product for microbiological analysis and 500 g for physicochemical analysis were prepared for shipment to the laboratory. In order to preserve their quality until testing, the bars were vacuum-packed in sealed bags. They were then sent to a certified laboratory in the country (SYNLAB BIOINDUSTRIAL Laboratory), where the parameters indicated in Table 1 were met.

Figure 1.

Flow chart for the production of chocolate bars with essential oils. Source: own elaboration.

Table 1.

Methods of analysis.

3. Results and Discussion

3.1. Location of the Study Population

According to the Agricultural Evaluations (EVA) report, the area in which cocoa was planted in the department of Cauca reached 3255 hectares in 2022 [6]. This growth was driven by public–private partnerships established in the region, involving entities such as SENA, the Cauca Governor’s Office, the Illicit Crop Substitution Program, and the Cauca Chamber of Commerce. These partnerships promote technology transfer, technical training, and assistance for small and medium-sized producers to improve productivity and grain quality.

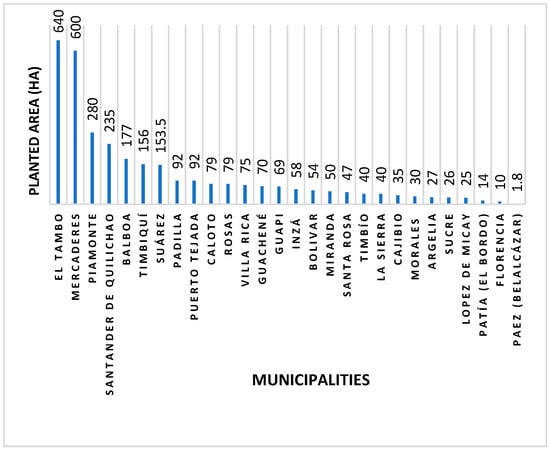

The same report details the distribution of cocoa cultivation across 28 municipalities in the department (see Figure 2). El Tambo (640 ha) and Mercaderes (600 ha) have the largest planted areas, followed by Piamonte (280 ha), Santander de Quilichao (235 ha), Balboa (177 ha), and Timbiquí (156 ha). Other municipalities, such as Suárez (153.5 ha), Puerto Tejada (92 ha), Padilla (79 ha), Caloto (75 ha), and Rosas (70 ha), also have significant cocoa-growing areas. Meanwhile, in the remaining localities (Villa Rica, Guachené, Guapi, Inzá, Bolívar, Miranda, Santa Rosa, Timbío, La Sierra, Cajibío, Morales, Argelia, Sucre, López de Micay, Patía, Florencia, and Páez-Belalcázar), the cultivated areas range between 69 ha and 1.8 ha. These figures highlight both the significance of the municipalities with the largest coverage and the widespread distribution of cocoa cultivation throughout the department. This expansion is the result of joint efforts between public and private institutions aimed at strengthening cocoa production in the region.

Figure 2.

Municipalities in the department of Cauca that grow cocoa. Source: EVAS. Own elaboration.

3.2. Characterization of the Cocoa Production Chain in the Department of Cauca

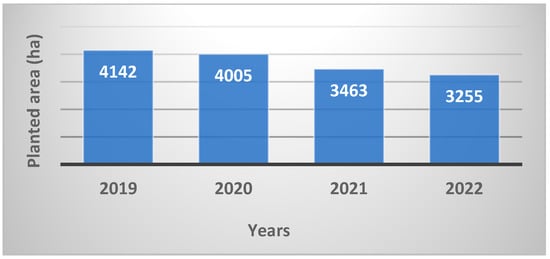

Figure 3 illustrates the evolution of the area in which cocoa was planted in the department of Cauca between 2019 and 2022. During this period, a decreasing trend in the cultivated area was observed: in 2019, 4142 hectares were recorded; in 2020, the area increased to 4995 hectares, but then declined to 3463 hectares in 2021 and finally to 3255 hectares in 2022. These data indicate a 21.4% reduction in the area in which cocoa was planted over the analyzed period [6].

Figure 3.

Areas planted with cocoa in the department of Cauca 2019–2022. Source: own elaboration.

Historically, Cauca was the leading cocoa producer in the country, recognized for its quality and deep-rooted cocoa tradition. This crop has been closely linked to the agricultural and economic development of the department, with such a significant financial and social impact that, a century ago, it was even listed on the stock exchange. However, over time, cocoa lost prominence as many farmers in Cauca chose to diversify their economies with other crops, both licit and illicit, relegating cocoa to a secondary or even tertiary role [20].

Interviews with cocoa farmers in the region highlight multiple challenges that have contributed to the reduction in cultivated area, including low yields per hectare, limited technical assistance, difficulties in accessing financing, and a lack of knowledge about bean processing technologies. Additionally, much of the commercialization is restricted to selling raw materials, which increases transportation costs and reduces profit margins. Other obstacles include insufficient government support, phytosanitary issues (pests and diseases), high production costs, and adverse weather conditions, among other factors.

