Abstract

Deepwater natural gas hydrate (NGH) exploration faces environmental and economic challenges due to the conventional seabed discharge of drilling mud. To address this, we developed an improved riserless mud recovery (RMR) system using hybrid risers to create a stable, decoupled circulation pathway. This innovative design fulfils three key operational needs: (1) closed-loop drilling fluid circulation with dual-gradient control, (2) completion fluid and test production returns, and (3) mechanical decoupling between the floating platform and subsea riser string. Numerical analysis shows that the system maintains operational stability under wave loading while effectively isolating seabed equipment from platform motion. Simulation results indicate that optimal performance requires a top tension ratio exceeding 1.5 and a submersion depth of 150–250 m, achieving a 70–80% reduction in drilling fluid consumption with full recovery capabilities. The hybrid riser-based RMR system provides a practical solution for sustainable NGH development, offering superior water depth adaptability for both drilling and completion operations in deepwater environments.

1. Introduction

Natural gas hydrate (NGH) has emerged as the most promising strategic alternative energy resource for the 21st century. The global NGH reserves are estimated at 2.1 × 1016 m3, containing approximately twice the carbon content of all conventional fossil fuels combined [1]. Geographically, 97% of these reserves occur in marine sediments along continental slopes, ranging from the seabed to depths exceeding 3000 m below sea level, with the remainder located in Arctic permafrost regions or plateaus [2,3].

Since the 1990s, the international community has actively pursued technological innovations in NGH development. Canada’s Mallik permafrost project (1998–2008) pioneered depressurization-based extraction technology, achieving cumulative gas production of 1.3 × 105 m3 [4]. In the U.S. North Slope trials (2012, 2019), the CO2-CH4 replacement method elevated the recovery rates to 58%. Japan’s three Nankai Trough pilot tests (2013, 2017, 2023) demonstrated sustained subsea NGH production, peaking at 3.5 × 104 m3/day, although sand production issues limited the cumulative output below projections [5,6,7,8].

China’s NGH development has undergone a strategic transition from permafrost exploration (Qinghai–Tibet Plateau trial production in 2008) [9] to marine exploitation, with breakthrough achievements in the Shenhu Area of the South China Sea through two pilot productions (2017 and 2020). The second-round trial production adopted an integrated “horizontal well + reservoir stimulation” technological system, setting a world record with a daily averaged gas output of 2.86 × 104 m3/d and cumulative production of 88.6 × 104 m3, demonstrating the engineering feasibility of deepwater depressurization extraction [10,11]. This milestone validates China’s comprehensive deepwater NGH development technology chain, which synergizes deepwater pile foundations, riserless drilling, horizontal well deployment, optimized sand control, and depressurization extraction, laying a robust foundation for future commercial-scale operations [11,12,13].

The commercial development of NGH continues to face significant environmental and techno-economic challenges [14]. Extensive research has identified three primary environmental concerns associated with NGH exploitation.

- (1)

- Methane Emissions and Climate Impacts: NGH extraction may release substantial quantities of methane, a potent greenhouse gas with a 100-year global warming potential (GWP100) that is 28–36 times greater than that of CO2 [15]. These emissions could significantly impact both marine and atmospheric systems [16], potentially exacerbating climate change through positive feedback mechanisms. Methane release occurs through two principal mechanisms: (1) the direct dissociation of hydrate structures and (2) the formation of migration pathways through compromised sediment seals. This leakage may influence large-scale ocean circulation patterns and increase the frequency of extreme weather events [17].

- (2)

- Geomechanical Stability Concerns: Hydrate dissociation alters sediment’s mechanical properties by reducing the cementation strength and effective stress while increasing the porosity [18]. Such changes may compromise the seabed stability, potentially triggering submarine landslides that could damage critical marine infrastructure and benthic ecosystems [19].

- (3)

- Marine Ecological Consequences: Methane seepage can locally alter carbon cycling, creating anoxic zones and reducing the seawater pH by 0.1–0.3 units [20]. These biogeochemical changes may disrupt marine food webs and biodiversity [21], particularly in sensitive marine ecosystems.

The environmental impacts of drilling fluid discharge during offshore exploration and development have become a significant concern for marine ecosystems [2]. International regulatory frameworks, particularly the 1998 OSPAR Convention, have established stringent “zero-discharge” requirements for offshore drilling operations in Europe [22]. National legislation in most maritime states now enforces strict limits on drilling fluid emissions, with particular attention to biotoxicity thresholds and heavy metal content. Drilling fluids, which are essential in maintaining wellbore stability, cutting removal, and pressure control, typically contain bentonite, barite, KCl, shale stabilizers, hydrate inhibitors, and so on. In a deepwater drilling operation in the Gulf of Mexico, the application of riserless drilling for a 264 m, 26-inch borehole section required a designed drilling fluid volume of 77,000 barrels (approximately 12,240 m3) [23]. This substantial volume necessitated seven to eight supply vessel trips, highlighting the critical logistical challenges associated with drilling fluid management in riserless drilling operations for NGH development.

The direct discharge of drilling fluid is a critical challenge for environmentally sustainable and economically viable commercial NGH exploration and development. To address these challenges, this study proposes an innovative integrated system for deepwater NGH drilling and production that incorporates a hybrid riser with a riserless mud recovery (RMR) system. Simulation analyses confirm the system’s structural feasibility, where the hybrid riser system replaces the conventional mud return line in the RMR system. This integrated configuration offers three principal technical benefits: (1) the mechanical decoupling of the drilling/production platform from mud return line, eliminating direct hydrodynamic impacts from floating platform motions and surface marine environment; (2) the establishment of a closed-loop circulation pathway for NGH drilling, completion, and production operations, preventing direct discharges while reducing the total fluid consumption by approximately 70–80%; (3) the significant extension of the operational depth capabilities, with the RMR system now viable for water depths exceeding 3000 m—a 100% improvement over existing technologies. This innovative approach combines the advantages of both rigid riser and flexible jumper technologies while addressing the operational challenges associated with traditional RMR configurations.

2. Technical Foundation of the Innovative Integrated System Technology

2.1. Riserless Drilling for Natural Gas Hydrates

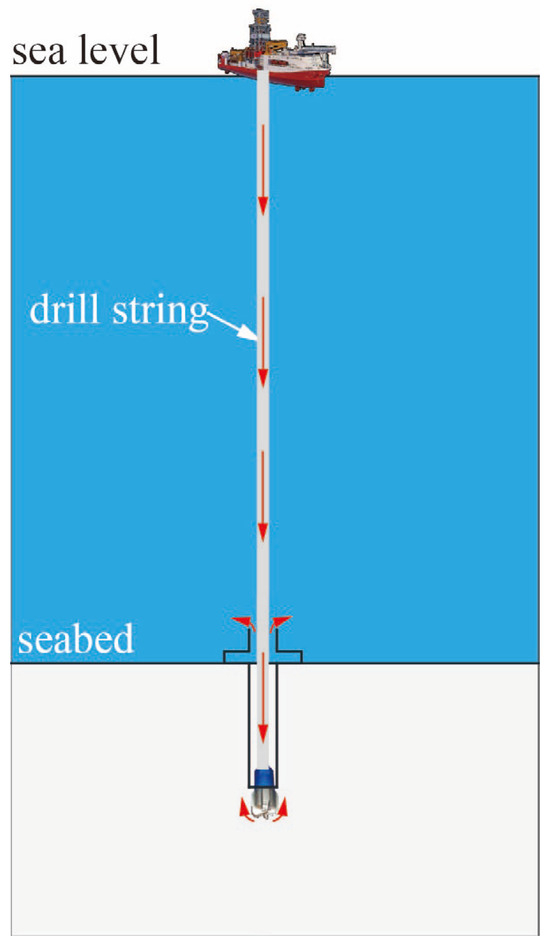

Riserless drilling (Figure 1) for natural gas hydrates (NGH) utilizes only the drill string to convey the bit into the seabed, eliminating the dependence on a riser for drilling fluid circulation. This technique creates vertically stratified density layers between the seawater and drilling fluid, effectively reducing the bottomhole pressure. The riserless drilling process is conventionally employed for shallow-water subsea operations.

Figure 1.

The principle of riserless drilling.

