Energy Storage: From Fundamental Principles to Industrial Applications

Abstract

1. Introduction

2. Methodology

3. Chemical Energy Storage: Concepts and Classification

3.1. Definition and Working Principles of Chemical Energy Storage

- Energy Conversion. Depending on the storage system, electrical energy is converted into chemical energy through processes such as electrochemical reactions or chemical syntheses of products with high energy potential. This process can be observed in batteries or fuel cells [23].

- Energy Storage. Chemical energy is stored in chemical substances such as electrolytes or metals, or gaseous fuels such as hydrogen. Taking into account the batteries, this process can be conducted through the movement of ions between an anode and a cathode in an electrolyte [24]. In other systems, energy storage is used to generate fuels such as ammonia, hydrogen, or synthetic methane [25].

- Energy Retrieval. When the stored energy is required, it is released by reversing the process. In batteries, the process involves connecting the power system to a reduction-oxidation reaction (REDOX), where the ions flow back, and the stored energy is discharged in the form of electrical energy useful for powering any electrical device [24]. In fuel cells, the storage system or chemical substance is subjected to a combustion reaction from which electricity, heat, and water are obtained [26].

3.2. Categorization of Chemical Energy Storage Systems

3.2.1. Electrochemical Storage: Batteries

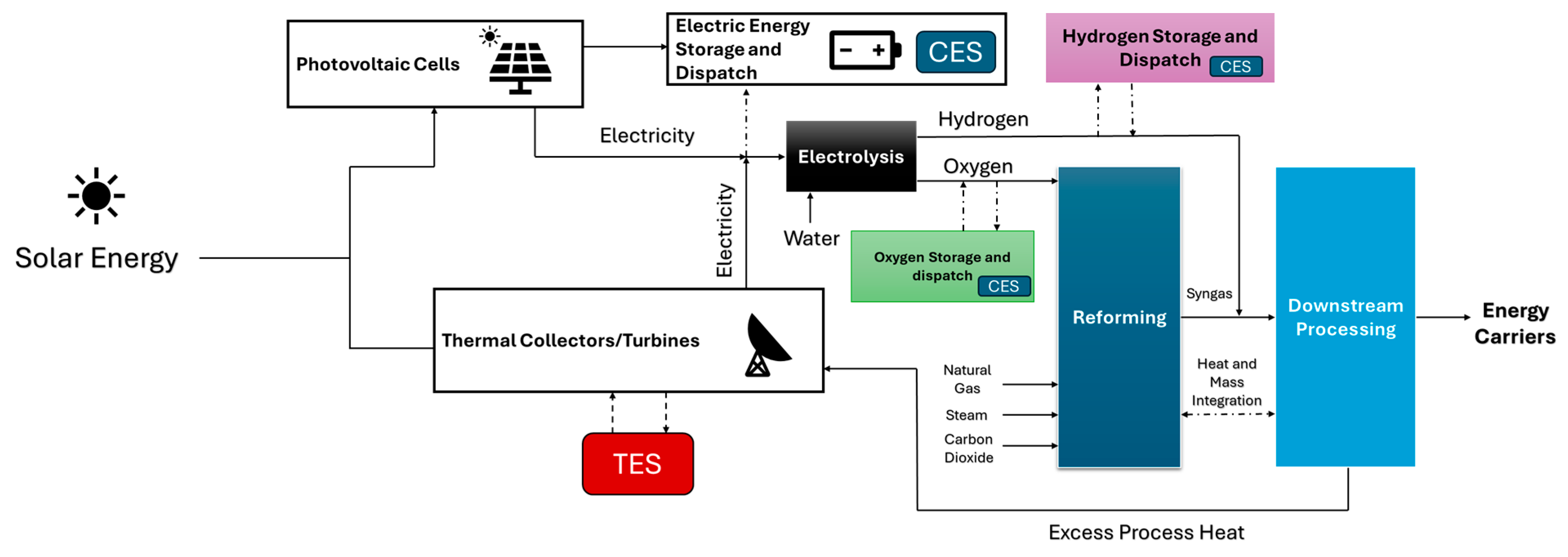

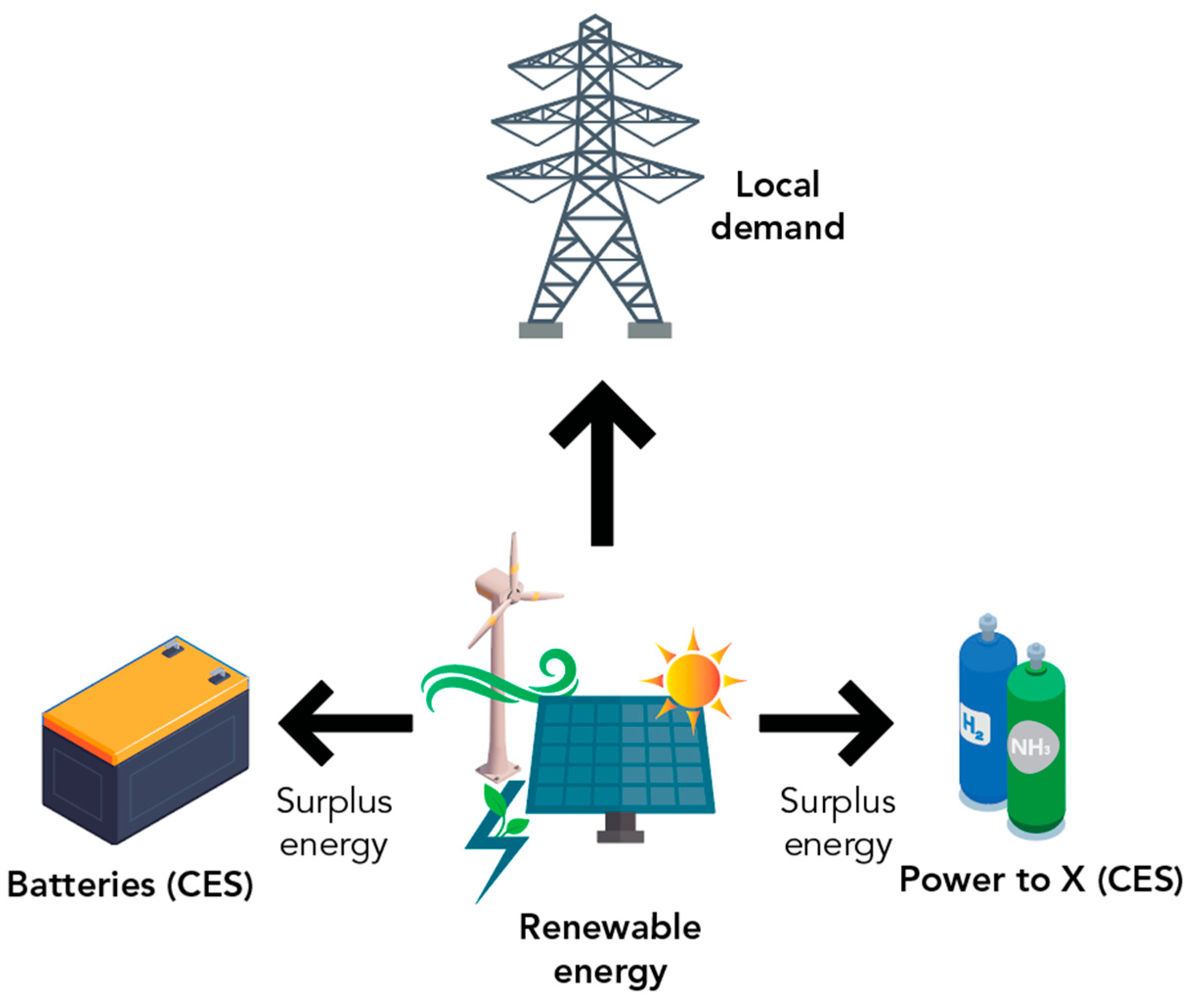

3.2.2. Power-to-X Technologies: Power-to-Gas and Power-to-Liquid

3.2.3. Hydrogen Storage Technologies

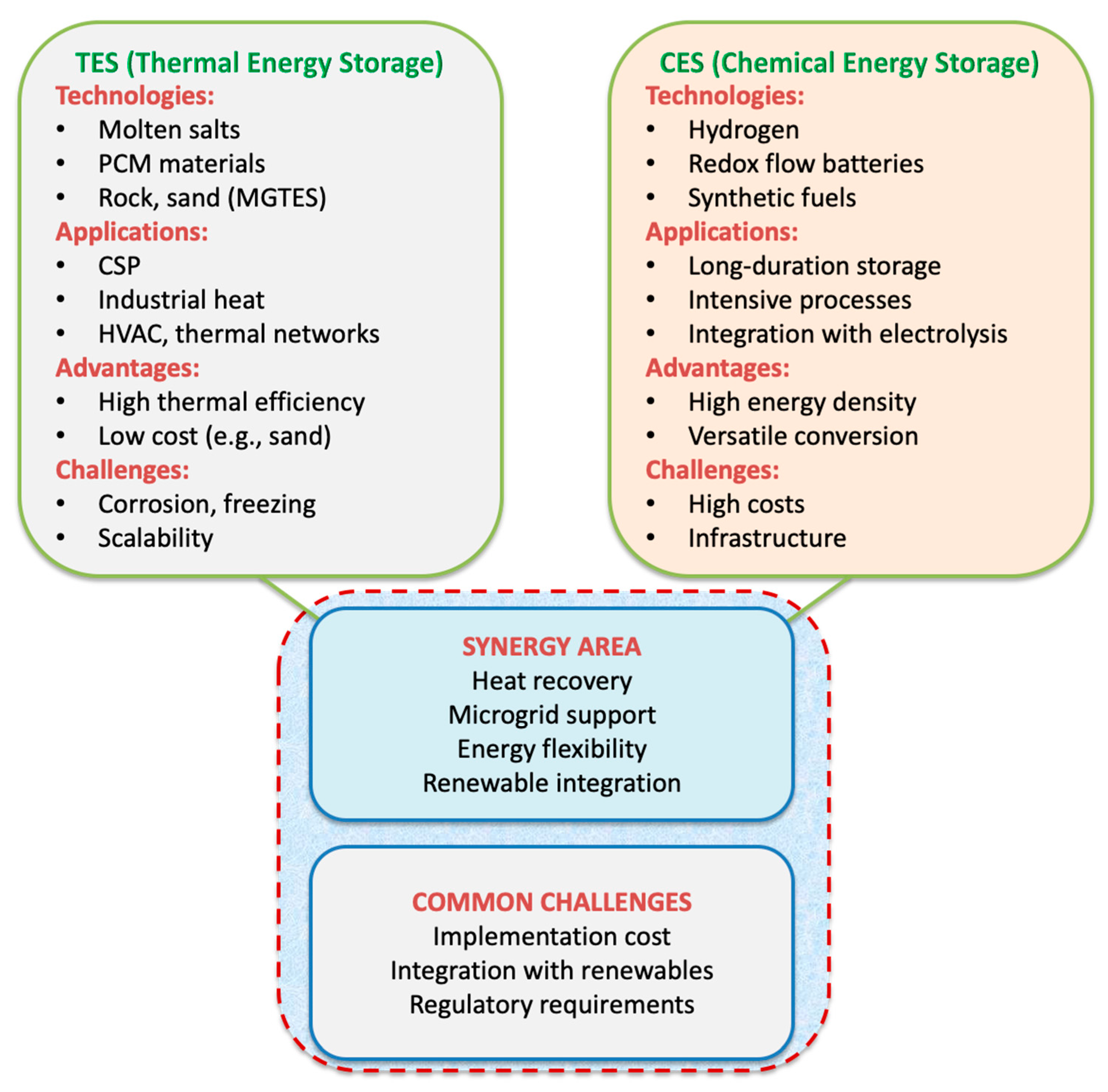

