Large Eddy Simulations on the Diffusion Features of the Cold-Vented Natural Gas Containing Sulfur

Abstract

1. Introduction

2. Governing Equations and the Numerical Method

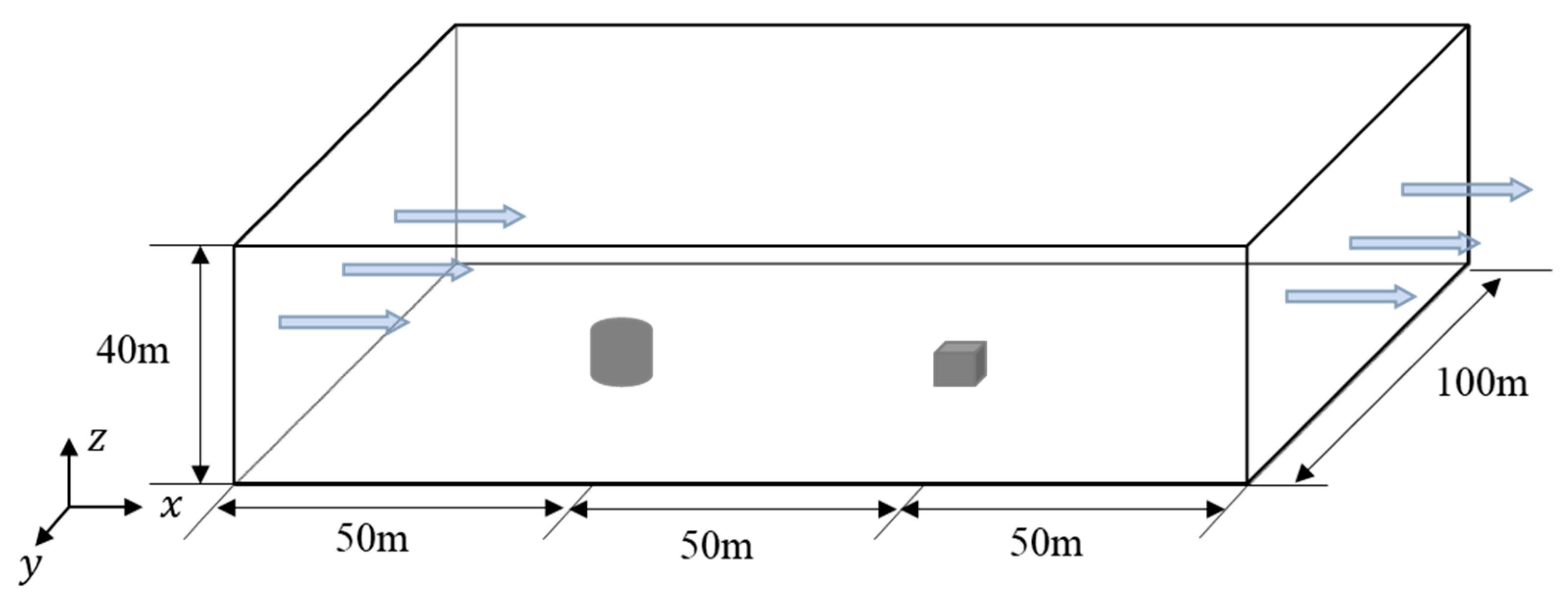

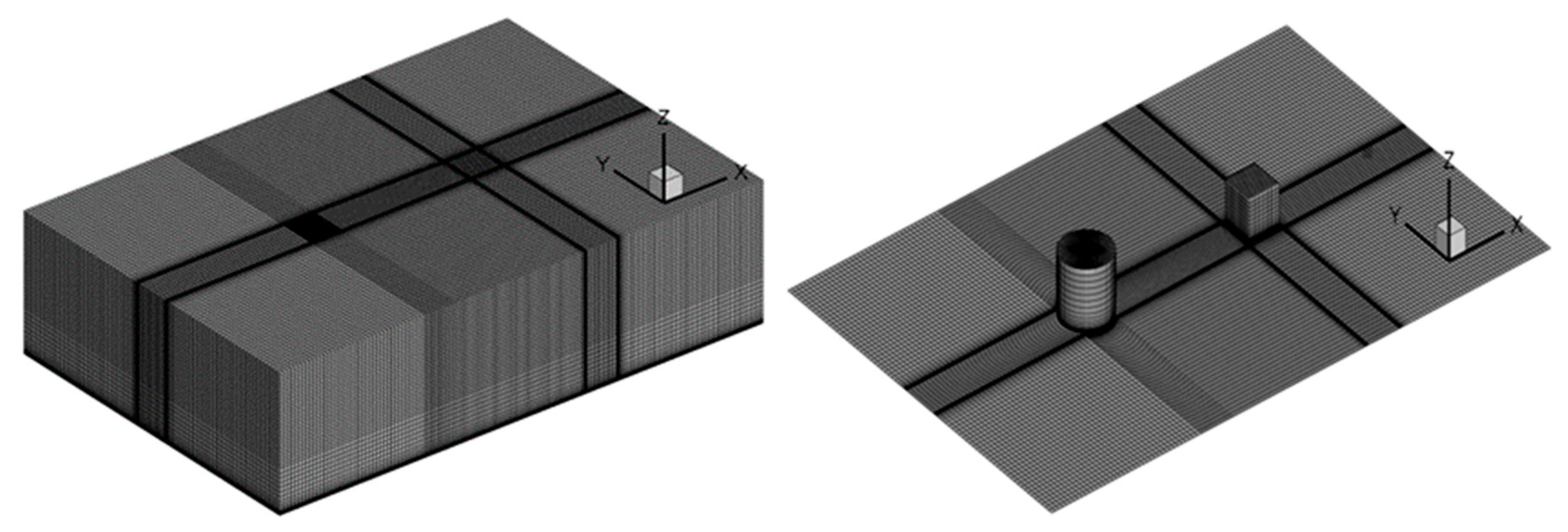

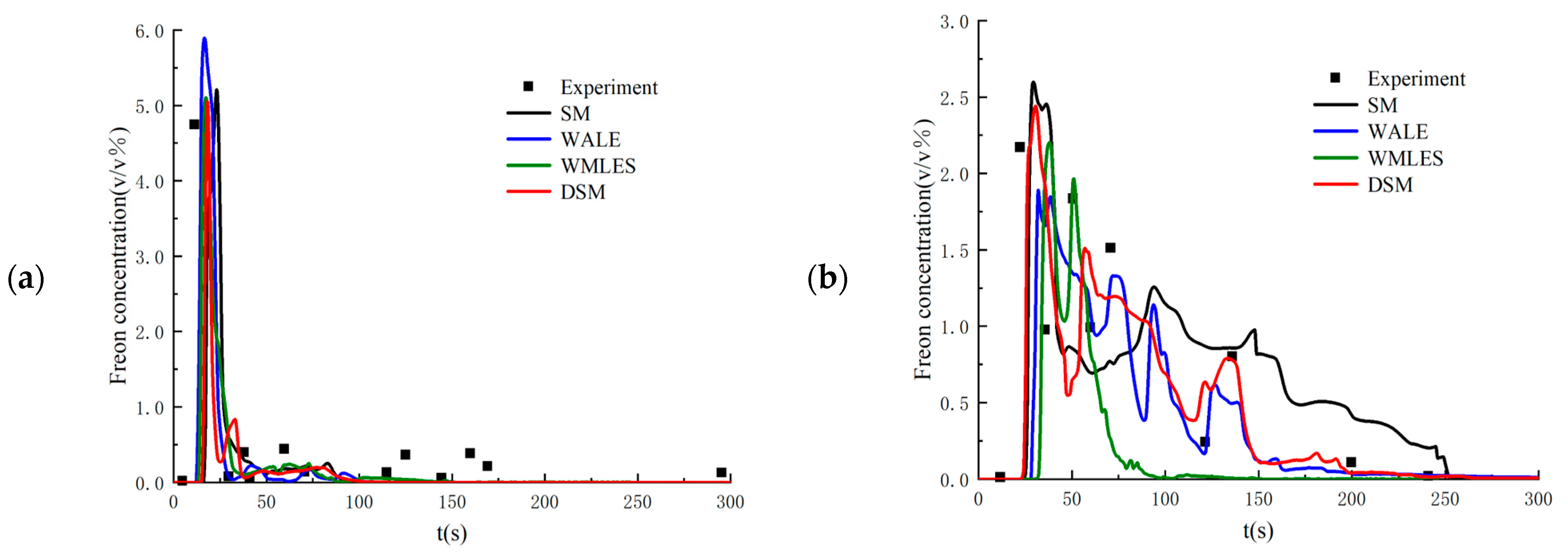

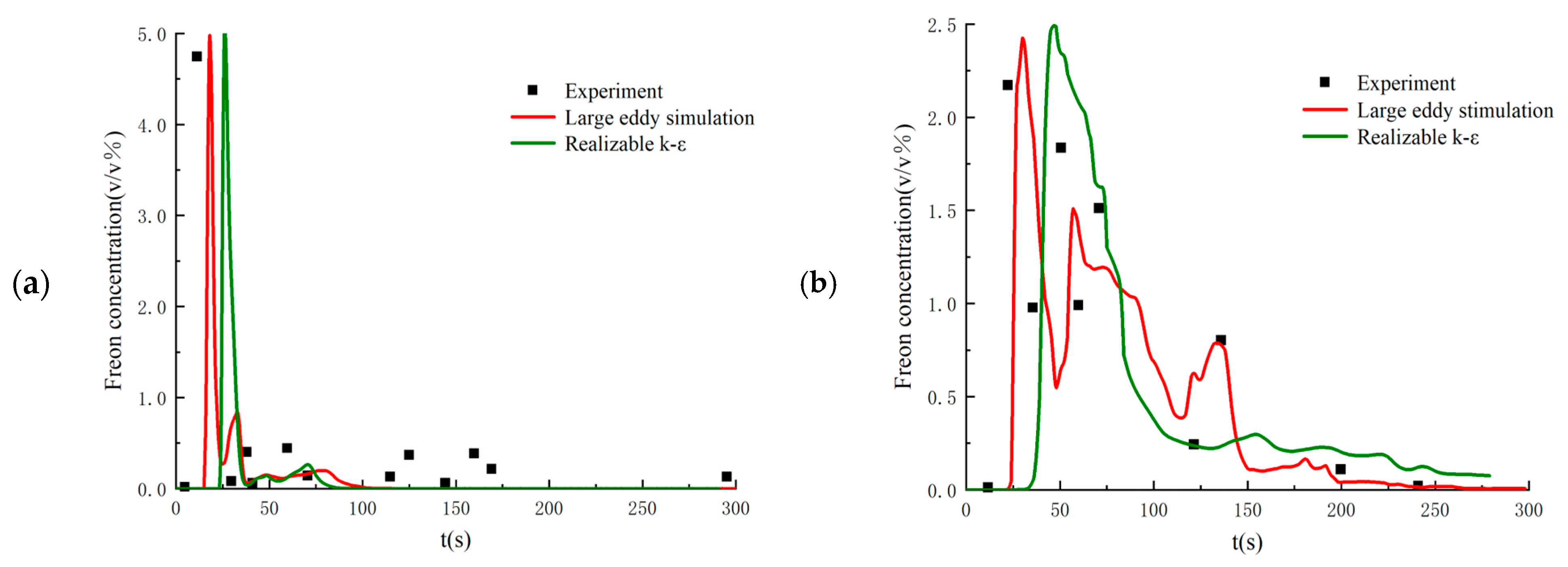

3. Validation of the LES Method

4. Diffusion Features of Cold-Vented Natural Gas Containing Sulfur

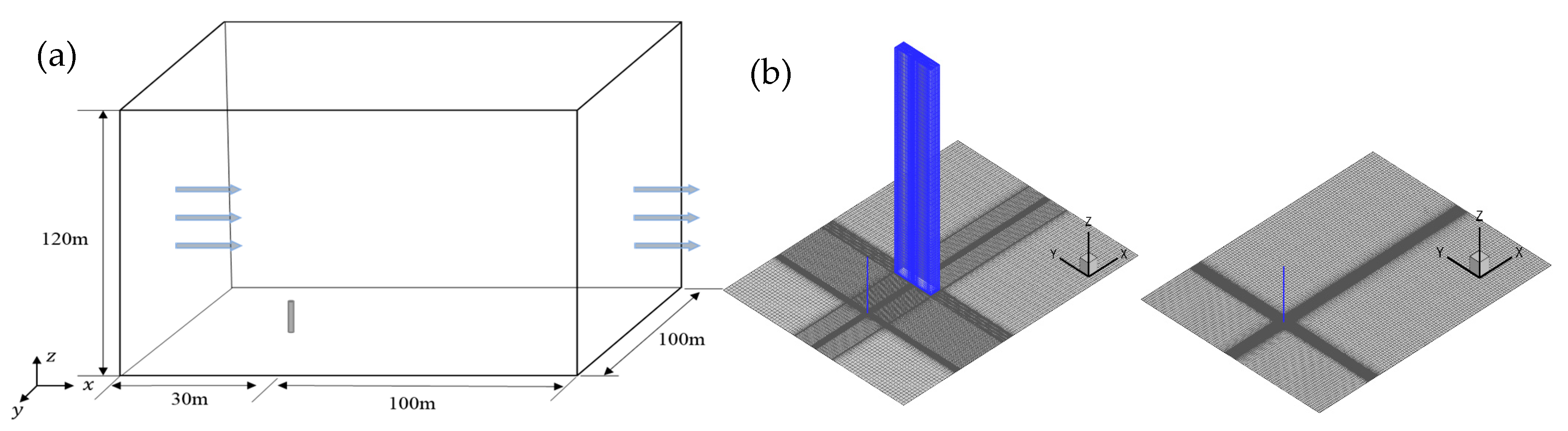

4.1. Computational Model

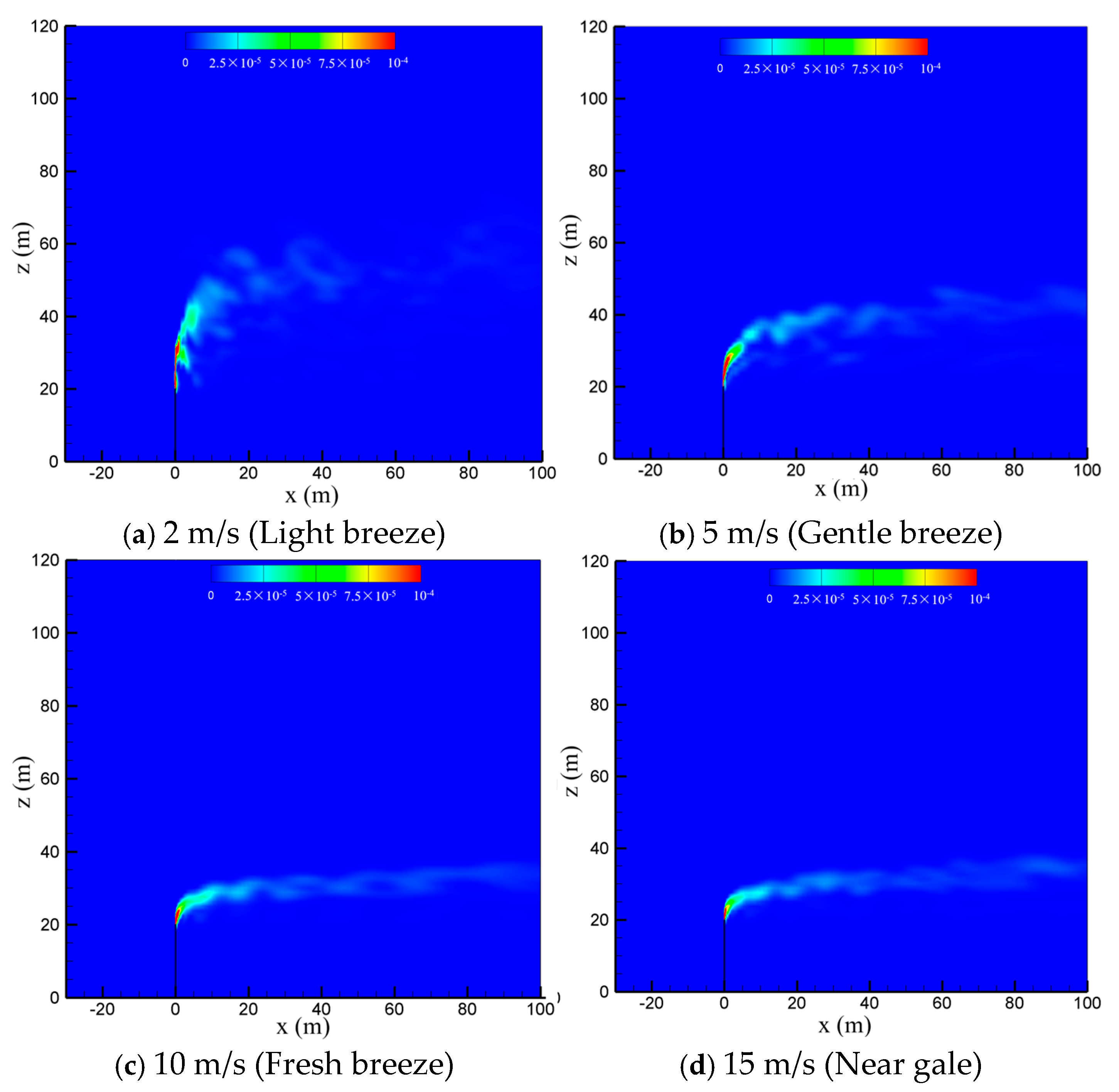

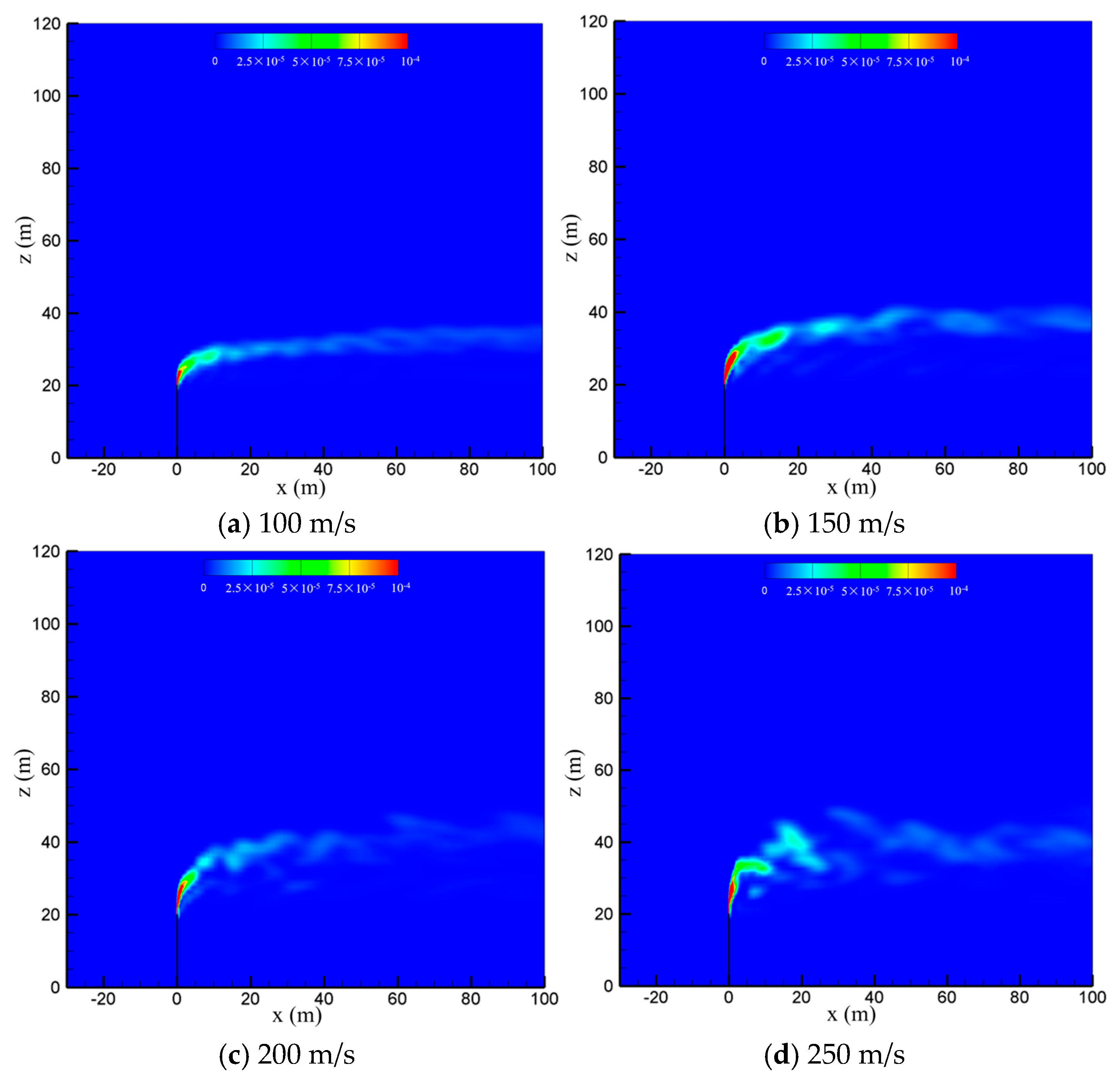

4.2. Effect of Wind Speed

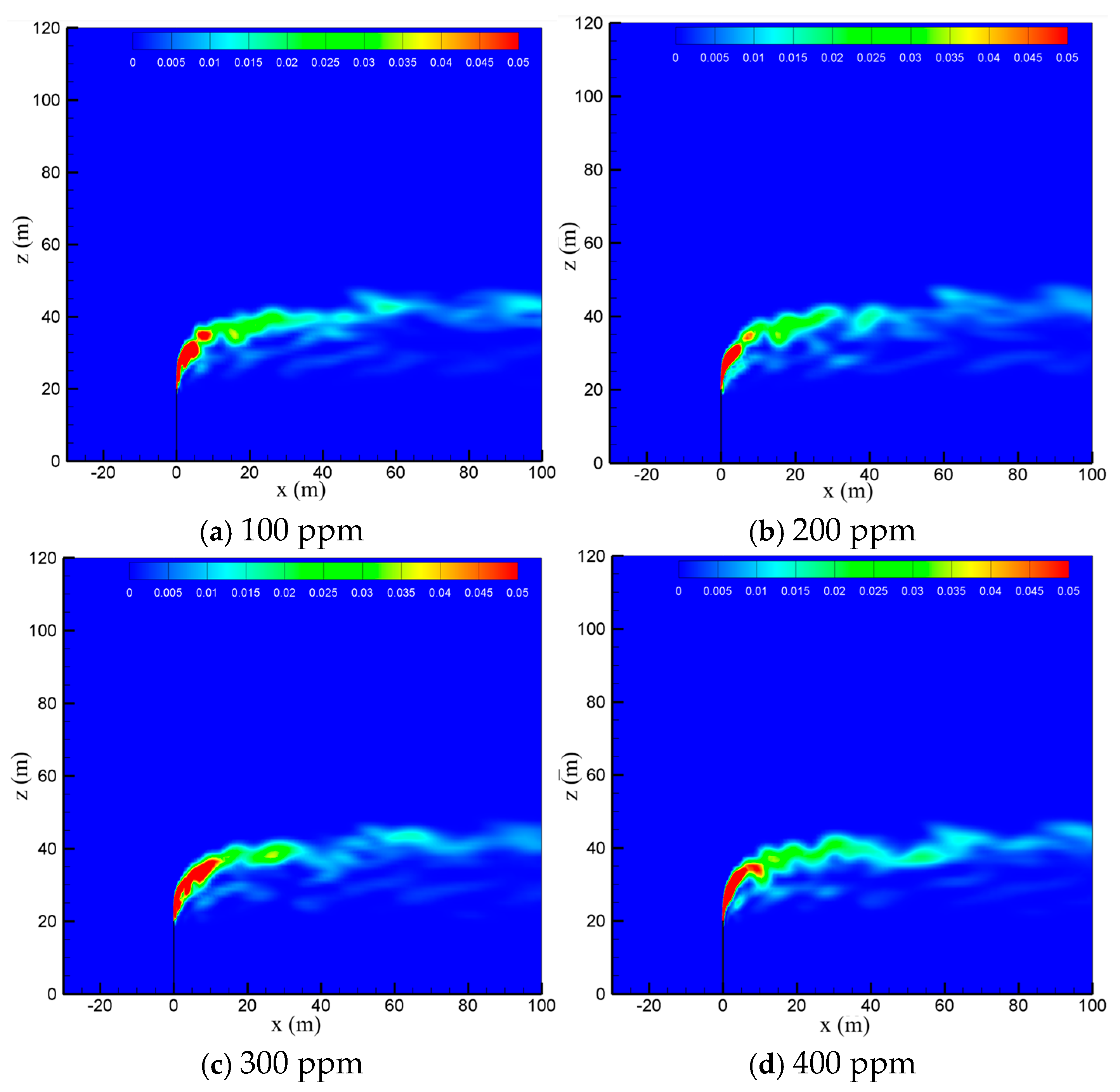

4.3. Effect of Sulfur Content

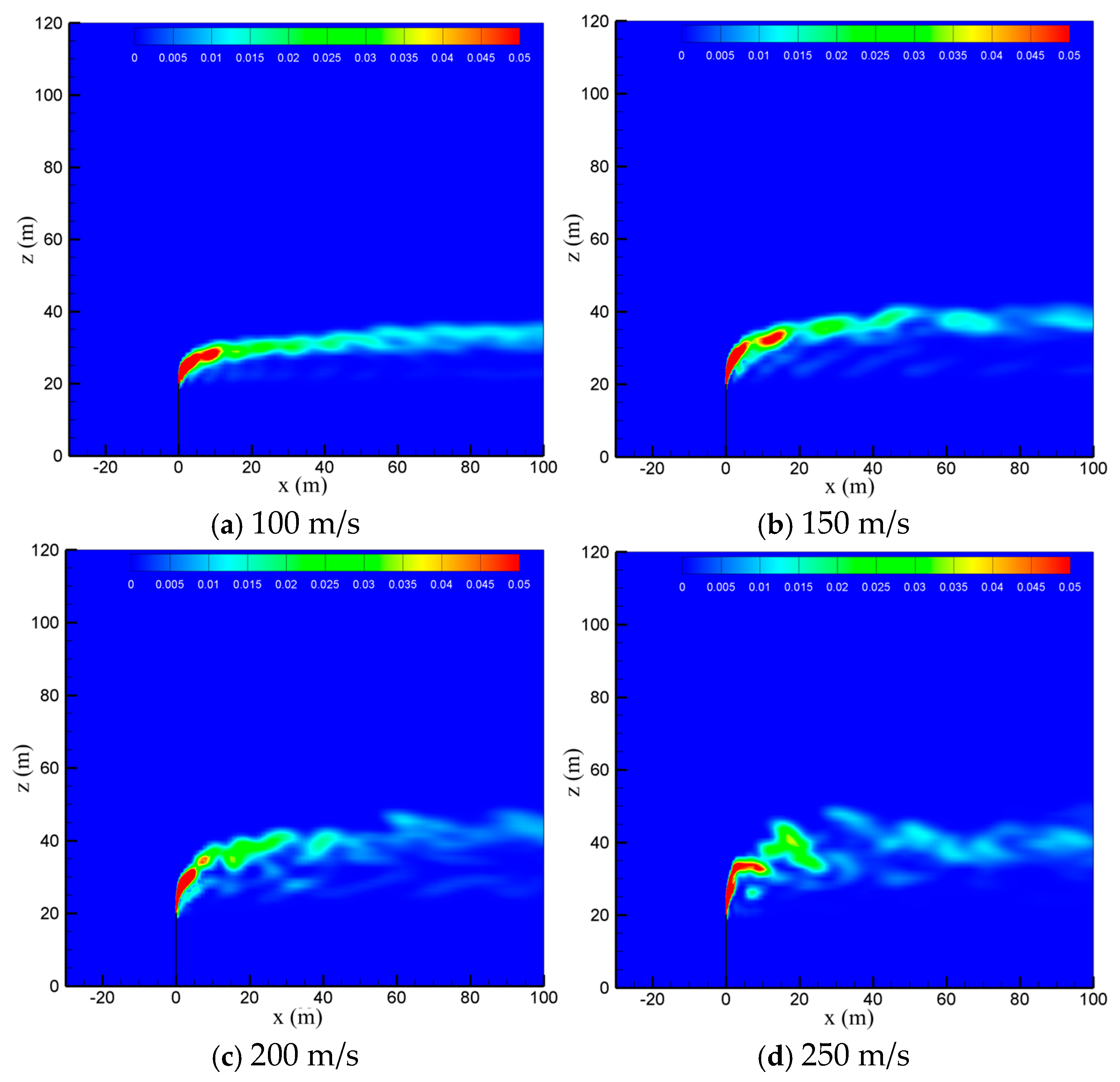

4.4. Effect of the Venting Rate

