E-Waste Unplugged: Reviewing Impacts, Valorization Strategies and Regulatory Frontiers for Efficient E-Waste Management

Abstract

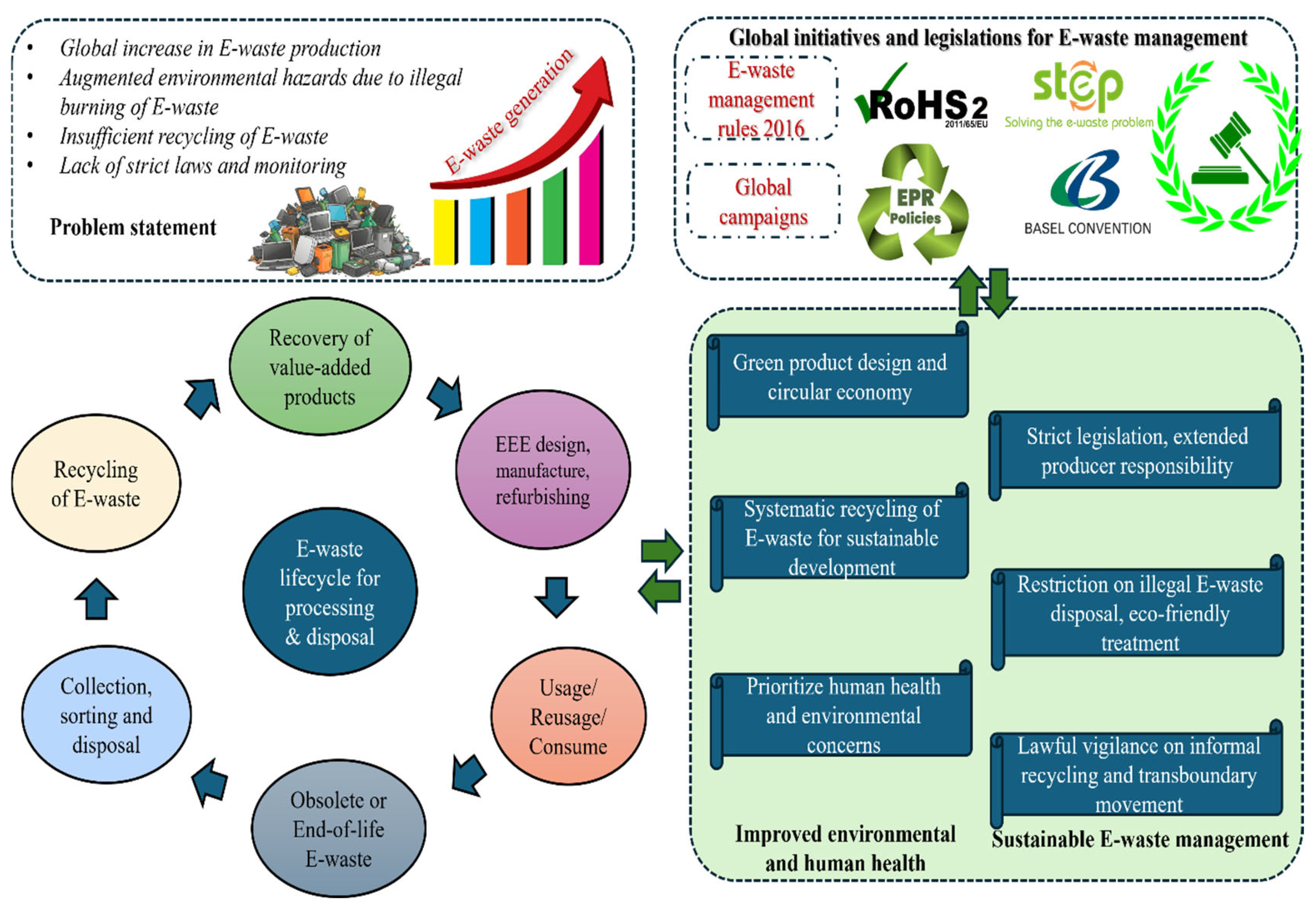

1. Introduction

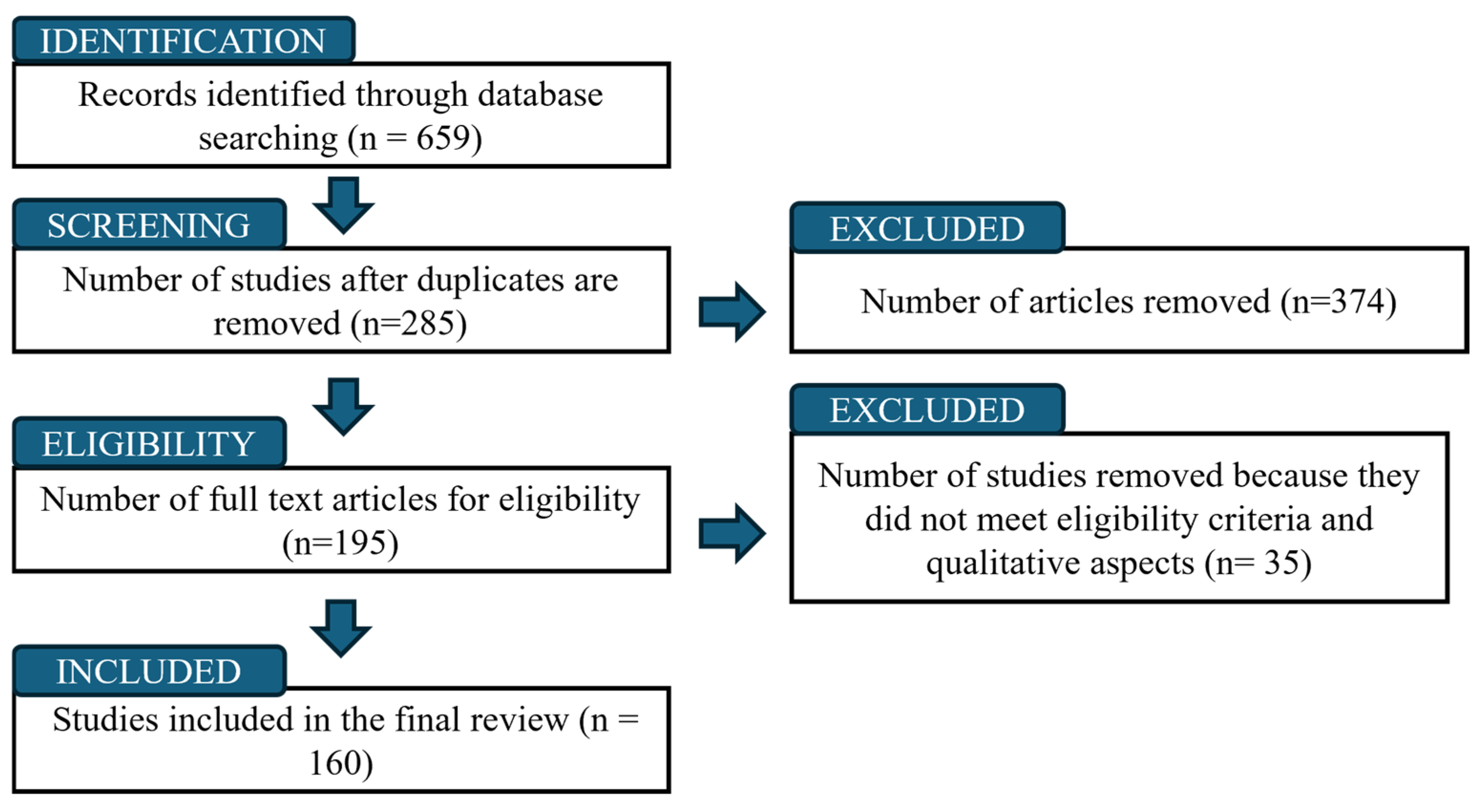

2. Methods: Review Structure Development

2.1. Research Question Development: VIRE Framework

2.2. Review Structure Development

3. Understanding the Sources, Composition, and Classification

3.1. Definition

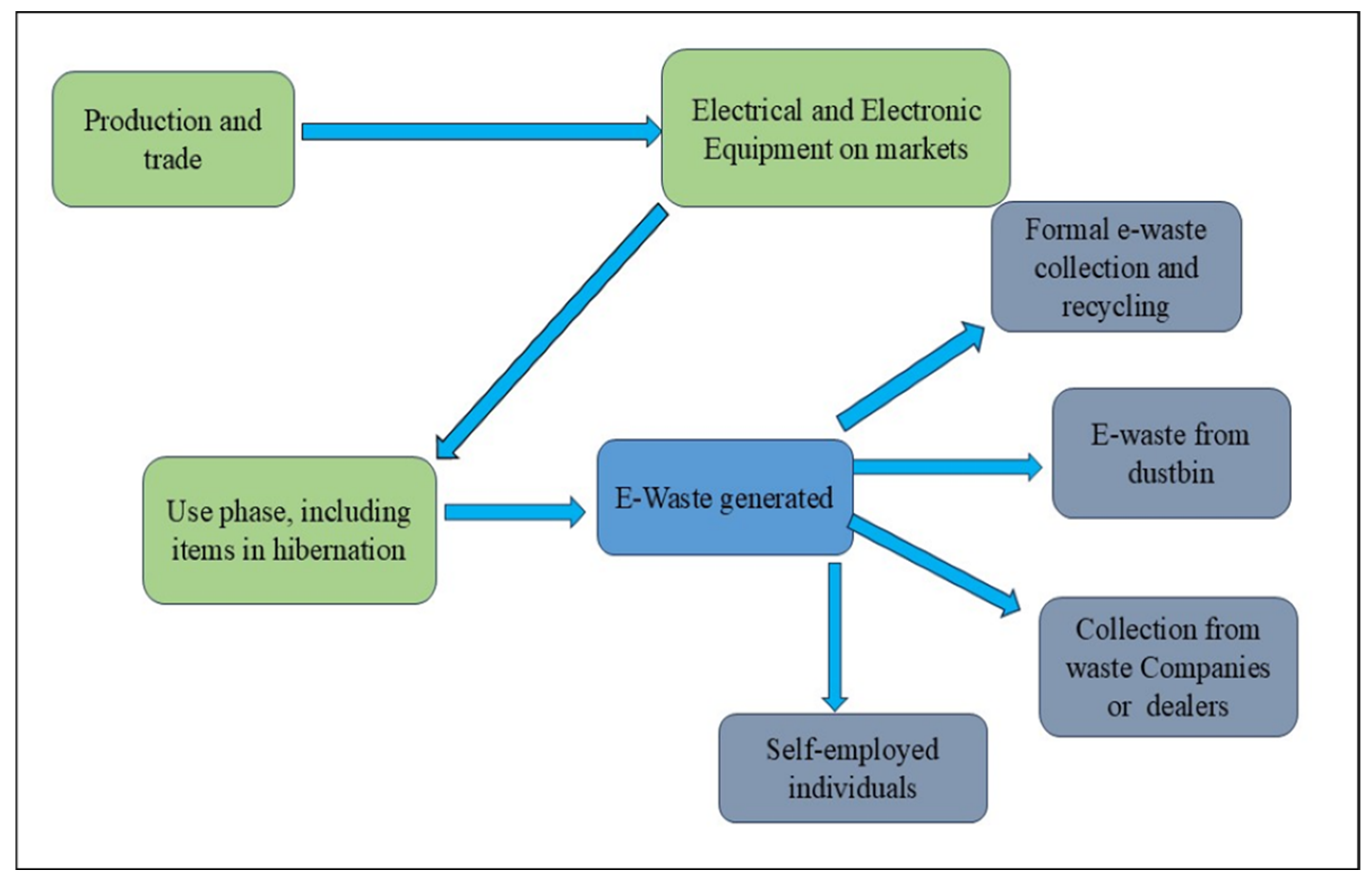

3.2. Cardinal Sources of E-Waste

3.2.1. Households’ E-Waste

3.2.2. Organizational E-Waste

3.2.3. E-Waste from Manufacturers and Retailers

3.3. Processing of E-Waste

3.4. Categorization of Diverse E-Waste Streams

3.5. Composition of E-Waste

3.5.1. Metals

- Precious metals: Circuit boards and connectors use gold (Au), silver (Ag), platinum (Pt), and palladium (Pd).

- Base metals [Cu, Al, Sn]: These materials are used for wiring, casings, and soldering, respectively.

- Heavy metals: Older components such as CRT monitors, batteries, and circuit boards contain Lead (Pb), Cadmium (Cd), and Mercury (Hg).

3.5.2. Plastics and Polymers

- Polyvinyl chloride (PVC): Used in cables and insulation.

- Acrylonitrile butadiene styrene (ABS): Used in keyboards and casings.

- Polycarbonate (PC) and Polypropylene (PP): Used in structural components.

3.5.3. Glass, Ceramics, and Silica

3.5.4. Toxic and Hazardous Substances

- Brominated flame retardants (BFRs): Used in circuit boards and plastic casings to reduce flammability but they can release toxic compounds when burned.

- Polychlorinated biphenyls (PCBs): Found in older transformers and capacitors; these have been banned in many countries due to their high toxicity.

- Chlorofluorocarbons (CFCs): Present in the cooling systems of old refrigerators and air conditioners, and are known to contribute to ozone layer depletion.

3.5.5. Batteries and Other Components

- Lithium-ion batteries: Used in laptops, smartphones, and power banks, and contain lithium (Li), cobalt (Co), and nickel (Ni).

- Nickel-cadmium (Ni-Cd) and lead-acid batteries: Older devices may still contain these batteries, which pose environmental hazards.

- Capacitors and resistors: Found in circuit boards, often containing rare earth elements.

