Abstract

Accurate understanding of natural fractures, faults, in situ stress, and mechanical properties of reservoir rocks is a prerequisite for evaluating well interference. During hydraulic fracturing, hydraulic fractures may connect with natural fractures or fault zones, leading to communication with adjacent wells and resulting in cross-well interference. Additionally, horizontal well spacing is a critical factor influencing the occurrence and severity of interference. The Mahu tight oil reservoir experiences severe fracturing interference issues, presenting multiple challenges. This study employs numerical simulation methods to quantitatively assess the influence of geological and engineering factors, including reservoir depletion volume, well spacing, natural fractures, and fracturing operation parameters on fracturing interference intensity. By integrating geological data, engineering parameters, and production data with microseismic monitoring and pressure information, this research aims to clarify key influencing factors and elucidate the fundamental mechanisms governing fracturing-driven interference occurrences. Through production performance analysis and microseismic monitoring, it has been established that well spacing, fracturing intensity, and natural fracture networks are the primary factors affecting interference in hydraulically fractured horizontal wells.

1. Introduction

With the advancement of unconventional oil and gas resource development, large-scale fracturing in tight reservoirs has become a critical technical approach to enhance single-well productivity. However, during the development of tight conglomerate reservoirs, the fracturing interference has become increasingly prominent. This phenomenon manifests as physical connectivity or stress interference between newly created fractures and existing fracture networks in adjacent wells during fracturing operations, triggering issues such as inter-well fluid channeling, abnormal pressure surges at wellheads of neighboring wells, and fluctuations in daily liquid/gas production rates. In severe cases, it may result in accidents like proppant intrusion into adjacent wells and casing deformation/damage [1].

Scholars have proposed multiple causal mechanisms for well fracturing interference based on field monitoring and theoretical models. Daneshy et al. [2] classified interference into two types using field pressure data from the Williston Basin: fracture intersection type (direct connectivity causing significant pressure imbalance) and frac-hit shadow type (short-term pressure perturbations induced by adjacent fractures). Schaeffer et al. [3], integrating microseismic monitoring and seismic moment tensor inversion techniques, confirmed a third interference form—natural fracture cluster connectivity type—a finding that aligns with studies on how natural fracture networks promote inter-well fracture connectivity [4,5,6]. Mukherjee et al. [7,8] first reported asymmetric fracture propagation caused by formation depletion (with wing length ratios reaching 20:1), revealing the significant influence of uneven energy distribution in reservoirs on fracture propagation paths.

To investigate the dynamic evolution of interference and the effects of multi-field coupling on fracturing-driven interference, multi-parameter diagnostic techniques was employed such as microseismic monitoring and fluid tracers, revealing that induced unpropped fractures formed during large-scale volumetric fracturing can trigger stress field reorientation, promoting preferential propagation of subsequent fractures toward existing fracture networks. Concurrently, the time-dependent closure characteristics of unpropped fractures provide theoretical foundations for optimizing fracturing sequencing. Fu et al. [9], through tracer-pressure joint analysis, confirmed that multi-well connectivity channels form during fracturing stages, and preferential flow paths within fracture networks lead to extended flowback periods. Duan et al. [10] established a coupled stress field–natural fracture model for deep shale gas reservoirs, discovering that low-stress fields in structural uplift zones and large-scale strip-shaped fractures induce hydraulic fracture capture effects, thereby elucidating the intensification mechanisms of inter-well interference under complex geological conditions. Roussel et al. [11] verified the existence of pressure perturbations at a 300-meter scale under non-direct hydraulic connectivity using poroelastic models and identified precursor pressure drops caused by tensile effects at fracture tips.

The presence of natural fractures in reservoirs significantly increases inter-well fracture network connectivity risks [12,13], while stress states play a decisive role in fracture morphology. Laboratory triaxial fracturing tests by Sharma et al. [14] demonstrated that under high horizontal stress difference conditions, fractures propagate along the maximum principal stress direction, whereas under low stress differences, rock matrix discontinuities dominate fracture propagation paths, forming complex fracture networks. Increasing volumetric fracturing scale (via elevated fracturing fluid and proppant volumes) generates longer hydraulic fractures that interact with natural fractures [15,16], further exacerbating interference risks. The dynamic parameter analysis system proposed by Hannah et al. [17], comprising the plasticity index (PI), diffusion index (DI), and stress index (SI), provides multi-dimensional evaluation metrics for interpreting microseismic data.

