Research on the Method of Determining the Loosening Circle and Sealing Depth of High-Gas Coal Bed Roadway Based on Direct Current Method

Abstract

1. Introduction

2. Basic Principles of Electrical Testing

2.1. Principle of High-Density DC Method Testing

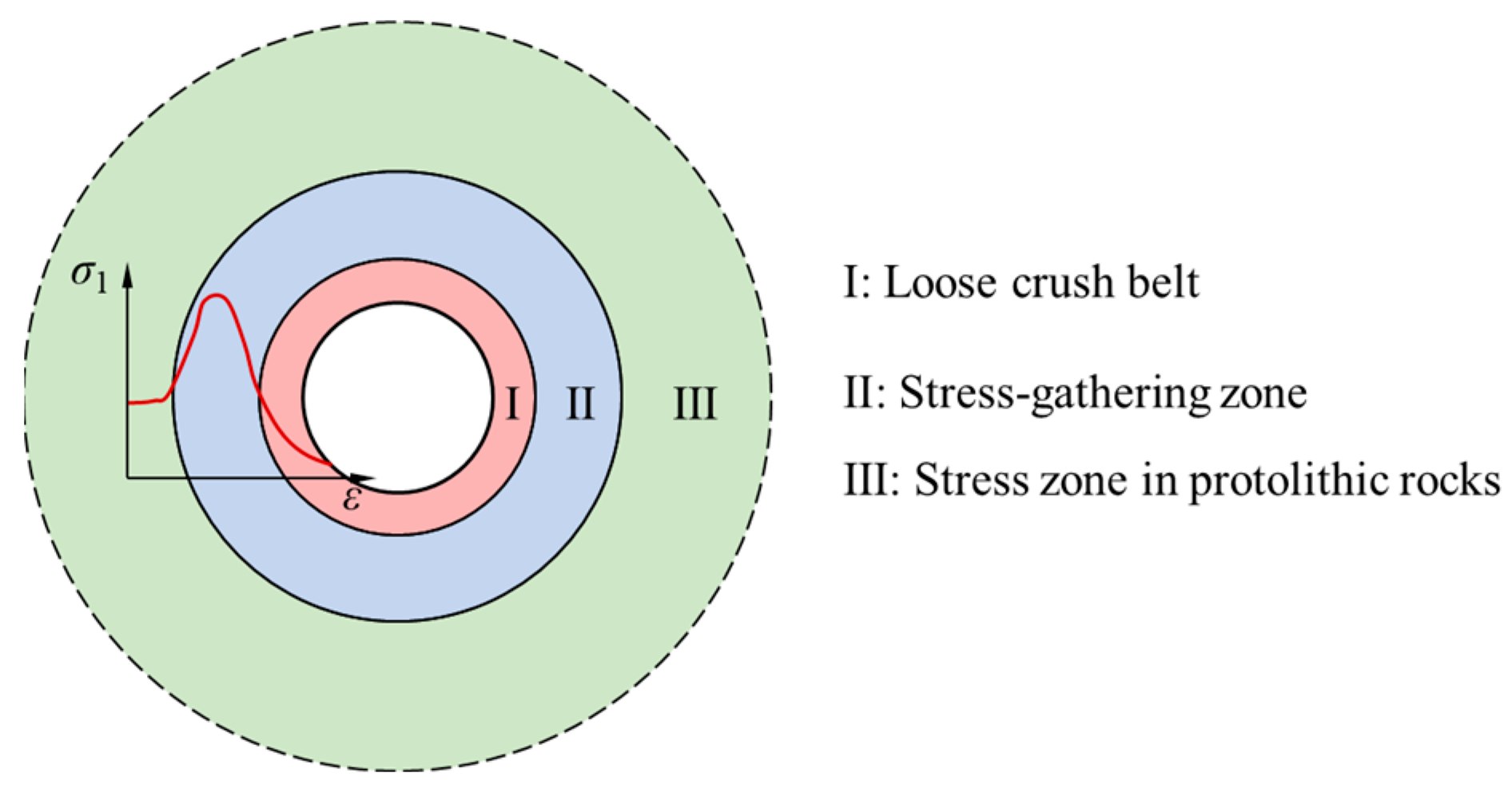

2.2. Change Rule of Resistivity After Disturbing Stress in the Roadway

3. Test Program Layout

3.1. Site Conditions

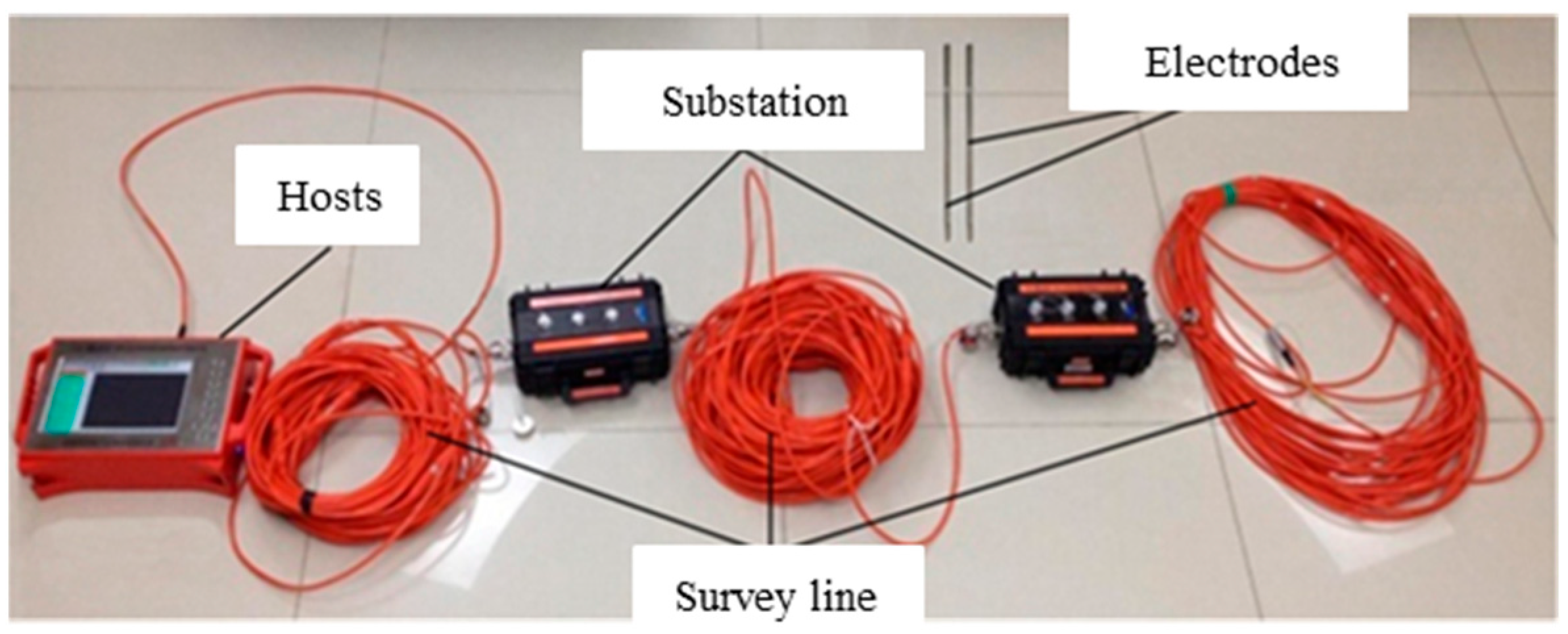

3.2. Test Program

4. Test Results

4.1. Site Monitoring

4.2. Detection of Small Faults in the Working Face

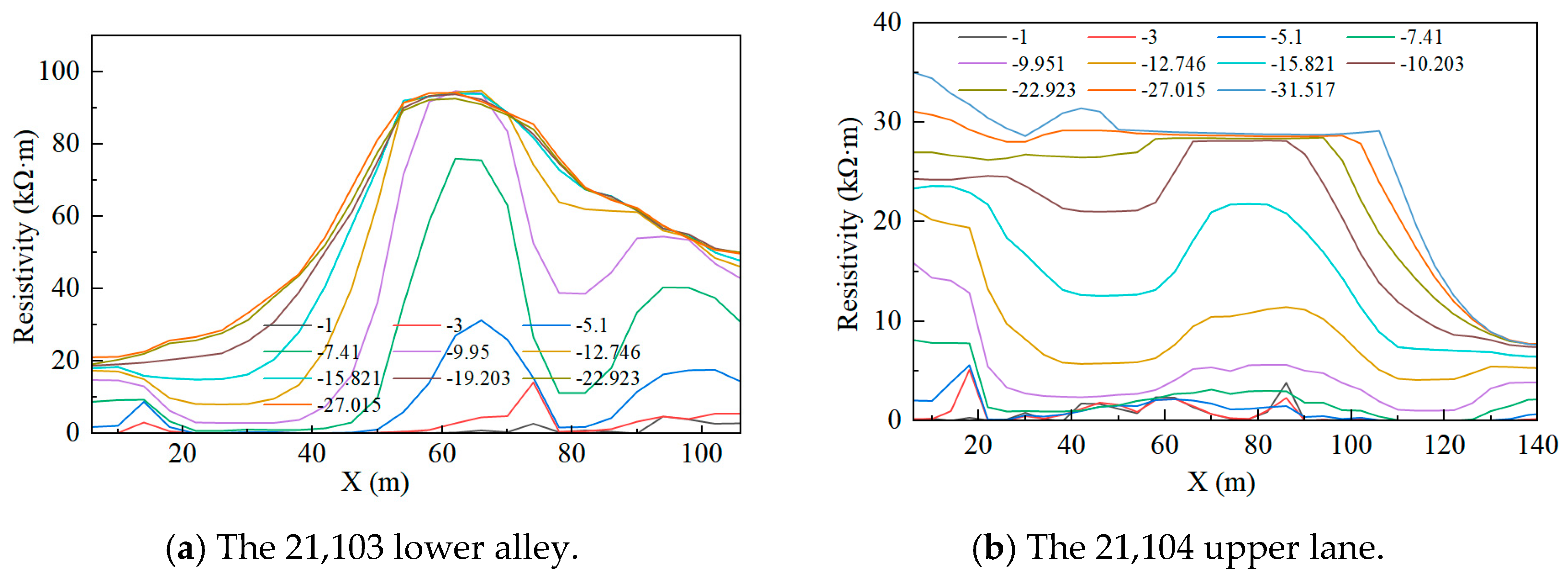

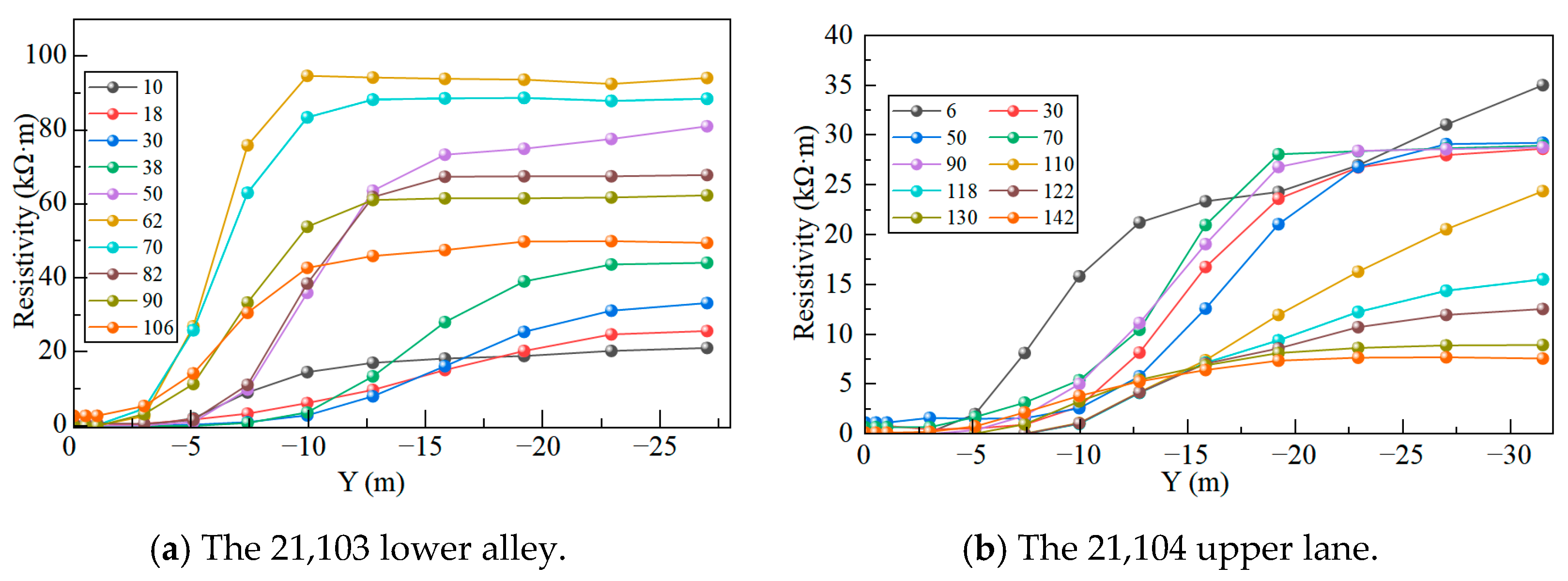

4.3. Characterization of Apparent Resistivity at Different Locations

5. Discussion

5.1. Comparison with Theoretical Calculations

5.2. Recommendations for Borehole Placement

6. Conclusions

- (1)

