Evaluating Waste Heat Potential for Fifth Generation District Heating and Cooling (5GDHC): Analysis Across 26 Building Types and Recovery Strategies

Abstract

1. Introduction

2. Materials and Methods

- Pc is energy consumption [kW];

- Er is the amount of heat removed converted into tons of coolant, since the temperature of chilled water is fixed.

- PCooling is the power demand of the cooling system;

- PElectrical are the distribution losses and auxiliary energy consumption;

- PIT is the energy demand for the Information and Communication Technology (ICT) processes.

3. Case Study

3.1. Example of Cold Storage

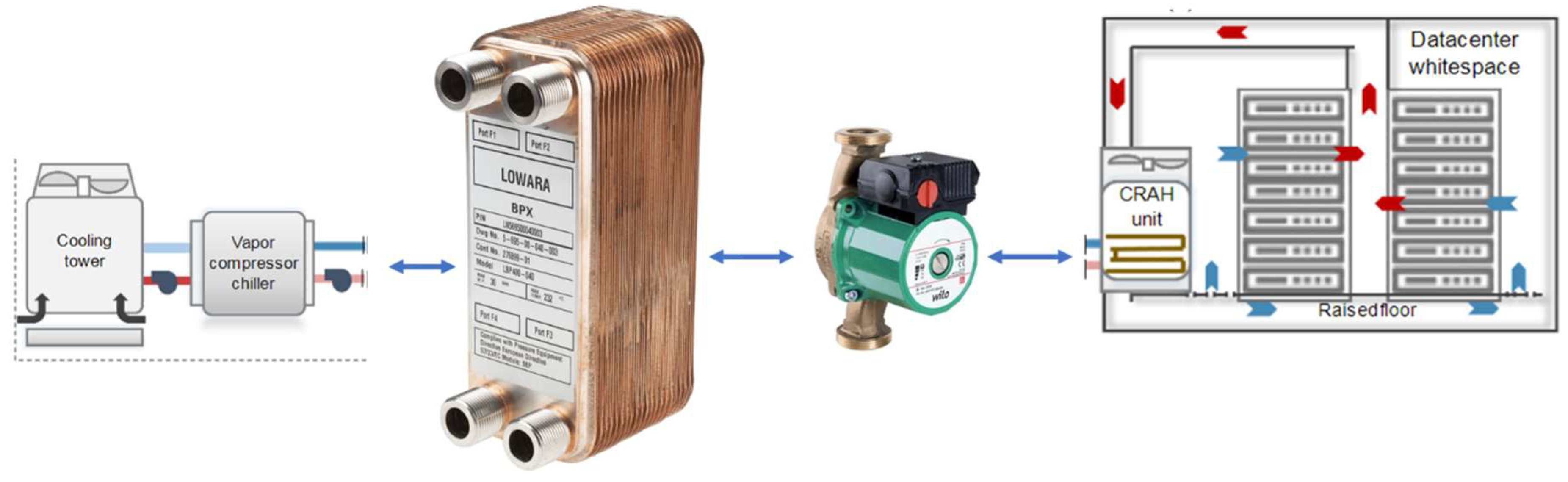

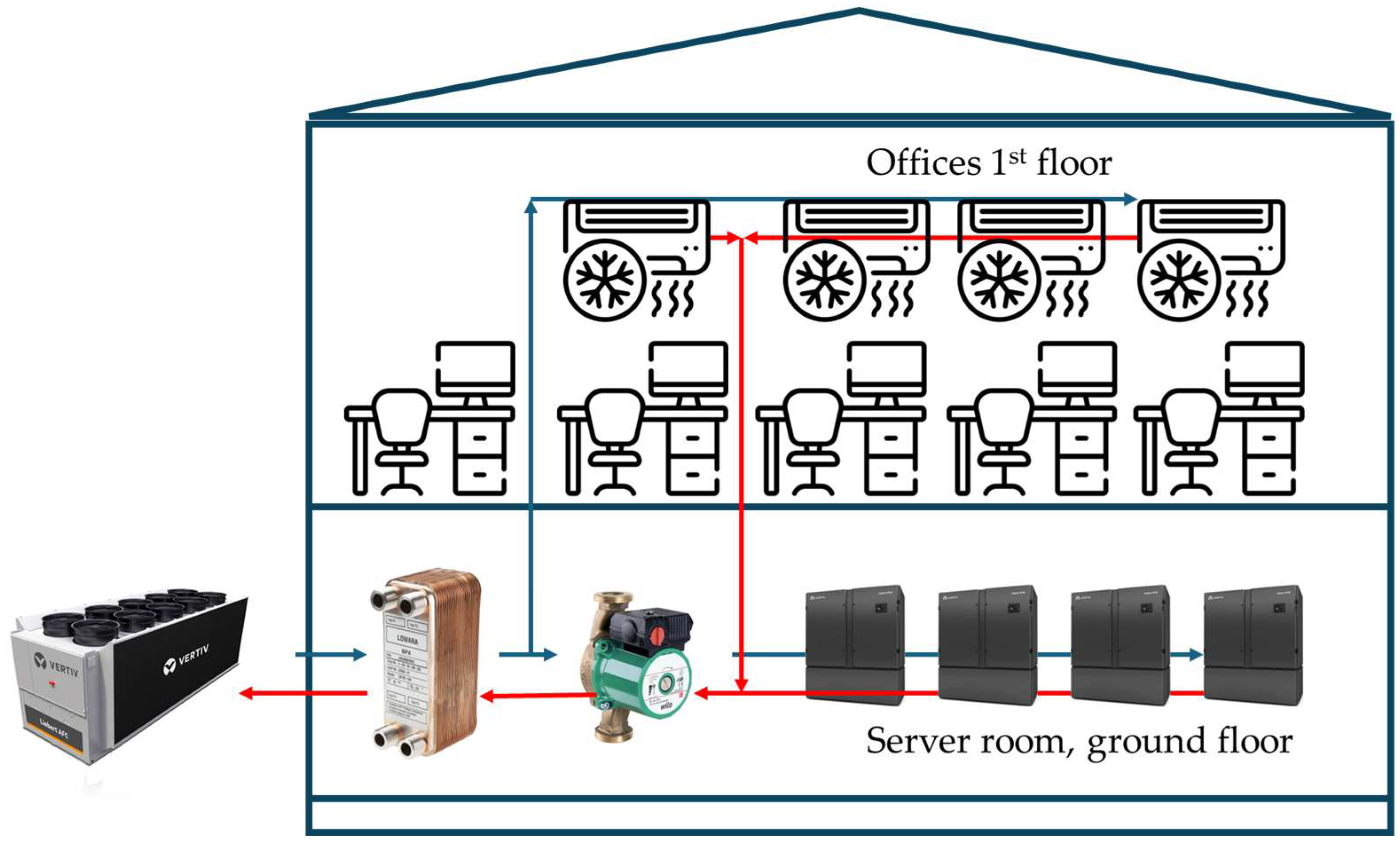

