1. Introduction

Tungsten (W) is widely used as a PFM in future fusion reactors due to its extremely high melting point (about 3422 °C), excellent thermal conductivity, low sputtering rate, and good radiation resistance [

1,

2,

3]. During the operation of fusion reactors, PFMs need to withstand extreme heat and particle loads, including transient pulses and long-term cumulative effects of helium plasma. These complex load environments may cause structural changes on the surface of the material, bubble aggregation, crack propagation, and degradation of mechanical properties, posing a potential threat to the service life of the material and the safe operation of the reactor [

4,

5,

6]. Therefore, in-depth research on the effects of pulse loads and cumulative effects of helium plasma on tungsten materials has important scientific significance and engineering value.

In recent years, researchers have been committed to exploring the effects of pulse loads or helium plasma on tungsten materials alone. Sharma used high-energy pulsed plasma to simulate the extreme environment of a fusion reactor and studied the damage evolution process of tungsten under pulse loads. It was found that pulse loads with a high heat flux can cause drastic microstructural reconstruction on the surface of the material and induce crack formation and propagation [

7]. Vas et al. used high-energy-density pulsed argon plasma to conduct an in-depth study on the structural evolution of tungsten materials. The results showed that under high heat load conditions, nanoscale structures will form on the surface of the material, which may have an important impact on the subsequent deposition of helium plasma and the long-term stability of the material [

8]. In addition, Buzi et al. investigated the long-term cumulative effect of helium–hydrogen plasma on the tungsten surface under the experimental environment related to ITER. The study found that the cumulative effect of helium plasma can significantly change the micromorphology of the material and promote structural embrittlement in local areas, making the material more susceptible to damage [

9].

In response to the influence of helium plasma cumulative load, Seyyedhabashy et al. used a plasma-focusing device to investigate the damage evolution process of tungsten under helium ion irradiation. The study showed that with the increase of helium ion implantation dose, nanoscale bubbles will form on the surface of the material, which will further aggregate and develop into holes, resulting in reduced strength and increased brittleness of the material [

10]. Das studied the aggregation behavior of helium bubbles and their influence on the structure of tungsten materials and pointed out that when helium bubbles reach a certain size, they may induce local stress concentration, leading to brittle fracture on the surface of the material, seriously affecting its application stability in fusion reactors [

11].

Although the above studies provide important experimental data for understanding the evolution mechanism of tungsten materials under single pulse load or single cumulative helium plasma, there are few studies on the synergistic effect of the two. Ouyang et al. pointed out that in the actual fusion-reactor-operating environment, tungsten materials need to withstand transient high heat loads and long-term helium plasma deposition at the same time, and the two may produce nonlinear interactions. For example, the formation of helium bubbles may affect the thermal conductivity of the material, making it more sensitive to subsequent pulse loads, while transient heat loads may aggravate the aggregation of helium bubbles, thereby accelerating the structural degradation of the material [

12]. Malykhin et al. further emphasized that a single pulse load may change the surface stress distribution of tungsten materials, thereby affecting the adsorption and diffusion behavior of helium plasma. This complex interaction requires more systematic experimental research and theoretical modeling to be deeply understood [

13]. Mykola Ialovega et al. studied helium-induced morphology evolution in tungsten under thermal treatment and found that thermal cycling leads to faceting of helium bubbles, surface smoothing, and partial defect recovery [

14]. T.W. Morgan et al. investigated the fatigue cracking behavior of ITER-like tungsten monoblocks under combined high-fluence plasma and ELM-like transient heat loads in Magnum-PSI and found that elevated surface temperatures and impurity seeding significantly reduce the cracking threshold and intensify surface roughening and damage [

15].

In addition, from the perspective of engineering application, the plasma load that tungsten materials bear in fusion reactors is not a single one but a combination of long-term accumulation and transient pulses. Therefore, only studying the single effect of pulse load or helium accumulation cannot accurately evaluate the evolution law and failure mechanism of the material under actual working conditions. In future fusion devices, such as ITER and DEMO reactors, the damage resistance of tungsten materials will directly affect the operating reliability of the device. Therefore, in-depth research on the synergistic effect of single pulse load and helium plasma accumulation, and exploring the interaction between the two under different parameter conditions, has important theoretical value and engineering guidance significance.

This study aims to systematically explore the effects of single pulse load and helium plasma accumulation on the damage evolution of tungsten materials, focusing on the formation and evolution of helium bubbles, crack propagation mechanism, changes in surface morphology, and the effect of cumulative load on mechanical properties. By comparing the evolution process of the material microstructure under different pulse energies and cumulative helium doses, experimental data support is provided for the optimal design of future fusion reactor PFMs, and optimization strategies are proposed to improve the damage resistance of materials.

2. Experimental Procedure

Ultra-high-purity tungsten blocks (W ≥ 99.999%, Xiamen Tungsten Co., Ltd., Xiamen, China) were selected as experimental materials, and according to the requirements of the experimental device for sample size, the tungsten blocks were precisely cut into standard samples of 10 mm × 10 mm × 1 mm. In order to ensure the surface quality of the samples, strict mechanical grinding and fine polishing were carried out before the experiment. First, metallographic sandpaper No. 240, 400, 800, 1200, and 2000 were used for step-by-step grinding to remove surface roughness and reduce processing damage. Subsequently, SiC-polishing agents with particle sizes of 0.25 μm and 0.5 μm were used to precisely polish the sample surface until it reached a mirror-level smooth state, ensuring that there were no visible scratches and defects on the surface. After mechanical grinding and polishing, the samples were placed in deionized water, anhydrous ethanol, and acetone for ultrasonic cleaning to thoroughly remove residual particles and impurities on the surface. After this series of treatments, clean, smooth, and pollution-free tungsten samples to be irradiated were obtained to ensure the accuracy and repeatability of the experimental data.

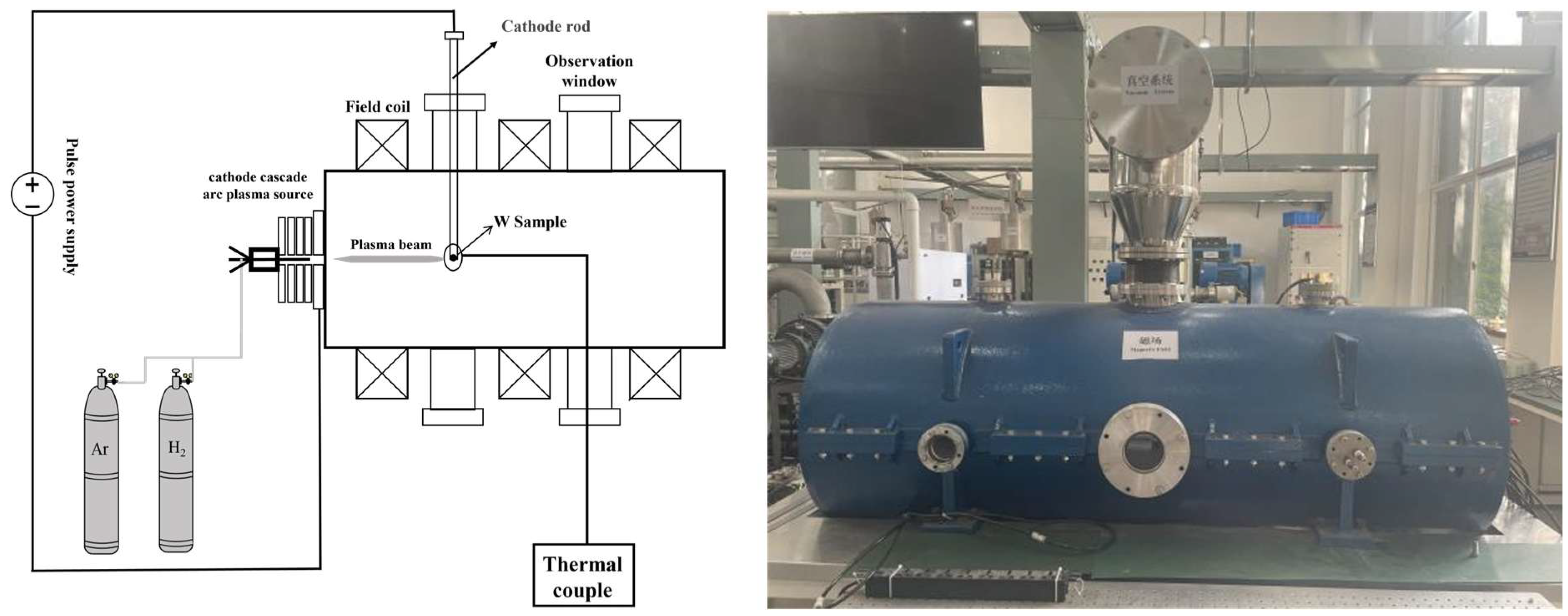

The pretreated samples were irradiated in a self-developed high-performance extreme environment linear plasma device, as shown in

