Comprehensive Study on Viscosity-Increasing and Oil Displacement Characteristics of Functional Polymer

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Instruments

2.2. Experimental Materials

2.3. Experimental Methods

2.3.1. Emulsification Experiment

2.3.2. Comparison Experiment of Matching Relationship Between Hydrodynamic Characteristic Size and Reservoir

2.3.3. Polymer Retention Experiment in Porous Media

2.3.4. Core Flow Experiment

2.3.5. Core Oil Displacement Experiment

3. Results

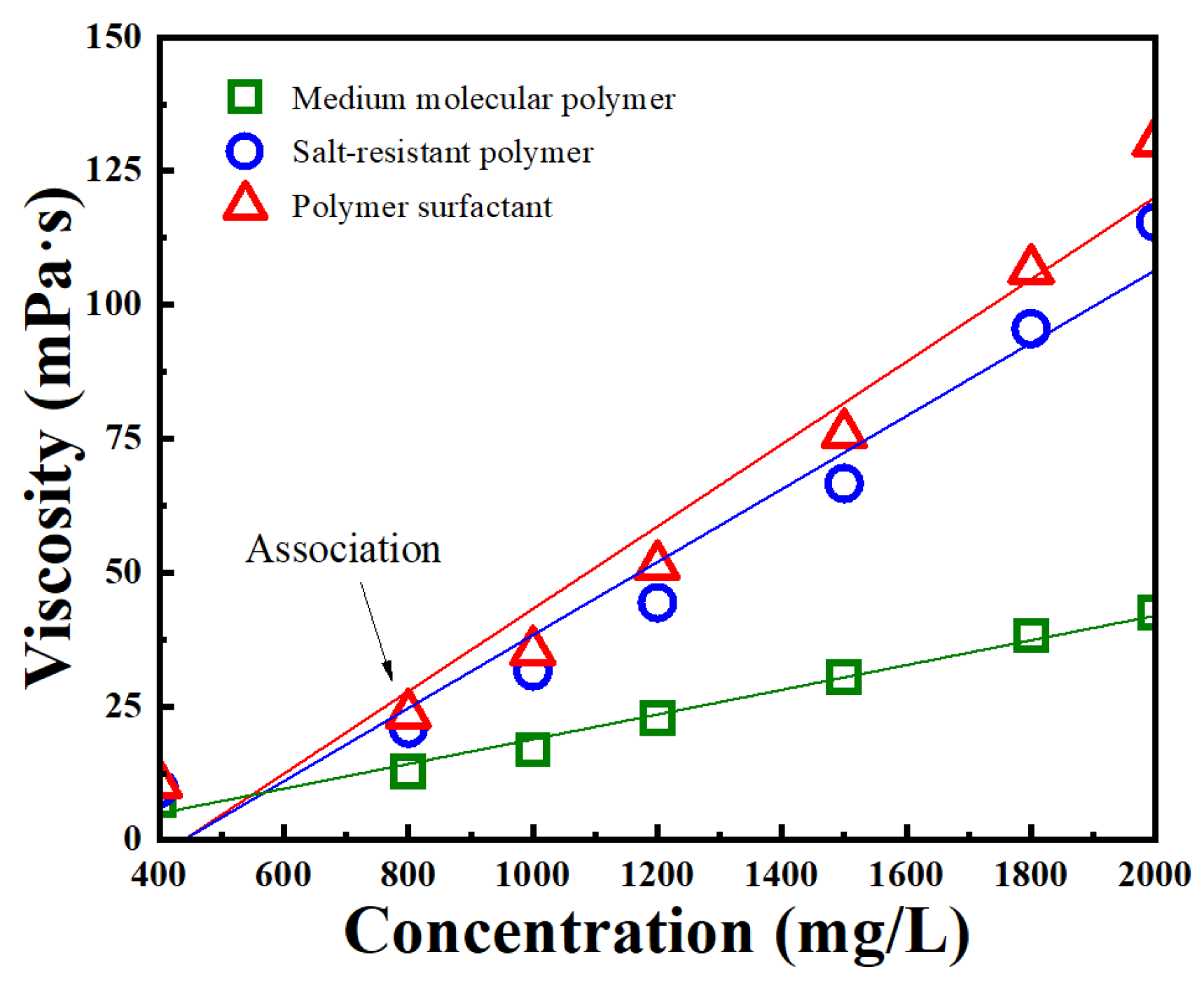

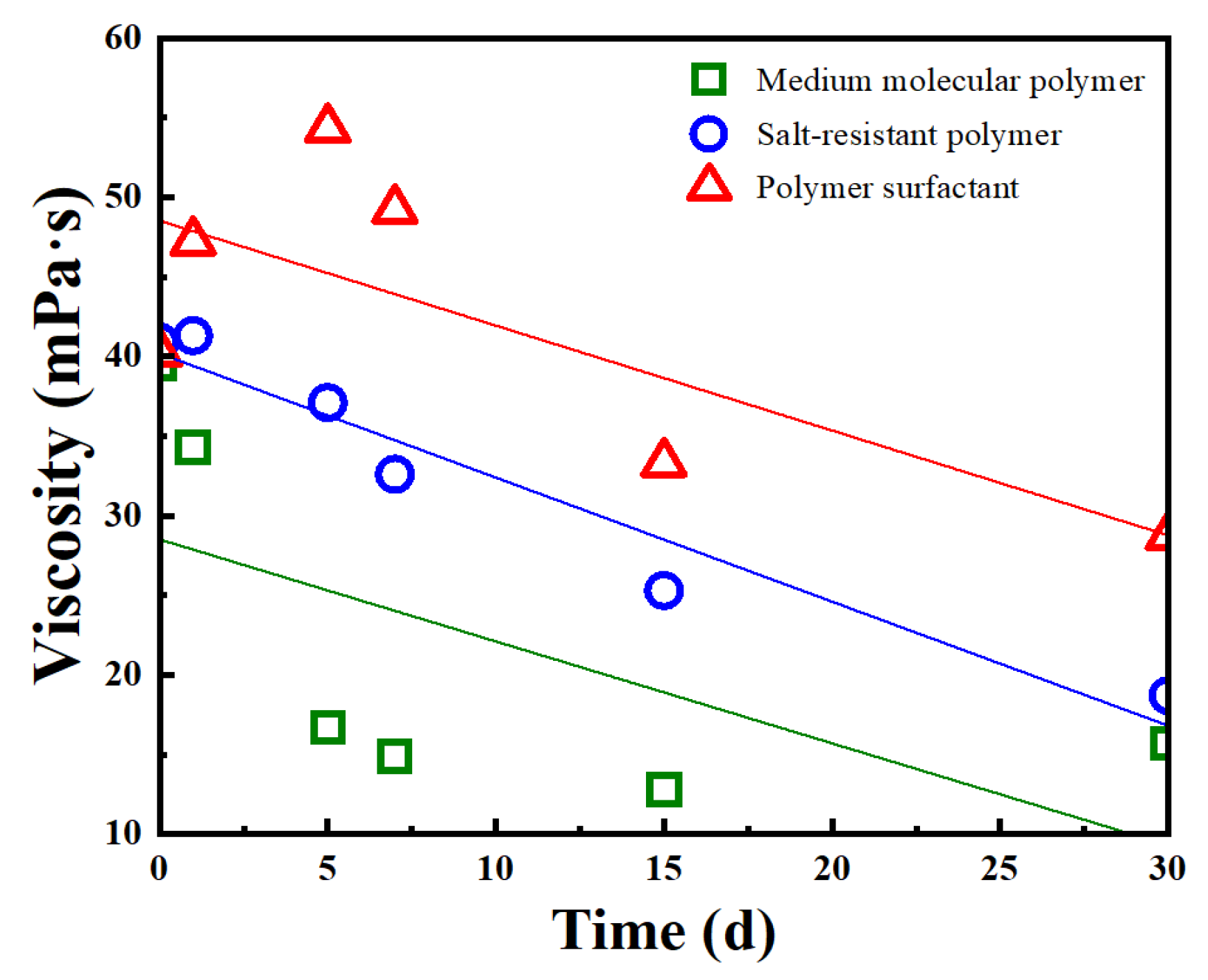

3.1. Viscosity Characteristics of Polymer

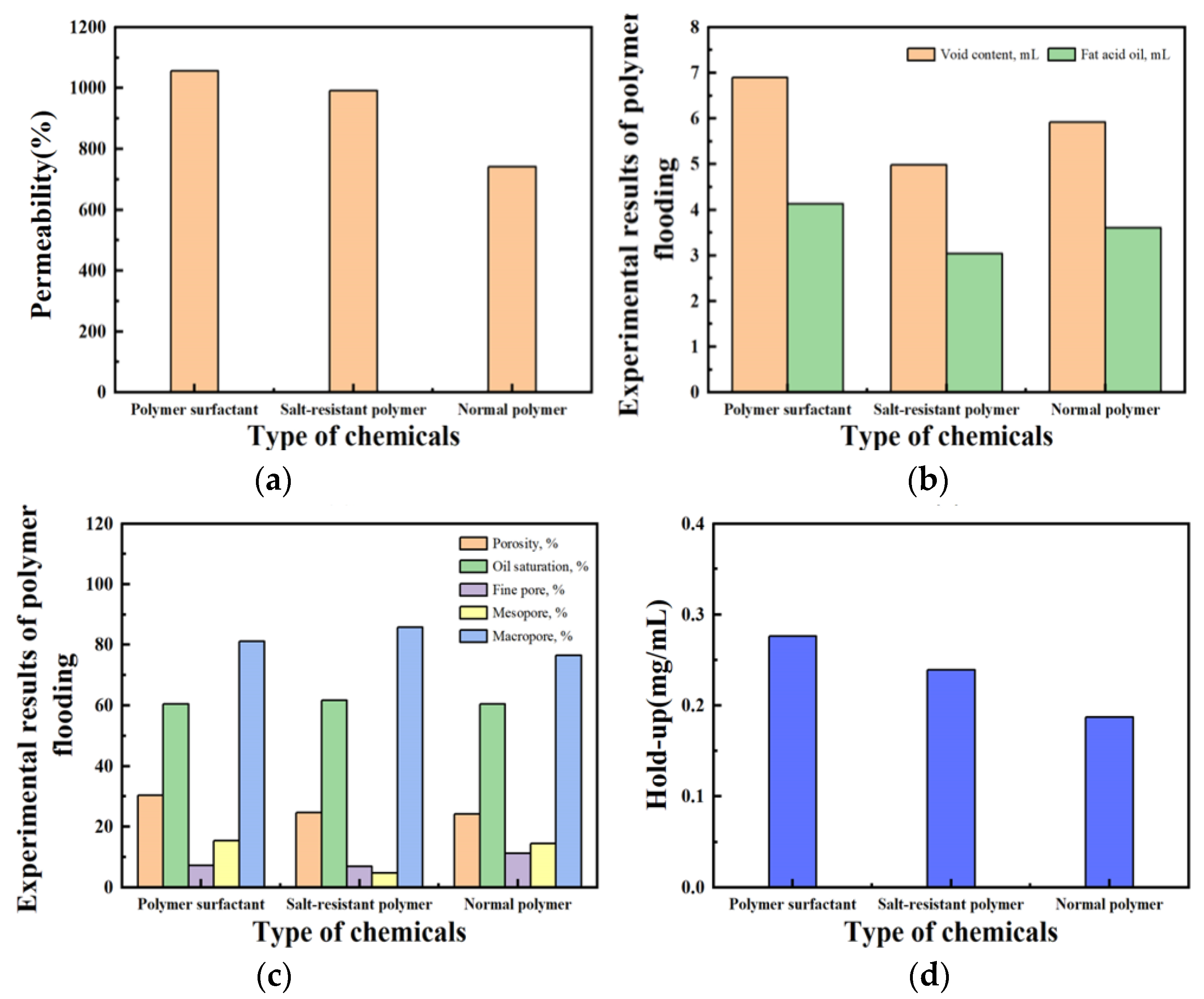

3.2. Evaluation of Polymer Transport Capacity

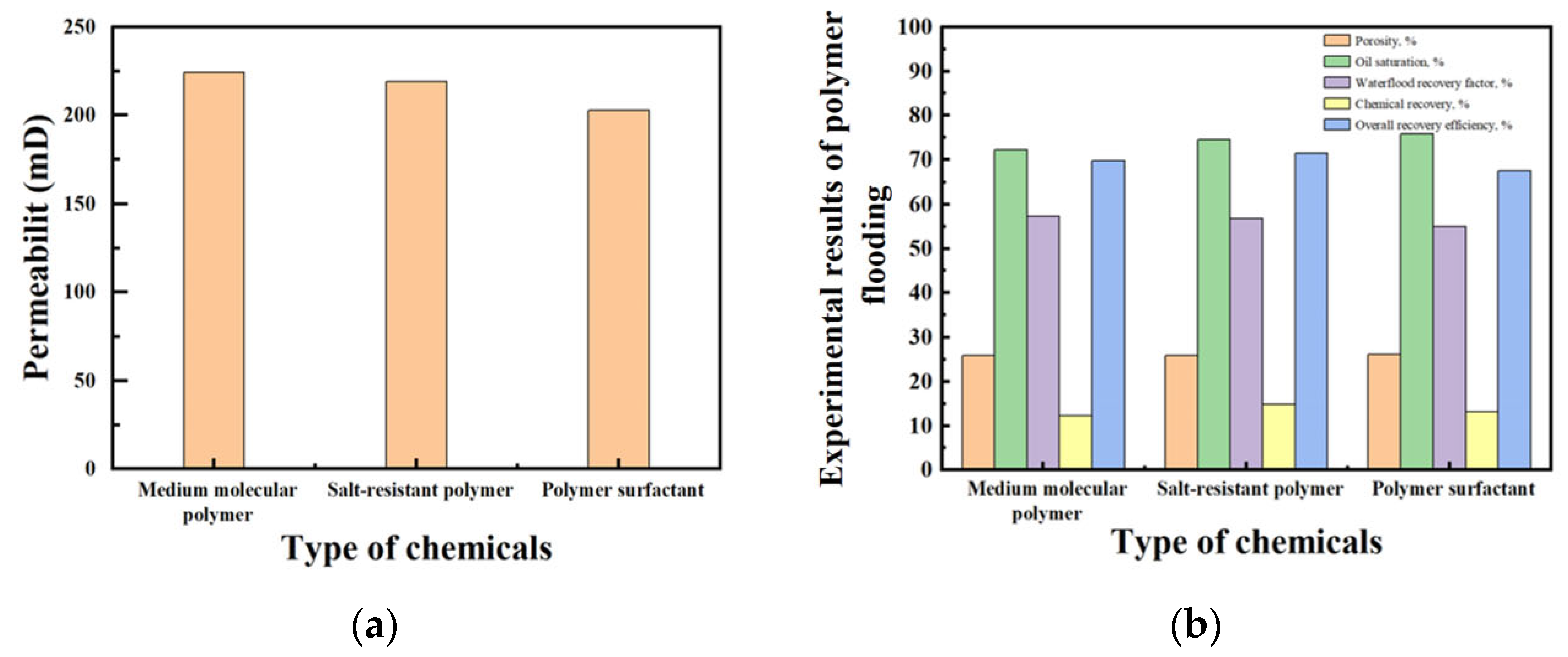

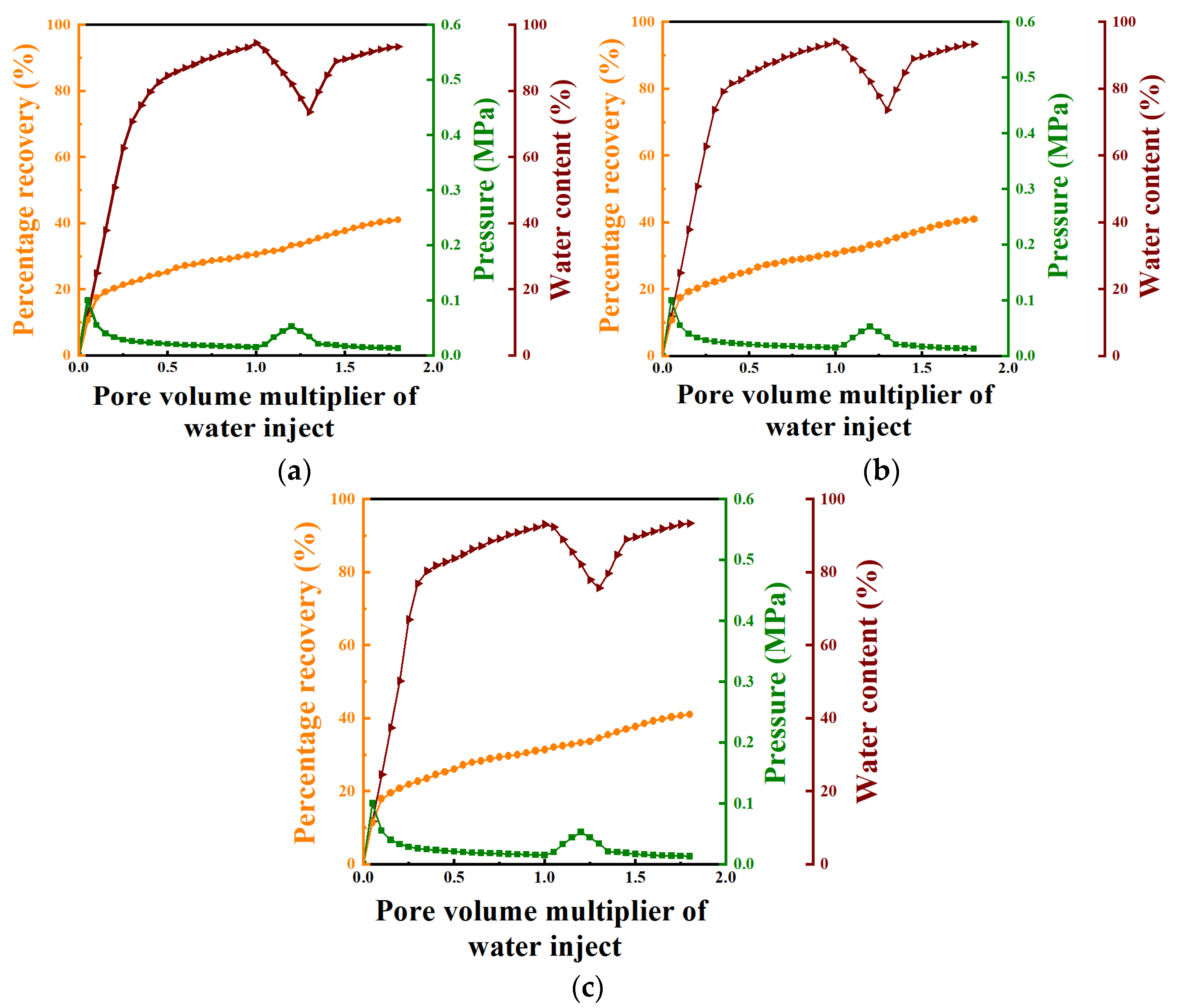

3.3. Evaluation of Oil Displacement Effect of Polymer Surfactant