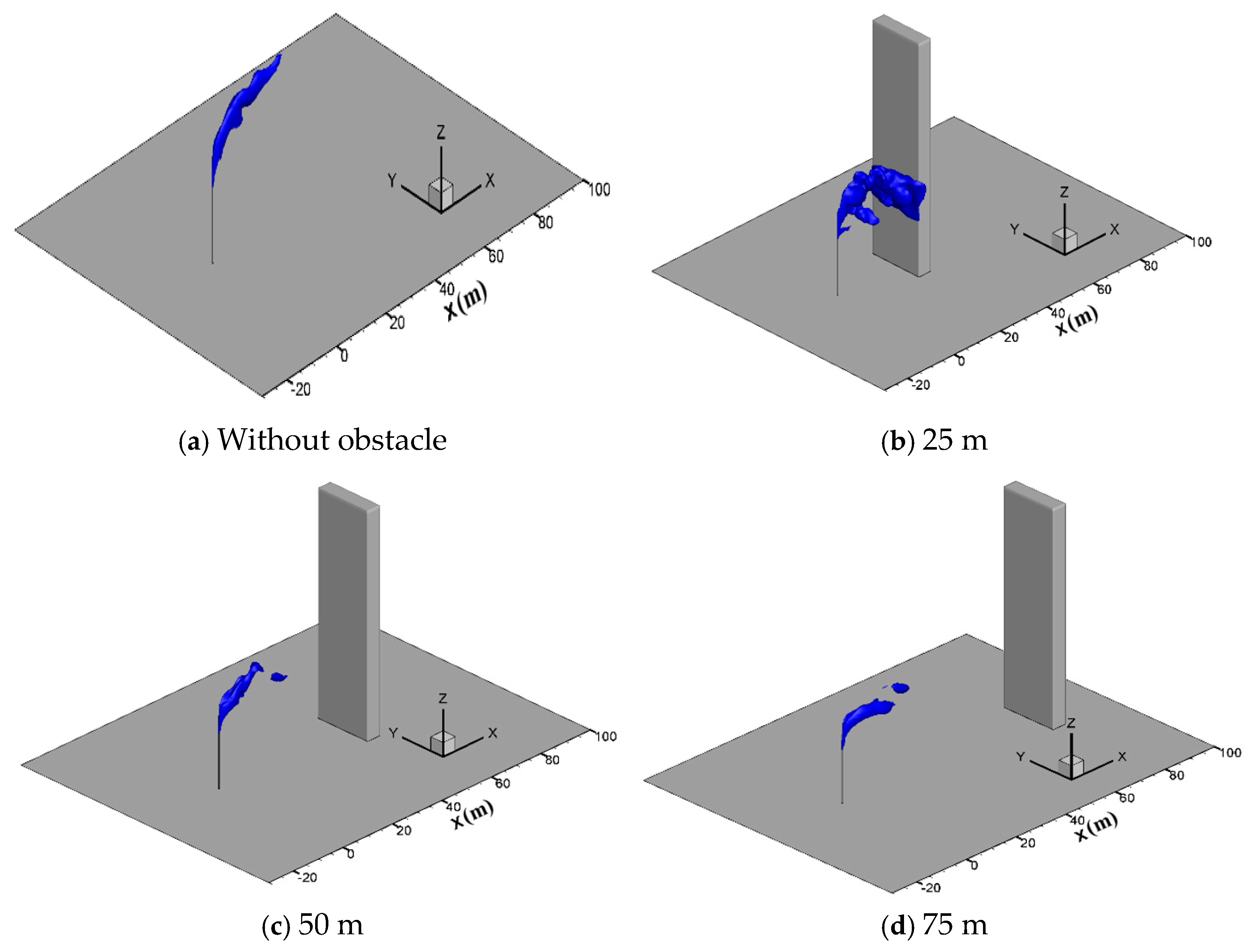

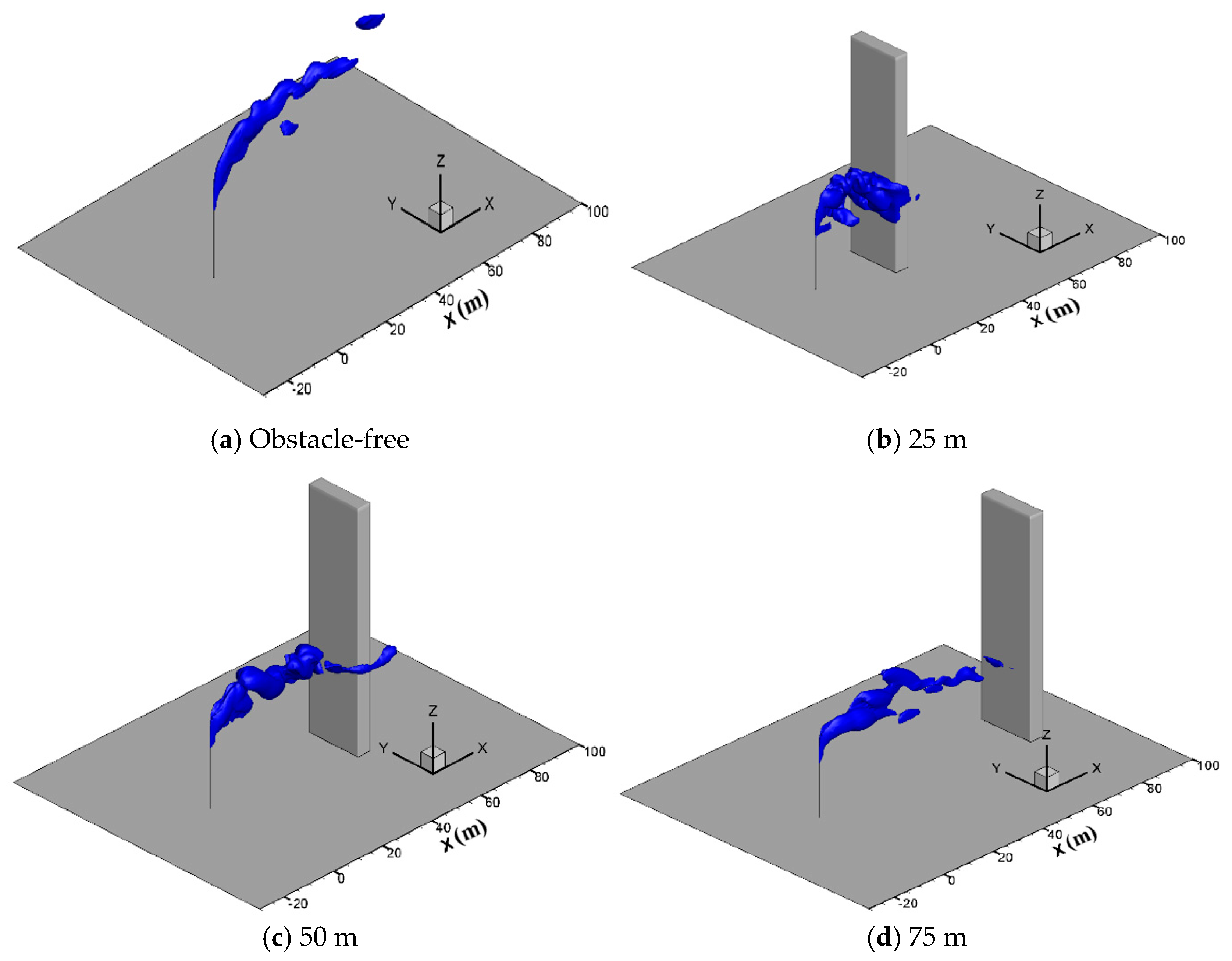

4.5. Effect of the Obstacle Behind the Venting Pipe

5. Conclusions

- (1)

- The large eddy simulation method is able to more precisely compute the transient diffusion process of the cold-vented natural gas containing sulfur. Compared with other SGS filtering models, the DSM SGS model shows better performance in simulating gas diffusion in the open atmosphere.

- (2)

- The relative value between the venting rate and wind speed has significant effects on the cold-vented process of natural gas containing sulfur. At a very small wind speed of 2 m/s and a relatively large venting rate of 200 m/s, the vented gas flow can “penetrate” the wind and move upward for about 30 m before it flows downward. As