Figure 1. The linear plasma device can produce high-flux steady-state He, Ar, and H plasma. The plasma parameter range is as follows: plasma flux: 10

19 m

−2 s

−1–10

23 m

−2 s

−1; electron temperature range: 0.5 eV~5 eV; irradiation area: 3 cm diameter at the target point.

The prepared sample was adhered to the sample fixture 40 cm downstream of the plasma beam by a conductive adhesive. Before the experiment, the pressure in the sample chamber was pumped to 6.0 × 10

−2 Pa to ensure that the plasma could operate stably. This experiment systematically studied the effects of helium plasma flux and pulse heat load on the experimental results through two sets of experimental designs. In the first set of experiments, the helium plasma flux was changed by adjusting the discharge current, magnetic field intensity and gas flow rate, while the pulse heat load was kept constant. Four different helium plasma flux conditions were set in the experiment. While keeping other experimental parameters unchanged, the influence of flux changes on the experimental phenomena was explored. In the second set of experiments, the helium plasma flux was kept constant, and the pulse heat load was changed by adjusting the discharge voltage. The heat load was mainly obtained by measuring the current and voltage at the power supply end through the Rogue coil and then calculating. Four different heat load conditions were set in this process. Before the experiment, we will use argon plasma for a short time to irradiate to remove surface impurities and oxides. Since the irradiation time of argon plasma is short and there is no additional energy input, its influence can be ignored. All experimental parameters except the discharge voltage remained unchanged to ensure the uniqueness of the experimental variables, so as to clarify the effect of the pulse heat load on the experimental system. This experimental design adopts the control variable method to ensure the comparability of the experimental conditions, so as to obtain a systematic understanding of the influence of helium plasma flux and pulse heat load on the experimental phenomena. The main parameters of thermal load and helium plasma exposure are shown in

Table 1.

A variety of characterization techniques were employed after the experiments. The surface morphology was analyzed using SEM (FEI Inspect F50, Thermo Fisher Scientific, Waltham, MA, USA) and optical profilometry (Superview WT, Chotest, Shenzhen, China), allowing for direct observation of sample morphology changes. In addition, optical profilometry was used to obtain the root mean square (RMS) roughness of the irradiated surface, providing an accurate quantification of the surface features. The changes in the crystal structure were meticulously analyzed by the XRD (Bruker D8 Advance, Bruker Corporation, Billerica, MA, USA) technique. In addition, the changes in surface hardness were measured using a Vickers hardness tester (HMV-G21, Shimadzu Corporation, Kyoto, Japan) to further evaluate the effect of temperature on the evolution of plasma surface material properties under synergistic irradiation.

3. Results and Discussion

3.1. Surface Morphology Analysis

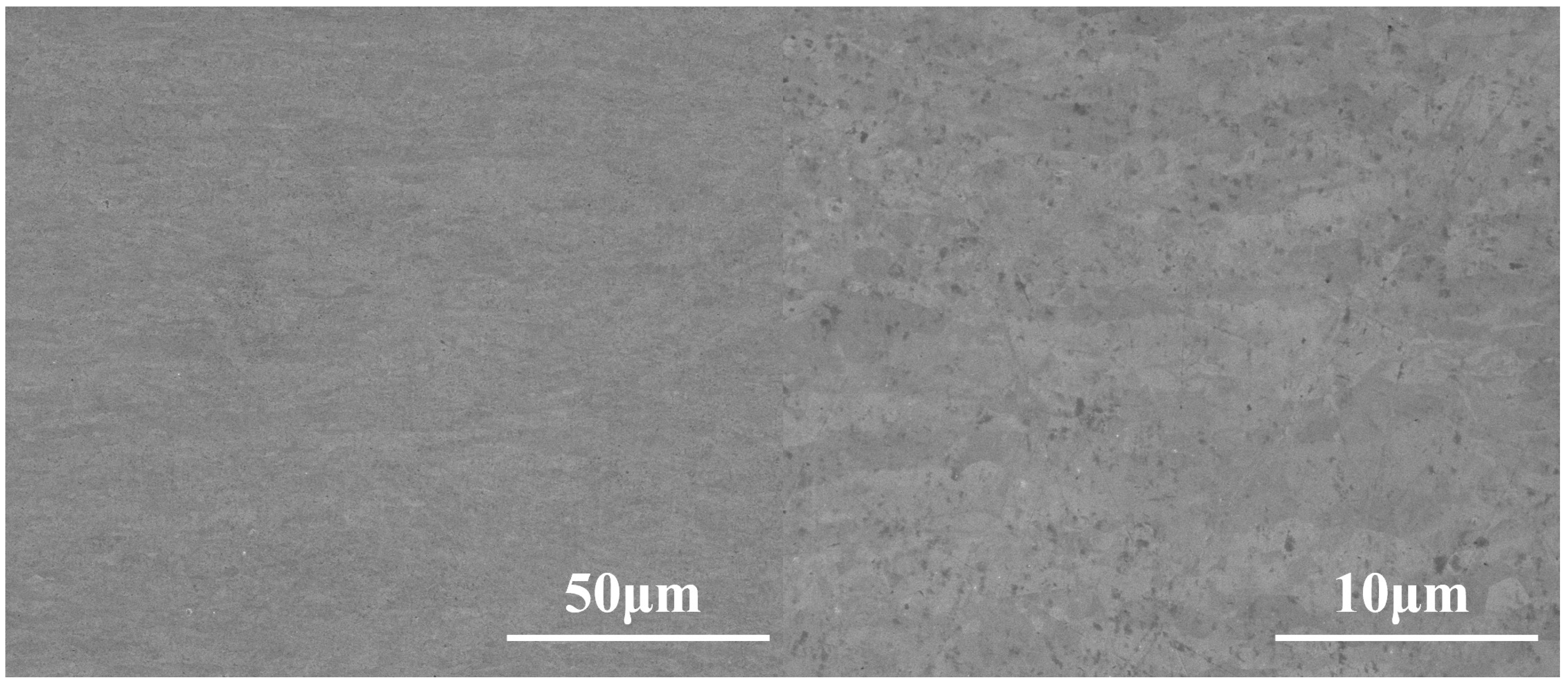

Figure 2 shows the SEM surface morphology of tungsten before the pulsed helium plasma heat load. As shown in

Figure 2, the initial tungsten sample surface is relatively smooth, but some scratches and small pits can still be seen. This is because tungsten is a high-hardness brittle material. During the polishing process, the mechanical action of the abrasive particles and the local stress concentration may cause micro-area material peeling.