Despite these challenges, in recent years, several initiatives have been promoted to strengthen and expand cocoa cultivation, aiming to improve its competitiveness and restore its position as a key product for regional development. Cauca has fertile soils, extensive traditional knowledge, and producers committed to rural progress, leveraging the versatility and high demand for this crop in both national and international markets [21]. Likewise, the cocoa industry is showing signs of resurgence, driven by process innovation and the development of new products, fostering its expansion on both local and global scales [20].

Cocoa Commercialization

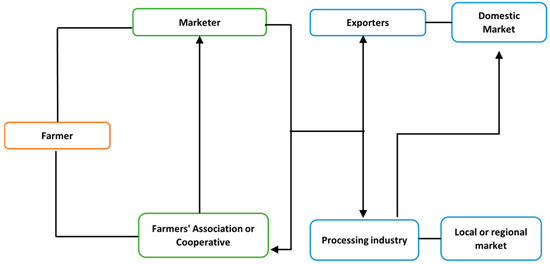

Figure 4 clearly illustrates the general structure of the cocoa production chain, highlighting the main interactions among its key actors. The farmer represents the initial and fundamental point of the process, from which various marketing routes emerge. The farmer’s production may go directly to a trader or be channeled through a farmers’ association or cooperative, which then liaises with the trader. The trader plays a central role, interacting with key players such as exporters and processors. Exporters facilitate the product’s entry into the international market, while the processing industry transforms the raw material into finished products for the national, local, or regional markets. This scheme underscores the strategic importance of agricultural associations and cooperatives, which enhance farmers’ bargaining power and strengthen connections between producers and other links in the chain. It also emphasizes the role of the processing industry, not only as an internal distribution channel but also as a key bridge to broader markets.

Figure 4.

Structure of the cocoa production chain. Source: own elaboration.

Ultimately, this production chain structure facilitates both local distribution and internationalization of the product, thereby enhancing the economic and social potential of cocoa cultivation.

In this department, cocoa farmers (small and medium-sized producers) plant and harvest cocoa in different municipalities of Cauca, such as El Tambo, Morales, Timbío, Piendamó, Cajibío, Balboa, among others. They then subject the cocoa beans to a fermentation and drying process to improve their quality. Producers sell their cocoa to associations, cooperatives, and cocoa collection and marketing companies in the Department of Cauca, such as the following:

- Cacao de Colombia S.A.S.: Located in Popayán, it is engaged in the production of cocoa, chocolate, and confectionery products.

- Almendra de Cacao S.A.S: This company is also based in Popayán and is engaged in the production of cocoa derivatives.

- Provinzzia Chocolate y Cacao S.A.S.: This company is located in Piendamó and produces chocolates and other cocoa products.

- Asociación de Mujeres Transformadoras de Cacao de Balboa: This non-profit association is dedicated to the production and transformation of cocoa.

- Asociación de Productores de Cacao de Morales Cauca: This cocoa producers’ association groups local producers for the joint marketing of cocoa [22].

These organizations typically purchase cocoa directly from local producers, fostering fair trade practices and ensuring high-quality whole beans. Within this framework, the sale process for entering agribusiness and industry involves collecting cocoa at designated centers, where the beans are stored and subjected to quality controls and validation. The cocoa is then sold to national and international processors, with Casa Luker and Compañía Nacional de Chocolates being among the most recognized companies in Colombia’s cocoa value chain [23]. Additionally, initiatives such as “Cauca Has a Cocoa Flavor” aim to strengthen the department’s cocoa industry by promoting process transformation and creating opportunities in both local and international markets [20].

3.3. Selection of Essential Oils

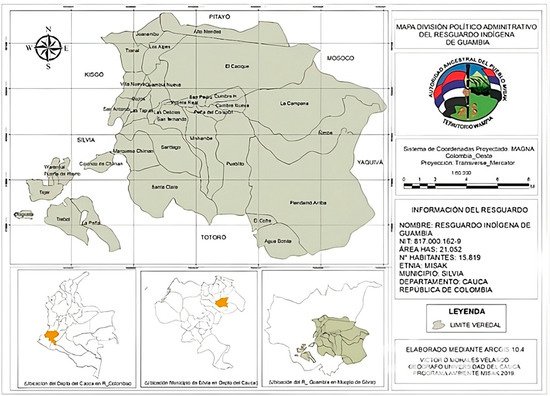

To select essential oils with specific properties for blending with chocolate, the first step was to identify those available in the department of Cauca. A review of institutional documents [24] was conducted, as was a field visit to the identified reservation. This review revealed that the Guambia Reservation (Misak people) is located in the municipality of Silvia, Cauca (see Figure 5). In this area, more than 200 species of flora are cultivated, including mint, rue, rosemary, marijuana, marigold, roses, jasmine, and lavender, as well as mint plants grown in gardens. Within the reservation, there is a laboratory where plant extracts are distilled using steam distillation. Various natural remedies are produced here, including treatments for respiratory infections such as the flu, calendula creams for inflammation, quinoa-based cereals for malnutrition, and other medicines designed to treat a range of internal, external, and emotional ailments.

Figure 5.

Map of the Guambia Resguardo. Source: own elaboration.