While horizontal well multi-cluster staged fracturing enhances fracture network volume and reduces costs, intra-stage multiple fractures often exhibit non-uniform propagation due to reservoir heterogeneity and inter-fracture interference [18]. Fiber-optic monitoring data reveals that only 50−70% of clusters within a stage contribute to effective fractures, with extreme flow imbalance observed where single clusters may account for over 30% of total fluid intake [19,20]. Numerical simulations by Lecampion et al. [21] using the boundary element method demonstrate that increasing wellbore friction pressure improves fluid distribution among clusters, promoting more uniform fracture propagation. Peirce et al. [22] further validated the feasibility of regulating fracture growth patterns through non-uniform perforation strategies using their planar 3D modeling framework.

2. Analysis of Controlling Factors of Well Fracturing Interference

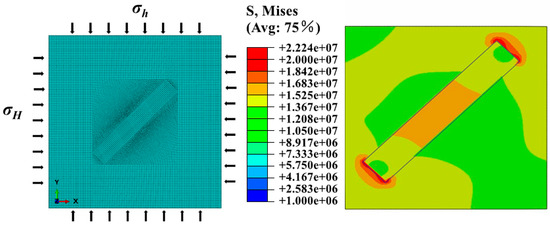

To address the limited understanding of diverse fracturing interference patterns in tight conglomerate reservoirs, a fully coupled numerical simulation model for multi-cluster simultaneous propagation in tight conglomerate horizontal well fracturing was established (as shown in Figure 1). This study clarified the influencing patterns of different interference types and proposed effective mitigation strategies. Research findings demonstrate the following: (1) In highly developed natural fracture reservoirs, hydraulic fractures tend to propagate preferentially along large-scale natural fracture corridors in single dominant directions, directly or indirectly impacting adjacent wells and causing abnormal pressure surges. (2) Avoiding fracturing in high-risk intervals or reducing stimulation intensity can partially alleviate interference effects. (3) When depleted adjacent wells exist near fracturing wells, hydraulic fractures exhibit stronger tendencies to propagate toward low-stress zones of neighboring wells, with interference severity being closely related to rock poroelastic properties.

Figure 1.

Geological model for numerical simulation of fracturing in tight conglomerate horizontal wells.

2.1. The Impact of Faults on Fracturing Interference

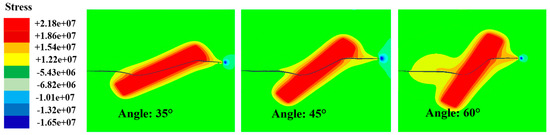

By examining the angle between faults and hydraulic fractures as well as the scale of fault fracture zones, it has been observed that as the angle between faults and the initial propagation direction of hydraulic fractures increases, the created fracture deflection amplitude shows an upward trend, as shown in Figure 2. This occurs because faults alter the local stress field of the reservoir: larger angles enhance shear stress concentration effects near the fault, causing fracture paths to deflect along the direction of least resistance [23]. When the angle increases from 30° to 60°, the deflection amplitude progressively intensifies, manifesting a phenomenon where fractures extend along the fault strike. Consequently, under larger-angle conditions, it is necessary to restrict injection pressure to suppress excessive fracture deflection, thereby preventing fractures from connecting with faults and causing fracturing fluid loss [24].

Figure 2.

Simulation plot of artificial fracture deflection amplitude variation with fault angle.

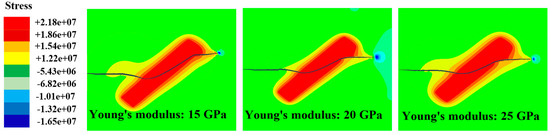

Through studies on the relationship between the Young’s modulus of fault fracture zones and fracture deflection amplitude, it has been discovered that as the Young’s modulus of fault fracture zones increases, the fracture deflection amplitude slightly decreases (as shown in Figure 3). When Young’s modulus rises, the rigidity of the fracture zone is enhanced. This increased stiffness suppresses energy concentration at the fracture tip and reduces local deformation capacity near the fault plane, thereby narrowing the stress field range at the fracture tip and diminishing the fracture deflection angle.

Figure 3.

Simulation plot of artificial fracture deflection amplitude variation with elastic modulus.

