Abstract

This study analyzes the effect of artificial aging on the mechanical deformational and optical properties of various paper samples, which allows us to evaluate their durability and suitability for long-term storage. The methods of accelerated aging, measuring the breaking length, specific resistance, elongation, and fracture strength, were used, and the optical characteristics were estimated by the R457 and CIE whiteness indices, as well as opacity. Mechanical measurements (breaking length, specific resistance, elongation, and fracture strength) revealed that bleaching reduces residual lignin and strengthens interfiber bonds, boosting pine pulp strength by up to 8%. Optical properties initially improve slightly, then increase sharply after the second bleaching cycle and stabilize, while opacity decreases, providing greater light transmittance. After accelerated aging, the following deterioration is observed: for bleached samples, R457 whiteness changes; and for unbleached samples, CIE whiteness and opacity increase. After aging, aspen pulps and kraft papers retained over 90% of their initial strength and whiteness, whereas untreated and office papers lost up to 20–25%. These findings identify that aspen-based and kraft papers demonstrate better mechanical deformational and optical properties, which makes it possible to predict the operational characteristics of paper depending on the processing and aging methods used.

1. Introduction

The paper industry ranks among the top sectors of the global economy. Global consumption of paper and cardboard is expanding at 1.1% each year and will reach 400 million tons by 2030 [1]. Paper and cardboard have a wide range of applications, which explains their high demand. Paper is a key component of the printing industry, which includes the production of books, newspapers, periodicals, and office documents, as well as hygiene items such as toilet paper, paper towels, and napkins, all of which are essential in today’s world.

Many pulp and paper companies now frequently publish sustainability reports based on Global Reporting Initiative (GRI) standards, providing transparency of their impact on the economy, environment, and society [2]. Such reports include not just environmental performance and corporate governance statistics, but also descriptions of companies’ initiatives to decrease emissions, conserve water and energy, and sustainably manage waste. The pulp and paper industry is one of the industries that considerably depletes natural resources such as wood and water. It also generates huge amounts of wastewater and other by-products, which present environmental issues and drive the development of new production technologies [3]. At the same time, there is an active search for ways to include the concepts of a circular economy, such as novel approaches to paper manufacturing, recycling, and the reuse of process waste, which allows for a reduction in the overall carbon footprint of production.

The primary basic ingredient for paper production is cellulose, which goes through various phases of processing, including heating, washing, sorting, and bleaching. During the heating process, wood chips are treated with chemicals that remove lignin and other non-cellulose components [4]. After cooking, the bulk is cleaned to eliminate any leftover chemicals or dissolved substances. The cellulose is next sifted to separate the uncooked particles and contaminants. The majority of the cellulose is then processed into paper using forming machines. Office paper made from cellulose must have a high level of brightness (80–90%) [5]. High brightness paper provides excellent text contrast, visual perception, and print quality. To obtain high brightness, at the end of cooking, cellulose is bleached with various chemical reagents, including chlorine- and oxygen-containing compounds, to eliminate lignin and other impurities that impair the optical properties of cellulose [6,7,8].

Office paper is known to have a service life of only a few days. In this scenario, the question is whether it is conceivable to substitute short-life paper with lesser-quality paper (with reduced whiteness) without significantly affecting its basic qualities. Using paper with a high cellulose satellite content reduces both environmental effects and production costs. SvetoCopy ECO and EKKO (Svetogorsk Pulp and Paper Mill, Russia) have established themselves as viable alternatives to high whiteness paper. Since semi-bleached cellulose is employed in its manufacture and no chlorine-containing chemicals are used in the bleaching process, SvetoCopy ECO has lowered whiteness (no more than 60%) and a light beige tinge, unlike conventional office paper. The paper comes in standard A4 format and has a density of 80 g/m², making it ideal for office printing. Paper sold under the brand name “EKKO” is also classified as semi-bleached or unbleached office paper.

Evaluation of the quality of office paper includes an analysis of its appearance and mechanical properties. Whiteness and opacity, two characteristics that influence visual perception and legibility of printed text, define appearance. Paper’s basic mechanical properties are bending stiffness and surface strength. Water absorbency is determined by the Cobb method (Cobb60). The latter indicator is especially essential because it represents the ability of paper to absorb moisture. This directly influences the quality of ink application and the prevention of ink bleeding during printing [9]. The standards do not take into account the roughness index according to the Bendtsen method, but it is included in the technical indicators of many manufacturers [10]. Paper’s main characteristics are determined by the qualities and arrangement of the original fibers that make up its structure [11].

Office paper’s appearance and interaction with office equipment depend on its structural and dimensional qualities [12,13,14]. The most suitable paper weight for printing is believed to be 80 g/m2, since it gives sufficient rigidity and clarity to the print [15]. Office paper has a density of at least 0.75 g/cm3 and a bulkiness of 1.3 cm3/g, ensuring opacity and ease of printing [16]. The paper’s strength and flexibility are determined by the fibers’ composition, arrangement, and degree of size, while its roughness (150–250 Bendtsen) regulates the quality of image transmission and prevents distortions [17]. The capillary-porous structure of paper influences moisture absorption, the degree of sizing, and the ability to retain ink or toner [18]. The optimum humidity level (4–5.2%) is critical for the proper operation of laser printers. Because when the paper is over-moistened, the toner containing pigments and resins used to form images begins to crumble, and if there is insufficient moisture, static electricity accumulates on the paper, causing sheet jams. Hydrophobicity is controlled by the Cobb index: the lower the absorbency, the better the paper repels moisture. Printing requires that the paper absorb paint evenly and provide high-quality toner fixation.

Cellulose, as a plant polymer, is prone to two types of degradation: oxidation and hydrolysis, which leads to its annihilation [19,20]. During paper aging, the polymer chains of cellulose break, where large molecules dissolve into shorter fragments, reducing the degree of polymerization. This process is most visible in the amorphous zones of cellulose fiber, where a less organized structure renders the chains more accessible to hydrolysis reactions [21]. Hydrolytic destruction of cellulose is initiated by the action of acids present in the paper pulp or formed as a result of side reactions, as well as metal ions that can act as catalysts [22]. Under the influence of water and acids, glycosidic bonds are broken, which leads to a gradual decrease in the molecular weight of cellulose and deterioration of the mechanical properties of paper [23,24]. It should be emphasized that hydrolytic reactions that degrade cellulose can occur at any temperature because they require the presence of water and acids. Even at very moderate temperatures, in the presence of moisture and acids, cleavage of glycosidic bonds can occur, reducing the degree of cellulose polymerization and decreasing the mechanical qualities of paper [25,26,27]. When exposed to air oxygen, cellulose undergoes oxidative destruction, particularly in the presence of light (photodegradation) and at high temperatures [28]. During cellulose oxidation, hydroxyl groups are immediately changed to carbonyl (C=O) and carboxyl (-COOH) groups, modifying the type and strength of hydrogen bonds between molecules. These modifications alter both cellulose’s crystalline and amorphous structures, promoting the creation of cross-links between threads. Thus, new functional groups are produced as a result of oxidation, which simultaneously leads to the breaking of hydrogen bonds [29,30].

Compared with cellulose, lignin is far more vulnerable to oxidation by ambient oxygen, since it is a polyphenolic polymer with a rich structure of functional groups, such as hydroxyl and methoxyl groups, which implies high reactivity [31]. As a result of oxidation, lignin undergoes structural changes, new compounds are formed that contribute to the yellowing of paper, and its mechanical strength deteriorates [28]. Hemicelluloses, having a less ordered (amorphous) structure and greater branching compared to cellulose, are more accessible to hydrolytic and oxidative reactions. They are more susceptible to destruction, since their amorphous regions are more accessible to reaction with water and oxygen. Paper that contains a lot of lignin, hemicelluloses, and chemical additives is less stable, ages faster, and loses its optical and mechanical properties. Additionally, these additives can act as catalysts for these processes, hastening the degradation of the material even more [21,31,32].