the wind speed increases from 2 m/s to 15 m/s, the sulfur-bearing natural gas released from the venting pipe moves upward for a shorter distance (10 m) first and then spreads downstream along the horizontal direction in a narrow regular area. At a very large venting rate of 250 m/s, the jet effect at the vent pipe outlet becomes very significant, and the gas cloud discharged from the venting pipe becomes more turbulent and fluctuated, which is helpful for the diffusion of the vented gas.

- (3)

- Within the range of sulfur content concerned, the sulfur content has little effect on the diffusion of methane gas. As the sulfur content increases, the diffusion area of hydrogen sulfide increases significantly.

- (4)

- The diffusion processes of both methane and hydrogen sulfide gases are influenced greatly by an obstacle closely downstream of the venting pipe. At a smaller distance of 25 m, the vented gases aggregate on and move along the windward side of the obstacle towards the ground, increasing the risk of explosion and poisoning on the ground. As the distance between the obstacle and venting pipe increases to 50 m, the obstacle no longer allows the vented gas to move to the ground; the horizontal diffusion becomes dominant, and the diffusion range after the obstacle increases. When the obstacle is placed far away from the vent pipe, its influence can be ignored.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ci | concentration coefficient of the ith gas component, kg/m3 | Sc | the Schmidt number of fluid diffusion |