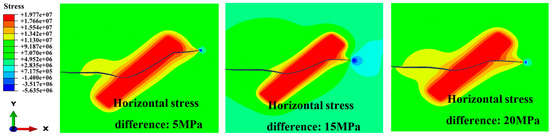

Through investigations on the horizontal stress difference in fault fracture zones, it has been found that as the horizontal stress difference increases, the fracture deflection amplitude decreases, with fractures tending to directly penetrate through the fault fracture zone, as shown in Figure 4. Elevated stress differences strengthen the dominance of the maximum principal stress in fracture propagation and weaken the disturbance from the boundary stress field of the fracture zone on the fracture tip. This accelerates the decay rate of the shear component in fracture tip stress intensity, thereby inhibiting fracture deflection. Increased horizontal stress difference drives the energy release rate distribution at the fracture tip toward anisotropy, promoting fracture propagation along the direction of maximum principal stress.

Figure 4.

Effect of horizontal stress difference on artificial fracture deflection amplitude.

Through research on fault softening effects that attract and truncate hydraulic fracture propagation, it has been determined that when fractures are arranged perpendicular to faults, controlling the fracturing scale can weaken the fault’s influence by limiting fracture extension to inhibit direct contact between fracture tips and fault planes, thereby reducing the disturbance range of shear stress; when fractures are arranged parallel to faults, reducing fluid intake in peripheral fractures mitigates fault effects through selective plugging of edge perforation clusters using diverting agents or adjusting fluid viscosity distribution to prioritize central fracture propagation, which decreases the driving force for peripheral fractures extending toward faults, as shown in Figure 5.

Figure 5.

Effect of faults on vertical fracture propagation.

2.2. Analysis of the Impact of Natural Fractures on Fracturing Interference

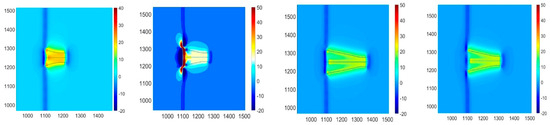

Through fracturing simulations conducted on four sets of parent–child well groups, the study demonstrates that the development of natural fractures between wells leads to non-uniform propagation of hydraulic fractures. Figure 6 shows that the degree of natural fracture development significantly influences interference intensity by controlling both the propagation paths and energy distribution of hydraulic fractures. During the low fracture density stage, hydraulic fractures preferentially propagate along high-conductivity natural fractures, forming elongated main fracture networks, with interference probability rising significantly as density increases. When fracture density further increases, the fractal dimension of fracture networks grows. Multi-stage branching fractures intensify fluid energy dissipation, resulting in reduced main fracture extension length and localized enrichment of fracture networks around wells, consequently lowering interference probability [25].

Figure 6.

Hydraulic fracture geometry under different natural fracture densities.

With the increase in cementation strength, the difficulty for main fractures to connect with natural fractures rises, consequently reducing the risk of inter-well fracturing interference. Natural fractures with high cementation strength exhibit elevated critical opening pressure and shear slip thresholds, causing main fractures to bypass or terminate at cemented zones rather than propagate along weak interfaces. The interference potential between adjacent wells is also affected. In cases where cemented fractures open under high pressure, they can facilitate long-range fracture propagation, increasing the likelihood of fracture-driven interactions between wells. The energy dissipation effect at cemented interfaces weakens the ability of the stress field at main fracture tips to activate natural fractures, thereby inhibiting fracture network interconnection [26].

2.3. Impact of Formation Depletion on Fracturing Interference

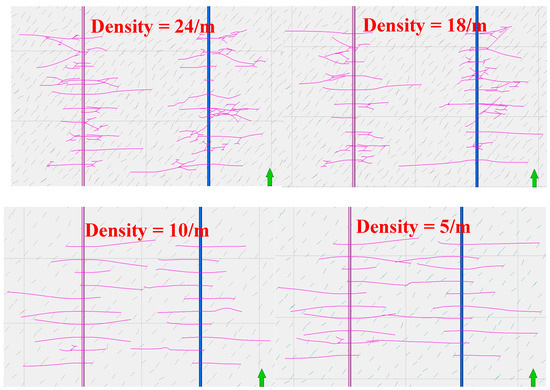

Numerical simulations of formation pressure distribution after long-term production in legacy wells revealed three distinct pressure zones radiating outward from the stimulation center, as shown in Figure 7: ① a low-pressure zone induced by production, ② a high-pressure zone created by fracturing fluid injection, and ③ the far-field formation pressure zone [27].

Figure 7.

Formation pressure distribution after long-term production in existing wells. Arrows are used for devision.