2.2. Closed-Loop Drilling with Riserless Mud Recovery System

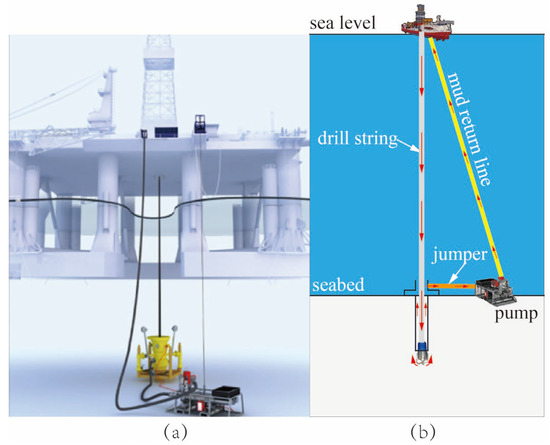

Deepwater drilling operations encounter significant challenges due to shallow geological hazards, including shallow gas flows, shallow water flows, and submarine landslides. Statistical analyses indicate that these hazards contribute to over 35% of all global deepwater drilling incidents. Since the 1990s, joint industry projects (JIPs) involving ExxonMobil, Chevron, and Deepstar in the Gulf of Mexico have systematically investigated dual-gradient drilling (DGD) systems, developing various solutions, including subsea mudlift drilling (SMD) technology. However, these efforts have not fully resolved the fundamental challenge of reconciling mud circulation systems with narrow formation pressure windows [24,25,26,27,28]. In 2003–2004, the Norwegian government restarted petroleum exploration and development activities in the Lofoten and Barents Sea, implementing a zero-discharge policy for all operational phases. This stringent environmental regulation compelled oil companies to develop innovative drilling technologies capable of eliminating all discharges, including tophole drilling operations [29]. In this context, Norwegian company AGR (later renamed Enhanced Drilling) pioneered RMR technology in 2004, building upon the Cuttings Transportation System (CTS). The innovative system establishes a closed-loop circulation network through dedicated mud return lines independent of the drill string and a specially designed subsea lifting pump. This configuration achieves dual technological breakthroughs, namely the elimination of drilling fluid discharge and effective adaptation to narrow density windows [30,31]. The process and principles of RMR are Shown in Figure 2.

Figure 2.

RMR system and operational diagram. (a) The main devices of the RMR system [32]; (b) the operational diagram of drilling with the RMR system.

The core innovation of the RMR technology lies in constructing a mud return flow channel that is independent of the traditional riser [33,34,35,36]. This breakthrough offers six key technical advantages.

- (1)

- Dual-gradient drilling optimization: Utilizing the seawater–mud interface above the mudline, the system maintains optimal wellbore pressure profiles, effectively managing narrow drilling windows while mitigating kick risks.

- (2)

- Closed-loop fluid circulation: Dedicated return pipelines enable direct mud recycling to surface facilities, with (a) an approximately 70–80% reduction in total fluid consumption in tophole drilling; (b) the complete elimination of seabed discharge and the associated biotoxicity.

- (3)

- Regulatory compliance: It fully satisfies the zero-discharge requirements for offshore operations.

- (4)

- Operational efficiency: It demonstrates a reduction in casing strings and the operation period.

- (5)

- Early hazard detection: Enhanced monitoring capabilities enable the quick identification of wellbore influxes by monitoring subsea modules, as well as an improved response to blowouts/losses through real-time diagnostics.

- (6)

- Well design advantages: It facilitates optimized casing programs and extended casing setting depths (by approximately 300–500 m in field applications).

RMR technology effectively addresses key deepwater drilling challenges, including narrow drilling windows, complex formations, deep casing requirements, and stringent environmental regulations. Industry data confirm the successful deployment of CTS/RMR systems in over 1000 wells to date [32]. A consortium comprising Enhanced Drilling (formerly AGR), Shell, and BP America conducted a field demonstration at a 1419 m water depth in offshore Malaysia using the Atwood Falcon drillship [33,37]. The test implemented several technical innovations:

- (1)

- Multi-stage mud lift system—series-connected pump units for reliable mud return;

- (2)

- Specialized casing design—a 193.7 mm diameter with vortex-induced vibration (VIV) suppression;

- (3)

- Subsea pipeline management—an anchoring system for pipeline and equipment stabilization [33,37].

The connection method between the mud return line and the platform constitutes another critical factor restricting the applicable water depth. Conventional platforms typically lack heave compensation systems for the return line, exposing the connection nodes to substantial dynamic loading. Under marine environmental conditions, wave-induced platform heave motion generates repetitive impact forces at these uncompensated connections, significantly increasing the dynamic stresses, which compromise both system performance and structural reliability.

The evolution of RMR system configurations demonstrates significant technological progression: (a) initial implementations primarily utilized flexible pipes for mud return channels; (b) a pivotal advancement occurred in 2008 when AGR introduced casing as a mud return line with dual series-connected mud lift pumps, enhancing the system performance; (c) a subsequent innovation by Enhanced Drilling in 2016 combined steel casing (upper section) with flexible pipes (lower section), enabling successful deployment at an 854 m water depth—a notable milestone in deepwater drilling technology development.

The structural optimization of the mud return pipeline configuration is essential in extending the operational water depth and expanding the application scope of RMR systems. This necessitates addressing critical technical constraints, including the structural load-bearing capacity, pump lift requirements, fatigue resistance, and vessel–connection compatibility. Through improved connection methodologies and optimized hydraulic design, RMR systems can achieve greater operational depths, thereby facilitating enhanced ultra-deepwater natural gas hydrate exploration and production capabilities.

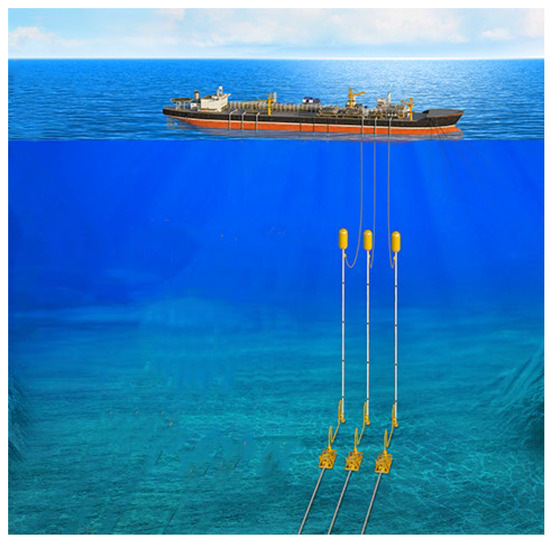

2.3. Hybrid Riser for Production

The hybrid riser system (Figure 3), alternatively referred to as the tower riser or free-standing riser, represents an advanced structural configuration that synergistically combines rigid pipe strings with flexible jumpers [38,39,40]. The hybrid riser employs a rigid vertical string (typically constructed of seamless steel pipes) at the base to establish a stable fluid conduit, while incorporating flexible jumpers at the top for connection to floating production storage and offloading (FPSO) units, thereby creating an effective mechanical decoupling mechanism [41,42]. This configuration proves particularly advantageous in marine environments where FPSOs and support vessels are subjected to dynamic wave-induced motions, including surge and heave. The hybrid riser design substantially attenuates motion transfer from the FPSO to the riser string, significantly reducing fatigue accumulation in critical components and enhancing the overall system reliability for extended operational durations [43,44].

Figure 3.

The hybrid riser system.

The hybrid riser system was pioneered by the Placid Oil Company in the Gulf of Mexico (1988), initiating its technological evolution. During 2001–2007, three deepwater developments in Angola (water depths > 1000 m) successfully implemented hybrid risers, marking significant advancements in design, fabrication, and installation technologies [38,45,46,47,48,49]. A notable breakthrough also occurred in 2010, when hybrid riser applications in the Gulf of Mexico achieved a 2600 m water depth—the current industry benchmark [50]. Demonstrating remarkable versatility, 2H Offshore adapted the system for shallow water (90 m) in Indonesian fields in 2013 [51]. This technological progression has yielded several innovative derivatives, including minimum production risers [49], single independent risers [52,53], multiline free-standing risers [54], and multiple-line configurations [55]. As evidenced in Table 1, HRS technology has now been extensively deployed across three principal deepwater basins: the Gulf of Guinea (West Africa), the Gulf of Mexico, and Brazil.

Table 1.

List of hybrid riser-based oilfield projects.