- The roadway was divided into a loose crushing zone, stress concentration zone, and original rock stress zone after the disturbing stress. When the degree of water enrichment was small, the resistivity of the loose crushing zone corresponded to the stage of plasticity and destruction of the coal body and the resistivity was larger compared with the original rock stress zone. The stress concentration zone corresponded to the compression stage of the coal and rock state, which was less destructive, and at this time, the resistivity was smaller compared with that of the original rock stress zone.

- (2)

- The DC method measured that the loose broken zone of the 2715 lower coal seam roadway was 6 m, and the stress concentration zone was 6–17.5 m. The loose whole circle of the 21,103 lower coal seam roadway was 8 m, and the stress concentration zone was 8–15 m. The loose whole circle of the 21,104 upper coal seam roadway was 9 m, and the stress concentration zone was 6–15 m. The resistivity of the loose broken zone varied greatly, which indicates that the damage pattern of the rocks around the roadway was random, while the stress concentration zone was basically consistent with the range of apparent resistivity. The lower resistivity of the loosely fractured zone compared with the original rock stress zone was due to the lower resistivity caused by the fractured coal–rock structure filled with water.

- (3)

- The DC method test results were consistent with the theoretical test results of the roadway loosening circle. Considering the redundant design of the mine’s current coal seam, a drilling sealing depth of 9 m was determined, which should be increased to more than 15 m after encountering faults.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, C.; Wang, E.; Wang, Y.; Zhou, X. Spatial-Temporal Distribution of Outburst Accidents from 2001 to 2020 in China and suggestions for prevention and control. Coal Geol. Explor. 2021, 49, 134–141. [Google Scholar]

- Xu, K.; Wang, B.; Zhu, J.; Zheng, L. Analysis on sealing depth of borehole in coal seam based on D - P criterion. J. Saf. Sci. Technol. 2017, 13, 111–117. [Google Scholar]

- Xu, L. Study on improving the sealing effect of CMM drainage boreholes and its application. China Coalbed Methane 2008, 5, 23–24. [Google Scholar]

- Han, Y.; Zhang, F.; Cheng, H. Research on main controlling factors of effective radius for gas extraction using hole drilled along seam based on grey relational analysis. J. Saf. Sci. Technol. 2015, 11, 44–49. [Google Scholar]

- Huang, Q.; Wang, X.; Chen, X.; Qin, D.; Zhang, J.; Cheng, H. Evolution of interior and exterior bearing structures of the deep-soft-rock roadway: From theory to field test in the Pingdingshan Mining area. Energies 2020, 13, 4357. [Google Scholar] [CrossRef]

