Leak Identification and Positioning Strategies for Downhole Tubing in Gas Wells

Abstract

1. Introduction

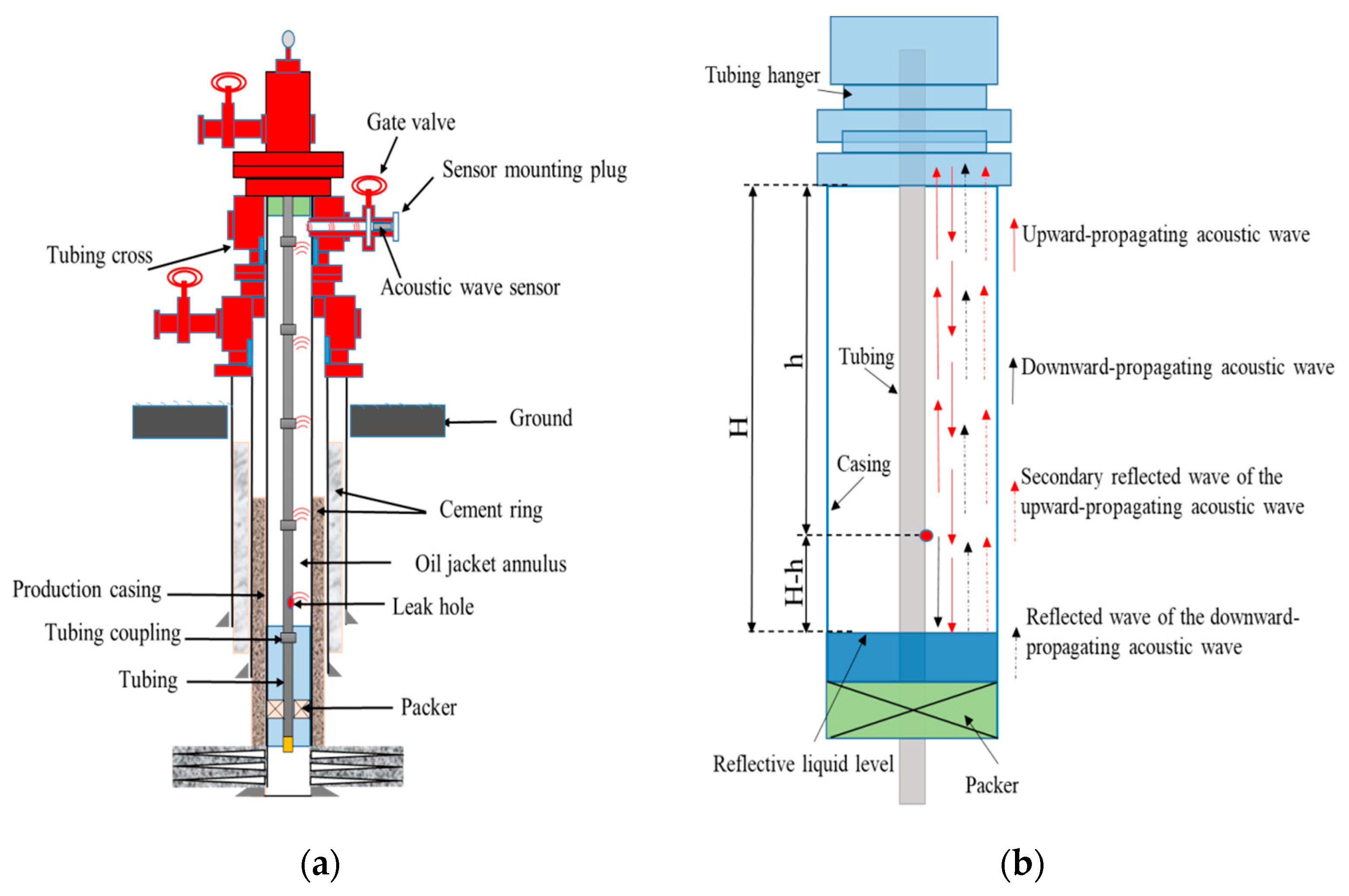

2. Principle of Tubing Leak Localization

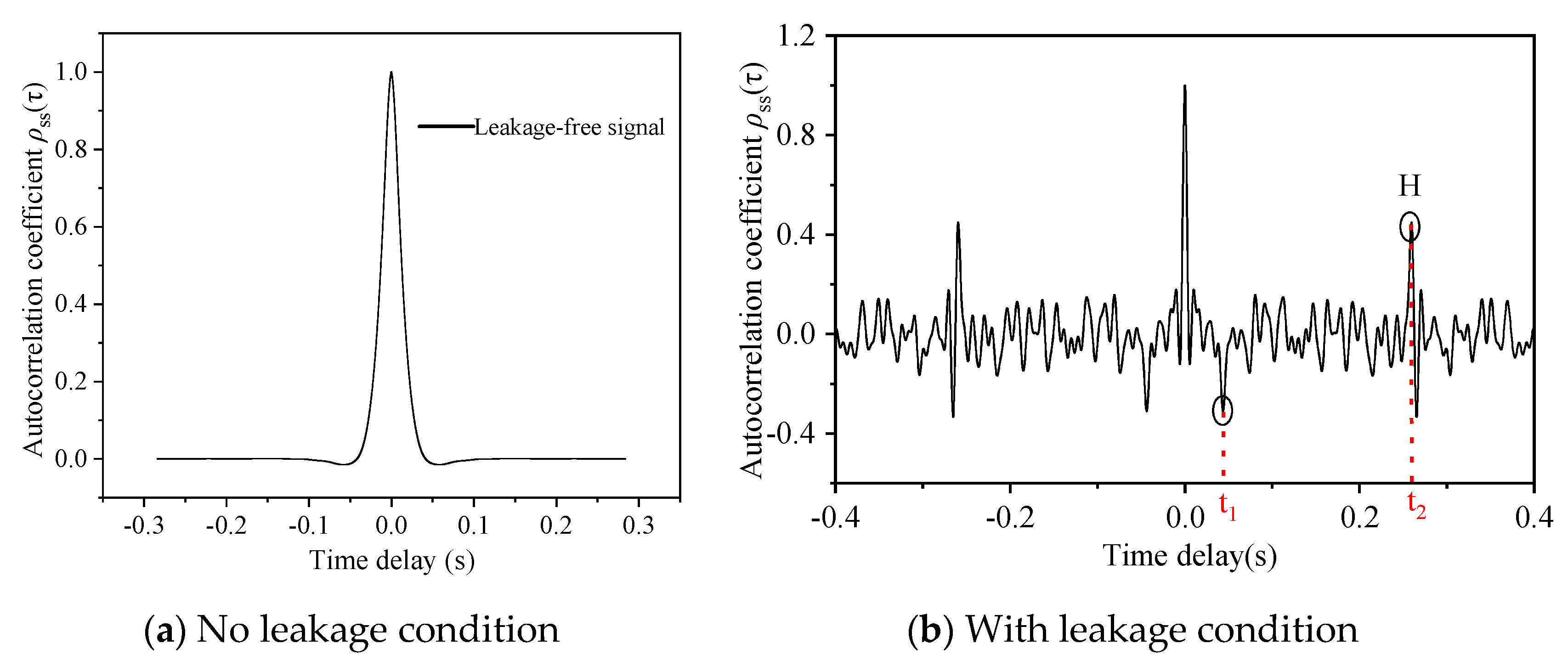

2.1. Extraction of Characteristic Time

- Random noise primarily originates from production noise, system noise, and field noise. Field noise, in particular, includes sounds generated during production operations, maintenance activities, and seawater impact on surface casing;

- Coherent noise mainly results from reflections of leakage-induced acoustic waves by downhole tubing collars, gas lift valves, or subsurface safety valves.