The successful implementation of hybrid riser systems has garnered significant academic interest, prompting extensive theoretical investigations and risk assessments encompassing the static responses, dynamic behavior, flow field effects, and pipe–soil interactions [56,57,58,59,60,61,62,63,64,65,66]. These studies have elucidated the mechanical decoupling characteristics of hybrid risers and validated their suitability for deepwater and ultra-deepwater applications. The system’s principal technical merits—combining superior mechanical performance, operational stability, and environmental adaptability—have substantially enhanced the efficiency and safety of offshore operations while advancing deep-sea resource development technologies. Key advantages include (a) onshore fabrication and quality inspection; (b) pre-installation capabilities prior to vessel mobilization; (c) a quasi-static response with vessel motion tolerance; (d) a simplified vessel interface through flexible jumper hang-off porches; (e) reduced payload requirements (limited to jumper partial weight); and (f) support for local fabrication through in-country infrastructure, facilities, and employment opportunities [51].

3. Hybrid Riser-Based Riserless Mud Recovery System

3.1. Technical Framework

3.1.1. Main Structural Forms

To address critical challenges in RMR systems—including excessive load-bearing requirements, forced vibration responses, and elevated failure risks in mud return lines—structural optimization through hybrid riser conversion presents a novel and practical solution. Replacing conventional ship-borne rigid articulations with hybrid riser configurations significantly mitigates hull motion and surface wave impacts, ensuring reliable mud return pathways. This approach incorporates strategically placed subsea lifting pumps at varying depths, utilizing multi-stage series configurations to enhance the lift capacity. Furthermore, integrating power/communication umbilical cables along the riser’s exterior converts dynamic cables to static installations, substantially reducing the entanglement risks among subsea pipelines and cables.

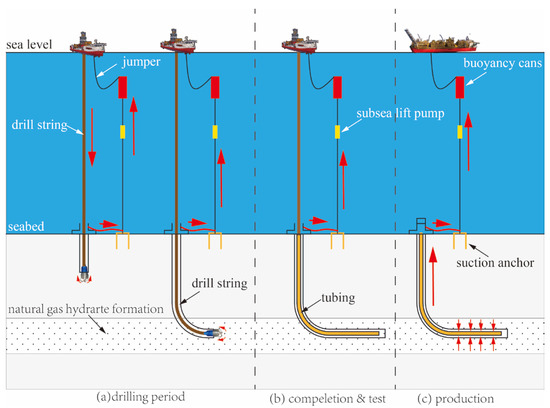

The hybrid riser-based RMR system comprises six key components (Figure 4): (1) a seabed anchor providing foundational stability; (2) a rigid structural column transferring loads between the anchor and upper assemblies; (3) strategically positioned lift pumps enabling adjustable mud return rates through parameter optimization; (4) buoyancy modules maintaining the vertical riser’s orientation while dampening surface wave effects; (5) a gooseneck assembly accommodating vessel motions through its engineered curvature; and (6) flexible jumpers facilitating fluid transfer to surface processing equipment while decoupling platform movements. This integrated system ensures reliable mud return by combining structural integrity (through the anchored column) with motion adaptability (via buoyancy compensation and flexible connections), effectively addressing both static and dynamic marine environmental challenges.

Figure 4.

Diagram of subsea lifting circulation system under drilling, completion and tests, and production: (a) subsea lifting circulation system is used for lifting of drilling fluid; (b) subsea lifting circulation system is used for lifting of completion fluid and production gas or fluid in testing; (c) subsea lifting circulation system lifts production fluid to FPSO.

3.1.2. Operation Process, from Drilling to Production

- (1)

- Drilling

The hybrid riser installation process commences with the precise positioning and secure seabed anchoring of the foundation structure. Utilizing specialized offshore installation vessels, rigid columns are sequentially assembled and lowered to the seabed while concurrently integrating subsea lift pumps and umbilical cables at designated intervals (150–300 m water depth). Buoyancy modules and gooseneck connectors are installed at the column top, with seawater ballast adjustment providing optimal vertical tension. Final connection to the surface facility is achieved through remote-operated vehicle (ROV)-assisted jumper installation, completing the mud return system’s deployment.

During drilling operations, the drilling fluid transports cuttings upward through the annulus and enters the hybrid riser via the subsea wellhead. The subsea lift pumps automatically regulate their operational power in response to the real-time monitoring of the fluid velocity and pressure, ensuring efficient mud return to the surface. Buoyancy modules maintain constant upward tension on the riser assembly, stabilizing the system against environmental disturbances, including wave and current forces. The gooseneck connector accommodates platform motions through its articulated design, enabling continuous mud flow to the surface processing system for effective solid separation and fluid recycling.

- (2)

- Completion and test

During the completion phase following drilling operations, the hybrid riser system maintains its critical function in fluid management while adapting to specialized completion requirements. The system facilitates a series of completion activities, including reservoir stimulation, screen deployment, downhole testing, tool placement, well flushing, killing, and abandonment operations—all of which consume substantial volumes of completion and kill fluids. The subsea lift pumps are precisely calibrated to modulate the fluid return rates according to the operational demands, enabling (1) optimal flow conditions for various testing procedures, (2) the efficient recovery of specialized completion fluids, and (3) closed-loop circulation during critical well control operations. This adaptive functionality not only ensures operational continuity between the drilling and completion phases but also enhances the fluid recovery efficiency by 70–80% compared to riserless drilling, while maintaining the inherent advantages of motion decoupling and environmental isolation characteristic of hybrid riser configurations.

- (3)

- Production

During natural gas hydrate production, the hybrid riser system demonstrates remarkable adaptability by serving as a multifunctional conduit for gas–liquid flow and water injection applications. When both the flexible jumpers and rigid risers meet the wellbore pressure limits, the mud return line can be directly converted into a production flow path, significantly reducing the project cost by eliminating additional infrastructure. For liquid-dominated production, the subsea lift pumps provide essential artificial lift to maintain optimal depressurization, while integrated manifolds enable flow direction modulation for thermal stimulation or water injection enhancement. Real-time monitoring systems dynamically adjust the pump parameters based on the production characteristics including the gas–liquid ratio, hydrate saturation, and fluid properties, ensuring efficient and stable transportation throughout the production cycle.

3.2. Characteristic Analysis

3.2.1. Mechanical Decoupling

The hybrid riser configuration employs buoyancy cans to maintain constant vertical tension while decoupling the mud return line from vessel motions, effectively eliminating heave-induced vertical dynamic loads. The rigid pipeline primarily experiences hydrodynamic forces from ocean currents, resulting in combined axial and lateral bending stresses. Extensive research has demonstrated that the innovative design configuration of the hybrid riser achieves optimal Von Mises stress distribution (maintaining < 60% of yield strength) while demonstrating exceptional fatigue resistance exceeding 25 years of service life, as verified through DNV-OS-F201-compliant analysis. These performance characteristics render the system ideally suited for challenging deepwater drilling applications across 300–3000 m water depths, where it maintains 97% operational reliability under typical metocean conditions.

3.2.2. Buoyancy Control for Top Tension

Buoyancy cans are utilized to maintain optimal top tension for the mud return line. By precisely adjusting the buoyancy through controlled inflation, the tension ratio can be effectively modulated, thereby regulating the axial and lateral bending deformations, as well as the stress distribution of the mud return line, under varying water depths (300–3000 m) and ocean current conditions (0.5–2.5 m/s). This adaptive control mechanism enhances the structural integrity and load-bearing capacity of the system while mitigating excessive stress concentration.

3.2.3. Strings Spacing Control

The drilling vessel interfaces with the mud return line through a specialized flexible jumper, which establishes an optimized standoff distance between the drill string and mud return line. This engineered spacing configuration effectively mitigates the collision risks between adjacent casing strings while simultaneously eliminating operational constraints on vessel heading adjustments caused by subsea tubular interference. Consequently, the system enables enhanced dynamic positioning capabilities, allowing the vessel to optimally align with the prevailing environmental forces, including ocean currents and wave actions.

3.2.4. Adaptation to Ultra-Deepwater Conditions

Under static loading conditions where dynamic loads are absent, the mud return line exhibits significantly improved stress characteristics. Structural verification analyses demonstrate that, while maintaining equivalent safety factors (typically 1.5–2.0), the allowable pipeline length can be extended by 150–200% compared to conventional dynamic load scenarios. This substantial length enhancement provides greater design flexibility for pipeline routing, enabling optimized wellsite layouts that reduce the construction complexity by 30–40% and potentially lower the associated costs, while simultaneously improving the overall process efficiency through expanded configuration options.

3.2.5. Multi-Stage Pump Suspension Adaptation

The static axial loading condition presents an optimal configuration for multi-stage lifting pump systems, eliminating the vibration-induced failure risks inherent in dynamic marine environments. Unlike shipborne operations that generate complex, multiple-degree-of-freedom coupled vibrations, which often cause localized stress concentration, exceeding the yield strength and potentially inducing compressive buckling in inter-pump tubular sections, the static loading mode maintains the structural integrity by sustaining purely axial stress distributions within safe operational limits.