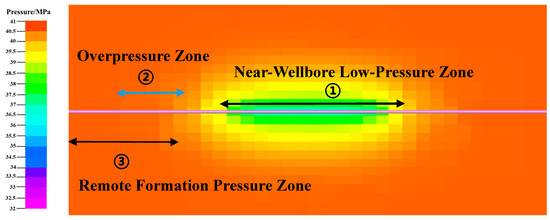

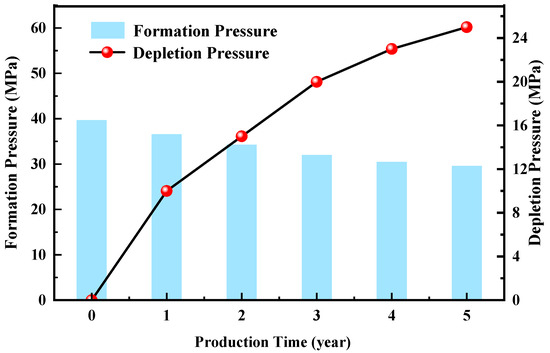

Simulations tracking formation pressure and geostress evolution over 1–5 years of parent well production in Figure 8 demonstrated synchronized declines in geostress with decreasing formation pressure, establishing a persistent low-pressure zone around fracture networks. The depleted zone progressively expanded with prolonged production duration. Subsequent child well fracturing exhibited fracture propagation preferentially oriented toward parent well depletion areas, significantly increasing interference risks [28].

Figure 8.

Evolution of formation pressure and minimum horizontal principal stress field during 1–5 years of parent well production. (a) Formation pressure. (b) Minimum horizontal principal stress.

Formation depletion caused by fluid withdrawal reduced reservoir pore pressure while elevating matrix stress and closure stress near production wells. This stress evolution enhanced the asymmetric development of bi-wing hydraulic fractures: the fracture wing adjacent to production wells exhibited progressively greater length compared to the opposite wing, with the near-wellbore/far-wellbore fracture length ratio showing an increasing trend. When formation depletion exceeded 20%, this length ratio demonstrated marked acceleration, substantially elevating inter-well interference potential, as shown in Figure 9.

Figure 9.

Formation pressure variation with production time.

2.4. Impact of Fracturing Fluid Injection Volume on Fracturing Interference

Numerical simulations were conducted for parent wells under two operational conditions (non-production and one-year production) with well spacings of 150 m, 300 m, and 450 m. Results revealed that the average fracture length of child wells was 239 m when fracturing parent wells under non-production conditions, significantly shorter than the 305 m observed after one year of parent well production. Smaller well spacing resulted in greater inter-well stress concentration effects, increased fluctuation in bi-wing fracture length ratios, and more severe asymmetric fracture propagation.

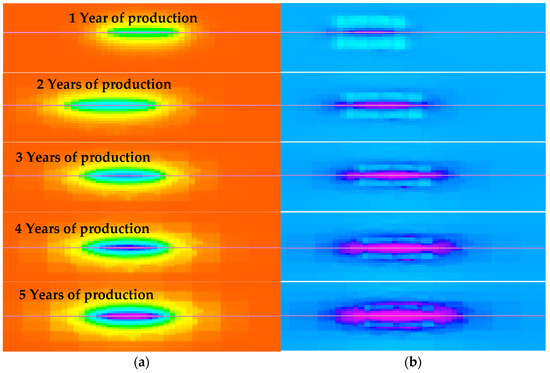

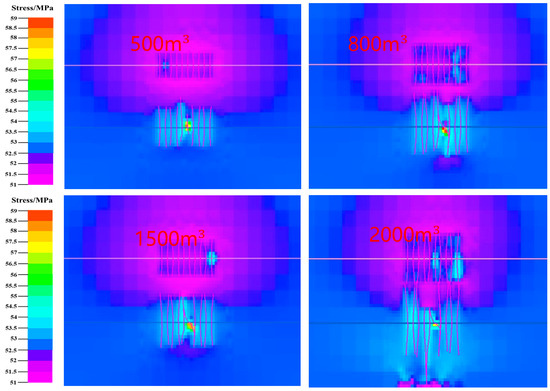

Additional simulations with fracturing fluid volumes ranging from 500 m3 to 2000 m3 showed fracture length increased from 256 m to 373 m with larger stimulation scales, as shown in Figure 10. However, both excessive and insufficient injection volumes enhanced asymmetric propagation of bi-wing fractures [29]. Larger fracturing volumes induced higher horizontal stress near parent well fractures, resulting in stronger interference effects on child well fracture extension. The volume of fracturing fluid injected plays a critical role in determining both the length and symmetry of bi-wing fractures. In production scenarios, larger fluid volumes lead to longer fractures but often with reduced symmetry due to cumulative effects of reservoir heterogeneity and stress shadowing. As more fluid is injected, the fracture extends further, but the growing length increases exposure to geological variation. In non-production settings, limited fluid volumes typically generate shorter, more symmetric fractures since the injection is brief and insufficient to overcome strong stress contrasts or natural barriers.

