Optimization of Profile Control and Displacement Physical Simulation for Reservoirs with Intra-Layer Heterogeneity

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials and Instruments

2.2. Experimental Methods

2.2.1. Plugging Performance Evaluation Experiment

2.2.2. Injection Parameter Optimization for Displacement Agents

- (1)

- Optimization of the injection weight percentage: Simulated formation water was used to prepare profile control and displacement agents with different weight percentages, specifically 2, 3, 4, 5, 6, and 7%.

- (2)

- Optimization of the injection volume: The injection volumes were set to 0.05, 0.10, 0.15, 0.20, 0.25, and 0.30 PV.

- (3)

- Optimization of the number of injection rounds: Based on the optimized profile control and displacement agent type, weight percentage, and injection volume determined from the experiments, injection experiments were conducted by injecting the profile control agent system and water in different numbers of rounds. The numbers of injection rounds tested were 1, 2, and 3.

3. Results and Discussion

3.1. Evaluation of Plugging Performance

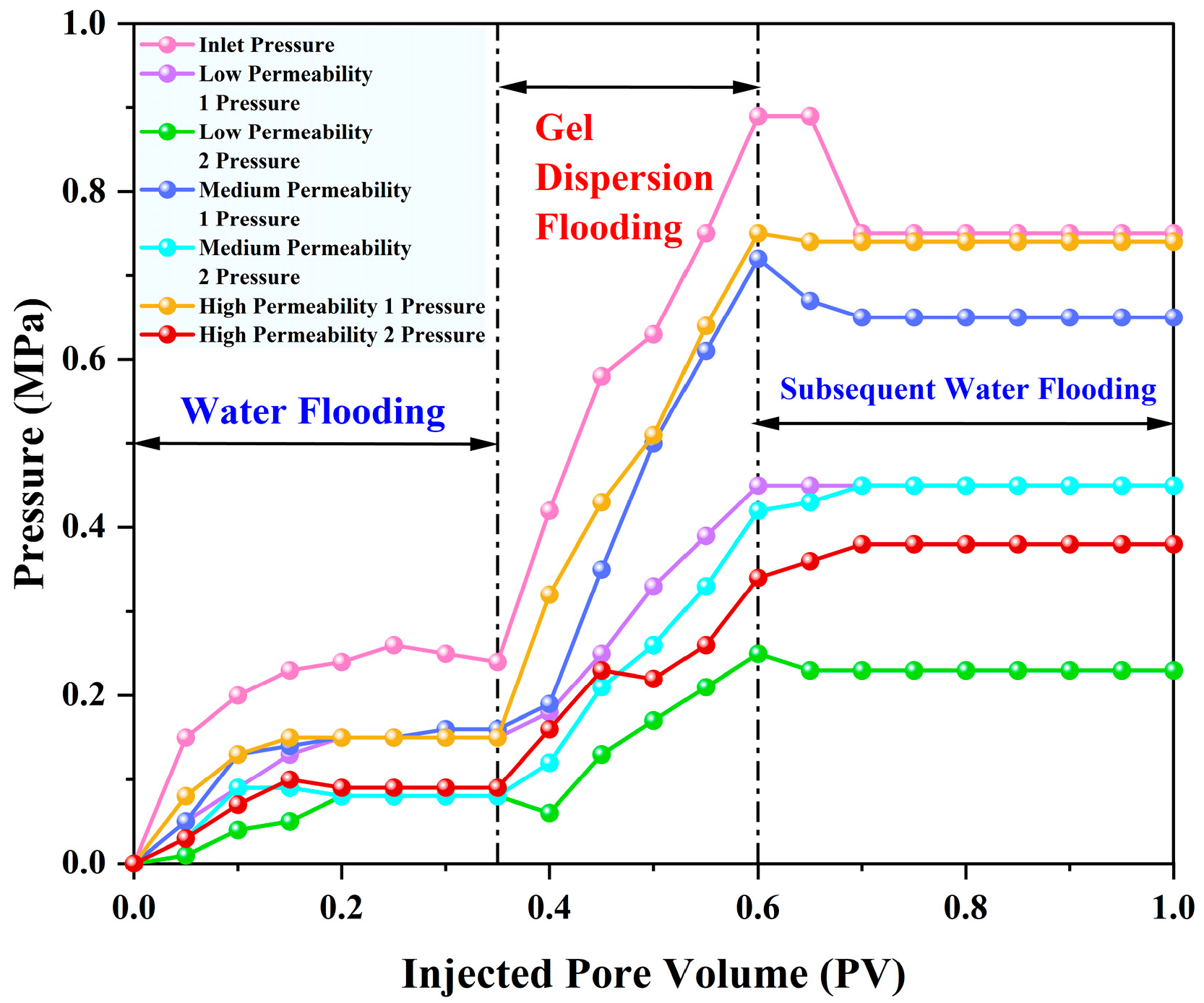

3.2. Optimization of Injection Parameters for the Profile Control and Displacement Agent

3.2.1. Optimization of Injection Weight Percentage

3.2.2. Optimization of Injection Volume

3.2.3. Injection Round Optimization

4. Conclusions

- (1)

- The plugging performance of three plugging agents was evaluated through experiments and their performances were ranked as microspheres < PEG < gel dispersion. Their plugging rates were 56.468%, 65.188%, and 86.574%, respectively. The plugging rate of the gel dispersion was 1.5 times that of the microspheres, demonstrating the highest efficacy in improving intra-layer reservoir heterogeneity.

- (2)

- The optimized injection parameters for the gel dispersion were as follows: a gel dispersion weight percentage of 5%, an injection volume of 0.25 PV, and one injection round; this combination increased the recovery rate by 28.01%.

- (3)