3.1.1. Morphology Analysis Under Different Helium Plasma Flux Conditions

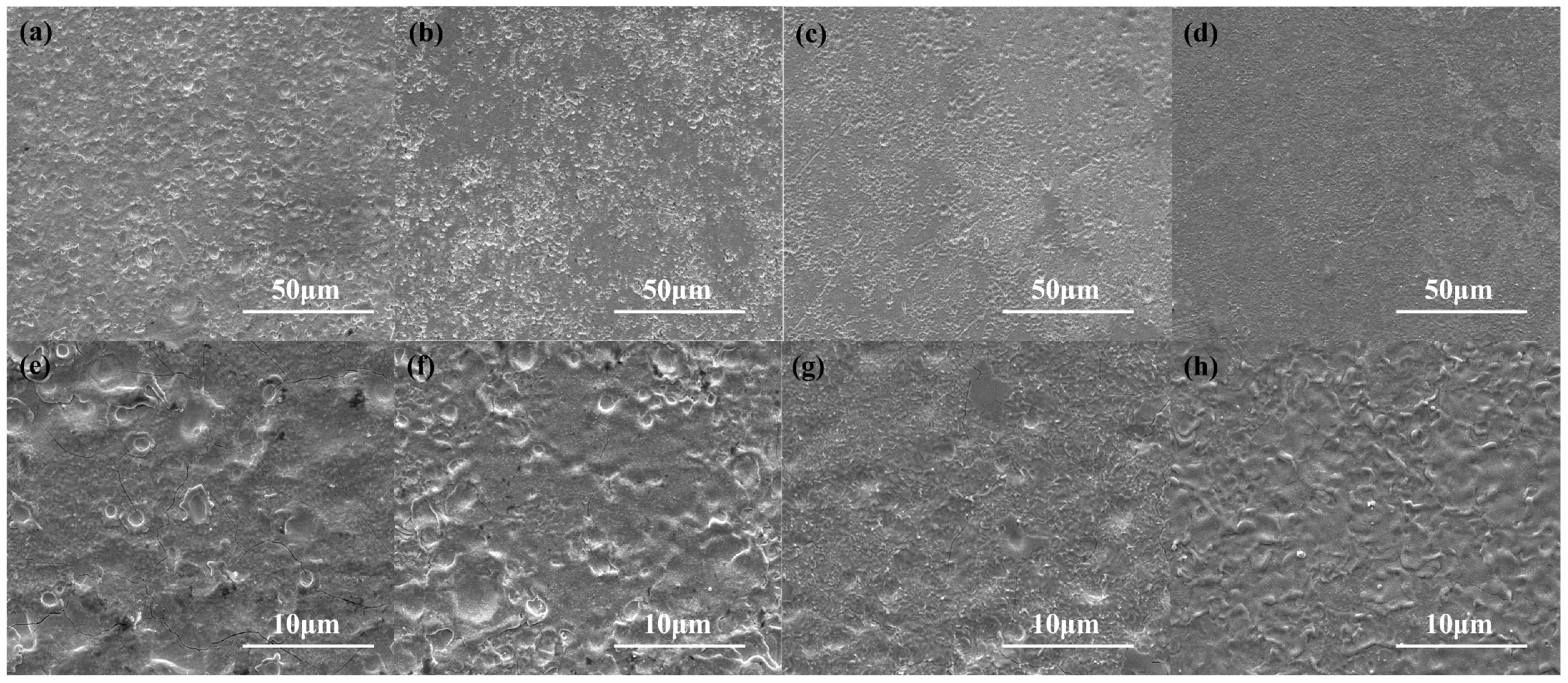

As shown in

Figure 3, the tungsten surface undergoes significant morphological changes under the combined effects of pulsed heat load and helium plasma flux, and the degree of damage gradually increases with the increase of helium flux. The experimental results show that these morphological features are an intuitive manifestation of the complex interaction mechanism of helium bubbles on the surface and near-surface areas of the material, including the formation, expansion, aggregation, rupture of bubbles, and the thermal stress release process induced by them [

16,

17,

18]. In addition, the instantaneous high-temperature effect of the pulsed heat load not only accelerates the evolution of helium bubbles but also enhances the release and accumulation of local stress, making the damage morphology more severe. The final damage manifestations range from slight surface roughening to cavitation, crack propagation, and then to severe degradation of the surface structure. These phenomena clearly reveal the profound impact of the strong synergistic effect of a single pulsed heat load and the helium bubble effect on the surface of tungsten materials, as shown in

Figure 4.

Under the lowest helium flux condition (7.76 × 10

22 ions m

−2 s

−1), as shown in

Figure 3a,e, the tungsten surface is only slightly roughened, with some small pits and shallow depressions sparsely distributed in local areas. Some typical features, such as pits, bubbles, and microcracks, appeared on the tungsten surface. This may be because after the helium ions were injected into the tungsten surface, they gathered on the surface [

9], which led to local expansion and the formation of microcracks. The transient high-temperature effect caused by the pulsed heat load accelerated the growth and rupture of the expanded area, causing local surface collapse to form pits. At the same time, the thermal stress induced by high temperature caused the microcracks to extend along the grain boundaries, making the cracks more obvious [

19]. At this stage, although the heat load and helium injection showed a synergistic effect, the overall damage characteristics were still dominated by bubble rupture and surface depression, and the morphological changes were relatively preliminary.

As the helium flux increases to 1.35 × 10

23 ions m

−2 s

−1 (

Figure 3b,f), the surface morphology changes further. It can be seen that the bubbling phenomenon is significantly reduced compared to the low-flux stage, but the number and distribution of pits are denser. This phenomenon does not mean that the effect of helium on surface damage is weakened. It may be that the higher flux of helium ions intensifies the helium aggregation inside the lattice, causing excessive aggregation of bubbles and accelerated collapse. Under the combined effect of the pulsed heat load, more surface areas directly form depressions, and it is difficult for bubbles to exist stably due to rupture or helium escape [

20]. This stage shows that the cumulative effect of the helium plasma flux has begun to dominate the formation of surface pit features, while the pulsed heat load continues to provide sufficient energy to drive surface reconstruction.

When the helium flux is further increased to 1.91 × 10

23 ions m

−2 s

−1 (

Figure 3d,g), the surface morphology begins to change from being dominated by pits to obvious pits and coral-like protrusions. These protrusions may be the initial stage of the formation of the “tungsten fuzz” structure during the helium plasma irradiation process, which manifests as some smaller needle-like protrusions and tiny holes. This phenomenon shows that the bombardment of helium plasma and the effect of heat load not only lead to the expansion of surface microcracks, but also begin to promote the formation of “fuzz” structure on the surface of tungsten materials. The changes in surface morphology at this stage not only reflect the cumulative effect of helium injection, but also reflect that the pulse heat load plays a key role in controlling the recrystallization and recasting process.

Under the condition of the highest flux of 2.4 × 10

23 ions m

−2 s

−1 (

Figure 3d,h), the surface pits basically disappeared and were replaced by a uniformly distributed coral-like tungsten fuzz structure, accompanied by bubbling in local areas [

21]. This stage shows that the helium injection on the tungsten surface has approached saturation, and the further accumulation of helium bubbles has reached a balance with the migration induced by the pulse heat load, which ultimately led to a fine and stable tungsten fuzz structure. At the same time, the reappearance of local bubbling may be due to the excessively high surface helium concentration, which prevented some helium bubbles from escaping.

3.1.2. Morphology Analysis Under Different Pulse Heat Load Conditions

As shown in

Figure 5, SEM morphology of tungsten after cumulative irradiation by pulsed helium plasma under different thermal load conditions shows that its surface morphology significantly evolves with the increase in pulsed thermal load. Specifically, the original tungsten sheet is mechanically polished, the surface is relatively flat and is not affected by radiation. Under the condition of the lowest heat load of 31 MW m

−2 (

Figure 5b), the tungsten surface showed slight local undulations, and relatively sparse coral-like microstructures were also observed. It is speculated that the appearance of the coral-like structure may be closely related to the surface degradation under the action of helium plasma flux and heat load. Compared with different helium plasma conditions, the helium plasma flux in this group of experiments is higher. Although the heat load is lower, the surface will still experience a certain temperature change, which increases the rate of helium bubble expansion, and the heat load can enhance the ability of helium bubbles to form protrusions on the surface of the material [

21,

22]. Due to the effects of thermal expansion and helium bubbles, the surface structure may gradually present a coral-like morphology, showing a relatively uniform, locally expanded microscopic protrusion structure.

