1. Introduction

The growing emphasis on sustainability and energy efficiency has transformed industrial manufacturing operations. As global energy prices continue to rise and environmental regulations become more stringent, industries are under increasing pressure to optimize their energy consumption and maintain production efficiency. Historically, energy efficiency in the manufacturing sector was largely viewed as an additional expense or afterthought, while throughput, quality, and cost minimization were of greater concern. But the trend has changed over the past few years, with energy-efficient production scheduling becoming a part of industrial competitiveness and sustainability.

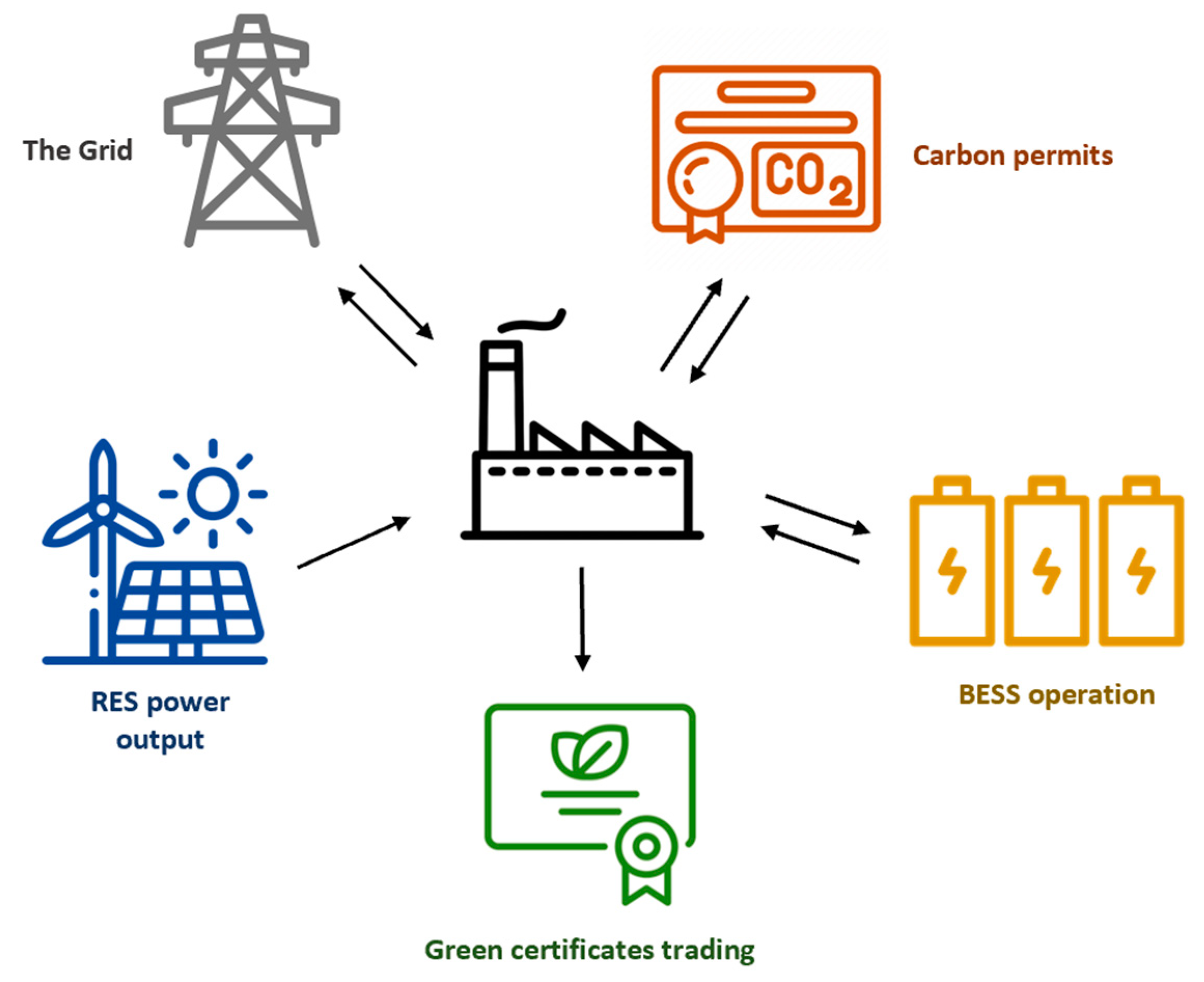

Manufacturing industries are increasingly investing in renewable energy sources (RESs) and battery energy storage systems (BESSs) to save on costs, lower carbon emissions, and meet environmental regulations. RESs, like solar, wind, and bioenergy, are clean sources of energy but can cause energy supply uncertainty due to their intermittent nature. This is mitigated by the BESS, which stores surplus energy during high generation periods and releases it during periods of high demand or when RES production tapers off. This integration offers clear advantages in production planning. Industries can reduce energy costs by planning production at times when there is high RES output. The BESS renders the supply of energy stable, preventing shutdowns and ensuring optimal energy utilization. These systems allow for more dynamic and cost-effective scheduling and enable manufacturers to be less reliant on grid power, making operations both more efficient and sustainable.