To reduce the environmental impact of the pulp and paper industry, it is important to implement the best available technologies. Paper quality is determined by the properties of semi-finished products and their processing modes. Thus, the use of deacidification technologies that can maintain a slightly alkaline pH significantly improves the durability of paper and reduces its degradation [33]. In addition, research into the properties of cellulose as a sustainable raw material demonstrates that the choice of starting material and optimization of production modes play a key role in ensuring the required characteristics of finished paper [20].

Eco-paper production processes are optimized to reduce water consumption and the use of aggressive chemicals, which has a positive effect on reducing the environmental footprint of production. However, eco-paper production largely repeats traditional technological schemes with a number of distinctive features aimed at reducing the environmental impact [34,35]. One of the advances in this area is the use of a dual-stream fiber feed. In this method, cellulose is delivered as a suspension flow, resulting in homogeneous fiber distribution and dispersion. In contrast, chemical thermomechanical pulp is given dry and subsequently hydrobroken. Furthermore, surface scaling is extensively utilized in eco-production to strengthen interfiber connections, boost paper strength, and improve printing qualities. Calendering, i.e., passing paper pulp through a series of rollers, improves surface smoothness and ensures uniform thickness, which further improves printing quality. To date, the production of eco-paper has not been fully described in the literature, and many unresolved issues remain, for example, the aging of such papers [3,36].

Since the natural aging of paper is long, accelerated artificial aging methods are used to assess its durability [37]. They enable one to easily establish the chemical stability of components, anticipate the service life of paper, and investigate the processes of its degradation [38]. There are different methods of artificial aging [39]: thermal (at high temperatures), thermal-humid (with increased humidity), light (ultraviolet and visible light), complex (temperature, light, and humidity), and exposure to gaseous impurities (NO2, S2) [40].

Keeping paper at high temperatures can dramatically increase its breakdown processes. According to studies reported in [41], conditioning paper in a chamber at 102 ± 2 °C for 72 h results in alterations similar to 25 years of natural aging [42].

Modern office paper has both fibrous (cellulose fibers) and non-fibrous components (chemicals), which influence its endurance. Wood pulp having residual lignin and hemicelluloses contributes to yellowing of paper, reducing its whiteness and transparency, which deteriorates its optical qualities [4]. Sizing agents and mineral fillers reduce the consumption of cellulose fiber, increase the service life of paper, slow down destruction, and preserve a slightly alkaline reaction [6,43]. In addition to production components, the toner used in printing impacts paper aging [23]. The resins in its composition produce cross-links between fibers, which at elevated temperatures speed up the destruction of the paper surface [44].

Currently, the endurance of “new” varieties of eco-paper and semi-finished goods utilized in their production is understudied. Thus, there is a need to investigate the influence of artificial aging on the physical, mechanical, and optical properties of semi-finished paper products, as well as the paper materials themselves. Based on the findings, the goal of this work is to assess changes in their features, including an analysis of the feasibility of employing new forms of paper for long-term preservation.

2. Materials and Methods

The study’s subject was fibrous cellulose semi-finished products used in the production of modern types of eco-paper, selected at various stages of bleaching—after cooking and washing, after treatment with chlorine dioxide (D0, D1, D2), and after alkaline treatment of cellulose in the presence of hydrogen peroxide (AP1, AP2) (Figure 1).

Figure 1.

Initial cellulose samples after the cooking and washing section (a), after D0 (b), after AP1 (c), after D1 (d), after AP2 (e), and after D2 (f).

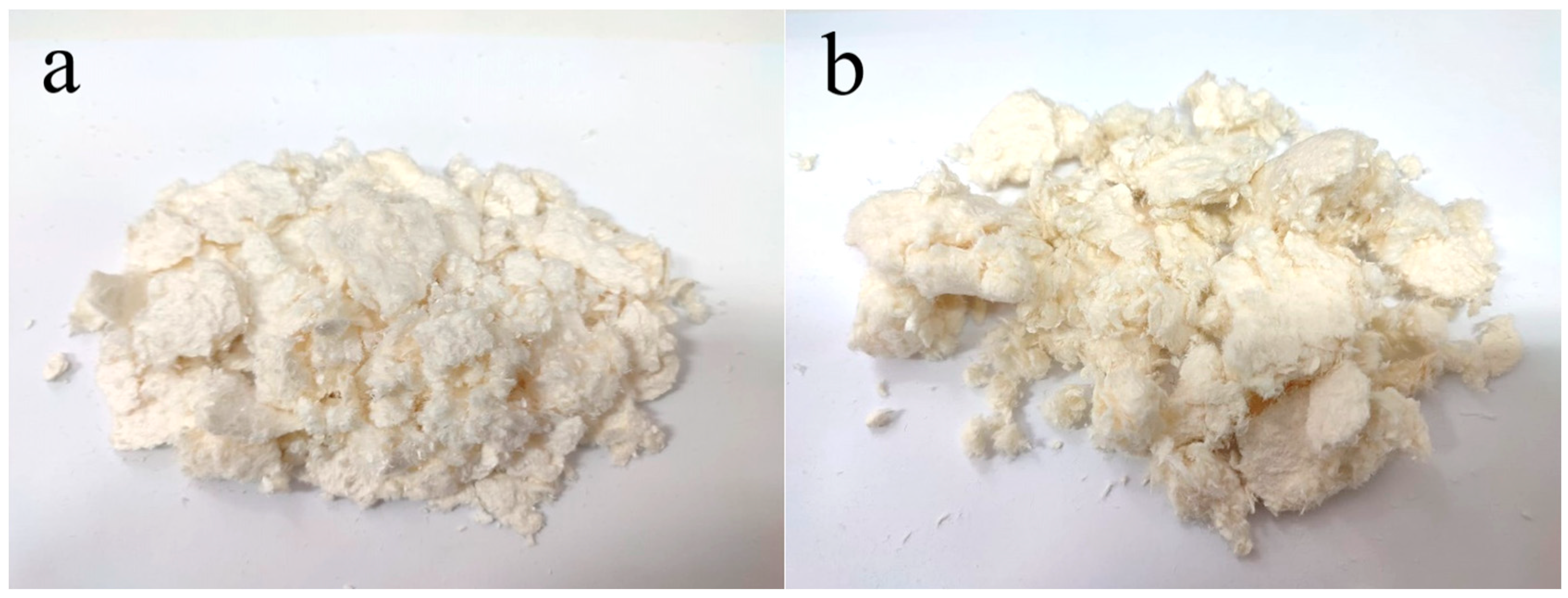

Arkhangelsk Pulp and Paper Mill (Novodvinsk, Arkhangelsk region, Russia) provided the analyzed samples of sulfate coniferous (pine) pulp, whereas Svetogorsk Pulp and Paper Mill (Svetogorsk, Russia) offered the bleached chemithermomechanical pulp (BCTMP) of aspen (Brand A400/80) and spruce (Brand S400/70) (Figure 2).

Figure 2.

Initial samples of bleached chemical thermomechanical pulp aspen BCTMP (a) and spruce BCTMP (b).

The main characteristics of aspen and spruce bleached chemical thermomechanical pulp are presented in Table 1.

Table 1.

Characteristics of the original samples of bleached chemical thermomechanical pulp.

Four types of white paper were used as objects of this study: SvetoCopy office paper (80 g/m2, International Paper CJSC (Svetogorsk, Russia)), Snegurochka office paper (80 g/m2, Mondi SLPK JSC (Syktyvkar, Russia)), InFORMAT Classic office paper (80 g/m2, Mondi SLPK JSC (Syktyvkar, Russia)), Space Office writing paper (60 g/m2, Relief-Center (Moscow, Russia)); and 5 types of new paper: eco-paper “SvetoCopy ECO” (80 g/m2, ZAO “International Paper” (Svetogorsk, Russia)), consumer paper “EKKO” (45 g/m2 and 60 g/m2) (JSC Kondopozhsky Pulp and Paper Mill (Kondopoga, Russia)), and kraft papers (60 g/m2 and 70 g/m2) (Arkhangelsk Pulp and Paper Mill, Novodvinsk, Arkhangelsk region, Russia).