When the heat load increases to 61 MW m

−2 (

Figure 5c), the coral-like structure gradually disappears and is replaced by denser pits. This may be because when the heat load increases to 61 MW/m

2, the higher temperature may cause the helium bubbles to expand too fast, making the relationship between the bubbles and the surface unstable. This instability may cause changes in the surface structure, and the originally formed coral-like structure is weakened or disappears due to the high temperature.

When the heat load is further increased to 98 MW m

−2 (

Figure 5d), the damage on the tungsten surface is further aggravated. Compared with the coral-like protrusion structure under low heat load conditions, the surface at this stage shows a large number of fine pits, honeycomb holes, and micro-nanoscale rough structures. The reason may be that although the high helium flux promotes the accumulation of helium bubbles, the transient high temperature caused by the pulsed high heat load may also cause them to rupture [

23,

24,

25], resulting in pits.

When the heat load reaches 124 MW m

−2 (

Figure 5e), the surface damage of tungsten reaches the most severe level. Large areas of irregular holes, deep depressions, and clustered residual structures can be observed in the SEM image, and the surface is basically destructively reshaped. At this time, the expansion, merging, and bursting process of the helium bubbles is very intense. The large number of surface defects produced after the bubble burst make the surface of the tungsten material highly porous and foaming, similar to the “coral-like” surface morphology induced by helium irradiation under high heat flux described in the literature. The degradation morphology under such extreme conditions shows that the surface structural stability of tungsten is greatly reduced in a high heat load environment, and the helium–heat synergy triggers severe material instability and structural reconstruction.

In general, compared with the previous helium flux variation experiments, the surface evolution achieved by regulating the pulse heat load under a fixed helium flux shows a different dominant mechanism. The increase in helium flux mainly leads to the gradual saturation and aggregation of helium bubbles and finally forms a “coral-like” structure, as shown in

Figure 3g,h and

Figure 5b,c, while the increase in heat load is more likely to cause bubble rupture, pit collapse, and melting and solidification, indicating that the control role of heat load in the synergistic irradiation process more directly determines the surface melting and damage scale. Therefore, the evolution of surface morphology under the synergistic effect of the two depends not only on the accumulation of helium flux but also on the transient high temperature environment provided by the pulse heat load.

