3.1. Full Stress–Strain Curve

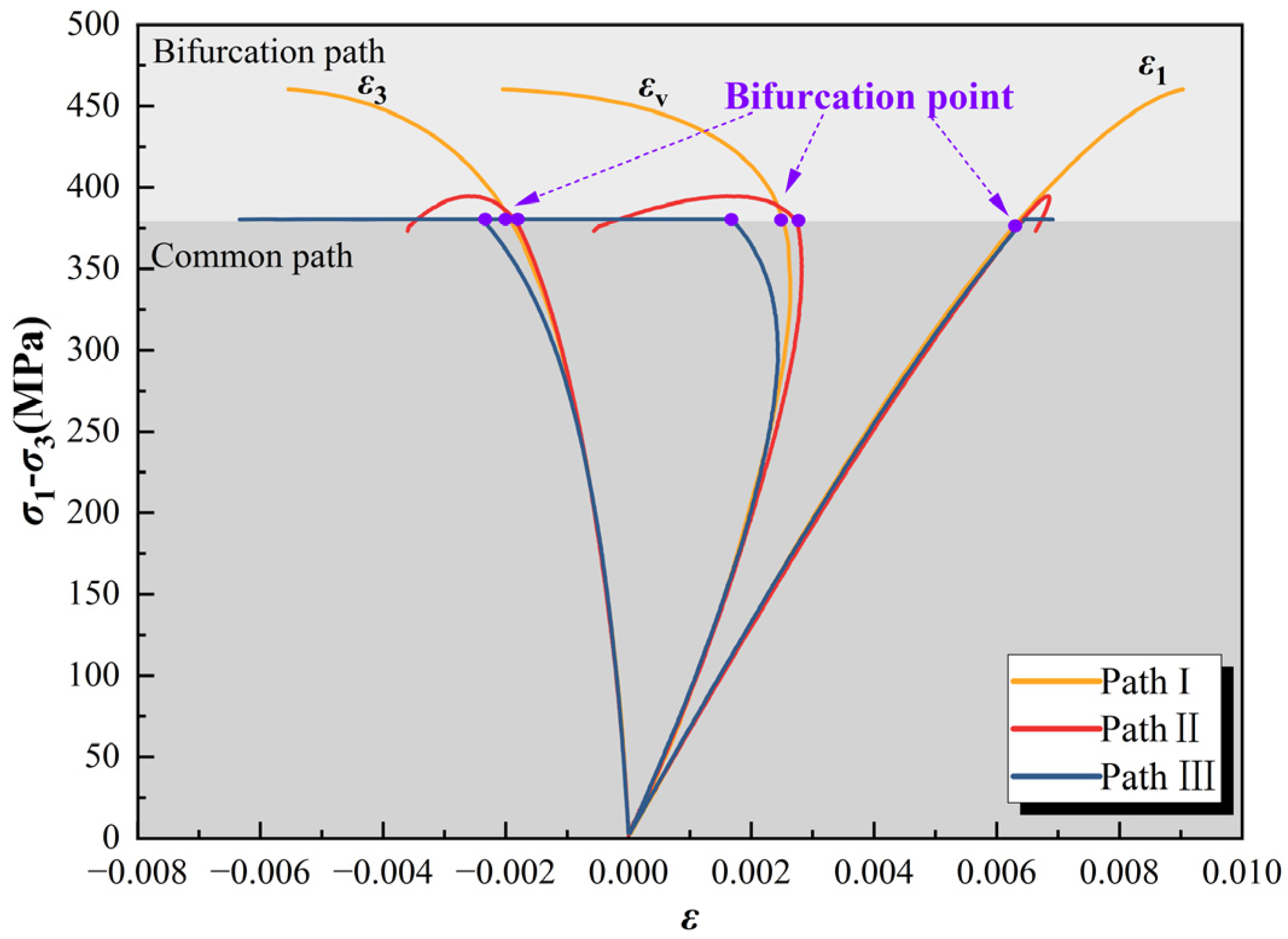

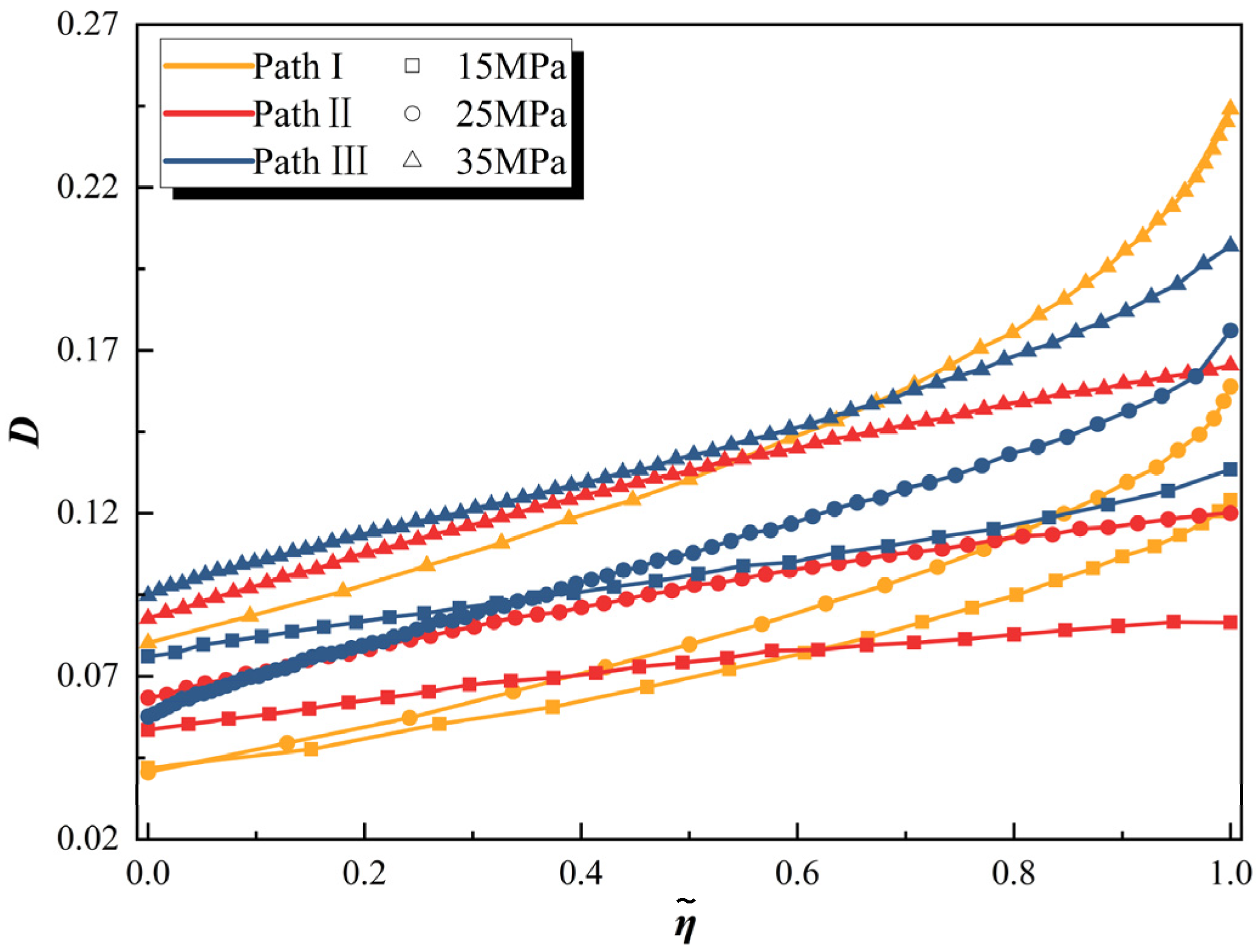

Figure 4 shows the stress–strain curves of different stress paths throughout the entire process, where

ε1,

ε3, and

εv are the axial, radial, and volumetric strains, respectively, and

εv =

ε1 + 2

ε3. The strains are all positive in compression and negative in tension.

- (1)

Stress path I

The full process curve of the axial strain shows that the specimen has fewer primary defects, and the characteristics of the pre-peak curve are basically the same under different initial confining pressures. The nonlinear characteristics of the crack compaction and propagation stages are not significant, and the overall behavior is linear elastic. However, as the initial confining pressure increases, the curve gradually exhibits yield characteristics near the peak stress, and the shape of the post-peak curve gradually changes from mode II to mode I, reducing axial rebound deformation and rock brittleness. When the initial confining pressure is 35 MPa, there is a strain softening phenomenon in the post-peak stage. After significant deformation (strain limit is 0.0276), it eventually enters the residual stage, but it is still brittle failure, far from reaching the confining pressure condition of brittle–ductile transformation.

The radial strain curve generally shows an accelerated growth trend in the pre-peak stage, but its acceleration characteristics are relatively weak before the proportional limit, approximately exhibiting linear growth. In addition, the growth rate of radial strain affected by confining pressure is relatively low, significantly lower than axial strain. When approaching the peak point, the slope of the curve rapidly decreases, showing a clear trend of accelerated growth. In the post-peak stage, as the stress decreases, the radial strain continues to increase until the specimen reaches the ultimate failure state.