To determine the physical, mechanical, and optical properties of fibrous semi-finished products used in the production of modern types of eco-paper, grinding was carried out in a PFI mill [50] to a grinding degree of 25–30 °SR. Samples of sulfate coniferous wood and bleached chemithermomechanical pulp were prepared for grinding according to [51]. When grinding in a PFI mill, 30 g of absolutely dry fiber was loaded into the vessel. The suspension concentration should be 10%. The rotation frequency of the drum (roll) under load in the PFI mill was 24.3 ± 0.5 rpm, and the rotation frequency of the housing was 11.8 ± 0.3 rpm. The grinding degree of the ground mass was determined using a Schopper–Riegler system device. The degree of grinding of the mass was determined using the formula, Schopper–Rigler:

where V is the volume of water that flowed out through the side hole, mL.

DG = (1000 − V)/10,

Table 2 shows the time and number of drum revolutions, as well as the initial and final degree of grinding.

Table 2.

Grinding mode of fibrous semi-finished products.

Following milling, each cellulose and BCTMP sample was cast in the laboratory. Castings were made from pre-prepared fibrous mass using a Rapid Köthen sheet casting machine (Frank-PTI GMBH, Birkenau, Germany). The prepared fibrous mass was selected to produce 1 m2 castings, which were laid on a sheet casting mesh and placed in a vacuum chamber. Then, the weight of the resulting product was verified. 80 castings with a weight of 75 g/m2 were produced.

To assess the humidity, air-dried BCTMP and wet cellulose were placed in sealed containers to equalize the humidity for at least 3 h. The humidity was then determined using [52].

The accelerated aging of samples [53] was carried out as follows: The finished samples of cellulose and BCTMP were subjected to heat treatment at a temperature of 120 °C for 7 days. Heat treatment of the samples was carried out in a drying cabinet. A drying cabinet with an air exchange rate of no more than 10 per 1 h was used. Heat treatment was carried out in the dark with uniform distribution of the test samples inside it. After completion of heat treatment, the test samples were left to condition for 24 h.

To ensure consistent findings, cellulose, BCTMP, and paper samples should be conditioned under standard conditions [54] of (50 ± 2)% relative humidity and (23 ± 2) °C prior to mechanical testing.

Before performing mechanical testing, the samples were cut with a laboratory knife into 15 × 165 mm pieces. The thickness was measured with a Lorentzen and Wettre SE 250 micrometer (Lorentzen & Wettre, Stockholm, Sweden) [55]. The tensile strength was measured with the TESTSYSTEM 101 testing machine (Test Engineering Ltd., Ivanovo, Russia) [56].

The fracture strength during multiple bending was evaluated according to [57]. The sample strip sustained numerous double bends (180°) under a tensile tension of 9.91 ± 0.2 N before failure occurred along the bend line.

To determine the optical properties of paper, BCTMP, and cellulose, a Noviprofibre spectrophotometer (Elmendorf, France) with three light sources (D65, C, and A) was employed. First, R457 whiteness [47] and CIE whiteness [58] were assessed. Then, transparency and opacity [59] of the samples were determined. Five test samples were selected in two series and stacked. The stack had to be opaque, i.e., a further increase in the number of sheets in the stack should not affect the value of the measured reflection coefficient. To ensure opacity, the required number of sheets of the same material were placed under the stack of five test samples. Measurements were taken on one side of the sample. For five samples, the reflectance of the sample placed on the opaque foot and the reflectance of the sample placed on the black backing were determined. First, the reflectance of the upper sample of the foot was measured, then the upper sample was placed under the foot, and the reflectance of the next sample was measured, etc. After that, each of the five samples was placed in turn on the black backing, and the reflectance was also determined. The results were calculated as the arithmetic mean of ten parallel sample tests.

3. Results

3.1. Mechanical Properties of Papers

The fibrous semi-finished products used to make modern eco-papers were ground before being thoroughly analyzed for mechanical, deformation, and optical properties.

Table 3 shows the mechanical properties of pine pulp castings prior to and after aging.

Table 3.

Mechanical characteristics of castings made of pine cellulose (25 °SR).

The breaking length of pine pulp samples (L) before and after aging significantly increased as the bleaching level was raised by 0.5–4%. It is assumed that the increase in the breaking length, accompanied by an increase in the pulp whiteness, is due to the fact that coniferous species are characterized by a high content of long-fiber high-molecular fractions and hemicellulose, as well as a more complete removal of lignin during the bleaching process, which improves interfiber interaction and, consequently, the mechanical properties of paper [60,61,62]. However, with aging, the breaking length of pine cellulose samples decreases by an average of 1.5–4%, which is associated with profound changes in the structure of the cellulose macromolecule—a decrease in the degree of polymerization due to chain rupture and the formation of new functional groups that accelerate the degradation processes [63,64].

Pine cellulose’s specific tensile strength (Fsp) improves by 1–4% after bleaching, and is related to sample density (ρ, g/cm3). With aging, Fsp drops by 0.2–8%. During the first three bleaching phases, the loss of strength is minimal, and at the last ones, it is obvious, which is most likely due to a decrease in residual lignin, which at the early stages still restricts the plasticity of the fibers [65]. The density of samples after aging decreases insignificantly (up to 1.5%) at the beginning stages of bleaching and 3–4% at the latter stages of bleaching.

The tensile elongation (l) of the cellulose increased regularly by 3–7% during the bleaching process. This is most likely owing to the high quantity of long softwood fibers and a decrease in the proportion of residual lignin, which increases the flexibility and elasticity of the material [60,66]. After aging, elongation values fall by 8–23%, which is connected with the system’s keratinization [62].

The multiple bending strength of cellulose samples increases by about 2–8% with each bleaching stage, indicating enhanced interfiber bonding due to a decrease in lignin content. As aging continues, hydrolysis and oxidation reduce the degree of cellulose polymerization, causing the fibers to become more brittle, as seen by a fall in multiple bending strength of 32–55%.

The mechanical and deformation characteristics of spruce and aspen BCTMP castings are shown in Table 4. BCTMP is a fibrous semi-finished product that contains a large amount of lignin and hemicelluloses. It is obtained by mechanical separation of wood into fibers with subsequent processing. In this case, non-cellulose components are preserved, resulting in fibers that are hydrophobic, shorter, stiffer, and less capable of interfiber bonds.

Table 4.

Mechanical characteristics of castings from spruce and aspen BCTMP (25 °SR).

The study’s findings revealed that bleached chemical-thermomechanical mass from aspen provides the best strength indicators, while spruce BCTMP provides superior deformation qualities. To explain the cause, consider the chemical composition of spruce and aspen wood. The chemical compositions of spruce and aspen wood are shown in Table 5.

Table 5.

Chemical composition of spruce and aspen wood.

In comparison to spruce, aspen wood contains 10% less cellulose, 25% less lignin, and 10% fewer extractive compounds, but 20% more hemicellulose. In deciduous wood, lignin is mostly concentrated in the middle plate, making it easier to remove after chemical treatment. Thus, aspen BCTMP has greater strength indicators due to lower lignin content on the fiber surface and better circumstances for its removal than spruce BCTMP. Coniferous fibers are longer and straighter, whereas deciduous fibers are 3–6 times shorter and contain tiny vascular components with a high degree of tortuosity.

Aspen BCTMP exhibited the highest strength property values. Although the differences are minor, the breaking lengths of aspen BCTMP and spruce are 2250 m and 2200 m, respectively, with specific resistances of 1.61 kN/m and 1.55 kN/m.