- Sand-pack experiments can provide references for field applications, but sand packs are mostly uniformly packed. Future studies could include further matching sand-pack properties to reservoir characteristics or using real core samples for physical simulation, as well as utilizing numerical simulation software such as COMSOL6.3 to accurately and efficiently obtain data to guide oilfield production.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Madalimov, M.; Li, D.; Haynes, B.; Dair, Y.; Ehighebolo, I.T.; Ionescu, C.L. Heterogeneity Modeling and Heterogeneity-Based Upscaling for Reservoir Characterization and Simulation. SPE J. 2025, 30, 942–956. [Google Scholar] [CrossRef]

- Hewett, T.A. Fractal Distributions of Reservoir Heterogeneity and Their Influence on Fluid Transport. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 5 October 1986. [Google Scholar]

- Song, Q.; Sun, Y.; Zhou, J. Quantifying the Reservoir Heterogeneity: A Case Study of Clastic Reservoirs, Bohai Bay Basin, China; OnePetro: Houston, TX, USA, 2009. [Google Scholar]

- Xie, R.J.; Ma, Y.L.; Li, Z.Y.; Zhen, H.; Yang, Z.P. Research on Reservoir Heterogeneity of Complex Region. AMM 2014, 608–609, 742–747. [Google Scholar] [CrossRef]

- Deng, X.; Huang, X.; Ye, Q.; Li, S.; Yu, C.; Zhang, X.; Wang, Z. Experimental Research on Production Law of Multilayer Heterogeneous Reservoirs. Front. Earth Sci. 2022, 10, 990554. [Google Scholar] [CrossRef]

- Al-Ibadi, H.; Stephen, K.; Mackay, E. Heterogeneity Effects on Low Salinity Water Flooding. In Proceedings of the SPE Europec, Virtual, 1 December 2020. [Google Scholar]

- Lu, X.; Cao, B.; Xie, K.; Cao, W.; Liu, Y.; Zhang, Y.; Wang, X.; Zhang, J. Enhanced Oil Recovery Mechanisms of Polymer Flooding in a Heterogeneous Oil Reservoir. Pet. Explor. Dev. 2021, 48, 169–178. [Google Scholar] [CrossRef]

- Tong, Q.; He, D.; Xia, Z.; Huang, J.; Di, K.; Xu, F.; Guo, S. Influence of Reservoir Pore-Throat Structure Heterogeneity on Water-Flooding Seepage: A Case Study of Yanchang Formation in Ordos Basin. Minerals 2022, 12, 1243. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, M.; Pi, Y.; Fan, X.; Cheng, G.; Jiang, L. Experimental Study on Enhanced Oil Recovery of the Heterogeneous System after Polymer Flooding. Processes 2023, 11, 2865. [Google Scholar] [CrossRef]