4. Power-to-Heat and Thermal Energy Storage

4.1. Thermal Energy Storage and Electro-Thermal Energy Storage

4.2. MGTES Technology (Fluidized Sand Bed): Principles to Industrial Applications

5. Industrial Applications of Chemical and Thermal Energy Storage

5.1. Decarbonization of Industrial Processes Using CES and TES

5.2. Sector-Specific Applications:

5.2.1. Heavy Industry (Steel, Cement, Glass)

5.2.2. Industrial Manufacturing

5.2.3. District Heating and CHP Plants

5.2.4. Impact and Challenges

6. Comparative Assessment of Storage Technologies

7. Challenges and Future Prospects

8. Conclusions

- ▪

- The advancement of ESS technologies is essential in order to mitigate the intermittency of renewable energy sources.

- ▪

- CES solutions, such as hydrogen storage and P2X strategies, offer long-term energy retention options allowing surplus renewable energy to be converted into valuable fuels and chemicals.

- ▪

- TES, on the other hand, provides immediate solutions for heat management, improving industrial efficiency and enabling waste heat recovery.

- ▪

- However, challenges remain in terms of material degradation, thermal stability, and large-scale implementation with the need for continued research into novel materials and system designs.

- ▪

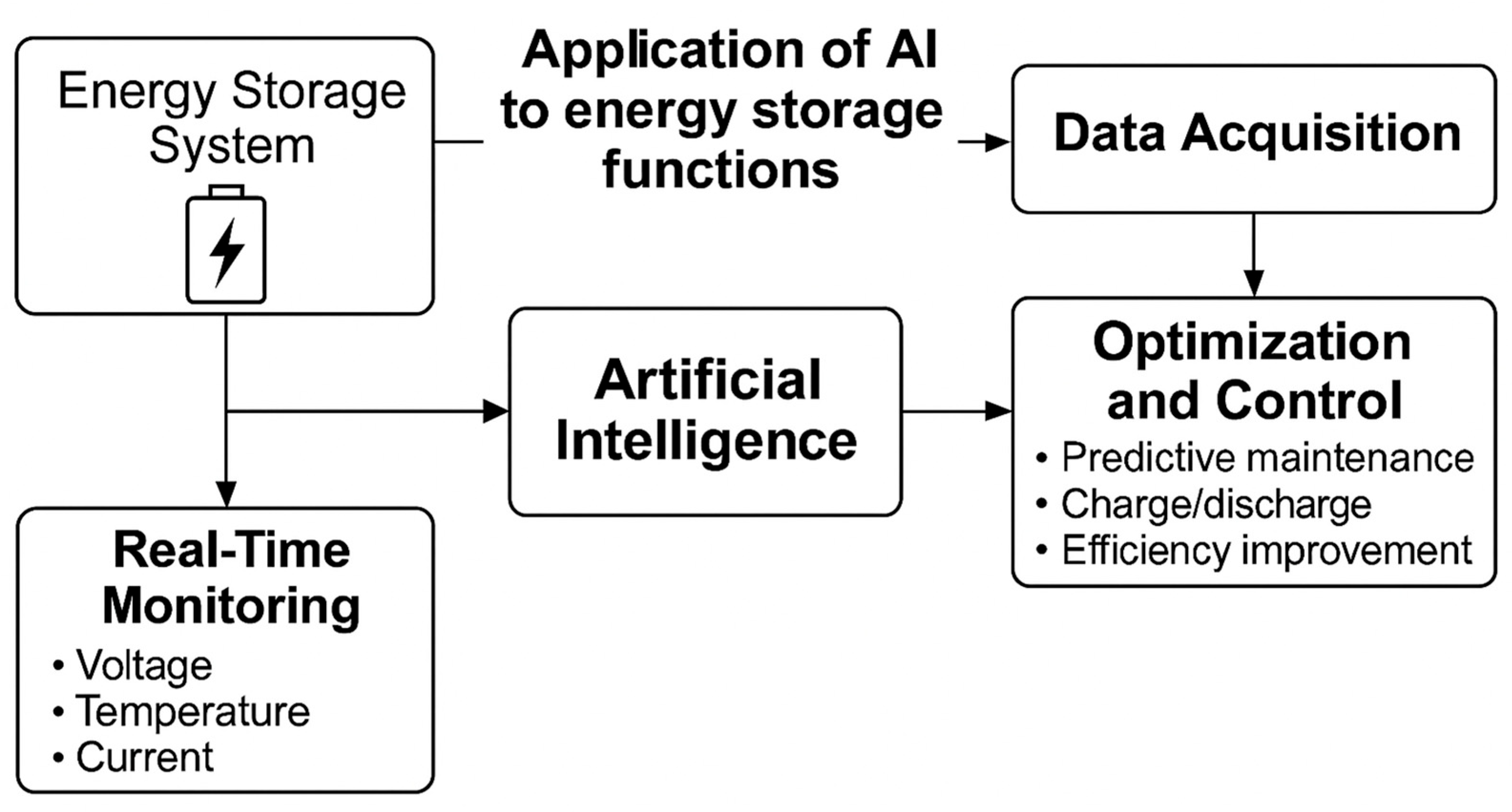

- AI and ML have demonstrated their potential in overcoming key limitations associated with ESS, particularly in predictive maintenance, real-time system monitoring, and energy demand forecasting.

- ▪

- Advanced analytics enable dynamic optimization of energy storage operations by identifying inefficiencies, predicting material degradation, and recommending adaptive control strategies.