- The characteristic time for leak point location;

- The abscissa (time coordinate) of the negative characteristic peak on the leakage acoustic wave’s autocorrelation curve.

- The characteristic time corresponding to fluid level depth;

- The abscissa of the positive characteristic peak on the autocorrelation curve.

- Multiple reflections of the leakage acoustic wave within the annulus;

- Higher-order harmonic components in the signal.

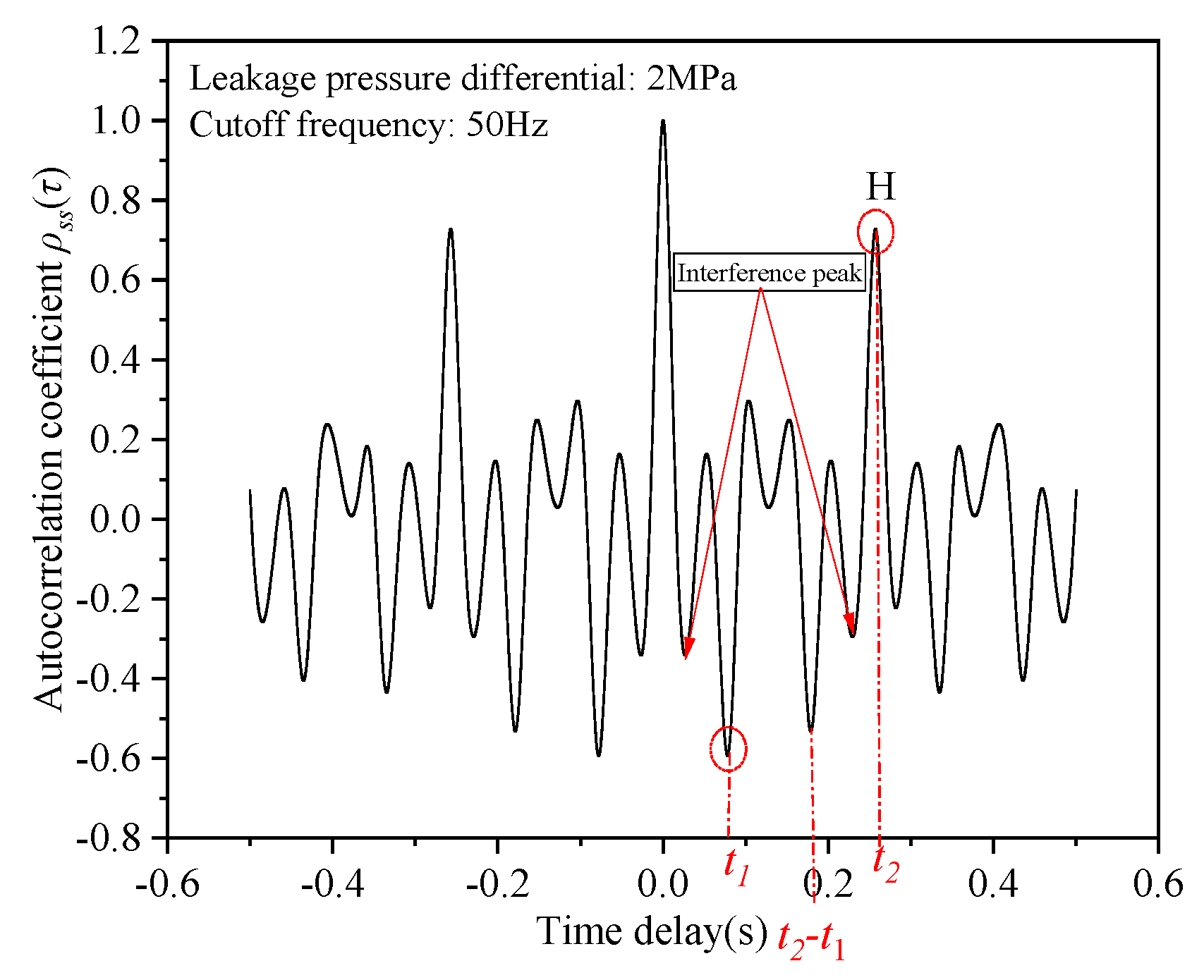

- t1 corresponds to the abscissa of the first maximum negative characteristic peak on the autocorrelation curve;

- t2 represents the abscissa of the first maximum positive characteristic peak;

- The series of minor characteristic peaks result from reflections of leakage acoustic waves by downhole tubing collars, gas lift valves, or subsurface safety valves.