The aforementioned search model (Section 2 allowed a systematic exploration of the use of essential oils in human consumption, considering their safety, regulations, and functional potential in the food industry. Upon reviewing the database results, several relevant articles were identified. Chelaghema et al. [25] stated that “essential oils (EO), as compounds extracted from plants, are liquids whose specific aromatic compounds give each essential oil its own unique characteristics. Due to their rich chemical composition, they possess many interesting properties, including antifungal activities”. Similarly, Hanková et al. [26] indicated that “EOs have gained attention as natural preservatives due to their antimicrobial properties and their safety for consumption”.

Moreover, multiple studies [25,26,27,28,29] indicate that essential oils suitable for consumption are those extracted from plants, such as lemongrass, citronella, eucalyptus, thyme, oregano, coriander, clove, cinnamon, red thyme, litsea, niaouli, fennel, anise, cumin, basil, rosemary, sage, bergamot mint, and marjoram. These essential oils are considered safe for human consumption due to their natural composition, which is rich in bioactive compounds with antioxidant, antimicrobial, and digestive properties. Many of these oils have traditionally been used in gastronomy, natural medicine, and the food industry as flavorings and preservatives. However, it is important to note that not all essential oils are safe for consumption in large quantities. Therefore, it is recommended to use them in low doses and properly diluted in food or beverages.

Finally, to ensure a more precise selection of essential oils for the research, a visit was made to the essential oil distillation laboratory located in the Misak Indigenous Reservation (Guambia Ancestral Territory) in the municipality of Silvia, Cauca, where rosemary, rue, and fennel essential oils were obtained. Among these, Foeniculum vulgare (fennel) essential oil was identified as the most suitable for the formulation of the functional chocolate bar, compared to rosemary (Rosmarinus officinalis) and rue (Ruta graveolens) essential oils. This selection was based on its food safety, sensory compatibility, functional benefits, and availability in the region.

From a regulatory perspective, fennel essential oil is widely used in the food industry and is recognized as safe by the FDA (Generally Recognized as Safe-GRAS) [30]. In contrast, although rosemary essential oil has antioxidant properties and is used in certain foods, its intense flavor and bitterness can negatively affect the sensory perception of a confectionery product such as chocolate. Meanwhile, rue essential oil is not commonly used in the food industry, as high concentrations may have toxic effects and its use is restricted in several countries.

In terms of sensory compatibility, fennel has an anise-like aromatic profile with sweet and slightly spicy notes, which enhances the flavors of cocoa and strawberry purée, improving the final product’s sensory acceptability. In contrast, rosemary has a strong herbal aroma that can be overpowering and inharmonious with chocolate, while rue has a bitter and pronounced flavor, making it unsuitable for confectionery products. From a functional standpoint, fennel essential oil contains bioactive compounds such as anethole, which possesses digestive, antioxidant, and anti-inflammatory properties, reinforcing its classification as a functional food ingredient [31]. Although rosemary is rich in antioxidants such as carnosic acid, its application in chocolate products is less common due to its distinctive flavor. Rue, despite its medicinal properties, is not recommended for food use due to potential adverse health effects.

Fennel is a readily available ingredient in the Cauca region and is widely used in the food industry. While rosemary and rue are also found in the area, their application in confectionery is less frequent and requires additional safety and sensory acceptance studies. In conclusion, fennel essential oil was selected as the most suitable for the formulation of the functional chocolate bar due to its food safety, compatibility with cocoa, bioactive benefits, and accessibility in the region.

3.4. Statistical Analysis of the Experimental Desing

3.4.1. Analysis of the Results of the Response Variables

Table 2 shows the results obtained for the variables of interest by formulation. It is possible to observe the quantities or restrictions that each component should have, ranging from 60% to 69% for bitter chocolate, 20% to 29% for sweet chocolate, 10% to 19% for strawberry purée, and 1% to 4% for fennel essential oil. By analyzing the different proportions of each ingredient, it can be deduced that formulations with a higher amount of sweet chocolate (12 and 13) tend to reduce the proportion of bitter chocolate, possibly to enhance sensory acceptance among consumers who prefer milder chocolates.

Table 2.

Experimental results of performance and sensory acceptance of each formulation.

Table 2.

Experimental results of performance and sensory acceptance of each formulation.

| Formulation | Bitter Chocolate (%) | Sweet Chocolate (%) | Fennel Essential Oil (%) | Strawberry Purity (%) | Performance | Sensory Acceptance |