Time-of-use (TOU) pricing and demand-response programs are important tools in energy market mechanisms that can have a significant impact on the production scheduling of manufacturing industries. TOU pricing adjusts electricity prices based on the time of day, in a manner that encourages industries to reschedule energy-intensive operations to off-peak hours, thereby reducing costs. To accomplish this, dynamic scheduling systems are required to adjust production plans in real time, optimizing energy usage while keeping the desired output. Demand-response programs provide monetary incentives for manufacturers to curtail or shift their energy usage during peak demand time periods. Participating in these programs allows industries to save money on energy and assist in the stabilization of the power grid. Coupling TOU pricing and demand response with production scheduling allows manufacturers to render production more cost-effective without compromising production efficiency.

Carbon credits enable industries to offset their emissions by buying credits from CO2 reduction or capture projects to comply with regulation or voluntary sustainability objectives. Scheduling for higher energy efficiency and using low-carbon energy sources can decrease the need for carbon credits, whereas inefficient scheduling can increase their demand. Cost savings can be achieved through better production scheduling by lowering the amount of credit required and enhancing the company’s environmental image.

Industries can also utilize green certificates (also known as renewable energy certificates, RECs) [

1]. These create economic incentives for industries to utilize renewable energy. The manufacturers can improve their sustainability profile and reap cost savings or regulatory benefits by including these certificates in their production planning process. This not only decreases the consumption of fossil fuels but also enhances the company’s market position by aligning with environmental goals, gaining favor with eco-conscious customers, and opening up possible new sources of revenue from the sale of excess certificates.

Lastly, efficient and optimized production scheduling can critically decrease energy costs by minimizing machine idle times and preventing overproduction, ensuring that energy is used only when necessary [

2]. It allows for the better coordination of production processes, leading to smoother operations and less energy waste. By balancing workloads, it optimizes equipment usage, thereby reducing the need for energy-intensive setups and reducing peak energy demands. This approach ultimately helps in lowering the overall energy consumption and associated costs in manufacturing operations.

Recent advancements in optimization techniques have greatly enhanced energy-aware production scheduling. Mixed-integer programming (MIP), heuristic algorithms, and hybrid optimization approaches enable producers to trade-off production efficiency and energy conservation. MIP offers exact modeling for scheduling constraints and energy goals and thus is most suitable for well-structured production processes. Yet, since optimal production scheduling is an NP-hard problem, heuristic and metaheuristic methods—such as genetic algorithms, particle swarm optimization, and simulated annealing—were proposed, offering near-optimal solutions in reduced computational times. Hybrid approaches, which blend mathematical programming and heuristics/metaheuristics, try to reap the benefits associated with each optimization approach.

Artificial intelligence (AI), particularly machine learning (ML) and deep learning (DL), has also transformed energy-aware scheduling. ML algorithms learn from extensive production and energy consumption data to predict optimal scheduling policies. These models improve flexibility, allowing production systems to respond dynamically to fluctuations in energy demand and availability. Deep learning, via neural networks such as convolutional (CNNs) and recurrent networks (RNNs), improves scheduling through the identification of complex patterns in energy consumption. Long short-term memory (LSTM) networks, in particular, improve forecast accuracy, allowing proactive scheduling adaptation. Reinforcement learning (RL) also maximizes scheduling policies for energy conservation while maintaining productivity. Through the integration of AI-based methods and traditional optimization methods, manufacturing industries are able to achieve more intelligent and efficient production planning. Data-driven methodologies enhance predictive capability and decision automation and support sustainable industrial operations for the provision of energy-efficient and high-performance manufacturing systems.

Energy-aware production scheduling is no longer a choice but a requirement for industries to flourish in a rapidly changing energy environment. The confluence of renewable energy penetration, electricity market dynamics, and carbon mitigation policies demands a holistic view of scheduling that balances manufacturing productivity and energy sustainability. This paper elaborates on current developments in energy-aware production scheduling, discussing approaches, challenges, and opportunities that define the frontier of energy-efficient manufacturing.

Figure 1 presents a conceptual overview of the key components and interactions involved in energy-aware production scheduling. The figure emphasizes the interplay between industrial production processes and essential external elements such as the RES, BESS, electricity grid, carbon emission permits, and green certificate trading. Understanding and effectively managing these interactions are critical for optimizing energy efficiency, cost reduction, and regulatory compliance in industrial settings.

The rest of this paper is structured as follows.

Section 2 gives the general literature review of recent research on energy-aware production scheduling, emphasizing methodological developments and application contexts.

Section 3 uncovers the current research gaps, while

Section 4 proposes a path that academia and industry should follow for the energy-aware production schedule of the future. Finally,

Section 5 recapitulates the key findings, emphasizes their implications, and suggests avenues for future research.