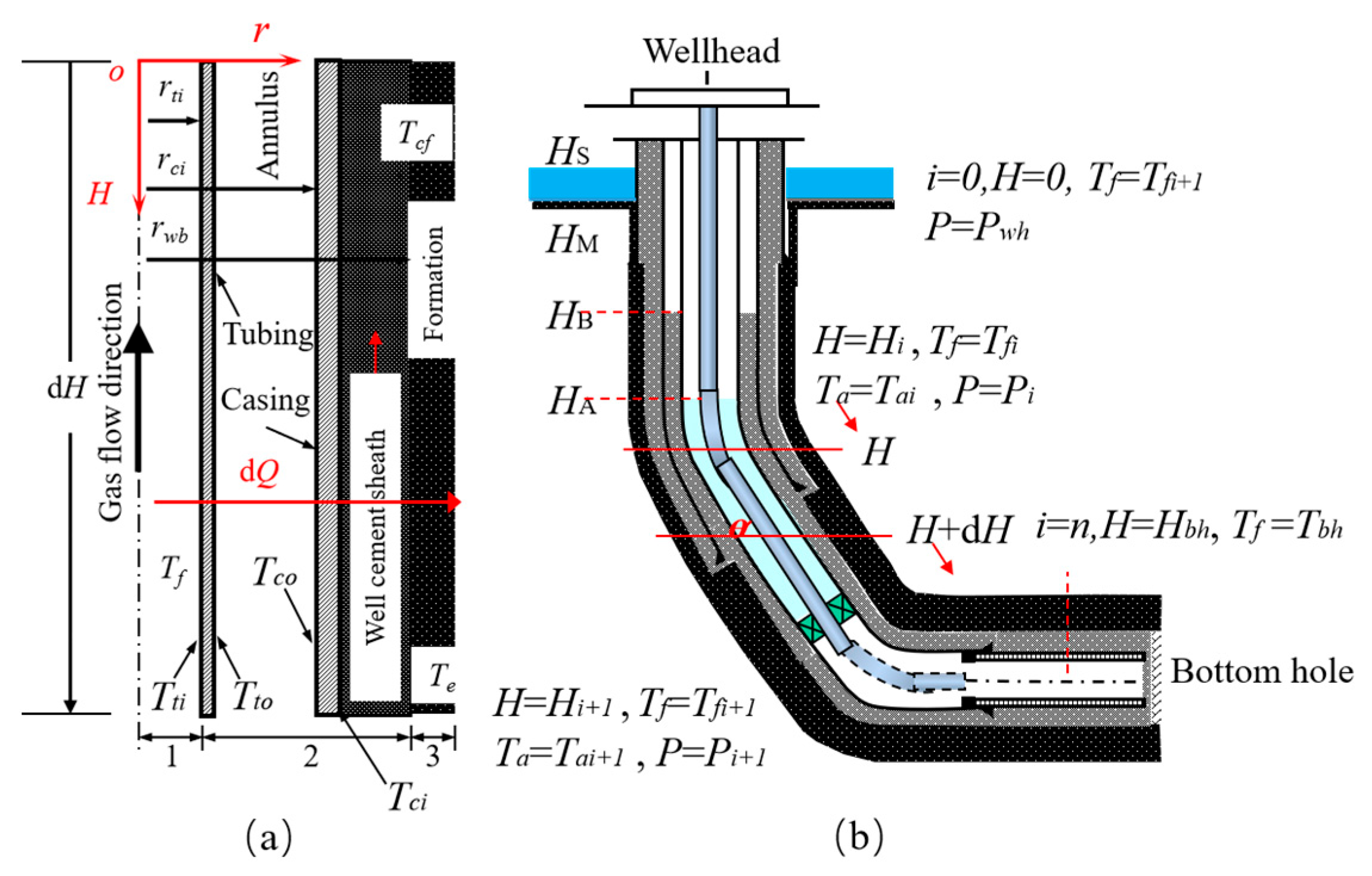

2.2. Determination of Annular Acoustic Velocity

- Steady-state conditions prevail for heat transfer within the wellbore, while transient heat transfer dominates between the wellbore and formation;

- Only radial heat transfer is considered;