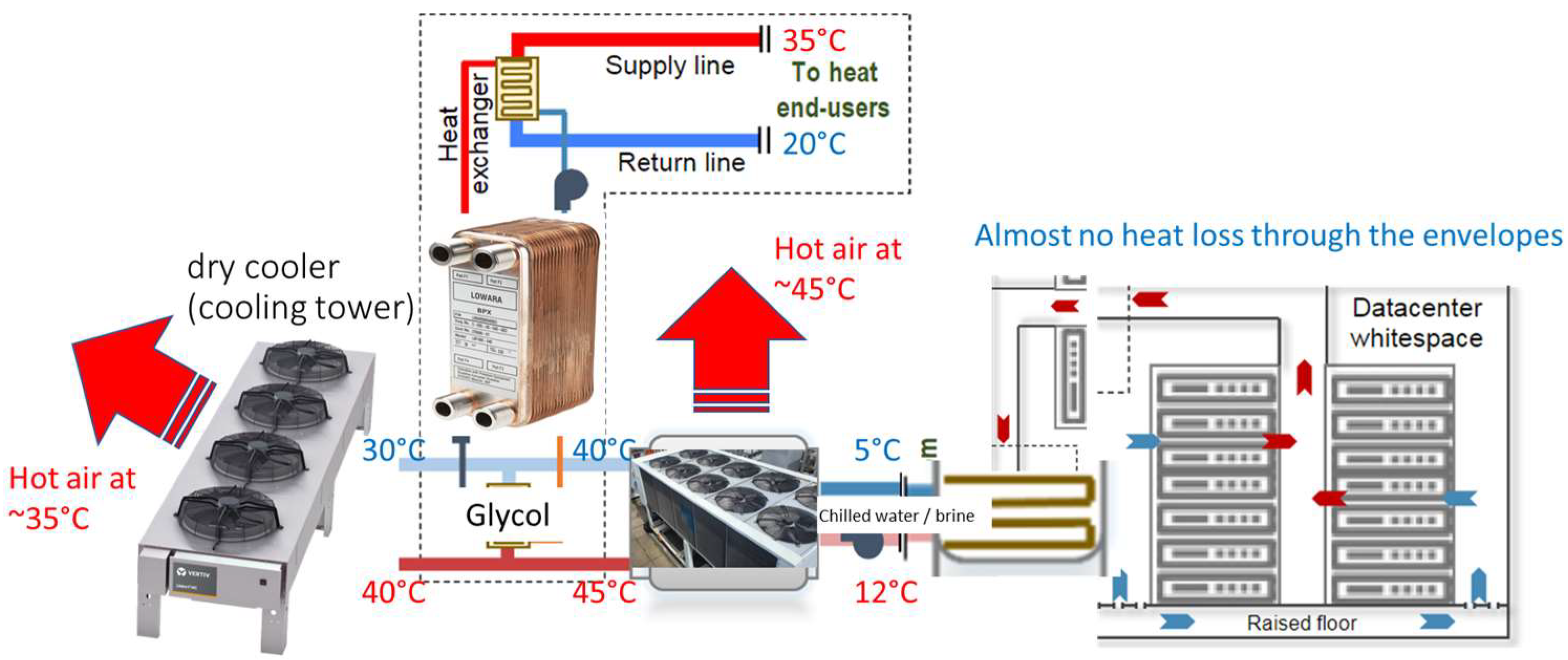

3.2. Example of a Data Center

3.3. Example of a Supermarket Building

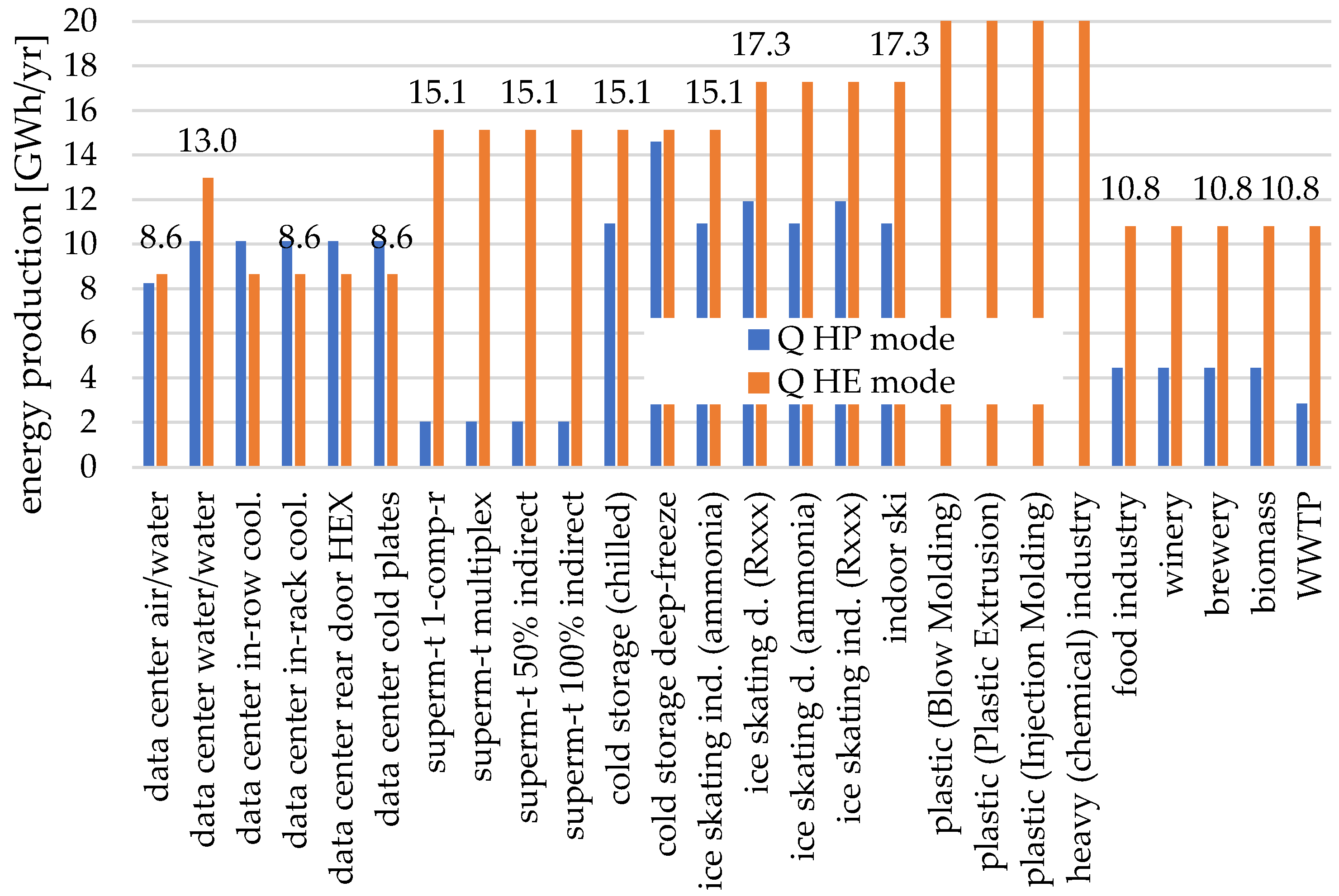

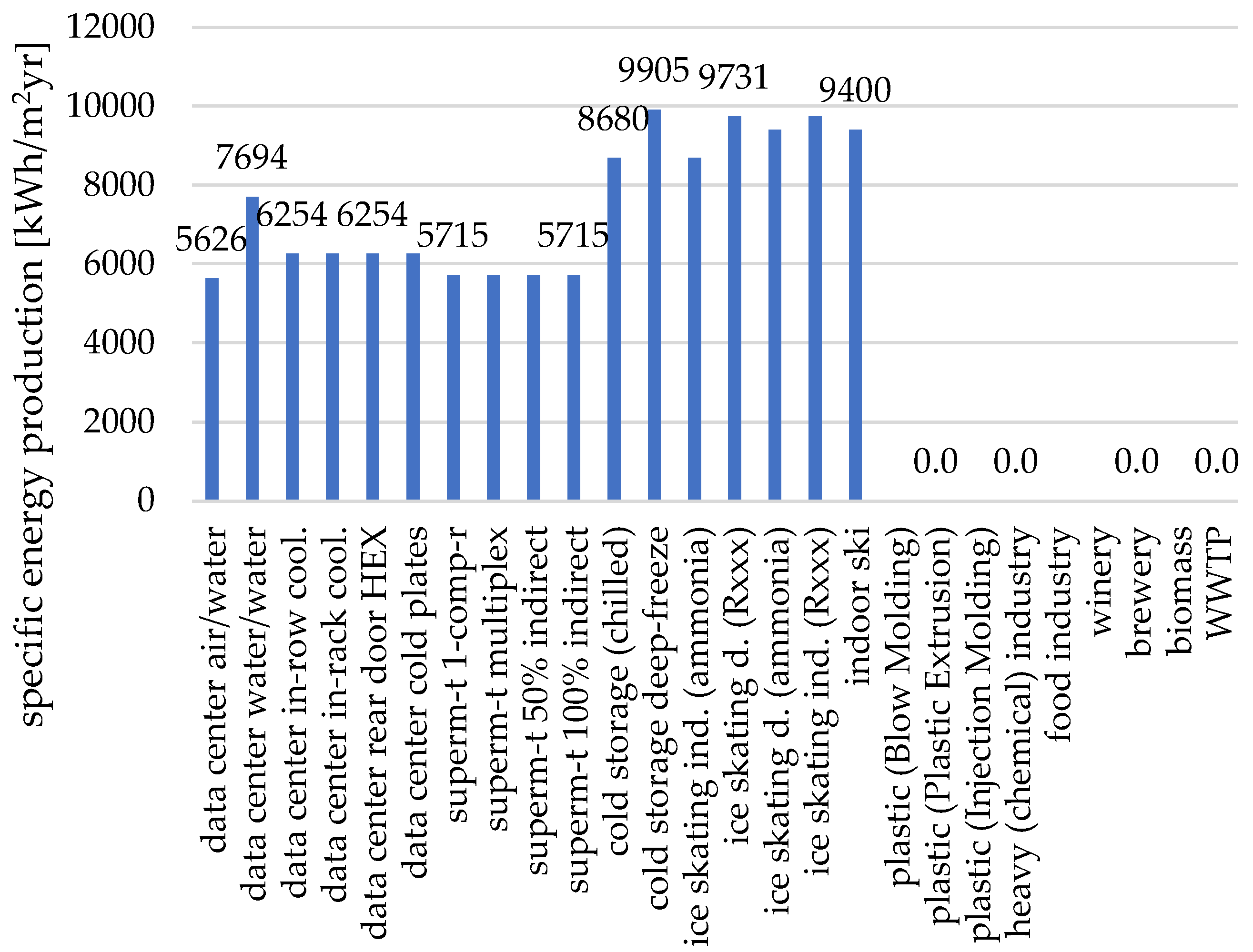

4. Results and Discussion

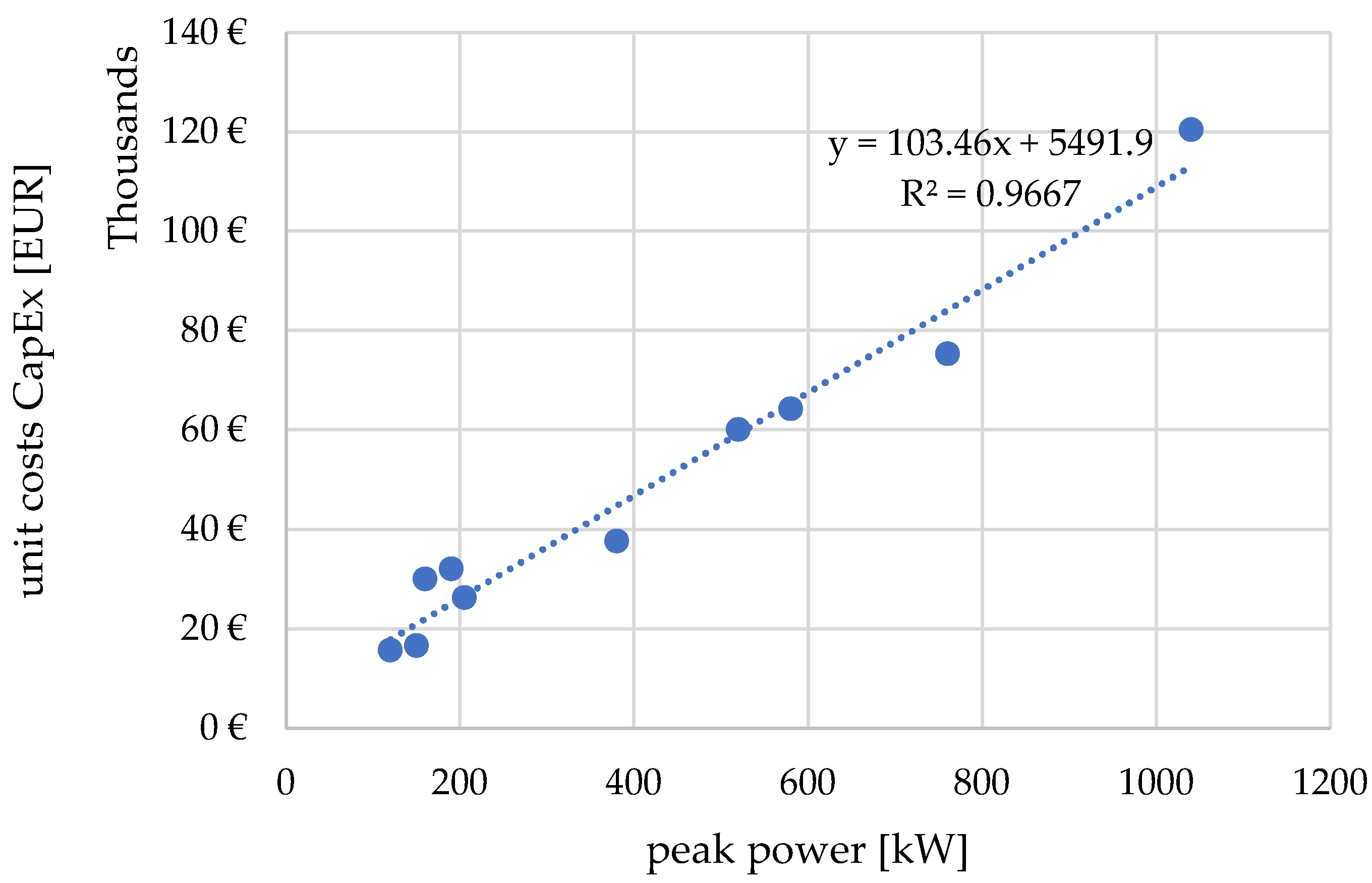

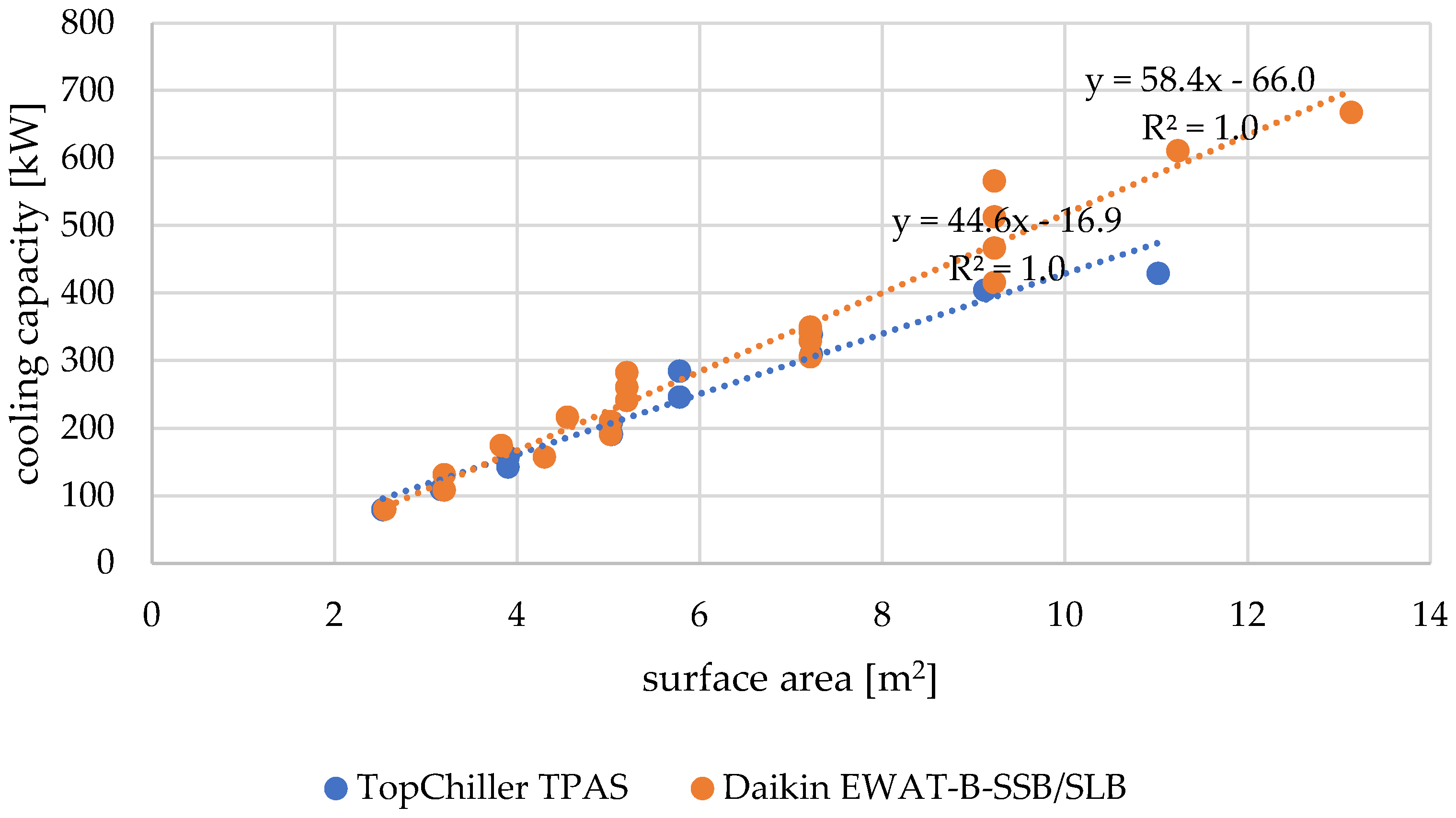

4.1. Example of a Data Center

4.2. Comparison

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbol/Abbreviation | Description |

| 5GDHC | Fifth-generation district heating and cooling |

| AHRI | Air-Conditioning, Heating, and Refrigeration Institute |

| CapEx | Capital expenditure |

| CaCl2 | Calcium chloride (used in desiccant systems) |

| COP | Coefficient of performance |

| CRAH | Computer room air handler |