According to deformation properties, spruce had an elongation under tension of 1.1 mm while aspen had 0.77 mm. The fracture strength of spruce BCTMP demonstrates that it is less brittle, with three times the amount of double bends as aspen.

All deformation and strength properties improved during artificial aging of spruce and aspen BCTMP samples. If aspen BCTMP had greater strength indicators (breaking length and specific resistance) prior to accelerated aging, then spruce BCTMP performed better after aging, with increased strength and deformation properties. This could be related to lignin depolymerization, which produces low molecular fractions during high-temperature heat treatment.

The fracture strength of spruce BCTMP increased with multiple bends, whereas it stayed constant in aspen. It can be hypothesized that the fracture strength of spruce BCTMP increased with age due to lignin depolymerization, whereas the change in lignin structure in aspen BCTMP is insufficient to increase the number of double bends.

The mechanical strength indicators of paper in the cross direction (CD) are much lower than those in the machine direction. This is related to the phenomena of anisotropy, which arises as a result of increased fiber orientation in the machine direction and cross-directional shrinking of the paper web in the paper machine’s drying phase.

In addition to fibrous semi-finished products, paper manufacture uses a variety of chemical additives, including sizing and strengthening agents, fillers, and optical brighteners. As previously stated, sizing in neutral or alkaline environments rather than acidic ones increases mechanical strength indicators. This is explained by the lack of the paper-weakening impact of aluminum polyhydroxocomplexes, which are necessarily utilized in rosin sizing in an acidic environment [67]. Fillers have a negative influence on the physical and mechanical qualities of paper, because any filler, especially coarsely scattered ones, is locked between the fibers, preventing their convergence, which is required for the development of strong hydrogen bonds [68]. At the same time, filler particle sorption on the fiber surface prevents hydroxyls from forming interfiber bonds. Strengthening additives, such as cationic starch, bond to cellulose fibers and fillers that contain anionic groups. Cationic starch promotes the retention of fine fibers and filler particles in paper, hence enhancing its tensile strength [69].

The strength properties of the SvetoCopy, Snegurochka, InFORMAT Classic papers in the transverse direction turned out to be approximately the same—the breaking length was 2250–2300 m, the specific tensile strength was 1.9–1.7 kN/m, and in the machine direction, the office paper “InFORMAT Classic” showed itself better, the breaking length was 6050 m, the specific tensile strength was 4.8 kN/m, while for the office papers “SvetoCopy” and “Snegurochka” the same indicators were 5300–5350 m; 4.2–4.3 kN/m, respectively. The InFORMAT Classi paper has higher elongation at tension in both the transverse and machine directions, at 5.1 and 1.6 mm, respectively. Other office sheets exhibited lower elongation values, ranging from 1.2 to 1.5 mm in machine and 2.7 to 4.2 mm in transverse. The strength attributes of the Space Office paper were the lowest; however, it should be noted that the mass of a square meter of this paper is 60 g/m2, whereas office papers have an 80 g/m2 density. Writing paper had slightly better deformation properties than SvetoCopy paper.

The InFORMAT Classic paper has the highest mechanical strength indicators in both the machine and transverse directions, while the Space Office brand’s writing paper and SvetoCopy paper have the lowest values. This is most likely due to the characteristics of the technological production process, the chemical reagents used, and the properties of the original fibrous raw material.

After accelerated aging, the deformation-strength properties of all white papers became lower, the most sensitive were the SvetoCopy paper and Space Office paper. The breaking length decreased by 7–11% in the machine direction and by 2.5–3% in the transverse direction, the specific tensile strength worsened by 5–10% in the machine direction, by 1–10% in the transverse direction, the elongation at stretching by 8–18% in the machine direction and by 7–13% in the transverse direction. This is most likely owing to the low whiteness of the semi-finished SvetoCopy paper caused by an increase in residual lignin, which has a detrimental impact on its longevity. In the case of Space Office paper, the reason appears to be the use of secondary fiber (waste paper), which has a lower strength and a higher tendency to age owing to repeated processing and thermal effects. For InFORMAT Classic and Snegurochka papers, the ultimate difference in mechanical strength indicators before and after aging does not exceed 6% in either the machine or transverse direction.

As is known, the tensile strength index for repeated bends in the machine direction is defined by the strength and elasticity of the fiber; for the transverse direction, this number depends on the strength of the bonds between the fibers [70]. The InFORMAT Classic paper has the highest tensile strength index in both the machine and transverse directions, while the Space Office and SvetoCopy papers have the lowest. It should be mentioned that the Space Office paper has the lowest tensile strength among all white papers. The SvetoCopy and Space Office papers were the most responsive to changes in the tensile strength index during accelerated aging. The modifications averaged 77% in the machine direction and 60% in the transverse direction, whereas the changes in the InFORMAT Classic and Snegurochka papers were 60% in the machine direction and 38% in the transverse direction.

Eco-papers are papers made from high-yield semi-finished goods such as mechanical pulp, wood waste from the forestry industry, or pulp and paper mill cooking shops. Eco-papers are made up of high-yield semi-finished goods such as mechanical pulp, wood refuse from the logging industry, or pulp and paper mill cooking shops. Consumer paper EKKO is made from spruce wood sawing waste; office eco-paper SvetoCopy ECO is made from semi-bleached hardwood pulp and CTMP [71], and kraft paper is made from uncooked coniferous and hardwood raw materials (branches). Mechanical characteristics of office papers “SvetoCopy”, “Snegurochka”, “InFORMAT Classic”, and eco-papers are presented in Table 6.

Table 6.

Mechanical characteristics of office papers and eco-papers.

The deformation and strength properties of kraft papers (60 and 70 g/m2) turned out to be much better than for office eco-paper SvetoCopy ECO and EKKO papers (45 and 60 g/m2)—breaking length, specific tensile strength and tensile elongation in the machine direction averaged 8100 m, 5.4 kN/m, and 1.9 mm, in the transverse direction—3650 m, 2.4 kN/m, and 2.2 mm, respectively. For office eco-paper and consumer papers, these indicators in the machine direction did not exceed 5750 m, 4.7 kN/m, and 1.6 mm, in the transverse direction—2550 m and 2.2 kN/m, respectively.

Kraft paper’s high strength qualities are explained by the absence of mechanical masses in its composition, which have a negative effect on paper strength. EKKO paper has low characteristics because of its modest mass per square meter and the utilization of wood waste with initially reduced paper-forming characteristics. Despite the usage of CTMP, which has lower strength characteristics than wood cellulose, eco-paper SvetoCopy ECO displayed good mechanical properties.

The eco-paper SvetoCopy ECO and consumer paper EKKO with a density of 45 g/m2 showed the most sensitivity to changes in deformation strength properties during accelerated aging. This is likely owing to the use of less durable semi-finished materials and light paper weight. In addition to wood pulp and less durable fibers, fillers (such as clays or slaked lime) are likely used in the production of eco-paper SvetoCopy ECO at the Svetogorsk facility, which promotes the creation of acidic chemicals and accelerates the aging of the paper. The low density (45 g/m2) of EKKO paper results in a less dense fiber structure, which exacerbates the deleterious impact of heat on aging.

Kraft papers provide the best fracture strength indication in both the machine and transverse directions (60 and 70 g/m2), while EKKO papers show the worst (45 and 60 g/m2). The most sensitive to changes in fracture strength during accelerated aging were EKKO papers.

The mechanical strength indicators for the SvetoCopy ECO eco-paper were better in almost every respect than those for the office paper SvetoCopy, with the exception of the elongation indicator in the transverse direction and the breaking strength in the machine direction (Table 7).

Table 7.

Comparative characteristics of deformation and strength properties of SvetoCopy paper and SvetoCopy ECO paper.

It is worth noting that the SvetoCopy ECO paper has proven to be less sensitive to the process of accelerated aging than the SvetoCopy paper, as evidenced by the final difference in the change in properties before and after accelerated aging.