3. Study on Characteristic Peaks of Leakage Acoustic Waves

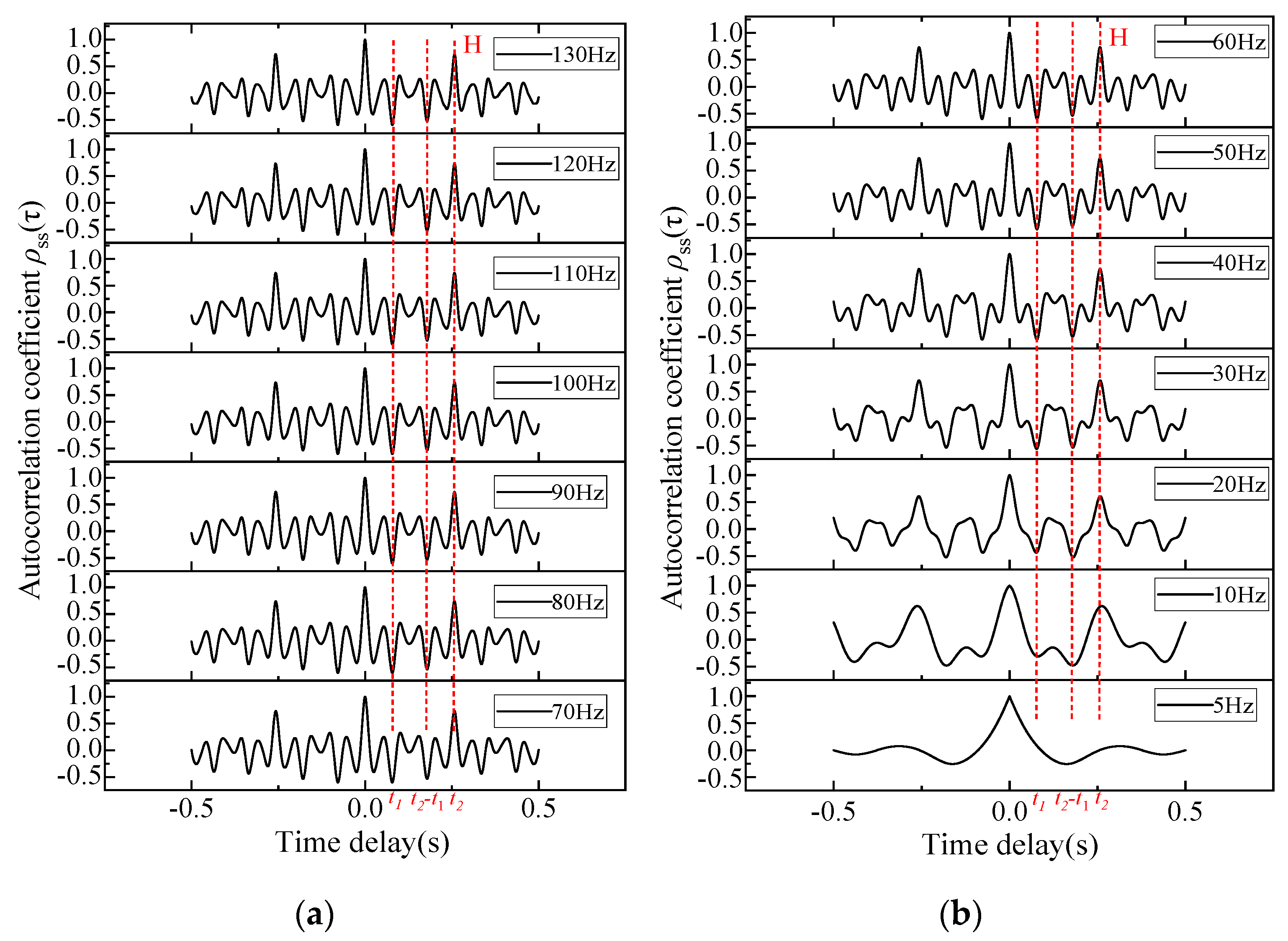

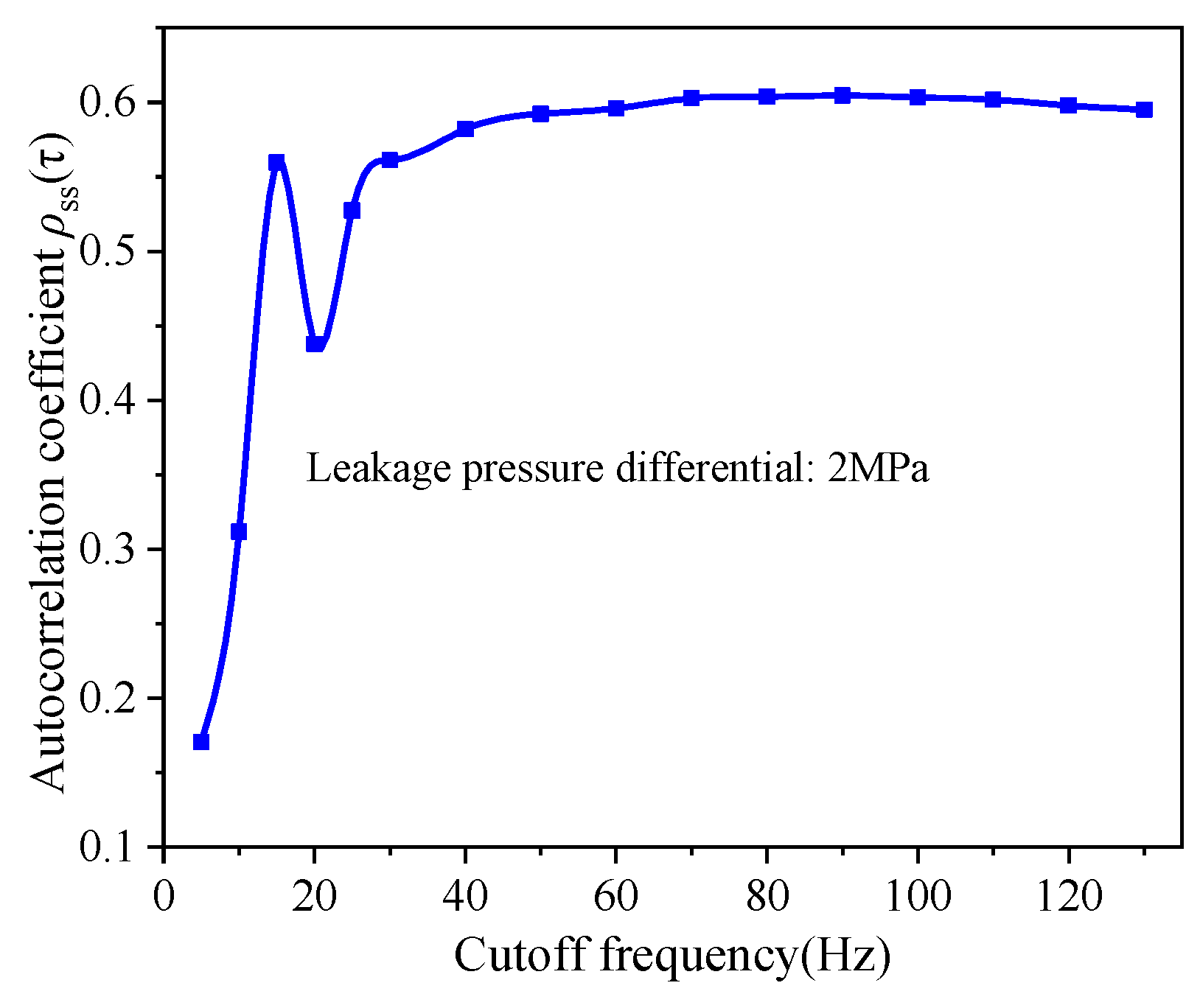

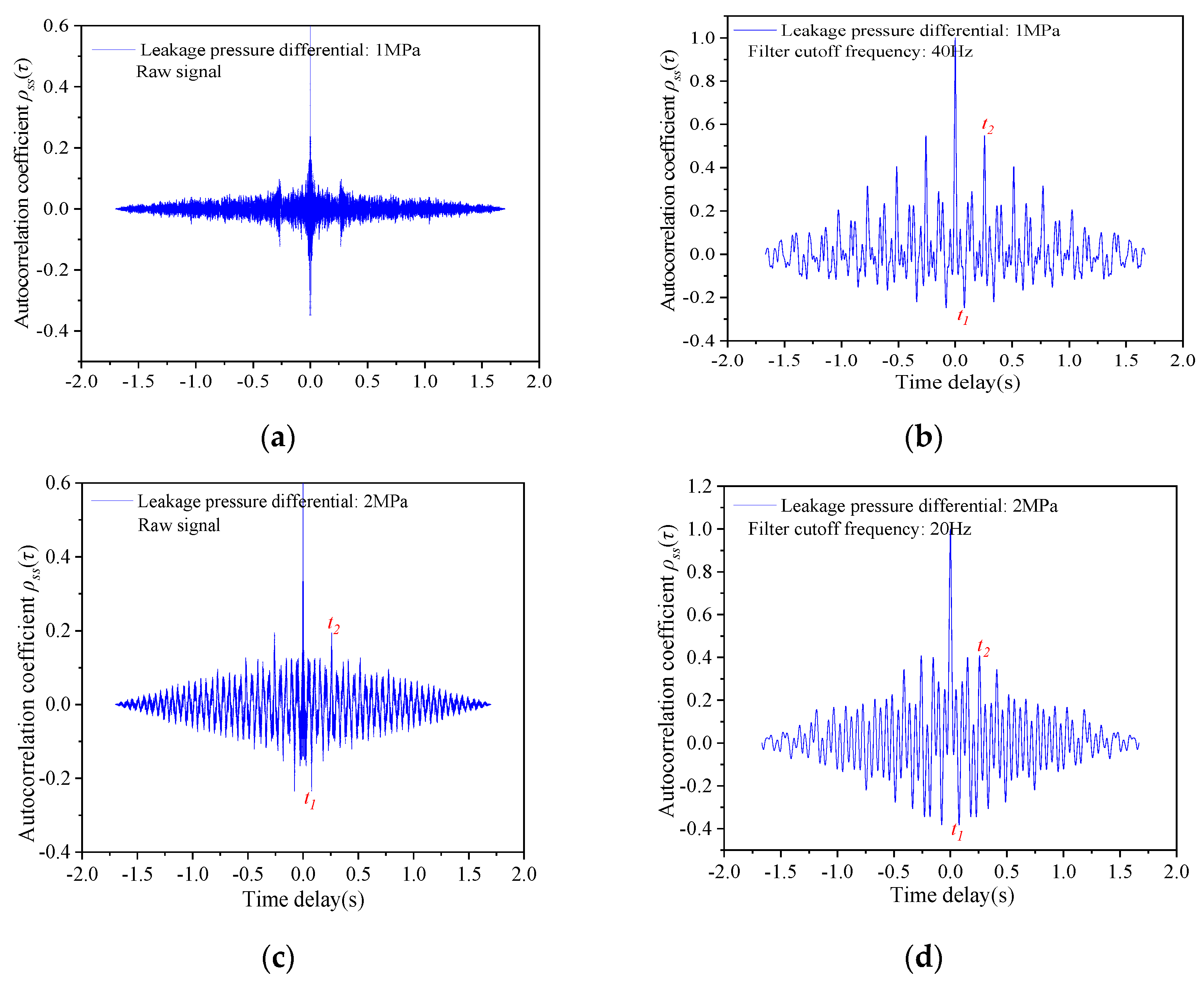

3.1. Effect of Filter Cutoff Frequency on Characteristic Peaks

- Interference Peak Reduction: Lowering the filter cutoff frequency effectively eliminates interference peaks, indicating that leakage acoustic wave energy is predominantly distributed in the low-frequency range, while random noise exhibits minimal low-frequency components;

- Trade-off in Frequency Selection: As shown in Figure 5b, excessively low cutoff frequencies cause the characteristic peak timings to deviate from theoretical values or even disappear entirely. This demonstrates that an arbitrarily low cutoff frequency is counterproductive, as it distorts the autocorrelation curve and degrades measurement accuracy.