| d. | Direct |

| ΔT | The temperature difference between the supply and return |

| HE | Heat exchanger |

| HP | Heat pump |

| ICT | Information and communication technology |

| in-row | Cooling configuration with units placed between server racks |

| in-rack | Cooling units integrated into racks |

| NPLV | Non-Standard Part Load Value |

| OpEx | Operational expenditure |

| PLR | Partial load ratio |

| Rxxx | Placeholder for specific refrigerants (e.g., R134a, R404a) |

| RH | Relative humidity |

| SCOP | Seasonal coefficient of performance |

| TES | Thermal energy storage |

| TR | Tons of refrigeration |

| w/w | Water-to-water configuration |

| WWTP | Wastewater treatment plant |

References

- Buffa, S.; Cozzini, M.; D’Antoni, M.; Baratieri, M.; Fedrizzi, R. 5th generation district heating and cooling systems: A review of existing cases in Europe. Renew. Sustain. Energy Rev. 2019, 104, 504–522. [Google Scholar] [CrossRef]

- Reiners, T.; Gross, M.; Altieri, L.; Wagner, H.J.; Bertsch, V. Heat pump efficiency in fifth generation ultra-low temperature district heating networks using a wastewater heat source. Energy 2021, 236, 121318. [Google Scholar] [CrossRef]

- Wirtz, M.; Heleno, M.; Moreira, A.; Schreiber, T.; Müller, D. 5th generation district heating and cooling network planning: A Dantzig–Wolfe decomposition approach. Energy Convers. Manag. 2023, 276, 116593. [Google Scholar] [CrossRef]

- Zhang, F.; Yin, Y.; Cao, B.; Wang, Y. Performance analysis of a novel dual-evaporation-temperature combined-effect absorption chiller for temperature and humidity independent control air-conditioning. Energy Convers. Manag. 2022, 273, 116417. [Google Scholar] [CrossRef]

- Ding, J.; Zhang, H.; Leng, D.; Xu, H.; Tian, C.; Zhai, Z. Experimental investigation and application analysis on an integrated system of free cooling and heat recovery for data centers. Int. J. Refrig. 2022, 136, 142–151. [Google Scholar] [CrossRef]

- Chicherin, S. Conversion to Fourth-Generation District Heating (4GDH): Heat Accumulation Within Building Envelopes. Energies 2025, 18, 2307. [Google Scholar] [CrossRef]