- ▪

- These capabilities significantly improve the reliability and cost-effectiveness of CES and TES, addressing major barriers such as system lifespan, safety, and performance variability.

- ▪

- Beyond operational enhancements, AI-driven modeling and digital twins provide a framework to simulate large-scale deployment scenarios, assess the economic viability of emerging technologies, and guide strategic decision-making.

- ▪

- Reinforcement learning algorithms can dynamically adjust storage dispatch strategies based on fluctuating electricity prices, grid conditions, and renewable energy availability, thereby maximizing economic returns and minimizing emissions.

- ▪

- AI-enabled automation enhances safety measures in chemical storage systems and mitigates risks related to fires, leakage, and reactivity.

- ▪

- Despite technological advancements, regulatory and economic barriers still hinder the widespread adoption of ESS.

- ▪

- Policy incentives, investment in research, development, and industry collaborations are crucial to accelerate the transition into a decarbonized energy system.

- ▪

- The development of standardized frameworks for energy storage deployment, safety, and grid integration will also be essential in ensuring the long-term viability of these solutions.

- ▪

- The rising demand for sustainable energy solutions calls for interdisciplinary methods that merge advances in materials science, chemical engineering, and digital technologies to optimize ESS performance.

- ▪

- The convergence of AI, ML, and ESS constitutes a paradigm shift in energy management, transcending traditional storage limitations and paving the way for a more adaptive, efficient, and low-carbon energy landscape.

- ▪

- Future research should focus on refining AI-based control strategies, advancing hybrid storage architectures, and fostering interdisciplinary collaborations to bridge the gap between theoretical advancements and real-world deployment.

- ▪

- Moreover, efforts to enhance the economic feasibility, safety, and regulatory acceptance of ESS technologies will be instrumental in achieving a cleaner and more resilient global energy infrastructure.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| CES | Chemical Energy Storage |

| CHP | Combined Heat and Power |

| COP | Coefficient of Performance |

| DSM | Demand-Side Management |

| DMC | Dimethyl Carbonate |

| ESS | Energy Storage Systems |

| ETES | Electro-Thermal Energy Storage |

| EV | Electric Vehicle |

| IEA | International Energy Agency |

| LAES | Liquid Air Energy Storage |

| Li-ion | Lithium-Ion |

| LOHC | Liquid Organic Hydrogen Carrier |

| ML | Machine Learning |

| MGTES | Magaldi Green Thermal Energy Storage |

| P2G | Power-to-Gas |

| P2H | Power-to-Heat |

| P2L | Power-to-Liquid |

| P2X | Power-to-X |

| PCM | Phase-Change Materials |

| PtX | Power-to-X |

| REDOX | Reduction-Oxidation Reaction |

| TES | Thermal Energy Storage |

| VRFB | Vanadium Redox Flow Battery |

| WHR | Waste Heat Recovery |

References

- International Energy Agency (IEA). World Energy Outlook 2024. Available online: https://www.iea.org/reports/world-energy-outlook-2024 (accessed on 17 January 2025).

- Kona, A.; Bertoldi, P.; Monforti-Ferrario, F.; Rivas, S.; Dallemand, J.F. Covenant of mayors signatories leading the way towards 1.5 degree global warming pathway. Sustain. Cities Soc. 2018, 41, 568–575. [Google Scholar] [CrossRef]

- Ahmad, T.; Zhang, D. A critical review of comparative global historical energy consumption and future demand: The story told so far. Energy Rep. 2020, 6, 1973–1991. [Google Scholar] [CrossRef]

- Jafari, M.; Botterud, A.; Sakti, A. Decarbonizing power systems: A critical review of the role of energy storage. Renew. Sustain. Energy Rev. 2022, 158, 112077. [Google Scholar] [CrossRef]

- Sayed, E.T.; Olabi, A.G.; Alami, A.H.; Radwan, A.; Mdallal, A.; Rezk, A.; Abdelkareem, M.A. Renewable energy and energy storage systems. Energies 2023, 16, 1415. [Google Scholar] [CrossRef]

- Mitali, J.; Dhinakaran, S.; Mohamad, A.A. Energy storage systems: A review. Energy Storage Sav. 2022, 1, 166–216. [Google Scholar] [CrossRef]

- Zhu, Z.; Jiang, T.; Ali, M.; Meng, Y.; Jin, Y.; Cui, Y.; Chen, W. Rechargeable batteries for grid scale energy storage. Chem. Rev. 2022, 122, 16610–16751. [Google Scholar] [CrossRef]

- Sterner, M.; Specht, M. Power-to-gas and power-to-X—The history and results of developing a new storage concept. Energies 2021, 14, 6594. [Google Scholar] [CrossRef]

- Nady, S.; El Fadil, H.; Koundi, M.; Hamed, A.; Giri, F. Power to X systems: State-of-the-art (PTX). IFAC-PapersOnLine 2022, 55, 300–305. [Google Scholar] [CrossRef]

- Shojaei, S.M.; Aghamolaei, R.; Ghaani, M.R. Recent Advancements in Applying Machine Learning in Power-to-X Processes: A Literature Review. Sustainability 2024, 16, 9555. [Google Scholar] [CrossRef]

- Battaglia, V.; Vanoli, L. Optimizing renewable energy integration in new districts: Power-to-X strategies for improved efficiency and sustainability. Energy 2024, 305, 132312. [Google Scholar] [CrossRef]

- Al-Aboosi, A.F.; Al-Aboosi, F.Y.; El-Halwagi, M.; Zhan, W. Low carbon methanol production through electrification and decarbonization. Gas Sci. Eng. 2025, 136, 205562. [Google Scholar] [CrossRef]

- Maruf, M.N.I.; Morales-España, G.; Sijm, J.; Helistö, N.; Kiviluoma, J. Classification, potential role, and modeling of power-to-heat and thermal energy storage in energy systems: A review. Sustain. Energy Technol. Assess. 2022, 53, 102553. [Google Scholar] [CrossRef]

- Amiri, L.; Ermagan, H.; Kurnia, J.C.; Hassani, F.; Sasmito, A.P. Progress on rock thermal energy storage (RTES): A state of the art review. Energy Sci. Eng. 2024, 12, 410–437. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Alsharif, A.; Yasser, N. Recent advances in energy storage technologies. Int. J. Electr. Eng. Sustain. 2023, 1, 9–17. [Google Scholar]

- Larcher, D.; Tarascon, J.-M. Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 2015, 7, 19–29. [Google Scholar] [CrossRef]

- Westphal, I. The effects of reducing renewable power intermittency through portfolio diversification. Renew. Sustain. Energy Rev. 2024, 197, 114415. [Google Scholar] [CrossRef]

- Ullah, F.; Zhang, X.; Khan, M.; Mastoi, M.S.; Munir, H.M.; Flah, A.; Said, Y. A comprehensive review of wind power integration and energy storage technologies for modern grid frequency regulation. Heliyon 2024, 10, e30466. [Google Scholar] [CrossRef]

- Khan, M.I.; Asfand, F.; Al-Ghamdi, S.G. Progress in research and technological advancements of thermal energy storage systems for concentrated solar power. J. Energy Storage 2022, 55, 105860. [Google Scholar] [CrossRef]

- Koohi-Fayegh, S.; Rosen, M.A. A review of energy storage types, applications and recent developments. J. Energy Storage 2020, 27, 101047. [Google Scholar] [CrossRef]

- Ragupathy, P.; Bhat, S.D.; Kalaiselvi, N. Electrochemical energy storage and conversion: An overview. Wiley Interdiscip. Rev. Energy Environ. 2023, 12, e464. [Google Scholar] [CrossRef]

- Schmidt-Rohr, K. How Batteries Store and Release Energy: Explaining Basic Electrochemistry. J. Chem. Educ. 2018, 95, 1801–1810. [Google Scholar] [CrossRef]

- Bello, I.T.; Jolaoso, L.A.; Ahmed, R.A.; Bello, A. Electrochemical energy conversion and Storage Systems: A perspective on the challenges and opportunities for sustainable energy in Africa. Energy Rev. 2025, 4, 100109. [Google Scholar] [CrossRef]

- Goodenough, J.B.; Park, K.-S. The Li-Ion Rechargeable Battery: A Perspective. J. Am. Chem. Soc. 2013, 135, 1167–1176. [Google Scholar] [CrossRef]

- Jayalakshmi, N.S. Chapter 9—Study of Hybrid Photovoltaic/Fuel Cell System for Stand-Alone Applications. In Current Trends and Future Developments on (Bio-) Membranes; Basile, A., Cassano, A., Figoli, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 213–234. [Google Scholar] [CrossRef]

- Kurti, N. Panel on thermal and thermochemical energy storage chairman’s introductory remarks. In Energy Storage; Silverman, J., Ed.; Pergamon: Tarrytown, NY, USA, 1980; pp. 259–263. [Google Scholar] [CrossRef]