- Zhao, L.; Zhao, W.; Sun, M.; Wang, J.; Ma, H.; Li, Y.; Zhao, X. Study on Improving Recovery of Highly Heterogeneous Reservoirs by Unsteady Water Injection Technology. Energies 2025, 18, 159. [Google Scholar] [CrossRef]

- He, L.; Hanbing, X. Deep Fluid Diversion for Profile Control and Oil Displacement Technologies; European Association of Geoscientists & Engineers: Bunnik, The Netherlands, 2012. [Google Scholar]

- Cao, B.; Xie, K.; Lu, X.; Cao, W.; He, X.; Xiao, Z.; Zhang, Y.; Wang, X.; Su, C. Effect and Mechanism of Combined Operation of Profile Modification and Water Shutoff with In-Depth Displacement in High-Heterogeneity Oil Reservoirs. Colloids Surf. A Physicochem. Eng. Asp. 2021, 631, 127673. [Google Scholar] [CrossRef]

- Liu, Y.; Zou, C.; Zhou, D.; Li, H.; Gao, M.; Zhao, G.; Dai, C. Novel Chemical Flooding System Based on Dispersed Particle Gel Coupling In-Depth Profile Control and High Efficient Oil Displacement. Energy Fuels 2019, 33, 3123–3132. [Google Scholar] [CrossRef]

- Velázquez, D.L.; Tellez, F.; Ramírez, C.J.; Fragachán, F.E.; Omer, M.; Figueroa, F.; Mejias, G.; Brito, B. Improving Acid Coverage in a Naturally Fractured HPHT Carbonate Reservoir by Combining Chelating Fluids and Chemical Diversion Optimization. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Port of Spain, Trinidad and Tobago, 7 June 2023. [Google Scholar]

- Cao, W.; Xie, K.; Lu, X.; Liu, Y.; Zhang, Y. Effect of Profile-Control Oil-Displacement Agent on Increasing Oil Recovery and Its Mechanism. Fuel 2019, 237, 1151–1160. [Google Scholar] [CrossRef]

- Zhao, L.; Chen, X.; Zou, H.; Liu, P.; Liang, C.; Zhang, N.; Li, N.; Luo, Z.; Du, J. A Review of Diverting Agents for Reservoir Stimulation. J. Pet. Sci. Eng. 2020, 187, 106734. [Google Scholar] [CrossRef]

- Gao, Q.; Zhong, C.; Han, P.; Cao, R.; Jiang, G. Synergistic Effect of Alkali–Surfactant–Polymer and Preformed Particle Gel on Profile Control after Polymer Flooding in Heterogeneous Reservoirs. Energy Fuels 2020, 34, 15957–15968. [Google Scholar] [CrossRef]

- Lai, N.; Chen, S.; Tang, L.; Huang, Y.; Xu, H. Migration Characteristics and Profile Control Capabilities of Preformed Particle Gel in Porous Media. Petroleum 2022, 8, 483–498. [Google Scholar] [CrossRef]

- Zhao, G.; You, Q.; Tao, J.; Gu, C.; Aziz, H.; Ma, L.; Dai, C. Preparation and Application of a Novel Phenolic Resin Dispersed Particle Gel for In-Depth Profile Control in Low Permeability Reservoirs. J. Pet. Sci. Eng. 2018, 161, 703–714. [Google Scholar] [CrossRef]

- Han, M.; Alshehri, A.J.; Krinis, D.; Lyngra, S. State-of-the-Art of In-Depth Fluid Diversion Technology: Enhancing Reservoir Oil Recovery by Gel Treatments. In Proceedings of the SPE Saudi Arabia Section Technical Symposium and Exhibition, Al-Khobar, Saudi Arabia, 21 April 2014. [Google Scholar]

- Sagbana, P.I.; Abushaikha, A.S. A Comprehensive Review of the Chemical-Based Conformance Control Methods in Oil Reservoirs. J. Pet. Explor. Prod. Technol. 2021, 11, 2233–2257. [Google Scholar] [CrossRef]

- Li, J.; Wang, Z.; Yang, H.; Yang, H.; Wu, T.; Wu, H.; Wang, H.; Yu, F.; Jiang, H. Compatibility Evaluation of In-Depth Profile Control Agents in Dominant Channels of Low-Permeability Reservoirs. J. Pet. Sci. Eng. 2020, 194, 107529. [Google Scholar] [CrossRef]