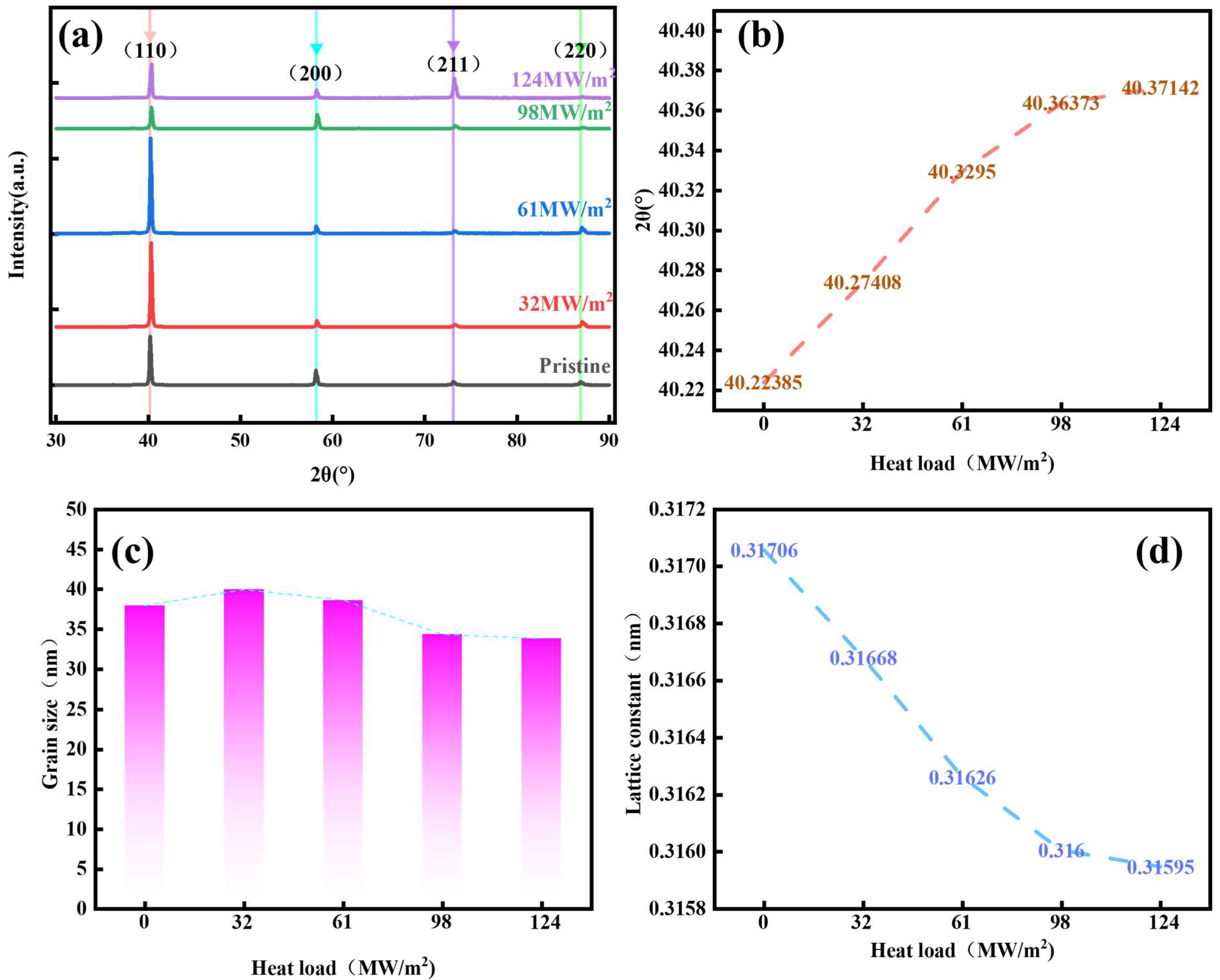

3.2. XRD Analysis

3.2.1. XRD Analysis Under Different Helium Plasma Flux Conditions

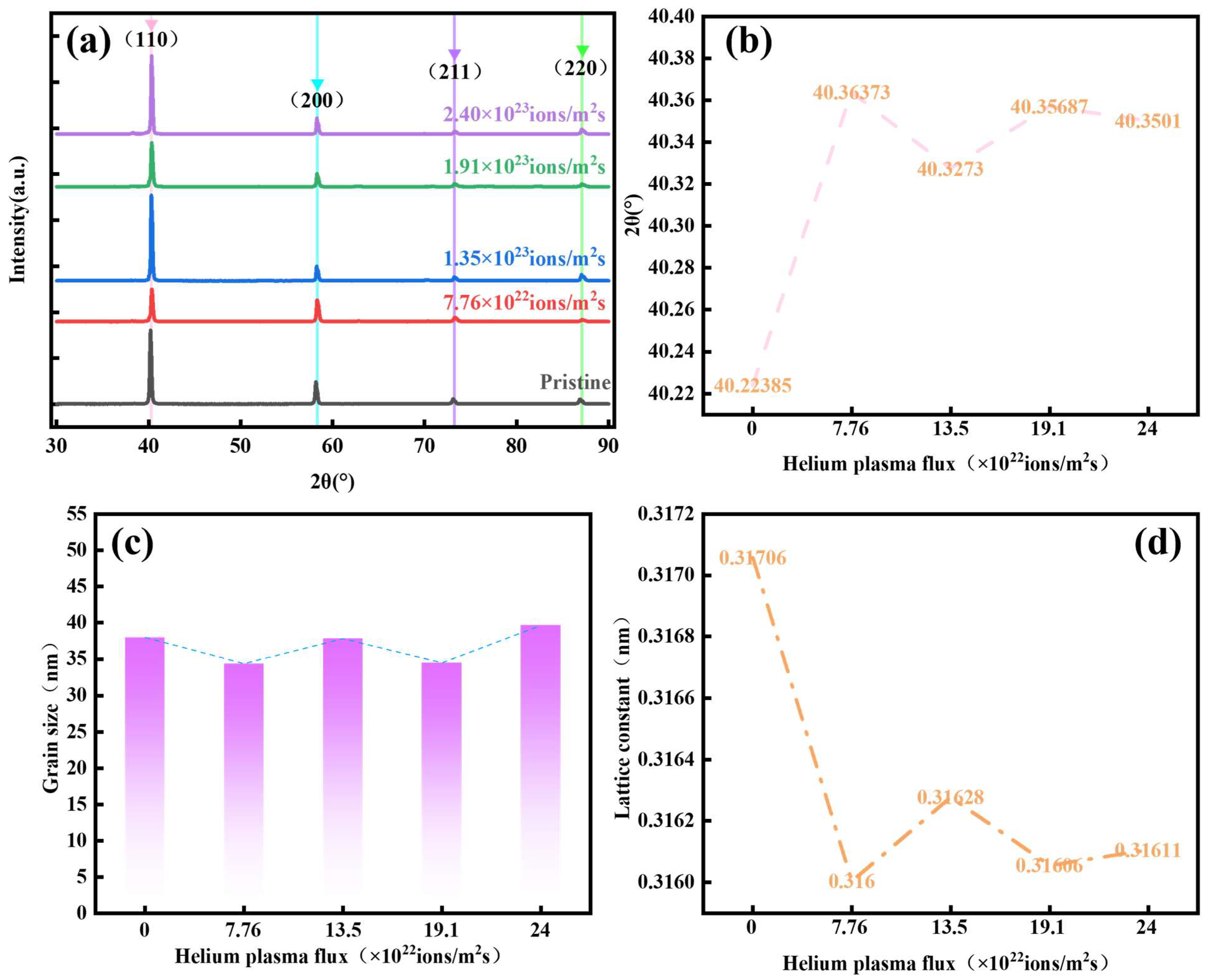

Figure 6 shows the XRD analysis under different helium plasma flux conditions.

Figure 6 shows the XRD data of tungsten after irradiation with pulsed helium plasma cumulative load under different helium plasma flux conditions. As can be seen from

Figure 6a, the intrinsic crystal structure of tungsten is maintained under all flux conditions, and no new phase is formed, indicating that the irradiation process does not induce phase change. However, with the increase of helium plasma flux, the detailed parameters, such as diffraction peak position, grain size, and lattice constant, all show certain regular changes, reflecting the stress evolution and structural adjustment inside the tungsten crystal under the action of synergistic load. Specifically, the position of the (110) main peak shows slight fluctuations with the increase in the helium flux. In the low-flux stage, the peak position of the (110) diffraction peak shifts slightly to the left, indicating that the lattice has a certain degree of expansion. This may be due to the formation of nanobubbles inside the lattice during the continuous injection of helium ions. These bubbles induce local tensile stress, resulting in a slight increase in the interplanar spacing. Under high-flux conditions, the peak position changes tend to be stable, which may be due to the rupture of helium bubbles under the action of high-temperature pulse loads, accompanied by local recrystallization and stress release on the surface, which alleviates the lattice distortion accumulated in the early stage [

19,

26].

At the same time, it can be seen from

Figure 6c that with the increase in the helium flux, the overall grain size shows a trend of first decreasing and then tending to be stable. In the low-flux stage, helium bubbles gather at grain boundaries and dislocations, which promotes grain refinement. In addition, the high-temperature environment brought by the pulse heat load further accelerates the migration of surface atoms and the movement of grain boundaries, and the refinement effect is more obvious. However, when the flux continues to increase, the cumulative effect of helium bubbles tends to balance with the surface reconstruction, so the grain size rebounds [

27]. In addition, the change in lattice constant also reflects the synergistic effect of helium plasma flux and pulse heat load. In the low-flux stage, the lattice constant increases slightly, which is consistent with the lattice expansion caused by bubble formation; in the high-flux stage, due to the rupture and escape of helium bubbles and the occurrence of local melting and resolidification of the surface, some residual stress is released, and the lattice constant shows a slight downward trend.

In summary, the evolution of the microstructure of the tungsten material under the conditions of pulsed helium plasma irradiation is the result of the combined effect of helium flux and pulse heat load. The bubble aggregation and lattice tensile stress caused by helium ion implantation are the main reasons for grain refinement and distortion; the transient high-temperature environment provided by the pulse heat load not only promotes the growth and rupture of helium bubbles but also accelerates the surface recrystallization and atomic migration process. Under the synergistic effect of the two, the tungsten surface and the internal structure of the crystal underwent continuous dynamic adjustments, which are finally reflected in the changes in the peak position, grain size, and lattice constant in the XRD spectrum.

3.2.2. XRD Analysis Under Different Pulse Heat Load Conditions

Figure 7 shows the XRD analysis under different pulse heat load conditions. From the overall XRD spectrum, it can be seen that the crystal phase has not undergone obvious transformation under the experimental conditions. However, with the increase in heat load, the (110) peak position shows a trend of gradually shifting to the right, especially under the high heat load condition of 124 MW m

−2. This change may be related to the residual stress release caused by the rupture of surface helium bubbles and local melting. In the stage of lower heat load, the nanobubbles formed by helium ion implantation mainly stay in the near-surface layer of the lattice, introducing local tensile stress, but the overall impact is limited. As the pulse heat load increases, the transient high temperature causes the helium bubbles to grow and rupture rapidly, resulting in the gradual release of stress and lattice contraction, which manifests as the phenomenon of peak position shifting to the right [

28]. The change trend of grain size can also prove this. Under low heat load conditions, helium bubbles mainly gather at the grain boundaries, and the grain refinement effect is more obvious [

29,

30]. Although the pulse heat load promotes local atomic migration, the overall migration range is limited, and the grain size remains at a large level. When the heat load increases to 61 MW/m

2 and above, the pulse high temperature drives the surface helium bubbles to rupture and induces recrystallization behavior, accelerating grain refinement. Especially in the 98 and 124 MW m

−2 stages, the grain size is significantly reduced, which is closely related to the surface recasting and grain boundary migration caused by the pulse heat load. At the same time, the change in the lattice constant also reflects this synergistic effect. The experimental results show that with the increase in heat load, the lattice constant shows a continuous downward trend. In the initial stage, the formation of helium bubbles has little effect on the lattice expansion, and the overall lattice distortion is limited. Under high heat load conditions, the local surface undergoes rapid melting and solidification under the action of high-temperature pulses. During the process, the residual stress is released, the lattice becomes denser, and the constant is reduced.

In summary, the microstructural evolution trend of tungsten materials during pulse helium plasma synergistic irradiation is highly dependent on the change in pulse heat load. The transient high temperature provided by the heat load not only intensifies the growth and rupture of helium bubbles, but also accelerates the grain refinement and recrystallization process, and plays a leading role in lattice distortion, grain evolution and surface reconstruction. Although the helium plasma flux remains constant, under the high heat load, its cumulative effect and surface thermal stress drive the continuous evolution of the crystal structure.