- Jiang, B.; Zhang, Q.; He, Y.; Han, L. Elastoplastic analysis of cracked surrounding rocks in deep circular openings. Chin. J. Rock Mech. Eng. 2007, 26, 982–986. [Google Scholar]

- Wu, W.; Wang, Z. Numerical simulation study on grouting pressure and borehole sealing depth of borehole sealing. Coal Sci. Technol. 2015, 43, 68–72. [Google Scholar]

- Zhao, C.; Yang, X.; Zhang, C.; Li, Y.; Wang, E. Investigation on applicability of common failure criteria considering intermediate principal stress. Chin. J. Rock Mech. Eng. 2011, 30, 327–334. [Google Scholar]

- Qiu, L.; Shen, R.; Song, D.; Li, W. Non-destructive testing principles and accurate evaluation of the hydraulic measure impact range using the DC method. J. Geophys. Eng. 2017, 14, 1521–1534. [Google Scholar] [CrossRef]

- Wang, G.; Qin, Y.; Shen, J.; Liu, Z. Resistivity response to the porosity and permeability of low rank coal. Int. J. Min. Sci. Technol. 2016, 26, 339–344. [Google Scholar] [CrossRef]

- Chen, P.; Wang, E.; Chen, X.; Zhang, H. Regularity and mechanism of coal resistivity response with different conductive characteristics in complete stress -strain process. Int. J. Min. Sci. Technol. 2015, 25, 779–786. [Google Scholar] [CrossRef]

- Chen, G.; Lin, Y. Stress-strain-electrical resistance effects and associated state equations for uniaxial rock compression. Int. J. Rock Mech. Min. Sci. 2004, 41, 223–236. [Google Scholar] [CrossRef]

- Li, N.; Zhao, H.; Yan, M.; Liu, Z.; Chen, P.; Cai, C.; Lan, X.; Huang, B. Temporal and spatial distribution characteristics of hydraulic crack propagation under true triaxial loading using the direct current method. Int. J. Rock Mech. Min. Sci. 2023, 168. [Google Scholar] [CrossRef]

- Song, D.; Liu, Z.; Wang, E.; Qiu, L.; Gao, Q.; Xu, Z. Evaluation of coal seam hydraulic fracturing using the direct current method. Int. J. Rock Mech. Min. Sci. 2015, 78, 230–239. [Google Scholar] [CrossRef]

- Liu, Q.; Song, D.; Qiu, L.; Xiao, Y.; Yin, S.; Peng, Y.; Cao, Y.; Wang, H.; Gao, L. An experimental study of the resistivity response on fracture process of sandstone with pre-existing flaw. Theor. Appl. Fract. Mech. 2022, 121, 103487. [Google Scholar] [CrossRef]

- Chen, P.; Wang, E.; Zhu, Y. Experimental study on resistivity variation regularities of loading coal. J. China Coal Soc. 2013, 38, 548–553. [Google Scholar]

- Qiu, L.; Dang, J.; Zhang, J.; Wang, M.; Liu, Q.; Si, L.; Jiang, Z.; Khan, M. Investigating nonlinear resistivity characteristics and mechanisms of coal during various loading stages. J. Appl. Geophys. 2025, 238, 105705. [Google Scholar] [CrossRef]

- Guo, H.; Qiu, L.; Liu, Q.; Yang, C. Research on visualization detection method of overlying strata three zones in thin coal seam mining. Saf. Coal Mines 2023, 54, 73–80. [Google Scholar]

- Wu, R.; Zhang, W.; Zhang, P. Exploration of parallel electrical technology for the dynamic variation of caving zone strata in coal face. J. China Coal Soc. 2012, 37, 571–577. [Google Scholar]

- Liu, S.; Wu, R.; Zhang, P.; Sun, X.; Xu, Z. High-density resistivity method for observing the destruction of overlying rock strata in coal seams. Coal Sci. Technol. 2001, 29, 18–19. [Google Scholar]