- Zhao, G.; Li, J.; Gu, C.; Li, L.; Sun, Y.; Dai, C. Dispersed Particle Gel-Strengthened Polymer/Surfactant as a Novel Combination Flooding System for Enhanced Oil Recovery. Energy Fuels 2018, 32, 11317–11327. [Google Scholar] [CrossRef]

- Wu, H.; Chang, J.; Xu, G.; Shao, W.; Li, G.; Hou, J. In-Situ Emulsification and Viscosification System of Surfactant-Assisted Janus Nanofluid and Its Profile Control Effect. Adv. Geo-Energy Res. 2024, 14, 135–146. [Google Scholar] [CrossRef]

- Gong, H.; Zhang, H.; Xu, L.; Li, K.; Yu, L.; Li, Y.; Dong, M. Further Enhanced Oil Recovery by Branched-Preformed Particle Gel/HPAM/Surfactant Mixed Solutions after Polymer Flooding in Parallel-Sandpack Models. RSC Adv. 2017, 7, 39564–39575. [Google Scholar] [CrossRef]

- Yao, C.; Lei, G.; Li, L.; Gao, X. Selectivity of Pore-Scale Elastic Microspheres as a Novel Profile Control and Oil Displacement Agent. Energy Fuels 2012, 26, 5092–5101. [Google Scholar] [CrossRef]

- Li, X.; Yue, X.; Yue, T.; Yan, R.; Olaleye, O.E.; Shao, M. Novel Chemical Flood Combination of CSA Particles and Strong Emulsifying Surfactant in Heterogeneous Reservoirs. Colloids Surf. A Physicochem. Eng. Asp. 2021, 625, 126838. [Google Scholar] [CrossRef]

- Dai, C.; Liu, Y.; Zou, C.; You, Q.; Yang, S.; Zhao, M.; Zhao, G.; Wu, Y.; Sun, Y. Investigation on Matching Relationship between Dispersed Particle Gel (DPG) and Reservoir Pore-Throats for in-Depth Profile Control. Fuel 2017, 207, 109–120. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Y.; Zheng, A.; Sun, X.; Dong, X.; Li, D.; Zhang, Q. Experimental Investigation on Improving Steam Sweep Efficiency by Novel Particles in Heavy Oil Reservoirs. J. Pet. Sci. Eng. 2020, 193, 107429. [Google Scholar] [CrossRef]

- Ismailova, J.A.; Delikesheva, D.N.; Akhymbayeva, B.S.; Logvinenko, A.; Narikov, K.A. Improvement of Sweep Efficiency in a Heterogeneous Reservoir. Smart Sci. 2021, 9, 51–59. [Google Scholar] [CrossRef]

- Al-Bayati, D.; Saeedi, A.; Xie, Q.; Myers, M.B.; White, C. Influence of Permeability Heterogeneity on Miscible CO2 Flooding Efficiency in Sandstone Reservoirs: An Experimental Investigation. Transp. Porous Med. 2018, 125, 341–356. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, X.; Wu, Y.; Li, X. Enhanced Oil Recovery by Air-Foam Flooding System in Tight Oil Reservoirs: Study on the Profile-Controlling Mechanisms. J. Pet. Sci. Eng. 2017, 150, 208–216. [Google Scholar] [CrossRef]

- Wei, P.; Zheng, L.; Yang, M.; Wang, C.; Chang, Q.; Zhang, W. Fuzzy-Ball Fluid Self-Selective Profile Control for Enhanced Oil Recovery in Heterogeneous Reservoirs: The Techniques and the Mechanisms. Fuel 2020, 275, 117959. [Google Scholar] [CrossRef]

- Li, J.; Jiang, Z.; Wang, Y.; Zheng, J.; Huang, G. Stability, Seepage and Displacement Characteristics of Heterogeneous Branched-Preformed Particle Gels for Enhanced Oil Recovery. RSC Adv. 2018, 8, 4881–4889. [Google Scholar] [CrossRef]

- Ding, B.; Dong, M.; Chen, Z.; Kantzas, A. Enhanced Oil Recovery by Emulsion Injection in Heterogeneous Heavy Oil Reservoirs: Experiments, Modeling and Reservoir Simulation. J. Pet. Sci. Eng. 2022, 209, 109882. [Google Scholar] [CrossRef]