The volumetric strain curve first shows a slowing growth trend along the compression direction in the pre-peak stage and, then, turns to the dilatancy direction after reaching the maximum compaction point, exhibiting an accelerated dilatancy trend. Under different initial confining pressure conditions, the stress peak points are in a state of volume dilatancy, and in the post-peak failure stage, the volume continues to increase.

- (2)

Stress path II

In the pre-peak stage, there is a significant linear relationship between axial strain and deviatoric stress, and the slope of the curve remains relatively constant after the bifurcation point. No yielding phenomenon was observed under different initial confining pressure conditions, showing strong elastic characteristics. In the post-peak stage, as the confining pressure decreases, the deviatoric stress undergoes a brittle drop, leading to the fracture of the specimen. After maintaining stable confining pressure, axial pressure continues to be applied, and the deviatoric stress slightly increases with the increase in axial strain. The curve shows a small strain strengthening characteristic, indicating that under the post-peak confining pressure holding condition, the rock still has a certain bearing capacity, and then the deviatoric stress falls again. Under different initial confining pressure conditions, rocks exhibit significant brittle failure characteristics, showing an overall trend of mode II curve development. However, as the initial confining pressure increases, its failure mode gradually evolves from direct brittle drop to multi-stage drop and eventually enters the strain-softening stage.

Before unloading, the radial strain curve has gradually deviated from a linear relationship. After unloading, the slope of the curve rapidly decreases and exhibits accelerated dilatancy characteristics along the unloading direction. However, because of the high stress level during unloading, the rock fractures after undergoing only small stress increments, resulting in a low radial strain value at the end of the unloading process. In the post-peak stage, with the occurrence of strain strengthening, brittle fracture, and strain softening, the radial strain increases rapidly.