- Zhang, P.; Liu, S.; Wu, R.; Wu, R.X. Dynamic detection of overburden deformation and failure in mining workface by 3D resistivity method. Chin. J. Rock Mech. Eng. 2009, 28, 1870–1875. [Google Scholar]

- Li, J.; Xie, H.; Sun, Z. Response characteristics of direct current method advanced exploration in mine with water rich structural geological anomaly. China Energy Environ. Prot. 2021, 43, 51–56. [Google Scholar]

- Gao, W.; Wang, L.; Zi, J.; Han, T.; Guo, Y.; Wang, N. Simulation and application research on the advanced detection by the dipole-dipole device of the DC method in the excavation roadway. Prog. Geophys. 2024, 39, 412–420. [Google Scholar]

- Zhang, Y. Study on the Application of Mine DC Electric In-Advance Detection in Coal Mine Goaf. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2015. [Google Scholar]

- Leucci, G.; Giorgi, D.L.; Scardozzi, G. Geophysical prospecting and remote sensing for the study of the San Rossore area in Pisa (Tuscany, Italy). J. Archaeol. Sci. 2014, 52, 256–276. [Google Scholar] [CrossRef]

- Zhou, K.; Yu, F.; Tan, Y.; Zhao, T.; Guo, W. In-situ investigation on fractured evolution law of surrounding rock in weakly cemented soft rock roadway. Energy Sources: Part A, Recovery, utilization, and environmental effects. 2021, 47, 1–13. [Google Scholar] [CrossRef]

- Li, G.; Ma, F.; Guo, J.; Zhao, H. Experimental research on deformation failure process of roadway tunnel in fractured rock mass induced by mining excavation. Environ. Earth Sci. 2022, 81, 243. [Google Scholar] [CrossRef]

- Wang, E.; Chen, P.; Li, Z.; Shen, R.-X.; Xu, J.-K.; Zhu, J.-F. Resistivity response in complete stress-strain process of loaded coal. J. China Coal Soc. 2014, 39, 2220–2225. [Google Scholar]

- Jolfaei, S.; Lakirouhani, A. Sensitivity Analysis of Effective Parameters in Borehole Failure, Using Neural Network. Adv. Civ. Eng. 2022, 1, 4958004. [Google Scholar] [CrossRef]

- Shen, B. Coal mine roadway stability in soft rock: A case study. Rock Mech. Rock Eng. 2014, 47, 2225–2238. [Google Scholar] [CrossRef]

- Liang, Z.; Tang, C.; Zhang, Y.; Ma, T. On probability model of physico-mechanical parameters of quasi-brittle materials and associated mechanical failure behaviors. Chin. J. Rock Mech. Eng. 2008, 27, 718–727. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Liu, Q.; Qiu, L.; Liu, H.; Li, Z.; Dang, J.; Wang, J. Research on the Method of Determining the Loosening Circle and Sealing Depth of High-Gas Coal Bed Roadway Based on Direct Current Method. Processes 2025, 13, 1743. https://doi.org/10.3390/pr13061743

Wang C, Liu Q, Qiu L, Liu H, Li Z, Dang J, Wang J. Research on the Method of Determining the Loosening Circle and Sealing Depth of High-Gas Coal Bed Roadway Based on Direct Current Method. Processes. 2025; 13(6):1743. https://doi.org/10.3390/pr13061743

Chicago/Turabian StyleWang, Chunguang, Qiang Liu, Liming Qiu, Hairui Liu, Zhenlei Li, Jintao Dang, and Jun Wang. 2025. "Research on the Method of Determining the Loosening Circle and Sealing Depth of High-Gas Coal Bed Roadway Based on Direct Current Method" Processes 13, no. 6: 1743. https://doi.org/10.3390/pr13061743

APA StyleWang, C., Liu, Q., Qiu, L., Liu, H., Li, Z., Dang, J., & Wang, J. (2025). Research on the Method of Determining the Loosening Circle and Sealing Depth of High-Gas Coal Bed Roadway Based on Direct Current Method. Processes, 13(6), 1743. https://doi.org/10.3390/pr13061743