Stress Analysis of High-Pressure Natural Gas Pipe with Flowmeter Clamping Apparatus Made of Steel Material

Abstract

1. Introduction

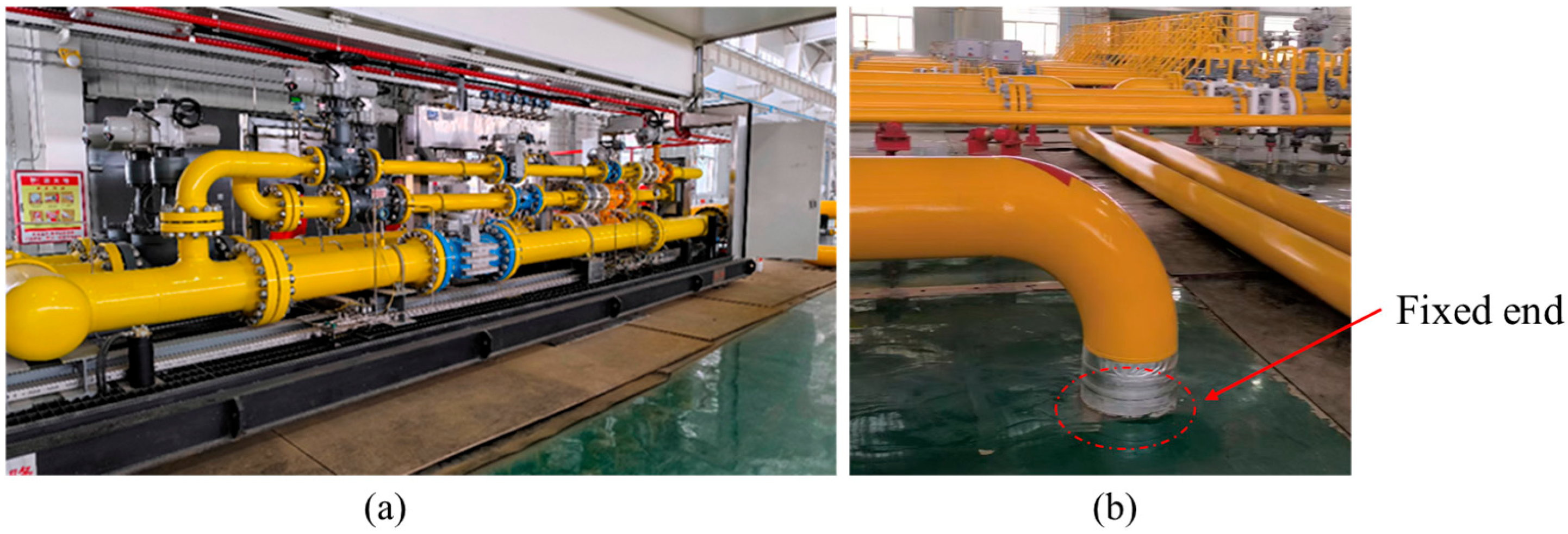

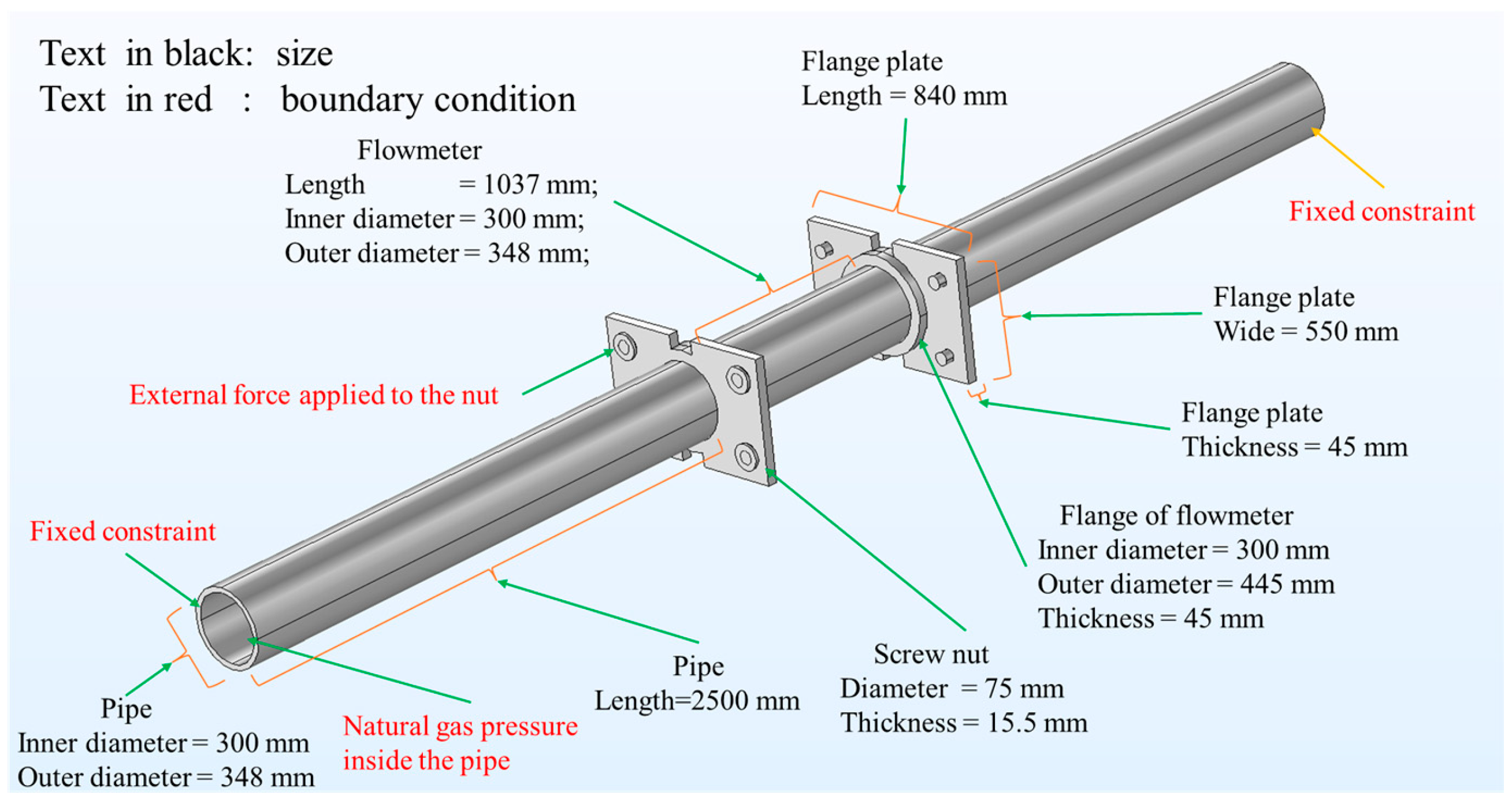

2. Model Description

2.1. Physical Model

2.2. Governing Equation

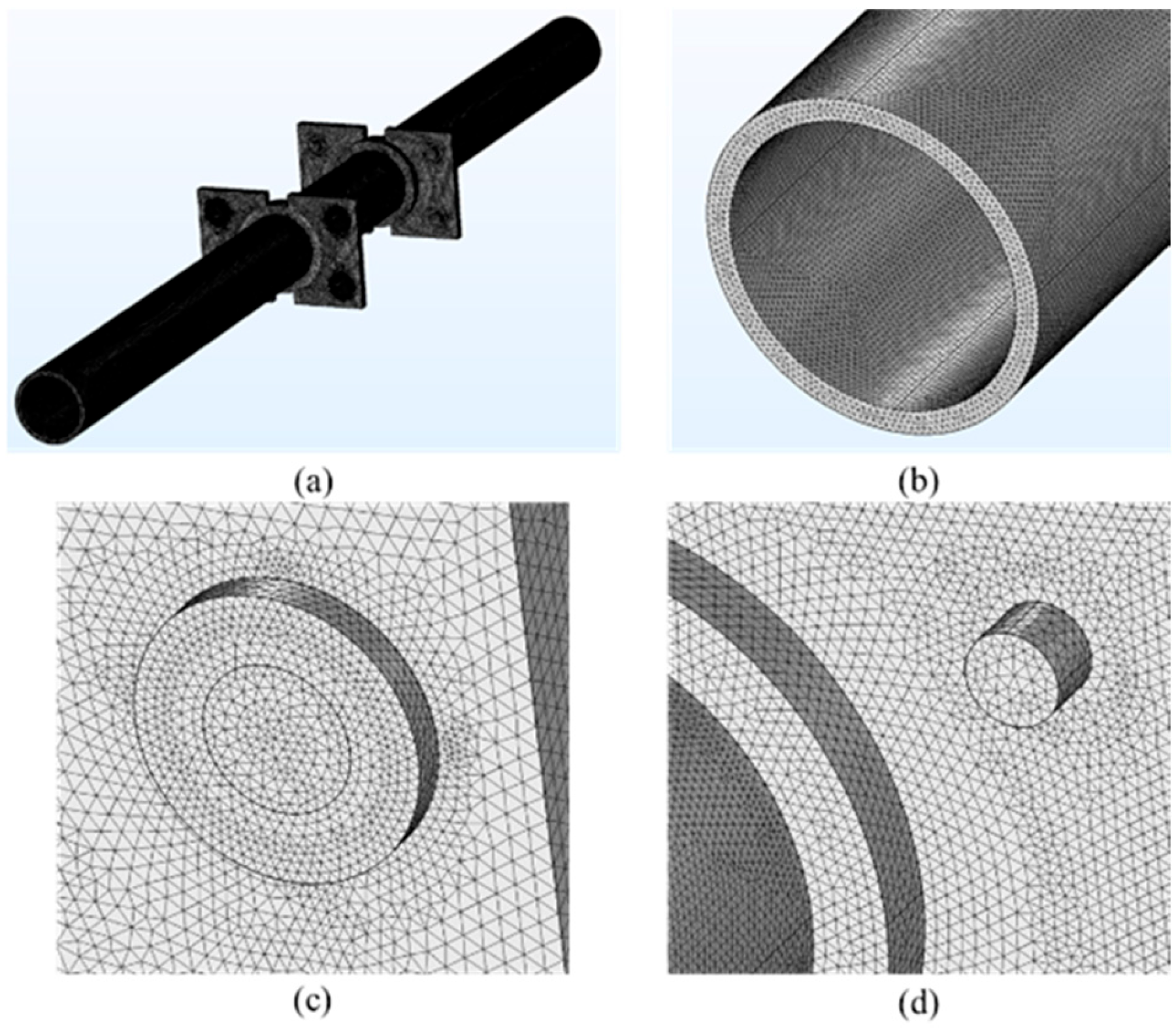

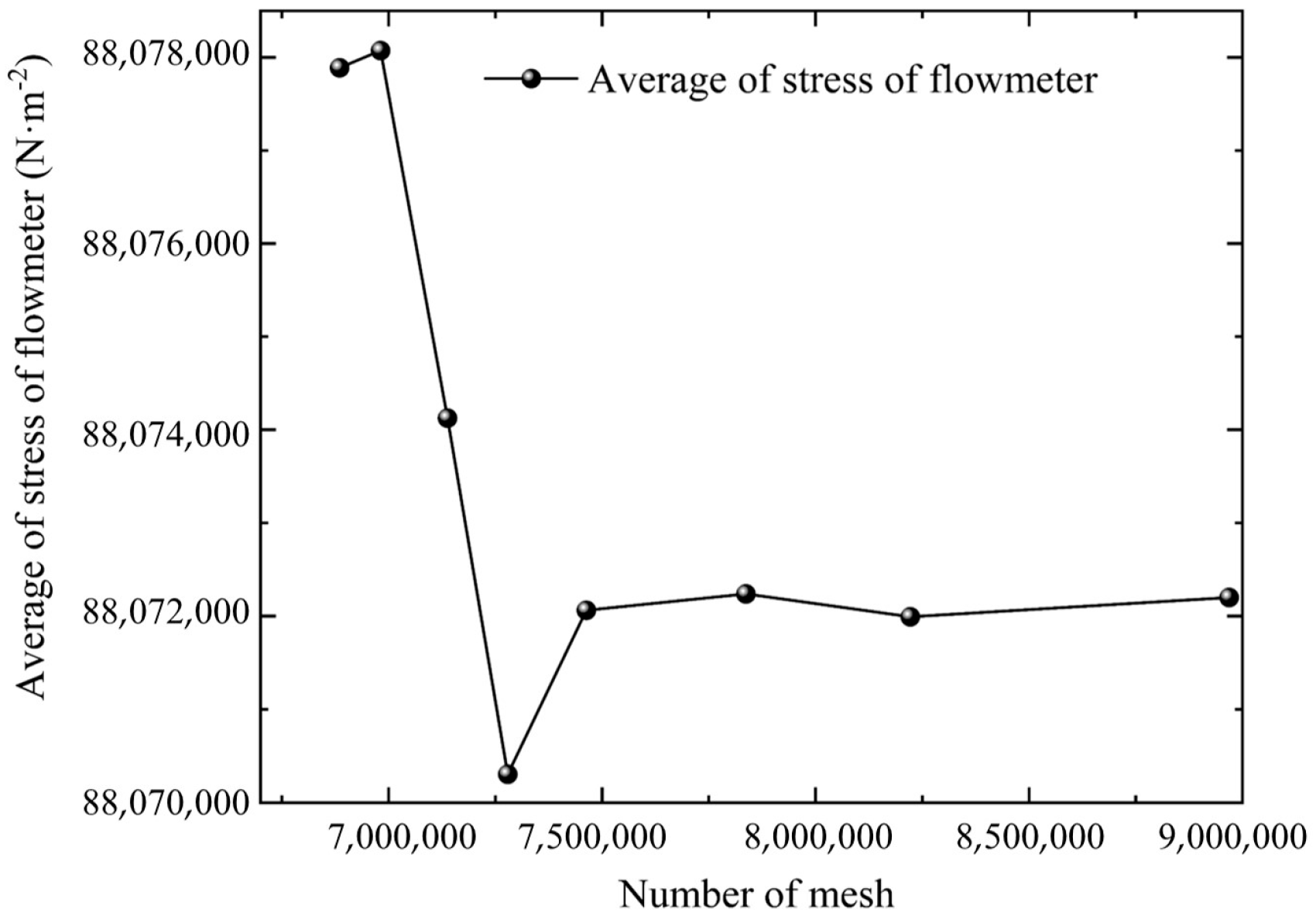

2.3. Mesh Generation

3. Results and Discussion

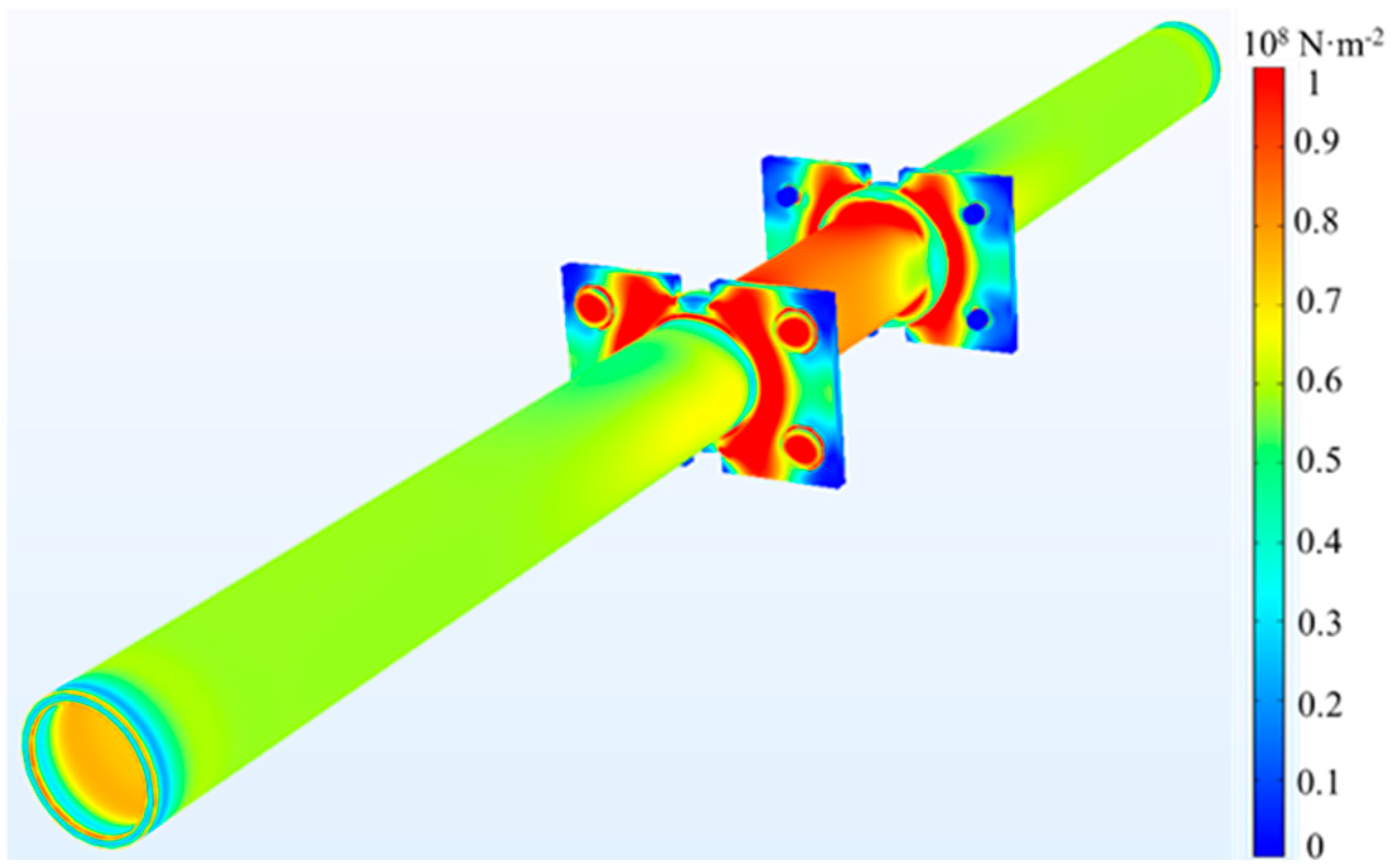

3.1. Stress Distribution of the Flowmeter Clamping Apparatus

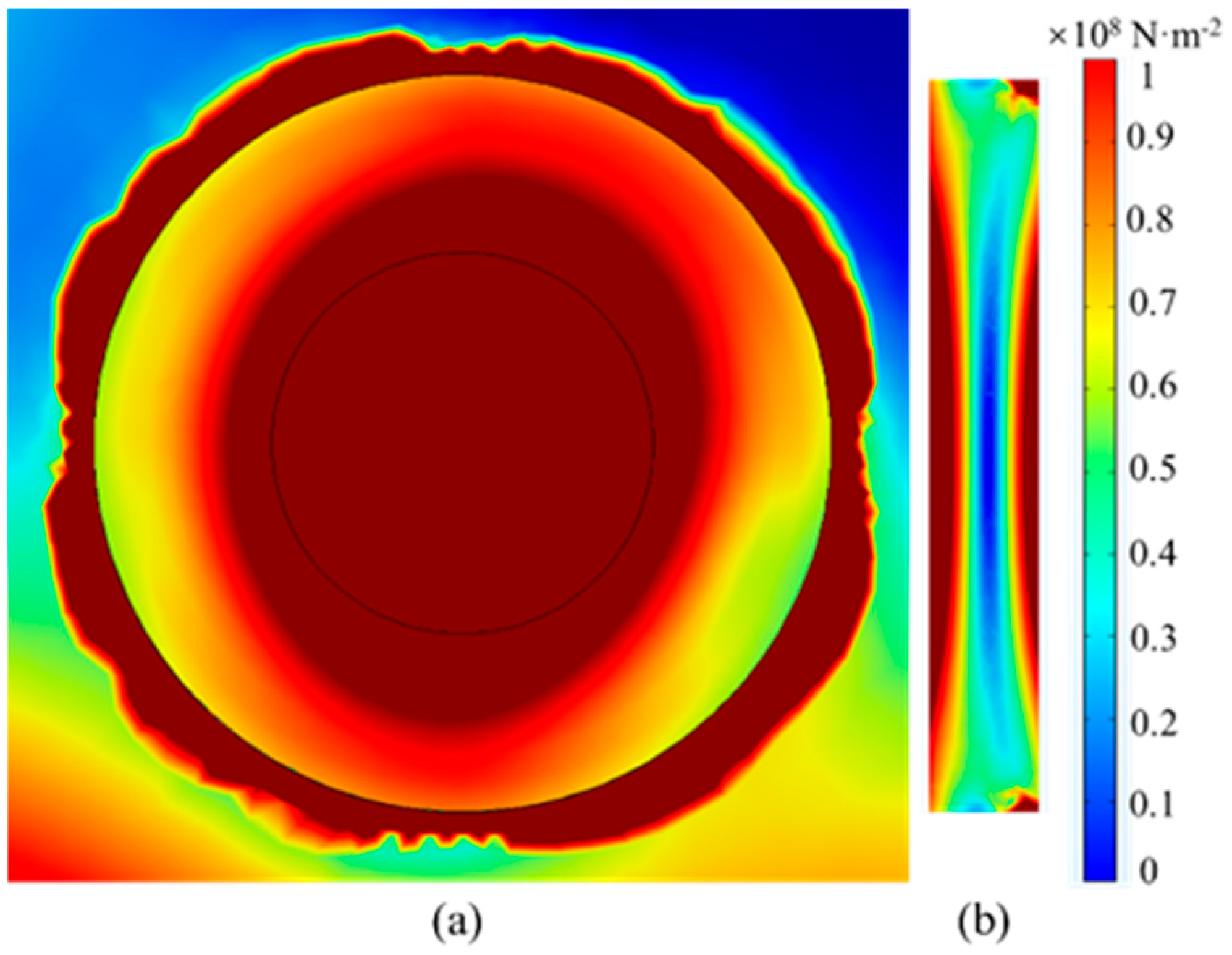