3.2.6. Pre-Installation

The pre-installation strategy demonstrates significant cost and efficiency advantages for medium to deepwater drilling operations (300–3000 m water depth). Phase I employs midsize vessels for rapid mobilization and mud return line installation, achieving 40–60% time savings compared to conventional methods. Phase II integrates large floaters (e.g., semi-submersibles) to establish critical interfaces, including high-pressure fluid transfer systems, power networks, fiber-optic communication links, and DP-assisted mooring connections. This phased operational approach utilizes differentiated vessel scheduling to mitigate the idle costs associated with installation delays for large floating drilling units, thereby substantially lowering the daily operational expenditures while optimizing resource allocation and project cost management.

3.2.7. Rapid Construction

The buoyancy cans and mud return lines can be domestically manufactured at the construction site location. Given their relatively shallow operating water depths, these components can be produced with controlled processing complexity when fabricated in accordance with specification-compliant design drawings and subjected to rigorous certification procedures. In natural gas hydrate development, the formation pressure conditions critically influence subsea equipment selection and design. The Shenhu Area exemplifies this relationship, where the hydrate reservoir pressures remain below 3000 psi. These moderate pressures relax the technical specifications for critical components, including mud return pipelines and valves, thereby simplifying equipment design and manufacturing while lowering the procurement costs. Furthermore, during operational phase transitions (drilling, completion, and production), the limited pressure differential minimizes the risks associated with riser repurposing, reducing both the equipment failure potential and operational complexity. This pressure stability enhances the operational safety and continuity while facilitating project execution.

4. Structural Feasibility Analysis

4.1. Model Establishment

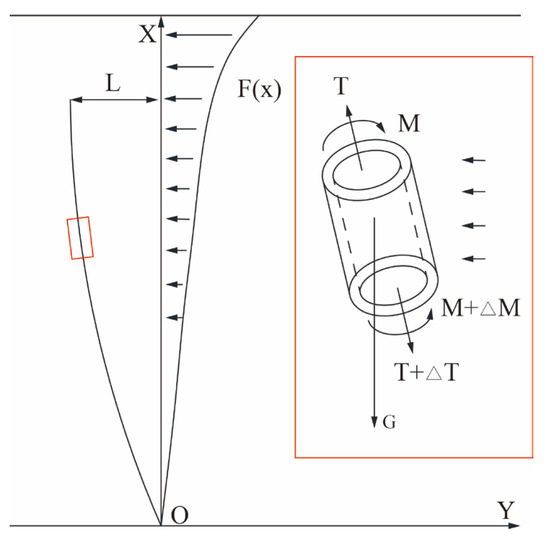

The hybrid riser-based RMR system experiences both longitudinal and transverse bending deformations when subjected to combined top tension and wave–current forces. For analytical purposes, the simplified mechanical model is shown in Figure 5.

Figure 5.

Differential element mechanical model of hybrid riser-based RMR system.

The simplified mechanical model enables deformation calculation and strength analysis using elastic mechanics principles, with its deformation control equation expressed as

where EI is the bending stiffness of the pipe section, N·m2; T(x) is the depth-dependent axial force distribution along the pipe, N; w is the submerged weight per unit length, N/m; and F(x) is the depth-varying transverse wave–current force distribution, N/m.

OrcaFlex is a commercial finite element analysis software program developed by Orcina in 1986, specialized for ocean engineering applications. This software employs the lumped mass method to simulate the nonlinear behavior of slender structures, including deep-water pipelines and steel catenary risers, enabling the efficient solution of complex offshore challenges such as deepwater drilling, subsea pipeline installation, and riser system design. By discretizing structures into mass points with calculated mass and inertia matrices based on geometric and material properties, OrcaFlex enables the accurate modeling of large deformation problems in marine environments [67].

This study employs the OrcaFlex software 11.0 to analyze the proposed operational model for the hybrid riser-based RMR system at a 2000 m water depth. In the model, the connection mode of the rigid riser is simplified: the bottom node of the riser and the subsea anchor are modeled with fixed constraints, prohibiting both displacement and rotation during operation. The buoyancy cans and the top node of the riser are also under fixed constraints, while maintaining flexible node connections to the surface platform. The buoyancy cans (3 m diameter × 50 m height) provide 159.13 t net buoyancy, supporting a 1800 m mud return line (168 mm OD, 12.7 mm wall thickness, 102.23 t dry weight) with a subsea mud lift pump (20 t dry weight) suspended 550 m below the buoy. The model configuration adopts 20 m nodal spacing for the mud return line, comprising 90 nodes in total. Given the hybrid riser’s reduced surface wave sensitivity, environmental conditions are modeled with a 7 m wave height, 8 m/s spectral wind speed, and 29.8 m/s design wind speed. The hydrodynamic analysis incorporates ocean current profiles modeled using the power-law distribution, with velocities ranging from 1.5 m/s at the surface to 0.3 m/s at the seabed, while applying uniform drag and added mass coefficients of 1.2 throughout the water column. The model assumptions adopted in this study consist of (a) negligible system torque, (b) an invariant ocean current direction, and (c) a total simulation duration of 4000 s with a time step of 0.1 s.

4.2. Load Analysis

4.2.1. Bending, Tension, and Stress

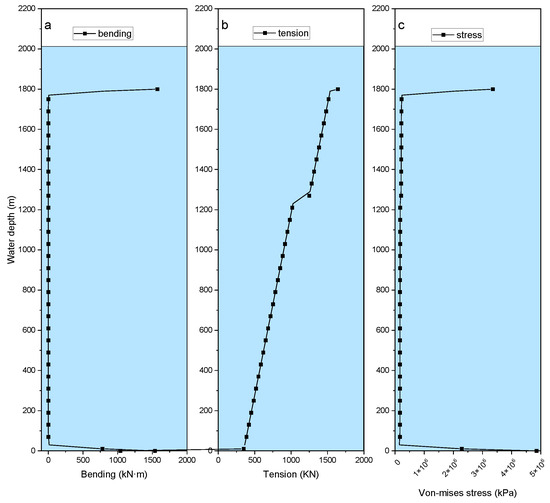

The simulation results (Figure 6) demonstrate systematic variations in the axial mechanical behavior of the mud return pipeline. Figure 6a reveals distinct jumps in the bending moment and stress at the system’s top and bottom nodes. The peak bending moments reach 1572.37 kN·m at the top connection node and 1537 kN·m at the bottom node, while the middle node exhibits near-zero values. These results demonstrate that the connection ends—particularly at the top buoy and seabed fixed point—constitute critical structural components for system integrity. Consequently, these regions require prioritized consideration in system design, with a particular emphasis on optimizing the nodal connection methodology. The axial tension decreases linearly from top to bottom, with a pronounced force discontinuity observed at 550 m below the mudline, corresponding to the submerged weight of the mud lift pump system. This confirms the pump body’s weight as the primary load source at this location. Subsurface currents exhibit a negligible influence on the axial tension, allowing for their omission in engineering calculations. Regarding the Von Mises stress distribution, minimal sectional variations were observed, with stress decomposition revealing axial tension as the dominant contributing factor. The structural design process must prioritize constraint mechanisms at the top and bottom nodal points. Spherical hinge connections are recommended to prevent the bending moments at connection nodes from exceeding their flexural capacity.

Figure 6.

Bending, tension, and stress distribution of rigid mud return line: (a) the bending distribution of the mud return line; (b) the wall tension distribution of the mud return line; (c) the Von Mises distribution of the mud return line.

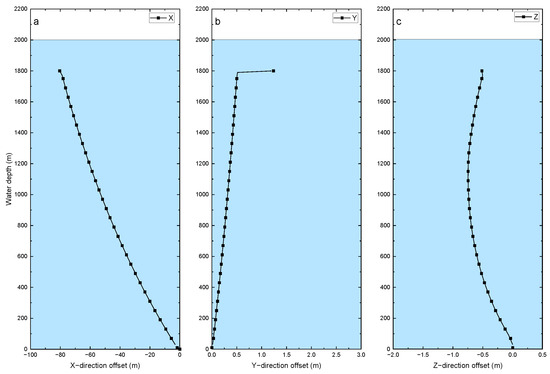

4.2.2. Longitudinal and Lateral Bending Deformation

The numerical analysis of nodal displacements (Figure 7) reveals distinct spatial variations in the mechanical response of the mud return pipeline across three axes. The X-direction displacements, predominantly observed at the pipeline top nodes, demonstrate the most significant magnitude due to direct ocean current forcing. The Z-direction displacements result from coupled buoyancy–gravity interactions between the buoy and pipe string. In the Y-direction, jumper tension induces substantial displacement at the pipeline top nodes (averaging 1.21 m), with a rapid 0.65 m linear attenuation observed in the lower nodes due to diminishing surface jumper gravitational effects.