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Seright, R.S.; Wang, D. Polymer flooding: Current status and future directions. Pet. Pet. Sci. 2023, 20, 910–921. [Google Scholar] [CrossRef]

- Kang, W.; Kang, X.; Lashari, Z.A.; Li, Z.; Zhou, B.; Yang, H.; Sarsenbekuly, B.; Aidarova, S. Progress of polymer gels for conformance control in oilfield. Adv. Colloid Interface Sci. 2021, 289, 102363. [Google Scholar] [CrossRef]

- Fang, Y.; Yang, E.; Guo, S.; Cui, C.; Zhou, C. Study on micro remaining oil distribution of polymer flooding in Class-II B oil layer of Daqing Oilfield. Energy 2022, 254, 124479. [Google Scholar] [CrossRef]

- De Vasconcelos, C.K.B.; Lopes, R.C.F.G.; Medeiros, F.S.; Viana, M.M.; Caliman, V.; Silva, G.G. Rheological and structural properties of nanofluids based on hydrolyzed polyacrylamide and aminated carbon nanotubes for enhanced oil recovery. Polymer 2024, 307, 127325. [Google Scholar] [CrossRef]

- Pal, N.; Vajpayee, M.; Mandal, A. Cationic/Nonionic Mixed Surfactants as Enhanced Oil Recovery Fluids: Influence of Mixed Micellization and Polymer Association on Interfacial, Rheological, and Rock-Wetting Characteristics. Energy Fuels 2019, 33, 6048–6059. [Google Scholar] [CrossRef]