| Di | mass diffusion coefficient of the ith gas component, kg/(m2·s) | normal stress, Pa | |

| Kronecker symbol | t | time, s | |

| E | the energy of fluid per unit mass, J/kg | tangential stress, Pa | |

| h | the specific enthalpy, J/kg | sub-grid stress, m2/s2 | |

| thermal conductivity, W/(m·K) | velocity components, m/s | ||

| the dynamic viscosity of the fluid, Pa·s | wind speed at the height of | ||

| p | pressure, Pa | wind speed at the height of | |

| heat flow density, W/m2 | coordinate components, m | ||

| density of the fluid, kg/m3 | z | height with respect to the ground, m |

References

- Koopman, R.P.; Baker, J.; Cederwall, R.T.; Goldwire, H.C.; Hogan, W.J.; Kamppinen, L.M.; Kiefer, R.D.; McClure, J.W.; McRae, T.G.; Morgan, D.L.; et al. LLNL/NWC 1980 LNG Spill Tests. Burro Series Data Report; Lawrence Livermore National Lab.: Livermore, CA, USA, 1982. [Google Scholar]

- Goldwire, H.C.; Rodean, H.C.; Cederwall, R.T.; Kansa, E.J.; Koopman, R.P.; McClure, J.W.; McRae, T.G.; Morris, L.K.; Kamppinen, L.; Kiefer, R.D.; et al. Coyote Series Data Report. LLNL/NWC 1981 LNG Spill Tests Dispersion, Vapor Burn, and Rapid-Phase-Transition; Lawrence Livermore National Lab.: Livermore, CA, USA, 1983; Volume 2. [Google Scholar]

- Puttock, J.S.; Colenbrander, G.W.; Blackmore, D.R. Maplin sands experiments 1980: Dispersion results from continuous releases of refrigerated liquid propane. In Heavy Gas and Risk Assessment II; Springer: Dordrecht, The Netherlands, 1983; pp. 147–161. [Google Scholar]

- Spicer, T.; Havens, J. Modeling the Phase I Thorney Island experiments. J. Hazard. Mater. 1985, 11, 237–260. [Google Scholar] [CrossRef]

- McQuaid, J. Objectives and design of the phase I heavy gas dispersion trials. J. Hazard. Mater. 1985, 11, 1–33. [Google Scholar] [CrossRef]

- Davies, M.; Singh, S. The phase II trials: A data set on the effect of obstructions. J. Hazard. Mater. 1985, 11, 301–323. [Google Scholar] [CrossRef]

- Krogstad, P.A.; Pettersen, R.M. Wind tunnel modelling of a release of a heavy gas near a building. Atmos. Environ. 1986, 20, 867–878. [Google Scholar] [CrossRef]

- Huber, A.H.; Snyder, W.H. Wind tunnel investigation of the effects of a rectangular-shaped building on dispersion of effluents from short adjacent stacks. Atmos. Environ. 1982, 16, 2837–2848. [Google Scholar] [CrossRef]