3. Challenges and Research Gaps

While the body of literature on energy-aware production scheduling has evolved at a rapid rate over the past few years, several critical challenges continue to hamper its practical applicability and implementation in real-world industrial settings. Such challenges are not merely technical in nature but are also conceptual and systemic and emerge from limitations in modeling paradigms, technology integration, market congruence, and cross-disciplinary collaboration. A more holistic and realistic strategy is necessary to move forward from theoretical optimization models to workable tools facilitating industrial decarbonization at scale.

3.1. Modeling Limitations

One of the key features of the majority of the existing work is that it tends to be based on deterministic models, with the supposition of the complete knowledge of future system states. Electricity prices, renewable power output, and electricity demand are typically assumed to be known and constant over the optimization horizon. In practice, these assumptions do not hold frequently. Power generation from renewables, such as solar power and wind, is weather-dependent and stochastic in nature. Market prices can fluctuate significantly, especially in real-time, and operational breakdowns such as machine failures or supply chain disruptions introduce another source of uncertainty into the production system. These realities call for the development of scheduling models that explicitly incorporate uncertainty, using stochastic programming, robust optimization, or hybrid approaches that blend optimization with real-time learning and forecasting. For example, robust optimization methods can provide solutions that hedge against worst-case scenarios, while probabilistic approaches can optimize expected performance under known distributions. Yet, such methods are still relatively underused in energy-aware scheduling. Even among the studies that address uncertainty, most are limited to narrow domains, simplistic assumptions, or small-scale case studies.

The requirement for long-term planning introduces an additional layer of complication. While TOU pricing is usually possible for the upcoming day, scheduling decisions tend to span longer horizons—e.g., weekly or monthly planning intervals—particularly when they are related to maintenance cycles, production campaigns, or inventory buildups. In these situations, dependence on accurate forecasts becomes paramount. Among the promising directions is the application of rolling-horizon methods, in which a longer-term plan is repeatedly revised as more precise information becomes available. Such a replanning strategy more accurately reflects industrial decision-making procedures in a dynamic way and enables an adaptive response to evolving market and operational conditions. However, despite their conceptual appeal, rolling-horizon models with long planning horizons that tackle forecast uncertainty remain largely unformalized in the current literature. We consider this an essential topic for future research, in which both new model formulations and case studies would be beneficial to bridge the gap between theoretical development and industrial practice.

3.2. Scalability and Industrial Applications

Another research gap is the disparity between the simplicity of most academic models and the complexity of actual industrial systems. Most research concentrates on idealized settings, dealing with single-machine systems, identical parallel machines, or simple job-shop setups. Such simplifications are helpful in methodology development but do not reflect the richness of real production settings, with multi-stage processes, intermediate inventories, departmental synchronization, and heterogeneous equipment with special operating constraints. In practice, manufacturers must contend with perishable products, product quality deterioration, machine state variation, and demanding delivery times. Scheduling under these conditions often entails process-dependent constraints such as cleaning, batching, tool switching, and interoperation dependencies. Along with these built-in complexities, real industrial scheduling must also be able to handle multi-dimensional constraints such as logistics coordination, product quality inspection, multi-site resource balancing, and preventive or predictive maintenance. But there are a few studies published that tackle these characteristics in detailed case studies, and most benchmarks continue to depend on highly simplified and small-scale examples. Therefore, the transferability and robustness of current scheduling techniques to real industrial environments are still limited. Additionally, the majority of the existing scheduling methods are based on discrete-time formulations, specifically in MILP-based formulations. The choice of this modeling approach is effective in representing time-dependent variables, e.g., electricity price variability along a specified horizon. However, discrete-time models are susceptible to computational scalability problems and a compromise on temporal accuracy, especially if high time granularity is required. These restrictions can have a major impact on the feasibility of employing such models for large-scale, real-world industrial settings. To facilitate accurate and large-scale scheduling, further effort must be placed on the development of continuous-time modeling frameworks, e.g., those relying on flexible time grids or precedence-based representations. Such frameworks provide improved accuracy in process dynamics and are better suited for complicated, dynamic, and data-rich industrial settings.

There have been few attempts to address these challenges via large-scale industrial case studies, and even fewer have directly collaborated with manufacturing firms to test and refine their models. Addressing this gap requires not only algorithmic advances but also closer collaboration between industry and academia, capable of co-developing solutions that are both technically sound and operationally viable.