- Armand, M.; Tarascon, J.-M. Building better batteries. Nature 2008, 451, 652–657. [Google Scholar] [CrossRef]

- Dahiru, A.R.; Vuokila, A.; Huuhtanen, M. Recent development in Power-to-X: Part I-A review on techno-economic analysis. J. Energy Storage 2022, 56, 105861. [Google Scholar] [CrossRef]

- El-Halwagi, M.M.; Campbell, J.E. An Integrated and Tunable System for the Production of Syngas and Chemicals via Solar-Assisted Electrolysis and Combined Reforming. U.S. Patent Application No 16/962,440, 4 March 2021. [Google Scholar]

- Panu, M.; Zhang, C.; El-Halwagi, M.M.; Davies, M.; Moore, M. Integration of excess renewable energy with natural gas infrastructure for the production of hydrogen and chemicals. Process Integr. Optim. Sustain. 2021, 5, 487–504. [Google Scholar] [CrossRef]

- Rangarajan, S.S.; Sunddararaj, S.P.; Sudhakar, A.V.V.; Shiva, C.K.; Subramaniam, U.; Collins, E.R.; Senjyu, T. Lithium-ion batteries—The crux of electric vehicles with opportunities and challenges. Clean Technol. 2022, 4, 908–930. [Google Scholar] [CrossRef]

- Koech, A.K.; Mwandila, G.; Mulolani, F.; Mwaanga, P. Lithium-ion battery fundamentals and exploration of cathode materials: A review. S. Afr. J. Chem. Eng. 2024, 50, 321–339. [Google Scholar] [CrossRef]

- Eaton. Lithium-Ion UPS Battery Backup Explained. Available online: https://www.eaton.com/us/en-us/products/backup-power-ups-surge-it-power-distribution/backup-power-ups/lithium-ion-batteries-/lithium-ion-explained.html (accessed on 28 January 2025).

- Daniel, M.; Byron, N.P.; Krowne, C.M. Harnessing redox flow batteries for industrial applications: Opportunities and future directions. J. Power Sources 2024, 591, 233889. [Google Scholar] [CrossRef]

- Roth, C.; Noack, J.; Skyllas-Kazacos, M. Flow Batteries: From Fundamentals to Applications, 3 Volume Set; Wiley-VCH: Weinheim, Germany, 2023; pp. 1–1244. [Google Scholar]

- Moa, E.H.Y.; Go, Y.I. Large-scale energy storage system: Safety and risk assessment. Sustain. Energy Res. 2023, 10, 13. [Google Scholar] [CrossRef]

- Hossain, E.; Faruque, H.M.R.; Sunny, M.S.H.; Mohammad, N.; Nawar, N. A comprehensive review on energy storage systems: Types, comparison, current scenario, applications, barriers, and potential solutions, policies, and future prospects. Energies 2020, 13, 3651. [Google Scholar] [CrossRef]

- Behabtu, H.A.; Messagie, M.; Coosemans, T.; Berecibar, M.; Anlay Fante, K.; Kebede, A.A.; Mierlo, J.V. A review of energy storage technologies’ application potentials in renewable energy sources grid integration. Sustainability 2020, 12, 10511. [Google Scholar] [CrossRef]

- Flash Battery. Solid-State Batteries: How They Work. Available online: https://www.flashbattery.tech/en/how-solid-state-batteries-work/ (accessed on 15 January 2025).

- Froese, M. Advancing Solid-State Batteries for the Aviation and Maritime Sectors. EV Engineering & Infrastructure. Available online: https://www.evengineeringonline.com/advancing-solid-state-batteries-for-the-aviation-and-maritime-sectors/ (accessed on 17 January 2025).

- Li, J.; Xie, Y.; Xu, B.; Gui, Q.; Mao, L. Comparative study of thermal runaway characteristics between sodium-ion battery and Li-ion battery under heat abuse. J. Phys. Conf. Ser. 2024, 2914, 012001. [Google Scholar] [CrossRef]

- Barton, J.; Gammon, R. The production of hydrogen fuel from renewable sources and its role in grid operations. J. Power Sources 2010, 195, 8222–8235. [Google Scholar] [CrossRef]

- Choi, W.; Kang, S. Greenhouse gas reduction and economic cost of technologies using green hydrogen in the steel industry. J. Environ. Manag. 2023, 335, 117569. [Google Scholar] [CrossRef] [PubMed]

- Hydrogen Fuel Cell Electric Vehicles (FCEV). Toyota Canada. Available online: https://www.toyota.ca/toyota/en/electrified/hydrogen-fuel-cell (accessed on 20 March 2025).

- European Biogas Association. About Biogas and Biomethane. Available online: https://www.europeanbiogas.eu/about-biogas-and-biomethane/ (accessed on 25 March 2025).

- Zheng, J.; Zhou, H.; Wang, C.-G.; Ye, E.; Xu, J.W.; Loh, X.J.; Li, Z. Current research progress and perspectives on liquid hydrogen rich molecules in sustainable hydrogen storage. Energy Storage Mater. 2021, 35, 695–722. [Google Scholar] [CrossRef]

- Ikäheimo, J.; Kiviluoma, J.; Weiss, R.; Holttinen, H. Power-to-ammonia in future North European 100 % renewable power and heat system. Int. J. Hydrogen Energy 2018, 43, 17295–17308. [Google Scholar] [CrossRef]

- Tian, P.; Wei, Y.; Ye, M.; Liu, Z. Methanol to olefins (MTO): From fundamentals to commercialization. ACS Catal. 2015, 5, 1922–1938. [Google Scholar] [CrossRef]

- Aouissi, A.; Al-Deyab, S.S. Comparative study between gas phase and liquid phase for the production of DMC from methanol and CO2. J. Nat. Gas Chem. 2012, 21, 189–193. [Google Scholar] [CrossRef]

- Segovia-Hernández, J.G. Advancing E-fuels production through process intensification: Overcoming challenges and seizing opportunities for a sustainable energy future-A critical review. Chem. Eng. Process. Process Intensif. 2025, 208, 110107. [Google Scholar] [CrossRef]

- Müller, G.; Kullmann, F.; Linssen, J.; Stolten, D. The costs of future energy technologies: A comprehensive review of power-to-X processes. J. CO2 Util. 2025, 92, 103019. [Google Scholar] [CrossRef]

- Abdin, Z.; Tang, C.; Liu, Y.; Catchpole, K. Large-scale stationary hydrogen storage via liquid organic hydrogen carriers. iScience 2021, 24, 102966. [Google Scholar] [CrossRef]

- Yao, J.; Zhu, P.; Guo, L.; Duan, L.; Zhang, Z.; Kurko, S.; Wu, Z. A continuous hydrogen absorption/desorption model for metal hydride reactor coupled with PCM as heat management and its application in the fuel cell power system. Int. J. Hydrogen Energy 2020, 45, 28087–28099. [Google Scholar] [CrossRef]

- El Bahri, A.; Ez-Zahraouy, H. Enhancing hydrogen storage properties of titanium hydride TiH2 with vacancy defects and uniaxial strain: A first-principles study. Int. J. Hydrogen Energy 2024, 87, 678–685. [Google Scholar] [CrossRef]

- Zeng, Z.; Li, J.; Zhang, B.; Ma, C.; Xia, C.; Yang, T. Effects of lanthanum addition on hydrogen storage properties in Li–Mg–N–H system. Int. J. Hydrogen Energy 2024, 66, 592–603. [Google Scholar] [CrossRef]

- Rullo, F.; Beier, C.-K.; Henseler, J.; Bösmann, A.; Preuster, P.; Wasserscheid, P.; Geißelbrecht, M. Pushing activity and stability of LOHC dehydrogenation catalysts by strict LOHC quality protocols. Int. J. Hydrogen Energy 2025, 98, 606–613. [Google Scholar] [CrossRef]

- Davies, E.; Ehrmann, A.; Schwenzfeier-Hellkamp, E. Safety of hydrogen storage technologies. Processes 2024, 12, 2182. [Google Scholar] [CrossRef]

- Arent, D.J.; Green, P.; Abdullah, Z.; Barnes, T.; Bauer, S.; Bernstein, A.; Berry, D.; Berry, J.; Burrell, T.; Carpenter, B.; et al. Challenges and opportunities in decarbonizing the US energy system. Renew. Sustain. Energy Rev. 2022, 169, 112939. [Google Scholar] [CrossRef]

- Shahzad, S.; Jasińska, E. Renewable revolution: A review of strategic flexibility in future power systems. Sustainability 2024, 16, 5454. [Google Scholar] [CrossRef]