Figure 10.

Distribution of minimum horizontal principal stress in parent–child wells under different fracturing fluid injection volume.

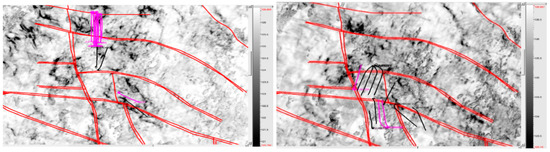

3. On-Site Fracturing Interference Analysis

During the fracturing operation at JLHW2009, JLHW2020 exhibited typical interference responses, including a 10 MPa abnormal pressure surge and a 27.6 t/d increase in liquid production rate. Coherence and curvature attribute analyses of the target intervals in Jinlong 2 Block revealed that secondary faults within the fault block and natural fracture networks formed interconnected pathways (Figure 11). During hydraulic fracture propagation, these natural weak planes established hydraulic connectivity with adjacent wells, serving as the primary geological factor for inter-well interference.

Figure 11.

Coherence attribute map of Jinlong 2 Block.

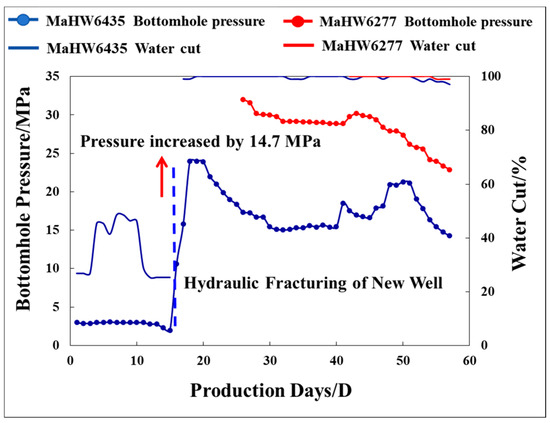

Figure 12 further illustrates the dynamic characteristics of fracturing interference through the engineering parameter evolution of a typical well group (MaHW6435-MaHW6277/6278/6279). MaHW6435 experienced interference from fracturing operations at MaHW6277/6278/6279, with its wellhead pressure surging from 2.85 MPa to 17.5 MPa. Concurrently, daily liquid production increased from 36.2 t/d to 96.6 t/d, and the water cut jumped from 35.6% to 98.6%. Notably, the production system remained in a high-pressure, high-water-cut state post-interference and did not return to baseline levels [30]. These irreversible engineering parameter changes confirm that artificial fracture networks formed during new-well fracturing established stable seepage channels with legacy well production systems, revealing that the anomalous responses in Type I characteristic wells stem from inter-well communication through hybrid artificial–natural fracture systems.

Figure 12.

Changes in wellhead pressure and water cut before and after interference in characteristic wells.

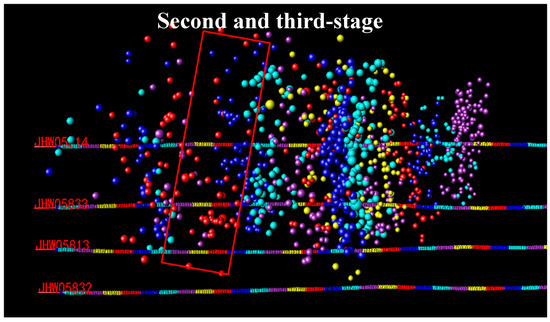

Figure 13 displays the fracture propagation patterns from microseismic monitoring during tight oil platform well fracturing. For the well group with 100 m inter-well spacing, microseismic data revealed single-well fracture half-lengths ranging from 100 to 250 m (average 150 m), with fracture systems exhibiting full planar coverage and partial intersections. If fractures extend 250 m (half-length), wells spaced at less than 500 m risk direct fracture-driven interactions, leading to parent–child well communication. When wellbores deviate from the minimum principal stress direction, hydraulic fractures develop as tensile–shear composite fractures with deflection angles positively correlated to the wellbore-stress misalignment angle. Specifically, during sequential fracturing, second- and third-stage fractures undergo deflection, whereas two-step leapfrog fracturing produces straighter intermediate fractures with reduced widths due to symmetrical stress interference from adjacent stages.