Before unloading, the volumetric strain curve has begun to shift towards the direction of dilatancy. After unloading, its development rate further accelerates. However, when reaching the peak stress, the volumetric strain is still mainly in a compressed state, and the dilatancy characteristics are not yet obvious. In the post-peak stage, as the confining pressure further decreases, the rock gradually enters a state of volume dilatancy and shows a sharp increase trend before failure.

- (3)

Stress path III

Under constant deviatoric stress, the axial strain curve does not show a clear peak point. After unloading, the axial strain continues to increase and forms a stress plateau. When the confining pressure drops to a certain level, the deviatoric stress rapidly decreases. Under low confining pressure (15 MPa) conditions, axial deformation exhibits significant rebound characteristics. However, as the initial confining pressure increases, the rebound strength gradually weakens. Nonetheless, under different initial confining pressure conditions, the axial strain curve still exhibits typical mode II characteristics, without entering the strain-softening stage, ultimately leading to severe brittle failure. The above results indicate that, due to the high stress level during the unloading process, the rock specimen has already suffered some degree of damage before unloading. When the confining pressure is released while maintaining a constant deviatoric stress, the axial strain does not gradually decrease according to the elastic theory calculation results or the deformation characteristics of unloading at low stress levels [

57], until it sharply increases at the time of failure, but continues to increase from the beginning of unloading. This phenomenon indicates that cracks rapidly propagate during the unloading stage, causing compression deformation that exceeds unloading rebound deformation.

Before unloading, the radial strain and volumetric strain curves showed a clear trend of dilatation. After unloading, both curves extend in an approximately horizontal manner, but their growth rate significantly accelerates, and the magnitude of change far exceeds the axial strain. Prior to failure, the specimen undergoes significant lateral dilatancy, exhibiting a rapid dilatancy in volume.

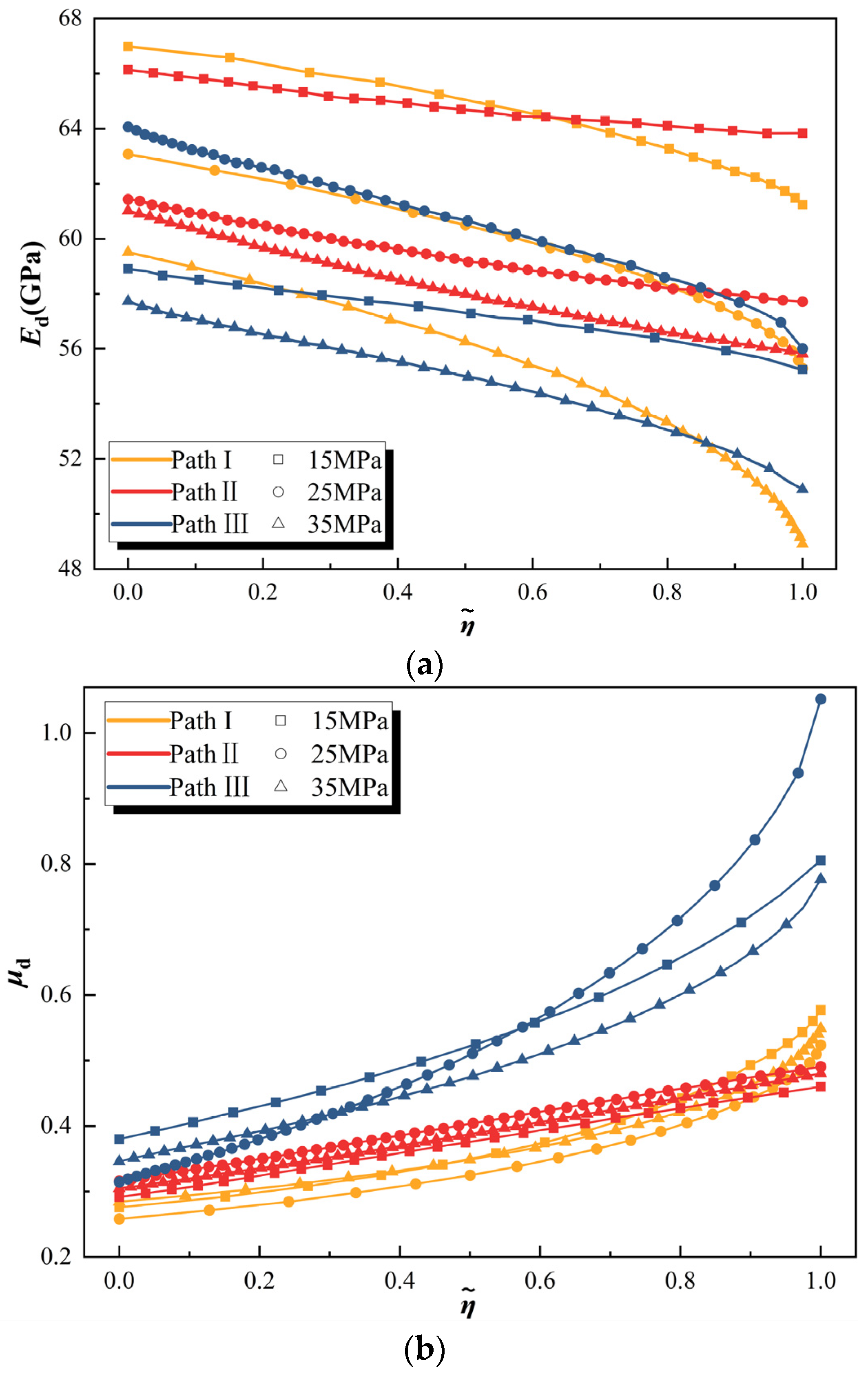

3.2. Comparison of Stress–Strain During Path Bifurcation Stage

From the above analysis, it can be seen that, under different stress path conditions, the stress–strain relationship curve of the specimen exhibits diverse variation characteristics. Among these, path III does not show obvious stress peaks, but all paths exhibit significant brittle failure characteristics. Therefore, in order to compare the effects of different stress paths on the mechanical response and failure behavior of the specimens, taking into account the evolution process of the stress states and referring to the research method in references [