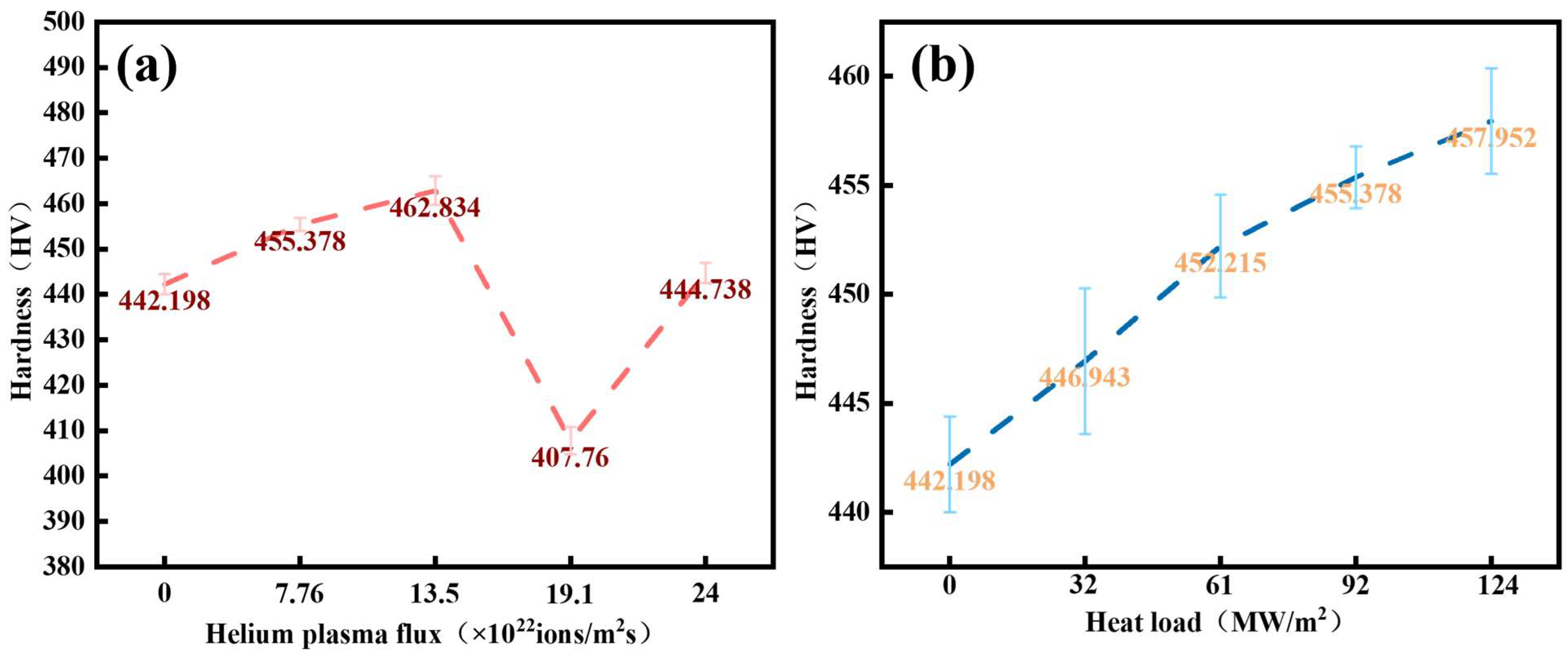

3.3. Mechanical and Optical Performance Analysis

Figure 8 shows the change in surface hardness before and after pulsed helium plasma co-irradiation.

Figure 8a shows the change in hardness of tungsten under pulsed helium plasma synergistic cumulative load irradiation. From the overall trend, whether it is the change in helium flux or the change in heat load, the surface hardness of tungsten samples has changed to varying degrees, indicating that the synergistic load has a significant effect on the surface-hardening behavior of tungsten. From the experimental results of

Figure 8a, as the flux gradually increases, the overall hardness shows a trend of first increasing, then decreasing, and then slightly recovering. In the initial stage, the continuous injection of helium ions forms a large number of nanobubbles in the tungsten lattice. These bubbles gather at grain boundaries and dislocations, increasing the defect density inside the crystal and promoting radiation hardening of the material. At the same time, the pulsed heat load provides sufficient thermal driving force for the growth of helium bubbles and local stress accumulation, which improves the surface hardness at a lower flux stage [

31,

32,

33,

34]. However, when the helium flux is further increased to a higher level, local helium bubbles rupture and escape, accompanied by surface recrystallization and the expansion of microcracks, resulting in a weakening of the hardening effect and a downward trend in hardness. Finally, under extremely high-flux conditions, the surface structure tends to be stable, and the hardness value recovers, but the overall change is limited.

In contrast, the hardness change in the tungsten surface in the experiment of

Figure 8b is more monotonous and obvious, showing a trend of continuous increase with the increase in heat load. As the heat load increases from 31 MW m

−2 to 124 MW m

−2, the pulsed high temperature environment significantly intensifies the aggregation and rupture process of helium bubbles in the lattice, and at the same time induces local recrystallization and recasting behavior in the surface layer, which improves the grain refinement and increases the surface defect density. This series of microstructural changes directly promotes the gradual increase in the surface hardness of the material. In addition, the accumulation of residual stress during the melting–solidification process under high heat load further enhances the hardness improvement effect [

35].

In summary, during the pulsed helium plasma synergistic irradiation process, the heat load not only directly affects the surface temperature rise and stress field distribution but also determines the dynamic process of helium bubble behavior, recrystallization, and microcrack extension. Compared with the simple change in helium flux, the increase in heat load has a more significant regulatory effect on hardness, showing a trend of continuous enhancement, reflecting the dominant position of pulsed heat load in the evolution of mechanical properties.

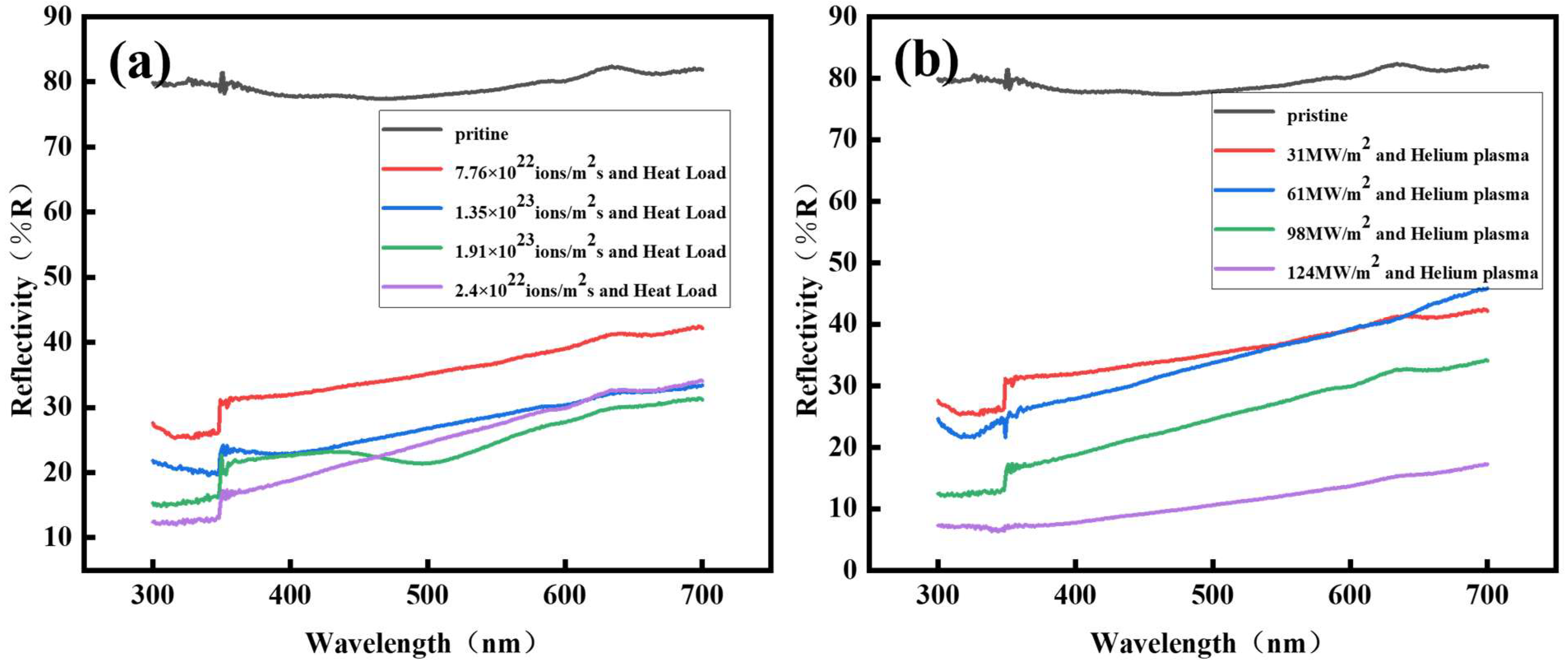

As shown in

Figure 9, after the tungsten sample was irradiated by pulsed helium plasma, the surface reflectivity of the sample changed significantly with the helium plasma flux and the heat load intensity. In