3.3. Integration of Multiple Decision Pillars Within a Unified Framework

The majority of research contributions are limited in their scope, addressing a single or only a few decision pillars in isolation. Models, for example, might include on-site renewable generation but neglect energy storage or account for TOU pricing but not real-time pricing. Even fewer account for carbon taxation, emissions trading, or regulatory caps in conjunction with operational scheduling. Furthermore, there is little integration with other enterprise operations. Production scheduling is tightly connected with logistics, inventory management, vehicle routing, and supply chain coordination. For instance, electric delivery trucks can also serve as mobile energy storage assets, yet their scheduling requirements may interfere with production and charging demands. Maintenance planning and labor availability are also constraints and opportunities that are typically not included in the current literature. Future work must prioritize the creation of integrated frameworks, consolidating these various pieces within a single optimization model. Such frameworks must include production decision-making, energy purchasing, market involvement, regulatory compliance, and supply chain concerns so that they are fully engaged and are accounted for simultaneously. Only the systems perspective enables trade-offs and synergies that single-domain models overlook to be captured.

3.4. Forecasting, Real-Time Data Integration, and System Connectivity

Forecasting and data integration are the cornerstone of any adaptive or real-time scheduling system yet are underdeveloped in the majority of the literature. The accurate forecasting of electricity prices, renewable generation [

51,

52], and production demand is crucial to make properly informed scheduling decisions, particularly in 15 min settlement and dynamic pricing markets. ML and DL provide effective ways of building predictive models from historical data. Specifically, the time-series prediction of solar irradiance, wind speeds, and electricity prices can be enhanced using RNNs, attention-based models, or hybrid statistical-ML models. Though a possibility, there are limited scheduling models that explicitly include forecasting modules within their optimization algorithms.

More critically, the infrastructure for linking real-time data streams with scheduling decisions is typically not present. Modern industrial facilities are becoming ever more equipped with sensors, IoT devices, and MESs that generate vast volumes of operational data. But such data is rarely leveraged for adaptive scheduling, primarily because there is typically no integration between IT systems, energy management systems, and optimization solutions. One of the directions for promising research is creating cyber-physical manufacturing systems (CPPSs) that integrate real-time monitoring, predictive analytics, and adaptive control. Such systems have the potential to modify schedules online at times based on streaming data, enabling reactive behavior and system resilience. The achievement of such a vision demands online optimization, incorporation with machine learning, as well as dependable communication protocols to industrial control systems.

3.5. Regulatory-Policy Integration and Multi-Objective Trade-Offs

Industrial scheduling is inherently a multi-objective problem. Not only do producers aim to reduce energy expenses but they also need to trade-off other objectives like makespan, on-time delivery, equipment use, emissions reduction, and labor contentment. Trade-offs among these objectives are generally unavoidable. For example, shifting production to off-peak times can reduce energy expenses but create longer lead times or greater labor needs. Most existing models focus on single-objective formulations to minimize electricity costs or emissions, thus neglecting to model such intricate interactions. There is an increasing demand for multi-objective optimization models that provide Pareto-efficient solutions and facilitate informed trade-off analysis. The models must also incorporate indirect returns—reputational gains, risk mitigation, and long-term sustainability—in addition to direct financial returns. In addition, regulatory contexts and policy changes must be dynamically modeled so that decision-makers can examine “what-if” scenarios and respond to changing policy contexts. Finally, the formulation of such overall models will necessitate interdisciplinary cooperation, spanning operations research, energy systems, economics, and industrial engineering. In the absence of such integration, the promise of energy-aware production scheduling in enabling real-world decarbonization will remain mostly theoretical.

3.6. Strategic Prioritization for Industrial Implementation

Although all five challenges introduced here are significant to advancing the frontiers of energy-aware production scheduling, their relative importance in terms of practical significance differs. The first three—modeling limitations (

Section 3.1), scalability and industrial applications (

Section 3.2), and the lack of unifying frameworks (

Section 3.3)—currently form the core of research agendas. These are most vital to enabling actual implementation, particularly by managing uncertainty, allowing the consideration of large-scale problems, and coupling the interdependent levels of decision-making across energy, manufacturing, and policy domains. Real-time connectivity and forecasting (

Section 3.4) is next in priority, as it allows the needed digital basis and adaptability through cyber-physical production systems. Regulatory-policy integration and multi-objective trade-offs (

Section 3.5) are, while extremely important, best dealt with after having robust and scalable optimization models. However, development in all these areas must occur to achieve the full potential of intelligent and sustainable industrial scheduling systems.

4. Designing the Future of Energy-Aware Production Scheduling

To unlock the full potential of energy-aware production scheduling in the interest of industrial decarbonization, a paradigm shift is needed—one that goes beyond fragmented, static, and oversimplified models towards an integrated, adaptive, and sustainability-driven approach. Future production scheduling needs to account for the growing complexity of industrial systems, energy market uncertainty, and escalating regulatory and societal pressure for reducing the environmental footprint. Proactive collaboration among academia, industry, and government—aligned with the Triple Helix model—is essential to accelerate this transition. Universities can drive methodological advances, industries can operationalize innovative solutions, and governments can foster enabling policy frameworks. Embedding this synergy into scheduling research and deployment will be key to impactful, scalable decarbonization. Our study’s unique contribution lies in systematically linking this collaboration to operational-level production scheduling practices that explicitly incorporate renewable energy integration and carbon mitigation policies. We articulate a novel interdisciplinary approach that connects policy frameworks, technological solutions (RES and BES), and industrial scheduling models, thereby bridging the gap between high-level collaboration and practical implementation in production systems. We provide the framework for this vision in this section, grounded in the constraints we delineated above and motivated by encouraging developments in forecasting, optimization, and digital technologies.