Figure 7.

Bending deformation distribution of mud return line in longitudinal and lateral directions: (a) X−direction offset, (b) Y−direction offset, and (c) Z−direction offset.

4.2.3. Motion Behavior of Submerged Buoyancy Cans

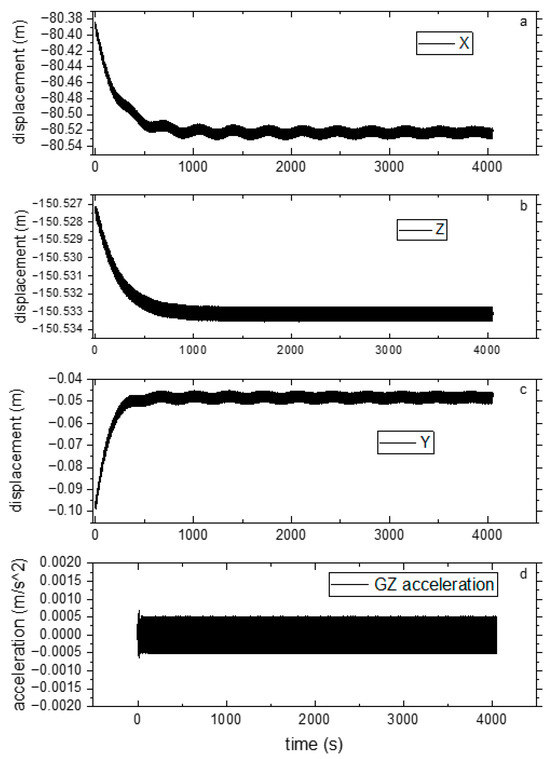

Through the continuous monitoring of the buoy displacement in three-dimensional space (X, Y, and Z axes), the dynamic response characteristics were systematically analyzed (Figure 8). The findings demonstrate a distinct motion attenuation trend, where the displacement amplitudes progressively diminish over time until reaching steady-state conditions.

Figure 8.

The motion characteristics of the top node in the mud return line: (a) X-direction offset, (b) Y−direction offset, (c) Z−direction offset, and (d) Z−direction acceleration.

In the X-direction (parallel to ocean current), the buoy exhibits periodic motion with a maximum amplitude below 0.5 m. The displacement progressively converges to −80.40 m with increasing operation time, reaching a steady state within one hour post-installation, demonstrating rapid self-balancing capabilities in stable current conditions. In the vertical (Z) direction, the buoy exhibits minimal motion characteristics, with the displacement amplitude remaining below 0.03 m and the peak vertical acceleration not exceeding 0.004 m/s2. These negligible dynamic responses demonstrate that the buoy operates in a quasi-static vertical environment, allowing for simplified pipeline tensile design without accounting for additional dynamic loading effects, thereby significantly mitigating the fatigue failure risks. Under static loading conditions, mud lift pumps can be installed in series at varying depths along the mud return pipeline to enhance the system’s total lifting capacity. The pipe string segments between these pumps are maintained under constant tension throughout operation.

In the Y-direction (perpendicular to ocean current), the buoy maintains a stable oscillation amplitude of approximately 0.8 m. Due to the coupled effects of the crossover pipe’s flexible connection and drilling vessel motion, the integrated buoy–mud return line system demonstrates a consistent 250 s oscillation period. This well-defined periodicity serves as a critical parameter for the system’s dynamic performance assessment and structural design optimization.

5. Key Parameter Analysis and Discussion

5.1. Water Depth

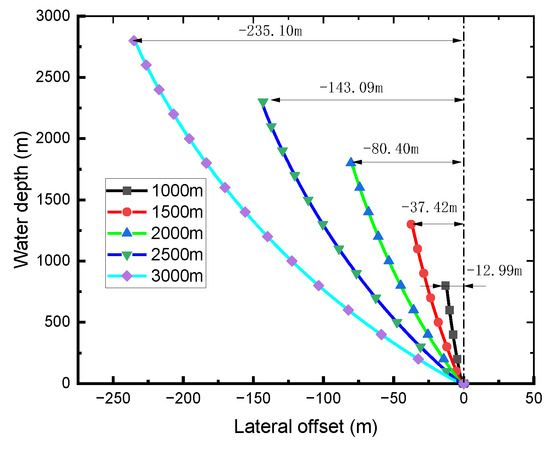

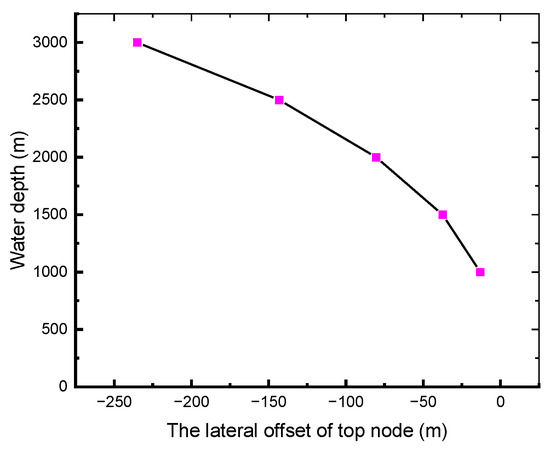

Assuming a fixed underwater buoy position as the boundary condition, this study investigates the effects of the operating water depth (1000–3000 m) on the axial and lateral bending deformations of hybrid riser-configured mud return pipelines, as shown in Figure 9. The results reveal a nonlinear increase in the buoy top displacement: the displacement at the top node of the entire string escalates sharply from −12.99 m to −235.10 m with increasing depth, as shown in Figure 10.

Figure 9.

The lateral offset distribution of the mud return line under varying water depths.

Figure 10.

The lateral offset of the top node of the mud return line under varying water depths.

The observed nonlinear response stems from the water-depth-dependent mechanical behavior: as the depth increases, the elongated mud return pipeline exacerbates the current-induced loads on the riser system, resulting in significant nonlinear increases in displacement. This hydrodynamic accumulation induces pronounced horizontal displacement in the lifting string, consequently magnifying the buoy top displacement.

The further analysis of Figure 9 indicates that, with the structural design unchanged, the lateral displacement of the buoy decreases with the water depth. During drilling or completion operations, insufficient annular clearance between the drill string and rigid riser significantly increases the collision risk, potentially compromising the operational safety and equipment integrity. This relationship is critical for pipeline string spacing control, as reduced buoy displacement in shallow water significantly lowers the technical complexity and cost of maintaining proper spacing—providing essential quantitative support for engineering design. These findings underscore that, for ultra-deepwater deployments, the comprehensive hydrological characterization of the operational area is essential to reliably predict system movement envelopes under extreme environmental loading conditions.

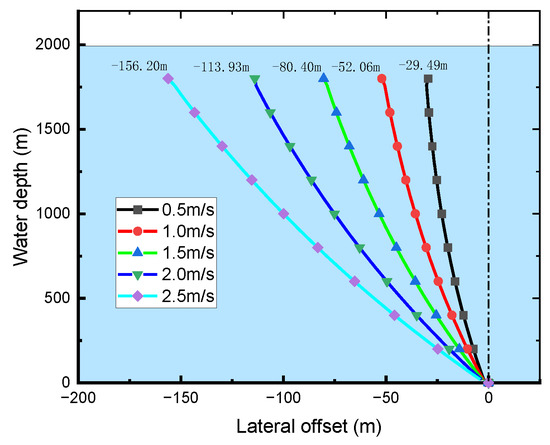

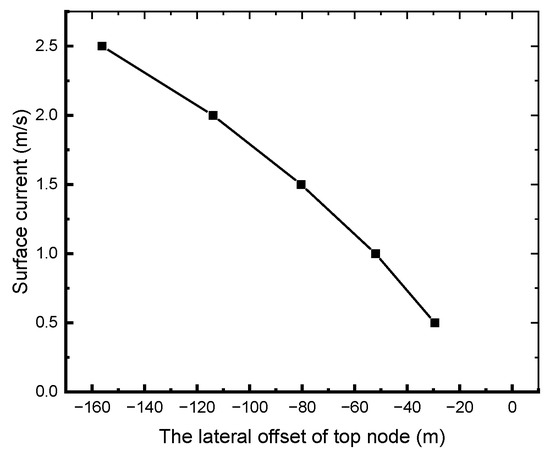

5.2. Current

This study investigates the effects of ocean current parameter variations on the axial and lateral bending deformations of the mud return pipeline while maintaining a constant structural design (Figure 11). Quantitative analysis reveals the significant sensitivity of the pipeline lateral displacement to current velocity changes. As shown in Figure 12, the lateral displacement exhibits a nonlinear increase with increasing surface current velocities (0.5–2 m/s range). These findings demonstrate that an increasing current velocity substantially enhances the hydrodynamic loading on the pipeline system, consequently amplifying the lateral offset; such displacements may compromise the jumper connector tolerances. The observed linear relationship enables the rapid estimation of the riser system’s maximum displacement during field operations based on the prevailing ocean current direction and velocity.