3.2. Stress Analysis Around Screw Nut

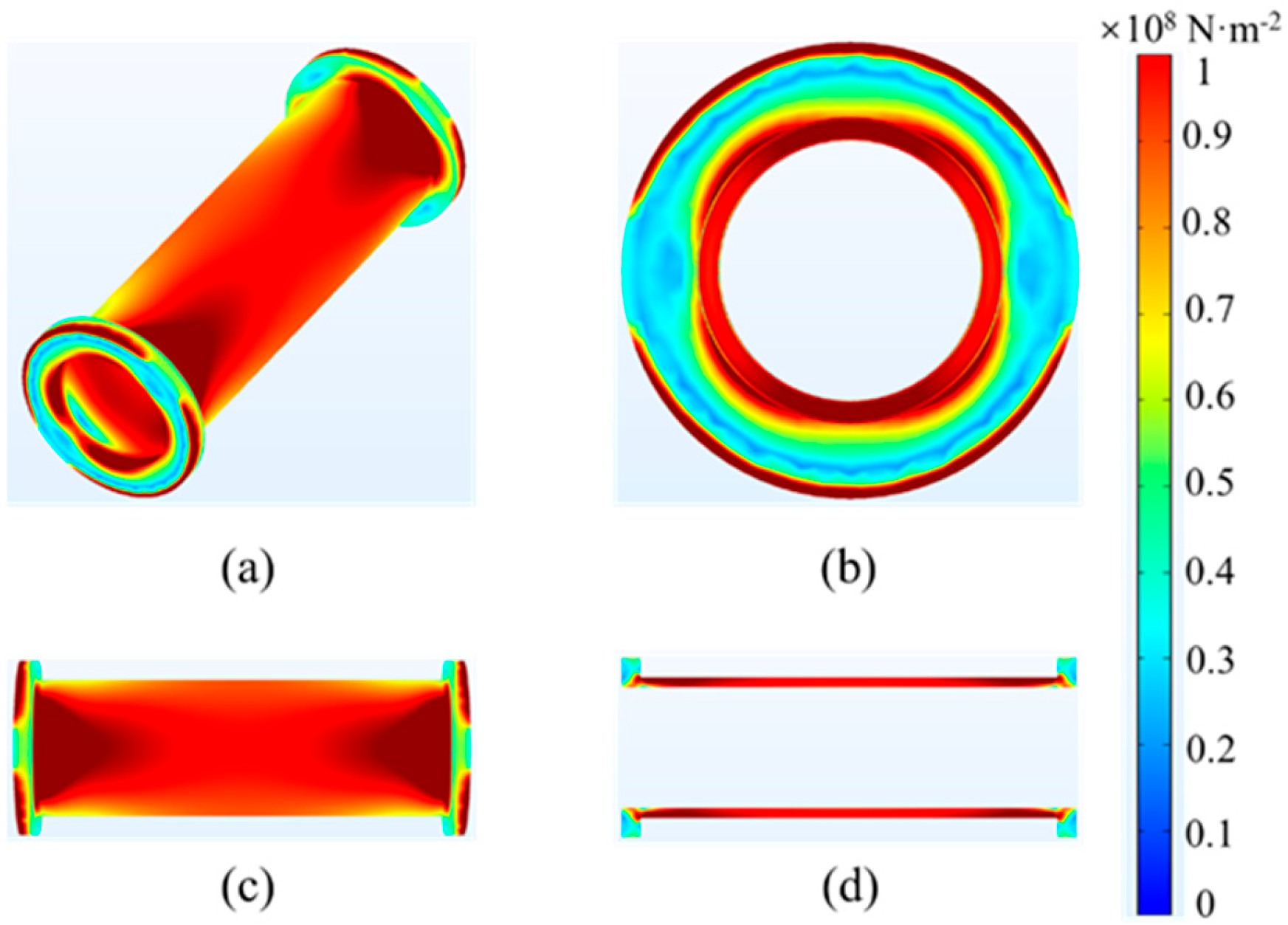

3.3. Stress Analysis of Flange Plate

3.4. Stress Analysis of Flowmeter

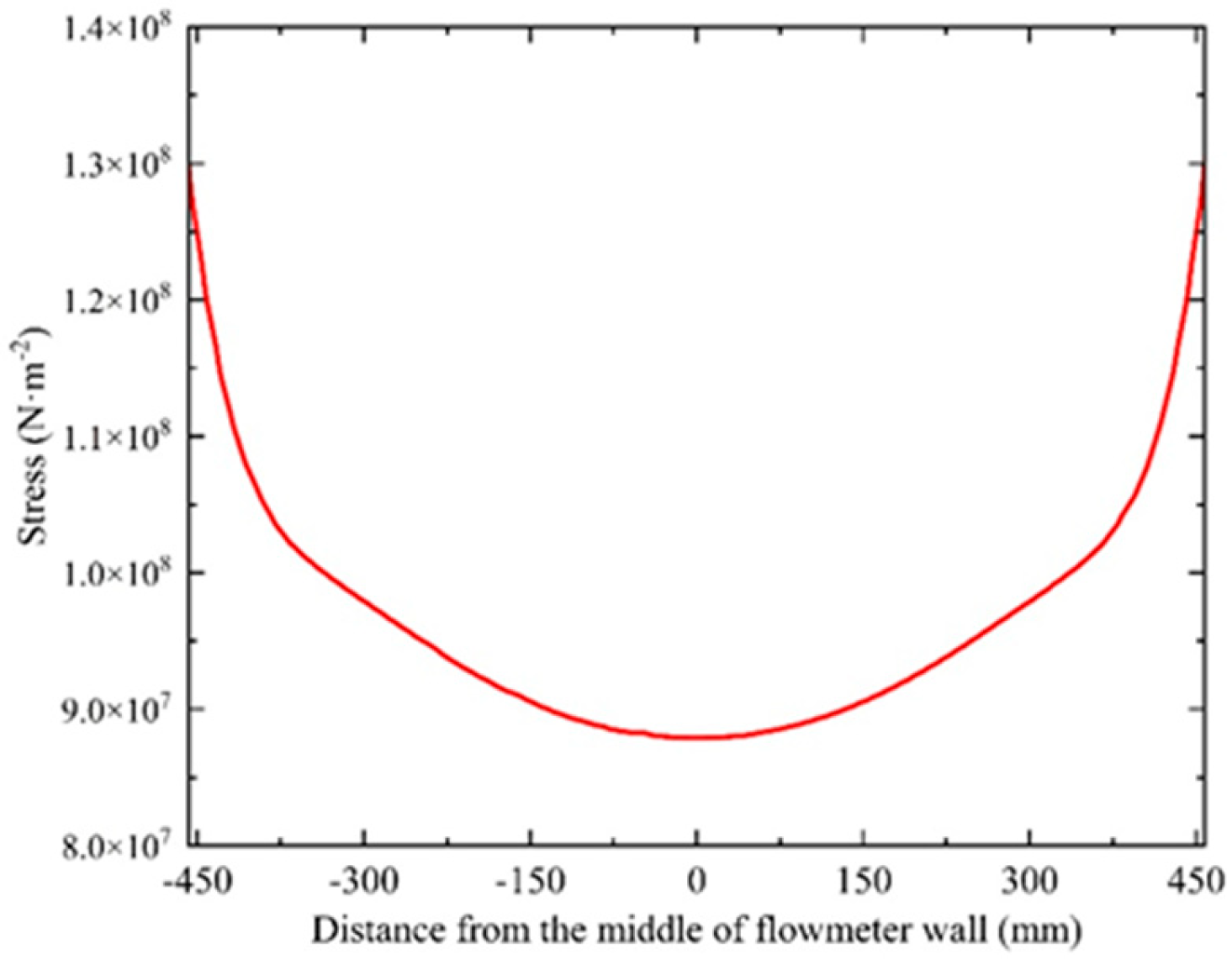

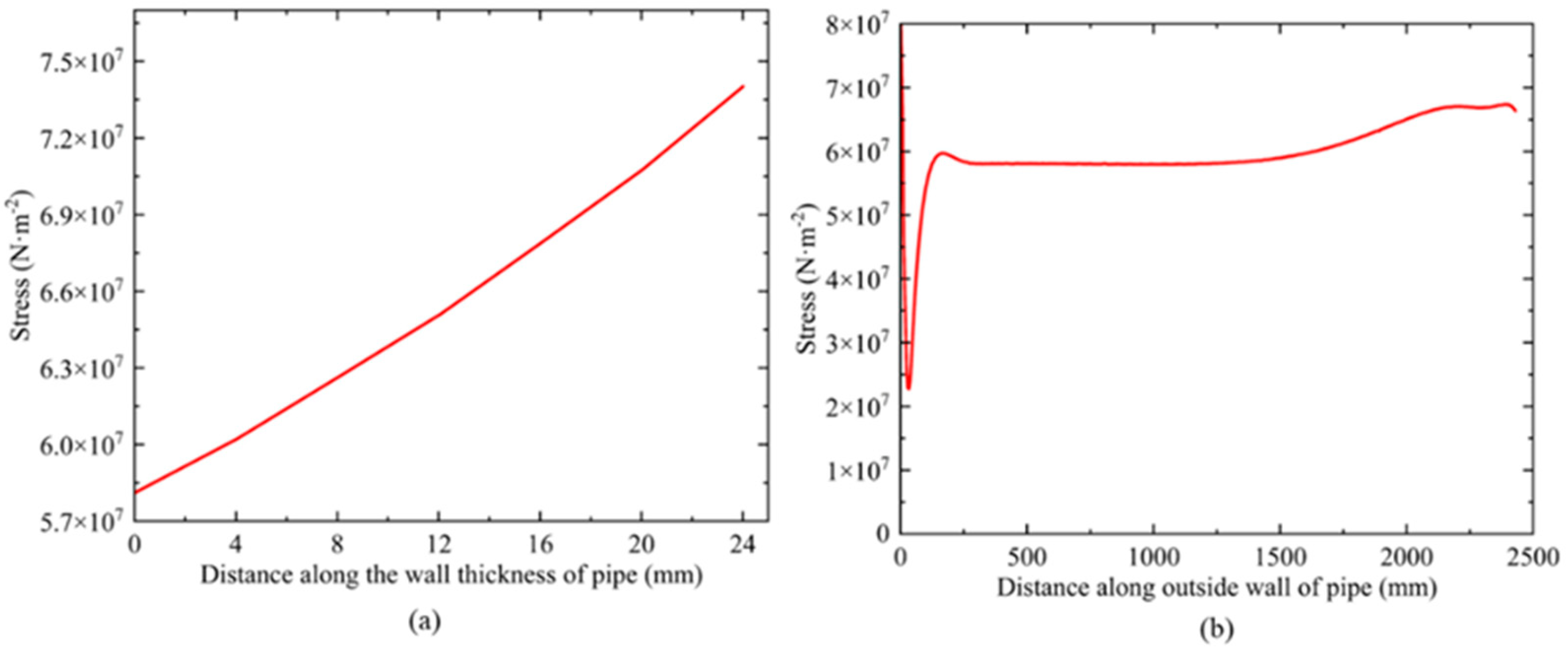

3.5. Stress Analysis of Pipe

4. Discussion

- (1)

- The peak stress of the device is significantly lower than 50% of the material’s yield strength. So, the flowmeter fastening mechanism, as designed, operates in a safe and reliable manner, and the design of the entire device is reasonable.

- (2)