3.2. Optical Properties

It is known that cellulose has a white color, and the residual presence of its satellites in it imparts additional coloring, such as lignin, which absorbs radiation in the UV region of the spectrum, and its chromophore groups with an extended system of conjugated double bonds. The UV part of the spectrum includes waves ranging in length from 100 to 400 nm, while lignin and its chromophore groups absorb light between 250 and 300 nm. When assessing whiteness at 457 nm, castings with higher reflectivity have less residual lignin on the fiber surface. At optimal bleaching conditions, 80% of cellulose whiteness can be obtained. Even with increased usage of bleaching reagents, further increases in whiteness are difficult to achieve. Bleaching destroys the chromophore structures that give fibers their color, but not the lignin itself. To obtain complete whiteness, lignin-removing bleaching chemicals are required. The removal of lignin is accompanied by the loss of hemicelluloses, which finally leads to a decrease in the strength of the resulting paper [72,73].

The optical characteristics of pine cellulose samples were measured following grinding to 25 °SR and then accelerated aging (Table 8).

Table 8.

R457 whiteness, CIE and opacity of pine pulp before and after aging.

Yellowing is a visible indicator of paper aging, which is characterized by a loss of whiteness. This is most likely due to the fact that hydroxyl groups exist in the elementary link of the cellulose macromolecule at the second and third carbon atoms, which, when oxidized, form carbonyl groups, which, in turn, can form chelate complexes with iron and copper ions that remain on the fibers even after washing and can impart color to cellulose fibers. Yellowing of cellulose is also induced by the existence of hemicelluloses, a low molecular fraction of cellulose that is actively subjected to damaging processes resulting in the production of new functional groups with increased acidic properties [74].

The CIE whiteness value of pine pulp castings before and after aging rises from the first to the final bleaching stage. Pine pulp after age has a lower CIE whiteness value than cellulose before aging. This means that during the degradation of cellulose at high temperatures, damaging processes occurred, resulting in the production of extra functional groups that contribute to the yellowing of cellulose. The change in CIE whiteness of pine pulp samples with aging is more severe than in R457 whiteness. Because the CIE method more properly represents the viewer’s impression of color and brightness than the R457 whiteness assessment system.

The opacity index decreases with each bleaching stage for both pine cellulose samples before and after aging. Cellulose becomes more translucent, allowing light to penetrate through the casting rather of dispersing it. The opacity index of pine cellulose samples rose after age as compared to pre-aging samples. Most likely, this is because cellulose crystallizes during aging, and the more crystalline the polymer, the more opaque it becomes.

The optical properties of spruce and aspen BCTMP castings are shown in Table 9. The exceptional whiteness of the original spruce and aspen BCTMP samples is accomplished by stabilizing the white color through bleaching of extractive compounds and lignin without its degradation into low molecular fractions. Bleaching is performed with reducing agents (dithionites, sulfur dioxide, sulfuric acid) or oxidizing agents (hypochlorites, peroxides), while increasing whiteness is performed with oxidizing reagents that are more effective at destroying lignin’s chromophore groups.

Table 9.

Optical characteristics of castings from spruce and aspen BHTMM (25 °SR).

Aspen BCTMP has higher R457 and CIE whiteness values than spruce, which is most likely owing to aspen pulp’s 25% reduced lignin concentration. At the same time, the opacity of spruce BCTMP is higher, indicating a poorer light transmittance. After aging, a considerable decline in whiteness is noted, resulting in yellowing of castings due to a decrease in reflectance in the violet region of the spectrum, as well as an increase in opacity.

Table 10 presents the optical characteristics for the SvetoCopy, Snegurochka, InFORMAT Classic papers.

Table 10.

Optical characteristics of white papers.

The R457 and CIE whiteness values for the three types of office paper were comparable, with SvetoCopy paper having the highest values. However, this paper has poor deformation resistance, which is most likely due to the excessive use of fillers to promote whiteness, which diminishes mechanical strength. Space Office writing paper, on the other hand, has poor whiteness before aging, which is due to the product’s lesser technical standards when compared to office paper [75].

The opacity index of the three office papers was equivalent, with the lowest value observed for SvetoCopy, indicating an inverse link between whiteness and opacity. After rapid aging, the whiteness (both R457 and CIE) of SvetoCopy paper declined dramatically, while the opacity rose. Visually, SvetoCopy went yellow, Snegurochka took on a pink-yellow tint, and InFORMAT Classic turned blue. A significant increase in opacity is observed for Space Office writing paper, while R457 whiteness decreased sharply and CIE whiteness remained virtually unchanged, owing to differences in measurement methods: R457 is determined by reflection in the blue range, whereas CIE is determined by reflection in the entire visible spectrum. Space Office maintains a grayish-yellow tone both before and after aging.

Eco-paper SvetoCopy ECO is light-yellow in color, while EKKO papers (45 and 60 g/m2) are light gray, and kraft papers (60 and 70 g/m2) are pale brown. The optical properties of the new publications are given in Table 11.

Table 11.

Optical characteristics of new papers.

Low R457 and CIE whiteness values for all new papers are attributable to the environmentally responsible production process, which precludes the use of chlorine and optical brighteners. Eco- and consumer papers better reflect the blue wave of the spectrum and have a more uniform color, whereas kraft papers, although low whiteness, display the highest opacity, which minimizes the translucency of printed text. After accelerated aging, SvetoCopy ECO and EKKO show a considerable decline in whiteness and a rise in opacity, although changes in kraft papers are less pronounced. Visually, eco-paper darkened, EKKO turned yellow-gray, and kraft sheets turned gray brown.

Table 12 compares the optical characteristics of office papers SvetoCopy and SvetoCopy ECO. After accelerated aging, both office papers’ R457 and CIE whiteness values decreased, with the R457 whiteness changing more for the SvetoCopy paper and the CIE whiteness changing more for the SvetoCopy ECO eco-paper.

Table 12.

Comparative characteristics of optical properties of office papers SvetoCopy and SvetoCopy ECO.