- Fu, Y.; Shi, J.; Li, X.; Kang, W.; Aidarova, S.; Wang, Y. Study of viscosity reduction mechanism of oilfield polymer solution by spectroscopy method. J. Mol. Liq. 2024, 414, 126156. [Google Scholar] [CrossRef]

- Du, Y.; Zhu, Y.; Ji, Y.; Xu, H.; Zhang, H.; Yuan, S. Effect of salt-resistant monomers on viscosity of modified polymers based on the hydrolyzed poly-acrylamide (HPAM): A molecular dynamics study. J. Mol. Liq. 2021, 325, 115161. [Google Scholar] [CrossRef]

- Zhou, M.; Luo, H.; Huang, J.; Cheng, X. Anti-temperature anti-salinity nanospheres: Preparation, characterization, thermal stability, plugging ability and oil displacement. Geoenergy Sci. Eng. 2024, 234, 212533. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, M.; Huang, J.X.; Chen, X.; Luo, H. Preparation of polymer microspheres as oil displacement agent for extra-high temperature and extra-high salinity reservoirs. Colloids Surf. A Physicochem. Eng. Asp. 2024, 685, 133303. [Google Scholar] [CrossRef]

- Jiang, F.; Feng, X.; Hu, R.; Pang, S.; Pu, W. Synthesis of a novel double-tailed hydrophobically associating polymer for ultra-high salinity resistance. J. Mol. Liq. 2022, 367, 120470. [Google Scholar] [CrossRef]

- Zhang, M.; Kang, W.; Yang, H.; Li, Z.; Zhang, H.; Wang, F.; Li, M.; Kang, X.; Jiang, H.; Xie, A. Emulsion stabilization of cyclodextrin polymer inclusion amphiphilic polymers with different hydrophobic chain. J. Mol. Liq. 2021, 326, 115259. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, X.; Lv, K.; Liu, J.; Xiu, Z.; Wang, Z.; Huang, X.; Bai, Y.; Wang, J.; Jin, J. Synthesis of hydrophobic associative polymers to improve the rheological and filtration performance of drilling fluids under high temperature and high salinity conditions. J. Pet. Sci. Eng. 2022, 209, 109808. [Google Scholar] [CrossRef]

- Beteta, A.; Nurmi, L.; Rosati, L.; Hanski, S.; Mclver, K.; Sorbie, K.; Toivonen, S.K. Impact of Acrylate and 2-Acrylamido-Tertiary-Butyl Sulfonic Acid Content on the Enhanced Oil Recovery Performance of Synthetic Polymers. SPE J. 2021, 26, 2092–2113. [Google Scholar] [CrossRef]

- Dai, C.; Zhao, G.; You, Q.; Zhao, M.; Liu, Y.; Zhao, F. Chapter 6-DPG-strengthened polymer/surfactant combination flooding technology. In Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile Control; Elsevier: Amsterdam, The Netherlands, 2022; pp. 259–286. [Google Scholar]

- Khlaifat, A.L.; Fakher, S.; Harrison, G.H. Evaluating Factors Impacting Polymer Flooding in Hydrocarbon Reservoirs: Laboratory and Field-Scale Applications. Polymers 2024, 16, 75. [Google Scholar] [CrossRef] [PubMed]

- Zeynalli, M.; Mushtaq, M.; Al-Shalabi, E.W.; Alfazazi, U.; Hassan, A.M.; Alameri, W. A comprehensive review of viscoelastic polymer flooding in sandstone and carbonate rocks. Sci. Rep. 2023, 13, 17679. [Google Scholar] [CrossRef]

- Lei, M.; Huang, W.; Tong, Y.; Sun, J.; Jin, Z.; Li, X.; Chen, W. Synthesis and characterization of chitosan-based graft copolymers with temperature-switchable and self-adaptive plugging performance for drilling in microporous formation. J. Mol. Liq. 2022, 366, 120246. [Google Scholar] [CrossRef]

- Huang, X.; Sun, J.; Lv, K.; Liu, J.; Shen, H.; Zhang, F. Application of core-shell structural acrylic resin/nano-SiO2 composite in water based drilling fluid to plug shale pores. J. Nat. Gas Sci. Eng. 2018, 55, 418–425. [Google Scholar] [CrossRef]