- Arabzadeh, V.; Frank, R. Creating a renewable energy-powered energy system: Extreme scenarios and novel solutions for large-scale renewable power integration. Appl. Energy 2024, 374, 124088. [Google Scholar] [CrossRef]

- Sihvonen, V.; Ollila, I.; Jaanto, J.; Grönman, A.; Honkapuro, S.; Riikonen, J.; Price, A. Role of power-to-heat and thermal energy storage in decarbonization of district heating. Energy 2024, 305, 132372. [Google Scholar] [CrossRef]

- Novotny, V.; Basta, V.; Smola, P.; Spale, J. Review of Carnot battery technology commercial development. Energies 2022, 15, 647. [Google Scholar] [CrossRef]

- Bloess, A.; Schill, W.P.; Zerrahn, A. Power-to-heat for renewable energy integration: A review of technologies, modeling approaches, and flexibility potentials. Appl. Energy 2018, 212, 1611–1626. [Google Scholar] [CrossRef]

- Ambrosetti, M. A perspective on power-to-heat in catalytic processes for decarbonization. Chem. Eng. Process. Process Intensif. 2022, 182, 109187. [Google Scholar] [CrossRef]

- Leicher, J.; Giese, A.; Wieland, C. Electrification or Hydrogen? The challenge of decarbonizing industrial (High-Temperature) process heat. J 2024, 7, 439–456. [Google Scholar] [CrossRef]

- Vinnemeier, P.; Wirsum, M.; Malpiece, D.; Bove, R. Integration of heat pumps into thermal plants for creation of large-scale electricity storage capacities. Appl. Energy 2016, 184, 506–522. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, S.; Wang, J.; Zhang, T.; Ma, Z.; Jiang, S. Key district heating technologies for building energy flexibility: A review. Renew. Sustain. Energy Rev. 2024, 189, 114017. [Google Scholar] [CrossRef]

- Li, J.; Lin, J.; Song, Y.; Xing, X.; Fu, C. Operation optimization of power to hydrogen and heat (P2HH) in ADN coordinated with the district heating network. IEEE Trans. Sustain. Energy 2018, 10, 1672–1683. [Google Scholar] [CrossRef]

- Fambri, G.; Badami, M.; Tsagkrasoulis, D.; Katsiki, V.; Giannakis, G.; Papanikolaou, A. Demand flexibility enabled by virtual energy storage to improve renewable energy penetration. Energies 2020, 13, 5128. [Google Scholar] [CrossRef]

- Abdelhady, F.; Bamufleh, H.; El-Halwagi, M.; Ponce-Ortega, J.M. Optimal design and integration of solar thermal collection, storage, and dispatch with process cogeneration systems. Chem. Eng. Sci. 2015, 136, 158–167. [Google Scholar] [CrossRef]

- Tovar-Facio, J.; Eljack, F.; Ponce-Ortega, J.M.; El-Halwagi, M.M. Optimal design of multi-plant cogeneration systems with uncertain flaring and venting. ACS Sustain. Chem. Eng. 2017, 5, 675–688. [Google Scholar] [CrossRef]

- Pfeifer, A.; Herc, L.; Bjelić, I.B.; Duić, N. Flexibility index and decreasing the costs in energy systems with high share of renewable energy. Energy Convers. Manag. 2021, 240, 114258. [Google Scholar] [CrossRef]

- Jokar, H.; Niknam, T.; Dehghani, M.; Siano, P.; Ouahada, K.; Aly, M. Integrated energy management in small-scale smart grids considering the emergency load conditions: A combined battery energy storage, solar PV, and power-to-hydrogen system. Smart Cities 2024, 7, 3764–3797. [Google Scholar] [CrossRef]

- Palacios, A.; Barreneche, C.; Navarro, M.E.; Ding, Y. Thermal energy storage technologies for concentrated solar power—A review from a materials perspective. Renew. Energy 2020, 156, 1244–1265. [Google Scholar] [CrossRef]

- Maia, C.B.; Rodrigues Neumann, L.; de Andrade Oliveira, G.; Marques Alves, Í.; Walczak, M.M.; Paiva Brito, P. A comprehensive review of solar tower CSP systems using TES and molten salts. Int. J. Ambient Energy 2023, 44, 1733–1747. [Google Scholar] [CrossRef]

- Ayinla, R.D.; Kwasi-Effah, C.C.; Egware, H.O. Thermal conductivity enhancement of quaternary nitrate salt mixtures for thermal energy storage with Al2O3 nanoparticle doping. NIPES J. Sci. Technol. Res. 2024, 6, 253–278. [Google Scholar] [CrossRef]

- Boretti, A. Optimizing concentrated solar power: High-temperature molten salt thermal energy storage for enhanced efficiency. Energy Storage 2024, 6, e70059. [Google Scholar] [CrossRef]

- Shi, Y. Advancements and Challenges in Molten Salt Energy Storage for Solar Thermal Power Generation. MATEC Web Conf. 2024, 404, 01003. [Google Scholar] [CrossRef]

- Yang, Z.L.; Walvekar, R.; Wong, W.P.; Sharma, R.K.; Dharaskar, S.; Khalid, M. Advances in phase change materials, heat transfer enhancement techniques, and their applications in thermal energy storage: A comprehensive review. J. Energy Storage 2024, 87, 111329. [Google Scholar] [CrossRef]

- Mier González, R. Energy Storage Systems: A State-of-the-Art Study. Savonia University of Applied Sciences. 2023. Available online: https://urn.fi/URN:NBN:fi-fe20231220156226 (accessed on 12 March 2025).

- Scanzano, M. Thermal Energy Storage: Design and Operation Optimization of Electrical Power Supply. Ph.D. Thesis, Sapienza University of Rome, Rome, Italy, 2024. Available online: https://hdl.handle.net/11573/1719985 (accessed on 15 February 2025).

- Scafuri, A. Thermal Energy Storage Integration in Electrical Grids and in Energy Industries for Decarbonization. Ph.D. Thesis, Sapienza University of Rome, Rome, Italy, 2025. Available online: https://hdl.handle.net/11573/1732050 (accessed on 15 February 2025).

- Aftab, W.; Usman, A.; Shi, J.; Yuan, K.; Qin, M.; Zou, R. Phase change material-integrated latent heat storage systems for sustainable energy solutions. Energy Environ. Sci. 2021, 14, 4268–4291. [Google Scholar] [CrossRef]

- Usman, A.; Xiong, F.; Aftab, W.; Qin, M.; Zou, R. Emerging solid-to-solid phase-change materials for thermal-energy harvesting, storage, and utilization. Adv. Mater. 2022, 34, 2202457. [Google Scholar] [CrossRef] [PubMed]

- Farid, M.; Khudhair, A.M.; Razack, S.A.K.; Al-Hallaj, S. A review on phase change energy storage: Materials and applications. Energy Convers. Manag. 2004, 45, 1597–1615. [Google Scholar] [CrossRef]

- Safari, A.; Saidur, R.; Sulaiman, F.A.; Xu, Y.; Dong, J. A review on supercooling of Phase Change Materials in thermal energy storage systems. Renew. Sustain. Energy Rev. 2017, 70, 905–919. [Google Scholar] [CrossRef]

- Said, Z.; Pandey, A.K.; Tiwari, A.K.; Kalidasan, B.; Jamil, F.; Thakur, A.K.; Tyagi, V.V.; Sari, A.; Ali, H.M. Nano-enhanced phase change materials: Fundamentals and applications. Prog. Energy Combust. Sci. 2024, 104, 101162. [Google Scholar] [CrossRef]

- Wadee, A.; Walker, P.; McCullen, N.; Ferrandiz-Mas, V. The effect of thermal cycling on the thermal and chemical stability of paraffin phase change materials (PCMs) composites. Mater. Struct. 2025, 58, 25. [Google Scholar] [CrossRef]

- Rehman, A.U.; Sheikh, S.R.; Kausar, Z.; Grimes, M.; McCormack, S.J. Experimental thermal response study of multilayered, encapsulated, PCM-integrated building construction materials. Energies 2022, 15, 6356. [Google Scholar] [CrossRef]

- Gunerhan, H.; Hepbasli, A. Utilization of basalt stone as a sensible heat storage material. Energy Sources 2005, 27, 1357–1366. [Google Scholar] [CrossRef]

- Xu, J.; Wang, R.Z.; Li, Y. A review of available technologies for seasonal thermal energy storage. Sol. Energy 2014, 103, 610–638. [Google Scholar] [CrossRef]

- Fan, X.; Xu, H.; Li, Y.; Li, J.; Wang, Z.; Gao, Z.; Ji, W.; Chen, L.; Wang, J. A novel liquid air energy storage system with efficient thermal storage: Comprehensive evaluation of optimal configuration. Appl. Energy 2024, 371, 123739. [Google Scholar] [CrossRef]