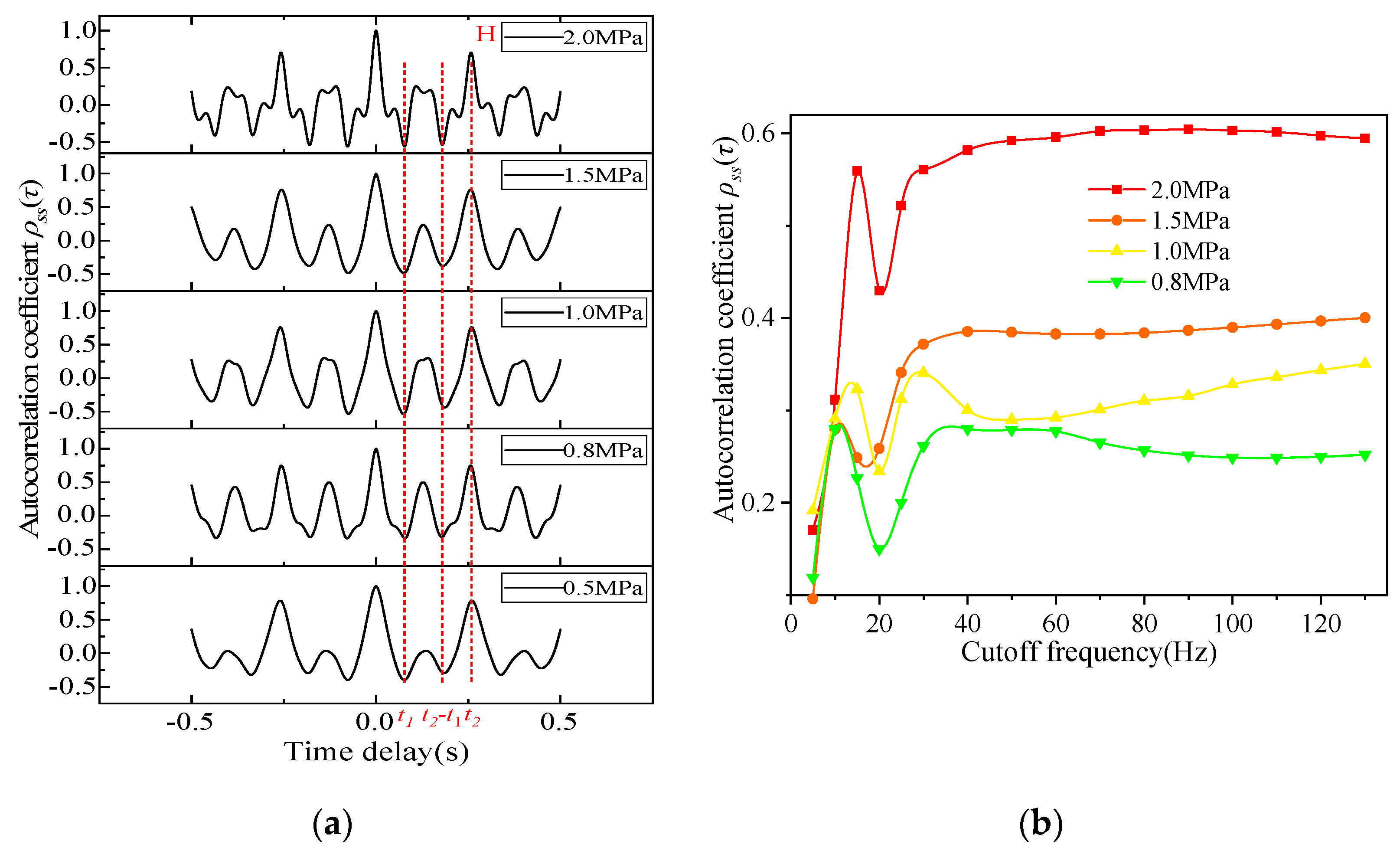

3.2. Influence of Leakage Pressure on Characteristic Peaks

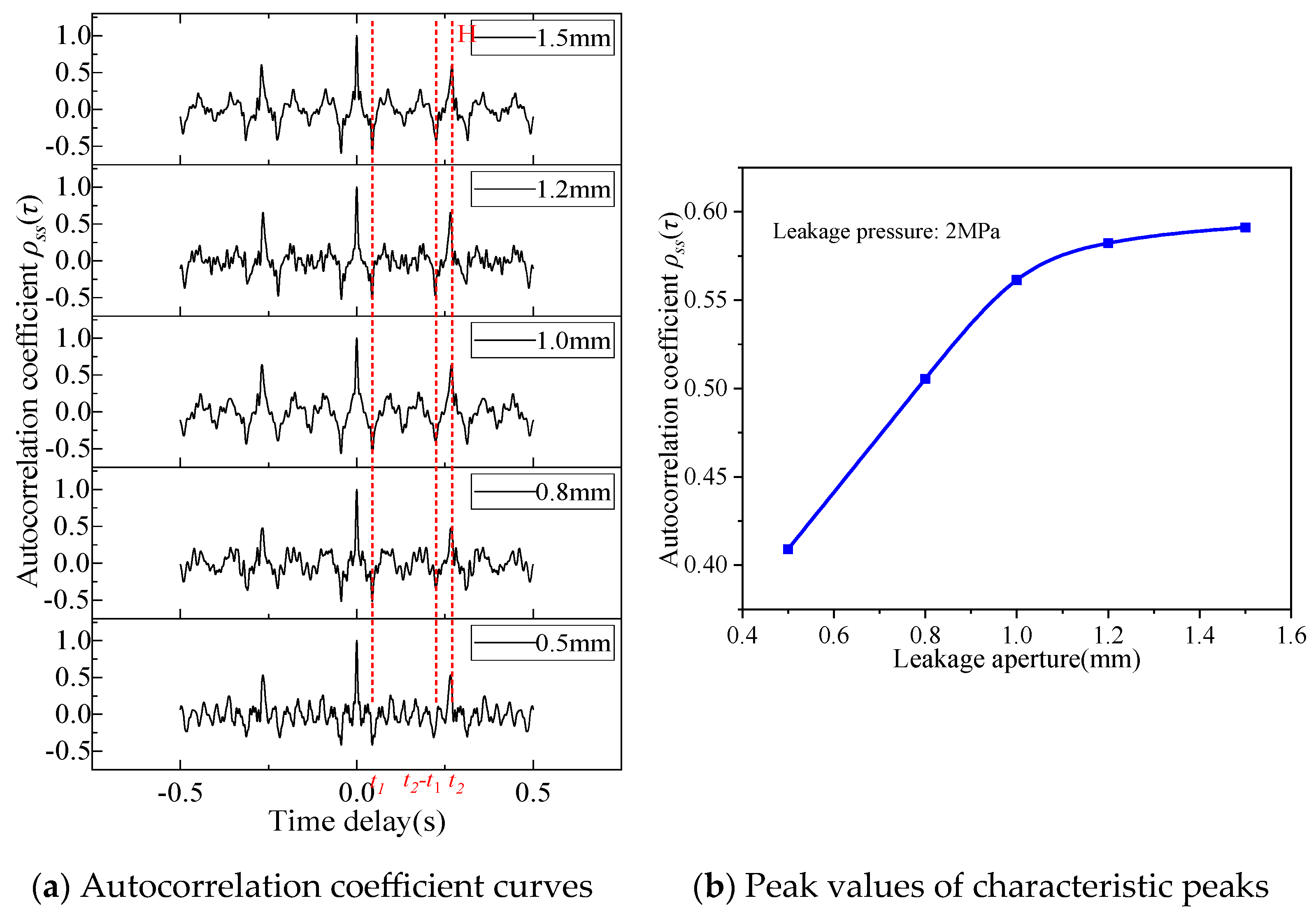

3.3. Influence of Leakage Aperture on Characteristic Peaks

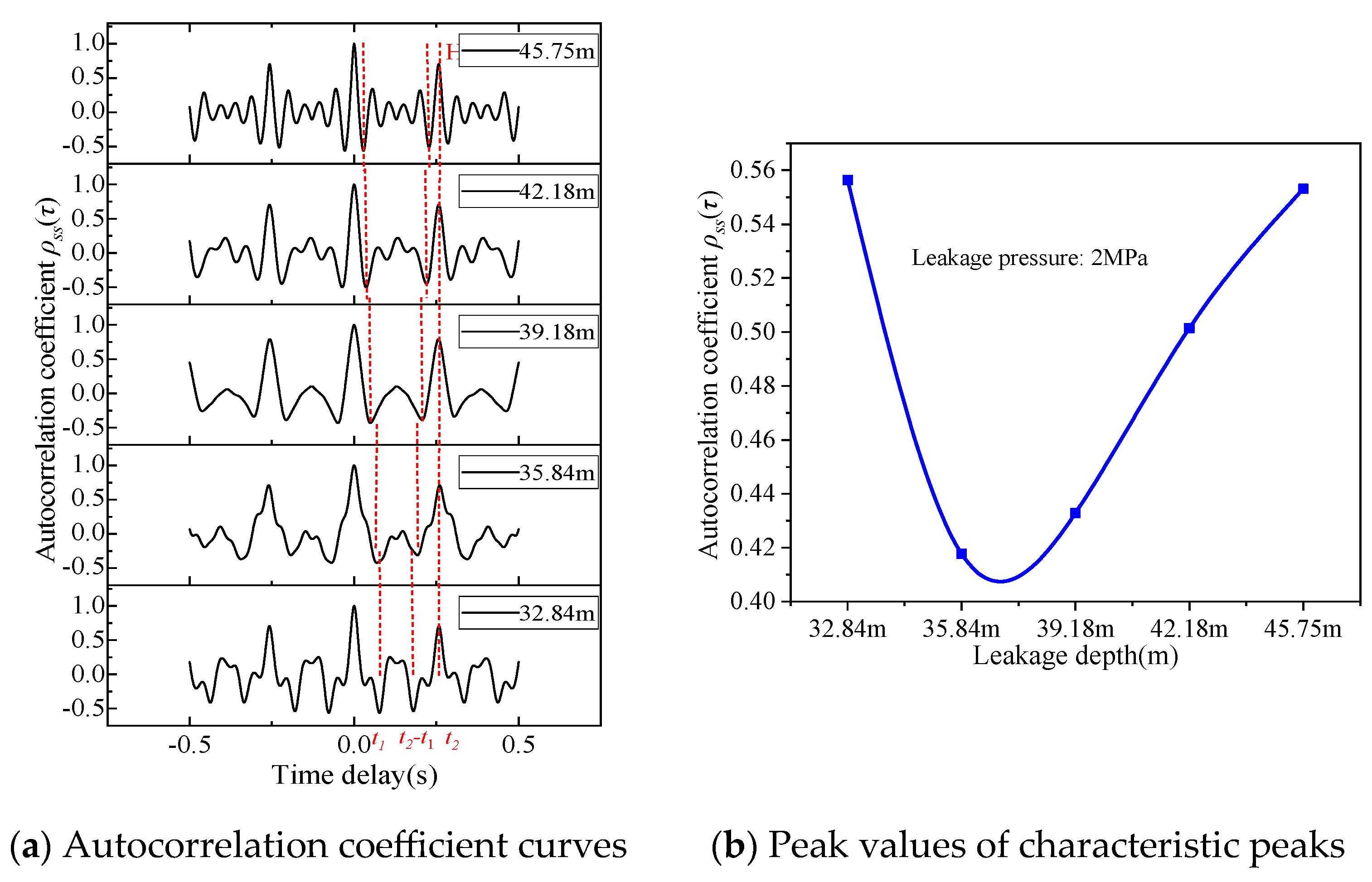

3.4. Influence of Leakage Depth on Characteristic Peaks

- Nonlinear Relationship: No evident linear correlation exists between leakage depth and the autocorrelation coefficient magnitude of leakage acoustic waves;