|---|---|---|---|---|---|---|

| 1 | 0.6250 | 0.2250 | 0.0250 | 0.1250 | 32.26 | 3.1516 |

| 2 | 0.6000 | 0.2000 | 0.0400 | 0.1600 | 28.76 | 3.1738 |

| 3 | 0.6000 | 0.2000 | 0.0100 | 0.1900 | 29.95 | 3.1696 |

| 4 | 0.6125 | 0.2425 | 0.0325 | 0.1125 | 29.39 | 3.1924 |

| 5 | 0.6575 | 0.2125 | 0.0175 | 0.1125 | 30.31 | 3.1928 |

| 6 | 0.6900 | 0.2000 | 0.0100 | 0.1000 | 29.99 | 3.1607 |

| 7 | 0.6425 | 0.2125 | 0.0325 | 0.1125 | 28.37 | 3.1866 |

| 8 | 0.6600 | 0.2000 | 0.0400 | 0.1000 | 29.09 | 3.1667 |

| 9 | 0.6125 | 0.2125 | 0.0325 | 0.1425 | 31.88 | 3.2308 |

| 10 | 0.6125 | 0.2125 | 0.0175 | 0.1575 | 28.14 | 3.1844 |

| 11 | 0.6125 | 0.2575 | 0.0175 | 0.1125 | 28.78 | 3.1743 |

| 12 | 0.6000 | 0.2900 | 0.0100 | 0.1000 | 28.26 | 3.1899 |

| 13 | 0.6000 | 0.2600 | 0.0400 | 0.1000 | 29.86 | 3.1543 |

The best performance in terms of yield was observed in formulations 1, 5, and 9, which exceeded 30%. In terms of sensory acceptance, formulation 9 achieved the highest score (3.2308 points). Overall, the formulation with the best yield and sensory acceptability effectively balances bitter and sweet chocolate content, with a moderate amount of strawberry purée and fennel essential oil.

- Performance response variable.

The experimental mixture design implemented for this variable yielded a confidence level of 7.79% (see Table 3), indicating that the results obtained are neither statistically significant nor reliable. This low confidence level may be due to several factors, such as excessive variability in the measurements. For instance, if the experimental procedure or the weight/yield measurement exhibits high variability, the model’s confidence level decreases. Other possible reasons include uncontrolled external factors, such as temperature, humidity, or poor calibration of the analytical balance used. Additionally, process conditions, such as the type of molds, cutting procedure, and other variables, may also influence the results.

Table 3.

Summary of the model for performance.

- Sensory acceptance response variable.

Table 4 presents the results of the experimental mixture design implemented for this variable, which yielded a confidence level of 15.42%. This value indicates that there is not enough statistical evidence to reject the null hypothesis, suggesting that the estimated effects are not significantly different from zero. Consequently, the results obtained lack statistical significance and cannot be considered reliable.

Table 4.

Summary of the model for sensory acceptance.

This low confidence level can be attributed to several factors. First is the inherent subjectivity of sensory evaluations, as sensory acceptance depends on the individual perception of the panelists, introducing high variability in the data. Additionally, a non-homogeneous sensory panel may generate inconsistent results, especially if the evaluators are not properly trained or have widely varying personal preferences.

Another determining factor is sensory fatigue or saturation, which occurs when panelists taste multiple samples in a short period, affecting the accuracy of their responses. Moreover, biases in the evaluations—such as the order of sample presentation, panelists’ expectations, or environmental conditions (e.g., lighting, noise, temperature)—can influence the ratings given.

Finally, a lack of sensitivity in the scale used can also impact the results. If the assessment scale is inadequate or too narrow, or contains ambiguous descriptions, the data may not accurately reflect the differences between the samples analyzed.

These factors highlight the need to optimize the experimental design to improve its predictive capacity and ensure a more robust and reliable analysis. For future research, it is recommended to standardize sensory evaluation conditions, train panelists, and adjust the measurement scale to minimize biases and enhance the statistical validity of the results.

With the data obtained, a simulation based on a response surface model with random components was carried out, with the purpose of estimating the yield (Y1) and sensory acceptability (Y2) of each formulation [32]. To determine the influence of the independent variables (X1, X2, X3, X4) on both responses, a significance level of 0.05 (p < 0.05) was established. Under this approach, the following research hypotheses were posed, Equations (3) and (4):

H0Y1 = β1 = β2 = β3 = β4 = β12 = β13 = β14 = β23 = β24 = β34 = 0

H0Y2 = Y1 = Y2 = Y3 = Y4 = Y12 = Y13 = Y14 = Y23 = Y24 = Y34 = 0

These hypotheses allowed for the establishment of specific statistical relationships between the factors of interest (ingredients) and the response variables analyzed, facilitating the identification of the relevance of each component in the final performance of the product. The results indicated that the proportions of X1, X2, X3, and X4 do not significantly influence the response variables: performance (Y1) and sensory acceptance (Y2). In other words, although the model is statistically valid, no significant effect of the ingredients on the response variables was found. This may be due to the fact that the variations in the formulation were not substantial enough, which is reflected in the low R2 values obtained, indicating a low level of confidence in the model’s ability to explain the results. The analysis was performed with 363 degrees of freedom (see Table 5) and 364 treatments, suggesting that the number of trials may have influenced the detection of significant effects.

Table 5.

ANOVA for sensory acceptance.

3.4.2. Selection of the Response Variable for the Optimization of the Prototype

Based on the R2 values mentioned above, the response variable with the highest coefficient of determination—sensory acceptance—will be analyzed, as it exhibited a higher R2 compared to yield. Therefore, the study will focus exclusively on the sensory acceptance data to determine the optimal proportions of ingredients in the sample formulation.

- Sensory analysis.