Figure 11.

The lateral offset distribution of the mud return line under varying ocean currents.

Figure 12.

The lateral offset of the top node of the mud return line under varying ocean currents.

In addition to the velocity, the ocean current direction significantly affects the pipeline’s dynamic response. Research indicates that operational current direction changes induce the synchronous displacement of both the mud return pipeline and its buoy, substantially increasing the spatial separation between the buoy and drilling well location. This displacement poses operational safety risks to surface jumpers, potentially leading to pipeline tensile stresses and bending stress concentration.

5.3. Top Tension

Top tension is critical in maintaining the mud return pipeline configuration and controlling axial/lateral bending deformations. An optimized tension design significantly improves the pipeline stability and operational reliability in complex marine environments. In practice, precise tension control can be achieved through buoyancy adjustment or float volume optimization.

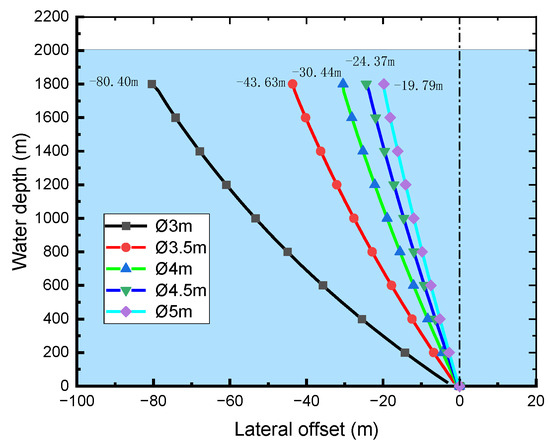

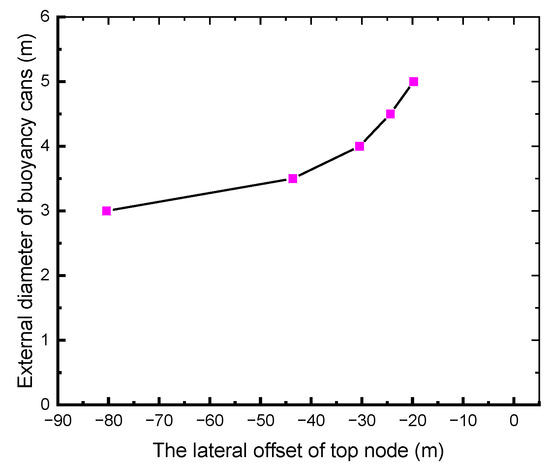

This study focuses on float volume adjustment as the primary method for tension control, conducting a comprehensive quantitative analysis. Rigorous calculations and simulations elucidate the effects of top tension variations on the axial and lateral bending deformations of the mud return pipeline (Figure 13). The results demonstrate that increasing the external diameter of the buoyancy cans from 3 m to 5 m induces a pronounced reduction in the float top lateral displacement, decreasing nonlinearly from −109.87 m to −28.11 m. This response confirms that the system top tension increases substantially with the float diameter, effectively constraining the lateral displacement through nonlinear mechanisms. For systems operating at >2000 m water depths, float diameters ≥ 4.5 m are recommended to maintain a tension ratio above 1.5. Concurrently, the pipeline configuration progressively approaches vertical alignment, significantly enhancing its mechanical performance and operational efficiency. Strategic float diameter enlargement represents an effective engineering solution for the optimization of the pipeline stress distribution, mitigating deformation risks and ensuring safe and efficient deepwater drilling operations. As shown in Figure 14, the optimal top tension can be effectively maintained within 3–4 m, as diameter expansions beyond 4.5 m offer progressively smaller benefits while significantly increasing the material costs. This balanced approach satisfies the displacement control requirements while simultaneously optimizing three key parameters: (1) the pipe string lateral deformation, (2) the structural stress distribution, and (3) the buoy manufacturing economics.

Figure 13.

The lateral offset distribution of the mud return line under varying external diameters of the buoyancy cans.

Figure 14.

The lateral offset of the top node of the mud return line under varying external diameters of the buoyancy cans.

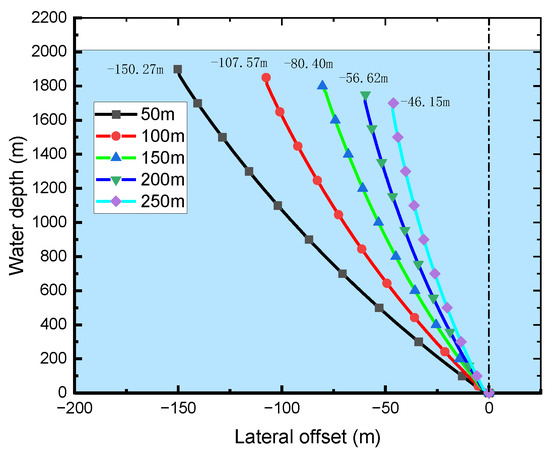

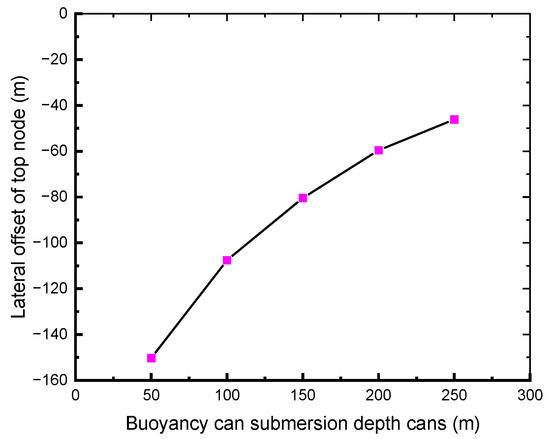

5.4. Submerged Depth of Buoyancy Cans

To investigate the effects of surface currents and wind waves on system deformation, this study analyzes the structural response while maintaining constant buoy specifications but varying the buoy’s submersion depth and rigid pipe string length. The results demonstrate that shallower buoy depths lead to increased lateral displacement of the riser string. Specifically in Figure 15, at a 50 m submersion depth, the buoy vertex exhibits a lateral y-displacement of −150.27 m, whereas, at a 250 m depth, this displacement reduces to −46.15 m. Figure 16 reveals a nonlinear trend in the maximum lateral displacement at the top with increasing submersion depths, although the rate of increase diminishes. For optimal engineering feasibility—particularly regarding jumper installation—the recommended buoy submersion depth ranges between 100 m and 250 m. Within this range, the lateral displacement remains under 80 m.

Figure 15.

The lateral offset distribution of the mud return line under varying submersion depths.

Figure 16.

The lateral offset of the top node of the mud return line under varying submersion depths.

6. Conclusions

This study proposes and evaluates a novel hybrid riser-based riserless mud recovery (RMR) system for deepwater NGH development, addressing the key limitations of conventional riserless drilling technologies. This research combines the structural flexibility of hybrid risers with closed-loop mud recovery to enhance the environmental sustainability, operational stability, and water depth adaptability. The key findings are as follows.

- (1)

- The proposed system maintains mechanical decoupling and structural stability under water depths ranging from 1000 to 3000 m, with 97% operational reliability in the modeled metocean conditions.

- (2)

- Ensuring the safe and stable operation of marine mud return pipeline systems requires the comprehensive collection and analysis of physical oceanographic data to accurately characterize the spatiotemporal current distributions in the operational area.

- (3)

- The strategic scheduling of construction activities during periods of reduced current velocity and directional stability would serve to minimize hydrodynamic impacts on the pipeline’s integrity.

Author Contributions

Writing—original draft, methodology, funding acquisition, J.Z., W.X. and Y.Y.; methodology, B.L. and F.H.; resources, validation, H.Y., H.C. and K.Z.; figure drafts, K.S. and Q.L.; translation, K.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Key Research and Development Program of China (2021YFC2800801; 2023YFC2813100).