Figure 13.

Microseismic-monitored fracture propagation in tight oil platform wells. Red box is to explain the fracturing scale.

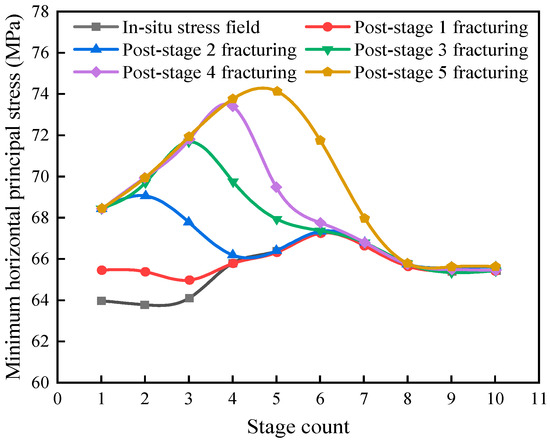

Based on the dynamic evolution of in situ stress fields (Figure 14), research shows that single-stage fracturing most significantly affects stress field perturbations within three stages (150 m) ahead of and behind the operation. Combining fracture propagation and production prediction analyses, an “interleaved zipper + balanced progression” implementation strategy was developed. The interleaved zipper modification staggers the fracturing sequence between wells, allowing previously stimulated zones to partially relax before adjacent stages are initiated. This reduces cumulative stress buildup and prevents concentrated deformation zones, with a balanced progression of fracture stages to ensure even pressure distribution and reduce asymmetric loading on the casing. This approach enhances reservoir stimulation effectiveness while improving stress balance on both sides of casings, thereby reducing casing deformation risks.

Figure 14.

Dynamic variation range of stress fields.

4. Conclusions

The study systematically reveals the influence of fault structures, natural fracture networks, formation depletion, well spacing optimization, and engineering factors on fracturing well interference through multi-dimensional numerical simulations and field case analyses. By quantitatively investigating the impacts of various geological conditions and stimulation on fracture propagation paths and inter-well connectivity, it provides theoretical support for fracturing process optimization and interference risk mitigation.

1. The angle between faults and the initial propagation direction of artificial fractures significantly influences fracture deflection behavior. As the angle increases from 30° to 60°, the fracture deflection amplitude intensifies, with fractures tending to extend along fault strikes. Increased Young’s modulus in fault fracture zones reduces deflection amplitude, while elevated horizontal stress differences reinforce principal stress dominance, enabling fractures to directly penetrate fracture zones (accelerated shear component decay rate). When fractures are arranged perpendicular to faults, controlling fracturing scale mitigates fault effects, whereas parallel arrangements require edge perforation cluster plugging or fluid viscosity adjustments to reduce driving forces.

2. The density of inter-well natural fractures regulates interference intensity through fractal dimension: at low densities, main fractures propagate along high-conductivity natural fractures, with interference probability rising as density increases. When density further increases, elevated fractal dimensions induce multi-stage branching fractures that dissipate energy, reducing main fracture length and enriching fracture networks near wells, thereby lowering interference probability.

3. After 1–5 years of parent well production, the low-pressure zone formed by formation depletion expands continuously, causing child well fractures to extend toward depleted areas (asymmetric fracture length increases). When formation depletion exceeds 20%, the near-well/far-well fracture length ratio rises significantly, intensifying inter-well interference risks. Reduced pore pressure in production zones increases matrix stress and fracture closure stress.

4. When parent wells are inactive, stress concentration effects intensify when well spacing is reduced to 150 m. Increasing fracturing volume from 500 m3 to 2000 m3 extends fracture length from 256 m to 373 m, but excessive or insufficient fluid volumes exacerbate asymmetric fracture propagation. Reduced well spacing amplifies horizontal stress concentration effects, increasing fracture deflection angles.

5. Microseismic monitoring shows fracture half-lengths of 100–250 m (average 150 m) at 100 m well spacing, with fracture intersections stabilizing flow channels. The “cross-zipper and aligned propagation” technique reduces casing deformation risks, with single-stage fracturing inducing the most significant stress field perturbations within 150 m of adjacent stages.