- The stress distribution on nuts usually has the characteristic of higher stress in the central area and lower stress in the surrounding area. The flowmeter’s surface stress shows greater stress at its two extremities and lower stress in the central zone.

- (3)

- A peak stress of 146 MPa is exhibited at the flowmeter flange within the clamping device. And the nut has the smallest maximum stress value among the four components, with a value of 117 MPa.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, X.; Lu, H.; Wu, S. Stress analysis of parallel oil and gas steel pipelines in inclined tunnels. SpringerPlus 2015, 4, 659. [Google Scholar] [CrossRef] [PubMed]

- Qiu, G.; Sun, M. Interaction Mechanism of Inter-Pipes in Double-Layer Pipelines and a Mechanical Model with Differential Thermal Deformation. Processes 2025, 13, 762. [Google Scholar] [CrossRef]

- Cho, Y.; Ulrich, B.A.; Zimmerle, D.J.; Smits, K.M. Estimating natural gas emissions from underground pipelines using surface concentration measurements. Environ. Pollut. 2020, 267, 115514. [Google Scholar] [CrossRef]

- Ulrich, B.A.; Mitton, M.; Lachenmeyer, E.; Hecobian, A.; Zimmerle, D.; Smits, K.M. Natural gas emissions from underground pipelines and implications for leak detection. Environ. Sci. Technol. Lett. 2019, 6, 401–406. [Google Scholar] [CrossRef]

- Li, L.; Zhu, L.; Yan, X.; Jia, H.; Xie, S.; Zou, Y. The impact of weld repairs on the microstructure and mechanical integrity of X80 pipelines in oil and gas transmission. Processes 2025, 13, 512. [Google Scholar] [CrossRef]

- Dong, J.; Jing, C.; Peng, Y.; Liu, Y.; Ren, H.; Liu, X. Study on the measurement accuracy of an improved cemented carbide orifice flowmeter in natural gas pipeline. Flow Meas. Instrum. 2018, 59, 52–62. [Google Scholar] [CrossRef]