Figure 9a, as the helium plasma flux gradually increased from 7.76 × 10

22 ions m

−2·s

−1 to 2.4 × 10

23 ions m

−2·s

−1, the reflectivity curve showed a continuous downward trend as a whole. The reflectivity of the initial sample remained at a high level, but the reflectivity decreased significantly after irradiation, especially when the flux reached 1.91 × 10

23 ions m

−2·s

−1 and 2.4 × 10

23 ions m

−2·s

−1, the reflectivity dropped significantly, and finally dropped to about 47% of the original sample, a decrease of nearly half. This is because the surface microstructure destruction and nanoscale roughening caused by helium plasma injection [

36]. When the helium ion flux increases, the density of helium bubbles on the surface increases sharply, accompanied by nanopores and dislocation rings, resulting in an increase in the roughness of the surface reflection surface, thereby reducing the reflectivity.

Similarly,

Figure 9b shows that the reflectivity also shows a trend of gradual decrease when the pulse heat load increases from 31 MW m

−2 to 124 MW m

−2. In particular, under the high heat load conditions of 98 MW m

−2 and 124 MW m

−2, the reflectivity curve drops most significantly, similar to the high-flux situation in

Figure 9a, and the reflectivity drops to about 50% of the original sample. This may be because the high-temperature environment also promotes the aggregation and rupture of helium bubbles, forming larger and denser holes and nanofiber structures on the surface, further reducing the reflectivity.

4. Conclusions

This study systematically reveals the damage evolution law of tungsten materials under the synergistic effect of pulsed helium plasma and high heat load through experimental and characterization methods. The main conclusions are as follows:

- (1)

In terms of morphological changes, with the gradual increase of helium plasma flux and pulse heat load, the tungsten surface shows the evolution characteristics from bubble aggregation, bubbling, pit collapse, to final melting. High-flux helium injection induces the formation and aggregation of a large number of bubbles, aggravating the surface undulation and roughening, while the strong heat load promotes bubble rupture, surface collapse, and local melting by strengthening thermal stress and local high temperature effect and finally forms a significant molten structure. The synergistic effect of the two factors significantly aggravates the degree of surface degradation, indicating that the dominant control role of transient heat load in synergistic irradiation is more prominent.

- (2)

In terms of microstructure, the XRD results show that under different flux and heat load conditions, the diffraction peak of the (110) crystal plane of tungsten material shifts to a high angle, the grain size decreases, and the lattice constant decreases, reflecting the enhanced trend of internal lattice compression and stress accumulation. The increase in helium flux mainly leads to an increase in the density of irradiation defects, while the change in heat load plays an important role in the reorganization and evolution of defects. Under the synergistic effect of the two factors, the stability of the crystal structure decreases, and the lattice distortion phenomenon dominated by irradiation-induced defects is significantly enhanced.

- (3)

In terms of mechanical and optical properties, the surface hardness of tungsten materials decreases after synergistic irradiation, and the reflectivity decreases significantly with the increase in flux and heat load. The surface optical properties of samples with high heat load degrade most seriously due to melting damage and increased roughness. In comparison, the heat load has a more direct effect on the reflectivity, while the helium flux indirectly affects the reflective performance through microstructural degradation.

This study provides key data for the damage-resistant design of tungsten-based PFM for fusion reactors. In the future, it is necessary to further explore the long-term synergistic effects of cyclic thermal fatigue and helium accumulation to improve the service stability of the material in extreme environments.

Author Contributions

Conceptualization, Z.Y., J.W. and F.G.; data curation, X.H., Z.Y. and J.W.; investigation, X.H., J.W. and F.G.; supervision, J.W.; visualization, X.H.; writing—original draft, X.H.; writing—review and editing, J.W., F.G. and Z.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the National Key Research and Development Program of China (Grant No. 22022YFE03030003).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liu, X.; Lian, Y.; Greuner, H.; Boeswirth, B.; Jin, Y.; Feng, F.; Wang, J.; Chen, L.; Song, J.; Yu, Y.; et al. Irradiation effects of hydrogen and helium plasma on different grade tungsten materials. Nucl. Mater. Energy 2017, 12, 1314. [Google Scholar] [CrossRef]

- Pitts, R.; Carpentier, S.; Escourbiac, F.; Hirai, T.; Komarov, V.; Lisgo, S.; Kukushkin, A.; Loarte, A.; Merola, M.; Naik, A.S.; et al. A full tungsten divertor for ITER: Physics issues and design status. J. Nucl. Mater. 2013, 438, S48. [Google Scholar] [CrossRef]

- Hirai, T.; Escourbiac, F.; Carpentier-Chouchana, S.; Durocher, A.; Fedosov, A.; Ferrand, L.; Jokinen, T.; Komarov, V.; Merola, M.; Mitteau, R.; et al. ITER full tungsten divertor qualification program and progress. Phys. Scr. 2014, 2014, 014006. [Google Scholar] [CrossRef]

- Hirai, T.; Pintsuk, G.; Linke, J.; Batilliot, M. Cracking failure study of ITER-reference tungsten grade under single pulse thermal shock loads at elevated temperatures. J. Nucl. Mater. 2009, 390–391, 751. [Google Scholar] [CrossRef]

- Linke, J.; Loewenhoff, T.; Massaut, V.; Pintsuk, G.; Ritz, G.; Rödig, M.; Schmidt, A.; Thomser, C.; Uytdenhouwen, I.; Vasechko, V.; et al. Performance of different tungsten grades under transient thermal loads. Nucl. Fusion 2011, 51, 073017. [Google Scholar] [CrossRef]

- Yuan, Y.; Greuner, H.; Böswirth, B.; Luo, G.-N.; Fu, B.; Xu, H.; Liu, W. Melt layer erosion of pure and lanthanum doped tungsten under VDE-like high heat flux loads. J. Nucl. Mater. 2013, 438, S229. [Google Scholar] [CrossRef]

- Sharma, P. Damage Studies of Tungsten Samples Using Dense Plasma Focus Devices. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2020. [Google Scholar]

- Sharma, P.; Vas, J.V.; Medwal, R.; Mishra, M.; Chaurasiya, A.; Luai, M.T.; Zheng, Z.; Chaudhary, V.; Ramanujan, R.V.; Paul, L.C.K.; et al. High energy density pulsed argon plasma synthesized nanostructured tungsten for damage mitigation under fusion relevant energetic he ion irradiation. Appl. Surf. Sci. Adv. 2021, 6, 100172. [Google Scholar] [CrossRef]

- Buzi, L.; De Temmerman, G.; Huisman, A.; Bardin, S.; Morgan, T.; Rasinski, M.; Pitts, R.; Van Oost, G. Response of tungsten surfaces to helium and hydrogen plasma exposure under ITER relevant steady state and repetitive transient conditions. Nucl. Fusion 2017, 57, 126009. [Google Scholar] [CrossRef]

- De Temmerman, G.; Bystrov, K.; Doerner, R.; Marot, L.; Wright, G.; Woller, K.; Whyte, D.; Zielinski, J. Helium effects on tungsten under fusion-relevant plasma loading conditions. J. Nucl. Mater. 2013, 438, S78. [Google Scholar] [CrossRef]