- Zhou, K.; Wu, D.; An, Z.; Liu, S. Selective Penetration and Profile Control Performance of Preformed Particle Gels for Heterogeneous Oil Reservoirs. Gels 2022, 8, 601. [Google Scholar] [CrossRef]

- Mwangupili, O.; Pu, C. Enhancing Oil Recovery in Vertical Heterogeneous Sandstone Reservoirs Using Low-Frequency Pulsating Water Injection. Processes 2025, 13, 296. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, F.; Zhang, S.; Ma, X. Experimental Research on Behavior of Spontaneous Imbibition and Displacement After Fracturing in Terrestrial Shale Oil Based on Nuclear Magnetic Resonance Measurements. Processes 2024, 12, 2685. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, Q.; Chen, G.; Liang, S.; Chen, L. Evaluation and Injection Parameter Optimization for Polymer Flooding with Different Kinds of Profile Control Agents. J. Chem. 2013, 2013, 370543. [Google Scholar] [CrossRef]

- Dong, L.; Wang, M.; He, J.; Ding, M.; Lin, H. Experimental Investigation of Self-Gathering Microsphere on Profile Control in Heterogeneous Reservoir. J. Pet. Sci. Eng. 2021, 205, 108826. [Google Scholar] [CrossRef]

- Shi, X.; Yue, X. Migration and Plugging Mechanisms of Self-Aggregated Microspheres as a Novel Profile Control. J. Pet. Sci. Eng. 2020, 184, 106458. [Google Scholar] [CrossRef]

- Li, J.; Niu, L.; Wu, W.; Sun, M. The Reservoir Adaptability and Oil Displacement Mechanism of Polymer Microspheres. Polymers 2020, 12, 885. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Qiao, C.; Ji, G.; Wang, Q.; Tao, L. Experimental Study of Profile Control with Foam Stabilized by Clay Particle and Surfactant. Energies 2019, 12, 781. [Google Scholar] [CrossRef]

- Zhao, G.; Dai, C.; Zhao, M. Investigation of the Profile Control Mechanisms of Dispersed Particle Gel. PLoS ONE 2014, 9, e100471. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Granick, S. Nanorheology of Aqueous Polyethylene Glycol (PEG). Macromolecules 2002, 35, 4017–4022. [Google Scholar] [CrossRef]

- Zhang, F.; Hou, B.; Wang, S.; Chen, H.; Yang, J.; Fan, H.; Gui, L. Study on the Profile Control and Oil Displacement Mechanism of a Polymer Nano-Microsphere for Oilfield. Energy Fuels 2023, 37, 2692–2701. [Google Scholar] [CrossRef]

- Jiaqi, L. Study on Heterogeneity Characteristics of Oil and Gas Reservoirs. IOP Conf. Ser. Earth Environ. Sci. 2019, 295, 052013. [Google Scholar] [CrossRef]

- Yin, N.; Qiao, Z.; Zhu, G.; Dai, J.; Shao, G.; Li, Y.; Luo, C.; Lv, Y.; Mao, Z. Heterogeneity of Porous Carbonate Reservoir and Its Influence on Water Injection Development—A Case Study from the Mishrif Formation in Y Oilfield, Middle East. Energy Explor. Exploit. 2025, 0, 01445987251327601. [Google Scholar] [CrossRef]

| Main Ion Concentrations (mg/L) | TDS (mg/L) | |||||

|---|---|---|---|---|---|---|

| K+ + Na+ | Mg2+ | Ca2+ | Cl− | SO42− | HCO3− | |

| 22,335.3 | 490.0 | 2344.5 | 39,776.6 | 120.7 | 196.1 | 65,203.1 |

| Type of Profile Control Agent | Liquid Permeability (mD) | Injection Pressure Increase (MPa) | Resistance Factor/FR | Plugging Efficiency (%) | |

|---|---|---|---|---|---|

| Before Profile Control and Water Flooding | After Profile Control and Water Flooding | ||||

| Gel Dispersion | 463.711 | 62.259 | 0.28 | 6.167 | 86.574 |

| PEG | 432.044 | 150.404 | 0.11 | 2.667 | 65.188 |

| Microsphere | 458.381 | 199.540 | 0.08 | 2.167 | 56.468 |

| Test Number | Permeability (mD) | Irreducible Water Saturation (%) | Injection Weight Percentage (%) | Injection Round | Gel Dispersion Injection Volume (PV) | Injection Pressure Increase (MPa) | Comprehensive Recovery Factor (%) (Cumulative) | ||