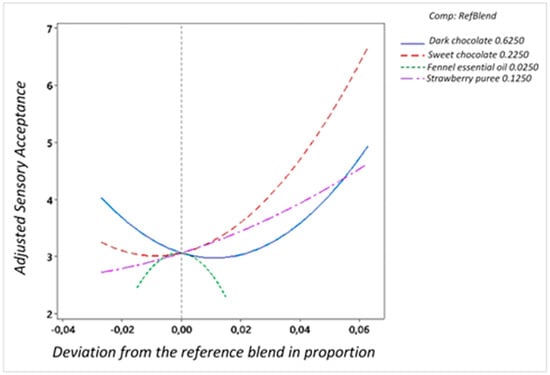

Figure 6 illustrates the behavior of the four components or ingredients, showing that the sensory score is highest at the highest concentrations of sweet chocolate, bitter chocolate, and strawberry purée. In contrast, at the highest concentrations of fennel essential oil, the sensory score is minimal. For the sweet chocolate component, as its proportion increases, the sensory score also increases. Similarly, in the bitter chocolate component, the sensory score increases with higher proportions, though not as significantly as with sweet chocolate. Likewise, for the strawberry purée component, higher proportions lead to a higher sensory score. The opposite trend is observed with fennel essential oil, where an increase in its proportion results in a considerable decrease in the sensory score. The graph shows that all components converge at a sensory acceptance score of 3, indicating that this was the most significant evaluation given by the panelists. This is further supported by Table 2, which shows that all thirteen formulations received a score of 3.

Figure 6.

Cox response tracking chart for sensory acceptance. Source: Minitab—own elaboration.

The model that best fits the sensory analysis data is the quadratic model, as it has the highest coefficient of determination compared to the other models (see Table 6).

Table 6.

Model fit for sensory acceptance.

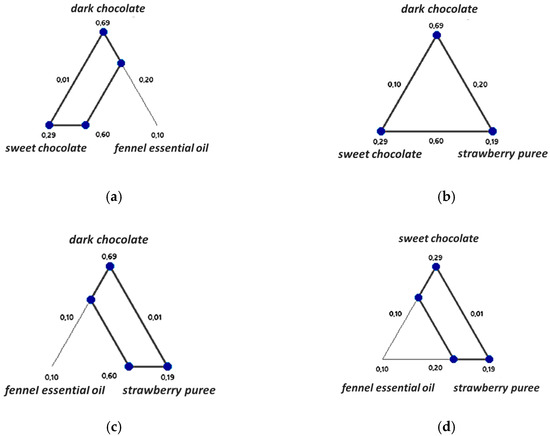

On the other hand, Figure 7 presents different graphs (a–d) corresponding to a simplex design in quantities, where various components are combined to evaluate their effects on the product’s response variable. In these plots, the blue dots represent the combinations of ingredient proportions used in the experiments, distributed to cover the range of interest within each simplex plot. The gray lines indicate the relationships between these points. Each triangle represents combinations of three components (ingredients), with one component held constant at a fixed proportion (bitter chocolate: 0.6; sweet chocolate: 0.2; fennel essential oil: 0.01; and strawberry purée: 0.1). The vertices correspond to the maximum proportions of the components in each mixture.

Figure 7.

Regions of the experimental study (a–d). Source: Minitab—own elaboration.

By keeping some variables constant, it is possible to observe how the others vary. In graph (a), based on the fixed values, bitter chocolate and sweet chocolate show notable variations, while fennel essential oil remains close to its lower limit. In graph (b), there is a greater interaction between the proportions of bitter chocolate and sweet chocolate, while strawberry purée varies within its permitted range. Graph (c) illustrates how the proportions of fennel essential oil and strawberry purée vary in relation to bitter chocolate. Finally, graph (d) shows the behavior of formulations with a lower content of bitter chocolate, emphasizing sweet chocolate and the other ingredients. This last graph is particularly important for identifying the optimal combinations for product formulation.

3.4.3. Response Optimization Component

With the help of Minitab software, the response optimization components were determined, indicating that to optimize sensory acceptance with a score higher than 3.98 and achieve a desirability of 0.49, it is necessary to use the specific proportions of each component detailed in Table 7. These values represent the optimal combination identified to maximize the desired outcome.

Table 7.

Optimal or global solution of the experiment.

After analyzing the results and running the model in Minitab software, it was determined that the most appropriate formulation for the preparation of the bars is formulation number 12, consisting of 60% bitter chocolate, 29% sweet chocolate, 1% fennel essential oil, and 10% pure strawberry (see Figure 8). Although this formulation did not yield a high level of confidence, these proportions ensure compliance with the specifications.

Figure 8.

Chocolate bar filled with strawberry puree and fennel essential oil. Source: own elaboration.

- Storage Conditions for Chocolate Bars.

The preservation process for chocolate is very delicate, given that this product and its derivatives are very sensitive to temperature changes. For proper preservation and industrial refrigeration of chocolate, and to maintain all its properties, the chocolate must generally be stored in the following conditions:

- It should be stored in a cool, dry place: Chocolate must be protected from moisture, as this could affect its texture and flavor.

- The temperature should be kept between 14 and 18 °C.

- It is very important that it not be subjected to sudden temperature changes.

- It should be kept away from odors. Chocolate attracts water in the form of vapor or liquid from its environment, and will therefore absorb the odors surrounding it.

- It should be protected from light: Direct exposure to sunlight can also damage the quality of the chocolate. Therefore, chocolate should be stored in a dark cupboard or drawer [33].