- Attenuation Mechanism: Leakage depth primarily affects the signal intensity detected at the wellhead annulus. Acoustic wave attenuation stems mainly from intermolecular friction and absorption, and exhibits a positive correlation with propagation distance [29].

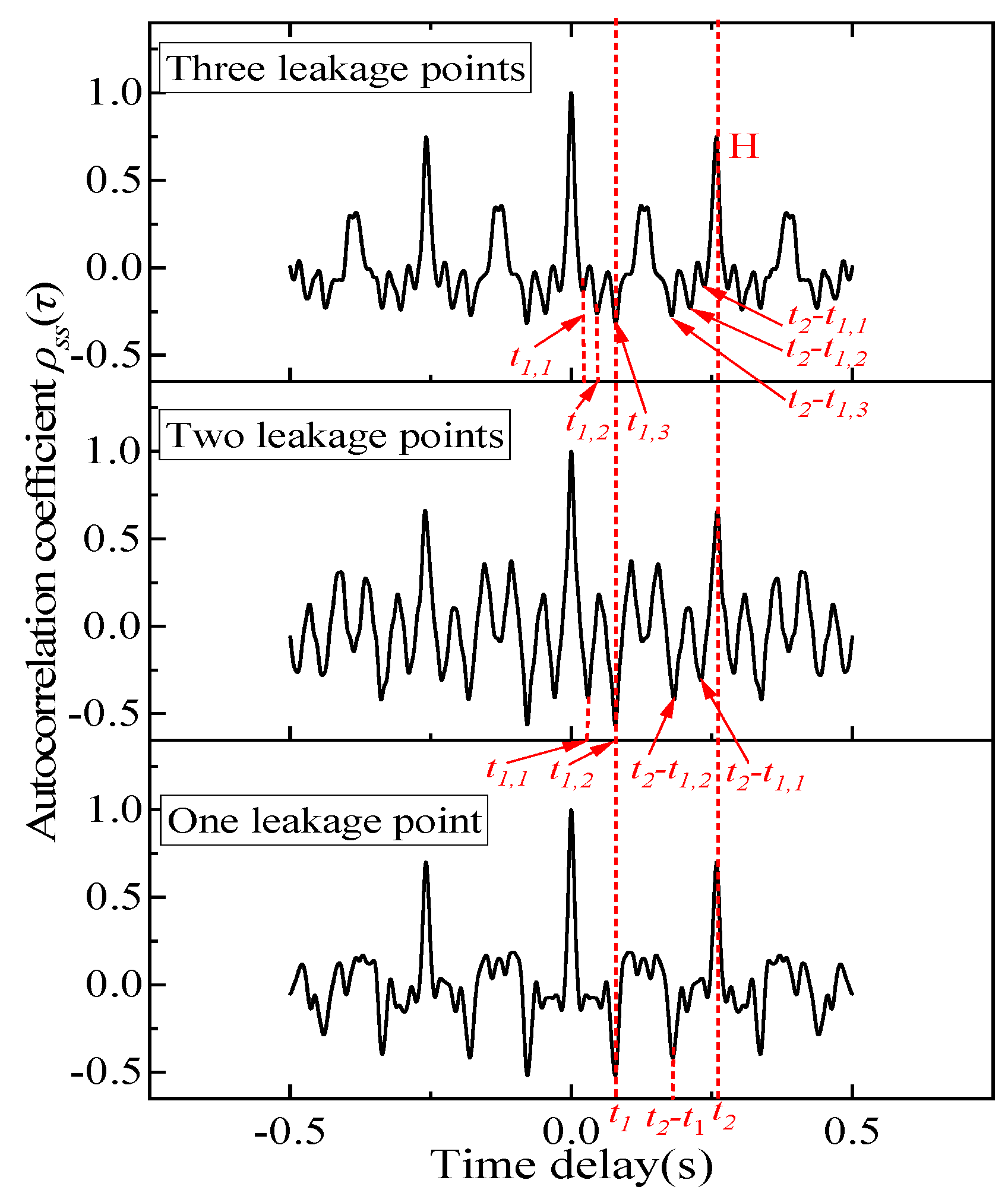

3.5. Effect of Leakage Point Quantity on Characteristic Peaks

- Single leakage point: 32.84 m from the acoustic sensor;

- Two leakage points: 39.18 m and 32.84 m from the sensor;

- Three leakage points: 45.75 m, 39.18 m, and 32.84 m from the sensor.