4.1. From Fragmented Models to Unified, System-Level Optimization

The upcoming generation of scheduling systems has to combine all the major pillars of energy-efficient production: on-site renewable energy sources (RESs), battery energy storage systems (BESSs), time-of-use (TOU) and real-time electricity pricing (RTP), demand side management (DMS), and sustainability policies such as carbon trading and green certificates. All these features no longer have to be addressed separately. Instead, they need to be modeled as the interdependent components of a combined system in which scheduling decisions simultaneously affect, and are affected by, energy resource availability, market prices, and policy constraints. Towards this, scheduling models must move beyond standalone implementations and towards full integration, where energy market participation, on-site energy assets, and policy levers have common representation within an integrated optimization framework. Several contributions already show how dynamic electricity pricing, in the form of RTP and TOU tariffs, can be integrated into production scheduling to offer decision support for grid consumption, energy storage management, or surplus power dispatch. Likewise, carbon pricing schemes, emissions trading, and sustainability constraints have been incorporated in some state-of-the-art models to influence energy procurement and job scheduling. However, the simultaneous and synergistic integration of all of these pillars—coupling dynamic pricing schemes, local renewable generation, storage facilities, demand-response involvement, and regulatory constraints—into one unifying model remains scarce. It is this system-level viewpoint that future work must converge on to transition from component-level optimization to holistic, energy-aware scheduling solutions.

Beyond energy and emissions, scheduling must also be linked to the broader enterprise-wide decisions that overlap logistics, vehicle routing, inventory management, and maintenance planning. Industrial systems do not exist in isolation; what is performed on the production floor has an immediate effect on downstream distribution schedules, storage requirements, and departmental resource allocation. A true system-level perspective must recognize these interdependencies and provide a way of optimizing global performance—not just localized energy consumption or cost. An example is the integration of energy-aware production scheduling and vehicle routing issues (VRPs), particularly when firms use electric vehicle (EV) fleets. Here, charging vehicles is part of the energy strategy. EV charging time, place, and quantity need to be synchronized with production schedules and the energy market (e.g., TOU and RTP signals) to prevent peak load, reduce cost, and have vehicles ready for timely dispatch. This is a multivariate optimization problem in which production tasks, energy purchasing, and transport planning need to be optimized together in concert. These scenarios pose potentially conflicting objectives—for instance, charging vehicles during the periods of lowest electricity cost may conflict with production schedules or strain local energy capacity. Such trade-offs are dealt with by model architectures capable of capturing cross-functional constraints, dynamic decision horizons, and interactions across a number of resources. In addition, it creates new opportunities for the application of EVs not just as transport assets but also as on-the-move storage devices, with the potential to engage in demand-response programs or grid services.

Apart from intra-factory coordination, the upcoming scheduling systems must also consider the synergistic advantages of cross-factory cooperation, especially in industrial symbiosis. In these systems, groups of factories or manufacturing plants—typically in the same industrial complex or area—share energy facilities, storage facilities, or even elastic loads so that as a group, they can improve energy efficiency as well as lower emissions. For example, excess energy produced on-site by one plant could be directed to a nearby facility that is experiencing a deficit, or runs could be staggered to reduce peak combined load profiles over a local grid.

For this degree of coordination to take place, scheduling systems in the future need to develop from standalone optimization techniques to enterprise-scale, interoperable decision systems that can handle the growing complexity of decarbonized industrial clusters. Beyond this, an important future direction lies in extending such systems to support multi-stakeholder coordination, not only between industrial sites but also involving external actors, such as utilities, regulators, and energy suppliers. Formalizing these interactions through game-theoretic or contract-theoretic models could enable collaborative decision-making within industrial symbiosis ecosystems, aligning economic incentives with decarbonization goals.

4.2. Modeling Perspectives

Industrial scheduling involves the consideration of multiple competing objectives, e.g., energy cost minimization, makespan minimization, and throughput maximization. Effective sustainable scheduling systems must handle such trade-offs explicitly and efficiently. Future research should focus on developing multi-objective optimization models that produce Pareto-optimal schedules, thereby offering decision-makers different alternatives adhering to different priorities. These models are particularly adept at balancing economic benefits, e.g., real-time pricing profits or carbon credits) against quantity and quality targets. Secondly, sustainability needs to be a design requirement and not simply an optimization objective, pushing systems towards long-term decarbonization and resilience as opposed to short-term cost-effectiveness.