58,

59], the state before brittle fracture is uniformly defined as the critical state. Therefore, when determining the critical point, the stability and controllability of the experimental loading and unloading process are used as the standard, and the determination methods for each path are different. Among them, the confining pressure of path I remains constant, and the peak point of its deviatoric stress is the critical point. Path II increases the axial pressure while unloading the confining pressure before brittle fracture, and the testing machine automatically stops unloading the confining pressure immediately after the fracture. Therefore, the critical point is determined by the termination of the unloading of the testing machine. The deviatoric stress of path III remains constant before the brittle drop, so the critical point can be determined by the sudden change in deviatoric stress from constant to drop. Based on this, quantitative comparative analysis can be conducted for the bifurcation stage of the path (from the bifurcation point to the critical point).

Figure 5 shows the stress–strain curves of different stress paths before the critical point under an initial confining pressure of 35 MPa. From this, it can be seen that, before the bifurcation point, due to the same stress paths, the curves basically coincide, especially the highly consistent linear elastic stage of each strain curve, indicating that the mechanical properties of the rock specimens used in the experiment are stable and have low discreteness. However, the curves during the bifurcation stage of the path show significant differences, exhibiting different mechanical response characteristics.

By analyzing the stress and strain values of the critical point in

Table 2 and referring to

Figure 4, it is evident that, under varying stress path conditions, the critical axial stress increases significantly with rising initial confining pressure. Additionally, the corresponding critical axial strain exhibits a near-linear growth trend. Furthermore, the critical radial strain exhibits a general upward trend as the initial confining pressure increases. The critical volumetric strain differs across the various paths. Specifically, for paths I and III, the critical volumetric strain progressively increases with a rising initial confining pressure, and the values are both below zero, suggesting that the sample is in an expanded state. Conversely, for path II, the critical volumetric strain progressively decreases with increasing initial confining pressure, and the values remain above zero, indicating the specimen is in a compressed state.

By comparing the critical stress–strain values of different paths under identical initial confining pressure conditions (with radial and volumetric strains defined as increasing in the dilatancy direction), the following observations can be made. The critical axial strain follows the order: path I > path III > path II; the critical radial strain follows: path III > path I > path II; and the critical volumetric strain also follows: path III > path I > path II. The critical axial stress exhibits the trend path I > path II > path III, with paths II and III demonstrating significantly lower critical axial stress than path I during the confining pressure unloading phase. Furthermore, the critical confining pressure follows the order: path I > path II > path III, suggesting that path II involves less confining pressure unloading at the time of failure compared to path III. Based on the aforementioned analysis of strain and stress under critical conditions, it can be inferred that rocks subjected to axial loading while unloading confining pressure are more susceptible to failure and display pronounced brittle behavior. Additionally, the deformation and dilatancy processes in these rocks do not fully develop prior to fracture.

Further analysis of the axial, radial, and volumetric strain increments (

Table 2) during the bifurcation stage of the path reveals that, under different stress path conditions, each strain increment is affected to varying degrees by the initial confining pressure and shows an increasing trend with the increase in initial confining pressure. Among them, the confining pressure effect of path I is the most significant; The axial strain increment of path II is relatively small, and the influence of the confining pressure on it is not obvious. Meanwhile, the radial and volumetric strain increments are positively correlated with the initial confining pressure. When the initial confining pressure of path III increases to a certain level (35 MPa), its influence on the strain increments gradually weakens.

There is a close relationship between strain increment and stress path. Among them, the axial strain increment of path I is significantly higher than that of path II and path III, reaching 6.30–14.30 times and 4.17–8.35 times of the latter, respectively. The radial strain increment of path III is the largest, which is 1.20–2.06 times that of path I and 2.88–4.89 times that of path II, respectively. In addition, path III has the highest degree of dilatancy, which is 1.61–3.13 times that of path I and 2.90–4.66 times that of path II, respectively. Further analysis shows that, during the process of unloading confining pressure, regardless of whether the axial pressure increases or decreases, the axial strain increment before the critical point is significantly lower than path I, where the confining pressure remains constant and only increases the axial pressure (

Figure 5). Especially in the case of unloading confining pressure while increasing the axial pressure, the axial strain increment is more limited. From this, it can be seen that changes in confining pressure have a significant impact on the development of axial strain. A decrease in confining pressure weakens the axial plastic deformation ability of the rock sample and further strengthens its brittle characteristics.