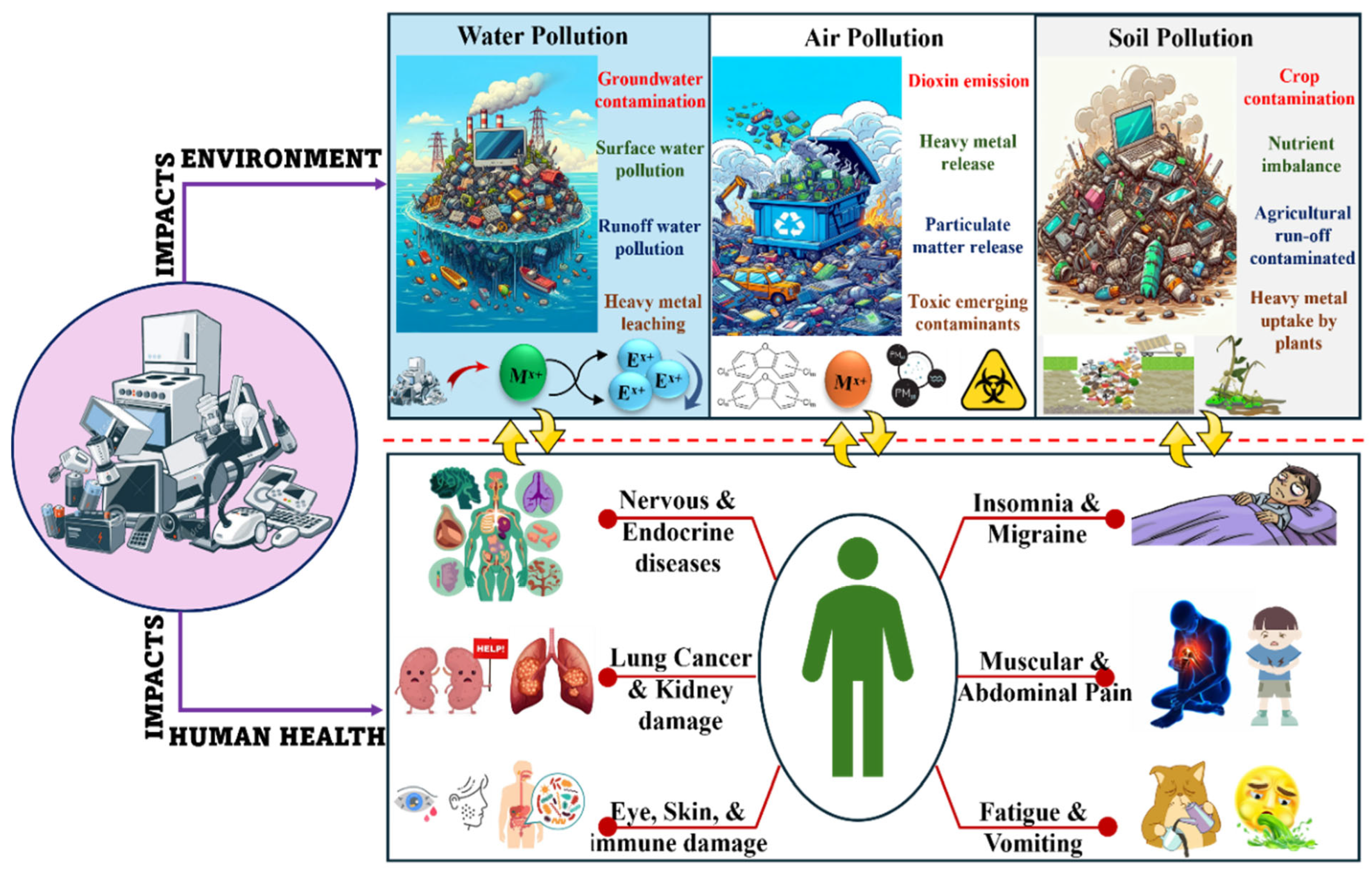

4. Impact of E-Waste on Humans and Ecosystem

4.1. Effects on Human Health

4.2. Effects on Environmental Systems

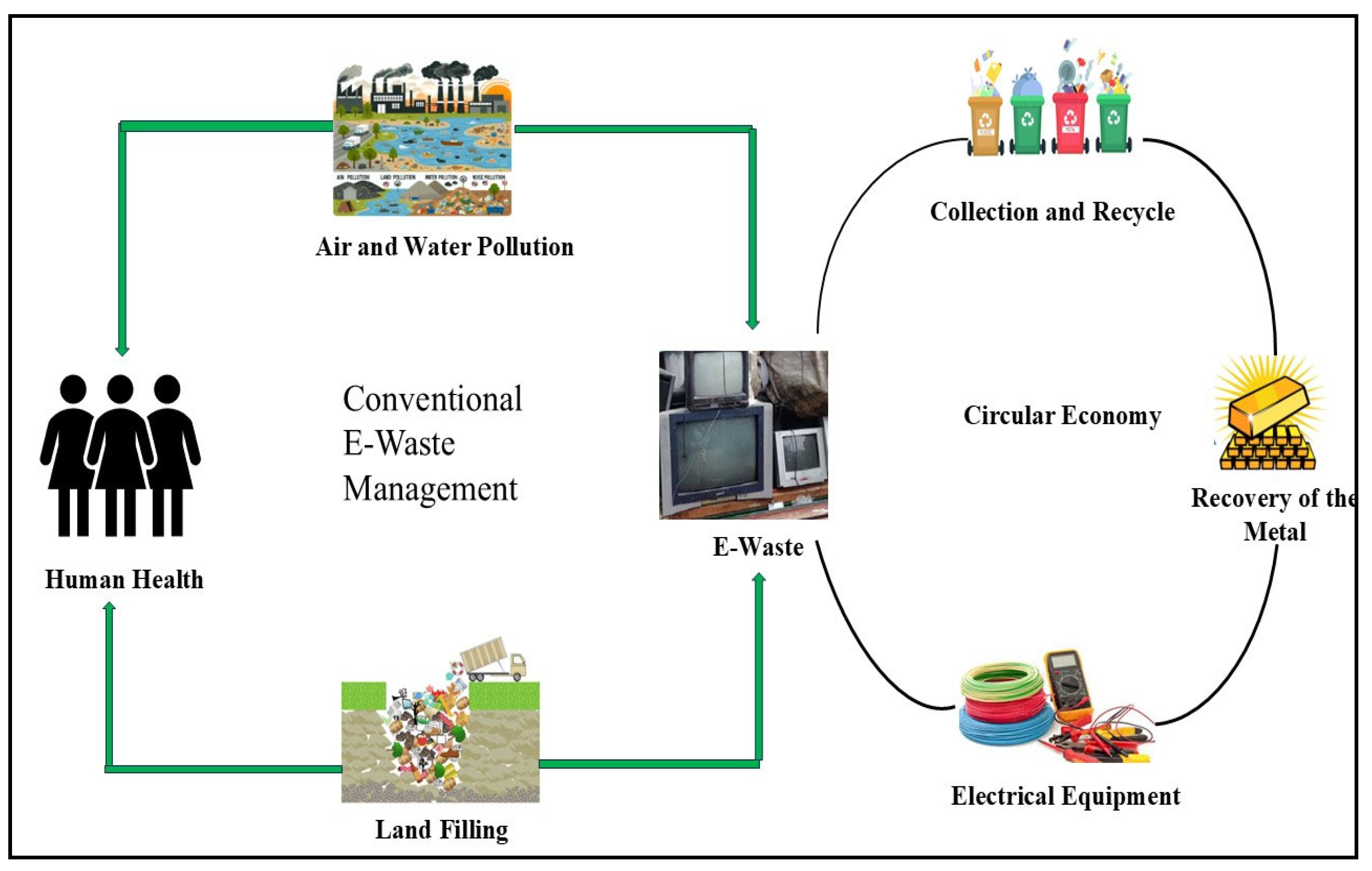

5. Conventional E-Waste Processing Pathways

5.1. Collection and Sorting

5.2. Mechanical Processing

5.3. Metallurgical Treatment

5.3.1. Pyrometallurgy

5.3.2. Hydrometallurgy

5.4. Landfilling

5.5. Recycling vs. Recovery of Reusable E-Waste Components

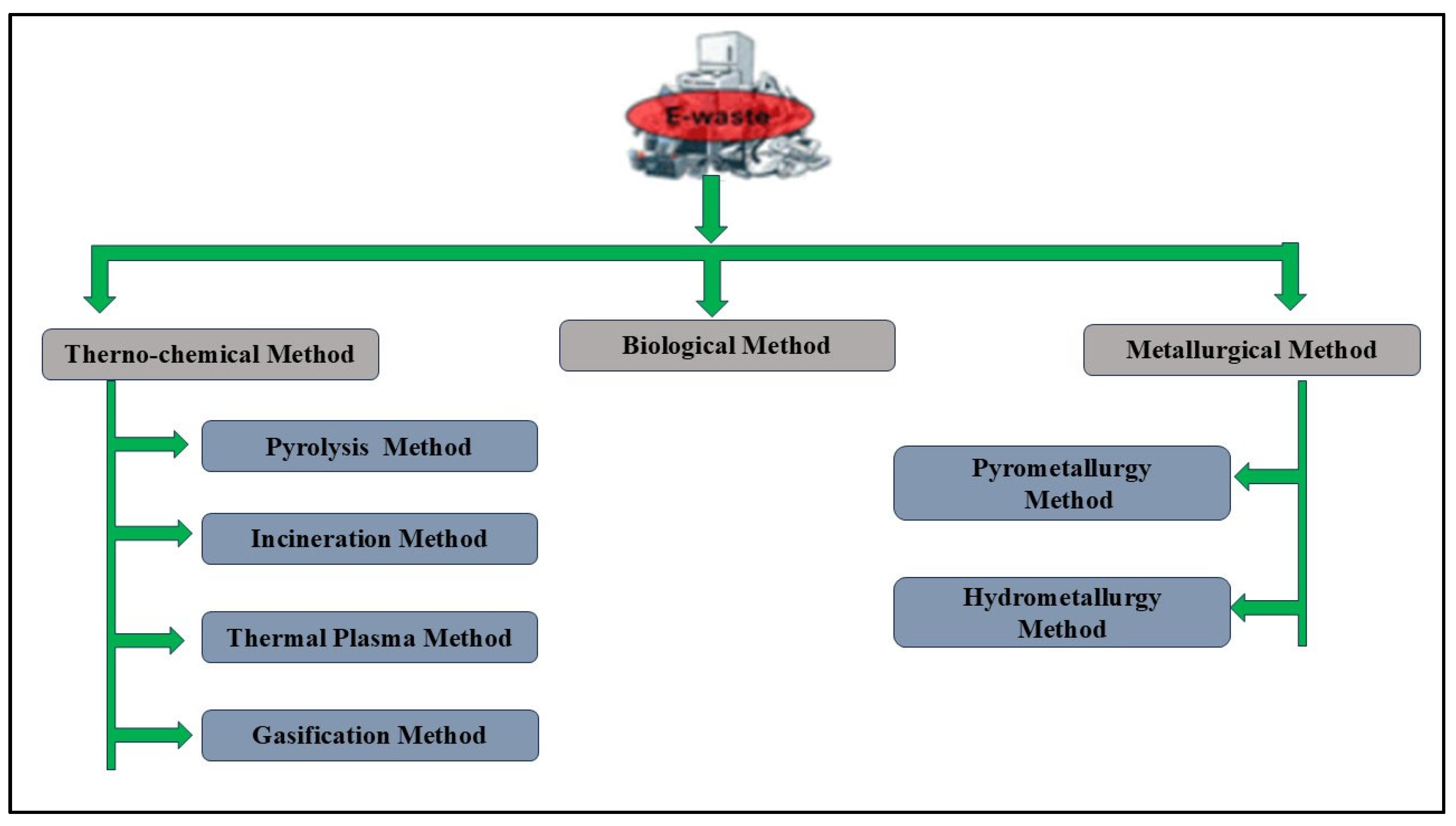

6. Advanced Treatment and Recovery Technologies

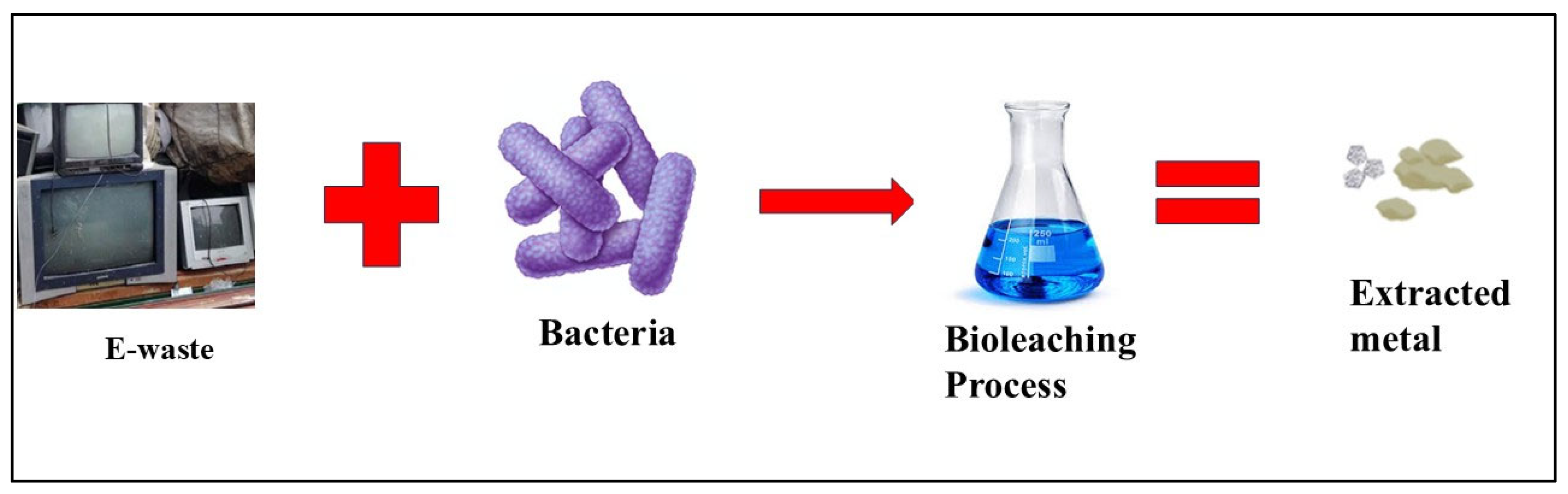

6.1. Biochemical Pathway

6.2. Thermochemical Treatment

6.2.1. Incineration

6.2.2. Pyrolysis

6.2.3. Gasification

6.2.4. Advanced Thermal Plasma Technology

7. Regulations Vis-à-Vis E-Waste Movement, Management, Handling, and Disposal

7.1. Transboundary Movement of E-Waste and SDGs

7.2. International Initiatives/Regulations on E-Waste Management

7.3. Perspectives on E-Waste Management Legislations Around the Globe

7.3.1. The United States of America (USA)

7.3.2. Germany

7.3.3. China

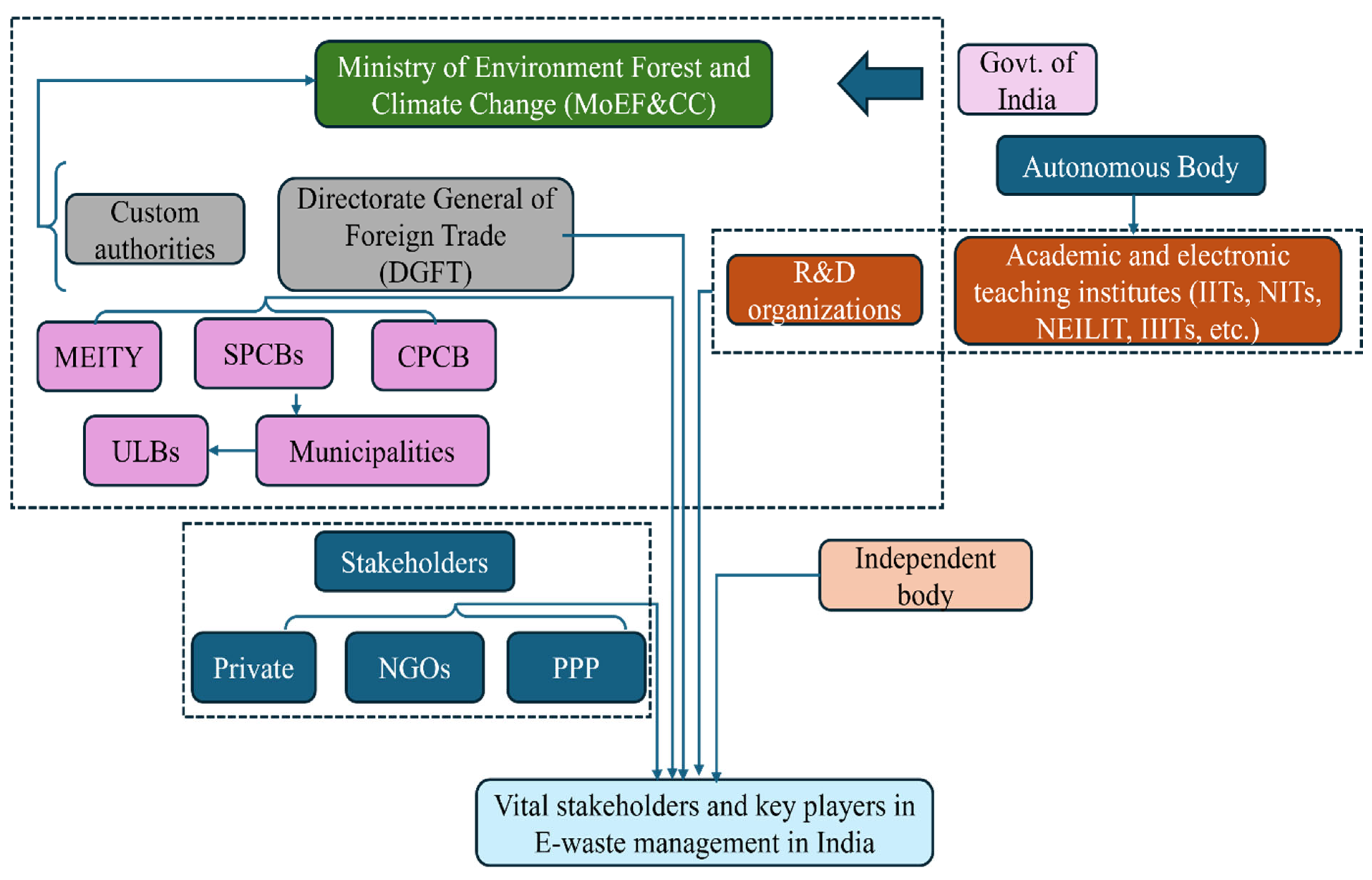

7.3.4. India

7.4. Barriers and Solutions Towards Effective Policy Implementation

| S. No. | Barrier to E-Waste Policy Implementation | Description | Country-Specific Example | Policy-Based Solution |

|---|---|---|---|---|

| 1 | Low public awareness | Population in developing countries lacks knowledge about environmental and human health imposed by e-waste mishandling because of limited technical outreach. | India: 70% of urban customers using electronics are unaware of collection and processing units [185]. | Initiatives such as educational schemes under India’s E-waste (management) rules 2016 mandate awareness training for producers. |

| 2 | Limited access and convenience | Developing countries lack formal collection facilities that discourage rule-based recycling. | Kenya: Less than 5% of counties in different states possess formal e-waste collection centers [186]. | Kenya’s National E-Waste Management Strategy recommends zonal e-waste collection and processing centers and county-level infrastructure. |

| 3 | Concerns for data security and misunderstandings | People in developing countries show concerns over data theft from discarded electronic items. | South Africa: A case study demonstrates that approximately 40% of people show reluctance to data misuse while handing over electronics to formal middlemen. [187]. | South Africa’s e-waste policy (National Environmental Management Waste Act 2008) recommends authorized recycling units and engineered processing services. |

| 4 | Weak public involvement | Insignificant outreach results in less participation in e-waste management policy acceptance. | Nigeria: Inferior people turnout despite significant campaigns [188]. | Nigeria’s National Environmental (Electrical/Electronic Sector) Regulation and NESREA guidelines recommend county authorities for enhanced involvement of community people. |

| 6 | Lack of stakeholder coordination and partnerships | Lack of cooperation and coordination between government authorities and non-profit organizations reduces the impact of policy implications. | Ghana: Only 13% of stakeholders are aware of e-waste rules, and overlapping of stakeholders’ roles inhibits regulation implementation [189]. | Country-wise supervision of implementation of Ghana’s Hazardous and Electronic Waste Control and Management Act (Act 917) that integrates roles for EPAs and local authorities. |

| 7 | Limited use of digital media | Uninterest in social media promotion for e-waste policy sharing and awareness despite extensive use of platforms. | Bangladesh: Almost 70.79% of the country’s population is active on social media but only 29% of them are aware of e-waste management rules [190]. | Digital Bangladesh Vision initiative may help in encouraging ICT platforms towards engineered recycling awareness via integration into apps and social media campaigns. |

| 8 | Limited financial incentives | Despite knowing recycling income, people hesitate to send WEEE items due to a lack of incentives or appropriate prices as a recycling motivation. | Brazil: Informal collectors provide very low recycling prices (R$0.40 to R$4.00 per kg), making e-waste unattractive for households. Only about ~3.6% of the population’s e-waste is formally recycled [191] | Brazil’s National Solid Waste Policy may include tax incentives or subsidies for e-waste recycling. The EPR amendment may increase subsidies for formal recyclers and fix a compulsory buy-back plan for WEEE-producing households. |

| 9 | Lack of community-driven initiatives | Lack of people’s participation weakens accountability and increases ignorance about e-waste policies. | Vietnam: Lack of pilot programs reinforced 81–100% of people in Ho Chi Minh city to go for informal recycling thereby undermining formal recycling policy efforts [192]. | Vietnam’s National Strategy on Integrated Waste Management and EPR policy should emphasize community-level awareness and grassroots-level engagements regarding WEEE formal recycling. |

| 10 | Disoriented WEEE recycling campaigns and policy promotion | Lack of policy promotion campaigns and inconsistent efforts by authorities impact successful policy implementation. | Pakistan: Despite 98% recycling potential, misalignment of policy and inefficient promotional campaigns affected recycling efforts [193]. | E-waste policy campaigns following a bottom-to-top approach would raise public awareness about Pakistan’s Draft E-waste Management Rules, which recommend long-term public cooperation and centralized follow-up of social campaigns. |

| 11 | Informal sector dominance | Dependency on informal recyclers following illegal pathways and offering irregular recycling prices ultimately limits successful policy implementation. | China (Guiyu): Informal e-waste recyclers process ~70% of e-waste, undermining formal policy implementation and causing major health risks [194]. | China’s 2016 e-waste policy may recommend financial incentives, training programs, and certification campaigns for integrating the informal sector. |

| S. No. | Country | Legislation | Producers Responsibility | Collection and Recycling | Export or Transboundary Movement | Audits and Monitoring System | RoHS Directives | References |

|---|---|---|---|---|---|---|---|---|

| 1. | United Kingdom (UK) | The Waste Electrical and Electronic Equipment (WEEE) Regulations 2013. The Waste Electrical and Electronic Equipment (Amendment) Regulations 2015 | Registration of E-waste under producer compliance scheme. Financing collection, recovery, and eco-friendly disposal of E-waste. Regular recording and reporting of E-waste to competent authorities. | DCFs and PCSs frame setups for E-waste collection via different ways—involvement of local authorities, retail collection stations, and direct collection points. The DEFRA monitors and sets annual targets for E-waste collection. | Permitted under the WSR and TFS rules. E-waste (hazardous or non-hazardous) must follow the import notification by the recipient country. Export of E-waste must be performed only by the approved exporter. | DEFRA is a monitoring agency for the collection and sorting of E-waste under different categories. The compliance scheme charges a one-time fee for monitoring and law enforcement. | Imported E-waste for market practice in the UK must hold compliance under RoHS directives. Mandatory requirements are—CE mark, compliance documents, importers’ details, tradename/mark, contact, and address of exchange partners. | [195,196] |