However, multi-objective models pose serious computational challenges due to their increased complexity. Surpassing these methodological limitations requires new solutions with the potential to effectively manage computational resources without sacrificing solution quality. Hybrid methods should be the priority going forward, given their potential to consolidate the complementary strengths of alternative approaches. The integration of ML techniques and MILP, in particular, appears very promising. MILP formulations ensure solution optimality by rigorously accounting for constraints and objectives, whereas ML has the potential to significantly enhance computational tractability by effectively pruning the search space. By leveraging data-driven knowledge, ML can propel MILP to highly prospective regions in the solution space with significantly less computational effort.

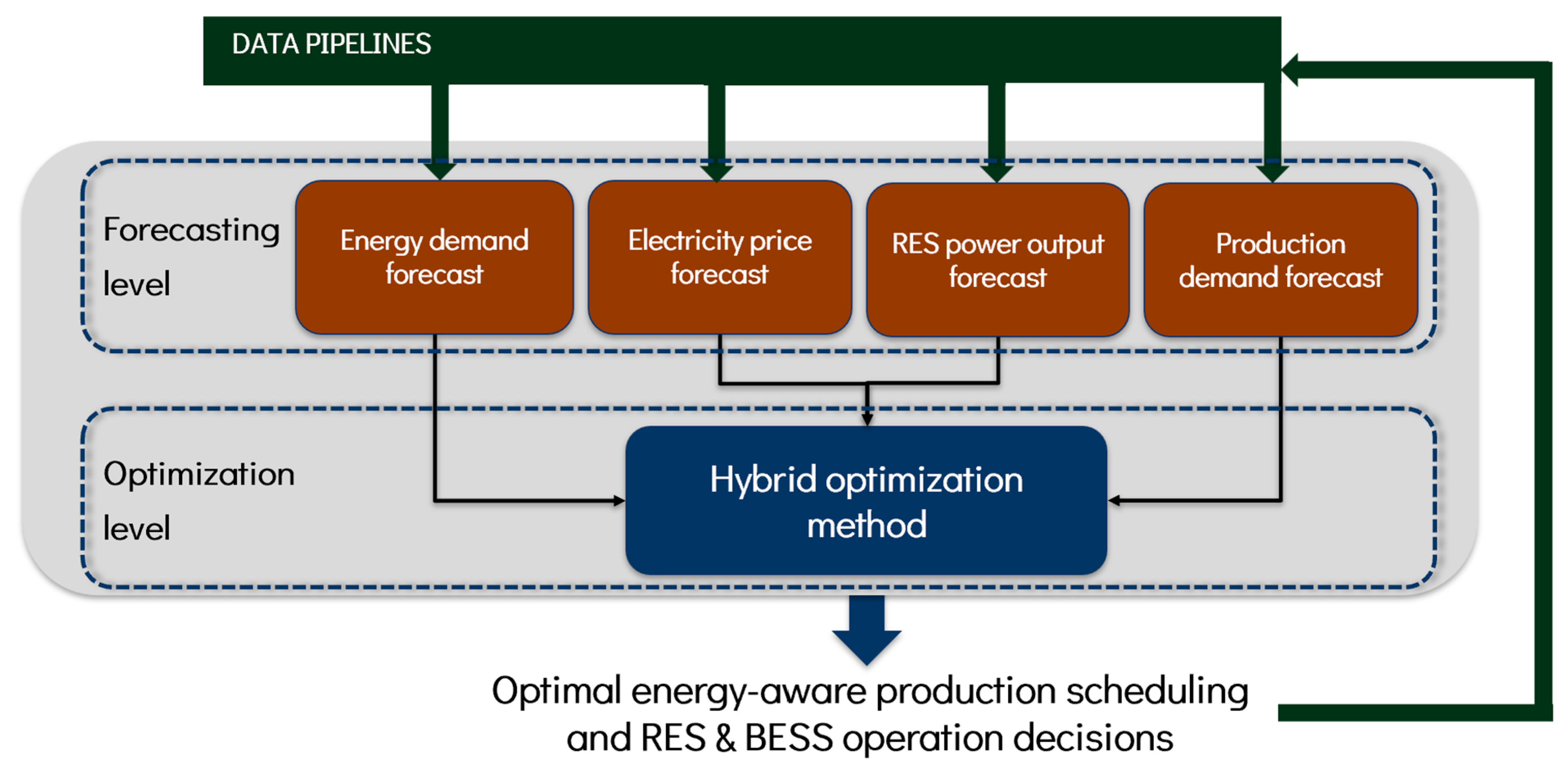

4.3. Leveraging Forecasting and Real-Time Adaptation

Flexibility is at the core of the suggested framework, which demands a close integration of cutting-edge forecasting methods and real-time data feeds. Accurate forecasting is not a supporting task—it is at the heart of enabling proactive, cost-saving, and sustainable decision-making in energy-aware production scheduling. Three key parameters at the focal point of this problem are electricity prices, renewable energy generation, and industrial energy demand. Electricity price forecasting is important in systems engaged in day-ahead and intraday markets, where prices are updated hourly or even every fifteen minutes. With access to timely price forecasts, companies can schedule energy-intensive operations for low-tariff periods or strategically participate in real-time operations to gain higher cost savings. Also important is the prediction of renewable generation, especially from on-site resources like solar and wind systems. While solar power can reliably be forecasted with acceptable precision from irradiance forecasts, wind generation is far more challenging to model because of high temporal and spatial variability. For wind energy or hybrid renewable setups that plants rely on, the production forecasts’ uncertainty can significantly affect scheduling flexibility and energy availability, emphasizing the need for probabilistic or ensemble forecasting techniques. Left relatively uncared for in the literature thus far—but no less important—is the prediction of industrial energy use. The power consumption of equipment in actual industrial environments is often condition-dependent and non-stationary. It may change with the task being undertaken, the characteristics of the material involved, the current state of the machine, and particular manufacturing operations like retooling or cleaning. Classical scheduling models have a tendency to employ average consumption values from manufacturers, which may be inaccurate and produce poor or infeasible schedules. More realistic models ought to include data-driven energy demand estimators, which are trained on real-time and historical data gathered through IoT sensors and manufacturing execution systems. Such estimators are required to learn dynamically in order to reflect the actual energy footprint of activities in changing conditions.