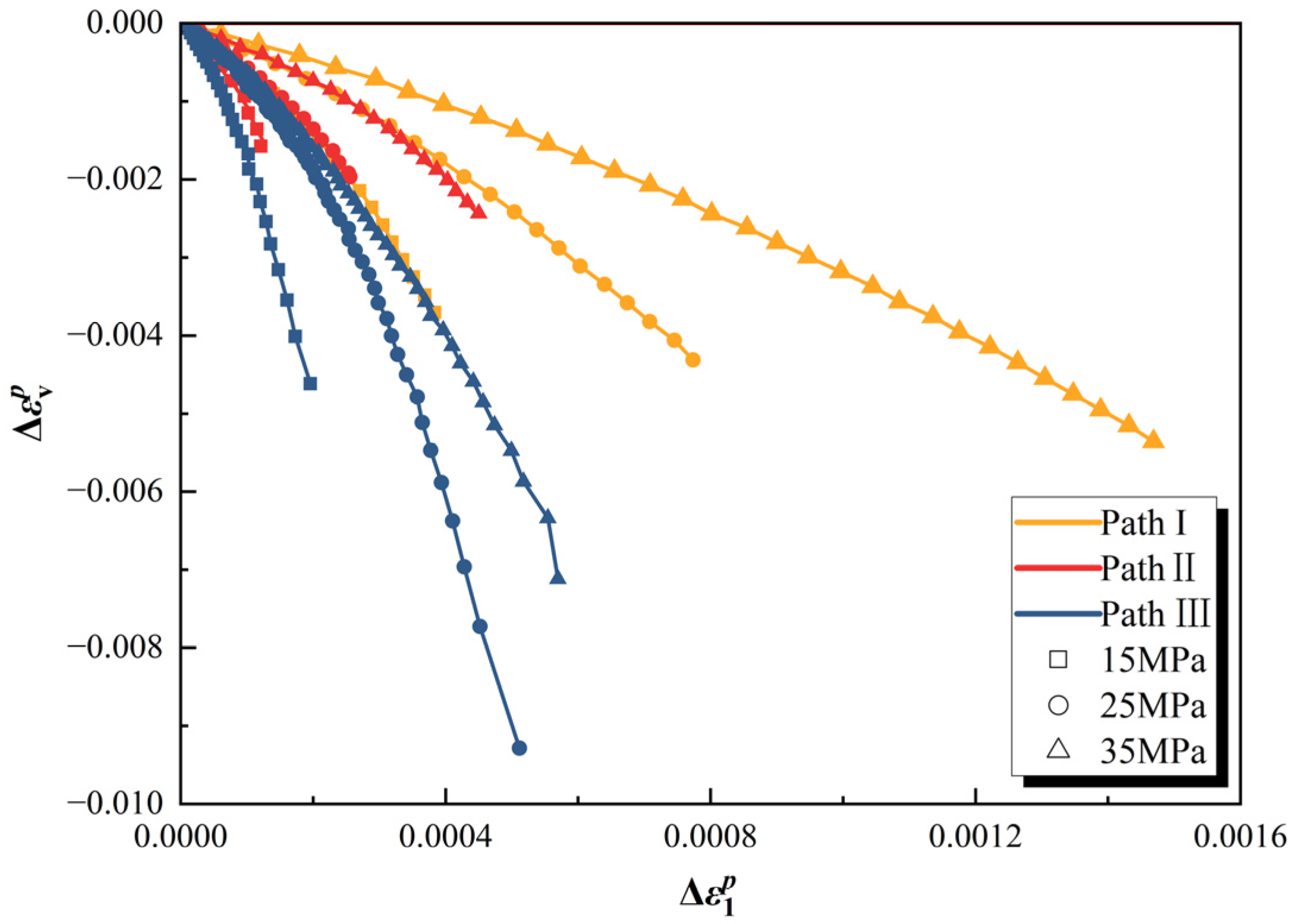

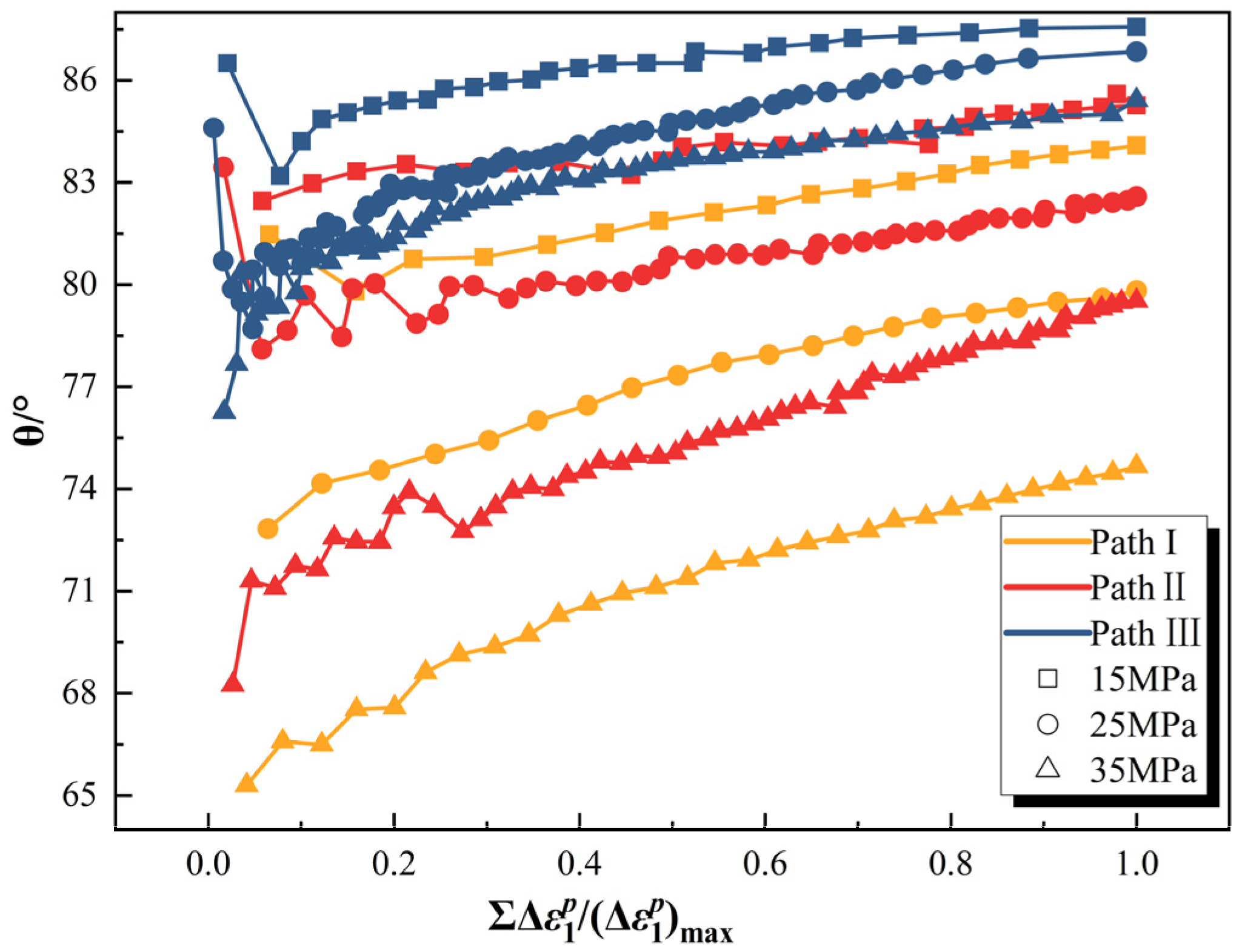

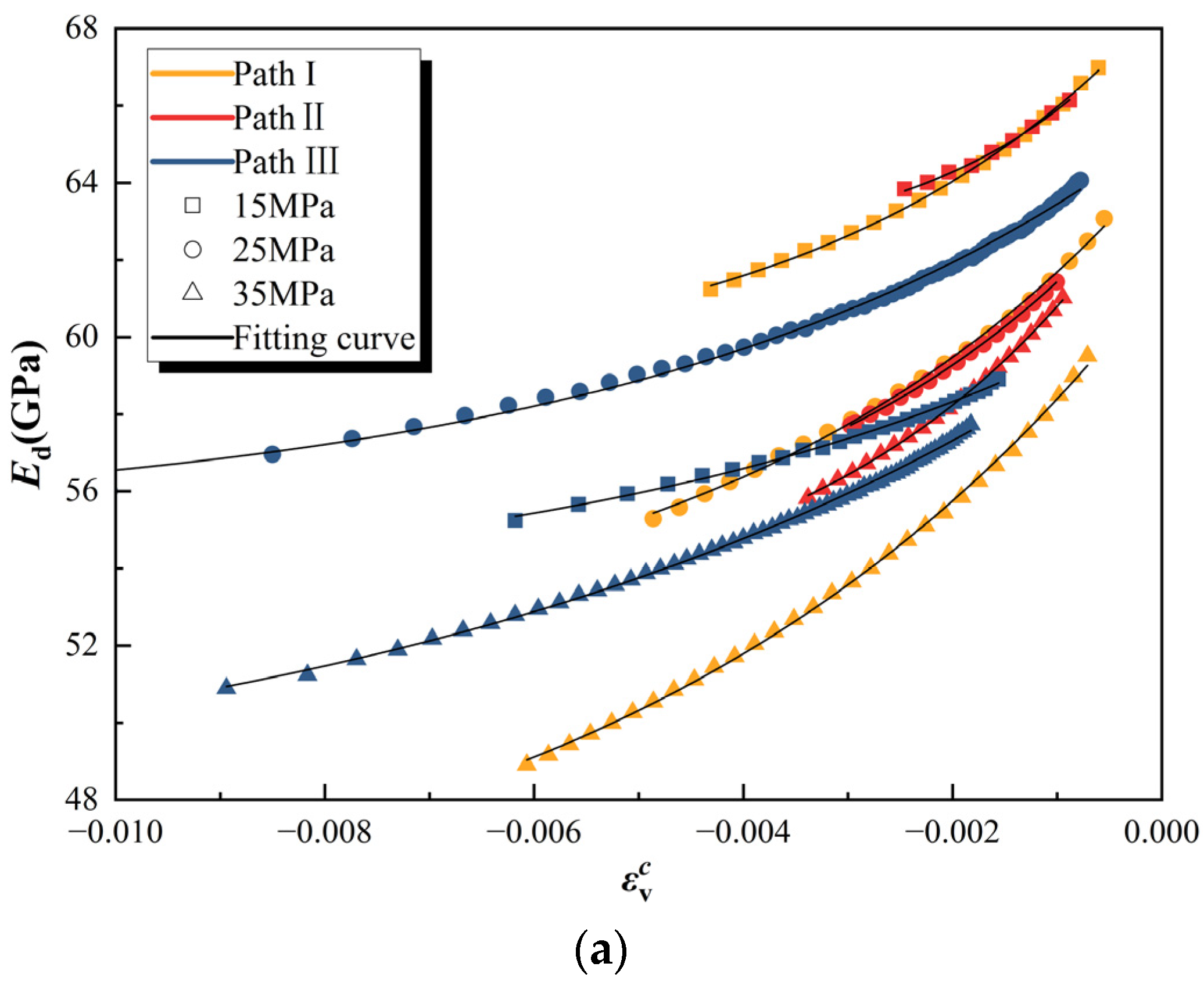

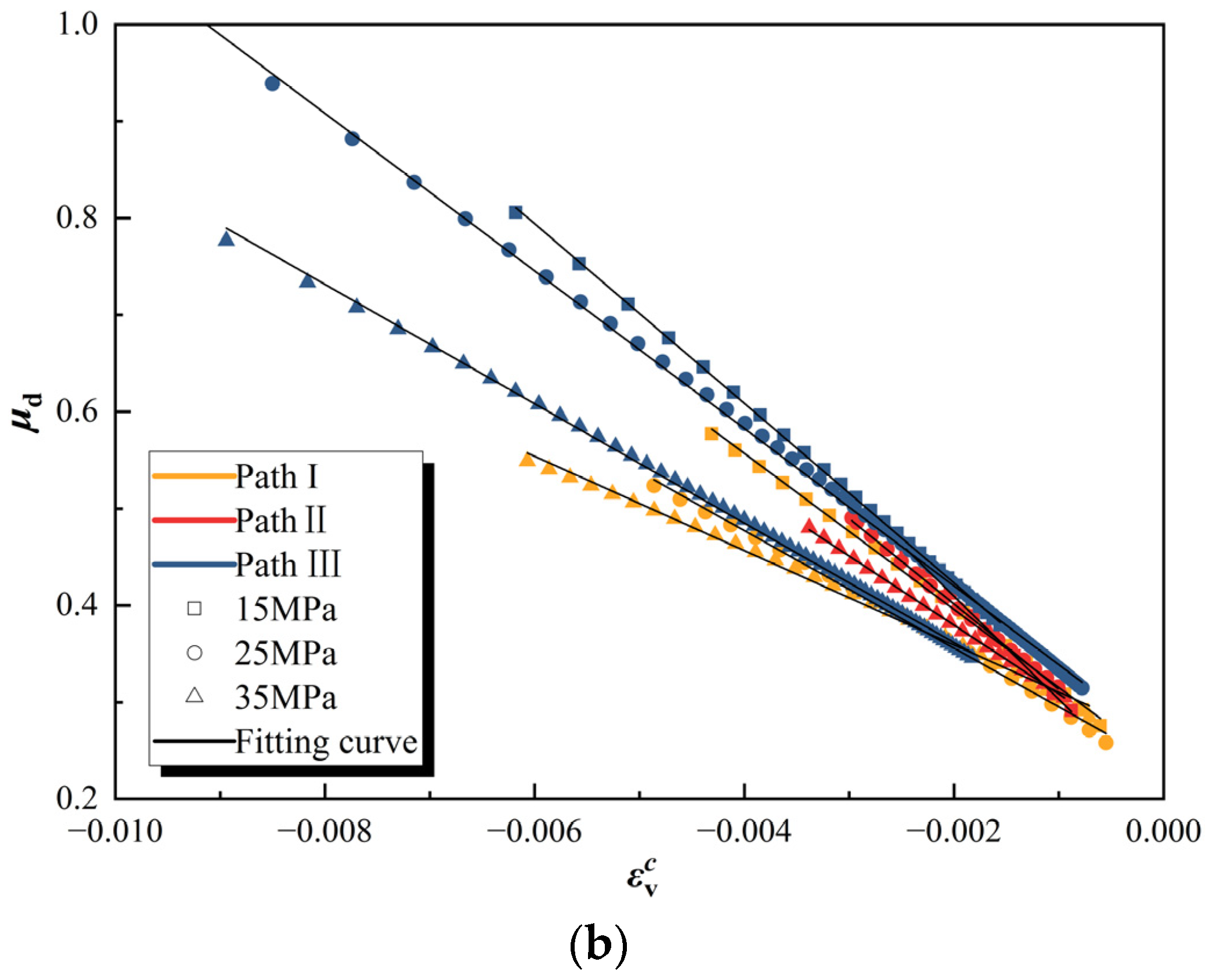

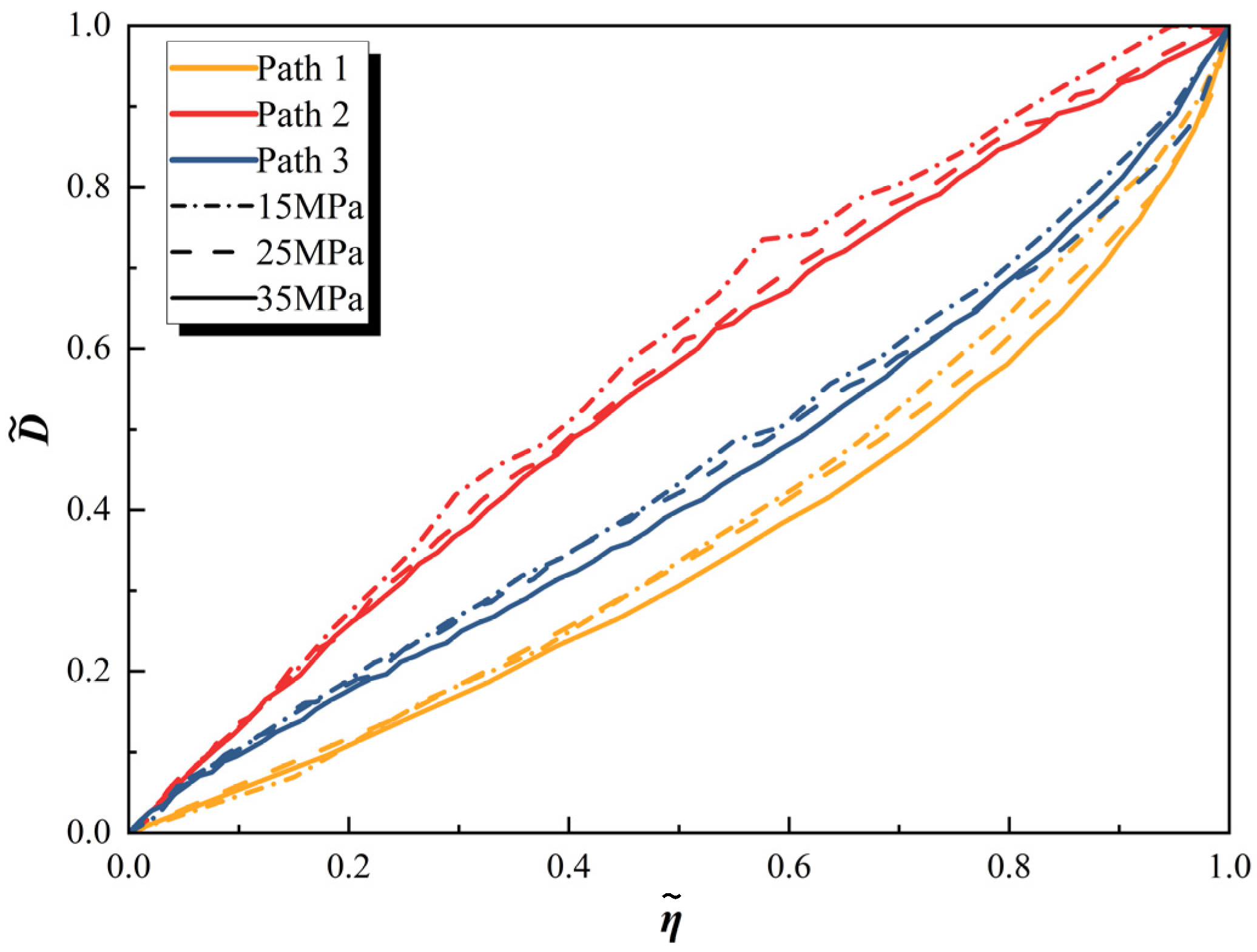

3.3. Relationship Between Various Strains

By comparing the absolute values of the different strain increments in

Table 2, it can be found that, under various stress path conditions, the axial strain increment is smaller than the radial strain increment and the volumetric strain increment. Specifically, the axial strain increment of path I is relatively large, ranging from 55.23% to ~73.78% of the radial strain increment, and gradually stabilizes with the increase in the initial confining pressure. The axial strain increment of path II is significantly lower than the radial strain increment, only ranging from 12.27% to ~21.62%; The axial strain increment of path III is the smallest, accounting for only 5.51%~10.96% of the radial strain