| 2. | France | The European Directive (2011/65/EU), RoHS directives = | Producers must register in Registre DEEE (French WEEE register). Fund the management of E-waste, inclusive of collection, treatment, and eco-friendly disposal. Proper labeling of E-waste. | Producers organize collections with the cooperation of municipalities. Household E-waste is collected by an authorized agency, OCAD3E. Producers are liable to provide details of e-waste for an appropriate recycling option. | The export of E-waste (either hazardous or non-hazardous) is not allowed outside the OECD. | Third-party audits are conducted by authorized agencies under the supervision of the government to monitor recycling and collection operators. | Not advocated for freight of E-waste that is non-compliant with RoHS directives. Imported E-waste items must follow RoHS directives and carry CE marks for resource recovery and appropriate disposal. | [197] |

| 3. | Japan | Classified based on EEE categories: The Home Appliance Recycling (THAR) Law, 2001—Televisions, Freezers, Air conditioners, and Washing machines. Small Home Appliances Recycling (SHAR) Law, 2013—Mobiles, small E&E equipment | Establishing recovery and recycling arrangements for used EEE. Producers are obligated to fund the collection and recycling of used EEE. | Designation of used products as “old or new” is imposed under THAR law (2001), which enables retailers to recollect consumers’ small, or several times sold products. EEE manufacturers can arrange collection by a third party such as AEHA. In rural areas, collection and recycling services are operated by the local government or AEHA, whichever is operable. | NA | The government has the authority to investigate recyclers anytime. Retailers must provide a special receipt to end users to track down the treatment of the collected used product, under the manifest system. | RoHS directives of Japan are combined with Japanese Recycling Law with the JIS C 0950 standard (J-MOSS) [150]. It also mandates restrictions on the same 6 substances (with the same upper limits) as prescribed by EU RoHS but under 7 product categories. | [198,199] |

| 4. | Australia | The National Television and Computer Recycling Scheme and the Product Stewardship (TVs and Computers) Regulations 2011, Australian Government’s Product Stewardship Act 2011. | Fund the E-waste management (collection to disposal). Provide information to consumers for end-use handling, reselling, or disposal. Obtain membership in an approved co-regulatory system. | End-of-life WEEE from domestic entities or small business units can be submitted to designated collection points. Co-regulatory systems are liable for organizing recycling services in spite of producers. They may even appoint third-party contract services or logistics handling companies for collection but under strict supervision. | Allowed as per Basel, OECD, and Waigani Conventions. A prescribed permit (evidentiary certificate by the government) is mandatory if E-waste is in the hazardous category. | Representatives of the Co-regulatory system must submit an annual audit report which is prepared by the auditor appointed by the company or authorized organization for WEEE audits. | NA | [200,201] |

| 5. | Ghana | Hazardous and Electronic Waste Control and Management, Law, (Act 917) (2016) Hazardous, Electronic, and Other Wastes (Classification) Control and Management Regulations (2016) | Ensure environmentally sound management of E-waste either individual or collaborative. Attaining environmental permits, preserving records, and reporting to concerned agencies. Labeling of products with symbols which prevent disposal of discarded waste into garbage. Financing e-waste management. | Only through informal channels. As per the legislation’s recommendation, collection must be by an authorized agency. Dissemblers and recyclers’ duty is to ensure proper treatment of E-waste in the special facility by employing the best treatment option available. | Most non-hazardous e-waste is allowed to be imported with a permit from competent authority. Used CFLs, refrigerators, Acs, and other ODSs are not permitted for import under any circumstances. | Competent authority has set (technical guidelines) the standard to ensure secure disposal of E-waste. Agency may seek stakeholders’ cooperation for maintaining monitoring data and calculation of market share by individual producers. | Restriction on six substances as recommended by the EU’s RoHS, but only change in product categories and scope. Decrease in utilization of hazardous substances in imported E-waste is opinionated by authority within two years after RoHS enforcement. | [150,202] |

| 6. | Switzerland | Ordinance on Movements of Waste (OWM, 2005), Ordinance on the Return, Take-Back, and Disposal of Electrical and Electronic Equipment (ORDEE, 2022) | Must follow theory of Extended Producer Responsibility (EPR). Customers are charged with advanced recycling fee (ARF), inclusive of retail price, which is taken for operating collection, utilization, and disposal of used products. Treatment and recycling facilities are paid according to an index-system which manifests impartial distribution. | Competent authorities (PROs) designate collection points such as public bus or train stations. Paid pick-up may be arranged for commercial units. Swiss PROs authorized 9 recyclers and 83 dissembling units as of 2018 ending. | The OWM is supervising law for the movement of E-waste. Export is subjected to adoption of Basel and the OECD considerations. | The PRO makes sure that assigned recycling companies perform quality checks and maintain standards for recycling. External audits funded by PROs are also employed to ensure transparency in recycling. The FOEN, acts as environmental monitoring & licensing authority | Trade in used electronic and electric products: The restraints on hazardous materials are same as those indicated by RoHS Directives (RoHS2). Banned materials under Swiss Chemical’s legislation are not exported. | [203,204] |

| 7. | Singapore | Resource Sustainability Act 2019; Resource Sustainability (Composition of Offences) Regulations, 2019; Resource Sustainability (Prescribed Regulated Products) Regulations, 2019 | Producers are mandated to register with NEA and keep detailed records (weight and number) of all regulated products. Contribution of funds by licensed producers of regulated consumer products under PRS. Regulated non-consumer product producers must ensure collection, monitoring, management, and disposal of their E-waste by proper tracking. | Only licensed collectors and recyclers authorized by NEA can perform treatment and disposal of E-waste. Collection of E-waste is bifurcated under categories of—regulated consumer products or regulated non-consumer products. Former ones are collected by operators under PRS. | NA | Audit of annual report produced by every licensee is conducted. Licensed recyclers are mandated to maintain the recovery/recycling standards. The NEA is responsible for monitoring collected, recycled, and disposed E-waste. | NA | [205,206] |

8. Case Study Overview on Technologies and Regulations

8.1. India

8.2. China

9. Conclusions and Perspectives

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Liu, K.; Tan, Q.; Yu, J.; Wang, M. A global perspective on e-waste recycling. Circ. Econ. 2023, 2, 100028. [Google Scholar] [CrossRef]

- Kerber, J.C.; de Souza, E.D.; Bouzon, M.; Cruz, R.M.; Govindan, K. Consumer behaviour aspects towards remanufactured electronic products in an emerging economy: Effects on demand and related risks. Resour. Conserv. Recycl. 2021, 170, 105572. [Google Scholar] [CrossRef]

- The Global E-Waste Monitor 2024—Electronic Waste Rising Five Times Faster than Documented E-Waste Recycling: UNITAR. Available online: https://ewastemonitor.info/the-global-e-waste-monitor-2024/ (accessed on 30 April 2025).