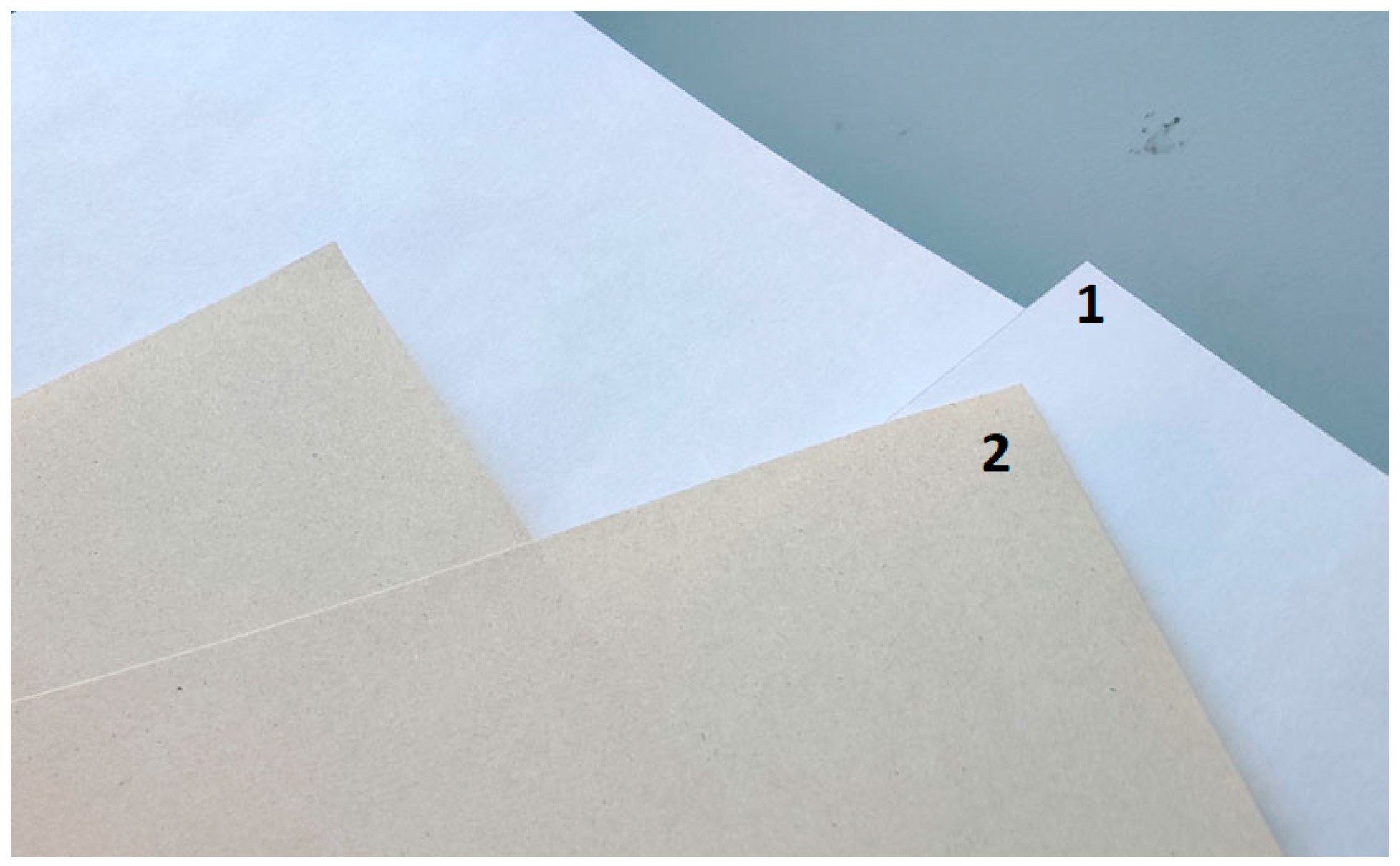

The optical qualities of SvetoCopy paper are far superior to those of SvetoCopy ECO eco-paper (Figure 3).

Figure 3.

Photos of the SvetoCopy” (1) and SvetoCopy ECO (2) papers.

The SvetoCopy paper has a more uniform hue with fewer shades throughout the whole surface of the paper sheet than the SvetoCopy ECO eco-paper. Although the optical qualities of SvetoCopy paper are superior to those of SvetoCopy ECO eco-paper, the latter has greater mechanical strength values and is more resistant to accelerated aging processes than standard SvetoCopy paper. The SvetoCopy ECO eco-paper can be stored for a maximum of 50 years.

It should be noted that the accelerated aging protocol, despite its widespread use, does not fully reflect the complex effects of real storage conditions, including temperature and humidity fluctuations, constant or cyclic light irradiation, and the presence of atmospheric pollutants. In future studies, it would be advisable to expand the experiment by including multiparameter tests with control of relative humidity and light conditions, as well as to conduct parallel real aging of samples under archival conditions. Comparison of accelerated and natural aging data will allow more accurate modeling of the durability of various types of paper and will increase the reliability of practical recommendations.

4. Conclusions

This study investigates the changes in deformation strength and optical properties of several paper samples after artificial aging, allowing us to assess their durability and appropriateness for long-term preservation. Pine pulp’s mechanical properties improve following treatment: breaking length increases by 0.5–4%, specific resistance by 1–4%, elongation by 3–7%, and fracture strength by 2–8%. Optical characteristics, as measured by the R457 and CIE whiteness indices, initially increase somewhat, then improve dramatically after the second bleaching cycle and stabilize, while opacity reduces, suggesting greater light transmission. After aging, mechanical and optical characteristics deteriorate: for bleached samples, the R457 whiteness changes more, and for unbleached and semi-bleached samples, the opacity increases by 0.5% for bleached and semi-bleached samples and 0.3–0.4% for unbleached samples.

A comparison of BCTMP produced of spruce and aspen wood revealed that aspen mass had somewhat better strength qualities, although spruce has higher deformation properties. Spruce fracture strength is proved by a higher number of double folds, indicating less brittleness. Aspen BCTMP has better optical characteristics than spruce; R457 and CIE whiteness are greater, and transparency is lower, resulting in higher whiteness. After aging, the mechanical characteristics of both BCTMP improve due to lignin depolymerization, which is more obvious for spruce mass: R457 whiteness falls by 25%, CIE whiteness by 56%, and opacity improves by 0.8–0.9%.

The SvetoCopy papers, Snegurochka, and InFORMAT Classic have similar transverse strength qualities, while InFORMAT Classic outperforms in the machine direction due to increased elongation. The writing paper Space Office has the lowest strength but significantly better deformation qualities compared to office samples. After aging, SvetoCopy and Space Office show considerable losses in mechanical properties: InFORMAT Classic and Snegurochka show changes of no more than 6%. R457 whiteness declines by 20% for SvetoCopy and Space Office, while CIE whiteness decreases by 23% for office papers, with writing papers changing less, while opacity remains almost unchanged.

Kraft papers outperform SvetoCopy ECO and consumer paper “EKKO” in mechanical properties. The whiteness R457 of eco-papers is approximately 72% (CIE whiteness—35%), but kraft papers have poor whiteness (R457—46%, CIE—negative). Kraft papers change insignificantly (up to 5.3%) with aging, but eco- and consumer papers are highly sensitive to aging, resulting in variations in breaking strength of up to 85% and 80% in the machine and transverse direction, respectively.

Thus, the acquired data show that aging has a substantial influence on the mechanical deformational and optical properties of distinct paper samples, allowing us to anticipate the operational properties of paper over time.

Author Contributions

Conceptualization, Y.S. and N.S.; methodology, K.K., G.S. and A.P.; software, A.P., E.N. and M.V.; validation, D.K., L.S. and Z.K.; formal analysis, A.P., D.K., L.S., S.B., G.S., E.N., M.V. and Z.K.; investigation, K.K., A.P. and E.P.; data curation, I.M.; writing—original draft preparation, Y.S., N.S. and K.K.; writing—review and editing, E.P. and I.M.; visualization, S.B.; supervision, Y.S. and N.S. All authors have read and agreed to the published version of the manuscript.

Funding

Preparation of the manuscript text was carried out within the State Program of TIPS RAS.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding authors.

Acknowledgments

NSF (grant No. DMR-2122108 (PREM)).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kamchatova, E.Y.; Perevozchikova, A.K. Trends in the development of the pulp and paper industry of the Russian Federation. Sci. Notes Russ. Acad. Entrep. 2022, 21, 43–49. [Google Scholar] [CrossRef]

- GRI, Global Reporting Initiative. Available online: https://www.globalreporting.org (accessed on 3 April 2025).

- Gavrilescu, D.; Puitel, A.C.; Dutuc, G.; Craciun, G. Environmental impact of pulp and paper mills. Environ. Eng. Manag. J. 2012, 11, 81–86. [Google Scholar] [CrossRef]

- Casey, J.P. Pulp and Paper: Chemistry and Chemical Technology, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1980; Volume 1, p. 848. [Google Scholar]

- ISO 11475:2017; Paper and Board—Determination of CIE Whiteness, D65/10 Degrees (Outdoor Daylight). International Organization for Standardization (ISO): Geneva, Switzerland, 2017.

- Biermann, C.J. Handbook of Pulping and Papermaking, 2nd ed.; Academic Press: San Diego, CA, USA, 1996; p. 754. [Google Scholar]

- Osipov, P.V. Chemical products as a part the Russian paper manufacture. Pulp. Paper. Cardboard 2002, 11–12, 14–16. [Google Scholar]

- Hubbe, M.; Gill, R.A. Fillers for Papermaking: A Review of their Properties, Usage Practices, and their Mechanistic Role. BioResources 2016, 11, 2886–2963. [Google Scholar] [CrossRef]

- GOST 12605-97; Method for Determining Surface Water Absorption with One-Sided Wetting (Cobb Method). Federal Agency on Technical Regulating and Metrology (GOST R): Moscow, Russia, 1997.