- Negative peaks in the autocorrelation curve increase in pairs with more leakage points;

- The left-side peak of the maximum negative peak may represent true leakage, while the right-side peak is necessarily an interference peak.

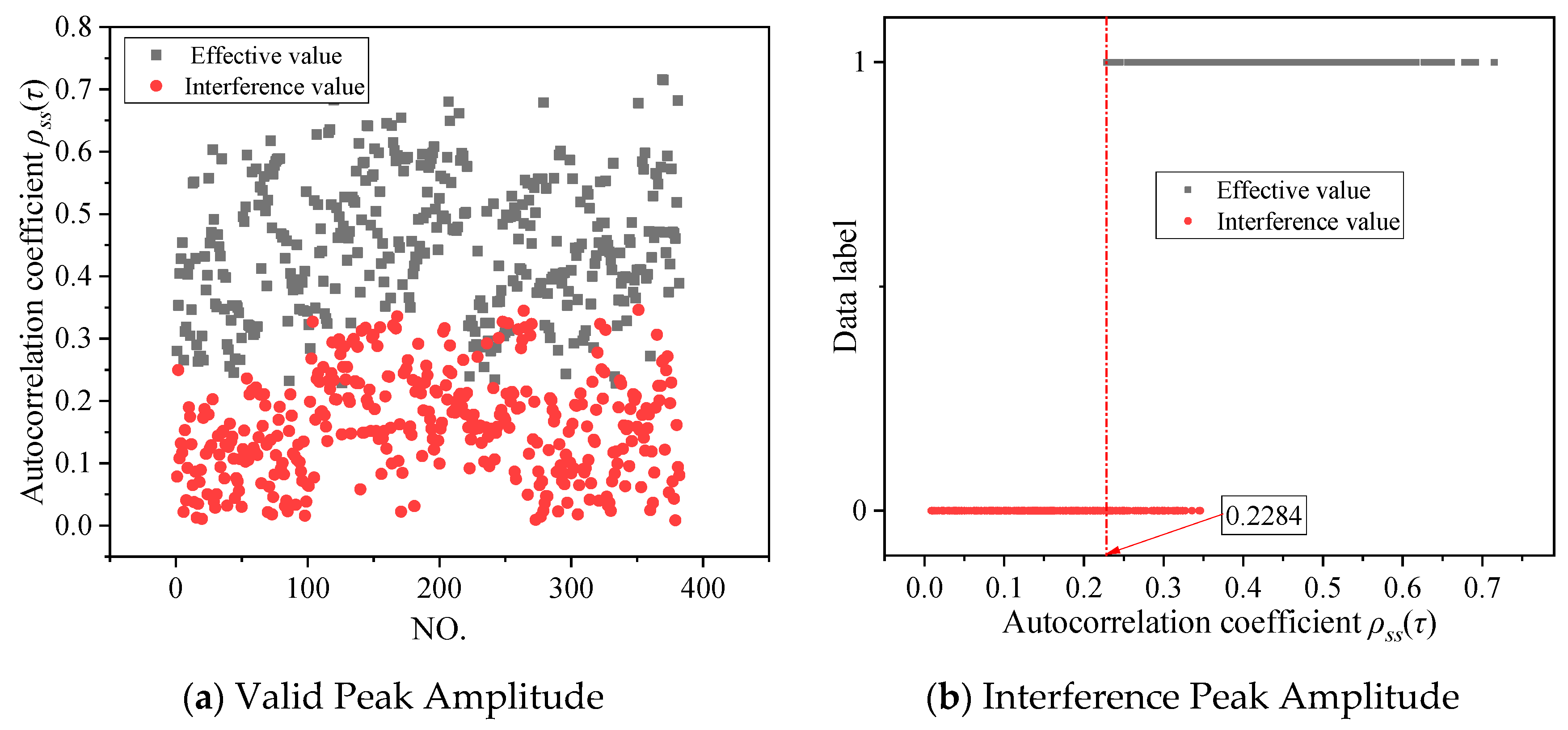

3.6. Comparative Study of Valid Peaks and Interference Peaks

- Filter frequency;

- Leakage pressure;

- Leakage aperture;

- Leakage depth.

4. Process for Extracting Characteristic Time

- Criterion: Select the lowest possible cutoff frequency without signal distortion, typically no lower than 10 Hz.

- Absolute autocorrelation coefficient > 0.2;

- Consistent presence across curves under different:

- ♦

- Pressure differentials;

- ♦

- Filter cutoff frequencies.

- Effectively eliminates interference peaks to the left of the first maximum negative peak on the positive semi-axis;

- Ensures the amplitude of characteristic peaks corresponding to leakage locations consistently exceeds 0.2;

- Achieves accurate extraction of leakage position characteristic times.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| IEA | International Energy Agency |

| API | American Petroleum Institute |

| AGA | The American Gas Association |

References

- Available online: https://www.iea.org/reports/gas-market-report-q1-2025 (accessed on 9 March 2025).

- Hachem, K.E.; Kang, M. Reducing oil and gas well leakage: A review of leakage drivers, methane detection and repair options. Environ. Res. Infrastruct. Sustain. 2023, 3, 012002. [Google Scholar] [CrossRef]

- Aljameel, S.S.; Alabbad, D.A.; Alomari, D.; Alzannan, R.; Alismail, S.; Alkhudir, A.; Aljubran, F.; Nikolskaya, E.; Rahman, A.-U. Oil and Gas Pipelines Leakage Detection Approaches: A Systematic Review of Literature. Int. J. Saf. Secur. Eng. 2024, 14, 773–786. [Google Scholar] [CrossRef]

- Zou, X.; Wang, T.; Chen, J.; Liao, Y.; Hu, H.; Song, H.; Yang, C. High-precision monitoring and point location optimization method of natural gas micro-leakage in the well site of salt cavern gas storage. Gas Sci. Eng. 2024, 124, 205262. [Google Scholar] [CrossRef]

- Zhang, B.; Pan, Z.; Cao, L.; Xie, J.; Chu, S.; Jing, Y.; Lu, N.; Sun, T.; Li, C.; Xu, Y. Measurement of wellbore leakage in high-pressure gas well based on the multiple physical signals and history data: Method, technology, and application. Energy Sci. Eng. 2024, 12, 4–21. [Google Scholar] [CrossRef]