- Grand View Research. E-Waste Management Market Size, Share, & Trends Analysis Report by Processed Material (Metal, Plastic), By Source (Industrial Electronics, Consumer Electronics), By Application (Disposal, Recycle), By Region, And Segment Forecasts, 2024–2030. 2022. Available online: https://www.grandviewresearch.com/industry-analysis/e-waste-management-market# (accessed on 12 May 2025).

- Rucevska, I.; Nellemann, C.; Isarin, N.; Yang, W.; Liu, N.; Yu, K.; Nilsen, R. Waste Crime–Waste Risks: Gaps in Meeting the Global Waste Challenge. A UNEP Rapid Response Assessment; United Nations Environment Programme and GRID-Arendal, Nairobi and Arendal: Arendal, Norway, 2015. [Google Scholar]

- Shamim, A.; Mursheda, A.K.; Rafiq, I. E-waste trading impact on public health and ecosystem services in developing countries. J. Waste Resour. 2015, 5, 1–18. [Google Scholar] [CrossRef]

- Ouro-Salim, O. Urban mining of e-waste management globally: Literature review. Clean. Waste Syst. 2024, 9, 100162. [Google Scholar] [CrossRef]

- Sethanan, K.; Khonjun, S.; Gonwirat, S.; Golinska-Dawson, P.; Srichok, T.; Boonmee, C.; Nanthasamroeng, N.; Pitakaso, R.; Luesak, P. Optimization-driven artificial intelligence-enhanced municipal waste classification system for disaster waste management. Eng. Appl. Artif. Intell. 2024, 133, 108614. [Google Scholar]

- Kumar, R.; Thakur, A.K.; Gupta, L.R.; Gehlot, A.; Sikarwar, V.S. Advances in phase change materials and nanomaterials for applications in thermal energy storage. Environ. Sci. Pollut. Res. 2024, 31, 6649–6677. [Google Scholar] [CrossRef]

- Arya, S.; Kumar, S. E-waste in India at a glance: Current trends, regulations, challenges and management strategies. J. Clean. Prod. 2020, 271, 122707. [Google Scholar] [CrossRef]

- Nassajfar, M.N.; Deviatkin, I.; Leminen, V.; Horttanainen, M. Alternative materials for printed circuit board production: An environmental perspective. Sustainability 2021, 13, 12126. [Google Scholar] [CrossRef]

- Asokan, V.A.; Teah, H.Y.; Kawazu, E.; Hotta, Y. Ambitious EV policy expedites the e-waste and socio-environmental impacts in India. Resour. Conserv. Recycl. 2022, 190, 106829. [Google Scholar] [CrossRef]

- Qiao, D.; Wang, G.; Gao, T.; Wen, B.; Dai, T. Potential impact of the end-of-life batteries recycling of electric vehicles on lithium demand in China: 2010–2050. Sci. Total Environ. 2021, 764, 142835. [Google Scholar] [CrossRef]

- Huang, Y.; Hsiang, E.L.; Deng, M.Y.; Wu, S.T. Mini-LED, Micro-LED and OLED displays: Present status and future perspectives. Light Sci. Appl. 2020, 9, 105. [Google Scholar] [CrossRef]

- Andeobu, L.; Wibowo, S.; Grandhi, S. A systematic review of e-waste generation and environmental management of Asia Pacific countries. Int. J. Environ. Res. Public Health 2021, 18, 9051. [Google Scholar] [CrossRef] [PubMed]

- Owusu-Sekyere, K.; Aladago, D.A.; Leverenz, D.; Oteng-Ababio, M.; Kranert, M. Environmental Impacts on Soil and Groundwater of Informal E-Waste Recycling Processes in Ghana. Sustainability 2024, 16, 4347. [Google Scholar] [CrossRef]

- Swami, S.; Suthar, S.; Singh, R.; Thakur, A.K.; Gupta, L.R.; Sikarwar, V.S. Potential of ionic liquids as emerging green solvent for the pretreatment of lignocellulosic biomass. Environ. Sci. Pollut. Res. 2024, 31, 12871–12891. [Google Scholar] [CrossRef]

- Tansel, B. PFAS use in electronic products and exposure risks during handling and processing of e-waste: A review. J. Environ. Manag. 2022, 316, 115291. [Google Scholar] [CrossRef]

- Kaim, V.; Rintala, J.; He, C. Selective recovery of rare earth elements from e-waste via ionic liquid extraction: A review. Sep. Purif. Technol. 2023, 306, 122699. [Google Scholar] [CrossRef]

- Teixeira, F.D.S.M.; Peres, A.C.D.C.; Pacheco, E.B.A.V. Mechanical recycling of acrylonitrile-butadiene-styrene copolymer and high impact polystyrene from waste electrical and electronic equipment to comply with the circular economy. Front. Sustain. 2023, 4, 1203457. [Google Scholar] [CrossRef]

- Morf, L.S.; Tremp, J.; Gloor, R.; Schuppisser, F.; Stengele, M.; Taverna, R. Metals, non-metals and PCB in electrical and electronic waste–Actual levels in Switzerland. Waste Manag. 2007, 27, 1306–1316. [Google Scholar] [CrossRef]

- Wang, C.; Sun, R.; Xing, B. Copper recovery from waste printed circuit boards by the flotation-leaching process optimized using response surface methodology. J. Air Waste Manag. Assoc. 2021, 71, 1483–1491. [Google Scholar] [CrossRef]

- Andeobu, L.; Wibowo, S.; Grandhi, S. Environmental and Health Consequences of E-Waste Dumping and Recycling Carried out by Selected Countries in Asia and Latin America. Sustainability 2023, 15, 10405. [Google Scholar] [CrossRef]

- Ohajinwa, C.M.; Van Bodegom, P.M.; Vijver, M.G.; Peijnenburg, W.J. Impact of informal electronic waste recycling on metal concentrations in soils and dusts. Environ. Res. 2018, 164, 385–394. [Google Scholar] [CrossRef] [PubMed]

- Forti, V.; Balde, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows and the Circular Economy Potential; United Nations University: Geneva, Switzerland, 2020. [Google Scholar]

- Sengupta, D.; Ilankoon, I.M.S.K.; Kang, K.D.; Chong, M.N. Circular economy and household e-waste management in India: Integration of formal and informal sectors. Miner. Eng. 2022, 184, 107661. [Google Scholar] [CrossRef]

- Jain, M.; Kumar, D.; Chaudhary, J.; Kumar, S.; Sharma, S.; Verma, A.S. Review on E-waste management and its impact on the environment and society. Waste Manag. Bull. 2023, 1, 34–44. [Google Scholar] [CrossRef]

- Mundada, M.N.; Kumar, S.; Shekdar, A.V. E-waste: A new challenge for waste management in India. Int. J. Environ. Stud. 2004, 61, 265–279. [Google Scholar] [CrossRef]

- International Solid Waste Association. Global Waste Management Outlook 2024: Beyond an Age of Waste, Turning Rubbish Into a Resource; International Solid Waste Association: Rotterdam, The Netherlands, 2024. [Google Scholar]

- Ikhlayel, M. An integrated approach to establish e-waste management systems for developing countries. J. Clean. Prod. 2018, 170, 119–130. [Google Scholar] [CrossRef]

- Abubakar, A.; Zangina, A.S.; Maigari, A.I.; Badamasi, M.M.; Ishak, M.Y.; Abdullahi, A.S.; Haruna, J.A. Pollution of heavy metal threat posed by e-waste burning and its assessment of human health risk. Environ. Sci. Pollut. Res. 2022, 29, 61065–61079. [Google Scholar] [CrossRef]

- Dai, Y.; Huo, X.; Cheng, Z.; Wang, Q.; Zhang, Y.; Xu, X. Alterations in platelet indices link polycyclic aromatic hydrocarbons toxicity to low-grade inflammation in preschool children. Environ. Int. 2019, 131, 105043. [Google Scholar] [CrossRef]

- Carpenter, D.; Aich, N.; Brune, M.-N.; Sly, P.D.; Jahan, F.; Knibbs, L.D.; Parvez, S.M.; Islam, Z.; Gorman, J.F.; Rahman, M.; et al. Health consequences of exposure to e-waste: An updated systematic review. Lancet Planet. Health 2021, 5, e905–e920. [Google Scholar]

- Singh, N.; Duan, H.; Ogunseitan, O.A.; Li, J.; Tang, Y. Toxicity trends in E-Waste: A comparative analysis of metals in discarded mobile phones. J. Hazard. Mater. 2019, 380, 120898. [Google Scholar] [CrossRef]

- Braun, J.M. Early-life exposure to EDCs: Role in childhood obesity and neurodevelopment. Nat. Rev. Endocrinol. 2017, 13, 161–173. [Google Scholar] [CrossRef]

- Botla, G.; Barmavatu, P.; Pohorely, M.; Jeremias, M.; Sikarwar, V.S. Optimization of value-added products using response surface methodology from the HDPE waste plastic by thermal cracking. Therm. Sci. Eng. Prog. 2024, 50, 102514. [Google Scholar] [CrossRef]

- Au, W.W.; Adliene, D.; Scheepers, P.T.; Budnik, L.T.; Göen, T.; Duca, R.-C.; Kassomenos, P.; Paschalidou, A.; Giurgiu, D.I.; Goksel, O.; et al. From inequitable to sustainable e-waste processing for reduction of impact on human health and the environment. Environ. Res. 2021, 194, 110728. [Google Scholar]

- Yang, C.; Duan, L.; Wang, J.; Jiang, C.; Zhang, T.; Chen, W. Preferential association of PBDEs and PAHs with mineral particles vs. dissolved organic carbon: Implications for groundwater contamination at e-waste sites. J. Environ. Sci. 2024, 150, 288–296. [Google Scholar] [CrossRef] [PubMed]

- Mašláni, A.; Hlína, M.; Hrabovský, M.; Křenek, P.; Sikarwar, V.S.; Fathi, J.; Raman, S.; Skoblia, S.; Jankovský, O.; Jiříčková, A.; et al. Impact of natural gas composition on steam thermal plasma assisted pyrolysis for hydrogen and solid carbon production. Energy Convers. Manag. 2023, 297, 117748. [Google Scholar] [CrossRef]

- Ohajinwa, C.M.; Van Bodegom, P.M.; Osibanjo, O.; Xie, Q.; Chen, J.; Vijver, M.G.; Peijnenburg, W.J. Health risks of polybrominated diphenyl ethers (PBDEs) and metals at informal electronic waste recycling sites. Int. J. Environ. Res. Public Health 2019, 16, 906. [Google Scholar] [CrossRef]

- Zeng, X.; Huo, X.; Xu, X.; Liu, D.; Wu, W. E-waste lead exposure and children’s health in China. Sci. Total Environ. 2020, 734, 139286. [Google Scholar] [CrossRef]

- Zhang, Y.; Huo, X.; Lu, X.; Zeng, Z.; Faas, M.M.; Xu, X. Exposure to multiple heavy metals associate with aberrant immune homeostasis and inflammatory activation in preschool children. Chemosphere 2020, 257, 127257. [Google Scholar] [CrossRef]

- Cai, H.; Xu, X.; Zhang, Y.; Cong, X.; Lu, X.; Huo, X. Elevated lead levels from e-waste exposure are linked to sensory integration difficulties in preschool children. Neurotoxicology 2019, 71, 150–158. [Google Scholar] [CrossRef]

- Zeng, X.; Xu, X.; Qin, Q.; Ye, K.; Wu, W.; Huo, X. Heavy metal exposure has adverse effects on the growth and development of preschool children. Environ. Geochem. Health 2019, 41, 309–321. [Google Scholar] [CrossRef]

- Ni, W.; Huang, Y.; Wang, X.; Zhang, J.; Wu, K. Associations of neonatal lead, cadmium, chromium and nickel co-exposure with DNA oxidative damage in an electronic waste recycling town. Sci. Total Environ. 2014, 472, 354–362. [Google Scholar] [CrossRef]

- Xu, X.; Liao, W.; Lin, Y.; Dai, Y.; Shi, Z.; Huo, X. Blood concentrations of lead, cadmium, mercury and their association with biomarkers of DNA oxidative damage in preschool children living in an e-waste recycling area. Environ. Geochem. Health 2018, 40, 1481–1494. [Google Scholar] [CrossRef]

- Huo, X.; Wu, Y.; Xu, L.; Zeng, X.; Qin, Q.; Xu, X. Maternal urinary metabolites of PAHs and its association with adverse birth outcomes in an intensive e-waste recycling area. Environ. Pollut. 2019, 245, 453–461. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Huo, X.; Yekeen, T.A.; Zheng, Q.; Zheng, M.; Xu, X. Effects of lead and cadmium exposure from electronic waste on child physical growth. Environ. Sci. Pollut. Res. 2013, 20, 4441–4447. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Ge, J.; Huo, X.; Zhang, Y.; Lau, A.T.; Xu, X. Differential proteomic expression of human placenta and fetal development following e-waste lead and cadmium exposure in utero. Sci. Total Environ. 2016, 550, 1163–1170. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, X.; Chen, A.; Davuljigari, C.B.; Zheng, X.; Kim, S.S.; Dietrich, K.N.; Ho, S.-M.; Reponen, T.; Huo, X. Maternal urinary cadmium levels during pregnancy associated with risk of sex-dependent birth outcomes from an e-waste pollution site in China. Reprod. Toxicol. 2018, 75, 49–55. [Google Scholar] [CrossRef]