Yet, forecasting is only part of the struggle. Schedules also need to be adjustable dynamically to react to the deviations from anticipated circumstances or to fresh market indicators. This involves formulating reactive and online scheduling algorithms that change operational strategies continuously as new data emerges. One way of performing this is by employing a rolling-horizon algorithm, in which the schedule is created for a longer horizon—e.g., a whole production week—but with different levels of confidence. In this arrangement, the initial portion of the horizon (e.g., the ensuing 24 h) is based on high-confidence inputs, i.e., TOU electricity prices on the day-ahead market. The subsequent days are calculated from the forecasted values of electricity price, renewable generation, and demand, for which the confidence of the forecast generally diminishes with time. The re-optimization of the schedule occurs daily or continuously as new parameters are updated with actual data. This replanning feature echoes the ways in which real-life industrial processes evolve and allows a dynamic reaction to a shift in market price, renewables availability, or production parameters.

Figure 2 illustrates the methodological framework proposed, structured around two primary levels: the forecasting and optimization levels. At the forecasting level, key inputs, such as energy demand, electricity price, renewable energy source output, and production demand forecasts, are automatically obtained via data pipelines. These forecasts feed into the optimization level, where a hybrid optimization approach integrates these predictions to derive optimal decisions regarding energy-aware production scheduling, renewable energy integration, and battery energy storage system operation. This structured approach allows the model to effectively handle uncertainties and optimize performance across multiple operational dimensions. Although this framework remains at a conceptual stage in the current study, we envision its implementation and validation in future research, ideally through pilot case studies or simulation-based experiments in collaboration with industrial partners.

To enable this degree of responsiveness, scheduling systems need to be underpinned by control mechanisms based on feedback, with the ability to track real-time deviations and initiate corrective actions. Approaches like digital twins—the real-time simulation of physical system dynamics—and reinforcement learning algorithms that adapt policies based on observed effects can be a crucial enabler in this regard. They not only facilitate predictive and prescriptive changes but also assist in accounting for process dynamics, equipment conditions, and unplanned events. These elements come together to form the basis of an adaptive scheduling system: one that schedules in advance based on the best predictions available, tracks in real time, and responds with agility as conditions evolve.

4.4. Embedding Intelligence and Interconnectivity

To achieve the level of responsiveness and sophistication noted herein, the scheduling systems need to be smarter and more networked. Technologies from Industry 4.0, including industrial IoT, cyber-physical systems (CPSs), and cloud-based systems, provide the technological foundation for such an upgrade. The scheduling framework needs to incorporate real-time automated machine, smart meter, and production line data feeds to properly estimate machine status and energy demand. There should be learning algorithms that adapt where these data streams drive the models for energy consumption and become more accurate with time, with resulting predictions and schedules being similarly more dependable. Real-time monitoring, automated decision streams, and interfaces to enterprise resource planning (ERP) and MESs will be needed to facilitate close communication between the controls and the optimization engines. Additionally, the growing ability to process large amounts of industrial data opens up the possibility of leveraging data-driven control approaches. For instance, real load profiles can be applied in bottleneck forecasting or DR opportunity identification, and historical energy consumption patterns can be used in predictive maintenance or work scheduling. Not only do these enhance operational efficiency but also system resilience and agility.