- Wang, C.; Bian, Y.; You, Z.; Luo, Y.; Zhang, X.; Peng, H.; Ding, Y.; She, X. Dynamic analysis of a novel standalone liquid air energy storage system for industrial applications. Energy Convers. Manag. 2021, 245, 114537. [Google Scholar] [CrossRef]

- Burian, O.; Dančová, P. Compressed air energy storage (CAES) and liquid air energy storage (LAES) technologies—A comparison review of technology possibilities. Processes 2023, 11, 3061. [Google Scholar] [CrossRef]

- Rabi, A.M.; Radulovic, J.; Buick, J.M. Comprehensive review of liquid air energy storage (LAES) technologies. Energies 2023, 16, 6216. [Google Scholar] [CrossRef]

- Denholm, P.; King, J.C.; Kutcher, C.F.; Wilson, P.P. Decarbonizing the electric sector: Combining renewable and nuclear energy using thermal storage. Energy Policy 2012, 44, 301–311. [Google Scholar] [CrossRef]

- Alva, G.; Lin, Y.; Fang, G. An overview of thermal energy storage systems. Energy 2018, 144, 341–378. [Google Scholar] [CrossRef]

- Tetteh, S.; Yazdani, M.R.; Santasalo-Aarnio, A. Cost-effective Electro-Thermal Energy Storage to balance small scale renewable energy systems. J. Energy Storage 2021, 41, 102829. [Google Scholar] [CrossRef]

- Koçak, B.; Fernandez, A.I.; Paksoy, H. Review on sensible thermal energy storage for industrial solar applications and sustainability aspects. Sol. Energy 2020, 209, 135–169. [Google Scholar] [CrossRef]

- Revankar, S.T. Chapter Six-Chemical energy storage. In Storage and Hybridization of Nuclear Energy; Bindra, H., Revankar, S.T., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 177–227. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Growth in Global Electricity Demand is Set to Accelerate in the Coming Years as Power-Hungry Sectors Expand. Available online: https://www.iea.org/news/growth-in-global-electricity-demand-is-set-to-accelerate-in-the-coming-years-as-power-hungry-sectors-expand (accessed on 10 February 2025).

- Basit, M.A.; Dilshad, S.; Badar, R.; Sami ur Rehman, S.M. Limitations, challenges, and solution approaches in grid-connected renewable energy systems. Int. J. Energy Res. 2020, 44, 4132–4162. [Google Scholar] [CrossRef]

- Sürer, M.G.; Arat, H.T. Advancements and current technologies on hydrogen fuel cell applications for marine vehicles. Int. J. Hydrogen Energy 2022, 47, 19865–19875. [Google Scholar] [CrossRef]

- Chavan, S.; Rudrapati, R.; Manickam, S. A comprehensive review on current advances of thermal energy storage and its applications. Alex. Eng. J. 2022, 61, 5455–5463. [Google Scholar] [CrossRef]

- Su, P.; Zhou, Y.; Wu, J. Multi-objective scheduling of a steelmaking plant integrated with renewable energy sources and energy storage systems: Balancing costs, emissions and make-span. J. Clean. Prod. 2023, 428, 139350. [Google Scholar] [CrossRef]

- ArcelorMittal. ArcelorMittal Launches Heat Recovery System at Dąbrowa Górnicza Plant. Available online: https://gmk.center/en/news/arcelormittal-launches-heat-recovery-system-at-dabrowa-gornicza-plant/ (accessed on 28 May 2025).

- Tenaris. New Consteel® EAF for Tenaris in Argentina. Available online: https://tenova.com/newsroom/latest-tenova/new-consteelr-eaf-tenaris-argentina (accessed on 28 May 2025).

- Thyssenkrupp. Waste Heat Recovery. Available online: https://www.thyssenkrupp-uhde.com/en/products-and-technologies/fertilizer-technologies/ammonia-plants/ammonia-technology-proprietary-equipment/waste-heat-recovery (accessed on 28 May 2025).

- Alshehhi, I.; Alnahdi, W.; Ali, M.; Bouabid, A.; Sleptchenko, A. Assessment of waste heat recovery in the steel industry. J. Sustain. Dev. Energy Water Environ. Syst. 2023, 11, 1100440. [Google Scholar] [CrossRef]

- Zhang, T.; Xiao, L.; Qiu, G.; Wang, H.; Guo, M.; Huo, X.; Zhang, M. Waste heat recovery from hot steel slag on the production line: Numerical simulation, validation and industrial test. Int. J. Miner. Metall. Mater. 2023, 30, 2191–2199. [Google Scholar] [CrossRef]

- Liu, X.; Li, X.; Yang, R. High-temperature thermal storage-based cement manufacturing for decarbonization. Carb. Neutrality 2022, 1, 29. [Google Scholar] [CrossRef]

- SolCement Website. Available online: http://www.solcement.certh.gr/en/solcement-website (accessed on 20 January 2025).

- Nikolakopoulos, A.; Steriotis, T.; Charalambopoulou, G.; Karagiannakis, G.; Dimitrakis, D.; Michalis, V.; Katsiotis, M. Reducing carbon emissions in cement production through solarization of the calcination process and thermochemical energy storage. Comput. Chem. Eng. 2024, 180, 108506. [Google Scholar] [CrossRef]

- CORDIS. High Temperature Solar-Heated Reactors for Industrial Production of Reactive Particulates (SOLPART). Available online: https://cordis.europa.eu/project/id/654663 (accessed on 28 May 2025).

- Synhelion. Synhelion and CEMEX Make Further Progress Toward the World’s First Fully Solar-Powered Cement Plant. Available online: https://synhelion.com/news/synhelion-and-cemex-make-further-progress-toward-the-world-s-first-fully-solar-powered-cement-plant (accessed on 28 May 2025).

- Ho, C.K.; Rao, P.; Iloeje, N.; Marschilok, A.; Liaw, B.; Kaur, S.; Slaughter, J.; Hertz, K.; Wendt, L.; Supekar, S.; et al. Energy Storage for Manufacturing and Industrial Decarbonization (Energy StorM); SAND2022-12303; Sandia National Laboratories: Albuquerque, NM, USA; Livermore, CA, USA, 2022. Available online: https://www.osti.gov/servlets/purl/1887337/ (accessed on 15 April 2025).

- Exergy ORC. Leveraging Waste Heat Potential in the Glass Industry. Exergy ORC. 2024. Available online: https://www.exergy-orc.com/wp-content/uploads/2024/08/Glassman-March-2024.pdf?utm_source=chatgpt.com (accessed on 15 April 2025).

- Dolianitis, I.; Giannakopoulos, D.; Hatzilau, C.-S.; Karellas, S.; Kakaras, E.; Nikolova, E.; Skarpetis, G.; Christodoulou, N.; Giannoulas, N.; Zitounis, T. Waste heat recovery at the glass industry with the intervention of batch and cullet preheating. Therm. Sci. 2016, 20, 1245–1258. [Google Scholar] [CrossRef]

- Tronchin, L.; Manfren, M.; Nastasi, B. Energy efficiency, demand side management and energy storage technologies—A critical analysis of possible paths of integration in the built environment. Renew. Sustain. Energy Rev. 2018, 95, 341–353. [Google Scholar] [CrossRef]

- Hurst, K.E.; Springer, M.; Wikoff, H.; Cory, K.; Garfield, D.; Ruth, M.; Reese, S.B. Industrial Energy Storage Review; NREL/TP-6A20-85634; National Renewable Energy Laboratory: Golden, CO, USA, 2024. Available online: https://www.nrel.gov/docs/fy25osti/85634.pdf (accessed on 28 April 2025).

- Bahr, M.T.; Immonen, J.; Billings, B.W.; Powell, K.M. Intelligent control of thermal energy storage in the manufacturing sector for plant-level grid response. Processes 2023, 11, 2202. [Google Scholar] [CrossRef]

- McMillan, C.; Boardman, R.; McKellar, M.; Sabharwall, P.; Ruth, M.; Bragg-Sitton, S. Generation and Use of Thermal Energy in the U.S. Industrial Sector and Opportunities to Reduce Its Carbon Emissions; NREL/TP-6A50-66763; National Renewable Energy Laboratory: Golden, CO, USA, 2016. [Google Scholar] [CrossRef][Green Version]

- Hasanbeigi, A.; Springer, C.; Wei, D. Low-Carbon Thermal Energy Technologies for the Textile Industry. Global Efficiency Intelligence, LLC, 2024. Available online: https://apparelimpact.org/wp-content/uploads/2024/08/Low-Carbon-Thermal-Energy-8.27.24.pdf (accessed on 12 March 2025).