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflicts of interest. The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Klauda, J.B.; Sandler, S.I. Global Distribution of Methane Hydrate in Ocean Sediment. Energy Fuels 2005, 19, 459–470. [Google Scholar] [CrossRef]

- Boswell, R.; Collett, T.S. Current perspectives on gas hydrate resources. Energy Environ. Sci. 2011, 4, 1206–1215. [Google Scholar] [CrossRef]

- Liang, J.Q.; Ning, F.L.; Zhang, R.W.; Liang, Q.Y.; Hu, G.W.; Yang, W. Advances and Future Perspectives in Offshore Gas Hydrate Exploration & Production. Acta Gologica Sin. 2024, 98, 1–8. (In Chinese) [Google Scholar]

- Dallimore, S.R.; Collett, T.S.; Taylor, A.E.; Uchida, T.; Weber, M.; Chandra, A.; Mroz, T.H.; Caddel, E.M.; Inoue, T. Summary and implications of the Mallik 2002 gas hydrate production research well program. In Scientific Results from the Mallik Gas Hydrate Production Well Program; Bulletin of the Geological Survey of Canada: Mackenzie Delta, NT, Canada, 2005; Volume 585, pp. 1–14. [Google Scholar]

- Yamamoto, K. Overview and introduction: Pressure core-sampling and analyses in the 2012-2013 MH21 offshore test of gas production from methane hydrates in the eastern Nankai Trough. Mar. Pet. Geol. 2015, 66, 296–309. [Google Scholar] [CrossRef]

- Zhang, W.; Shao, M.; Yao, S. Analysis of development process of natural gas hydrate in Japan and its enlightenment to China. Sino-Glob. Energy 2023, 28, 15–22. [Google Scholar]

- Zhang, W.; Shao, M.; Wang, H. The latest progress in the research and development of pro-filling type gas hydrate in Japan. Mar. Geol. Front. 2025, 41, 1–11. [Google Scholar]

- Gajanan, K.; Ranjith, P.G.; Yang, S.Q.; Xu, T. Advances in research and developments on natural gas hydrate extraction with gas exchange. Renew. Sustain. Energy Rev. 2024, 190, 114045. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Y.; Yin, H. Application of Horizontal Multilateral Well Drilling Technology in Natural Gas Hydrate Production Testing. Explor. Eng. (Rock Soil Drill. Tunneling) 2017, 44, 13–17. [Google Scholar]

- Li, J.; Ye, J.; Qin, X.; Qiu, H.J.; Wu, N.Y.; Lu, H.L.; Xie, W.W.; Lu, J.A.; Peng, F.; Xu, Z.Q.; et al. The first offshore natural gas hydrate production test in South China Sea. China Geol. 2018, 1, 5–16. [Google Scholar] [CrossRef]

- Ye, J.; Qin, X.; Xie, W.; Lu, H.-L.; Ma, B.-J.; Qiu, H.-J.; Liang, J.-Q.; Lu, J.-A.; Kuang, Z.-G.; Lu, C.; et al. The second natural gas hydrate production test in the South China Sea. China Geol. 2020, 3, 197–209. [Google Scholar] [CrossRef]

- Li, B.; Kou, B.; Li, B.; Li, J.; Zeng, J.; Niu, Q.L.; Shao, Y.T.; Zhang, K.W.; Yu, H.Y.; Wang, Y.S. Application of wellhead suction anchor technology in the second production test of natural gas hydrates in the South China Sea. China Geol. 2022, 5, 293–299. [Google Scholar]

- Zeng, J.; Xie, W.; Kou, B.; Lu, J.-A.; Li, X.-C.; Cai, D.-J.; Shi, H.-X.; Zhang, K.-W.; Liu, H.-Q.; Li, J.; et al. Lateral bearing characteristics of subsea wellhead assembly in the hydrate trial production engineering. China Geol. 2023, 6, 455–465. [Google Scholar]

- Sloan Jr, E.D.; Koh, C.A. Clathrate Hydrates of Natural Gases, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Intergovernmental Panel on Climate Change. Climate Change 2021—The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2023. [Google Scholar]

- Shakhova, N.; Semiletov, I.; Leifer, I.; Sergienko, V.; Salyuk, A.; Kosmach, D.; Chernykh, D.; Stubbs, C.; Nicolsky, D.; Tumskoy, V.; et al. Ebullition and storm-induced methane release from the East Siberian Arctic Shelf. Nat. Geosci. 2014, 1, 64–70. [Google Scholar] [CrossRef]

- Ruppel, C.D.; Kessler, J.D. The interaction of climate change and methane hydrates. Rev. Geophys. 2016, 55, 126–168. [Google Scholar] [CrossRef]

- Xu, W.; Germanovich, L.N. Excess pore pressure resulting from methane hydrate dissociation in marine sediments. J. Geophys. research. Solid Earth JGR 2006, 111, B1. [Google Scholar] [CrossRef]

- Kvenvolden, K.A. Gas hydrates—Geological perspective and global change. Rev. Geophys. 1993, 31, 173–187. [Google Scholar] [CrossRef]

- Boetius, A.; Wenzh, F.F. Seafloor oxygen consumption fuelled by methane from cold seeps. Nat. Geosci. 2013, 6, 725–734. [Google Scholar] [CrossRef]

- Biastoch, A.; Treude, T.; Rüpke, L.H. Rising Arctic Ocean temperatures cause gas hydrate destabilization and ocean acidification. Geophys. Res. Lett. 2011, 38, L08602. [Google Scholar] [CrossRef]

- OSPAR Convention. Convention for the Protection of the Marine Environment of the North-East Atlantic. 1998. Available online: https://www.ospar.org/convention/text (accessed on 25 March 1998).

- Cohen, J.H.; Kleppe, J.; Grønås, T.; Martin, T.B.; Tveit, T.; Gusler, W.; Christian, C.F.; Golden, S. Gulf of Mexico’s First Application of Riserless Mud Recovery for Top-Hole Drilling—A Case Study. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 2010. [Google Scholar] [CrossRef]

- Michael, V.R. Advances in riserless drilling pushing the deepwater surface string envelope. Offshore: Inc. Oilman 2001, 61, 56–58. [Google Scholar]

- Eggemeyer, J.C.; Akins, M.E.; Brainard, R.R.; Judge, R.A.; Peterman, C.P.; Scavone, L.J.; Thethi, K.S. SubSea MudLift Drilling: Design and Implementation of a Dual Gradient Drilling System. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LO, USA, 30 September–3 October 2001. [Google Scholar] [CrossRef]

- Schumacher, J.P.; Dowell, J.D.; Ribbeck, L.R.; Eggemeyer, J.C. Subsea Mudlift Drilling: Planning and Preparation for the First Subsea Field Test of a Full-Scale Dual Gradient Drilling System at Green Canyon 136, Gulf of Mexico. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LO, USA, 30 September–3 October 2001. [Google Scholar] [CrossRef]

- Roller, P.R. Riserless Drilling Technique Saves Time and Money by Reducing Logistics and Maximizing Borehole Stability. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 19–21 February 2003. [Google Scholar] [CrossRef]

- Schubert, J.J.; Juvkam-Wold, H.C.; Choe, J. Well Control Procedures for Dual Gradient Drilling as Compared to Conventional Riser Drilling. SPE Drill. Complet. 2003, 21, 287–295. [Google Scholar] [CrossRef]

- Stave, R.; Fossli, B.; Endresen, C.; Rezk, R.H.; Tingvoll, G.I.; Thorkildsen, M. Exploration Drilling with Riserless Dual Gradient Technology in Arctic Waters. In Proceedings of the OTC Arctic Technology Conference, Houston, TX, USA, 10–12 February 2014. [Google Scholar] [CrossRef]

- Stave, R.; Farestveit, R.; Hyland, S.; Rochmann, P.; Rolland, N. Demonstration and Qualification Of A Riserless Dual Gradient System. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2005. [Google Scholar] [CrossRef]

- Alford, S.E.; Asko, A.; Campbell, M.; Aston, A.M.; Kvalvaag, E. Silicate-Based Fluid, Mud Recovery System Combine to Stabilize Surface Formations of Azeri Wells. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 23–25 February 2005. [Google Scholar] [CrossRef]

- Enhanced-Drilling, RMR® System—Drilling Technology for Top Holes|Enhanced Drilling. Available online: https://www.enhanced-drilling.com/rmr-solution (accessed on 11 March 2025).