- Puangprasert, S.; Prueksasit, T. Health risk assessment of airborne Cd, Cu, Ni and Pb for electronic waste dismantling workers in Buriram Province, Thailand. J. Environ. Manag. 2019, 252, 109601. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Huo, X.; Liu, D.; Zeng, X.; Zhang, Y.; Xu, X. S100β in heavy metal-related child attention-deficit hyperactivity disorder in an informal e-waste recycling area. Neurotoxicology 2014, 45, 185–191. [Google Scholar] [CrossRef]

- Lin, X.; Xu, X.; Zeng, X.; Xu, L.; Zeng, Z.; Huo, X. Decreased vaccine antibody titers following exposure to multiple metals and metalloids in e-waste-exposed preschool children. Environ. Pollut. 2017, 220, 354–363. [Google Scholar] [CrossRef]

- Zeng, X.; Xu, X.; Boezen, H.M.; Huo, X. Children with health impairments by heavy metals in an e-waste recycling area. Chemosphere 2016, 148, 408–415. [Google Scholar] [CrossRef]

- Kaviti, A.K.; Akkala, S.R.; Sikarwar, V.S.; Sai Snehith, P.; Mahesh, M. Camphor-soothed banana stem biowaste in the productivity and sustainability of solar-powered desalination. Appl. Sci. 2023, 13, 1652. [Google Scholar] [CrossRef]

- Zheng, X.; Huo, X.; Zhang, Y.; Wang, Q.; Zhang, Y.; Xu, X. Cardiovascular endothelial inflammation by chronic coexposure to lead (Pb) and polycyclic aromatic hydrocarbons from preschool children in an e-waste recycling area. Environ. Pollut. 2019, 246, 587–596. [Google Scholar] [CrossRef]

- Chen, H.; Ma, S.; Yu, Y.; Liu, R.; Li, G.; Huang, H.; An, T. Seasonal profiles of atmospheric PAHs in an e-waste dismantling area and their associated health risk considering bioaccessible PAHs in the human lung. Sci. Total Environ. 2019, 683, 371–379. [Google Scholar] [CrossRef]

- Liang, W.-B.; Chen, X.-C.; Xu, X.-Y.; Li, L.-Z.; Lin, B.-G.; Hong, Y.-D.; Xiang, M.-D.; Huang, S.; Yu, Y.-J. Associations between PBDEs exposure from house dust and human semen quality at an e-waste areas in South China—A pilot study. Chemosphere 2018, 198, 266–273. [Google Scholar]

- Cai, K.; Song, Q.; Yuan, W.; Ruan, J.; Duan, H.; Li, Y.; Li, J. Human exposure to PBDEs in e-waste areas: A review. Environ. Pollut. 2020, 267, 115634. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Yang, Q.; Qiu, X.; Li, K.; Li, G.; Zhu, P.; Zhu, T. Reactive oxygen species alteration of immune cells in local residents at an electronic waste recycling site in northern China. Environ. Sci. Technol. 2013, 47, 3344–3352. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Zhao, Y.; Li, K.; Li, G.; Wang, J.; Jing, Y.; Ge, J.; Li, R.; Qiu, X.; He, X. Significant accumulation of persistent organic pollutants and dysregulation in multiple DNA damage repair pathways in the electronic-waste-exposed populations. Environ. Res. 2015, 137, 458–466. [Google Scholar]

- Zhao, Y.; Li, K.; Jing, Y.; Yuan, J.; Geng, X.; Liu, Y.; Li, G.; Wang, J.; Zhang, X.; Wang, F.; et al. Long-term persistent organic pollutants exposure induced telomere dysfunction and senescence-associated secretary phenotype. J. Gerontol. Ser. A 2018, 73, 1027–1035. [Google Scholar]

- Shi, J.; Xiang, L.; Luan, H.; Wei, Y.; Ren, H.; Chen, P. The health concern of polychlorinated biphenyls (PCBs) in a notorious e-waste recycling site. Ecotoxicol. Environ. Saf. 2019, 186, 109817. [Google Scholar] [CrossRef]

- Lu, C.; Qiao, Z.; Lin, K.; Hu, S.; Fu, M.; Peng, C.; Zhou, B.; Zhou, S.; Zhang, W.; Ling, S. Distribution characteristics and risks assessment of brominated flame retardants in surface soil from both a legacy and a new e-waste dismantling site. J. Clean. Prod. 2022, 373, 133970. [Google Scholar]

- Zapata-Corella, P.; Ren, Z.H.; Liu, Y.E.; Rigol, A.; Lacorte, S.; Luo, X.J. Presence of novel and legacy flame retardants and other pollutants in an e-waste site in China and associated risks. Environ. Res. 2023, 216, 114768. [Google Scholar] [CrossRef]

- Garg, S.; Kumar, P.; Mishra, V.; Guijt, R.; Singh, P.; Dumée, L.F.; Sharma, R.S. A review on the sources, occurrence and health risks of per-/poly-fluoroalkyl substances (PFAS) arising from the manufacture and disposal of electric and electronic products. J. Water Process Eng. 2020, 38, 101683. [Google Scholar] [CrossRef]

- Hu, H.; Zeng, X.; Zheng, K.; Zeng, Z.; Dai, C.; Huo, X. Risk assessment and partitioning behavior of PFASs in environmental matrices from an e-waste recycling area. Sci. Total Environ. 2023, 905, 167707. [Google Scholar] [CrossRef]

- Brindhadevi, K.; Barceló, D.; Chi, N.T.L.; Rene, E.R. E-waste management, treatment options and the impact of heavy metal extraction from e-waste on human health: Scenario in Vietnam and other countries. Environ. Res. 2023, 217, 114926. [Google Scholar] [CrossRef]

- Kang, D.H.P.; Chen, M.; Ogunseitan, O.A. Potential environmental and human health impacts of rechargeable lithium batteries in electronic waste. Environ. Sci. Technol. 2013, 47, 5495–5503. [Google Scholar] [CrossRef]

- Lin, S.; Ali, M.U.; Zheng, C.; Cai, Z.; Wong, M.H. Toxic chemicals from uncontrolled e-waste recycling: Exposure, body burden, health impact. J. Hazard. Mater. 2022, 426, 127792. [Google Scholar] [CrossRef] [PubMed]

- Beula, D.; Sureshkumar, M. A review on the toxic E-waste killing health and environment—Today’s global scenario. Mater. Today Proc. 2021, 47, 2168–2174. [Google Scholar] [CrossRef]

- Emenuga, V.; Egbenta, I.R.; Obi, N.I.; Okosun, A.; Oloto, M.C.; Ubani, O.; Eneh, O.C.; Eneh, C.A.; Eneonwo, C.I.; Akah, P.A. Mitigating potential public health risks and challenges from hazardous materials contained in electronic waste items in a developing country setting. Environ. Anal. Health Toxicol. 2023, 38, e2023001. [Google Scholar]

- Chakraborty, P.; Selvaraj, S.; Nakamura, M.; Prithiviraj, B.; Cincinelli, A.; Bang, J.J. PCBs and PCDD/Fs in soil from informal e-waste recycling sites and open dumpsites in India: Levels, congener profiles and health risk assessment. Sci. Total Environ. 2018, 621, 930–938. [Google Scholar] [CrossRef]

- Yu, Y.; Chen, X.; Liu, J.; Wang, W.; Li, Y.; Zhao, X.; Liu, Y.; Li, W. Legacies and health risks of heavy metals, polybrominated diphenyl ethers, and polychlorinated dibenzo-dioxins/furans at e-waste recycling sites in South China. Front. Environ. Sci. Eng. 2023, 17, 79. [Google Scholar]

- Orlins, S.; Guan, D. China’s toxic informal e-waste recycling: Local approaches to a global environmental problem. J. Clean. Prod. 2016, 114, 71–80. [Google Scholar] [CrossRef]

- Wu, Q.; Leung, J.Y.S.; Geng, X.; Chen, S.; Huang, X.; Li, H.; Huang, Z.; Zhu, L.; Chen, J.; Lu, Y. Heavy metal contamination of soil and water in the vicinity of an abandoned e-waste recycling site: Implications for dissemination of heavy metals. Sci. Total Environ. 2015, 506, 217–225. [Google Scholar] [CrossRef] [PubMed]

- Singh, M.; Thind, P.S.; John, S. Health risk assessment of the workers exposed to the heavy metals in e-waste recycling sites of Chandigarh and Ludhiana, Punjab, India. Chemosphere 2018, 203, 426–433. [Google Scholar] [CrossRef] [PubMed]

- Dutta, D.; Goel, S.; Kumar, S. Health risk assessment for exposure to heavy metals in soils in and around E-waste dumping site. J. Environ. Chem. Eng. 2022, 10, 107269. [Google Scholar] [CrossRef]

- Ngo, H.T.T.; Watchalayann, P.; Nguyen, D.B.; Doan, H.N.; Liang, L. Environmental health risk assessment of heavy metal exposure among children living in an informal e-waste processing village in Viet Nam. Sci. Total Environ. 2021, 763, 142982. [Google Scholar] [CrossRef]

- Mowla, M.; Rahman, E.; Islam, N.; Aich, N. Assessment of heavy metal contamination and health risk from indoor dust and air of informal E-waste recycling shops in Dhaka, Bangladesh. J. Hazard. Mater. Adv. 2021, 4, 100025. [Google Scholar] [CrossRef]

- Cao, P.; Fujimori, T.; Juhasz, A.; Takaoka, M.; Oshita, K. Bioaccessibility and human health risk assessment of metal (loid) s in soil from an e-waste open burning site in Agbogbloshie, Accra, Ghana. Chemosphere 2020, 240, 124909. [Google Scholar] [CrossRef]

- Wang, Y.; He, J.; Wang, S.; Luo, C.; Yin, H.; Zhang, G. Characterisation and risk assessment of polycyclic aromatic hydrocarbons (PAHs) in soils and plants around e-waste dismantling sites in southern China. Environ. Sci. Pollut. Res. 2017, 24, 22173–22182. [Google Scholar] [CrossRef]

- Chakraborty, P.; Sampath, S.; Mukhopadhyay, M.; Selvaraj, S.; Bharat, G.K.; Nizzetto, L. Baseline investigation on plasticizers, bisphenol A, polycyclic aromatic hydrocarbons and heavy metals in the surface soil of the informal electronic waste recycling workshops and nearby open dumpsites in Indian metropolitan cities. Environ. Pollut. 2019, 248, 1036–1045. [Google Scholar] [CrossRef]

- Hu, J.; Bao, J.; Wei, B.; Liu, C.; Chen, W.; Zeng, F.; Wang, Y.; Jin, J. Uptake and translocation of polybrominated diphenyl ethers in the rhizosphere soil–crop–atmosphere system in e-waste dismantling areas in Taizhou, China. Chemosphere 2021, 280, 130586. [Google Scholar]

- Takahashi, S.; Someya, M.; Tanabe, S.; Suzuki, G.; Viet, P.H.; Takigami, H.; Uchida, N.; Tuyen, L.H.; Matsukami, H.; Tue, N.M. Concentrations of polybrominated diphenyl ethers and alternative flame retardants in surface soils and river sediments from an electronic waste-processing area in northern Vietnam, 2012–2014. Chemosphere 2017, 167, 291–299. [Google Scholar]

- Gupta, N.; Nath, M. Groundwater contamination by E-waste and its remedial measure-a literature review. J. Phys. Conf. Ser. 2020, 1531, 012023. [Google Scholar] [CrossRef]

- Sepúlveda, A.; Schluep, M.; Renaud, F.G.; Streicher, M.; Kuehr, R.; Hagelüken, C.; Gerecke, A.C. A review of the environmental fate and effects of hazardous substances released from electrical and electronic equipments during recycling: Examples from China and India. Environ. Impact Assess. Rev. 2010, 30, 28–41. [Google Scholar] [CrossRef]

- Mokarat, M.; Ruangsakunporn, A.; Chaianunporn, T.; Lomthaisong, K.; Robson, M.G.; Keithmaleesatti, S. Heavy metal contamination and bioaccumulation in Khorat snail-eating turtles (Malayemys khoratensis) from an e-waste recycling activity site in Thailand. Hum. Ecol. Risk Assess. Int. J. 2022, 28, 133–153. [Google Scholar] [CrossRef]

- Arya, S.; Rautela, R.; Chavan, D.; Kumar, S. Evaluation of soil contamination due to crude E-waste recycling activities in the capital city of India. Process Saf. Environ. Prot. 2021, 152, 641–653. [Google Scholar] [CrossRef]

- Moeckel, C.; Breivik, K.; Nøst, T.H.; Sankoh, A.; Jones, K.C.; Sweetman, A. Soil pollution at a major West African E-waste recycling site: Contamination pathways and implications for potential mitigation strategies. Environ. Int. 2020, 137, 105563. [Google Scholar] [CrossRef]

- Sanusi, A.I. Impact of burning e-waste on soil physicochemical properties and soil microorganisms. Br. Microbiol. Res. J. 2015, 8, 434–442. [Google Scholar] [CrossRef]

- Guo, Y.; Huang, C.; Zhang, H.; Dong, Q. Heavy metal contamination from electronic waste recycling at Guiyu, Southeastern China. J. Environ. Qual. 2009, 38, 1617–1626. [Google Scholar] [CrossRef]

- Huang, J.; Nkrumah, P.N.; Anim, D.O.; Mensah, E. E-waste disposal effects on the aquatic environment: Accra, Ghana. Rev. Environ. Contam. Toxicol. 2014, 229, 19–34. [Google Scholar] [PubMed]

- Uwimana, A.; Xia, H.; Nizeyimana, J.C.; Itangishaka, A.C.; Manzi, H.P.; Nambajemariya, F.; Twagirayezu, G.; Huang, K.; Irumva, O. Environmental effects of electrical and electronic waste on water and soil: A review. Pol. J. Environ. Stud 2022, 31, 2507–2525. [Google Scholar]

- Wirgin, I.; Chukwu, L.O.; Oyewo, E.O.; Schanzer, A.; Meltzer, G.Y.; Roy, N.K.; Zelikoff, J.T.; Igbo, J.K.; Blum, J.L. The Chemistry and Health Outcomes of Electronic Waste (E-Waste) Leachate: Exposure to E-Waste Is Toxic to Atlantic Killifish (Fundulus heteroclitus) Embryos. Sustainability 2022, 14, 11304. [Google Scholar]