- Neff, E.D. Physical Modeling of Heavy Plume Dispersion; Colorado State University: Fort Collins, NC, USA, 1989. [Google Scholar]

- Havens, J.; Walker, H.; Spicer, T.O. Wind tunnel study of air entrainment into two-dimensional dense gas plumes at the Chemical Hazards Research Center. Atmos. Environ. 2001, 35, 2305–2317. [Google Scholar] [CrossRef]

- Almanza, V.H.; Molina, L.T.; Sosa, G. Soot and SO2 contribution to the supersites in the MILAGRO campaign from elevated flares in the Tula Refinery. Atmos. Meas. Tech. 2012, 12, 10583–10599. [Google Scholar] [CrossRef]

- Nourbakhsh, H.; Mowla, D.; Esmaeilzadeh, F. Predicting the Three Dimensional Distribution of Gas Pollutants for Industrial-type Geometries in the South Pars Gas Complex Using Computational Fluid Dynamics. Ind. Eng. Chem. Res. 2013, 52, 6559–6570. [Google Scholar] [CrossRef]

- Wang, A.; Lou, H.H.; Chen, D.; Yu, A.; Dang, W.; Li, X.; Martin, C.; Damodara, V.; Patki, A. Combustion mechanism development and CFD simulation for the prediction of soot emission during flaring. Front. Chem. Sci. Eng. 2016, 10, 459–471. [Google Scholar] [CrossRef]

- Fiates, J.; Santos, R.R.; Neto, F.F.; Francesconi, A.Z.; Simoes, V.; Vianna, S.S. An alternative CFD tool for gas dispersion modelling of heavy gas. J. Loss Prev. Process Ind. 2016, 44, 583–593. [Google Scholar] [CrossRef]

- Simon, E.G.; Harvey, T. Computational Fluid Dynamics (CFD) modelling of atmospheric dispersion for land-use planning around major hazards sites in Great Britain. J. Loss Prev. Process Ind. 2018, 54, 340–345. [Google Scholar]

- Teng, L.; Li, X.; Lu, S.; Liu, B.; Li, Y.; Li, W. Computational fluid dynamics study of CO2 dispersion with phase change of water following the release of supercritical CO2 pipeline. Process Saf. Environ. Prot. 2021, 154, 315–328. [Google Scholar] [CrossRef]

- Yet-Pole, I.; Cheng, T.L. Application of CFD model in an LPG tank explosion accident. J. Loss Prev. Process Ind. 2021, 69, 104367. [Google Scholar]

- Cao, Y.; Liu, T.; Song, G.; Zhou, W.; Han, H.; Li, Y.; Hu, Q.; Jing, R. Investigation of Pipeline CO2 Leakage and Diffusion on Offshore Platforms Based on Numerical Simulation. ACS Omega 2024, 9, 27537–27548. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yu, Y.; Li, P.; Wang, K.; Li, J.; Zhao, Z.; Zhang, Y.; Zhou, N.; Yin, Q.; Sun, T.; et al. Numerical simulation of leakage, dispersion and explosion behavior of LPG in kitchen. Energy Sources Part A Recover. Util. Environ. Eff. 2024, 46, 3996–4011. [Google Scholar] [CrossRef]

- Luo, Z.; Wu, P.; Wen, H.; Liu, C.; Xie, L.; Peng, S.; Du, X. Numerical investigation on the multiphase jet dispersion and sublimation cooling characteristics during accidental release of liquid CO2. Saf. Sci. 2025, 186, 106832. [Google Scholar] [CrossRef]

- Zhang, J.; Jing, S.; Fan, Z.; Liang, H.; Zhang, J.; Zhang, Y.; Sun, C.; Zhang, J. Experimental and numerical investigation on near-field temperature and surface CO2 concentrations of buried dense phase CO2 pipeline leakage. Int. J. Greenh. Gas Control 2025, 143, 104360. [Google Scholar] [CrossRef]

- Garnier, E.; Adams, N.; Sagaut, P. Large Eddy Simulation for Compressible Flows; Springer Science: New York, NY, USA, 2009. [Google Scholar]

- Pandey, B.; Prajapati, Y.K.; Sheth, P.N. CFD analysis of the downdraft gasifier using species-transport and discrete phase model. Fuel 2022, 328, 125302. [Google Scholar] [CrossRef]

- Sun, X.; Li, W.; Huang, Q.; Zhang, J.; Sun, C. Large eddy simulations of wind loads on an external floating-roof tank. Eng. Appl. Comput. Fluid Mech. 2020, 14, 422–435. [Google Scholar] [CrossRef]

- ANSYS-FLUENT. ANSYS FLUENT Theory Guide 19.2; ANSYS Inc.: Canonsburg, PA, USA, 2022. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Song, M.; Dong, S.; Wang, D.; Guo, Y.; Wang, J.; Yu, J. Large Eddy Simulations on the Diffusion Features of the Cold-Vented Natural Gas Containing Sulfur. Processes 2025, 13, 1940. https://doi.org/10.3390/pr13061940

Sun X, Song M, Dong S, Wang D, Guo Y, Wang J, Yu J. Large Eddy Simulations on the Diffusion Features of the Cold-Vented Natural Gas Containing Sulfur. Processes. 2025; 13(6):1940. https://doi.org/10.3390/pr13061940

Chicago/Turabian StyleSun, Xu, Meijiao Song, Sen Dong, Dongying Wang, Yibao Guo, Jinpei Wang, and Jingjing Yu. 2025. "Large Eddy Simulations on the Diffusion Features of the Cold-Vented Natural Gas Containing Sulfur" Processes 13, no. 6: 1940. https://doi.org/10.3390/pr13061940

APA StyleSun, X., Song, M., Dong, S., Wang, D., Guo, Y., Wang, J., & Yu, J. (2025). Large Eddy Simulations on the Diffusion Features of the Cold-Vented Natural Gas Containing Sulfur. Processes, 13(6), 1940. https://doi.org/10.3390/pr13061940