Author Contributions

Conceptualization, K.L. (Kun Liu) and Y.Y.; Original writing, K.L. (Kun Liu) and K.L. (Kaixin Liu), Methodology, Z.Z., Reviewing, T.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was support from Xinjiang Tianshan talent training program (2023TSYCJC0002), Xinjiang Tianshan Innovation Team (2024D14004) is highly appreciated.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Kun Liu, Yiping Ye, Kaixin Liu, Zhemin Zhou were employed by the PetroChina Xinjiang Oilfield Company. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Yan, X.; Mou, J.; Tang, C.; Xin, H.; Zhang, S.; Ma, X.; Duan, G. Numerical investigation of major impact factors influencing fracture-driven interactions in tight oil reservoirs: A case study of Mahu sug, Xinjiang, China. Energies 2021, 14, 4881. [Google Scholar] [CrossRef]

- Daneshy, A.A.; Au-Yeung, J.; Thompson, T.; Tymko, D.W. Fracture shadowing: A direct method for determination of the reach and propagation pattern of hydraulic fractures in horizontal wells. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 6–8 February 2012. SPE-151980-MS. [Google Scholar]

- Schaeffer, B.; McGreaham, L.; Reshetnikov, A. Unconventional parent-child well completion evaluation via microseismic analysis: A delaware basin case study. In Proceedings of the SEG International Exposition and Annual Meeting, Houston, TX, USA, 17–20 September 2017. SEG-2017-17787435. [Google Scholar]

- Vulgamore, T.; Clawson, T.; Pope, C.; Wolhart, S.; Mayerhofer, M.; Machovoe, S.; Waltman, C. Applying hydraulic fracture diagnostics to optimize stimulations in the woodford shale. In Proceedings of the SPE Annual Technical Conference and Exhibition, Anaheim, CA, USA, 11–14 November 2007. SPE-110029-MS. [Google Scholar]

- King, G. 60 years of multi-fractured vertical, deviated and horizontal wells: What have we learned? In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014. SPE-170952-MS. [Google Scholar]

- Vargas-Silva, S.; Khodabakhshnejad, A.; Paryani, M.; Venepalli, K.; Ouenes, A. Pressure depletion’s impact on induced strain during hydraulic fracturing in child wells: The key to mitigate fracture hits and pressure interference. In Proceedings of the SPE Canada Unconventional Resources Conference, Calgary, AB, Canada, 13–14 March 2018. SPE-189801-MS. [Google Scholar]

- Mukherjee, H.; Poe, B.J.; Heidt, J.H.; Watson, T.B.; Barree, R.D. Effect of pressure depletion on fracture-geometry evolution and production performance. SPE Prod. Facil. 2000, 15, 144–150. [Google Scholar] [CrossRef]

- Manchanda, R.; Sharma, M.M.; Holzhauser, S. Time-Dependent fracture-interference effects in pad wells. SPE Prod. Oper. 2014, 29, 274–287. [Google Scholar] [CrossRef]

- Ezulike, O.; Fu, Y.; Dehghanpour, H.; Virues, C. Investigating well interference in a multi-well pad by combined flowback and tracer analysis. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017. URTEC-2017-2697593. [Google Scholar]

- Duan, G.; Mou, J.; Yan, X.; Song, Y.; Xu, Y.; Wang, N. Key controlling factors and inducement mechanism of fracture-driven interactions(FDIs) between deep shale gas horizontal wells in southern Sichuan Basin. China Pet. Explor. 2024, 29, 146–158. [Google Scholar]

- Roussel, N.; Samarth, A. Introduction to poroelastic response monitoring-quantifying hydraulic fracture geometry and srv permeability from offset-well pressure data. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017. URTEC-2017-2645414. [Google Scholar]

- Gu, H.; Weng, X.; Lund, J.; Mack, M.; Ganguly, U.; Suarez-Rivera, R. Hydraulic fracture crossing natural fracture at non-orthogonal angles, a criterion, its validation and applications. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 24–26 January 2011. SPE-139984-MS. [Google Scholar]

- Zhang, F.; Damjanac, B.; Maxwell, S. Investigating hydraulic fracturing complexity in naturally fractured rock masses using fully coupled multiscale numerical modeling. Rock Mech. Rock Eng. 2019, 52, 5137–5160. [Google Scholar] [CrossRef]