- Chicherin, S. Top-down GIS-driven method for configuring the network layout of a 5th generation district heating and cooling (5GDHC) system. Energy 2025, 328, 136639. [Google Scholar] [CrossRef]

- Hu, T.; Shen, Y.; Kwan, T.H.; Pei, G. Absorption chiller waste heat utilization to the desiccant dehumidifier system for enhanced cooling—Energy and exergy analysis. Energy 2022, 239, 121847. [Google Scholar] [CrossRef]

- Song, J.; Peng, J.; Cao, J.; Yin, R.; He, Y.; Zou, B.; Zhao, W. Global sensitivity analysis of fan coil air conditioning demand response—A case study of medium-sized office buildings. Appl. Therm. Eng. 2023, 230, 120721. [Google Scholar] [CrossRef]

- Keskin, I.; Soykan, G. Optimal cost management of the CCHP based data center with district heating and district cooling integration in the presence of different energy tariffs. Energy Convers. Manag. 2022, 254, 115211. [Google Scholar] [CrossRef]

- Hnayno, M.; Chehade, A.; Klaba, H.; Bauduin, H.; Polidori, G.; Maalouf, C. Performance analysis of new liquid cooling topology and its impact on data centres. Appl. Therm. Eng. 2022, 213, 118733. [Google Scholar] [CrossRef]

- Ljungdahl, V.; Jradi, M.; Veje, C. A decision support model for waste heat recovery systems design in Data Center and High-Performance Computing clusters utilizing liquid cooling and Phase Change Materials. Appl. Therm. Eng. 2022, 201, 117671. [Google Scholar] [CrossRef]

- Understanding Chiller Efficiency. Available online: https://www.linkedin.com/pulse/understanding-chiller-efficiency-omair-farooq (accessed on 20 April 2025).

- Afonicevs, V.; Strauts, U.; Bogdanovs, N.; Lesinskis, A. Evaporative cooling technology efficiency compared to traditional cooling system—Case study. In Proceedings of the 19th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, Msy 2020; Latvia University of Life Sciences and Technologies; Volume 19, pp. 877–883. [Google Scholar]

- Retail Energy Reduction Solutions | Hillphoenix AMS Group. Available online: https://www.hillphoenix.com/products/the-ams-group-products/energy-reduction-solutions/ (accessed on 20 April 2025).

- Energy Savings Tips for Small Businesses: Grocery and Convenience Stores | ENERGY STAR. Available online: https://www.energystar.gov/buildings/resources-audience/small-biz/grocery (accessed on 20 April 2025).

- Evans, J.A.; Hammond, E.; Gigiel, A.; Fostera, A.; Reinholdt, L.; Fikiin, K.; Zilio, C. Assessment of methods to reduce the energy consumption of food cold stores. Appl. Therm. Eng. 2014, 62, 697–705. [Google Scholar] [CrossRef]

- Ni, J.; Bai, X. A review of air conditioning energy performance in data centers. Renew. Sustain. Energy Rev. 2017, 67, 625–640. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Y.; Dai, S.; Nie, B.; Ma, H.; Li, J.; Miao, Q.; Jin, Y.; Tan, L.; Ding, Y. Cooling technologies for data centres and telecommunication base stations—A comprehensive review. J. Clean. Prod. 2022, 334, 130280. [Google Scholar] [CrossRef]

- Performance Rating of Water-Chilling and Heat Pump Water-Heating Packages Using the Vapor Compression Cycle. AN-SI/AHRI Standard 551/591 (SI) with Addendum 3, 2021. Available online: https://www.ahrinet.org/search-standards/ahri-550590-i-p-and-551591-si-performance-rating-water-chilling-and-heat-pump-water-heating-packages (accessed on 20 April 2025).

- Google. Zaventem. 2023. Available online: https://maps.google.com/ (accessed on 20 April 2025).

- Arias, J. Energy Usage in Supermarkets—Modelling and Field Measurements; Trita-REFR NV—2005:45; Energy Technology, School of Industrial Engineering and Management (ITM), KTH: Stockholm, Sweden, 2005. [Google Scholar]

- Bram, S. ThermischGrid Zellik. Confidential Report; Bram, S.: Brussels, Belgium, 2020; 79p. (In Dutch) [Google Scholar]

| Parameter | How It Is Measured | Equipment Used | Preliminary Evaluation | Uncertainty and Consistency |

|---|---|---|---|---|

| Internal Cooling Load (kW or TR) | Calculated via building energy simulation, sub-metering, or from equipment specs and operating hours | Energy meters (BTU meters)—Chiller logs/SCADA systems—Building Management Systems (BMS) | Assigned according to the category of waste heat source (Table 2, Category and Source columns), see the Cooling Capacity column | ±5–10% depending on measurement method. Metered data are more accurate than estimates. Inconsistent in older facilities without BMS |

| Total Floor Area/Volume (m2/m3) | Direct measurement from architectural drawings or on-site survey | CAD/BIM models—Laser scanners or manual tape measurement | Derived from GIS databases (e.g., OpenStreetMap and Google Maps) | ±1–2% for documented buildings. Reliable and consistent unless the documentation is outdated |

| Space Usage | Based on the facility function and occupancy profile. Documented in operational or zoning data | Site inspections—Facility zoning records—Occupancy schedules | Assigned according to the category of waste heat source (Table 2, Category and Source columns), see Space Usage column | Qualitative, but generally consistent. May vary slightly due to mixed-use areas |

| Envelope Performance | Estimated from construction documents or thermal imaging; assessed with U-values and infiltration rates | IR cameras—Blower door tests—Construction specs (R/U-values) | Assigned according to the category of waste heat source (Table 2, Category and Source columns), see Envelope Performance column | ±10–20% if undocumented. Consistency varies greatly, especially in retrofitted or poorly documented buildings |