- Guzzini, A.; Pellegrini, M.; Saccani, C.; Dudek, A.; Gajec, M.; Kr’ol, A.; Kulaga, P.; Gislon, P.; Cigolotti, V.; Robino, M.; et al. Hydrogen in natural gas grids: Prospects and recommendations about gas flow meters. Int. J. Hydrog. Energy 2024, 86, 343–362. [Google Scholar] [CrossRef]

- Mehmanparast, A.; Lotfian, S.; Vipin, S.P. A review of challenges and opportunities associated with bolted flange connections in the offshore wind industry. Metals 2020, 10, 732. [Google Scholar] [CrossRef]

- Łaciak, M.; Włodek, T.; Kozakiewicz, T.; Krystian, L. Impact of flood water on the technical condition of natural gas transmission pipeline valves. J. Loss Prev. Process Ind. 2020, 63, 103998. [Google Scholar] [CrossRef]

- Zhang, Z.; Guo, Y.; Wang, D.; Li, G.; Peng, D. A Noisy-OR gate based fuzzy fault tree approach for micro-leakage evaluation of bolt-gasket-flange connection (BGFC). J. Loss Prev. Process Ind. 2021, 71, 104521. [Google Scholar] [CrossRef]

- Sabokrouh, M.; Farahani, M. Experimental study of the residual stresses in girth weld of natural gas transmission pipeline. J. Appl. Comput. Mech. 2019, 5, 199–206. [Google Scholar] [CrossRef]