- Idahosa, P.E.G.; Oluyemi, G.F.; Oyeneyin, M.B.; Prabhu, R. Rate-dependent polymer adsorption in porous media. J. Pet. Sci. Eng. 2016, 143, 65–71. [Google Scholar] [CrossRef]

- Wang, X.; Liu, W.; Shi, L.; Liang, X.; Wang, X.; Zhang, Y.; Wu, X.; Gong, Y.; Shi, X.; Qin, G. Application of a Novel Amphiphilic Polymer for Enhanced Offshore Heavy Oil Recovery: Mechanistic Study and Core Displacement Test. J. Pet. Sci. Eng. 2022, 215, 110626. [Google Scholar] [CrossRef]

- Jie, C.; Hu, M.; Cheng, Y.; Li, P.; Zhang, H.; Zang, L.; Guo, J. Design of degradable hybrid dual-crosslinked polymer for high-efficiency profile control in high temperature reservoirs. Colloids Surf. A Physicochem. Eng. Asp. 2024, 698, 134530. [Google Scholar] [CrossRef]

- Co, L.; Zhang, Z.; Ma, Q.; Watts, G.; Zhao, L.; Shuler, P.J.; Tang, Y. Evaluation of functionalized polymeric surfactants for EOR applications in the Illinois Basin. J. Pet. Sci. Eng. 2015, 134, 167–175. [Google Scholar] [CrossRef]

- Chen, Q.; Ye, M.; Wang, D.; Wang, Y.; Wang, Z.; Pu, W.; Wei, B. Active polymer flooding for strongly heterogeneous reservoir associate with foam combination technology. Geoenergy Sci. Eng. 2024, 242, 213288. [Google Scholar] [CrossRef]

- Liu, Y.; Hou, J.; Cao, X.; Wei, B.; Ji, Y.; Wang, H. Laboratory studies of the feasibility for microencapsulated polymer flooding. Fuel 2023, 354, 129378. [Google Scholar] [CrossRef]

- Ahmadi, Y.; Malekpour, M.; Kikhavani, T.; Bayati, B. The study of the spontaneous oil imbibition in the presence of new polymer-coated nanocomposites compatible with reservoir conditions. Pet. Sci. Technol. 2022, 42, 974–992. [Google Scholar] [CrossRef]

- Gao, S.; Lin, D.; Li, A.; Deng, L.; Dong, A.; Zhang, J. Synergistic effects of covalent crosslinking and hydrophobic association on enhancing thermal and salt resistance of polymeric filtrate reducer. J. Mol. Liq. 2024, 407, 125204. [Google Scholar] [CrossRef]

- Chu, Q.; Lin, L. Synthesis and properties of an improved agent with restricted viscosity and shearing strength in water-based drilling fluid. J. Pet. Sci. Eng. 2019, 173, 1254–1263. [Google Scholar] [CrossRef]

- Larin, D.E.; Shibaev, A.V.; Liu, C.; Emelyanenko, A.V. The effect of dynamic cross-links and mesogenic groups on the swelling and collapse of polymer gels. Giant 2024, 20, 100341. [Google Scholar] [CrossRef]

- Cheng, J.; Yang, H.; Gao, J.; Gu, X.; Yu, X.; Su, G.; Jiang, Z.; Zhu, Y. Synthesis and molecular dynamics simulation of amphoteric hydrophobically associating polymer. J. Mol. Liq. 2023, 388, 122751. [Google Scholar] [CrossRef]

- Zhang, Z.; Sun, L.; Liu, X.; Huo, X. Multi-supramolecular and double-network strategy improves rheological properties and oil displacement efficiency of polymers. Colloids Surf. A Physicochem. Eng. Asp. 2023, 678, 132445. [Google Scholar] [CrossRef]