- Kwarteng, L.; Baiden, E.A.; Fobil, J.; Arko-Mensah, J.; Robins, T.; Batterman, S. Air quality impacts at an E-waste site in Ghana using flexible, moderate-cost and quality-assured measurements. GeoHealth 2020, 4, e2020GH000247. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Sharma, D.; Gaur, D.; Liu, Y. Sustainable waste electrical and electronic equipment management guide in emerging economies context: A structural model approach. J. Clean. Prod. 2022, 336, 130391. [Google Scholar] [CrossRef]

- Heacock, M.; Trottier, B.; Adhikary, S.; Asante, K.A.; Basu, N.; Brune, M.N.; Caravanos, J.; Carpenter, D.; Suk, W.; Huo, X.; et al. Prevention-intervention strategies to reduce exposure to e-waste. Rev. Environ. Health 2018, 33, 219–228. [Google Scholar] [CrossRef]

- Tsydenova, O.; Bengtsson, M. Chemical hazards associated with treatment of waste electrical and electronic equipment. Waste Manag. 2011, 31, 45–58. [Google Scholar] [CrossRef]

- Ghosh, B.; Ghosh, M.K.; Parhi, P.; Mukherjee, P.S.; Mishra, B.K. Waste printed circuit boards recycling: An extensive assessment of current status. J. Clean. Prod. 2015, 94, 5–19. [Google Scholar] [CrossRef]

- Vegliò, F.; Birloaga, I. (Eds.) Waste Electrical and Electronic Equipment Recycling: Aqueous Recovery Methods; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar]

- Wang, Z.; Huang, G.; An, C. Recyclability and recovery of carbon from waste printed circuit boards within a circular economy perspective: A review. J. Environ. Manag. 2025, 375, 124266. [Google Scholar] [CrossRef]

- Hsu, E.; Barmak, K.; West, A.C.; Park, A.H.A. Advancements in the treatment and processing of electronic waste with sustainability: A review of metal extraction and recovery technologies. Green Chem. 2019, 21, 919–936. [Google Scholar] [CrossRef]

- Birloaga, I.; Vegliò, F.; de Michelis, I.; Ferella, F.; Buzatu, M. Study on the Influence of Various Factors in the Hydrometallurgical Processing of Waste Electronic Materials for Gold Recovery. Waste Manag. 2013, 33, 935–941. [Google Scholar] [CrossRef] [PubMed]

- Swami, S.; Suthar, S.; Singh, R.; Thakur, A.K.; Gupta, L.R.; Sikarwar, V.S. Integration of anaerobic digestion with artificial intelligence to optimise biogas plant operation. Environ. Dev. Sustain. 2025, 27, 9773–9803. [Google Scholar] [CrossRef]

- Jaiswal, P.; Verma, S.; Paul, A.R.; Haque, N.; Bruckard, W. Economic Valuation of Metal Recovery from Mobile Phones in India. Minerals 2025, 15, 259. [Google Scholar] [CrossRef]

- Ilankoon, I.M.S.K.; Ghorbani, Y.; Chong, M.N.; Herath, G.; Moyo, T.; Petersen, J. E-waste in the international context–A review of trade flows, regulations, hazards, waste management strategies and technologies for value recovery. Waste Manag. 2018, 82, 258–275. [Google Scholar] [CrossRef] [PubMed]

- Singhal, D.; Tripathy, S.; Jena, S.K. Sustainability through remanufacturing of e-waste: Examination of critical factors in the Indian context. Sustain. Prod. Consum. 2019, 20, 128–139. [Google Scholar] [CrossRef]

- Gulliani, S.; Volpe, M.; Messineo, A.; Volpe, R. Recovery of metals and valuable chemicals from waste electric and electronic materials: A critical review of existing technologies. RSC Sustain. 2023, 1, 1085–1108. [Google Scholar] [CrossRef]

- Manikandan, S.; Inbakandan, D.; Nachiyar, C.V.; Namasivayam, S.K.R. Towards sustainable metal recovery from e-waste: A mini review. Sustain. Chem. Environ. 2023, 2, 100001. [Google Scholar] [CrossRef]

- An, J. Characteristics of metals leached from waste printed circuit boards using acidithiobacillus ferrooxidans. Minerals 2021, 11, 224. [Google Scholar] [CrossRef]

- Ilyas, S.; Ruan, C.; Bhatti, H.N.; Ghauri, M.A.; Anwar, M.A. Column bioleaching of metals from electronic scrap. Hydrometallurgy 2010, 101, 135–140. [Google Scholar] [CrossRef]

- Ilyas, S.; Lee, J.C.; Chi, R.A. Bioleaching of metals from electronic scrap and its potential for commercial exploitation. Hydrometallurgy 2013, 131, 138–143. [Google Scholar] [CrossRef]

- Goyal, N.; Goyal, D. Exploring E-waste Management: Strategies and Implications. In Handbook of Solid Waste Management: Sustainability through Circular Economy; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1–14. [Google Scholar]

- Sikarwar, V.S.; Hrabovský, M.; Van Oost, G.; Pohořelý, M.; Jeremiáš, M. Progress in waste utilization via thermal plasma. Prog. Energy Combust. Sci. 2020, 81, 100873. [Google Scholar] [CrossRef]

- Robinson, B.H. E-waste: An assessment of global production and environmental impacts. Sci. Total Environ. 2009, 408, 183–191. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Reichert, A.; Pohorely, M.; Meers, E.; Ferreira, N.L.; Jeremias, M. Equilibrium modeling of thermal plasma assisted co-valorization of difficult waste streams for syngas production. Sustain. Energy Fuels 2021, 5, 4650–4660. [Google Scholar] [CrossRef]

- Woynarowska, A.; Baron, J.; Kandefer, S.; Żukowski, W. Charakterystyka procesu spalania odpadów elektronicznych w reaktorze z pęcherzowym złożem fluidalnym. Przemysł Chem. 2013, 92. [Google Scholar]

- Cui, J.; Zhang, L. Metallurgical recovery of metals from electronic waste: A review. J. Hazard. Mater. 2008, 158, 228–256. [Google Scholar] [CrossRef]

- Woynarowska, A. Termiczna Utylizacja Odpadów Elektronicznych w Reaktorze Fluidyzacyjnym; Politechnika Krakowska: Kraków, Poland, 2014. [Google Scholar]

- Gurgul, A.; Szczepaniak, W.; Zabłocka-Malicka, M. Incineration and pyrolysis vs. steam gasification of electronic waste. Sci. Total Environ. 2018, 624, 1119–1124. [Google Scholar] [CrossRef] [PubMed]

- Jadhao, P.R.; Panda, R.; Pant, K.K.; Nigam, K.D. Integrated approach for metallic fraction recovery and generation of valuable products from electronic waste. Ind. Eng. Chem. Res. 2023, 62, 19372–19380. [Google Scholar] [CrossRef]

- Mir, S.; Dhawan, N. Investigation of Pyrolysis Followed by Leaching for Metal Recovery from Integrated Circuits. Jom 2023, 75, 3467–3479. [Google Scholar] [CrossRef]

- Huang, Y.F.; Pan, M.W.; Lo, S.L. Hydrometallurgical metal recovery from waste printed circuit boards pretreated by microwave pyrolysis. Resour. Conserv. Recycl. 2020, 163, 105090. [Google Scholar] [CrossRef]

- Bachér, J.; Laatikainen-Luntama, J.; Rintala, L.; Horttanainen, M. The distribution of valuable metals in gasification of metal-containing residues from mechanical recycling of end-of-life vehicles and electronic waste. J. Environ. Manag. 2025, 373, 123526. [Google Scholar] [CrossRef]

- Zhou, Y.; Qiu, K. A new technology for recycling materials from waste printed circuit boards. J. Hazard. Mater. 2010, 175, 823–828. [Google Scholar] [CrossRef]

- Nie, Y.; Jiang, Y.; Wang, Q.; Chen, J.; Wang, S.; Zhang, Q. Gold recovery from printed circuit board waste using coal gasification slag. J. Environ. Chem. Eng. 2023, 11, 109934. [Google Scholar] [CrossRef]

- Srivastava, A.N.; Jeremias, M.; Sikarwar, V.S. Gasification of Sewage Sludge for Hydrogen Production. In Hydrogen Production from Renewable Resources and Wastes; CRC Press: Boca Raton, FL, USA, 2024; pp. 157–176. [Google Scholar]

- Parveg, A.S.; Ordikhani-Seyedlar, R.; Sharma, T.; Shaw, S.K.; Ratner, A. A Recycling Pathway for Rare Earth Metals (REMs) from E-Waste through Co-Gasification with Biomass. Energies 2022, 15, 9141. [Google Scholar] [CrossRef]

- Khaobang, C.; Kathongthung, N.; Phitsuwan, P.; Sitthichirachat, P.; Wibowo, H.; Areeprasert, C. In-situ adsorptive pyrolysis of e-waste using coal and rice husk fly ash as alternative adsorbents for energy and precious metal recovery by solvent extraction. J. Anal. Appl. Pyrolysis 2024, 179, 106465. [Google Scholar] [CrossRef]

- Samal, S.; Blanco, I. An overview of thermal plasma arc systems for treatment of various wastes in recovery of metals. Materials 2022, 15, 683. [Google Scholar] [CrossRef]

- Szałatkiewicz, J. Metals recovery from artificial ore in case of printed circuit boards, using plasmatron plasma reactor. Materials 2016, 9, 683. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, Y. Dechlorination behavior on the recovery of useful resources from WEEE by the steam gasification in the molten carbonates. Procedia Environ. Sci. 2016, 31, 903–910. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Won, S.; Ha, M.G.; Nguyen, D.D.; Kang, H.Y. Bioleaching for environmental remediation of toxic metals and metalloids: A review on soils, sediments, and mine tailings. Chemosphere 2021, 282, 131108. [Google Scholar] [CrossRef]

- Yang, Y.; Hu, B. Bio-based chemicals from biorefining: Lipid and wax conversion and utilization. In Advances in Biorefineries; Elsevier: Amsterdam, The Netherlands, 2014; pp. 693–720. [Google Scholar]

- Changming, D.; Chao, S.; Gong, X.; Ting, W.; Xiange, W. Plasma methods for metals recovery from metal–containing waste. Waste Manag. 2018, 77, 373–387. [Google Scholar] [CrossRef]

- Al Hassan, M.K.; Alfarsi, A.; Nasser, M.S.; Hussein, I.A.; Khan, I. Ionic Liquids and NADES for Removal of Organic Pollutants in Wastewater: A Comprehensive Review. J. Mol. Liq. 2023, 391, 123163. [Google Scholar] [CrossRef]

- Juve, J.M.A.; Christensen, F.M.S.; Wang, Y.; Wei, Z. Electrodialysis for metal removal and recovery: A review. Chem. Eng. J. 2022, 435, 134857. [Google Scholar] [CrossRef]

- Kaviti, A.K.; Teja, M.; Madhukar, O.; Teja, P.B.; Aashish, V.; Gupta, G.S.; Sivaram, A.; Sikarwar, V.S. Productivity augmentation of solar stills by coupled copper tubes and parabolic fins. Energies 2023, 16, 6606. [Google Scholar] [CrossRef]

- Thapa, K.; Vermeulen, W.J.; Deutz, P.; Olayide, O.E. Transboundary movement of waste review: From binary towards a contextual framing. Waste Manag. Res. 2023, 41, 52–67. [Google Scholar] [CrossRef]

- Amos, O.; Abiodun, O.A.; Olalekan, O.; Opeodu, O.T.; Ademola, A. Investigation of Efforts and Problems in Implementing the Basel Convention on the Control of Transboundary Movements of wastes and their Disposal in Nigeria. Asian J. Geogr. Res. 2024, 7, 69–84. [Google Scholar] [CrossRef]

- Huisman, J.; Botezatu, I.; Herreras, L.; Liddane, M.; Hintsa, J.; Luda di Cortemiglia, V.; Leroy, P.; Vermeersch, E.; Mohanty, S.; van den Brink, S.; et al. Countering WEEE Illegal Trade (CWIT) Summary Report, Market Assessment, Legal Analysis, Crime Analysis and Recommendations Roadmap. Lyon 2015, France, 61. Available online: https://weee4future.eitrawmaterials.eu/wp-content/uploads/2020/09/03_CWIT-Final-Report_WEEE-Flow.pdf (accessed on 30 April 2025).

- Schumacher, K.A.; Agbemabiese, L. Towards comprehensive e-waste legislation in the United States: Design considerations based on quantitative and qualitative assessments. Resour. Conserv. Recycl. 2019, 149, 605–621. [Google Scholar] [CrossRef]

- Zhang, S.; Ding, Y.; Liu, B.; Chang, C.C. Supply and demand of some critical metals and present status of their recycling in WEEE. Waste Manag. 2017, 65, 113–127. [Google Scholar] [CrossRef]

- Ilankoon, C.; Choudhari, R.; Chauhan, A.; Kumar, A.; Singh, A.; Tripathi, A. Assessment of air pollution caused by illegal e-waste burning to evaluate the human health risk. Environ. Int. 2019, 125, 191–199. [Google Scholar]

- Anuardo, R.G.; Espuny, M.; Costa, A.C.F.; Espuny, A.L.G.; Kazançoğlu, Y.; Kandsamy, J.; de Oliveira, O.J. Transforming E-waste into opportunities: Driving organizational actions to achieve sustainable development goals. Sustainability 2023, 15, 14150. [Google Scholar] [CrossRef]

- Basel Convention. Controlling Transboundary Movements of Hazardous Wastes and Their Disposal. 2017. Available online: http://www.basel.int/TheConvention/Overview/tabid/1271/Default.aspx (accessed on 5 November 2024).

- Salhofer, S.; Steuer, B.; Ramusch, R.; Beigl, P. WEEE management in Europe and China–A comparison. Waste Manag. 2016, 57, 27–35. [Google Scholar] [CrossRef]

- Khetriwal, D.S.; Widmer, R.; Kuehr, R.; Huisman, J. One WEEE, many species: Lessons from the European experience. Waste Manag. Res. 2011, 29, 954–962. [Google Scholar] [CrossRef]

- Hazardous, Electronic and Other Wastes (Classification) Control and Management Regulations. 2016. Available online: https://faolex.fao.org/docs/pdf/gha206927.pdf (accessed on 29 October 2024).

- European Commission, 2017. Environment Waste. Available online: http://ec.europa.eu/environment/waste/weee/index_en.htm (accessed on 5 November 2024).