- Gu, X.; Zhang, Y.; Huang, C.; Luo, X.; Zhang, H.; Zhou, R.; Qiu, Y. Sensitivity analysis of influencing factors of gas pipelines with corrosion defects under the action of landslides. Energies 2022, 15, 6640. [Google Scholar] [CrossRef]

- Pourazizi, R.; Mohtadi-Bonab, M.A.; Szpunar, J.A. Investigation of different failure modes in oil and natural gas pipeline steels. Eng. Fail. Anal. 2020, 109, 104400. [Google Scholar] [CrossRef]

- Eames, I.; Austin, M.; Wojcik, A. Injection of gaseous hydrogen into a natural gas pipeline. Int. J. Hydrog. Energy 2022, 47, 25745–25754. [Google Scholar] [CrossRef]

- Cerniauskas, S.; Junco, A.J.C.; Grube, T.; Robinius, M.; Stolten, D. Options of natural gas pipeline reassignment for hydrogen: Cost assessment for a Germany case study. Int. J. Hydrog. Energy 2020, 45, 12095–12107. [Google Scholar] [CrossRef]

- Liao, C.; Lu, H.; Fan, S.; Chang, X.; Sun, H. Study on stress relaxation characteristics of bolted flanged joints with metal C-rings. Int. J. Press. Vessel. Pip. 2019, 171, 207–216. [Google Scholar] [CrossRef]

- Peng, Z.; Zhao, H.; Li, X.; Yuan, L.; Zhu, T. Ductile fracture of X80 pipeline steel over a wide range of stress triaxialities and Lode angles. Eng. Fract. Mech. 2023, 289, 109470. [Google Scholar] [CrossRef]

- Yu, D.; Yang, C.; Sun, Q.; Dai, L.; Wang, A.; Xuan, H. Impact of process parameters on temperature and residual stress distribution of X80 pipe girth welds. Int. J. Press. Vessel. Pip. 2023, 203, 104939. [Google Scholar] [CrossRef]

- Qin, G.; Cheng, Y.F. Failure pressure prediction by defect assessment and finite element modelling on natural gas pipelines under cyclic loading. J. Nat. Gas Sci. Eng. 2020, 81, 103445. [Google Scholar] [CrossRef]

- Khater, M.A.; Arroussi, C.; Memchout, S.A. Finite element analyses of buckling behavior in x60 steel pipelines under axial compression load. Stud. Eng. Exact Sci. 2024, 5, e6708. [Google Scholar] [CrossRef]

- Xiang, Y.; Zhu, L.; Jia, B.; Zhao, L.; Li, N.; Gu, Y.; Ren, P. Sensitivity analysis and failure prediction of X80 pipeline under transverse landslide. J. Constr. Steel Res. 2025, 224, 109090. [Google Scholar] [CrossRef]

- Jafari, A.; Broumand, P.; Vahab, M.; Khalili, N. An eXtended finite element method implementation in COMSOL multiphysics: Solid mechanics. Finite Elem. Anal. Des. 2022, 202, 103707. [Google Scholar] [CrossRef]

| Young’s Modulus | Poisson’s Ratio | Density | Yield Strength |

|---|---|---|---|

| 200 MPa | 0.3 | 7850 kg·m−3 | 552 MPa |

| Component | Value (mm) | |

|---|---|---|

| Pipe | Length (one side) | 2500 |

| Inner diameter | 300 | |

| Outer diameter | 348 | |

| Flange plate | Length | 840 |

| Wide | 550 | |

| Thickness | 45 | |

| Flowmeter | Length | 1037 |

| Inner diameter | 300 | |

| Outer diameter | 348 | |

| Flange of flowmeter | Inner diameter | 300 |

| Outer diameter | 445 | |

| Thickness | 45 | |

| Screw nut | Diameter | 75 |

| Thickness | 15.5 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Z.-Y.; Yang, Y.-X.; Zhang, M.; Yao, Z.-Q.; Mu, C.-Y.; Lin, J.-Z. Stress Analysis of High-Pressure Natural Gas Pipe with Flowmeter Clamping Apparatus Made of Steel Material. Processes 2025, 13, 1841. https://doi.org/10.3390/pr13061841

Song Z-Y, Yang Y-X, Zhang M, Yao Z-Q, Mu C-Y, Lin J-Z. Stress Analysis of High-Pressure Natural Gas Pipe with Flowmeter Clamping Apparatus Made of Steel Material. Processes. 2025; 13(6):1841. https://doi.org/10.3390/pr13061841

Chicago/Turabian StyleSong, Zhao-Yong, Yu-Xing Yang, Man Zhang, Zhi-Qiang Yao, Chao-Yi Mu, and Jun-Zhe Lin. 2025. "Stress Analysis of High-Pressure Natural Gas Pipe with Flowmeter Clamping Apparatus Made of Steel Material" Processes 13, no. 6: 1841. https://doi.org/10.3390/pr13061841

APA StyleSong, Z.-Y., Yang, Y.-X., Zhang, M., Yao, Z.-Q., Mu, C.-Y., & Lin, J.-Z. (2025). Stress Analysis of High-Pressure Natural Gas Pipe with Flowmeter Clamping Apparatus Made of Steel Material. Processes, 13(6), 1841. https://doi.org/10.3390/pr13061841