- International Energy Agency (IEA). Digitalization and Energy. Available online: https://www.iea.org/reports/digitalisation-and-energy (accessed on 21 January 2025).

- Enescu, D.; Chicco, G.; Porumb, R.; Seritan, G. Thermal energy storage for grid applications: Current status and emerging trends. Energies 2020, 13, 340. [Google Scholar] [CrossRef]

- Serrano-Arévalo, T.I.; Tovar-Facio, J.; Ponce-Ortega, J.M. Optimal incorporation of intermittent renewable energy storage units and green hydrogen production in the electrical sector. Energies 2023, 16, 2609. [Google Scholar] [CrossRef]

- Cunha, J.M.; Faria, A.S.; Soares, T.; Mourão, Z.; Nereu, J. Decarbonization potential of integrating industrial excess heat in a district heating network: The Portuguese case. Clean. Energy Syst. 2022, 1, 100005. [Google Scholar] [CrossRef]

- Manz, P.; Kermeli, K.; Persson, U.; Neuwirth, M.; Fleiter, T.; Crijns-Graus, W. Decarbonizing district heating in EU-27+ UK: How much excess heat is available from industrial sites? Sustainability 2021, 13, 1439. [Google Scholar] [CrossRef]

- Mäki, E.; Kannari, L.; Hannula, I.; Shemeikka, J. Decarbonization of a district heating system with a combination of solar heat and bioenergy: A techno-economic case study in the Northern European context. Renew. Energy 2021, 175, 1174–1199. [Google Scholar] [CrossRef]

- Dorotić, H.; Ban, M.; Pukšec, T.; Duić, N. Impact of wind penetration in electricity markets on optimal power-to-heat capacities in a local district heating system. Renew. Sustain. Energy Rev. 2020, 132, 110095. [Google Scholar] [CrossRef]

- Gambini, M.; Mazzoni, S.; Vellini, M. The role of cogeneration in the electrification pathways towards decarbonization. Energies 2023, 16, 5606. [Google Scholar] [CrossRef]

- Johnson, M.; Vogel, J.; Hempel, M.; Dengel, A.; Seitz, M.; Hachmann, B. High temperature latent heat thermal energy storage integration in a co-gen plant. Energy Procedia 2015, 73, 281–288. [Google Scholar] [CrossRef]

- Elio, J.; Phelan, P.; Villalobos, R.; Milcarek, R.J. A review of energy storage technologies for demand-side management in industrial facilities. J. Clean. Prod. 2021, 307, 127322. [Google Scholar] [CrossRef]

- Miró, L.; Gasia, J.; Cabeza, L.F. Thermal energy storage (TES) for industrial waste heat (IWH) recovery: A review. Appl. Energy 2016, 179, 284–301. [Google Scholar] [CrossRef]

- Olabi, A.G.; Onumaegbu, C.; Wilberforce, T.; Ramadan, M.; Abdelkareem, M.A.; Al–Alami, A.H. Critical review of energy storage systems. Energy 2021, 214, 118987. [Google Scholar] [CrossRef]

- Rana, M.M.; Uddin, M.; Sarkar, M.R.; Meraj, S.T.; Shafiullah, G.M.; Muyeen, S.M.; Islam, M.A.; Jamal, T. Applications of energy storage systems in power grids with and without renewable energy integration—A comprehensive review. J. Energy Storage 2023, 68, 107811. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Olawumi, M.A.; Omigbodun, F.T. Machine Learning for Optimising Renewable Energy and Grid Efficiency. Atmosphere 2024, 15, 1250. [Google Scholar] [CrossRef]

- Lemaoui, T.; Darwish, A.S.; Almustafa, G.; Boublia, A.; Sarika, P.R.; Jabbar, N.A.; Ibrahim, T.; Nancarrow, P.; Yadav, K.K.; Fallatah, A.M.; et al. Machine learning approach to map the thermal conductivity of over 2000 neoteric solvents for green energy storage applications. Energy Storage Mater. 2023, 59, 102795. [Google Scholar] [CrossRef]

- Chen, C.; Tao, G.; Shi, J.; Shen, M.; Zhu, Z.H. A lithium-ion battery degradation prediction model with uncertainty quantification for its predictive maintenance. IEEE Trans. Ind. Electron. 2023, 71, 3650–3659. [Google Scholar] [CrossRef]

- Patrizi, G.; Martiri, L.; Pievatolo, A.; Magrini, A.; Meccariello, G.; Cristaldi, L.; Nikiforova, N.D. A review of degradation models and remaining useful life prediction for testing design and predictive maintenance of lithium-ion batteries. Sensors 2024, 24, 3382. [Google Scholar] [CrossRef]

- Jagadeeswara Reddy, V.; Fairusham Ghazali, M.; Kumarasamy, S. Innovations in phase change materials for diverse industrial applications: A comprehensive review. Results Chem. 2024, 8, 101552. [Google Scholar] [CrossRef]

- Singh, R.; Altaee, A.; Gautam, S. Nanomaterials in the advancement of hydrogen energy storage. Heliyon 2020, 6, e04487. [Google Scholar] [CrossRef]

- Khambhawala, A.; Lee, C.H.; Pahari, S.; Nancarrow, P.; Jabbar, N.A.; El-Halwagi, M.M.; Kwon, J.S.I. Advanced transformer models for structure-property relationship predictions of ionic liquid melting points. Chem. Eng. J. 2025, 503, 158578. [Google Scholar] [CrossRef]

- Zhu, L.; Cao, Y.; Xu, T.; Yang, H.; Wang, L.; Dai, L.; Pan, F.; Chen, C.; Si, C. Covalent organic framework membranes for energy storage and conversion. Energy Environ. Sci. 2025. [Google Scholar] [CrossRef]

- Eljack, F.; Eden, M.; Kazantzi, V.; Qin, X.; El-Halwagi, M.M. Simultaneous process and molecular design—A property based approach. AIChE J. 2007, 53, 1232–1239. [Google Scholar] [CrossRef]

- Sarkar, S.; Swamy, D.; Amin, M.T.; El-Halwagi, M.; Khan, F. Safer operating areas (SOA) of cylindrical lithium-ion battery—A probabilistic approach. Process Saf. Environ. Prot. 2024, 190, 708–725. [Google Scholar] [CrossRef]

- Quintiere, J.G. On a method to mitigate thermal runaway and propagation in packages of lithium ion batteries. Fire Saf. J. 2022, 130, 103573. [Google Scholar] [CrossRef]

- El-Kady, A.H.; Amin, M.T.; Khan, F.; El-Halwagi, M.M. Analysis of CO2 pipeline regulations from a safety perspective for offshore carbon capture, utilization, and storage (CCUS). J. Clean. Prod. 2024, 439, 140734. [Google Scholar] [CrossRef]

- El-Kady, A.H.; Amin, M.T.; Khan, F.; El-Halwagi, M.M. A novel methodology to determine the safe operating regime for an offshore wind-integrated electrolysis system. AIChE J. 2025, 71, e18807. [Google Scholar] [CrossRef]

- El-Halwagi, M.M.; Sengupta, D.; Pistikopoulos, E.N.; Sammons, J.; Eljack, F.; Kazi, M.K. Disaster-resilient design of manufacturing facilities through process integration: Principal strategies, perspectives, and research challenges. Front. Sustain. 2020, 1, 595961. [Google Scholar] [CrossRef]

- Mostafa, M.; Varela, C.; Zondervan, E. Optimization of electrolysis and carbon capture processes for sustainable production of chemicals through Power-to-X. Phys. Sci. Rev. 2023, 8, 4805–4819. [Google Scholar] [CrossRef]

- Zhao, X.; Xiao, J.; Hou, J.; Wu, J.; Lyu, X.; Zhang, J.; Liu, Y. Economic and scale prediction of CO2 capture, utilization and storage technologies in China. Pet. Explor. Dev. 2023, 50, 751–764. [Google Scholar] [CrossRef]

- Elbashir, N.; Afzal, S.; El-Halwagi, M.; Sengupta, D. Processing Methane for Syngas Production with Reduced CO2 Emissions. WO Patent WO2019194694A2, 10 October 2019. [Google Scholar]

- Abdelkarim, Y.; Musa, T.; Challiwala, M.S.; Katbeh, T.; Choudhury, H.; El-Halwagi, M.; Elbashir, N.O. Retrofitting low carbon aviation fuels processes from natural gas to renewables energy-based systems. Greenh. Gases Sci. Technol. 2025. [Google Scholar] [CrossRef]

- Ibrahim, G.; Challiwala, M.S.; Zang, G.; El-Halwagi, M.M.; Elbashir, N.O. A novel framework for the economic and sustainability assessment of carbon capture and utilization technologies. Gas Sci. Eng. 2024, 131, 205462. [Google Scholar] [CrossRef]