3.5. Microbiological and Physicochemical Analysis

Table 8 presents the physicochemical analysis, indicating that the samples have a high total carbohydrate content (56.65 g/100 g), which suggests a sweet taste and a potentially high glycemic impact. They also contain a moderate amount of fiber, primarily insoluble (4.01 g/100 g), which promotes digestion and intestinal health. Additionally, they have a high fat content (28.21 g/100 g), characteristic of filled chocolates, and a moderate protein content, likely derived from cocoa and other ingredients.

Table 8.

Physicochemical analysis of the chocolate bars.

On the other hand, the moisture content is relatively low (7.14 g/100 g), indicating good product stability, as a higher moisture level could affect texture and shelf life. Furthermore, its high energy value (506.25 kcal/100 g) makes it a suitable option for consumers seeking a quick and effective source of energy [34].

In summary, the chocolate bar with fennel essential oil is a highly energetic product with a high carbohydrate and fat content. Its nutritional profile suggests that it is an indulgent food, providing some fiber and protein, ideal for moments of self-indulgence.

To support the physicochemical results obtained in this research, it is essential to consider comparative studies on similar products. A relevant case is PACARI, an Ecuadorian company that produces and markets organic chocolate with added essences [35]. Its bars include detailed nutritional information; for example, 100 g of its organic chocolate with mint essence contains 600 kcal, 40 g of fat, 50 g of carbohydrates, and 10 g of protein [36], with similar compositions across its other products.

Similarly, in 2022, a related study was conducted in which a nutraceutical food product based on cocoa (Theobroma cacao L.) and ginger oleoresin (Zingiber officinale) was developed. After its production, a proximate chemical analysis was performed, determining that the main components of the chocolate were carbohydrates (50.17%), fat (23.07%), and protein (14.71%), giving it a high energy value beneficial for the body and daily activities [37]. Additionally, the product was highly accepted by consumers.

In this context, the physicochemical results obtained in the present research are relevant, as they show similarities with other studies on related products. This underscores the growing demand for foods with these characteristics, highlighting the importance of their development to meet market needs.

On the other hand, regarding the microbiological results (see Table 9), it can be observed that the samples showed no growth of yeasts, molds, Salmonella, or Escherichia coli [38]. According to Resolution 1407 of 2022 from the Ministry of Health, which establishes the microbiological criteria that food and beverages intended for human consumption must meet to protect public health [39], it can be inferred that the analyzed product (chocolate bars filled with strawberry purée and fennel essential oil) falls below the permitted limits and is therefore considered safe and suitable for consumption.

Table 9.

Microbiological analysis of chocolate bars.

4. Conclusions

The most suitable formulation obtained through the experimental mix design consisted of 60% bitter chocolate, 29% sweet chocolate, 10% strawberry purée, and 1% fennel essential oil, achieving an average sensory acceptability of 3.23 on a five-point hedonic scale. Although the model showed a low R2 (15.42% for sensory acceptability and 7.79% for yield), the selection of this formulation was based on achieving the best possible sensory combination. These results underscore the need to further optimize the experimental model and conduct complementary studies to improve the prediction of product acceptance.

Physicochemical and microbiological analyses confirmed that the Theobroma cacao bar with added Foeniculum vulgare essential oil is safe and suitable for human consumption, meeting established quality standards, as it showed no microbial growth. It also provides a high energy content, along with significant amounts of carbohydrates and fats. Its nutritional profile suggests that it is an indulgent food with a moderate amount of fiber and protein, making it ideal for occasional consumption as a treat.

Author Contributions

Conceptualization, J.S.C., Z.Y.D.E., N.P.R. and J.C.R.V.; methodology, J.S.C. and Z.Y.D.E.; software, J.S.C. and N.P.R.; validation, N.P.R. and Z.Y.D.E.; formal analysis, J.S.C., Z.Y.D.E. and N.P.R.; writing, revising and editing, J.S.C., N.P.R., Z.Y.D.E. and E.V.R.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Acknowledgments

We thank MinCiencias for the stipend to initiate the research project through the national royalty system for the year 2024.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Chacón Ortiz, C.Y.; Mori Culqui, P.L.; Chavez Quintana, S.G. Antioxidants and total polyphenols of dark chocolate with incorporation of raw cocoa (Theobroma cacao L.). Rev. Investig. Altoandinas-J. High Andean Res. 2021, 23, 266–273. [Google Scholar] [CrossRef]

- Zimmermann, B.F.; Ellinger, S. Cocoa, Chocolate, and Human Health. Nutrients 2020, 12, 698. [Google Scholar] [CrossRef] [PubMed]

- Archivos Latinoamericanos de Nutrición (ALAN). Alkaloids and polyphenols of cocoa: Mechanisms regulating their biosynthesis and their implications for flavor and aroma. J. Lat. Am. Soc. Nutr. 2016, 66. Available online: https://www.alanrevista.org/ediciones/2016/3/art-10/ (accessed on 2 January 2025).

- Cacao: From Science to the Table. Available online: https://www.fen.org.es/storage/app/media/2024/MONOGRAFIA_CACAO.pdf (accessed on 2 January 2025).