- Jing, Y.; Wang, T.; Zhang, B.; Zheng, Y.; Li, X.; Lu, N. Safety Risk Analysis of Well Control for wellbore with sustained annular pressure and Prospects for Technological Development. Chem. Technol. Fuels Oils 2025, 61, 1676–1685. [Google Scholar] [CrossRef]

- Sun, T.; Zhang, Z.; Zhang, Y.; Ma, Y.; Liu, H.; Zhang, Q.; Zhang, B. Enhanced Heat Transfer of Variable Pitch Helical BafflePlate Orifice Plate Type Heater for Downhole In-Situ OilShale Extraction. Phys. Fluids 2025, 37, 057110. [Google Scholar] [CrossRef]

- Shao, S.R.; Hu, H.; Yang, Z.X.; Tan, P. Quantitative Evaluation of Controlling Factors of Nonuniform Production in Deep Shale Gas Based on Optic Fiber Logging Technology. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, Golden, CO, USA, 23–26 June 2024. [Google Scholar]

- Chen, S.; You, H.; Xu, J.; Wei, M.; Xu, T.; Wang, H. Leakage monitoring of carbon dioxide injection well string using distributed optical fiber sensor. Pet. Res. 2025, 10, 166–177. [Google Scholar] [CrossRef]

- Jiang, C.; Zhao, W.; Yu, M.; Zhang, K. A Model-Based Systematic Innovative Design for Sonic Logging Instruments in Natural Gas Wells. Sensors 2024, 24, 6087. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Zakharova, N.; Adeyilola, A.; Gentzis, T.; Carvajal-Ortiz, H.; Fowler, H. Understanding the CO2 adsorption hysteresis under low pressure: An example from the Antrim Shale in the Michigan Basin: Preliminary observations. J. Pet. Sci. Eng. 2021, 203, 108693. [Google Scholar] [CrossRef]

- Liu, D.; Fan, J.C.; Wu, S.N. Acoustic Wave-Based Method of Locating Tubing Leakage for Offshore Gas Wells. Energies 2018, 11, 3454. [Google Scholar] [CrossRef]

- Donoho, D.L. De-noising by soft-thresholding. IEEE Trans. Inf. Theory 1995, 41, 613–627. [Google Scholar] [CrossRef]

- Heilbronner, R.P. The autocorrelation function: An image processing tool for fabric analysis. Tectonophysics 1992, 212, 351–370. [Google Scholar] [CrossRef]

- Zhang, M.; Wen, S.P. Applied Numerical Analysis, 4th ed.; Petroleum Industry Press: Beijing, China, 2012; pp. 211–228. ISBN 978-7-5021-9201-3. [Google Scholar]

- Speed of Sound in Natural Gas and Other Related Hydrocarbon Gases; AGA Report No. 10; AGA XQ0310; American Gas Association: Washington, DC, USA, 2003; pp. 12–17.

- Coquelet, C.; Chapoy, A.; Richon, D. Development of a new alpha function for the Peng–Robinson equation of state: Comparative study of alpha function models for pure gases (natural gas components) and water-gas systems. Int. J. Thermophys. 2004, 25, 133–158. [Google Scholar] [CrossRef]

- Izgec, B. Transient Fluid and Heat Flow Modeling in Coupled Wellbore/Reservoir Systems. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, May 2008. [Google Scholar]

- Lin, J.; Xu, H.L.; Shi, T.H.; Zou, A.Q.; Mu, A.L.; Guo, J.H. Downhole multistage choke technology to reduce sustained casing pressure in a HPHT gas well. J. Nat. Gas Sci. Eng. 2015, 26, 992–998. [Google Scholar]

- Sagar, R.; Doty, D.R.; Schmidt, Z. Predicting temperature profiles in a flowing well. SPE Prod. Eng. 1991, 6, 441–448. [Google Scholar] [CrossRef]

- Hasan, A.R.; Kabir, C.S. Wellbore heat-transfer modeling and applications. J. Pet. Sci. Eng. 2012, 86–87, 127–136. [Google Scholar] [CrossRef]

- Xu, R. Analysis of Diagnostic Testing of Sustained Casing Pressure in Wells. Ph.D. Thesis, Louisiana State University, Baton Rouge, LA, USA, 2002. [Google Scholar]

- Hasan, A.R.; Kabir, C.S. Heat transfer during two-phase flow in wellbores: Part I—Formation temperature. In Proceedings of the 66th Annual Technical Conference and Exhibition of the Society of Petroleum Engineers, Dallas, TX, USA, 6–9 October 1991; pp. 469–478. [Google Scholar]

- Zhang, X.M.; Fan, J.C.; Wu, S.N.; Liu, D. A novel acoustic liquid level determination method for coal seam gas wells based on autocorrelation analysis. Energies 2017, 10, 1961. [Google Scholar] [CrossRef]

- Liu, D.; Chun, F.J.; Jie, L.S.; Yu, W.C.; Wei, L.Z.; Li, F.Z. Experimental Research on the Location of Multiple Leaks in Downhole Tubing of Gas Wells. China Saf. Sci. J. 2018, 14, 6. [Google Scholar]

- Mo, J. Research on Different Filtering Algorithms Based on Adaptive Noise Cancellation System. Master’s Dissertation, Yunnan Normal University, Kunming, China, 2014. [Google Scholar]

- Heng, P. Research on Generalized Chebyshev Lossy Filters. Master’s Dissertation, University of Electronic Science and Technology, Chengdu, China.

- Zhang, Y. Synthesis of the Coupling Matrix for Generalized Chebyshev Bandpass Filters. Master’s Dissertation, Anhui University, Hefei, China, 2016. [Google Scholar]

- Liu, Y. Research on Key Issues of Butterworth Filters and Single-Phase Phase-Locked Loops. Master’s Dissertation, Huazhong University of Science and Technology, Wuhan, China, 2016. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.-P.; Luan, G.-H.; Zhang, L.-F.; Niu, M.-Y.; Zou, G.-G.; Zhang, X.-L.; Wang, J.-Y.; Yang, J.-F.; Li, M.-S. Leak Identification and Positioning Strategies for Downhole Tubing in Gas Wells. Processes 2025, 13, 1708. https://doi.org/10.3390/pr13061708

Yang Y-P, Luan G-H, Zhang L-F, Niu M-Y, Zou G-G, Zhang X-L, Wang J-Y, Yang J-F, Li M-S. Leak Identification and Positioning Strategies for Downhole Tubing in Gas Wells. Processes. 2025; 13(6):1708. https://doi.org/10.3390/pr13061708

Chicago/Turabian StyleYang, Yun-Peng, Guo-Hua Luan, Lian-Fang Zhang, Ming-Yong Niu, Guang-Gui Zou, Xu-Liang Zhang, Jin-You Wang, Jing-Feng Yang, and Mo-Song Li. 2025. "Leak Identification and Positioning Strategies for Downhole Tubing in Gas Wells" Processes 13, no. 6: 1708. https://doi.org/10.3390/pr13061708

APA StyleYang, Y.-P., Luan, G.-H., Zhang, L.-F., Niu, M.-Y., Zou, G.-G., Zhang, X.-L., Wang, J.-Y., Yang, J.-F., & Li, M.-S. (2025). Leak Identification and Positioning Strategies for Downhole Tubing in Gas Wells. Processes, 13(6), 1708. https://doi.org/10.3390/pr13061708