- Sharma, A.; Damani, A.; Sondergeld, C.; Rai, C. Understanding the microscale physics of hydraulic fracturing: A laboratory approach. In Proceedings of the 2013 SEG Annual Meeting, Houston, TX, USA, 22–27 September 2013. SEG-2013-1227. [Google Scholar]

- Weng, X.; Kresse, O.; Cohen, C.-E.; Wu, R.; Gu, H. Modeling of hydraulic-fracture-network propagation in a naturally fractured formation. SPE Prod. Oper. 2011, 26, 368–380. [Google Scholar]

- Shrivastava, K.; Sharma, M. Proppant transport in complex fracture networks. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 23–25 January 2018. SPE-189895-MS. [Google Scholar]

- Chittenden, H.; Cannon, D.; Jeziorski, K.; Bowman-Young, S.; Smith-Boughner, L. Understanding the role of well sequencing in managing reservoir stress response in the permian: Implications for child-well completions using high-resolution microseismic analysis. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2020. SPE-199758-MS. [Google Scholar]

- Lecampion, B.; Desroches, J.; Weng, X.; Burghardt, J.; Brown, J.E. Can we engineer better multistage horizontal completions? evidence of the importance of near-wellbore fracture geometry from theory, lab and field experiments. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 3–5 February 2015. SPE-173363-MS. [Google Scholar]

- Sookprasong, P.A.; Hurt, R.S.; Gill, C.C.; LaFollette, R.F. Fiber optic das and dts in multicluster, multistage horizontal well fracturing: Interpreting hydraulic fracture initiation and propagation through diagnostics. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014. SPE-170723-MS. [Google Scholar]

- Ugueto, G.A.; Huckabee, P.T.; Molenaar, M.M.; Wyker, B.; Somanchi, K. Perforation cluster efficiency of cemented plug and perf limited entry completions; insights from fiber optics diagnostics. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 9–11 February 2016. SPE-179124-MS. [Google Scholar]

- Lecampion, B.; Desroches, J. Simultaneous initiation and growth of multiple radial hydraulic fractures from a horizontal wellbore. J. Mech. Phys. Solids 2015, 82, 235–258. [Google Scholar] [CrossRef]

- Peirce, A.P.P.; Bunger, A.P.P. Interference fracturing: Nonuniform distributions of perforation clusters that promote simultaneous growth of multiple hydraulic fractures. SPE J. 2015, 20, 384–395. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, Y.; Wang, Q.; Zhao, J.; Zhu, J.; Li, X.; Yang, Y. The propagation laws of hydraulic fractures under the influence of natural fracture zones. Phys. Fluids 2025, 37, 1–13. [Google Scholar] [CrossRef]

- Zeng, Q.; Yao, J.; Shao, J. Numerical study of hydraulic fracture propagation accounting for rock anisotropy. J. Pet. Sci. Eng. 2018, 160, 422–432. [Google Scholar] [CrossRef]

- Zheng, H.; Pu, C.; Sun, C. Study on the interaction between hydraulic fracture and natural fracture based on extended finite element method. Eng. Fract. Mech. 2020, 230, 106981. [Google Scholar] [CrossRef]

- Sun, X.; Zhao, K.; Song, X. Experimental study on dynamic fracture propagation and evolution during coal seam supercritical CO2 fracturing. Phys. Fluids 2024, 36, 1–12. [Google Scholar] [CrossRef]

- Daneshy, A.; King, G. Horizontal well frac-driven interactions: Types, consequences, and damage mitigation. J. Pet. Technol. 2019, 71, 45–47. [Google Scholar] [CrossRef]

- Fisher, M.K.; Heinze, J.R.; Harris, C.D.; Davidson, B.M.; Wright, C.A.; Dunn, K.P. Optimizing horizontal completion techniques in the barnett shale using microseismic fracture mappin. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26–29 September 2004. SPE-90051-MS. [Google Scholar]

- Miller, C.K.; Waters, G.A.; Rylander, E.I. Evaluation of production log data from horizontal wells drilled in organic shales. In Proceedings of the North American Unconventional Gas Conference and Exhibition, The Woodlands, TX, USA, 14–16 June 2011. SPE-144326-MS. [Google Scholar]

- Wu, R.; Kresse, O.; Weng, X.; Cohen, C.; Gu, H. Modeling of Interaction of Hydraulic Fractures in Complex Fracture Networks. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 6–8 February 2012. SPE-152052-MS. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).