To realize this vision in practice, we propose a CPPS architecture of a layered cyber-physical production system that integrates real-time sensing, data processing, forecasting, optimization, and control. The architecture includes the following:

(i) a data acquisition layer connecting machines, smart meters, and sensors via industrial IoT networks;

(ii) a communication layer based on protocols such as OPC UA or MQTT, providing efficient, secure data exchange;

(iii) a data processing and analytics layer, in which forecasting algorithms operate;

(iv) an optimization and decision layer, responsible for adaptive scheduling;

(v) a control and interface layer, integrating MES, ERP, and plant control systems to execute decisions in real-time.

This multi-layer design supports real-time responsiveness, data-driven adaptation, and seamless IT-OT integration, transcending current limitations in industrial scheduling systems. This design concept may serve as a reference for the upcoming deployments of integrated energy-aware scheduling systems and guide academic prototypes and industrial pilot systems accordingly.

4.5. Enabling Cross-Disciplinary and Collaborative Innovation

Realizing this vision will necessitate an interdisciplinary R&D community that transcends conventional disciplinary borders. Operations researchers, computer scientists, control engineers, energy economists, and industrial practitioners will have to collaborate to co-design theoretically sound and operationally feasible solutions. Academic studies need to go beyond stylized problem formulations and join with industry partners in experimenting with solutions on actual systems. This involves applying scheduling models to pilot projects, creating open-access datasets and benchmarks, and verifying outcomes under realistic operational constraints. Similarly, industries need to see the strategic importance of energy-aware scheduling—not merely as a cost-reduction strategy but as a means to regulatory compliance, reputation capital, and ultimate competitiveness. In parallel, regulators and policymakers also need to enable market frameworks, pricing mechanisms, and incentive structures in accordance with industrial flexibility and sustainability. Energy efficiency scheduling will be most effective if complemented by policies that encourage load shifting, facilitate entry into ancillary service markets, and internalize the carbon externality of emissions.

4.6. Industry Initiatives and Challenges in Developing Countries

Many industries worldwide have initiated efforts toward decarbonization, including the adoption of renewable energy sources, the deployment of battery energy storage systems, and adherence to carbon mitigation policies and green certification programs. These initiatives are particularly prominent in developed economies where resources and regulatory frameworks support their implementation. In contrast, industries in developing countries often encounter significant challenges, such as the high costs and administrative burdens associated with obtaining sustainable certifications, limited access to financing, and infrastructural constraints. These factors can impede the widespread adoption of decarbonization measures and highlight the need for tailored strategies that consider local economic and regulatory contexts. The future design of energy-aware production scheduling frameworks should therefore incorporate flexibility and adaptability to accommodate such regional disparities, enabling scalable and context-specific solutions that support decarbonization efforts globally.

5. Conclusions and Future Directions

This work has charted the state of the art of energy-aware production scheduling, assessing methodological innovation, practice uptake, and persistent challenges. Although the literature demonstrates considerable progress on optimization methodologies, renewable integration, and demand-response interaction, it is still limited by fragmented methodologies, simplifying assumptions, and a lack of system-wide integration. To be successful in facilitating industrial decarbonization, the scheduling systems of the next generation need to overcome these limitations through integrated design, real-time responsiveness, and cross-disciplinary collaboration. One of the principal findings of this analysis is the necessity to unify disjointed operational and energy-related decisions within a single adaptive framework. Scheduling needs to be transformed into an enterprise-wide, data-driven activity that aligns production with energy markets, regulatory frameworks, and sustainability objectives, rather than an isolated activity. This involves introducing on-site renewable energy facilities, utilizing flexible energy storage, engaging in dynamic pricing schemes, and aligning with emission reduction policies and sustainability regulations. In addition, scheduling decisions must increasingly factor in extended domains of operation, including the logistics, maintenance, and use of electric vehicle fleets as flexible energy resources. Their representation will require robust forecasting models for electricity prices, renewable output (wind especially), and machine-level energy requirements—each posing its own data issues and model uncertainties. Rolling-horizon techniques, supported by real-time monitoring and feedback, present a viable compromise between short-term precision and long-term adaptability. Digital twins, industrial Internet of Things, and cloud-accessible cyber-physical systems are the technologies that will bridge planning and execution. Going forward, several key research directions emerge. New models must better capture real-world variability and scale, through stochastic or robust formulations informed by actual industrial data. Integrated frameworks must be formulated that explicitly balance multi-objective trade-offs in support of not only cost-effectiveness but also emissions reduction, operational flexibility, and labor considerations. Moreover, there needs to be more active collaboration between industry and academia to validate approaches and develop viable implementation strategies. To this end, pilot studies involving on-site renewable generation, battery energy storage systems (BESSs), demand-response mechanisms, and real-time electricity pricing schemes (e.g., TOU and RTP) would be essential to bridge theoretical advances with practical feasibility. Lastly, policy coordination will be essential to rendering scheduling tools not just technologically viable but economically and environmentally effective. In conclusion, energy-aware production scheduling is where digitalization meets industrial sustainability. Integration, flexibility, and collaboration are keys to the next generation of research being able to deliver not only more efficient plants but also smarter, greener, and more sustainable industrial systems.