increment, and this proportion increases with the increase in initial confining pressure. Radial deformation shows the most significant dominant role in path III. In summary, under different initial confining pressure conditions, the ratio relationship between axial and radial strain increments is as follows: path I > path II > path III.

Figure 6 shows the relationship curve between volumetric strain and axial strain before the critical point under different stress paths. An analysis shows that, under all path conditions, the volume of the specimen undergoes a transition from compression to dilatancy before the critical point and gradually tends to expand when reaching the critical point. In addition, after the bifurcation point, the curve shapes corresponding to different initial confining pressures on the same path exhibit good consistency, almost showing a parallel distribution. However, there are significant differences in the curve shapes under different stress paths. Specifically, under the condition of path I, the volume of the specimen smoothly transitions to the dilatancy stage after being compressed to the maximum compaction point, with a smooth curve and no obvious turning points. In contrast, the curves of path II and path III deviate at the bifurcation point, and the volumetric strain rapidly accelerates and turns towards the dilatancy state.

By comparing the curves after the bifurcation point, it can be found that, under the same axial strain conditions, the corresponding volumetric strain exhibits path I > path II > path III. This means that, when the same axial strain is reached, the dilatancy of path III is the largest, while the dilatancy of path I is the smallest. The average gradient of the curve after the bifurcation point, which is the ratio of the volumetric strain dilatancy increment to the axial strain increment (Δεv/Δε1), shows the following order under different paths: path III (17.24~35.29) > path II (8.46~16.33) > path I (1.70~2.62). In addition, during this stage, the axial strain growth of path III and path II is significantly lower than that of path I. This indicates that the dilatancy speed of path III is the fastest and most intense, while the dilatancy process of path I is the smoothest. Although path II exhibits a stronger dilatancy trend compared to path I, the overall dilatancy capacity at the critical point is actually lower for Path II due to the specimen being more susceptible to fracture when simultaneously unloading confining pressure and applying axial pressure. In addition, the analysis shows that all bifurcation points have exceeded the maximum compaction point, indicating that, when the stress path bifurcates, the rock has entered the stage of crack propagation, which is consistent with the high stress level and initial conditions for rock damage preset in this article.