| Cooling Equipment Type/Model | Taken from technical datasheets, on-site audits, or maintenance logs | Nameplates—Maintenance records—Equipment tags/photos | Assigned according to the category of waste heat source (Table 2, Category and Source columns) | ±0% if tagged correctly, but errors occur if undocumented or equipment has been modified |

| Flow Rates | Measured with flow meters in HVAC loops or inferred from pump curves | Ultrasonic/electromagnetic flow meters—Pressure sensors + pump specs | Assigned according to the category of waste heat source (Table 2, Category and Source columns) and total floor area/volume (Table 2) | ±2–10%, depending on calibration. Consistency depends on flow meter maintenance and placement |

| ΔT (Temperature Difference) | Directly measured between supply and return lines | Thermocouples/RTDs—BMS temperature sensors | Assigned according to the category of waste heat source (Table 3, Waste Heat Temp. column) and 5GDHC network temperatures | ±1–2 °C, more reliable in digital systems. Potential errors if sensors are miscalibrated or poorly located |

| Compressor and Refrigerant Types | From equipment specs, labels, or maintenance documentation | Equipment datasheets—On-site inspection | Assigned according to the category of waste heat source (Table 3, Equipment Specification column) | High confidence if the documentation is recent. Inconsistent in older or modified plants |

| Waste Heat Potential | Derived from cooling load + ΔT + run hours. Estimated or calculated | Engineering assessment tools—SCADA or BMS trend logs | Assigned according to the category of waste heat source (Table 3, Waste Heat Temp. column) | Uncertainty is high (±15–30%) if based on assumptions. Medium if monitored data are available |

| # | Category | Source | Cooling Capacity | Total Floor Area/Volume | Space Usage | Envelope Performance |

|---|---|---|---|---|---|---|

| N/A | N/A | N/A | kW/MW | m2/m3 | N/A | N/A |

| 1 | Data Center | Air/Water | 200–400 kW | 1000–3000 m2 | Data center (hot aisle) | Moderate (R-7 walls, R-4 roof) |

| 2 | Water/Water | 200–400 kW | 2000–5000 m2 | Data center | Good (raised floor, R-10 walls) | |

| 3 | In-row Cooling | 300–600 kW | 1000–2000 m2 | High-density racks | High-performance, R-10+ | |

| 4 | In-rack Cooling | 600–1200 kW | 800–1500 m2 | Blade racks | Very high, controlled environment | |

| 5 | Rear Door HE | 200–400 kW | 1000–3000 m2 | Server room | Good (pressurized room) | |

| 6 | Cold Plates | 300–800 kW | 600–1200 m2 | GPU/CPU racks | Very high | |

| 7 | Supermarket | 1-comp-r (single compressor) | 200–600 kW | 500–1500 m2 | Retail + cold aisles | Basic, single-glazed front |

| 8 | Multiplex | 1–10 MW | 1000–3000 m2 | Grocery retail | Basic-medium | |

| 9 | 50% indirect cooling | 500–1500 kW | 1200–2500 m2 | Supermarket | Medium | |

| 10 | 100% indirect | 80–200 kW | 1500–3000 m2 | Supermarket | Medium-good | |

| 11 | Cold Storage | Chilled | 200–400 kW | 800–1500 m3 | Logistics warehouse | High (insulated, R-30 walls) |

| 12 | Deep-freeze | 1–5 MW | 500–1000 m3 | Frozen storage | Very high (foam walls, <R-35) | |

| 13 | Ice Skating | Industrial (ammonia) | ~500–1000 kW equiv. | 1800–3000 m2 | Recreation/sports | Poor to moderate |

| 14 | Decentralized (Rxxx refrigerant) | 200–400 kW | 1200–2500 m2 | Sports rink | Variable | |

| 15 | Decentralized (ammonia) | 200–400 kW | 1000–2000 m2 | Sports/recreation | Variable | |

| 16 | Industrial (Rxxx refrigerant) | 300–600 kW | 1800–3000 m2 | Recreation | Medium | |

| 17 | Indoor Ski | - | 600–1200 kW | 10,000–20,000 m3 | Sports and leisure | Very high (enclosed, foam-insulated) |

| 18 | Plastic Industry | Blow Molding | 200–400 kW | 2000–5000 m2 | Industrial hall | Poor to medium |

| 19 | Plastic Extrusion | 300–800 kW | 3000–6000 m2 | Industrial hall | Poor to medium | |

| 20 | Injection Molding | 200–600 kW | 2000–5000 m2 | Industrial | Medium | |

| 21 | Heavy Industry | Chemical | 1–10 MW | 10,000–30,000 m2 | Industrial | N/A (process buildings) |

| 22 | Food Industry | - | 500–1500 kW | 3000–8000 m2 | Processing | Good (hygienic panels) |

| 23 | Winery | - | 80–200 kW | 1500–3000 m2 | Fermentation halls | Moderate (brick/concrete) |

| 24 | Brewery | - | 200–400 kW | 2000–4000 m2 | Brew hall + cold storage | Moderate |

| 25 | Biomass | Boiler Plant | 1–5 MW | N/A | Thermal plant | N/A |

| 26 | WWTP (Wastewater) | Effluent | ~500–1000 kW | Variable | Utility/process | Moderate |

| # | Category | Source | Waste Heat Temp. | Cooling Type | Equipment Specification | Conclusion |

|---|---|---|---|---|---|---|

| N/A | N/A | °C | N/A | N/A | N/A | |

| 1 | Data Center | Air/Water | 28–35 | CRAH + chiller | CRAH + air-cooled chiller, ~60–80 L/s, ΔT ≈ 7 °C, Scroll/Rotary, R410A | Moderate temp., medium-grade heat |

| 2 | Water/Water | 30–40 | Rear door HE | Rear-door HE + chilled water loop, ~100 L/s, ΔT ≈ 10 °C, Screw, R134a | Higher-grade heat; ideal for 5GDHC | |