|---|---|---|---|---|---|---|---|---|---|

| Water Flooding | Gel Dispersion Flooding | Increase | |||||||

| 1-1 | 161/348/559 | 25.16 | 2 | 1 | 0.1 | 0.02 | 29.38 | 55.08 | 25.70 |

| 1-2 | 163/349/564 | 24.69 | 3 | 0.25 | 30.53 | 56.73 | 26.26 | ||

| 1-3 | 149/345/573 | 26.23 | 4 | 0.37 | 30.07 | 57.16 | 27.09 | ||

| 1-4 | 187/336/559 | 25.77 | 5 | 0.44 | 30.39 | 58.40 | 28.01 | ||

| 1-5 | 156/353/567 | 25.07 | 6 | 0.51 | 30.21 | 57.47 | 27.26 | ||

| 1-6 | 170/348/581 | 24.54 | 7 | 0.62 | 42 | 59.49 | 17.49 | ||

| Test Number | Permeability (mD) | Irreducible Water Saturation (%) | Injection Weight Percentage (%) | Injection Round | Gel Dispersion Injection Volume (PV) | Injection Pressure Increase (MPa) | Comprehensive Recovery Factor (%) (Cumulative) | ||

|---|---|---|---|---|---|---|---|---|---|

| Water Flooding | Gel Dispersion Flooding | Increase | |||||||

| 2-1 | 159/349/572 | 25.96 | 5 | 1 | 0.05 | 0.05 | 29.49 | 53.85 | 24.36 |

| 2-2 | 187/336/559 | 25.77 | 0.1 | 0.44 | 30.39 | 58.40 | 28.01 | ||

| 2-3 | 137/368/581 | 26.46 | 0.15 | 0.43 | 29.9 | 60.43 | 30.53 | ||

| 2-4 | 169/346/564 | 26.84 | 0.2 | 0.62 | 30.92 | 62.42 | 31.50 | ||

| 2-5 | 149/352/539 | 26.56 | 0.25 | 0.65 | 28.31 | 62.99 | 34.68 | ||

| 2-6 | 157/353/576 | 26.67 | 0.3 | 0.71 | 30.59 | 58.74 | 28.15 | ||

| Test Number | Permeability (mD) | Irreducible Water Saturation (%) | Injection Weight Percentage (%) | Number of Injection Rounds | Total Injection Volume of Gel Dispersion (PV) | Injection Pressure Increase (MPa) | Comprehensive Recovery Factor (%) (Cumulative) | ||

|---|---|---|---|---|---|---|---|---|---|

| Water Flooding | Gel Dispersion Flooding | Increase | |||||||

| 3-1 | 187/336/559 | 25.77 | 5 | 1 | 0.1 | 0.44 | 30.39 | 58.40 | 28.01 |

| 3-2 | 149/363/582 | 26.74 | 2 | 0.2 | 0.38 | 30.13 | 60.90 | 30.73 | |

| 3-3 | 151/367/574 | 25.90 | 3 | 0.3 | 0.3 | 30.18 | 61.27 | 31.09 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, W.; Wang, C.; Xu, S.; Jin, X.; Lei, Y. Optimization of Profile Control and Displacement Physical Simulation for Reservoirs with Intra-Layer Heterogeneity. Processes 2025, 13, 1898. https://doi.org/10.3390/pr13061898

Fu W, Wang C, Xu S, Jin X, Lei Y. Optimization of Profile Control and Displacement Physical Simulation for Reservoirs with Intra-Layer Heterogeneity. Processes. 2025; 13(6):1898. https://doi.org/10.3390/pr13061898

Chicago/Turabian StyleFu, Weijie, Changquan Wang, Shijing Xu, Xinke Jin, and Yunfei Lei. 2025. "Optimization of Profile Control and Displacement Physical Simulation for Reservoirs with Intra-Layer Heterogeneity" Processes 13, no. 6: 1898. https://doi.org/10.3390/pr13061898

APA StyleFu, W., Wang, C., Xu, S., Jin, X., & Lei, Y. (2025). Optimization of Profile Control and Displacement Physical Simulation for Reservoirs with Intra-Layer Heterogeneity. Processes, 13(6), 1898. https://doi.org/10.3390/pr13061898