- Kirsankin, A.; Mikhaleva, M.; Nikolskii, S.N.; Musohranova, A.V.; Stovbun, S.V. Direct method of quality control surface coated types of paper. Russ. J. Bioorg. Chem. 2016, 4, 159–163. [Google Scholar] [CrossRef]

- Pego, M.; Bianchi, M.; Yasumura, P. Physical and Mechanical Properties of Papers Produced from Different Cellulosic Pulps Blending. Res. Sq. 2022, 1–25. [Google Scholar] [CrossRef]

- Novikov, A.O.; Temruk, V.I.; Shkirando, T.P.; Khmyzov, I.A. Technology of printing paper designed for a long service life. Proc. BSTU Chem. Technol. Org. Subst. Biotechnol. 2011, 4, 148–151. [Google Scholar]

- Martyanova, O.S.; Kononov, G.N.; Govyazin, I.O. Study of the properties of paper for inkjet printing. For. Bull. 2008, 6, 88–90. [Google Scholar]

- Kornilov, I.K.; Markova, S.G.; Romanov, P.T. Study of the influence of printing modes and paper type on product quality. Bull. Mosc. State Univ. Print. Arts 2016, 1, 67–72. [Google Scholar]

- Yudenkov, V.S.; Sulim, P.Y. Study of the influence of paper parameters on quality rizographic printing. Syst. Anal. Appl. Inform. 2020, 1, 11–16. [Google Scholar] [CrossRef]

- Sampson, W.; Engin, M.; Bloch, J.-F. Grammage dependence of paper thickness. Appita J. 2019, 72, 30–40. [Google Scholar]

- Fomicheva, I.N.; Vaganov, V.V. Determination of optimal optical density parameters when printing with unified paints. Bull. Tula State Univ. Tech. Sci. 2021, 596–598. Available online: https://cyberleninka.ru/article/n/opredelenie-optimalnyh-parametrov-opticheskoy-plotnosti-pri-pechati-unifitsirovannymi-kraskami/viewer (accessed on 20 May 2025).

- Baudin, G.; Rousset, E. Inkjet Printing: Effect of Paper Properties on Print Quality. NIP Digit. Fabr. Conf. 2001, 17, 120–124. [Google Scholar] [CrossRef]

- Łojewska, J.; Missori, M.; Lubańska, A.; Grimaldi, P.; Ziȩba, K.; Proniewicz, L.M.; Congiu Castellano, A. Carbonyl groups development on degraded cellulose. Correlation between spectroscopic and chemical results. Appl. Phys. A 2007, 89, 883–887. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating Biopolymer and Sustainable Raw Material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef]

- Barański, A. Ageing kinetics of cellulose and paper. Restaurator 2002, 23, 77–88. [Google Scholar] [CrossRef]

- Novikov, A.O.; Temruk, V.I.; Shkirando, T.P.; Gorzhanov, V.V. Influence of the composition of paper on its durability. News of higher educational institutions. For. J. 2012, 5, 145–149. [Google Scholar]

- Banik, G.; Brückle, G. Paper and Water: A Guide for Conservators; Butterworth-Heinemann: Oxford, UK, 2011. [Google Scholar]

- Mleziva, M.M.; Wang, J.H. Polymers for a sustainable environment and green energy. In Polymer Science: A Comprehensive Reference; Matyjaszewski, K., Möller, M., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Calvini, P.; Gorassini, A. On the rate of paper degradation: Lessons from the past. Restaurator 2006, 27, 275–290. [Google Scholar] [CrossRef]

- Jönsson, L.J.; Martín, C. Pretreatment of lignocellulose: Formation of inhibitory by-products and strategies for minimizing their effects. Bioresour. Technol. 2016, 199, 103–112. [Google Scholar] [CrossRef]

- Zou, X.; Uesaka, T.; Gurnagul, N. Prediction of paper permanence by accelerated aging I. Kinetic analysis of the aging process. Cellulose 1996, 3, 243–267. [Google Scholar] [CrossRef]

- Strlič, M.; Kolar, J.; Kočar, D.; Rychlý, J. Theromo-oxidative degradation. In Aging and Stabilization of Paper; Strlič, M., Kolar, J., Eds.; National and University Library: Ljubljana, Slovenia, 2004; pp. 101–120. [Google Scholar]

- Knott, B.C.; Momeni, M.H.; Crowley, M.F.; Mackenzie, L.F.; Götz, A.W.; Sandgren, M.; Withers, S.G.; Ståhlberg, J.; Beckham, G.T. The mechanism of cellulose hydrolysis by a two-step, retaining cellobiohydrolase elucidated by structural and transition path sampling studies. J. Am. Chem. Soc. 2014, 136, 321–329. [Google Scholar] [CrossRef] [PubMed]

- Strlič, M.; Cigić, I.K.; Možir, A.; de Bruin, G.; Kolar, J.; Cassar, M. The effect of volatile organic compounds and hypoxia on paper degradation. Polym. Degrad. Stab. 2011, 96, 608–615. [Google Scholar] [CrossRef]

- Zervos, S. Natural and accelerated aging of cellulose and paper: A literature review. In Cellulose: Structure and Properties Derivatives and Industrial Uses; Lejeune, A., Deprez, T., Eds.; Nova Publishing: New York, NY, USA, 2010; pp. 155–203. [Google Scholar]

- Lojewski, T.; Zięba, K.; Knapik, A.; Bagniuk, J.; Lubańska, A.; Łojewska, J. Evaluating paper degradation progress. Cross-linking between chromatographic, spectroscopic and chemical results. Appl. Phys. A 2010, 100, 809–821. [Google Scholar] [CrossRef]

- Baty, J.W.; Maitland, C.L.; Minter, W.; Hubbe, M.A.; Jordan-Mowery, S.K. Deacidification for the conservation and preservation of paper-based works: A review. BioResources 2010, 5, 1955–2023. [Google Scholar] [CrossRef]

- Sousa, A.M.; Pinto, I.S.S.; Machado, L.; Gando-Ferreira, L.; Quina, M.J. Sustainability of kraft pulp mills: Bleaching technologies and sequences with reduced water use. J. Ind. Eng. Chem. 2023, 125, 58–70. [Google Scholar] [CrossRef]

- Solomon, K.R. Chlorine in the Bleaching of Pulp and Paper. Pure Appl. Chem. 1996, 68, 1721–1730. [Google Scholar] [CrossRef]

- Debnath, M.; Sarder, R.; Pal, L.; Hubbe, M.A. Molded pulp products for sustainable packaging: Production rate challenges and product opportunities. BioResources 2022, 17, 3810–3870. [Google Scholar] [CrossRef]

- Małachowska, E.; Pawcenis, D.; Dańczak, J.; Paczkowska, J.; Przybysz, K. Paper Ageing: The Effect of Paper Chemical Composition on Hydrolysis and Oxidation. Polymers 2021, 13, 1029. [Google Scholar] [CrossRef]

- Salgo, M.J. International journal of conservation science physico-chemical assessment of biodeteriorated and biodegraded archival paper. Int. J. Conserv. Sci. 2010, 4, 209–220. [Google Scholar]

- ISO 5630-3:1996; Paper and Board—Accelerated Ageing. International Organization for Standardization: Geneva, Switzerland, 1996.

- Strlič, M.; Kolar, J. Ageing and Stabilisation of Paper; Strlič, M., Kolar, J., Eds.; National and University Library: Ljubljana, Slovenia, 2005; p. 196. [Google Scholar]

- Stuhrke, R.A. The development of permanent paper. In Preservation of Paper and Textiles of Historic and Artificial Value; Williams, J.G., Ed.; ACS: New York, NY, USA, 1977; pp. 24–36. [Google Scholar]

- Luxford, N.; Thickett, D. Designing accelerated ageing experiments to study silk deterioration in historic houses. J. Inst. Conserv. 2011, 34, 115–127. [Google Scholar] [CrossRef]

- DIN EN ISO 9706:2010; Information and Documentation—Paper for Documents—Requirements for Permanence. German Institute for Standardization (DIN): Berlin, Germany, 2010.