| 3 | In-row Cooling | 25–30 | Localized air cooling | In-row DX or glycol-cooled units, ΔT ≈ 6 °C, Scroll/Rotary, R410A | Short loop, fast cycling | |

| 4 | In-rack Cooling | 30–38 | Liquid cooling | Direct liquid (cold plate), ~15–25 L/s, ΔT ≈ 8 °C, Micro-compressor, R1234yf | Higher temp; compact HE potential | |

| 5 | Rear Door HE | 32–45 | Water loop | Water loop, rear door HE, ~60–80 L/s, ΔT ≈ 10 °C, Scroll/Screw, R513A | High-grade recovery; scalable | |

| 6 | Cold Plates | 40–50 | Direct-to-chip | Cold plate + liquid loop, low flow high ΔT, Pump-driven, R1233zd | Highest quality niche adoption | |

| 7 | Supermarket | 1-comp-r (single compressor) | 20–28 | Air cooled | R404A DX units, ~40 L/s, ΔT ≈ 6 °C, Reciprocating, R404A | Low-temp recovery, limited use |

| 8 | Multiplex | 25–35 | Centralized rack | Central rack with remote condensers, ~80 L/s, R407F or R448A | Better recovery potential | |

| 9 | 50% indirect cooling | 28–34 | Glycol loop | Glycol loop, centralized rack, ΔT ≈ 6–8 °C, Scroll, R448A | Compatible with 5GDHC | |

| 10 | 100% indirect | 30–36 | Fully decoupled | Full secondary loop, ΔT ≈ 8 °C, Semi-hermetic, R744 (CO2) | Efficient for HE integration | |

| 11 | Cold Storage | Chilled | 15–25 | DX system | R717 (ammonia) or CO2, Recip/Screw, ~60 L/s, ΔT ≈ 5 °C | Low-grade; depends on usage |

| 12 | Deep-freeze | 5–15 | NH3 or CO2 | Screw compressor, cascade system, R744 or R717 | Very low-grade; not ideal | |

| 13 | Ice Skating | Industrial (ammonia) | 20–28 | Ammonia loop | Flooded NH3 system, ΔT ≈ 4–5 °C, Open-screw | Low-grade, but steady |

| 14 | Decentralized (Rxxx refrigerant) | 22–30 | DX split systems | DX system, Scroll/Semi-hermetic, R407C | Common in older rinks | |

| 15 | Decentralized (ammonia) | 20–28 | NH3 | Reciprocating NH3 units, ΔT ≈ 5 °C | Similar performance | |

| 16 | Industrial (Rxxx refrigerant) | 20–28 | Packaged chillers | Chiller plant + secondary glycol, R448A or R404A | Often retrofitted | |

| 17 | Indoor Ski | - | 10–20 | Mixed ammonia/CO2 | NH3/CO2 cascade, ΔT ≈ 4 °C, Twin-screw, flooded | Very low-grade, hard to reuse |

| 18 | Plastic Industry | Blow Molding | 35–60 | Process cooling | Chiller + tower loop, ΔT ≈ 6–10 °C, Scroll/Screw, R407C | Good match for heat pumps |

| 19 | Plastic Extrusion | 40–70 | Closed-loop glycol | Glycol loop, ΔT ≈ 8–10 °C, Screw, R134a | High-grade waste heat | |

| 20 | Injection Molding | 30–55 | Mixed circuits | Process chiller + loop, ΔT ≈ 6 °C, Scroll/Recip, R410A | Compatible with heat pump recovery | |

| 21 | Heavy Industry | Chemical Sector | 60–100 °C | Heat exchangers | Steam exchangers, Shell and Tube HE, Open-screw, R717/R245fa | Industrial-grade recovery |

| 22 | Food Industry | - | 35–60 °C | Steam or hot water | Process chillers + glycol loops, ΔT ≈ 8 °C, Scroll/Screw | Often uses internal recovery |

| 23 | Winery | - | 30–45 °C | Chillers | Chiller + fan coils, R410A, ΔT ≈ 5–7 °C | Seasonal operation limits use |

| 24 | Brewery | - | 45–65 °C | Steam/CO2 | Chiller plant + jacket cooling, ΔT ≈ 6 °C, R404A | Good integration potential |

| 25 | Biomass Plant | - | 60–90 °C | Steam/water loop | Steam turbines + ORC, ΔT ≈ 15–25 °C, Water/Steam, R245fa | Excellent recovery profile |

| 26 | WWTP (Wastewater) | - | 20–30 °C | Heat exchangers | Sludge digestion + effluent heat exchanger, ΔT ≈ 5 °C | Needs heat pump boost |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chicherin, S. Evaluating Waste Heat Potential for Fifth Generation District Heating and Cooling (5GDHC): Analysis Across 26 Building Types and Recovery Strategies. Processes 2025, 13, 1730. https://doi.org/10.3390/pr13061730

Chicherin S. Evaluating Waste Heat Potential for Fifth Generation District Heating and Cooling (5GDHC): Analysis Across 26 Building Types and Recovery Strategies. Processes. 2025; 13(6):1730. https://doi.org/10.3390/pr13061730

Chicago/Turabian StyleChicherin, Stanislav. 2025. "Evaluating Waste Heat Potential for Fifth Generation District Heating and Cooling (5GDHC): Analysis Across 26 Building Types and Recovery Strategies" Processes 13, no. 6: 1730. https://doi.org/10.3390/pr13061730

APA StyleChicherin, S. (2025). Evaluating Waste Heat Potential for Fifth Generation District Heating and Cooling (5GDHC): Analysis Across 26 Building Types and Recovery Strategies. Processes, 13(6), 1730. https://doi.org/10.3390/pr13061730