- Gobernación del Cauca. “Profile of the Department of Cauca”, Popayán. Available online: www.cauca.gov.co (accessed on 3 January 2025).

- “Eva Departamentales”, EVAS UPRA—Base Agrícola. Available online: https://experience.arcgis.com/experience/17859d5712b046fca6b0df5781e0b560/page/EVAs/?views=EVA-Departamentales (accessed on 22 May 2024).

- Ayuda en Acción. “Cacao for Peace: Strengthening the Cacao Value Chain in the Department of Cauca”, Ayuda en Acción Colombia. Available online: https://ayudaenaccion.org.co/actualidad/cacao-del-cauca/?utm_source=chatgpt.com (accessed on 9 April 2025).

- Ayuda en Acción. Challenges and Opportunities for the Competitiveness of Cacao in the Department of Cauca. Available online: https://ayudaenaccion.org.co/actualidad/retos-y-oportunidades-para-la-competitividad-del-cacao-en-el-departamento-del-cauca/# (accessed on 2 September 2024).

- de Sousa, D.P.; Damasceno, R.O.S.; Amorati, R.; Elshabrawy, H.A.; de Castro, R.D.; Bezerra, D.P.; Nunes, V.R.V.; Gomes, R.C.; Lima, T.C. Essential Oils: Chemistry and Pharmacological Activities. Biomolecules 2023, 13, 1144. [Google Scholar] [CrossRef] [PubMed]

- Blogposter. “Benefits of Essential Oils in Preoperative Health”, Phoenix Liposuction. Available online: https://phoenixliposuction.com/es/blog-es/beneficios-de-los-aceites-esenciales-en-la-salud-preoperatoria/ (accessed on 8 April 2025).

- Thurrott, S. “A Detailed Guide to Essential Oils and Aromatherapy”, Banner Health. Available online: https://www.bannerhealth.com/es/healthcareblog/teach-me/essential-oils-and-their-benefits (accessed on 8 April 2025).

- Benkhoud, H.; M’Rabet, Y.; Gara ali, M.; Mezni, M.; Hosni, K. Essential oils as flavoring and preservative agents: Impact on volatile profile, sensory attributes, and the oxidative stability of flavored extra virgin olive oil. J. Food Process. Preserv. 2022, 46, e15379. [Google Scholar] [CrossRef]

- Fernandes, B.; Oliveira, M.C.; Marques, A.C.; Santos, R.G.D.; Serrano, C. Microencapsulation of Essential Oils and Oleoresins: Applications in Food Products. Foods 2024, 13, 3873. [Google Scholar] [CrossRef] [PubMed]

- De Almeida-Couto, J.M.F.; Ressutte, J.B.; Cardozo-Filho, L.; Cabral, V.F. Current extraction methods and potential use of essential oils for quality and safety assurance of foods. An. Acad. Bras. Ciênc. 2022, 94, e20191270. [Google Scholar] [CrossRef] [PubMed]

- Bibliometrix. Available online: https://www.bibliometrix.org/home/ (accessed on 22 February 2025).

- Ramirez, E.J.P.; López, R.R.; Borbón, M.I.R.; Mandujano, H.A.T. Application of mixture design in the food industry. Culcyt/Ing. Ind. 2015, 12, 140–151. [Google Scholar]

- Calvo, A.P.; Ruiz, N.P.; Espinoza, Z.D. Coffee Pulp: A Sustainable and Affordable Source for Developing Functional Foods. Processes 2023, 11, 1693. [Google Scholar] [CrossRef]

- Minitab. “Minitab Statistical Software 22.1”, Addlink Software Científico. Available online: https://www.addlink.es/noticias/minitab/3412-minitab-statistical-software-22-1 (accessed on 4 January 2025).

- Thimoteo, D.; Botelho, R.A.; Ribeiro, R.; Pineli, L.; Stedefeldt, E. Methods for applying acceptance tests for school feeding: Validation of the playful card. Rev. Chil. Nutr. 2013, 40, 357–363. Available online: http://www.redalyc.org/articulo.oa?id=46929416005 (accessed on 5 January 2025).

- El Tiempo. Cauca Has a Taste of Cocoa. Available online: https://www.eltiempo.com/contenido-comercial/cauca-tiene-sabor-a-cacao-837321 (accessed on 12 September 2024).

- Diario del Cauca. Cauca Ranks 16th Among the Most Fertile Lands in the Country. Available online: https://diariodelcauca.com.co/cauca-ocupa-el-puesto-16-entre-las-tierras-mas-fertiles-del-pais/ (accessed on 16 December 2024).

- Empresite Colombia. “Cocoa companies in Cauca”, Empresite.eleconomistaamerica.co. Available online: https://empresite.eleconomistaamerica.co/Actividad/CACAO/departamento/CAUCA/?utm_source=chatgpt.com (accessed on 12 February 2025).

- EUREDD Facility. Diagnosis of the Cocoa Value Chain, and Mapping of Existing Indicators and Information Systems. November 2021; pp. 1–40. Available online: https://euredd.efi.int/wp-content/uploads/2022/09/Informe-1_Diagnostico-cadena-Cacao_Colombia.pdf?utm_source=chatgpt.com (accessed on 12 February 2025).