- Hotta, Y.; Visvanathan, C.; Kojima, M.; Pariatamby, A. Developing 3R policy indicators for Asia and the Pacific region: Experience from Regional 3R Forum in Asia and the Pacific. J. Mater. Cycles Waste Manag. 2016, 18, 22–37. [Google Scholar] [CrossRef]

- StEP (Solving the E-Waste Problem) Annual Report, 2015/2016. Available online: http://www.stepinitiative.org/files/step2014/Publications/Step_ARs/2015_16/Step_Annual_Report_2015_16_ebook.html (accessed on 12 May 2025).

- Faibil, D.; Asante, R.; Agyemang, M.; Addaney, M.; Baah, C. Extended producer responsibility in developing economies: Assessment of promoting factors through retail electronic firms for sustainable e-waste management. Waste Manag. Res. 2023, 41, 117–142. [Google Scholar] [CrossRef]

- Compagnoni, M. Is Extended Producer Responsibility living up to expectations? A systematic literature review focusing on electronic waste. J. Clean. Prod. 2022, 367, 133101. [Google Scholar] [CrossRef]

- Dias, P.; Bernardes, A.M.; Huda, N. E-waste management and practices in developed and developing countries. In Electronic Waste: Recycling and Reprocessing for a Sustainable Future; John Wiley & Sons: Hoboken, NJ, USA, 2022; pp. 15–32. [Google Scholar]

- Shittu, O.S.; Williams, I.D.; Shaw, P.J. Global E-waste management: Can WEEE make a difference? A review of e-waste trends, legislation, contemporary issues and future challenges. Waste Manag. 2021, 120, 549–563. [Google Scholar] [CrossRef]

- Lehman, J.P. Resource Conservation and Recovery Act of 1976. In Hazardous Waste Management; Routledge: Oxfordshire, UK, 2020; pp. 7–25. [Google Scholar]

- Serpe, A.; Purchase, D.; Bisschop, L.; Chatterjee, D.; De Gioannis, G.; Garelick, H.; Kumar, A.; Peijnenburg, W.J.G.M.; Piro, V.M.I.; Cera, M.; et al. 2002–2022: 20 years of e-waste regulation in the European Union and the worldwide trends in legislation and innovation technologies for a circular economy. RSC Sustain. 2025, 3, 1039–1083. [Google Scholar] [CrossRef]

- Ongondo, F.O.; Williams, I.D.; Cherrett, T.J. How are WEEE doing? A global review of the management of electrical and electronic wastes. Waste Manag. 2011, 31, 714–730. [Google Scholar] [CrossRef] [PubMed]

- Mihai, F.C.; Gnoni, M.G.; Meidiana, C.; Schneider, P.; Ezeah, C.; Elia, V. A global outlook on the implementation of the Basel Convention and the Transboundary Movement of E-waste. In Paradigm Shift in E-Waste Management; CRC Press: Boca Raton, FL, USA, 2022; pp. 49–75. [Google Scholar]

- Ignatuschtschenko, E. E-waste management in China: Bridging the formal and informal sectors. J. Chin. Gov. 2017, 2, 385–410. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, F.; Handwerker, C. Transforming and integrating informal sectors into formal e-waste management system: A case study in Guiyu, China. Clean Technol. Recycl. 2022, 2, 225–246. [Google Scholar] [CrossRef]

- Yu, Z.; Gao, C.; Yang, C.; Zhang, L. Insight into quantities, flows, and recycling technology of E-waste in China for resource sustainable society. J. Clean. Prod. 2023, 393, 136222. [Google Scholar] [CrossRef]

- Directive, E.U. Restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS). Off. J. Eur. Communities 2013, 46, 19–23. [Google Scholar]

- Sharma, H.; Arora, R.; Radulovic, V.; Sinha, S.; Khetriwal, D.S.; Turaga, R.M.R.; Singhal, P.; Bhaskar, K.; Hinchliffe, D.; Hemkhaus, M.; et al. E-waste management in India: Issues and strategies. Vikalpa 2019, 44, 127–162. [Google Scholar]

- Dutta, D.; Goel, S. Understanding the gap between formal and informal e-waste recycling facilities in India. Waste Manag. 2021, 125, 163–171. [Google Scholar] [CrossRef]

- Heinrich, V.; Bansal, H.; Fröhling, M. Electronic waste management in Northern India: A regional case study of Chandigarh. J. Mater. Cycles Waste Manag. 2025, 27, 1944–1961. [Google Scholar] [CrossRef]

- Bagwan, W.A. Electronic waste (E-waste) generation and management scenario of India, and ARIMA forecasting of E-waste processing capacity of Maharashtra state till 2030. Waste Manag. Bull. 2024, 1, 41–51. [Google Scholar] [CrossRef]

- Sengupta, D.; Ilankoon, I.M.S.K.; Kang, K.D.; Chong, M.N. Circular economy and household e-waste management in India. Part II: A case study on informal e-waste collectors (Kabadiwalas) in India. Miner. Eng. 2023, 200, 108154. [Google Scholar] [CrossRef]

- Kumar, A.; Holuszko, M.E.; Janke, T. Characterization of the non-metal fraction of the processed waste printed circuit boards. Waste Manag. 2018, 75, 94–102. [Google Scholar] [CrossRef] [PubMed]

- Das, S. E-Waste Management: A Comparative Study Between the Legal Framework of Bangladesh and United States of America (USA). Dent. Sci. Innov. Res. 2025, 4. [Google Scholar]

- Neves, S.A.; Marques, A.C.; de Sá Lopes, L.B. Is environmental regulation keeping e-waste under control? Evidence from e-waste exports in the European Union. Ecol. Econ. 2024, 216, 108031. [Google Scholar] [CrossRef]

- Datsyuk, P.; Mikhaylov, A.; Pinter, G. Group correlation analysis of socio-economic indicators and the volume of collected E-waste in European countries. Environ. Res. Commun. 2023, 5, 115004. [Google Scholar] [CrossRef]

- Boubellouta, B.; Kusch-Brandt, S. Driving factors of e-waste recycling rate in 30 European countries: New evidence using a panel quantile regression of the EKC hypothesis coupled with the STIRPAT model. Environ. Dev. Sustain. 2023, 25, 7533–7560. [Google Scholar] [CrossRef]

- Kamasa, J. Mind the E-Waste: A Case for Switzerland; CSS Policy Perspectives; Center for Security Studies: Zurich, Switzerland, 2023; Volume 11. [Google Scholar]

- Mourshed, M.; Khatun, S.; Islam, K.; Masuk, N.I.; Masud, M.H. Generation, Composition, Collection, and Treatment of E-Waste. In Management of Electronic Waste: Resource Recovery, Technology and Regulation; Intech Open: London, UK, 2024; pp. 39–72. [Google Scholar]

- Neves, S.A.; Marques, A.C.; Silva, I.P. Promoting the circular economy in the EU: How can the recycling of e-waste be increased? Struct. Change Econ. Dyn. 2024, 70, 192–201. [Google Scholar] [CrossRef]

- Sandwal, S.K.; Jakhar, R.; Styszko, K. E-Waste Challenges in India: Environmental and Human Health Impacts. Appl. Sci. 2025, 15, 4350. [Google Scholar] [CrossRef]

- Kumari, S.; Sharma, P.; Panesar, S.; Chandrawanshi, L.; Yadav, G.; Jugal, K. Exploring the awareness regarding e-waste and its management among electronic repair workers and scrap dealers of South Delhi, India. Indian J. Occup. Environ. Med. 2021, 25, 178–181. [Google Scholar] [CrossRef]

- Wang, B.; Ren, C.; Dong, X.; Zhang, B.; Wang, Z. Determinants shaping willingness towards on-line recycling behaviour: An empirical study of household e-waste recycling in China. Resour. Conserv. Recycl. 2019, 143, 218–225. [Google Scholar] [CrossRef]

- Wang, K.; Qian, J.; Liu, L. Understanding environmental pollutions of informal e-waste clustering in global south via multi-scalar regulatory frameworks: A case study of Guiyu Town, China. Int. J. Environ. Res. Public Health 2020, 17, 2802. [Google Scholar] [CrossRef]

- Zhong, Y.; Tobias, M.; Ma, Z.; Lu, C.; Mu, Z.; Zhang, L.; Geng, Y.; Ren, W.; Xue, B. An overview of e-waste management in China. J. Mater. Cycles Waste Manag. 2015, 17, 1–12. [Google Scholar]

- Moško, J.; Jeremiáš, M.; Skoblia, S.; Beňo, Z.; Sikarwar, V.S.; Hušek, M.; Wang, H.; Pohořelý, M. Residual moisture in the sewage sludge feed significantly affects the pyrolysis process: Simulation of continuous process in a batch reactor. J. Anal. Appl. Pyrolysis 2022, 161, 105387. [Google Scholar] [CrossRef]

- Goyal, S.; Gupta, S. A Comprehensive Review of Current Techniques, Issues, and Technological Advancements in Sustainable E-Waste Management. e-Prime Adv. Electr. Eng. Electron. Energy 2024, 9, 100702. [Google Scholar] [CrossRef]

- Bimir, M.N. Revisiting e-waste management practices in selected African countries. J. Air Waste Manag. Assoc. 2020, 70, 659–669. [Google Scholar] [CrossRef] [PubMed]

- Maphosa, V.; Maphosa, M. E-waste management in Sub-Saharan Africa: A systematic literature review. Cogent Bus. Manag. 2020, 7, 1814503. [Google Scholar] [CrossRef]

- Nnorom, I.C.; Odeyingbo, O.A. Electronic waste management practices in Nigeria. In Handbook of Electronic Waste Management; Butterworth-Heinemann: Oxford, UK, 2020; pp. 323–354. [Google Scholar]

- Adanu, S.K.; Gbedemah, S.F.; Attah, M.K. Challenges of adopting sustainable technologies in e-waste management at Agbogbloshie, Ghana. Heliyon 2020, 6, e04548. [Google Scholar] [CrossRef]

- Masud, M.H.; Akram, W.; Ahmed, A.; Ananno, A.A.; Mourshed, M.; Hasan, M.; Joardder, M.U.H. Towards the effective E-waste management in Bangladesh: A review. Environ. Sci. Pollut. Res. 2019, 26, 1250–1276. [Google Scholar] [CrossRef]

- Vargas, D.B.; Campos, L.M.D.S.; Luna, M.M.M. Brazil’s Formal E-Waste Recycling System: From Disposal to Reverse Manufacturing. Sustainability 2024, 16, 66. [Google Scholar] [CrossRef]

- Thi Thu Nguyen, H.; Hung, R.J.; Lee, C.H.; Thi Thu Nguyen, H. Determinants of residents’ E-waste recycling behavioral intention: A case study from Vietnam. Sustainability 2018, 11, 164. [Google Scholar] [CrossRef]

- Jones, K.C.; Birgul, A.; Harner, T.; Dumanoglu, Y.; Nasir, J.; Saqib, Z.; Amin, F.R.; Syed, J.H.; Akram, S.; Zhang, G.; et al. Informal E-waste recycling in nine cities of Pakistan reveals significant impacts on local air and soil quality and associated health risks. Environ. Pollut. 2024, 355, 124259. [Google Scholar]

- Li, B.; Liu, D.; Zhang, L.; Wu, Y.; Ding, X.; Zeng, X. Challenges of E-Waste Dismantling in China. Toxics 2024, 12, 867. [Google Scholar] [CrossRef] [PubMed]

- Bhaskar, K.; Turaga, R.M.R. India’s e-waste rules and their impact on e-waste management practices: A case study. J. Ind. Ecol. 2018, 22, 930–942. [Google Scholar] [CrossRef]

- WEEE Regulations. The Waste Electrical and Electronic Equipment (WEEE) Regulations. 2013. Available online: https://www.gov.uk/guidance/regulations-waste-electrical-and-electronic-equipment (accessed on 30 April 2025).

- WEEE Amendment. The Waste Electrical and Electronic Equipment (Amendment) Regulations. 2015. Available online: https://www.legislation.gov.uk/uksi/2015/1968/contents (accessed on 30 April 2025).

- Restriction on Hazardous Substances Directive (RoHS) Directive [2011/65/EU] of the European Parliament and of the Council on the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment (Recast). Official Journal of the European Union. L 174/88. 2011. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2011:174:0088:0110:en:PDF (accessed on 30 April 2025).

- THAR. The Home Appliance Recycling (THAR) Law. 2001. Available online: https://www.env.go.jp/recycle/english/law/houjin.html (accessed on 29 October 2024).

- SHAR. The Small Home Appliances Recycling (SHAR) Law. 2013. Available online: https://www.env.go.jp/recycle/english/law/haiki.html (accessed on 29 October 2024).

- Australian Government Department of the Environment, 2011a. Australian Government Department of the Environment, National Television and Computer Recycling Scheme. 2011. Available online: https://www.environment.gov.au/protection/national-waste-policy/publications (accessed on 29 October 2024).

- Australian Government Department of the Environment, 2011b. Australian Government Department of the Environment, Product Stewardship Act 2011b (Cwlth). Available online: https://www.environment.gov.au/protection/national-waste-policy/publications (accessed on 29 October 2024).

- Ordinance on Movements of Waste (OWM). 2005. Available online: http://www.admin.ch/opc/de/classified-compilation/20021080/index.html (accessed on 30 April 2025).

- The Swiss Ordinance on the Return, Taking Back and Disposal of Electrical and Electronic Equipment (ORDEE). SR 814.620. 2022. Available online: http://www.admin.ch/opc/de/classified-compilation/19980114/index.html (accessed on 30 April 2025).

- Resource Sustainability (Composition of Offences) Regulations. 2019. The Ministry of the Environment and Water Resources (MEWR), Government of Singapore. 2019. Available online: https://www.fao.org/faolex/results/details/fr/c/LEX-FAOC211084/ (accessed on 29 October 2024).