- Das, S. Investigating Irradiation Damage in Tungsten for Fusion Power. Oxford University Research Archive. Ph.D. Thesis, University of Oxford, Oxford, UK, 2019. [Google Scholar]

- Javadi, S.; Ouyang, B.; Zhang, Z.; Ghoranneviss, M.; Salar Elahi, A.; Rawat, R.S. Effects of fusion relevant transient energetic radiation, plasma and thermal load on PLANSEE double forged tungsten samples in a low-energy plasma focus device. Appl. Surf. Sci. 2018, 443, 311. [Google Scholar] [CrossRef]

- Malykhin, S.V.; Garkusha, I.E.; Makhlai, V.A.; Surovitskiy, S.V.; Herashchenko, S.S.; Girka, O.I. Mechanisms of crack generation in high-pure tungsten exposed to high power density plasma. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2020, 481, 6. [Google Scholar] [CrossRef]

- Ialovega, M.; Bernard, E.; Barthe, M.-F.; Bisson, R.; Campos, A.; Cabié, M.; Neisius, T.; Sakamoto, R.; Kreter, A.; Grisolia, C.; et al. Helium-induced morphology evolution in tungsten under thermal treatment. Nucl. Fusion 2022, 62, 126022. [Google Scholar] [CrossRef]

- Morgan, T.W.; Li, Y.; Balden, M.; Brezinsek, S.; De Temmerman, G. Combined high fluence and high cycle number transient loading of ITER-like monoblocks in Magnum-PSI. Nucl. Fusion 2021, 61, 116045. [Google Scholar] [CrossRef]

- Nishijima, D.; Ye, M.Y.; Ohno, N.; Takamura, S. Formation mechanism of bubbles and holes on tungsten surface with low-energy and high-flux helium plasma irradiation in NAGDIS-II. J. Nucl. Mater. 2004, 329–333, 1029. [Google Scholar] [CrossRef]

- Noiri, Y.; Kajita, S.; Ohno, N. Nanostructure growth by helium plasma irradiation to tungsten in sputtering regime. J. Nucl. Mater. 2015, 463, 285. [Google Scholar] [CrossRef]

- Ito, A.M.; Takayama, A.; Oda, Y.; Tamura, T.; Kobayashi, R.; Hattori, T.; Ogata, S.; Ohno, N.; Kajita, S.; Yajima, M.; et al. Hybrid simulation research on formation mechanism of tungsten nanostructure induced by helium plasma irradiation. J. Nucl. Mater. 2015, 463, 109. [Google Scholar] [CrossRef]

- Wirtz, M.; Bardin, S.; Huber, A.; Kreter, A.; Linke, J.; Morgan, T.; Pintsuk, G.; Reinhart, M.; Sergienko, G.; Steudel, I.; et al. Impact of combined hydrogen plasma and transient heat loads on the performance of tungsten as plasma facing material. Nucl. Fusion 2015, 55, 123017. [Google Scholar] [CrossRef]

- Tokunaga, K.; Tamura, S.; Yoshida, N.; Ezato, K.; Taniguchi, M.; Sato, K.; Suzuki, S.; Akiba, M. Synergistic effects of high heat loading and helium irradiation of tungsten. J. Nucl. Mater. 2004, 329–333, 757. [Google Scholar] [CrossRef]

- Ribis, J. Structural and chemical matrix evolution following neutron irradiation in a MA957 oxide dispersion strengthened material. J. Nucl. Mater. 2013, 434, 178. [Google Scholar] [CrossRef]

- Tanabe, T. Review of hydrogen retention in tungsten. Phys. Scr. 2014, 2014, 014044. [Google Scholar] [CrossRef]

- Wang, J.-C.; Wang, W.; Sun, Z.; Wang, X.; Wei, R.; Xie, C.; Li, Q.; Luo, G.-N. Microstructure and mechanical analysis of W/P91 steel HIP-joint with Ti interlayer. Fusion Eng. Des. 2016, 112, 67. [Google Scholar] [CrossRef]

- Loarte, A.; Saibene, G.; Sartori, R.; Riccardo, V.; Andrew, P.; Paley, J.; Fundamenski, W.; Eich, T.; Herrmann, A.; Pautasso, G.; et al. Transient heat loads in current fusion experiments, extrapolation to ITER and consequences for its operation. Phys. Scr. 2007, 2007, 222. [Google Scholar] [CrossRef]

- Huber, A.; Arakcheev, A.; Sergienko, G.; Steudel, I.; Wirtz, M.; Burdakov, A.V.; Coenen, J.W.; Kreter, A.; Linke, J.; Mertens, P.; et al. Investigation of the impact of transient heat loads applied by laser irradiation on ITER-grade tungsten. Phys. Scr. 2014, 2014, 014005. [Google Scholar] [CrossRef]

- Hamaji, Y.; Tokitani, M.; Kreter, A.; Sakamoto, R.; Sagara, A.; Tamura, H.; Masuzaki, S. Influence of thermal shocks on the He induced surface morphology on tungsten. Nucl. Mater Energy 2019, 18, 321. [Google Scholar] [CrossRef]

- Wu, Y. Research progress in irradiation damage behavior of tungsten and its alloys for nuclear fusion reactor. Acta Metall. Sin. 2019, 55, 939. [Google Scholar]

- Huber, A.; Wirtz, M.; Sergienko, G.; Steudel, I.; Arakcheev, A.; Burdakov, A.; Esser, H.G.; Freisinger, M.; Kreter, A.; Linke, J.; et al. Combined impact of transient heat loads and steady-state plasma exposure on tungsten. Fusion Eng. Des. 2015, 98–99, 1328. [Google Scholar] [CrossRef]

- Baldwin, M.J.; Doerner, R.P.; Wampler, W.R.; Nishijima, D.; Lynch, T.; Miyamoto, M. Effect of He on D retention in W exposed to low-energy, high-fluence (D, He, Ar) mixture plasmas. Nucl. Fusion 2011, 51, 103021. [Google Scholar] [CrossRef]

- Sinclair, G.; Tripathi, J.K.; Diwakar, P.K.; Wirtz, M.; Linke, J.; Hassanein, A. Structural evolution of tungsten surface exposed to sequential low-energy helium ion irradiation and transient heat loading. Nucl. Mater. Energy 2017, 12, 405. [Google Scholar] [CrossRef]

- Loewenhoff, T.; Linke, J.; Pintsuk, G.; Thomser, C. Tungsten and CFC degradation under combined high cycle transient and steady state heat loads. Fusion Eng. Des. 2012, 87, 1201. [Google Scholar] [CrossRef]

- Rieth, M.; Dudarev, S.; de Vicente, S.G.; Aktaa, J.; Ahlgren, T.; Antusch, S.; Armstrong, D.; Balden, M.; Baluc, N.; Barthe, M.-F.; et al. Recent progress in research on tungsten materials for nuclear fusion applications in Europe. J. Nucl. Mater. 2013, 432, 482. [Google Scholar] [CrossRef]

- Wu, Y.; Hou, Q.; Luo, L.; Zan, X.; Zhu, X.; Li, P.; Xu, Q.; Cheng, J.; Luo, G.; Chen, J. Preparation of ultrafine-grained/nanostructured tungsten materials: An overview. J. Alloys Compd. 2019, 779, 926. [Google Scholar] [CrossRef]

- Philipps, V. Tungsten as material for plasma-facing components in fusion devices. J. Nucl. Mater. 2011, 415, S2. [Google Scholar] [CrossRef]

- Baldwin, M.J.; Doerner, R.P. Helium induced nanoscopic morphology on tungsten under fusion relevant plasma conditions. Nucl. Fusion 2008, 48, 035001. [Google Scholar] [CrossRef]

- Wang, T.; Kim, H.; Wang, X.; Pacheco, A.M.; Garner, F.A.; Shao, L. Helium retention, bubble superlattice formation and surface blistering in helium-irradiated tungsten. J. Nucl. Mater. 2021, 545, 152722. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).