- Strlič, M.; Kolar, J.; Scholten, S. Paper and durability. In Ageing and Stabilisation of Paper; Strlič, M., Kolar, J., Eds.; Narodna in univerzitetna knjižnica: Ljubljana, Slovenia, 2005; pp. 3–8. [Google Scholar]

- Freeness of Pulp (Canadian Standard Method), Test Method T 227 om-21. Available online: https://imisrise.tappi.org/TAPPI/Products/01/T/0104T227.aspx (accessed on 3 April 2025).

- GOST 30437-96; Pulps. Method for Determination of Brightness. Federal Agency on Technical Regulating and Metrology (GOST R): Moscow, Russia, 1996.

- GOST 7690-76; Pulp, Paper and Cardboard. Method for Determination of Whiteness. Federal Agency on Technical Regulating and Metrology (GOST R): Moscow, Russia, 1976.

- GOST R ISO 1924-2-2012; Paper and Board. Method of Tensile Strength Determination. Part 2. Constant Rate of Elongation Method (20 mm/min). Federal Agency on Technical Regulating and Metrology (GOST R): Moscow, Russia, 2012.

- GOST 13525.3-97; Pulp and Paper. Method for Determination of Tearing Resistance (Elmendorf Method). Federal Agency on Technical Regulating and Metrology (GOST R): Moscow, Russia, 1997.

- ISO 5264–2:2011; Pulps—Laboratory Beating. Part 2: PFI Mill Method. International Organization for Standardization: Geneva, Switzerland, 2011.

- GOST 14363.4–89; Method of Sample Preparation for Physical and Mechanical Testing. Federal Agency on Technical Regulating and Metrology (GOST R): Moscow, Russia, 1989.

- GOST 16932-93; Cellulose. Determination of Dry Matter Content. Federal Agency on Technical Regulating and Metrology (GOST R): Moscow, Russia, 1993.

- GOST 29331–92; Paper and Cardboard. Accelerated Aging. Dry Heat Treatment at 120 or 150 °C. Federal Agency on Technical Regulating and Metrology (GOST R): Moscow, Russia, 1992.

- GOST 13523-78; Semi-Finished Fibrous Products, Paper and Cardboard. Method of Conditioning Samples. Federal Agency on Technical Regulating and Metrology (GOST R): Moscow, Russia, 1978.

- GOST 27015-86; Paper and Cardboard. Methods for Determining Thickness, Density and Specific Volume. Federal Agency on Technical Regulating and Metrology (GOST R): Moscow, Russia, 1986.

- GOST 13525.1-79; Semi-Finished Fibrous Products, Paper and Cardboard. Methods for Determining Tensile Strength and Elongation Under Tension. Federal Agency on Technical Regulating and Metrology (GOST R): Moscow, Russia, 1979.

- GOST 13525.2–80; Semi-Finished Fibrous Products, Paper and Cardboard. Methods for Determining the Breaking Strength at Repeated Bending. Federal Agency on Technical Regulating and Metrology (GOST R): Moscow, Russia, 1980.

- GOST R ISO 11475-2010; Paper and Cardboard. CIE Method of Determining Whiteness. D65/10° Illuminant (Daylight). Federal Agency on Technical Regulating and Metrology (GOST R): Moscow, Russia, 2010.

- GOST 8874–80; Paper. Method for Determining Transparency and Opacity. Federal Agency on Technical Regulating and Metrology (GOST R): Moscow, Russia, 1980.

- Małachowska, E.; Dubowik, M.; Boruszewski, P.; Łojewska, J.; Przybysz, P. Influence of lignin content in cellulose pulp on paper durability. Sci. Rep. 2020, 10, 19998. [Google Scholar] [CrossRef] [PubMed]

- Young, R.A. Structure, Swelling and Bonding of Cellulose Fibers. In Cellulose: Structure, Modification and Hydrolysis; Young, R.A., Rowell, R.M., Eds.; Wiley: New York, NY, USA, 1986; pp. 91–128. [Google Scholar]

- Kato, K.L.; Cameron, R.E. A Review of the Relationship Between Thermally-Accelerated Aging of Paper and Hornification. Cellulose 1999, 6, 23–40. [Google Scholar] [CrossRef]

- Emsley, A.M.; Stevens, G.C. Kinetics and mechanisms of the low-temperature degradation of cellulose. Cellulose 1994, 1, 26–56. [Google Scholar] [CrossRef]

- Łojewska, J.; Lubańska, A.; Łojewski, T.; Miśkowiec, P.; Proniewicz, L.M. Kinetic approach to degradation of paper, In situ FTIR transmission studies on hydrolysis and oxidation. e-PS 2005, 2, 1–12. [Google Scholar]

- Zou, X.; Gurnagul, N.; Uesaka, T.; Bouchard, J. Accelerated aging of papers of pure cellulose: Mechanism of cellulose degradation and paper embrittlement. Polym. Degrad. Stabil. 1994, 43, 393–402. [Google Scholar] [CrossRef]

- Larsson, P.T.; Lindström, T.; Carlsson, L.A.; Fellers, C. Fiber length and bonding effects on tensile strength and toughness of kraft paper. J. Mater. Sci. 2018, 4, 3006–3015. [Google Scholar] [CrossRef]

- Pruszynski, P. Recent developments in papermaking chemicals. Przegląd Pap. 2014, 70, 545–551. [Google Scholar]

- Wagberg, L. Polyelectrolyte adsorption onto cellulose fibres—A review. Nord. Pulp Pap. Res. J. 2000, 15, 586. [Google Scholar] [CrossRef]

- Antal, M.; Pikulik, I.; Laleg, M. Starches with primary amino groups—papermaking additives for mechanical pulps. In Proceedings of the 5th International Paper and Coating Symposium, Montreal, QC, Canada, 16–19 June 2003; Volume 239. [Google Scholar]

- Lindstrom, T. The role of fibre surface and bulk charge in papermaking. In Proceedings of the 5th International Paper and Coating Symposium, Montreal, QC, Canada, 16–19 June 2003; Volume 1. [Google Scholar]

- TU 17.12.14-001-00253497-2022. Office Paper for Semi-Bleached Pulp. Available online: https://www.komus.ru/medias/sys_master/root/hc3/h27/11356635660318/-17.12.14-001-00253497-2022-1-.pdf?attachment=true (accessed on 20 May 2025).

- Kiaei, M.; Kord, B.; Vaysi, R. Influence of residual lignin content on physical and mechanical properties of kraft pulp/PP composites. Maderas-Cienc. Tecnol. 2014, 16, 495–503. [Google Scholar] [CrossRef]

- El Khayat Driaa, Y.; Maarir, H.; Mennani, M.; Grimi, N.; Moubarik, A.; Boussetta, N. Ultrasound, pulsed electric fields, and high-voltage electrical discharges assisted extraction of cellulose and lignin from walnut shells. Int. J. Biol. Macromol. 2025, 292, 139319. [Google Scholar] [CrossRef]

- Shambilova, G.K.; Bukanova, A.S.; Kalauova, A.S.; Kalimanova, D.Z.; Abilkhairov, A.I.; Makarov, I.S.; Vinogradov, M.I.; Makarov, G.I.; Yakimov, S.A.; Koksharov, A.V.; et al. An Experimental Study on the Solubility of Betulin in the Complex Solvent Ethanol-DMSO. Processes 2024, 12, 1179. [Google Scholar] [CrossRef]

- GOST R 58611-2019. Writing Paper. General Specifications. Available online: https://meganorm.ru/Data/721/72156.pdf (accessed on 3 April 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).