- Chavaco Trochez, S.M. Analisis De Las Prácticas De Medicina Alternativa De La Comunidad Misak Que Involucren El Uso Y Manejo De Las Plantas Ancestrales En El Resguardo De Guambia, Municipio De Silvia. Fundacion Universitaria De Popayan Facultad De Ciencias Naturales 2020; pp. 1–19. Available online: https://fupvirtual.edu.co/repositorio/files/original/685a70b1021e326ca8b24cc696bd142a65c923ba.pdf (accessed on 30 April 2025).

- Chelaghema, A.; Durand, N.; Servent, A.; Mamouni, M.; Poucheret, P.; Schorr-Galindo, S.; Fontana, A.; Strub, C. Antifungal and antimycotoxic activities of 3 essential oils against 3 mycotoxinogenic fungi. Arch. Microbiol. 2022, 204, 504. [Google Scholar] [CrossRef] [PubMed]

- Hanková, K.; Lupoměská, P.; Nový, P.; Všetečka, D.; Klouček, P.; Kouřimská, L.; Hlebová, M.; Božik, M. Effect of Conventional Preservatives and Essential Oils on the Survival and Growth of Escherichia coli in Vegetable Sauces: A Comparative Study. Foods 2023, 12, 2832. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Ahmad, R.; Saeed, S.; Azeem, M.; Mozūraitis, R.; Borg-Karlson, A.-K.; Zhu, G. Chemical Composition of Fresh Leaves Headspace Aroma and Essential Oils of Four Coriander Cultivars. Front. Plant Sci. 2022, 13, 820644. [Google Scholar] [CrossRef] [PubMed]

- Hlebová, M.; Foltinová, D.; Vešelényiová, D.; Medo, J.; Šramková, Z.; Tančinová, D.; Mrkvová, M.; Hleba, L. The Vapor Phase of Selected Essential Oils and Their Antifungal Activity In Vitro and In Situ against Penicillium commune, a Common Contaminant of Cheese. Foods 2022, 11, 3517. [Google Scholar] [CrossRef] [PubMed]

- Nelson, P.; Adimabua, P.; Wang, A.; Zou, S.; Shah, N.C. Surface-Enhanced Raman Spectroscopy for Rapid Screening of Cinnamon Essential Oils. Spectroscopy 2020, 74, 1341–1349. [Google Scholar] [CrossRef] [PubMed]

- U.S. FOOD & DRUG ADMINISTRATION. Generally Recognized as Safe (GRAS)|FDA.FDA. Available online: https://www.fda.gov/food/food-ingredients-packaging/generally-recognized-safe-gras (accessed on 7 March 2025).

- Yuqui, E. “Efficacy of Fennel Essential Oil”, Riobamba. July 2023. Available online: https://dspace-api.istmas.edu.ec/server/api/core/bitstreams/908bf57b-507b-4dfc-9314-c539571bb8e2/content (accessed on 16 December 2024).

- Pulido, H.G.; De la Vara Salazar, R. Analysis and Design of Experiments; McGraw-Hill Interamericana: São Paulo, Brazil, 2012. [Google Scholar]

- Tauferová, A.; Tkadlecová, T. Effect of storage on sensory quality of chocolate. Maso Int.—J. Food Sci. Technol. 2022, 12, 41–48. [Google Scholar] [CrossRef]

- SYNLAB BIOINDUSTRIAL. Laboratory Report; SYNLAB BIOINDUSTRIAL: Cali Valle del Cauca, Colombia, 2024. [Google Scholar]

- Arteaga, M.G. The Story of Pacari: The 45 Flavored Chocolates That Have Taken Over Latin America and the World. DFSUD. Available online: https://dfsud.com/america/la-historia-de-pacari-los-chocolates-de-45-sabores-que-se-han-tomado (accessed on 6 March 2025).

- Fitia. “Marca: Pacari—Calories and Nutritional Information”, Fitia Ecuador. Available online: https://fitia.app/es/ec/calorias-informacion-nutricional/Chocolates%20y%20Dulces/Pacari/ (accessed on 6 March 2025).

- García, T.; Gómez, F. “Design of a Nutraceutical Food Based on Cacao (Theobroma cacao L) and Ginger Oleoresin (Zingiber officinale)”, TUXTLA GUTIÉRREZ, CHIAPAS. November 2022. Available online: https://repositorio.unicach.mx/bitstream/handle/20.500.12753/4679/Licenciatura-Tamara%20Garci%CC%81a-Fermi%CC%81n%20Go%CC%81mez%20.pdf?sequence=1&isAllowed=y (accessed on 7 March 2025).

- Ministry of Health and Social Protection. Resolution 1407 of 2022—Microbiological Criteria for Food. August 2022. Available online: https://www.icbf.gov.co/cargues/avance/compilacion/docs/pdf/resolucion_minsaludps_1407_2022.pdf (accessed on 3 February 2025).

- SYNLAB BIOINDUSTRIAL. INFORME DE LABORATORIO; SYNLAB BIOINDUSTRIAL: Cali Valle del Cauca, Colombia, 2024. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).