- Chen, X.; Gao, Y.; Wang, Y.; Zhang, T.; Peng, Y. A study on the emulsification ability and oil displacement efficiency of polymeric surfactant in porous media. Colloids Surf. A Physicochem. Eng. Asp. 2024, 700, 134690. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, D.; Kang, W.; Wu, D.; Dong, Y.; Wang, J.; Yang, h.; Sarsenbekuly, B. Salt thickening performance and mechanism of an N-Vinyl-2-Pyrrolidinone based amphiphilic polymer. J. Mol. Liq. 2024, 408, 125277. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, J.; Jiang, H.; Bi, W.; Pan, S.; Li, H.; Sarsenbekuly, B.; Kang, W.; Zhang, X. Study on the rheological properties and salt resistance mechanism of an amphiphilic polymer with twin-tailed group. Colloids Surf. A Physicochem. Eng. Asp. 2024, 700, 134748. [Google Scholar] [CrossRef]

- Zhang, Q.; Mao, J.; Liao, Y.; Mao, J.; Yang, X.; Lin, C.; Wang, Q.; Huang, Z.; Xu, T.; Liu, B.; et al. Salt resistance study and molecular dynamics simulation of hydrophobic-association polymer with internal salt structure. J. Mol. Liq. 2022, 367, 120520. [Google Scholar] [CrossRef]

- Golab, E.G.; Ghamarpoor, R.; Kondori, F.J.; Hosseini, S.; Al-Saedi, H.N. Synthesis of hydrophobic polymeric surfactant (Polyacrylamide/Zwitterionic) and its effect on enhanced oil recovery (EOR). Chem. Phys. Impact 2024, 9, 100756. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, L.; Chen, H.; Zhao, N.; Chang, G.; Ren, H.; Cheng, H.; Wang, X.; Li, Z. Synergistic collaborations between surfactant and polymer for in-situ emulsification and mobility control to enhance heavy oil recovery. J. Mol. Liq. 2024, 406, 125113. [Google Scholar] [CrossRef]

| Water Sample | Title 2 Ion Content (mg·L−1) | Mineralization (mg·L−1) | ||||||

|---|---|---|---|---|---|---|---|---|

| Cl− | HCO3− | CO32− | SO42− | Ca2+ | Mg2+ | Na++K+ | ||

| Clear water | 70.9 | 87.5 | 57.6 | 12.5 | 30.1 | 2.5 | 83.5 | 344.6 |

| Deep sewage | 895.3 | 2379.2 | 300.5 | 48.1 | 44.2 | 2.4 | 1654.8 | 5324.5 |

| Simulated formation water | 2155.8 | 2063.5 | / | 287.5 | 23.1 | 52.6 | 2196.5 | 6779.0 |

| Scheme | Water Drive | Chemical Flooding | Subsequent Water Flooding |

|---|---|---|---|

| 1 | The water content is over 98%. | Common polymer, 0.70 PV | The water content is over 98%. |

| 2 | Salt-resistant polymer, 0.70 PV | ||

| 3 | Polymer surfactant, 0.70 PV |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, J.; Jin, X.; Liu, X.; Yuan, L.; Liu, R.; Chen, S.; Wu, H.; Yang, W.; Wang, J.; Zhang, H.; et al. Comprehensive Study on Viscosity-Increasing and Oil Displacement Characteristics of Functional Polymer. Processes 2025, 13, 1859. https://doi.org/10.3390/pr13061859

He J, Jin X, Liu X, Yuan L, Liu R, Chen S, Wu H, Yang W, Wang J, Zhang H, et al. Comprehensive Study on Viscosity-Increasing and Oil Displacement Characteristics of Functional Polymer. Processes. 2025; 13(6):1859. https://doi.org/10.3390/pr13061859

Chicago/Turabian StyleHe, Jingang, Xiangao Jin, Xiaoying Liu, Lin Yuan, Ruina Liu, Sian Chen, Hao Wu, Wei Yang, Jingyu Wang, Haixiang Zhang, and et al. 2025. "Comprehensive Study on Viscosity-Increasing and Oil Displacement Characteristics of Functional Polymer" Processes 13, no. 6: 1859. https://doi.org/10.3390/pr13061859

APA StyleHe, J., Jin, X., Liu, X., Yuan, L., Liu, R., Chen, S., Wu, H., Yang, W., Wang, J., Zhang, H., An, X., Fan, M., & Gan, B. (2025). Comprehensive Study on Viscosity-Increasing and Oil Displacement Characteristics of Functional Polymer. Processes, 13(6), 1859. https://doi.org/10.3390/pr13061859