- Frøyen, J.; Rommetveit, R.; Jaising, H.; Stave, R.; Rolland, N.L. Riserless Mud Recovery (RMR) System Evaluation for Top Hole Drilling with Shallow Gas. In Proceedings of the SPE Russian Oil and Gas Technical Conference and Exhibition, Moscow, Russia, 3–6 October 2006. [Google Scholar] [CrossRef]

- Vernon, R.; Buchan, S.; Halland, M. Riserless mud system solves North Sea drilling problem. Offshore Inc. Oilman 2006, 66. Available online: https://www.offshore-mag.com/business-briefs/equipment-engineering/article/16754250/riserless-mud-system-solves-north-sea-drilling-problem (accessed on 11 March 2025).

- Hannegan, D.; Stave, R. The time has come to develop riserless mud recovery technology’s deepwater capabilities. Drill. Contract. 2006, 62, 50–54. [Google Scholar]

- He, G.; Xu, B.; Chen, H.; Qin, R.; Li, C.; Yin, G. Study of the Relationships among the Reverse Torque, Vibration, and Input Parameters of Mud Pumps in Riserless Mud Recovery Drilling. Appl. Sci. 2023, 13, 11878. [Google Scholar] [CrossRef]

- Vernon, R.; Buchan, S.; Halland, M.; Hewson, J. Riser-Less Mud Recovery Solves Top-Hole Drilling Problems; Society of Petroleum Engineers: Houston TX, USA, 2008; SPE111422-MS. [Google Scholar]

- Roveri, F.E.; Filho, A.G.; Mello, V.C.; Marques, L.F. Crude Export Riser—1: Hybrid riser application provides deepwater crude export solution. Oil Gas J. 2008, 106, 58–65. [Google Scholar]

- Kang, Z.; Jia, L.; Sun, L. Design and analysis methodology of Single line offset riser buoyancy can. Shipbuild. China 2011, 52, 118–129. [Google Scholar]

- Kang, Z.; Sun, L.; Sha, Y. A review of hybrid tower riser. Ship Ocean Eng. 2011, 40, 174–179. [Google Scholar]

- Romagnoli, R.; Carpignano, A. Hybrid Riser Risk Analysis in Deepwater Production Contexts. In Proceedings of the Offshore Mediterranean Conference and Exhibition, Ravenna, Italy, 28–30 March 2001. OMC-2001-060. [Google Scholar]

- Petruska, D.J.; Zimmermann, C.A.; Krafft, K.M.; Thurmond, B.; Duggal, A. Riser System Selection and Design for a Deepwater FSO in the Gulf of Mexico. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2002. [Google Scholar] [CrossRef]

- Wang, B.; He, N.; Chen, G. Hybrid riser for deepwater oil & gas field development. China Offshore Platf. 2013, 28, 46–51. [Google Scholar]

- Gong, J.; Yang, Z.; Ma, L.; Wang, P. Severe Slugging in Air-Water Hybrid Riser System. Adv. Mech. Eng. 2014, 2014, 1–10. [Google Scholar] [CrossRef]

- des Déserts, L. Hybrid Riser for Deepwater Offshore Africa. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2000. [Google Scholar] [CrossRef]

- Denney, D. Solution for Improved Riser-Tower- Systems Installability and Operability in Deep Water West of Africa. J. Pet. Technol. Pet Technol 2005, 57, 66. [Google Scholar] [CrossRef]

- Alliot, V.; Legras, J.L. Lessons Learned From The Evolution And Development Of Multiple-Lines Hybrid Riser Towers for Deep Water Production Applications. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2005. [Google Scholar] [CrossRef]

- Denney, D. Tow Methods for Deepwater Riser-Tower Transportation in West-of-Africa Environment. J. Pet. Technol. 2007, 59, 76. [Google Scholar] [CrossRef]

- Saint-Marcoux, J.; Legras, J.; Wu, M. Minimum Production Riser System For Deepwater Application. In Proceedings of the Eighteenth International Offshore and Polar Engineering Conference, Vancouver, BC, Canada, 6–11 July 2008. ISOPE-I-08-071. [Google Scholar]

- Cassity, T.G.; O’Donnell, M.; Weigle, J.; Masson, C.; Kochi, K.; Porciuncula, S.L. Cascade and Chinook Subsea Development: A Challenging and Successful Case History. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2013. [Google Scholar] [CrossRef]

- Lim, F.; Natarajan, S. Hybrid Riser Towers—Not Just for Deepwater. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 20–23 March 2018. [Google Scholar]

- Arbey, J.P.; Delebecque, L.; Verdeil, J.; Szyszka, D.; Pionetti, F.R.; Mahoney, G.; Casola, F. Single Independent Riser (SIR) For Future Ultra Deep Water Field Developments. In Proceedings of the Offshore Mediterranean Conference and Exhibition, Kuala Lumpur, Malaysia, 20–23 March 2018. OTC-28455-MS. [Google Scholar]

- Lirola, F.; Revault, E.; Lunven, J. Single Independent Riser: A Cost Efficient Ultra-Deep Water Riser. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2019. OTC-29389-MS. [Google Scholar]

- Luppi, A.; Cousin, G.; O’Sullivan, R. Deepwater Hybrid Riser Systems. In Proceedings of the Offshore Technology Conference-Asia, Kuala Lumpur, Malaysia, 25–28 March 2014. OTC-24802-MS. [Google Scholar]

- Bomfimsilva, C.T.P.; Netto, T.A. On the feasibility of a novel concept for a free standing riser. Ocean. Eng. 2020, 214, 107731. [Google Scholar] [CrossRef]

- Dai, H.; Abdelkefi, A.; Wang, L. Modeling and nonlinear dynamics of fluid-conveying risers under hybrid excitations. Int. J. Eng. Sci. 2014, 81, 1–14. [Google Scholar] [CrossRef]

- Brouard, Y.; Seguin, B.; Germanetto, F.; Shah, V. Riser Solutions for Turret Moored FPSO in Arctic Conditions. In Proceedings of the Arctic Technology Conference, Newfoundland and Labrador, St. John’s, NL, Canada, 24–26 October 2016. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, F. Output feedback boundary control of a flexible marine riser system. J. Vib. Control: JVC 2018, 24, 3617–3630. [Google Scholar] [CrossRef]

- Zhen, X.W.; Han, Y.; Huang, Y.; Yao, J.-J.; Wu, J.-H. Analytical approach for the establishment of critical length criterion for the safe and economical design of the flexible jumper in deepwater applications. Appl. Ocean Res. 2018, 75, 193–200. [Google Scholar] [CrossRef]

- Hong, K.S.; Shah, U.H. Vortex-induced vibrations and control of marine risers: A review. Ocean Eng. 2018, 152, 300–315. [Google Scholar] [CrossRef]

- Tan, R.; Duan, M.; Wang, Z.; He, N.; Zhou, X.; Yong, Q. Numerical calculation model investigation on response for connector assembly of a free-standing hybrid riser with experimental validation. Ocean. Eng. 2018, 155, 144–155. [Google Scholar] [CrossRef]

- Gu, J.; Huang, J.; Xu, X.; Gao, L.; Chen, L.; Jia, J.; Levi, C. Parametric analysis for free standing riser by a new calculation procedure. Ocean Eng. 2021, 242, 110144. [Google Scholar] [CrossRef]

- Wang, J.; Xu, L.; Cao, J.; Sheng, L.; Li, C. Numerical and experimental investigation for extreme storm-safe drilling riser. Ships Offshore Struct. 2022, 17, 1462–1474. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, L.; Cao, Q.; Cheng, L.; Tang, G. Nonlinear motion regimes and phase dynamics of a free standing hybrid riser system subjected to ocean current and vessel motion. Ocean. Eng. 2022, 252, 111197. [Google Scholar] [CrossRef]

- Adegoke, A.; Fashanu, A.; Adewumi, O.; Oyediran, A. Modelling and nonlinear analysis of the wave-induced vibrations of a single hybrid riser conveying two-phase flow. Ocean. Eng. 2023, 278, 114305. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Butler, H.O.; Beddu, S.B.; Syamsir, A.; Ja’e, I.A.; Reda, A.; Ju, X. Parametric analysis on the global design of flexible riser under different environmental conditions using OrcaFlex. PLoS ONE 2024, 19, 310360. [Google Scholar] [CrossRef] [PubMed]

- Orcina, OrcaFlex User Manual. UK. Available online: https://www.orcina.com/webhelp/OrcaFlex/Default.htm (accessed on 11 March 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).