- Zhang, Y.; Liu, S.; Xie, H.; Zeng, X.; Li, J. Current status on leaching precious metals from waste printed circuit boards. Procedia Environ. Sci. 2012, 16, 560–568. [Google Scholar] [CrossRef]

- Pant, D.; Joshi, D.; Upreti, M.K.; Kotnala, R.K. Chemical and biological extraction of metals present in E waste: A hybrid technology. Waste Manag. 2012, 32, 979–990. [Google Scholar] [CrossRef]

- Jha, M.K.; Hocheng, H. Hydrometallurgical recovery of valuable metals from waste printed circuit boards. Miner. Eng. 2013, 25, 1111–1119. [Google Scholar]

- MoEFCC. Draft National Resource Efficiency Policy; Ministry of Environment, Forest and Climate Change, Government of India: New Delhi, India, 2019. [Google Scholar]

- Arya, S.; Kumar, S. Bioleaching: Urban mining option to curb the menace of E-waste challenge. Bioengineered 2020, 11, 640–660. [Google Scholar] [CrossRef]

- Kaur, P.; Sharma, S.; Albarakaty, F.M.; Kalia, A.; Hassan, M.M.; Abd-Elsalam, K.A. Biosorption and bioleaching of heavy metals from electronic waste varied with microbial genera. Sustainability 2022, 14, 935. [Google Scholar] [CrossRef]

- Kumar, R.; Sharma, P.; Jain, N. Policy effectiveness of Extended Producer Responsibility in Indian E-waste management: A case from Bangalore. Waste Manag. 2022, 142, 88–96. [Google Scholar]

- Borthakur, A.; Govind, M. How well are we managing E-waste in India: Evidences from the city of Bangalore. Energy, Ecol. Environ. 2017, 2, 225–235. [Google Scholar] [CrossRef]

- Wahab, S.N.; Lim, F.Y.J. China’s national sword policy reaction to Southeast Asia’s waste trade and the transition to a circular economy. J. Technol. Oper. Manag. 2022, 17, 1–10. [Google Scholar] [CrossRef]

- Cheng, Z.; Sun, Z.; Shi, Q.; Li, X.; Liu, N.; Lu, Y.; Sun, H.; Su, G.; Wang, L.; Wang, Y.; et al. Electronic-waste-driven pollution of liquid crystal monomers: Environmental occurrence and human exposure in recycling industrial parks. Environ. Sci. Technol. 2022, 56, 2248–2257. [Google Scholar] [CrossRef]

- Li, J.; Lu, H.; Guo, J.; Xu, Z. Bioleaching of copper from waste printed circuit boards by bacterial consortium enriched from acid mine drainage. J. Hazard. Mater. 2017, 321, 50–58. [Google Scholar]

- Zhou, Y.; Zhang, S.; Li, X. Integrated hydrometallurgical process for recovery of precious metals from e-waste in Jiangsu Province. Waste Manag. 2019, 88, 324–332. [Google Scholar]

- Zhang, S.; Wang, C.; Hu, B. Environmental impact mitigation in e-waste industrial parks: A five-year assessment in Guiyu, China. Environ. Sci. Pollut. Res. 2020, 27, 9873–9882. [Google Scholar]

- Chen, A.; Song, Q.; Li, J. Transformation of informal e-waste recycling in China: Policy effectiveness and social inclusion. J. Clean. Prod. 2022, 346, 131164. [Google Scholar]

- Zhang, S.; Chen, L.; Wang, Z. Environmental and health impacts of electronic waste recycling in Guiyu: A 10-year longitudinal study. Environ. Pollut. 2020, 267, 115548. [Google Scholar]

| Database | Search String | Operators/Techniques Used |

|---|---|---|

| Scopus | (“E-waste” OR “Electronic waste” OR “WEEE”) AND (“management” OR “valorization” OR “recycling”) AND (“policy” OR “regulation”) | Boolean (AND, OR), Truncation (recycl*), Phrase search (“ “) |

| Web of Science | (“e-waste” OR “WEEE”) AND (“impact” OR “environmental burden”) AND (“recovery” OR “valorization”) | Boolean (AND, OR), Phrase search |

| Google Scholar | allintitle: (“E-waste management” AND “valorization” AND “regulatory framework”) | Boolean, Keyword matching |

| S. No. | Contaminant | Component of E-Waste as Source | Health Effects | Reference(s) |

|---|---|---|---|---|

| 1. | Lead (Pb) | Cathode ray tubes (CRTs) of TVs, computer monitors, light lamps, CFLs, circuit boards, and batteries. | Brain damage in children, mutated nervous system, damage to reproductive system, anemia, neurological disorders in adults and children, and kidney damage. | [41,43,44] |

| 2. | Mercury (Hg) | Liquid-crystal display (LCD) screens for TVs and monitors, CRTs, Printed Circuit Boards (PCBs), temperature sensors, computer screens, and CFLs (~1–2 g per unit). | Brain damage, neurological disorders, Methylmercury disease (brain and spinal cord damage), Minamata disease, anemia, chronic neurological diseases (insomnia, cognitive dysfunction, and neuromuscular defects) | [46,67] |

| 3. | Chromium (Cr, Cr (VI)) | Anti-corrosive coating in metal bodies of electronic devices, floppies, CDs, Emerald green glass, pigmentation, and data tapes. | Highly toxic and carcinogenic metal, lung cancer (long exposure), eye damage, muscular contraction, causes Genotoxicity (DNA mutation, mutation of cells, and cancerous tumors), affects reproductive organs and endocrine functions. | [53,54,55] |

| 4. | Nickel (Ni) | Power storage devices (batteries), anti-corrosive plating, electron gun in CRTs, electrical connectors, circuit breakers, Ni alloys (Nickel 270, NILO alloy, and NILOMAG alloy 77) in transistor and anode plates and shanks. | Skin diseases (Ni allergy or dermatitis), rashes/itching upon direct contact; Ni fumes cause lung fibrosis and respiratory cancers (long exposure); cardiovascular diseases, high blood pressure. | [51,53] |

| 5. | Lithium (Li) | Lithium-ion batteries (phones, laptops, tablets, electric vehicles, etc.), Heart pacemakers, and electronic toys. | Inhalation via air is toxic, causing nausea, digestive system damage, fatigue, chemical burns, eye irritation, and corneal damage. | [67,68,69] |

| 6. | Cadmium (Cd) | Batteries (Cd-Ni), rechargeable storage, stabilizers, pigment agents, solar cells, wireless power banks, and laptops. | Kidney damage, skeletal and respiratory system defects, fever, muscular pain, lung diseases (lung emphysema and cancer), and reproductive organ damage. | [44,45,46] |

| 7. | Barium (Ba) | Used as Barium titanate (BaTiO3) in capacitors, and in transducers, optical devices, CRTs, and CFLs. | Paralysis upon long-term exposure affects heart rate, respiratory illness, cardio-muscular diseases, digestive system damage, and cardiac arrhythmias. | [34,70] |

| 8. | Zinc (Zn) | Light-Emitting Diodes (LEDs), Batteries, solder joints, sensors, piezoelectric devices, conductive films, and varistors. | Diarrhea, copper deficiency, damage to the pancreas, respiratory illness, anemia, and neurological disorders. | [54,67,70] |

| 9. | Beryllium (Be) | ICT equipment—cellular phones, computers, Power storage devices, X-ray machines, ceramic parts of electronic equipment. | Lung damage/cancer, Skin disease—Beryllium sensitization, chronic beryllium disease (CBD)—chest pain, cough, breathing loss, fatigue, weight loss, fever. | [71] |

| 10. | Polycyclic aromatic hydrocarbons (PAHs) | Organic semiconductors, organic fuel cells, bio-photonics, bio-imaging devices, UV spectroscopy. | Highly toxic, immunotoxicogenic, carcinogenic, and teratogenic, causing kidney and liver damage, jaundice. | [31,44,56] |

| 11. | Polychlorinated dibenzo-p-dioxins (PCDDs) | Smelting and soldering of electronic components having synthetic polymer bodies. | Skin diseases—Chloracne; immune system damage, reproductive diseases, endocrine disruption, cancerous, developmental abnormalities, gastrointestinal organ damage. | [72,73] |

| 12. | New flame retardants (NFRs) | Plastic covers in electronic devices, PCBs, Wire insulation, Electric connectors, and components | Neurological damage in children, cancerous, endocrine damage, neurotoxicity, and reproductive organ damage. | [63,64] |

| 13. | Per- and Polyfluoroalkyl Substances (PFAS) | Electrical components, semiconductors, thermal insulation applications, and water-resistant coatings in electronic devices. | Highly cancerous compounds—testicular and kidney cancers, Liver damage, immune system damage, and low birth weight. | [18,65,66] |

| 14. | Polybrominated Diphenyl Ethers (PBDEs) | Used in flame-retardant wires and plastic coatings. | Thyroid, ovarian dysfunction, cancerous, affects glucose metabolism, affects neurodevelopment, and endocrine rupture. | [40,57,58] |

| S. No. | Contaminant | Country | E-Waste Site(s) | Targeted Environmental System (Soil/Air/Water) | Contaminant Concentrations and/or Remarks | Reference(s) |

|---|---|---|---|---|---|---|

| 1. | Heavy metals (Cu, Pb, Cr, Mn, Ni, Zn) | China | Six sites in Longtang, China (burning, dumping, acid-leaching, paddy field, farm field, reference sites) | Soil and water | In Burning and acid-leaching sites: Cd (>0.39 mg kg−1) & Cu (>1981 mg kg−1), exceeded permissible limits. Cd: 0.62 mg/kg; Cu: 329 mg/kg (Paddy field). | [75] |

| 2. | As, Cu, Co, Cd, Cr, Ni, Fe, Zn, Pb, and Ba | India | E-waste dismantling sites at Chandigarh and Ludhiana, Punjab, India | Soil (sand, dust, dermal samples) | Soil concentrations: As: 39.98 mg/kg; Cr: 287.19 mg/kg; Cu: 14,543.4 mg/kg; Pb: 1615.8 mg/kg. Hazard index for soil: As = 1.69, Cr = 1.38, Cu = 4.5 and Pb = 5.82 and dust samples: Pb = 2.97. High concentrations of Cr, Pb, and Zn in dermal samples. | [76] |

| 3. | Pb, Cr, Mn, Fe, Co, Ni, Cu, and Cd | India | E-waste site at Sangrampur, West Bengal | Soil | Pb: 125.86–577.64 ppm; Cr: 50.47–219.41 ppm; Mn: 1083.89–4674.92 ppm; Fe: 1238.33–12,987.56 ppm; Co: 33.43–49.04 ppm; Ni: 84.52–157.35 ppm; Cu: 505.58–1156.18 ppm; Cd: 17.37–178.97 ppm The non-carcinogenic risk for a child was more than for an adult. Carcinogenic risks: 6.1 × 10−7 (child); 1.57 × 10−7 (adult) | [77] |

| 4. | Pb, Cd, Cr, Ni, As | Viet Nam | E-waste processing sites at Bui Village and Nhuan Trach Village, Northern Viet Nam | Soil, rice, and drinking water samples | Bui Village (highest concentration only): Soil: Pb = 460.43 mg/kg; cooked rice: Ni = 9.57 mg/kg; water: Ni = 2.55 μg/L Nhuan Trach Village: Soil: Cr = 35.75 mg/kg; Cooked rice: Ni = 2.21 mg/kg; Water: Ni = 4.13 μg/L | [78] |

| 5. | Pb, Cu, Ni, Cr, and Mn | Bangladesh | Nimtoli and Elephant Road areas, Dhaka, Bangladesh | Dust and air samples | Health quotient (HQ) and hazard index (HI) for heavy metals: Severe range The geo-accumulation index (Igeo) for the analyzed heavy metals was moderate to severe range. | [79] |

| 6. | Cr, Zn, Cd, Pb, Ni, As, Ba, Cu, Ge, Pb, Se, and Zn and Cu | Nigeria | Ibadan, Lagos, and Aba (major E-waste recycling cities in Nigeria) | Soil and dust samples | All analyzed heavy metals were found to exceed the limits of Nigerian standards. Cu: 9420 mg/kg; Zn: 4533 mg/kg; Pb: 3810 mg/kg | [41] |

| 7. | Cu, As, Cd, Sb, and Pb | Ghana | Agbogbloshie site, Accra, Ghana | Soil samples | analyzed heavy metals were bio-accessible in the gastric and intestinal systems, posing a human health risk. Percentage of these metal(loid)s: - Cu: 1.3–60, As: 1.3–40, Cd: 4.2–67, Sb: 0.7–85, Pb: 4.1–57 | [80] |

| 8. | Heavy metals (Cu, Cr, Zn, As, Cd, Sb, Pb, Hg, V, Co, Au); PBDE, PAH | Ghana | Agbogbloshie sites (dismantling, reference, ICT dismantling, oil collection workshop, printer dismantling, CRT dismantling), Accra, Ghana | Soil and groundwater samples | Based on contamination factors and potential ecological risk coefficients, heavy metals were found in the ‘very high’ range, in both soil and groundwater. Recycling of CRT and ICT devices has resulted in an 85% reduction in heavy metals. Cu, Pd, Cd, Sb, and Au are considerably high in topsoil. | [16] |

| 9. | PAHs | China | E-waste recycling site, Longtang, South China | Soil and Plant (shoots, roots) samples | PAH concentrations (soil): 133 to 626 ng/g PAH concentrations (plants): 96 to 388 ng/g (shoots) and 143 to 605 ng/g (roots) Daily intake of PHA through vegetables: 99 and 22 ng/kg/day | [81] |

| 10. | PAHs, Heavy metals | India | Four Indian metropolitan cities: Delhi, Kolkata, Mumbai, Chennai | Dumpsite soil samples, E-waste sites | PAHs and copper (Cu) were dominant in E-waste sites. e.g., PAH concentration: (1259 ng/g-New Delhi, E-waste site) PAH concentration: (1029 ng/g-New Delhi, dumpsites) | [82] |

| 11. | PBDEs | China | Taizhou City, Zhejiang Province, China | Air, crop, and soil samples | PBDEs concentration: 91.9 μg/kg (dry weight)—soil samples; 27.8–25.1 pg/m3 (air) and 664–1380 pg/g (crop samples) | [83] |

| 12. | PBDEs | Vietnam | E-waste-processing site, Bui Dau, Hung Yen Province, northern Vietnam | Soil samples, river sediments | PBDEs concentration (soil): 37–9200 ng g−1 PBDEs concentration (sediments): 23–6800 ng g−1 | [84] |

| Material | Extraction Method | Efficiency | Environmental Impact |

|---|---|---|---|

| Gold, Palladium, Silver | Hydrometallurgy (aqua regia, cyanide leaching) | High (~95%) | Moderate; needs wastewater management |

| Copper, Aluminum | Pyrometallurgy (smelting) | High (~90%) | High emissions; energy-intensive |

| Plastic | Mechanical separation (shredding, density separation) | Medium (~60–70%) | Low environmental impact if sorted properly |

| Rare Earths | Ion exchange, bioleaching | Emerging | Environmentally safer, but lower yields currently |