- Filho, R.D.; Monteiro, A.C.; Costa, T.; Vasconcelos, A.; Rode, A.C.; Marinho, M. Strategic guidelines for battery energy storage system deployment: Regulatory framework, incentives, and market planning. Energies 2023, 16, 7272. [Google Scholar] [CrossRef]

- Lu, Y.; Khan, Z.A.; Alvarez-Alvarado, M.S.; Zhang, Y.; Huang, Z.; Imran, M. A critical review of sustainable energy policies for the promotion of renewable energy sources. Sustainability 2020, 12, 5078. [Google Scholar] [CrossRef]

| Battery Type | Materials | Cost | Efficiency | Limits/Risk | Operating Conditions | Lifecycle (Cycles) | Applications |

|---|---|---|---|---|---|---|---|

| Flow | Vanadium or iron redox | Medium–High | 65–80% | Low energy density; low thermal risk | ~20–40 °C, atmospheric pressure | >10,000 | Grid storage, renewables |

| Na-ion | Sodium-based | Low | 80–90% | Lower density than Li-ion; low fire risk | −20 to 60 °C, atmospheric pressure | 2000–4000 | Stationary, backup |

| Li-ion | Lithium-based | Medium | 90–95% | Temp-sensitive; high thermal risk | 0–45 °C, atmospheric pressure | 1000–3000 | EVs, electronics |

| Solid-state | Li metal + solid electrolyte | High | 90–98% | High cost; interface stability | ~20–80 °C, moderate pressure | >5000 | Future EVs, aerospace |

| Technology | Main Output Products | Main Process | Operating Conditions | Applications |

|---|---|---|---|---|

| P2H | Hydrogen (H2) | Electrolysis | 50–80 °C (Alkaline), 60–80 °C, 30–60 bar | Fuel cells, industry (steel), transport |

| P2G | Synthetic methane | Methanation (Sabatier reaction) | 250–400 °C, 10–30 bar | Injection into gas grid, heating |

| P2L | Ammonia, Methanol, E-fuels | Haber-Bosch, catalytic synthesis | 400–500 °C, 100–200 bar (ammonia); 200–300 °C, 50–100 bar (methanol) | Fuel, chemicals, fertilizers, energy storage |

| TES Technology | Main Material | Temperature/Efficiency | Limitations/Risks | Key Advantages | Applications |

|---|---|---|---|---|---|

| Molten Salt Storage | NaNO3 and KNO3 | 290–566 °C; high thermal capacity | Corrosion, degradation, freezing below 240 °C | Long-duration, efficient heat storage | CSP plants, cement and metallurgy industries |

| Solid-State (MGTES) | Sand | >1000 °C; high thermal stability | No phase transition (advantage) | Low cost, sustainable, reliable, low maintenance | Industrial heating, district heating, waste heat recovery |

| Phase Change Materials (PCM) | Materials with solid-liquid transition | High energy density; compact solution | Low thermal conductivity, phase separation | Efficiency in HVAC, compact thermal regulation | Drying, food and pharmaceutical storage, HVAC, buildings |

| High-Temperature Rock Storage | Basalt, granite | High temperature; stable efficiency | Dependent on conductivity, porosity | Low cost; durable; low environmental impact | Large-scale heat storage; renewable integration |

| Liquid Air Energy Storage (LAES) | Liquefied air (−196 °C) | 50–60% efficiency | High energy consumption | Long-duration storage | Industrial refrigeration; electricity storage |

| Sector | Main Use | Applications | References |

|---|---|---|---|

| Cement | Waste heat recovery | Optimization of energy consumption in the kiln and other process stages | [111,112] |

| Glass | Waste heat recovery | Thermochemical recovery, natural gas preheating, batch or glass preheating, as well as electricity generation and steam or hot water production | [118] |

| Steel and metals | Waste heat recovery | Energy recovery from electric arc furnace and hot steel slag. | [109,110] |

| Chemical and petrochemical industry | Waste heat recovery | Heat utilization in distillation, cracking, and chemical synthesis processes | [122] |

| Textile, food, automotive and assembly industries | Emission reduction and energy efficiency | Store and manage energy more efficiently in drying, dyeing, washing, pasteurization, refrigeration, and thermal management processes such as welding and painting. | [123] |

| Data centers and electronic devices | Efficiency and sustainability improvement | Reduction of energy consumption in cooling systems and backup energy management | [124] |

| General in various industries | Energy system flexibility and sustainability | Integration with renewable energy sources and energy management optimization through TES and CES | [125,126] |

| Technology | Type | TRL | CAPEX | OPEX | Utilization Potential | Energy Efficiency (%) | Emission Reduction Potential | Current Limitation for Adoption |

|---|---|---|---|---|---|---|---|---|

| Li-ion batteries | CES | 9 | Medium–High (€300–500/kWh) | Medium | EVs, small-scale grid, industry backup | 90–95% | High (transportation, mobile loads) | Fire risk, resource dependency (Li, Co), recycling barriers |

| VRFBs | CES | 7–8 | High (€500–800/kWh) | Low | Stationary storage for grids/industry | 75–90% | High (stationary decarbonization) | Low energy density, vanadium cost |

| Na-ion batteries | CES | 6–7 | Low–Medium (€100–300/kWh) | Low | Emerging grid & industrial applications | 80–90% | Moderate–High | Immature market, lower density than Li-ion |

| Solid-state batteries | CES | 5–6 | Very High (>€800/kWh) | Medium–High | Future high-energy EVs, aerospace | 90–98% | High (long-term) | High fabrication complexity, interfacial issues |

| Zinc–bromine batteries | CES | 6–7 | Medium | Medium | Stationary storage | 65–80% | Moderate | Corrosion, toxicity, low round-trip efficiency |

| Hydrogen | CES | 7–8 | High | High | Steel, ammonia, fuel, H2 turbines | 65–75% | Very High (hard-to-abate sectors) | Costly infrastructure, compression/liquefaction challenges |

| LOHCs/Metal hydrides | CES | 5–6 | High | Medium | Portable/mid-scale storage | 40–60% (system-level) | Moderate | Catalyst degradation, reversibility limitations |

| Methanol | CES | 6–7 | High | Medium–High | Drop-in fuel, chemicals | ~60% | High | Dependent on CCU, catalyst optimization |

| Molten salts | TES | 8–9 | Medium (€30–80/kWh) | Low | CSP, cement, metallurgy | >90% | High | Freezing below 240 °C, material degradation |

| MGTES | TES | 6–7 | Low (€10–30/kWh) | Very Low | High-temp industries (metal, glass) | ~90–95% | High | Scaling and heat exchanger integration |

| PCMs | TES | 6–7 | Medium (€50–150/kWh) | Medium | HVAC, food, low-medium temp industries | 75–85% | Moderate | Phase stability, low thermal conductivity |

| Rock thermal storage | TES | 7–8 | Low | Very Low | District heating, high-temp storage | 60–80% | Moderate | Low energy density |

| LAES (Cryogenic storage) | CES/TES | 6–7 | High (€100–300/kWh) | Medium | Long-duration storage, industrial cooling | 50–60% | Moderate | Energy-intensive liquefaction, low RTE |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serrano-Arévalo, T.I.; Ochoa-Barragán, R.; Ramírez-Márquez, C.; El-Halwagi, M.; Abdel Jabbar, N.; Ponce-Ortega, J.M. Energy Storage: From Fundamental Principles to Industrial Applications. Processes 2025, 13, 1853. https://doi.org/10.3390/pr13061853

Serrano-Arévalo TI, Ochoa-Barragán R, Ramírez-Márquez C, El-Halwagi M, Abdel Jabbar N, Ponce-Ortega JM. Energy Storage: From Fundamental Principles to Industrial Applications. Processes. 2025; 13(6):1853. https://doi.org/10.3390/pr13061853

Chicago/Turabian StyleSerrano-Arévalo, Tania Itzel, Rogelio Ochoa-Barragán, César Ramírez-Márquez, Mahmoud El-Halwagi, Nabil Abdel Jabbar, and José María Ponce-Ortega. 2025. "Energy Storage: From Fundamental Principles to Industrial Applications" Processes 13, no. 6: 1853. https://doi.org/10.3390/pr13061853

APA StyleSerrano-Arévalo, T. I., Ochoa-Barragán, R., Ramírez-Márquez, C., El-Halwagi, M., Abdel Jabbar, N., & Ponce-Ortega, J. M. (2025). Energy Storage: From Fundamental Principles to Industrial Applications. Processes, 13(6), 1853. https://doi.org/10.3390/pr13061853